Numerical Study of Pulsation-Controlled Droplet Generation in a Microfluidic T-Junction

Abstract

1. Introduction

2. Materials and Methods

2.1. Governing Equations and Flow Assumptions

2.2. Level Set Method for Interface Tracking

2.3. Surface Tension and Contact Angle Treatment

2.4. Numerical Implementation

2.5. Computational Domain and Assumptions

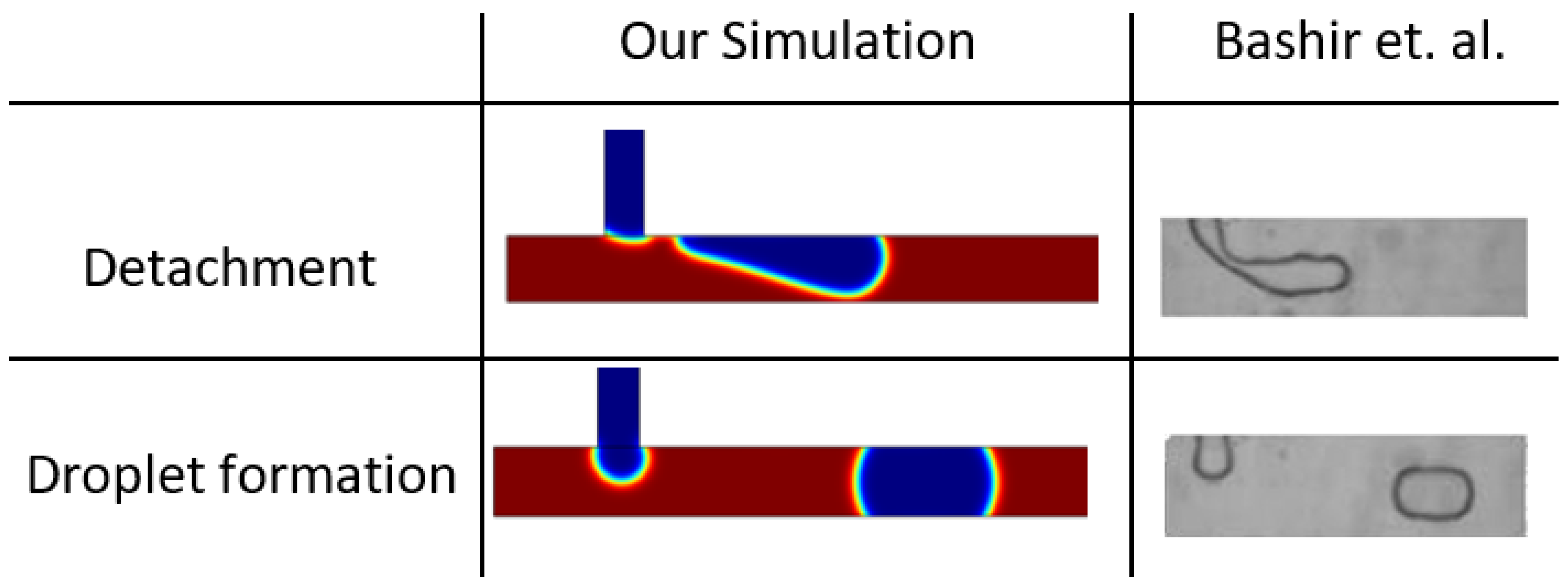

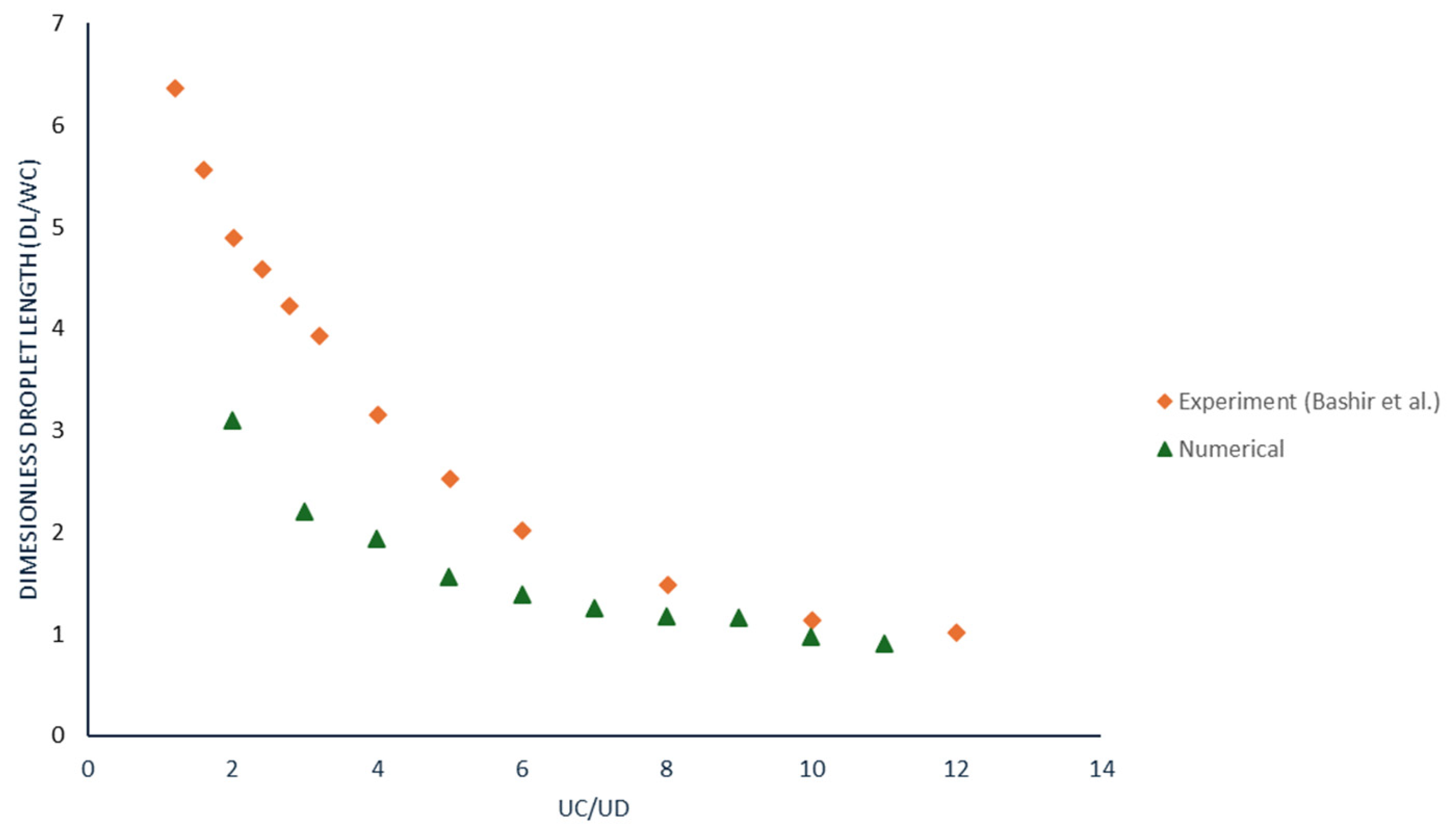

3. Model Validation

4. Results and Discussion

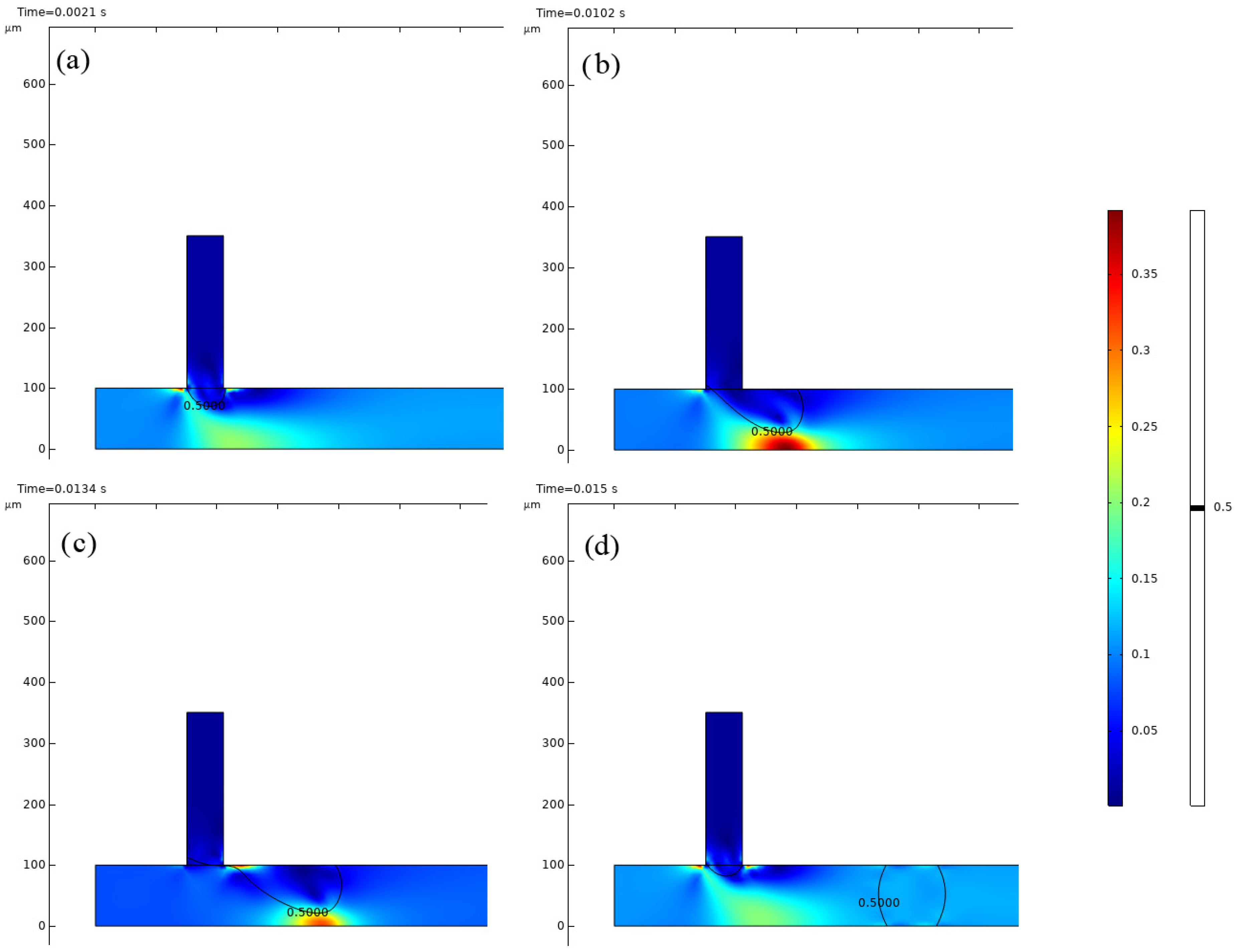

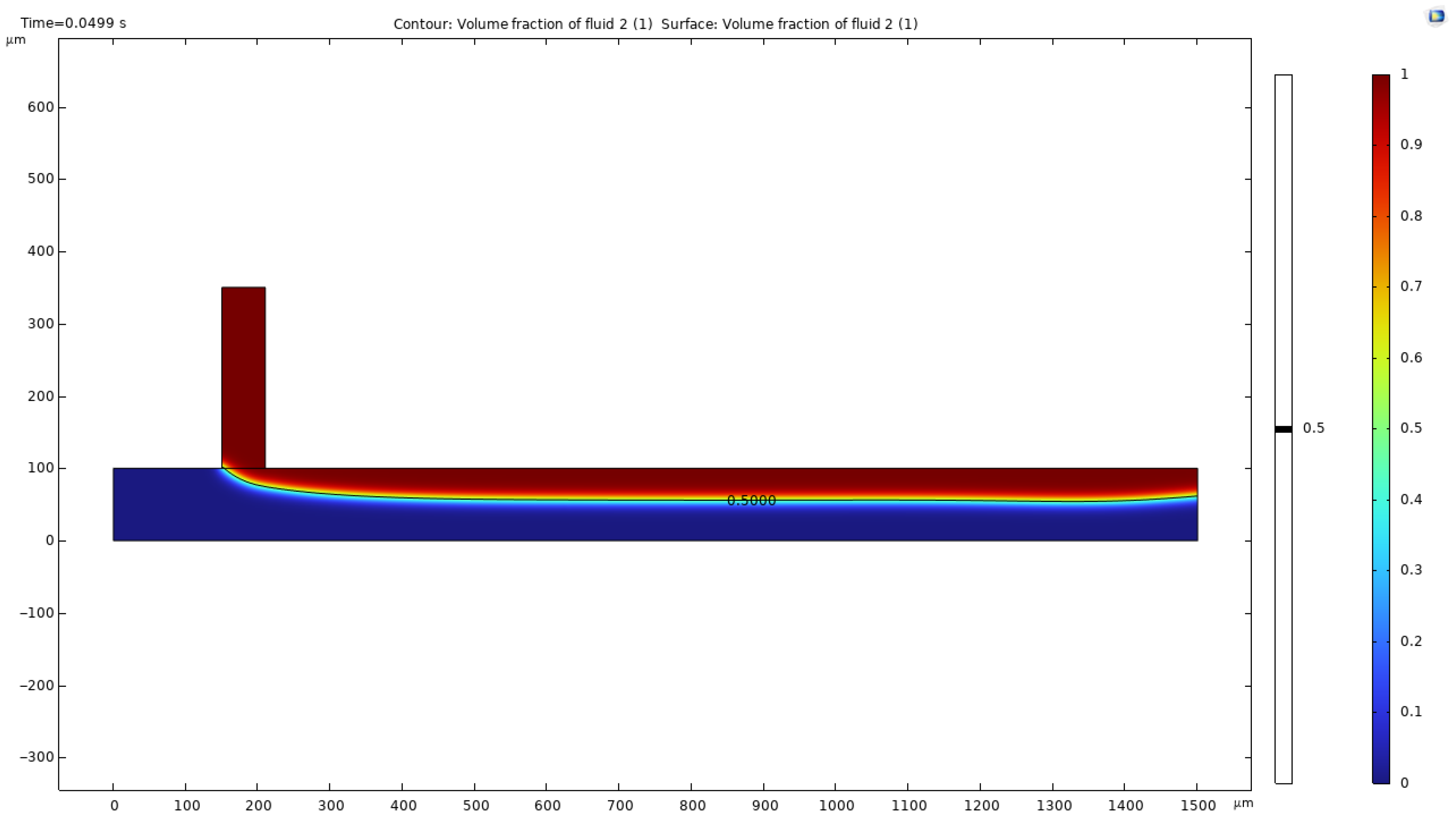

4.1. Pulsation-Induced Droplet Generation in a Co-Flow System

- Step 1: Increase dispersed-phase velocity to reach co-flow. We slowly ramped U_d to 0.024 m/s, corresponding to the transition to a co-flow regime (no jet break-up) as shown in Figure 8.

- Step 2: Achieve steady-state flow. After reaching U_d = 0.024 m/s, we waited until flow parameters stabilized and no transient oscillations remained.

- Step 3: Initiate pulsations in the dispersed phase. At this point, we applied a periodic perturbation to the velocity to disturb the co-flow regime according to the formula below.

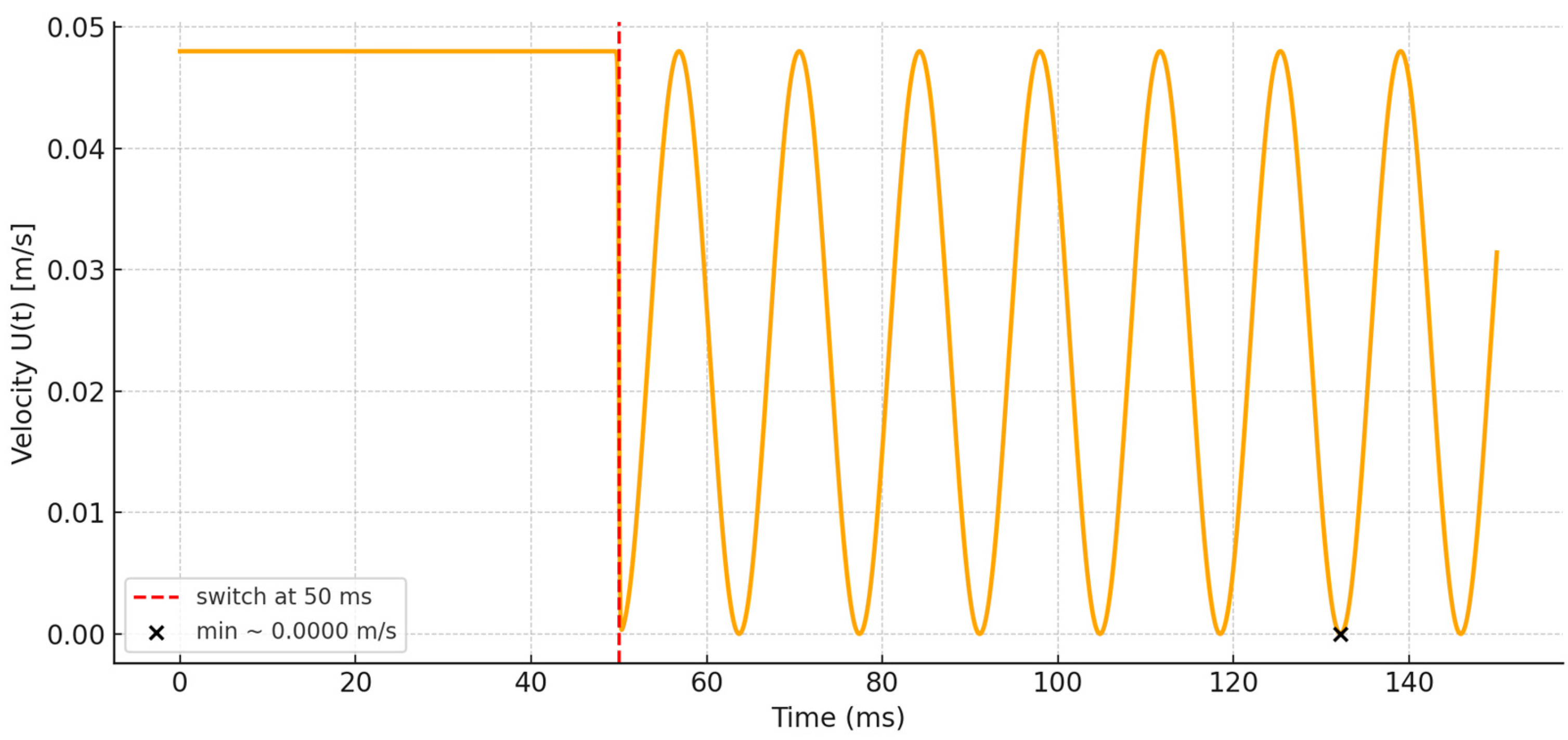

4.2. Introducing Flow Pulsations

- For t < 0.05 s: U(t) = U_d, (constant velocity, no perturbation).

- For t ≥ 0.05 s: U(t) = U_d − A(1 − sin(ωt + Φ))

4.3. Observations of Droplet Formation

4.4. Pulsatile Injection After Co-Flow Establishment

- Stable regime (35–60 Hz): Each pulse produced one droplet of nearly constant size.

- High-frequency regime (>60 Hz): Breakup became chaotic (multiple drops or satellite droplets), and droplet volume varied widely.

4.5. Full Pulsatile Injection from t = 0

4.6. Droplet Size and Pulsation Frequency

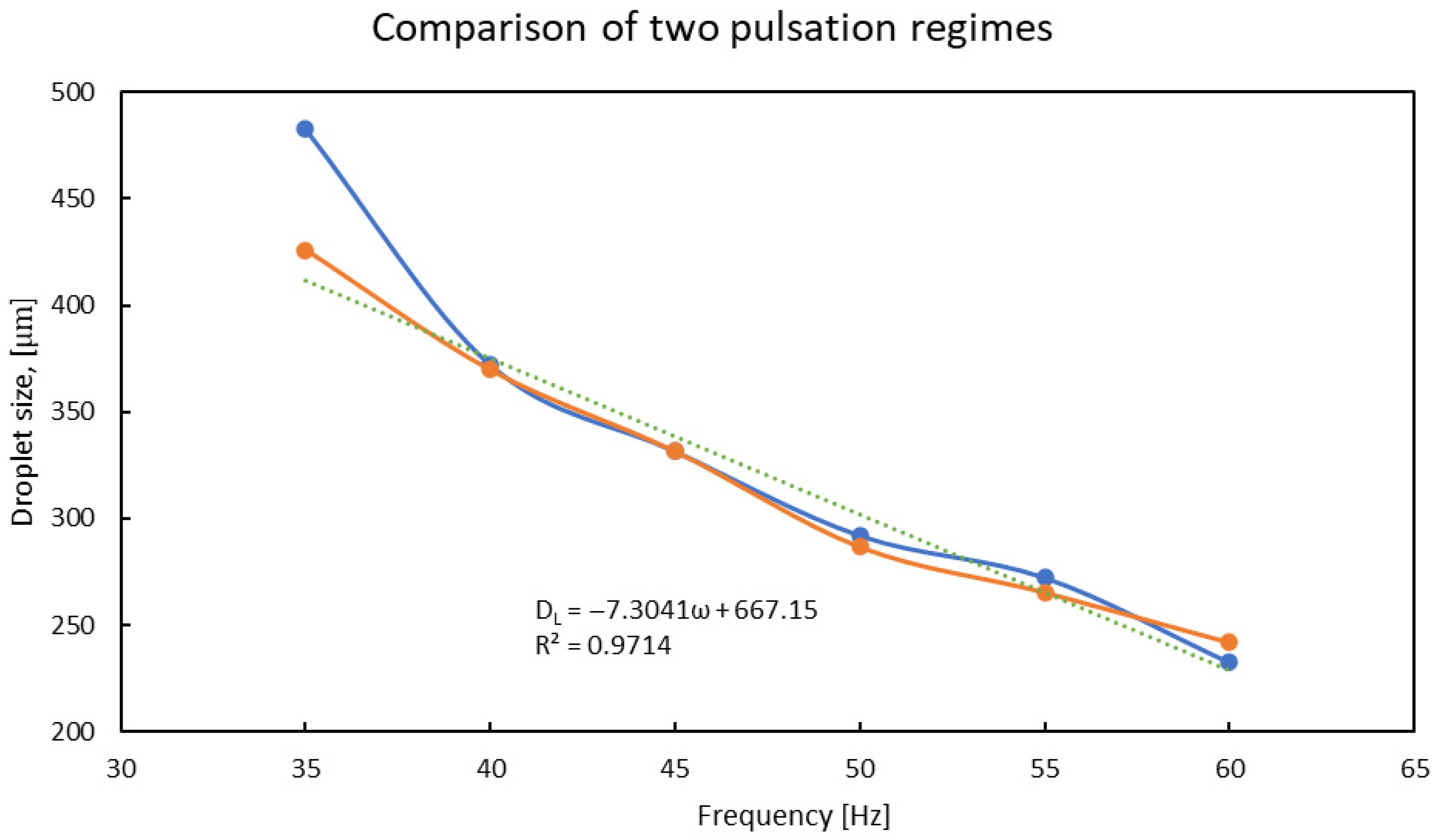

- One-to-one regime (35–60 Hz): For both starting conditions, each sinusoidal cycle produced exactly one droplet. The mean diameters in this range were nearly constant (within experimental scatter), indicating a decoupling of droplet size from time between pulses. This stable plug-flow regime is predicted by pulsatile flow models [7].

- Beyond 60 Hz: The breakup became irregular. At 65 Hz and above, some pulses failed to produce any droplet or produced multiple satellite droplets. This loss of control is consistent with earlier studies showing that at pulsation frequencies comparable to the natural droplet frequency, multi-mode and chaotic droplet formation emerges [7].

4.7. Effect of Initial Flow Condition on Droplet Size

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| LBM | Lattice Boltzmann method |

| VOF | Volume of fluid |

| PINN | Physics-informed neural network |

| Ca | Capillary number |

| Re | Reynolds number |

| St | Strouhal number |

| We | Weber number |

| CV | Coefficient of variation |

| σ | Standard deviation |

| ρ | Density (kg·m−3) |

| μ | Dynamic viscosity (Pa·s) |

| ν | Kinematic viscosity (m2·s−1) |

| σ | Surface tension (N·m−1) |

| ω | Angular frequency (rad·s−1) |

| f | Frequency (Hz) |

| A | Amplitude of velocity oscillation |

| U0 | Base vselocity (m·s−1) |

| DL | Droplet length (µm) |

| W_c, W_d | Widths of continuous and dispersed channels (µm) |

| Q_c, Q_d | Flow rates of continuous and dispersed phases (µL·min−1) |

| p | Pressure (Pa) |

| v | Velocity (m·s−1) |

| ϕ | Level-set phase field variable |

References

- Fergola, A.; Ballesio, A.; Frascella, F.; Napione, L.; Cocuzza, M.; Marasso, S.L. Droplet Generation and Manipulation in Microfluidics: A Comprehensive Overview of Passive and Active Strategies. Biosensors 2025, 15, 345. [Google Scholar] [CrossRef]

- Garstecki, P.; Fuerstman, M.J.; Stone, H.A.; Whitesides, G.M. Formation of Droplets and Bubbles in a Microfluidic T-Junction—Scaling and Mechanism of Break-Up. Lab Chip 2006, 6, 437. [Google Scholar] [CrossRef]

- Viswanathan, H. The Effect of Junction Gutters for the Upscaling of Droplet Generation in a Microfluidic T-Junction. Microgravity Sci. Technol. 2022, 34, 43. [Google Scholar] [CrossRef]

- Jahangirifard, S.; Salomon, R.; Razavi Bazaz, S. Deformable Baffles Coupled with Pulsatile Flow Improve Mixing in Microfluidic Devices. Chem. Eng. Res. Des. 2024, 208, 588–598. [Google Scholar] [CrossRef]

- Dincau, B.; Dressaire, E.; Sauret, A. Pulsatile Flow in Microfluidic Systems. Small 2020, 16, e1904032. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, J.; Tang, Z.; Wu, Q. Regulation of Gas-Liquid Taylor Flow by Pulsating Gas Intake in Micro-Channel. Chem. Eng. J. 2021, 417, 129055. [Google Scholar] [CrossRef]

- Kovalev, A.; Yagodnitsyna, A.; Bartkus, G.; Bilsky, A. Control of Plug Flow Dynamics in Microfluidic T-Junction Using Pulsations of Dispersed Phase Flow Rate. Int. J. Thermofluids 2024, 23, 100720. [Google Scholar] [CrossRef]

- Bransky, A.; Korin, N.; Khoury, M.; Levenberg, S. A Microfluidic Droplet Generator Based on a Piezoelectric Actuator. Lab Chip 2009, 9, 516–520. [Google Scholar] [CrossRef]

- Cheung, Y.N.; Qiu, H. Characterization of Acoustic Droplet Formation in a Microfluidic Flow-Focusing Device. Phys. Rev. E 2011, 84, 066310. [Google Scholar] [CrossRef]

- Oléron, M.; Clément, G.; Hidalgo-Caballero, S.; Gunny, M.; Box, F.; Labousse, M.; McGraw, J.D. Droplet-on-Demand Using a Positive Pressure Pulse. Eur. Phys. J. E Soft Matter 2025, 48, 35. [Google Scholar] [CrossRef]

- Sripadaraja, K.; Umesh, G.; Satyanarayan, M.N. Simulation Studies on Picolitre Volume Droplets Generation and Trapping in T-Junction Microchannels. SN Appl. Sci. 2020, 2, 1413. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Xia, H.M.; Wu, J.W.; Zhang, J.; Wang, Z.P. Synchronized Generation and Coalescence of Largely Dissimilar Microdroplets Governed by Pulsating Continuous-Phase Flow. Appl. Phys. Lett. 2019, 114, 073701. [Google Scholar] [CrossRef]

- Mudugamuwa, A.; Roshan, U.; Hettiarachchi, S.; Cha, H.; Musharaf, H.; Kang, X.; Trinh, Q.T.; Xia, H.M.; Nguyen, N.; Zhang, J. Periodic Flows in Microfluidics. Small 2024, 20, e2404685. [Google Scholar] [CrossRef]

- Sun, Z.; Yao, Q.; Jin, H.; Xu, Y.; Hang, W.; Chen, H.; Li, K.; Shi, L.; Gu, J.; Zhang, Q.; et al. A Novel In-Situ Sensor Calibration Method for Building Thermal Systems Based on Virtual Samples and Autoencoder. Energy 2024, 297, 131314. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, F.; Li, J.; Chen, X. Multi-Field Coupling Particle Flow Dynamic Behaviors of the Microreactor and Ultrasonic Control Method. Powder Technol. 2025, 454, 120731. [Google Scholar] [CrossRef]

- Ziemecka, I.; van Steijn, V.; Koper, G.J.M.; Rosso, M.; Brizard, A.M.; van Esch, J.H.; Kreutzer, M.T. Monodisperse Hydrogel Microspheres by Forced Droplet Formation in Aqueous Two-Phase Systems. Lab Chip 2011, 11, 620–624. [Google Scholar] [CrossRef] [PubMed]

- Sauret, A.; Shum, H. Forced generation of simple and double emulsions in all-aqueous systems. Appl. Phys. Lett. 2012, 100, 154106. [Google Scholar] [CrossRef]

- Hamidović, M.; Marta, U.; Bridle, H.; Hamidović, D.; Fink, G.; Wille, R.; Springer, A.; Haselmayr, W. Off-Chip-Controlled Droplet-on-Demand Method for Precise Sample Handling. ACS Omega 2020, 5, 9684–9689. [Google Scholar] [CrossRef]

- Meng, X.; Yu, Y.; Jin, G. Numerical Simulation and Experimental Verification of Droplet Generation in Microfluidic Digital PCR Chip. Micromachines 2021, 12, 409. [Google Scholar] [CrossRef]

- Zhu, P.; Tang, X.; Tian, Y.; Wang, L. Pinch-off of Microfluidic Droplets with Oscillatory Velocity of Inner Phase Flow. Sci. Rep. 2016, 6, 31436. [Google Scholar] [CrossRef]

- Bashir, S.; Rees, J.M.; Zimmerman, W.B. Simulations of Microfluidic Droplet Formation Using the Two-Phase Level Set Method. Chem. Eng. Sci. 2011, 66, 4733–4741. [Google Scholar] [CrossRef]

- The Level Set Method (COMSOL Documentation). Available online: https://doc.comsol.com/6.0/doc/com.comsol.help.cfd/cfd_ug_math_levelset_phasefield.14.33.html (accessed on 1 January 2020).

- Olsson, E.; Kreiss, G. A Conservative Level Set Method for Two Phase Flow. J. Comput. Phys. 2005, 210, 225–246. [Google Scholar] [CrossRef]

- Sussman, M.; Smereka, P.; Osher, S. A Level Set Approach for Computing Solutions to Incompressible Two-Phase Flow. J. Comput. Phys. 1994, 114, 146–159. [Google Scholar] [CrossRef]

- COMSOL Multiphysics®, version 6.2; COMSOL AB: Stockholm, Sweden, 2023.

- Yin, J.; Kuhn, S. Numerical Simulation of Droplet Formation in a Microfluidic T-Junction Using a Dynamic Contact Angle Model. Chem. Eng. Sci. 2022, 261, 117874. [Google Scholar] [CrossRef]

- Shams Khorrami, A.; Rezai, P. Oscillating Dispersed-Phase Co-Flow Microfluidic Droplet Generation: Jet Length Reduction Effect. Soft Matter 2018, 14, 9870–9876. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Dispersed phase velocity, U_d | 0.05 m/s |

| Continuous phase velocity, U_c | 0.10 m/s |

| Dispersed phase density, ρ _d | 1000 kg/m3 |

| Continuous phase density, ρ _c | 900 kg/m3 |

| Dispersed phase viscosity, μ _d | 1.0 × 10−3 Pa·s |

| Continuous phase viscosity, μ _c | 2.0 × 10−2 Pa·s |

| Interfacial tension, δ | 0.015 N/m |

| Contact angle, θ | 135° |

| Capillary number, Ca_c (continuous) | 0.133 |

| Capillary number, Ca_d (dispersed) | 0.003 |

| Main channel width W_c (horizontal) | 100 µm |

| Side channel width W_d (vertical) | 25 µm |

| Frequency [Hz] | Phase [rad] | Amplitude in % | Droplet Length [μm] | Droplet Formation Frequency [Hz] |

|---|---|---|---|---|

| 35 | Pi/2 | 100% | 426 | 0.029 |

| 40 | Pi/2 | 100% | 369.7 | 0.0249 |

| 45 | Pi/2 | 100% | 331.5 | 0.025 |

| 50 | Pi/2 | 100% | 286.7 | 0.02 |

| 55 | Pi/2 | 100% | 265.41 | 0.018 |

| 60 | Pi/2 | 100% | 241.89 | 0.016 |

| 65 | Pi/2 | 100% | Irregular droplet sizes |

| Frequency [Hz] | Phase [rad] | Amplitude in % | Droplet Length [μm] | Droplet Formation Frequency [Hz] |

|---|---|---|---|---|

| 35 | 3 Pi/2 | 0.024 | 482.79 | 0.0285 |

| 40 | 3 Pi/2 | 0.024 | 372.14 | 0.025 |

| 45 | 3 Pi/2 | 0.024 | 331.59 | 0.022 |

| 50 | 3 Pi/2 | 0.024 | 291.97 | 0.019 |

| 55 | 3 Pi/2 | 0.024 | 272.23 | 0.018 |

| 60 | 3 Pi/2 | 0.024 | 232.34 | 0.0145 |

| 65 | 3 Pi/2 | 0.024 | Irregular droplet sizes |

| Frequency (Hz) | Droplet Size (Zero Velocity Start, µm) | Droplet Size (Co-Flow Start, µm) | Mean Droplet Size (µm) | Standard Deviation σ (µm) | Coefficient of Variation CV (%) |

|---|---|---|---|---|---|

| 35 | 482.79 | 426 | 454.4 | 40.09 | 8.82 |

| 40 | 372.14 | 369.7 | 370.92 | 1.73 | 0.47 |

| 45 | 331.59 | 331.5 | 331.55 | 0.06 | 0.02 |

| 50 | 291.97 | 286.7 | 289.34 | 3.73 | 1.29 |

| 55 | 272.23 | 265.41 | 268.82 | 4.83 | 1.8 |

| 60 | 232.34 | 241.89 | 237.12 | 6.75 | 2.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuljabekov, A.; Bolysbek, D.; Akasheva, Z.; Zhantayev, Z. Numerical Study of Pulsation-Controlled Droplet Generation in a Microfluidic T-Junction. Processes 2025, 13, 3690. https://doi.org/10.3390/pr13113690

Kuljabekov A, Bolysbek D, Akasheva Z, Zhantayev Z. Numerical Study of Pulsation-Controlled Droplet Generation in a Microfluidic T-Junction. Processes. 2025; 13(11):3690. https://doi.org/10.3390/pr13113690

Chicago/Turabian StyleKuljabekov, Alibek, Darezhat Bolysbek, Zhibek Akasheva, and Zhumabek Zhantayev. 2025. "Numerical Study of Pulsation-Controlled Droplet Generation in a Microfluidic T-Junction" Processes 13, no. 11: 3690. https://doi.org/10.3390/pr13113690

APA StyleKuljabekov, A., Bolysbek, D., Akasheva, Z., & Zhantayev, Z. (2025). Numerical Study of Pulsation-Controlled Droplet Generation in a Microfluidic T-Junction. Processes, 13(11), 3690. https://doi.org/10.3390/pr13113690