Multiscale Gas Flow Mechanisms in Ultra-Deep Fractured Tight Sandstone Reservoirs with Water Invasion

Abstract

1. Introduction

2. Experimental Materials and Methods

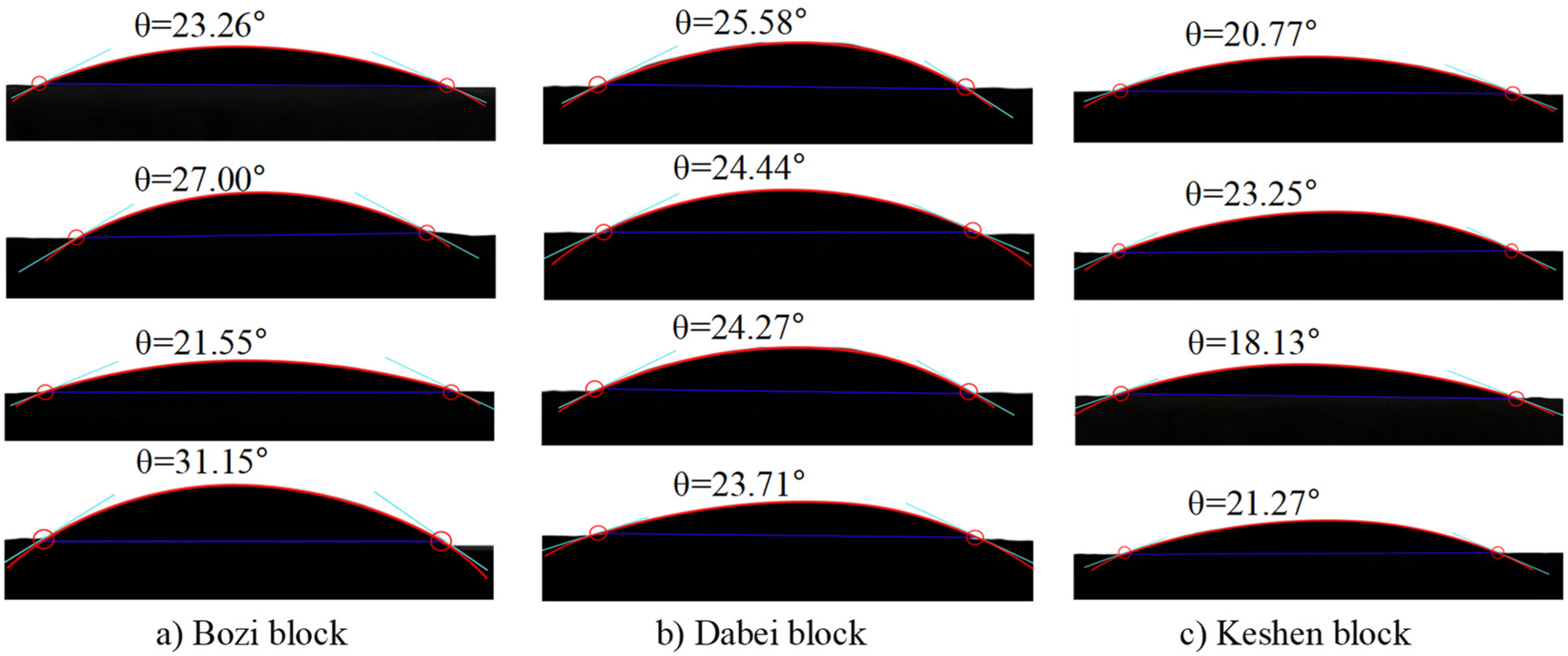

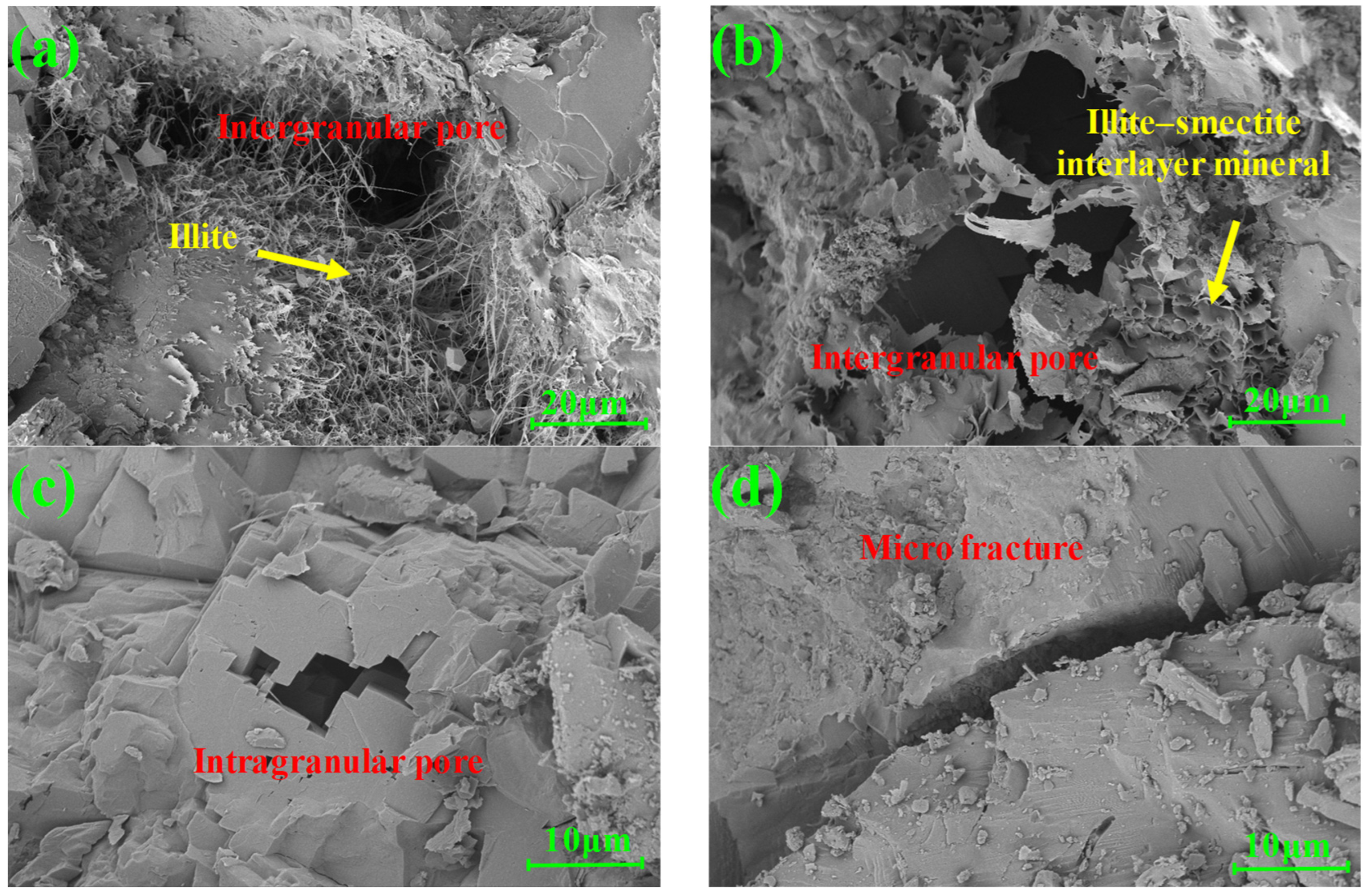

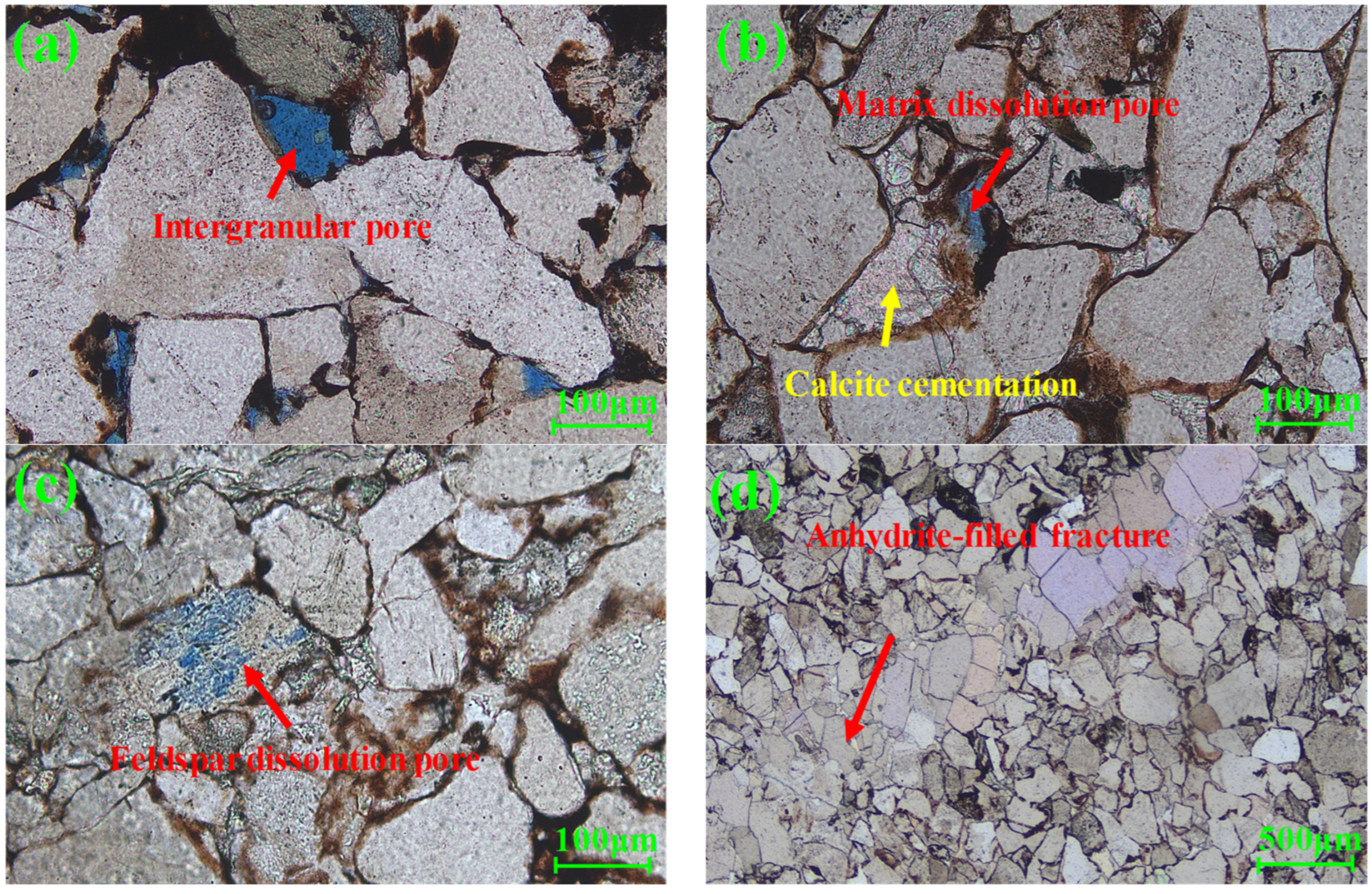

2.1. Experimental Materials

2.2. Experimental Methods

- (1)

- Sample preparation. The samples obtained from drilling were subjected to oil and salt removal, followed by drying in an oven at 110 °C for 24 h before use.

- (2)

- Pre-experiment preparation. The sample was mounted in the core holder, and the gas cylinder was opened. The confining pressure, inlet pressure, and outlet pressure were then loaded to the initial target values, while the temperature was increased to the specified level. The pressure and temperature conditions varied among the Bozi, Dabei, and Keshen blocks, with the specific values listed in Table 3.

- (3)

- Gas seepage experiments. With the inlet pressure held constant, the outlet pressure was gradually reduced in steps. The pressure difference between the inlet and outlet was controlled within 5 MPa for matrix cores and within 1 MPa for fractured cores corresponding to their respective permeability levels and ensuring stable gas flow under high-temperature and high-pressure conditions. The outlet flow was subsequently monitored using the metering pump. Equilibrium was confirmed when the outlet flow rate and pressure differential remained constant for more than 30 min, indicating that transient effects had subsided.

- (4)

- After gas seepage experiment, the gas cylinder was closed and the sample was removed.

- (5)

- Establishment of different water saturations. Different target water saturations were achieved using the imbibition method, after which steps (2–4) were repeated for each water saturation level. Specifically, a 3 wt% KCl solution was used as the imbibition fluid. The core surface was gently rolled on fibers soaked with the solution, and its mass was continuously measured in real time. The amount of absorbed water was converted into the equivalent initial water saturation of the core. The saturated cores were then placed in a vacuum chamber to ensure a uniform distribution of the water phase prior to the gas flow experiments.

- (6)

- Data processing. The experimental data were analyzed to quantify the effects of water saturation on the gas seepage capacity of both matrix and fractured cores.

3. Results

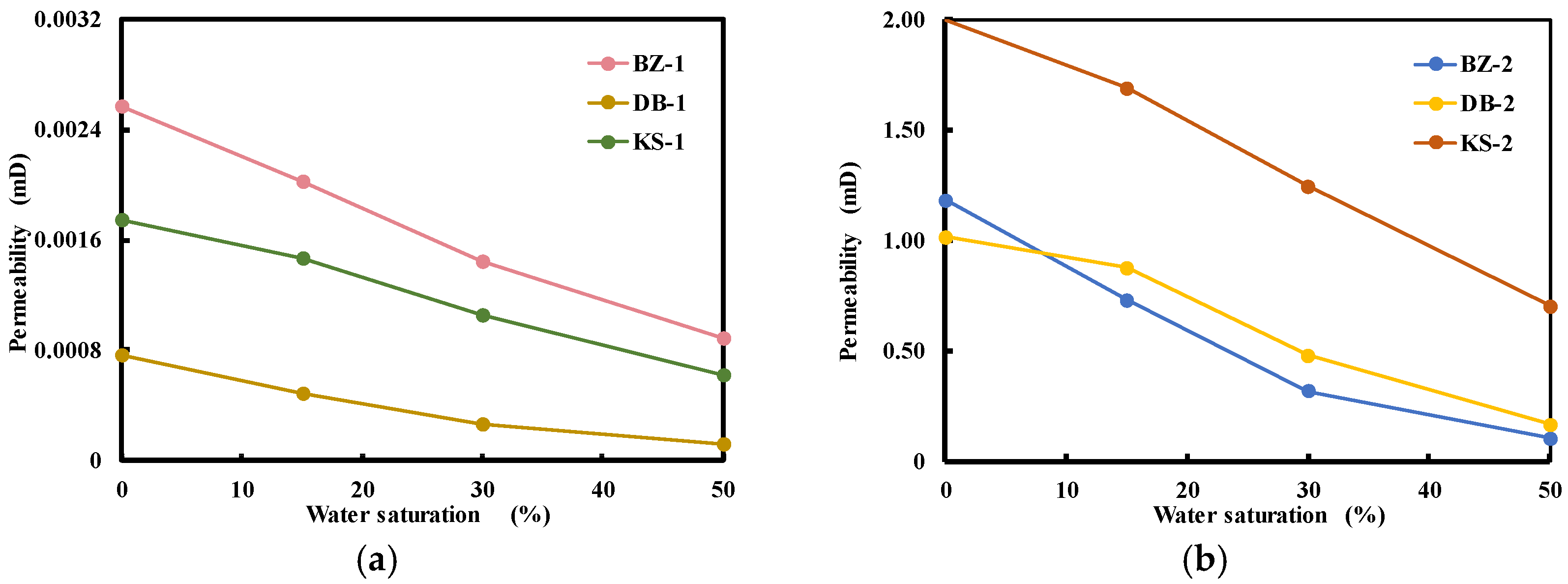

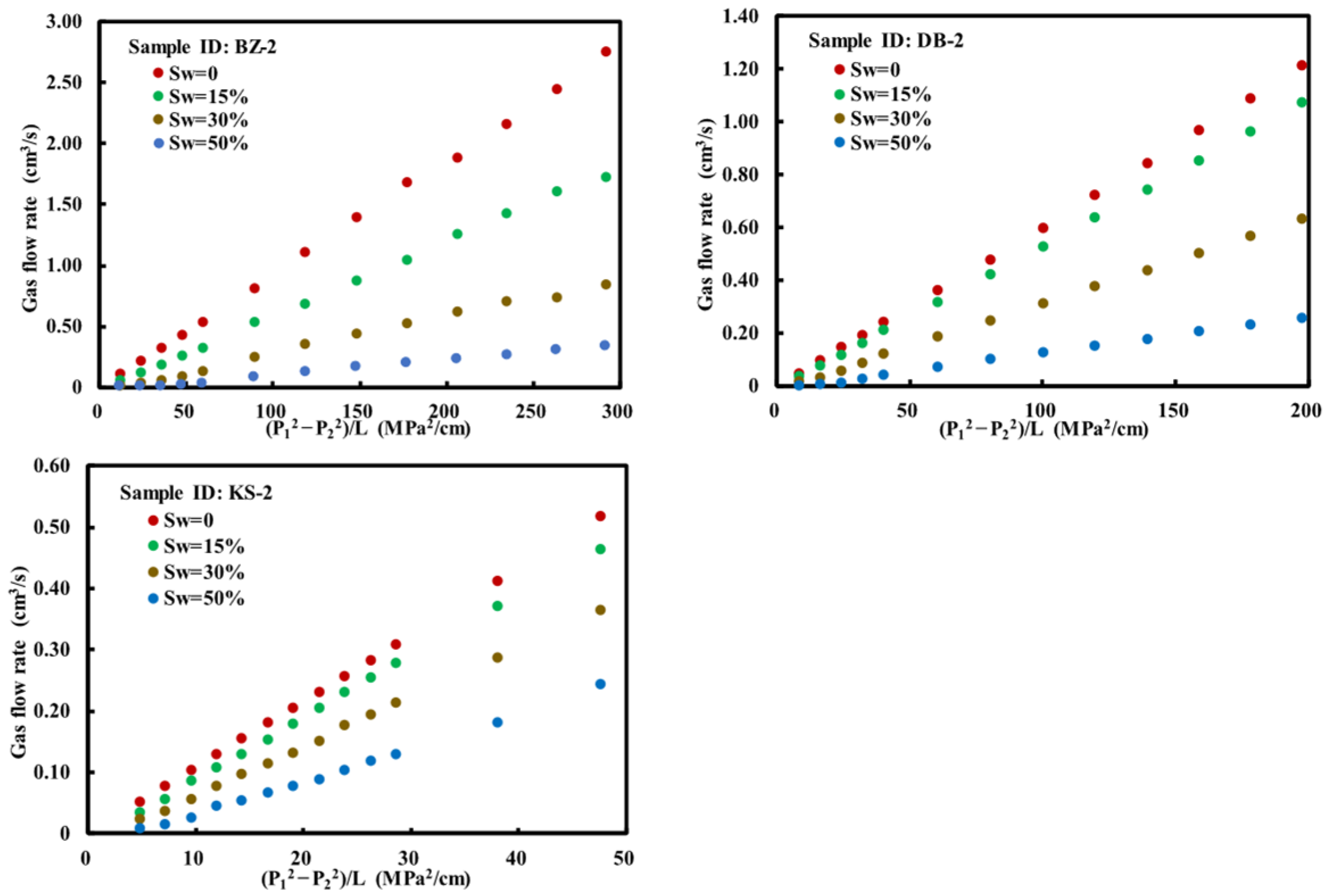

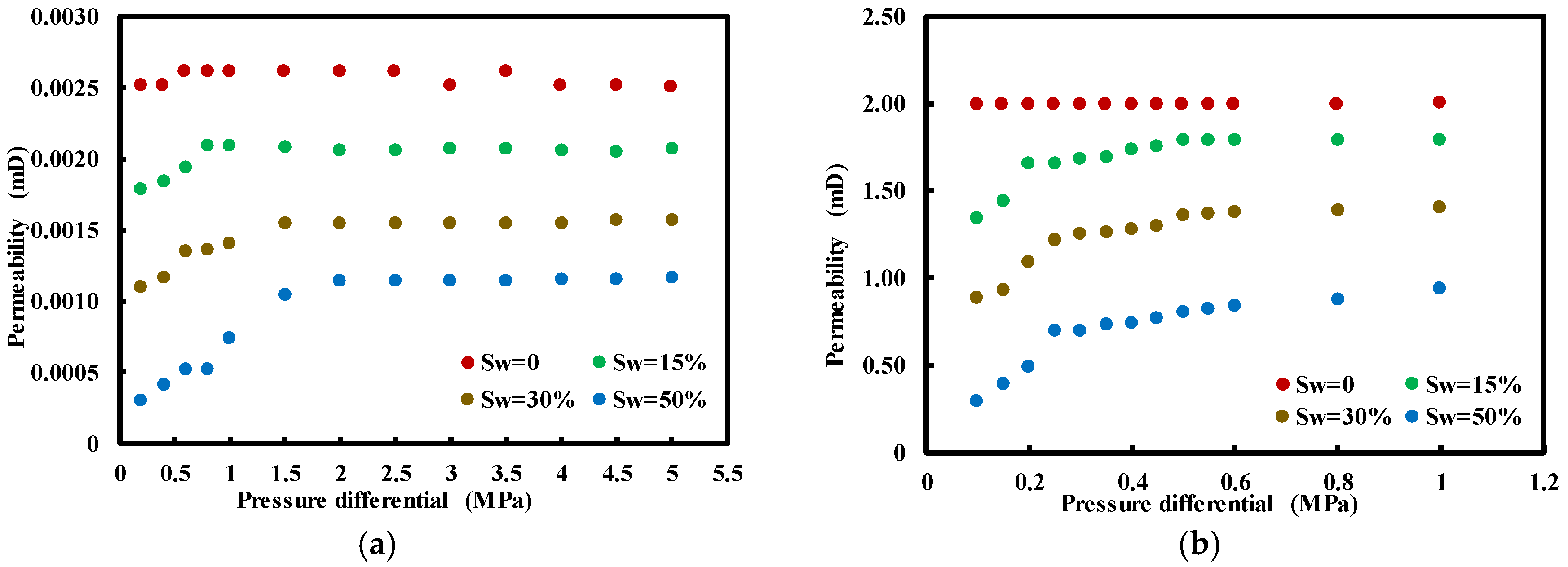

3.1. Gas Flow in Matrix Samples Under Different Water Saturations

3.2. Gas Flow in Fractured Samples Under Different Water Saturations

4. Discussion

4.1. Impact of Gas Slippage on Flow Behavior

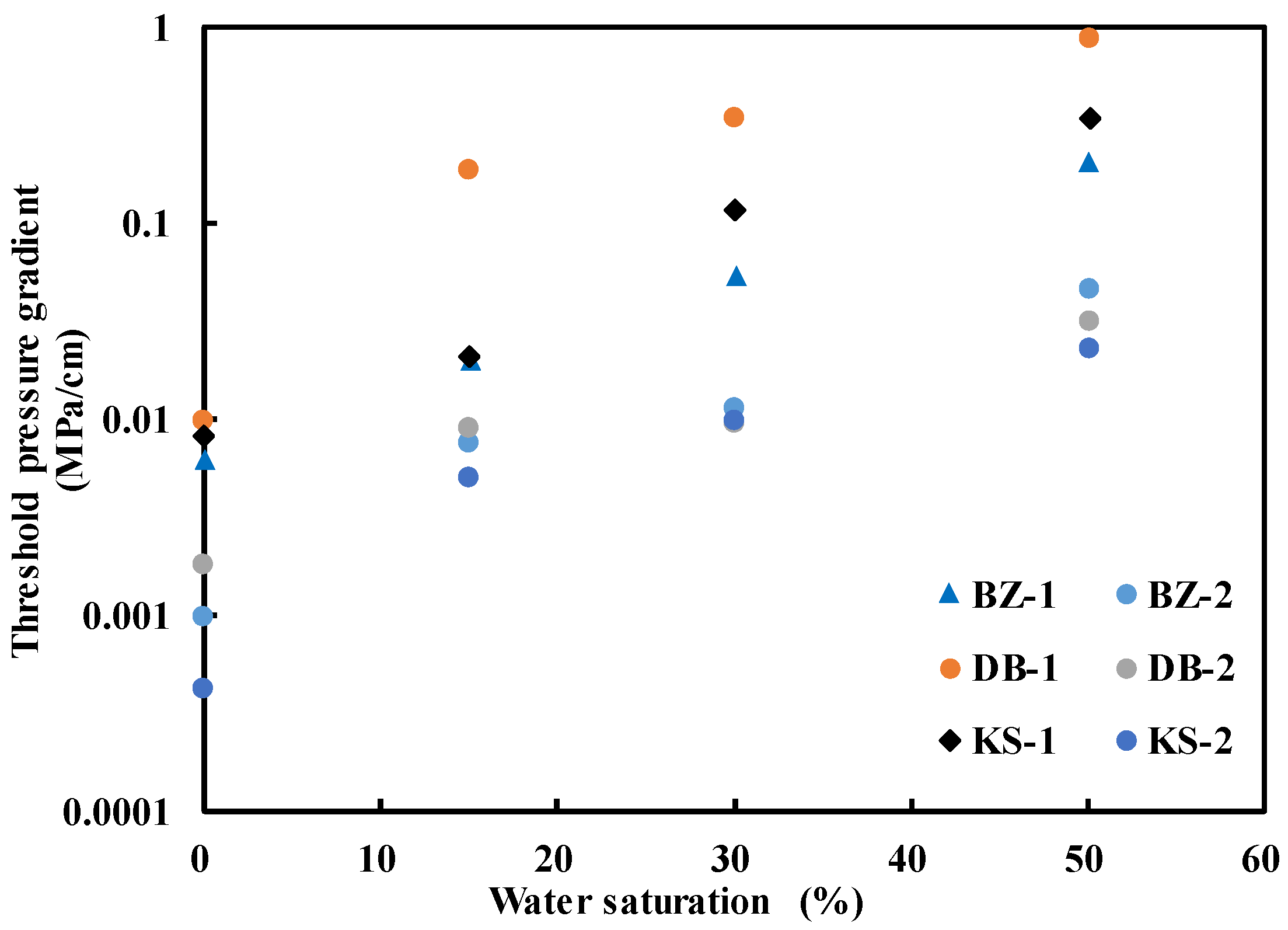

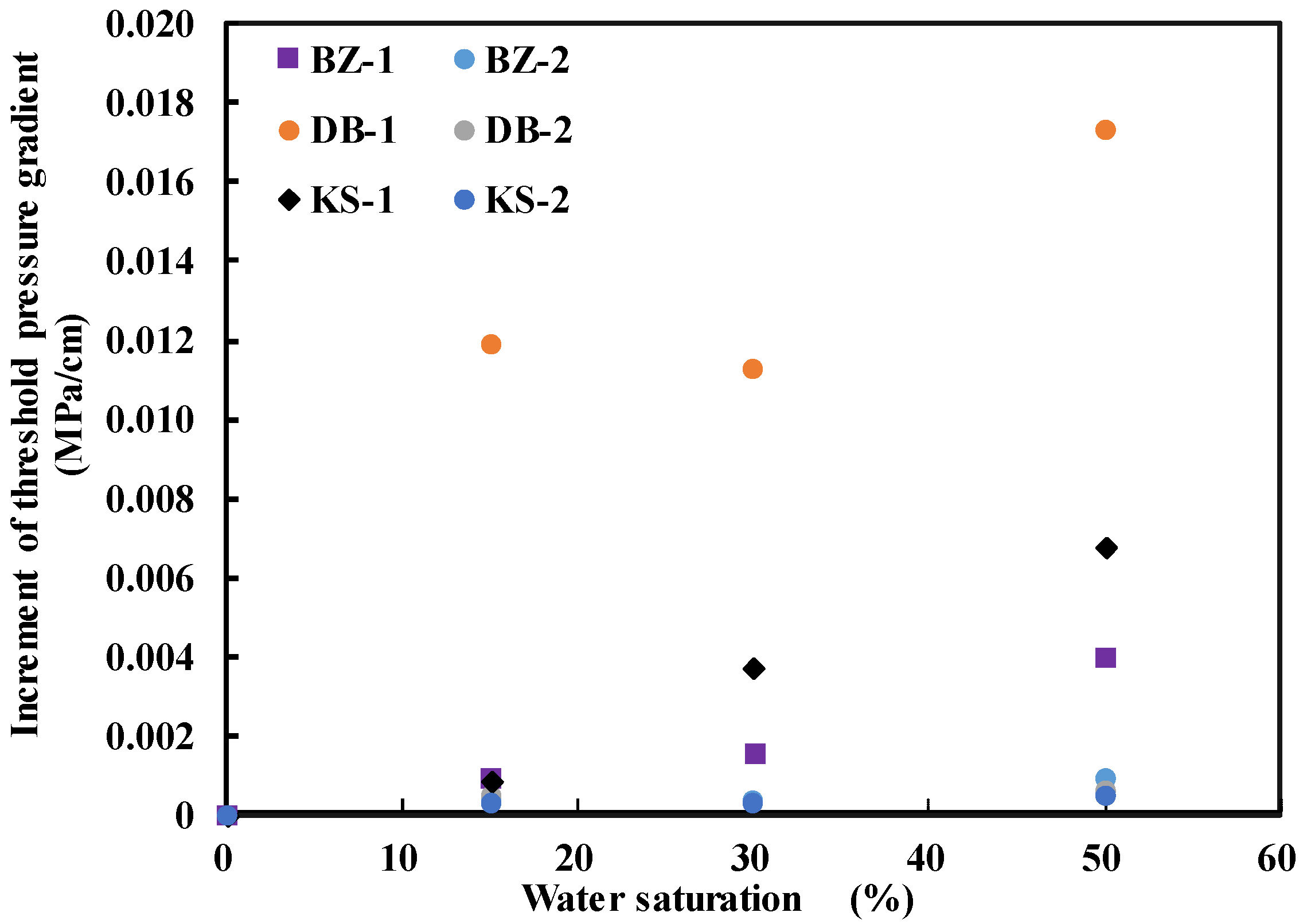

4.2. Threshold Pressure Gradient in Nonlinear Gas Flow

4.3. Multiscale Gas Flow Mechanisms

4.4. Effective Flow Conditions of Ultra-Deep Tight Sandstone Gas

5. Conclusions

- (1)

- The water saturation has a significant impact on the permeability of ultra-deep tight sandstones. As water saturation increases, the permeability of both matrix and fractured cores decreases markedly. When the water saturation increases from 0% to 50%, the permeability of matrix and fractured cores decreases by 71.15% and 79.67%, respectively, indicating a strong blocking effect of the water phase on gas flow.

- (2)

- Under the in situ high-temperature and high-pressure conditions, both the matrix and fractured cores demonstrate an absence of gas slippage effect. The relationship between the gas flow rate and pressure-squared gradient transitions from a concave curve to nearly linear behavior, suggesting that nonlinear gas flow is primarily controlled by the tight pore structure and increasing water saturation.

- (3)

- The TPG of ultra-deep tight sandstones ranges from 0.0004 to 0.8762 MPa/cm and increases significantly with rock compaction and water saturation. Under the same water saturation, the TPG of matrix cores is approximately 13.21 times higher than that of fractured cores, indicating that the fractures can effectively reduce the critical pressure required for gas flow.

- (4)

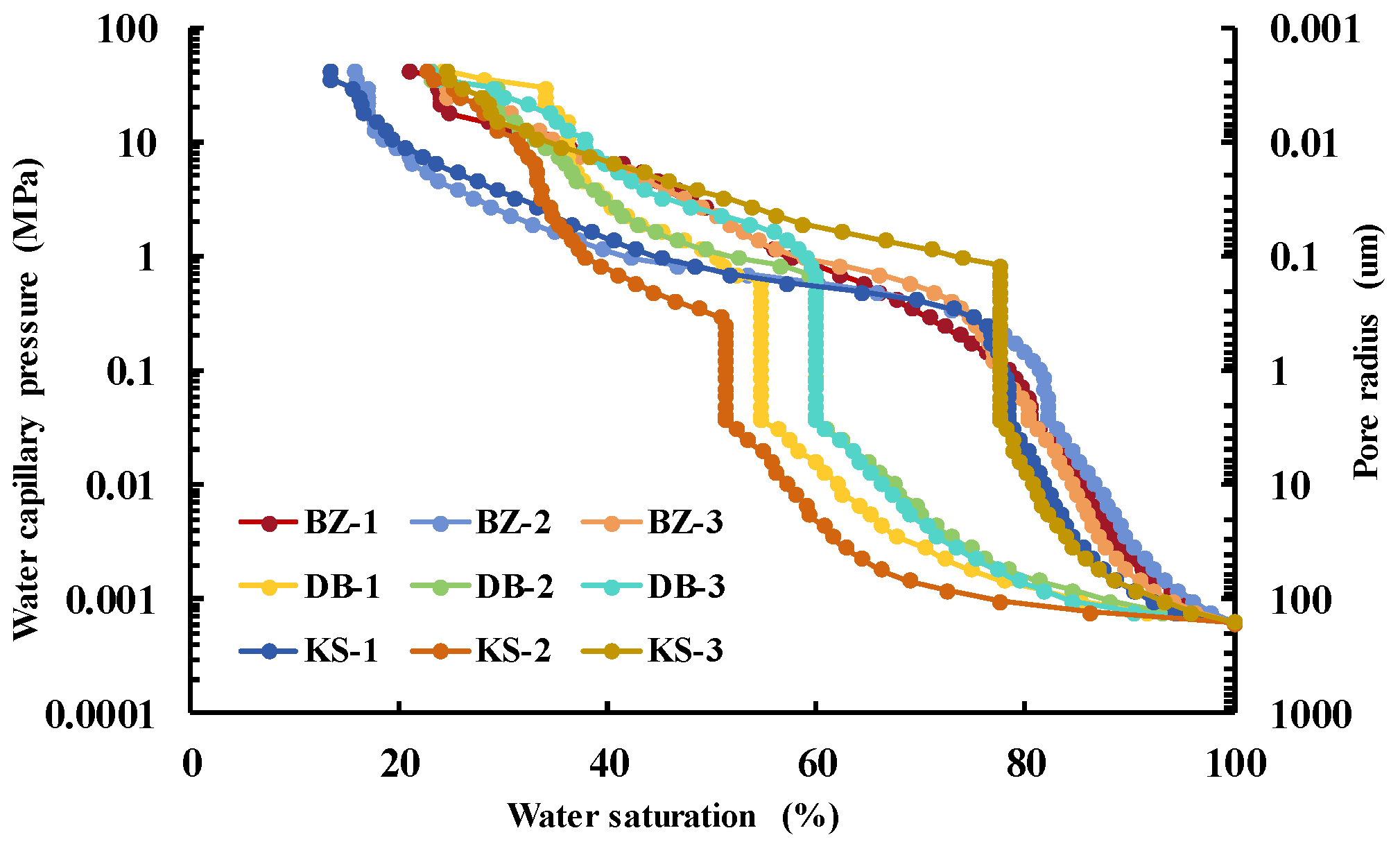

- The water phase can preferentially occupy the larger pores, forcing the gas flow to rely on finer pores. The pores with a maximum radius of 0.21 μm require 0.66 MPa of driving pressure, whereas pores with a median radius of 0.033 μm require about 4.18 MPa. This indicates that the fracture networks can significantly reduce the lower limit for gas flow and serve as the primary flow channels for efficient development of ultra-deep tight sandstone gas.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zou, C.; Zhu, R.; Liu, K.; Su, L.; Bai, B.; Zhang, X.; Yuan, X.; Wang, J. Tight gas sandstone reservoirs in China: Characteristics and recognition criteria. J. Pet. Sci. Eng. 2012, 88, 82–91. [Google Scholar] [CrossRef]

- Jia, A.; Wei, Y.; Guo, Z.; Wang, G.; Meng, D.; Huang, S. Development status and prospect of tight sandstone gas in China. Nat. Gas Ind. B 2022, 9, 467–476. [Google Scholar] [CrossRef]

- Liu, Z.; Song, X.; Fu, X.; Luo, X.; Wang, H. Energy Production Potential of Ultra-Deep Reservoirs in Keshen Gas Field, Tarim Basin: From the Perspective of Prediction of Effective Reservoir Rocks. Energies 2025, 18, 2913. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, R. Characterization and evaluation of ultra-deep fracture-pore tight sandstone reservoirs: A case study of Cretaceous Bashijiqike Formation in Kelasu tectonic zone in Kuqa foreland basin, Tarim, NW China. Pet. Explor. Dev. 2014, 41, 175–184. [Google Scholar] [CrossRef]

- Zhang, R.; Yang, H.; Wang, J.; Shou, J.; Zeng, Q.; Liu, Q. The formation mechanism and exploration significance of ultra-deep, low-porosity and tight sandstone reservoirs in Kuqa depression, Tarim Basin. Acta Pet. Sin. 2014, 35, 1057. [Google Scholar] [CrossRef]

- Zeng, L.; Song, Y.; Liu, G.; Tan, X.; Xu, X.; Yao, Y.; Mao, Z. Natural fractures in ultra-deep reservoirs of China: A review. J. Struct. Geol. 2023, 175, 104954. [Google Scholar] [CrossRef]

- Wang, J.; Yang, X.; Zhang, J.; Wang, K.; Zhang, R.; Wang, Q.; Ren, B.; Ukar, E. Subsurface fracture characterization in a folded ultra-deep tight-gas sandstone reservoir: A case study from the Keshen gas field, Tarim Basin, China. J. Struct. Geol. 2023, 172, 104867. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, C.; Yang, M.; Li, H.; Wang, C.; Diwu, P.; Jiang, H.; Wang, Y. Research on water invasion law and control measures for ultradeep, fractured, and low-porosity sandstone gas reservoirs: A case study of Kelasu gas reservoirs in Tarim Basin. Processes 2024, 12, 310. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Gu, J.; Yu, Z.; Yang, X.; Chang, Y.; Lu, A. Research and Practice on Liquid Extraction in Late Water Flooding of Ultra Deepwater Facies Sandstone Reservoirs. In Proceedings of the International Field Exploration and Development Conference 2023, Wuhan, China, 20–22 September 2023; Springer: Singapore, 2023; pp. 1775–1784. [Google Scholar] [CrossRef]

- Zhang, D.; Kang, Y.; Selvadurai, A.P.S.; You, L.; Tian, J. The role of phase trapping on permeability reduction in an ultra-deep tight sandstone gas reservoirs. J. Pet. Sci. Eng. 2019, 178, 311–323. [Google Scholar] [CrossRef]

- Wang, F.; Kobina, F. The Influence of Geological Factors and Transmission Fluids on the Exploitation of Reservoir Geothermal Resources: Factor Discussion and Mechanism Analysis. Reserv. Sci. 2025, 1, 3–18. [Google Scholar] [CrossRef]

- Wu, J.; Ansari, U. From CO2 Sequestration to Hydrogen Storage: Further Utilization of Depleted Gas Reservoirs. Reserv. Sci. 2025, 1, 19–35. [Google Scholar] [CrossRef]

- Persoff, P.; Pruess, K. Two-phase flow visualization and relative permeability measurement in natural rough-walled rock fractures. Water Resour. Res. 1995, 31, 1175–1186. [Google Scholar] [CrossRef]

- Fang, F.; Shen, W.; Gao, S.; Liu, H.; Wang, Q.; Li, Y. Experimental study on the physical simulation of water invasion in carbonate gas reservoirs. Appl. Sci. 2017, 7, 697. [Google Scholar] [CrossRef]

- Shen, W.; Xu, Y.; Li, X.; Huang, W.; Gu, J. Physical simulation of water influx mechanism in fractured gas reservoirs. J. Cent. South Univ. Sci. Technol. 2014, 45, 3283–3287. [Google Scholar]

- Johnson, E.F.; Bossler, D.P.; Bossler, V.O.N. Calculation of relative permeability from displacement experiments. Trans. AIME 1959, 216, 370–372. [Google Scholar] [CrossRef]

- Babadagli, T.; Raza, S.; Ren, X.; Develi, K. Effect of surface roughness and lithology on the water–gas and water–oil relative permeability ratios of oil-wet single fractures. Int. J. Multiph. Flow 2015, 75, 68–81. [Google Scholar] [CrossRef]

- Beltrán, A.; Hernández-Díaz, D.; Chávez, O.; García, A.; Mena, B.; Zenit, R. Experimental study of the effect of wettability on the relative permeability for air–water flow through porous media. Int. J. Multiph. Flow 2019, 120, 103091. [Google Scholar] [CrossRef]

- Yacoub, A.; Djerbi, A.; Fen-Chong, T. The effect of the drying temperature on water porosity and gas permeability of recycled sand mortar. Constr. Build. Mater. 2019, 214, 677–684. [Google Scholar] [CrossRef]

- Guo, P.; Zhang, H.; Du, J.; Wang, Z.; Zhang, W.; Ren, H. Study on gas-liquid relative permeability experiments of fractured-porous reservoirs. Petroleum 2017, 3, 348–354. [Google Scholar] [CrossRef]

- Guo, X.; Zou, G.; Wang, Y.; Wang, Y.; Gao, T. Investigation of the temperature effect on rock permeability sensitivity. J. Pet. Sci. Eng. 2017, 156, 616–622. [Google Scholar] [CrossRef]

- Chen, F.; Duan, Y.; Wang, K. Productivity Model Study of Water-Bearing Tight Gas Reservoirs Considering Micro-to Nano-Scale Effects. Processes 2024, 12, 1499. [Google Scholar] [CrossRef]

- Li, J.; Liu, L.; Zhu, Y.; Zhao, L.; Chai, X.; Tian, L. A new dynamic model of supply boundary at low pressure in tight gas reservoir. Sci. Rep. 2025, 15, 12178. [Google Scholar] [CrossRef]

- Lu, C.; Qin, X.; Ma, C.; Yu, L.; Geng, L.; Bian, H.; Zhang, K.; Zhou, Y. Investigation of the impact of threshold pressure gradient on gas production from hydrate deposits. Fuel 2022, 319, 123569. [Google Scholar] [CrossRef]

- Yang, J.; Chen, W.; Tian, H.; Yu, H. Study of permeability evolutions in low permeability media under different stresses and temperatures. Rock Soil Mech. 2009, 30, 3587–3594. [Google Scholar] [CrossRef]

- Fang, J.; Guo, P.; Xiao, X.; Du, J.; Dong, C.; Xiong, Y.; Long, F. Gas-water relative permeability measurement of high temperature and high pressure tight gas reservoirs. Pet. Explor. Dev. 2015, 42, 92–96. [Google Scholar] [CrossRef]

- Li, Y.L.; Li, X.P.; Wu, F.; Lu, H.; Lei, X.; Wang, W.; Lu, R.; Li, J.; Tan, X. Experimental study on stress sensitivity of high-temperature and high-pressure sandstone gas reservoirs in Yingqiong Basin. Energy Sci. Eng. 2020, 8, 4116–4125. [Google Scholar] [CrossRef]

- Mao, W.; Yao, Y.; Qin, Z.; Liu, Y.; Han, J.; Liu, Z. Pore structure characterization of sandstone under different water invasion cycles using micro-CT. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 53. [Google Scholar] [CrossRef]

- Yang, D.; Xie, K.; Lu, X.; Hu, Y.; Chen, F.; Jiao, C.; Jia, N.; Shen, W. Mechanisms of permeability alteration during water invasion in unconsolidated sandstone gas reservoirs. Phys. Fluids 2025, 37, 043312. [Google Scholar] [CrossRef]

- Zhou, L.; Fan, X.; He, Y.; Gou, S.; Bi, Q.; Chen, J.; Chen, L.; Wang, J.; Guo, H.; Wu, Y.; et al. Enhanced the permeability of water invasion sandstone by effectively inhibiting the swelling and dispersion of montmorillonite. J. Mol. Liq. 2023, 372, 121196. [Google Scholar] [CrossRef]

- Yan, Q.; He, Q.; Wei, L.; Qu, Z.; Ren, X. A laboratory study on percolation characteristics of single phase flow in low-permeability reservoirs. J. Xi’An Pet. Inst. 1990, 5, 1–6. [Google Scholar]

- Li, A.; Zhang, S.; Liu, M.; Wang, W.; Zhang, L. A new method of measuring starting pressure for low permeability reservoir. J. China Univ. Pet. 2008, 32, 68–72. [Google Scholar]

- Yang, Z.; Li, X.; Liu, S.; Gao, S. Threshold pressure effect of low permeability tight gas reservoirs in Sulige gas field. Acta Pet. Sin. 2015, 36, 347. [Google Scholar] [CrossRef]

- Ding, J.; Yang, S.; Cao, T.; Wu, J. Dynamic threshold pressure gradient in tight gas reservoir and its influence on well productivity. Arab. J. Geosci. 2018, 11, 783. [Google Scholar] [CrossRef]

- Hu, A.; Su, L.; Cao, G.; Luo, Z.; Yan, C.; Chen, Q. Experimental Study on the Effect of Fractures on the Irreducible and Movable Water in Water-Bearing Tight Sandstone Gas Reservoirs. Processes 2025, 13, 1685. [Google Scholar] [CrossRef]

- Li, Y.; Fu, J.; Yan, W.; Chen, K.; Ding, J.; Wu, J. Experimental study on the dynamic threshold pressure gradient of high water-bearing tight sandstone gas reservoir. Front. Earth Sci. 2024, 12, 1487433. [Google Scholar] [CrossRef]

- Tian, W.; Li, A.; Ren, X.; Josephine, Y. The threshold pressure gradient effect in the tight sandstone gas reservoirs with high water saturation. Fuel 2018, 226, 221–229. [Google Scholar] [CrossRef]

- Li, S.; Cheng, L.; Li, X.; Hao, F. Nonlinear seepage flow of ultralow permeability reservoirs. Pet. Explor. Dev. 2008, 35, 606–612. [Google Scholar] [CrossRef]

- Song, H.; Cao, Y.; Yu, M.; Wang, Y.; Killough, J.E.; Leung, J. Impact of permeability heterogeneity on production characteristics in water-bearing tight gas reservoirs with threshold pressure gradient. J. Nat. Gas Sci. Eng. 2015, 22, 172–181. [Google Scholar] [CrossRef]

- Yao, J.; Ding, Y.; Sun, H.; Fan, D.; Wang, M.; Jia, C. Productivity analysis of fractured horizontal wells in tight gas reservoirs using a gas–water two-phase flow model with consideration of a threshold pressure gradient. Energy Fuels 2023, 37, 8190–8198. [Google Scholar] [CrossRef]

- Zafar, A.; Su, Y.L.; Li, L.; Fu, J.-G.; Mehmood, A.; Ouyang, W.-P.; Zhang, M. Tight gas production model considering TPG as a function of pore pressure, permeability and water saturation. Pet. Sci. 2020, 17, 1356–1369. [Google Scholar] [CrossRef]

- Lei, W. Exact analytical solutions for moving boundary problems of one-dimensional flow in semi-infinite porous media with consideration of threshold pressure gradient. J. Hydrodyn. Ser. B 2015, 27, 542–547. [Google Scholar] [CrossRef]

- Zhu, W.; Song, H.; Huang, X.; Liu, X.; He, D.; Ran, Q. Pressure characteristics and effective deployment in a water-bearing tight gas reservoir with low-velocity non-Darcy flow. Energy Fuels 2011, 25, 1111–1117. [Google Scholar] [CrossRef]

- Zhu, W.; Zou, G.; Liu, Y.; Liu, W.; Pan, B. The influence of movable water on the gas-phase threshold pressure gradient in tight gas reservoirs. Energies 2022, 15, 5309. [Google Scholar] [CrossRef]

- Du, J.; Liu, Q.; Guo, P.; Jiang, T.; Xiong, Y.; Jiang, X. Study on water displacing gas relative permeability curves in fractured tight sandstone reservoirs under high pressure and high temperature. ACS Omega 2020, 5, 7456–7461. [Google Scholar] [CrossRef] [PubMed]

- Mo, F.; Du, Z.; Peng, X.; Liang, B.; Tang, Y.; Yue, P. Analysis of Pressure-Dependent Relative Permeability in Permeability Jail of Tight Gas Reservoirs and its Influence on Tight Gas Production. J. Porous Media 2019, 22, 1667–1683. [Google Scholar] [CrossRef]

- Khalaf, M.S.; Soliman, N.; El-Banbi, A.H. Wellbore storage removal in pressure transient analysis for gas wells. J. Pet. Sci. Eng. 2022, 208, 109712. [Google Scholar] [CrossRef]

| Sample Type | Sample ID | Length (cm) | Diameter (cm) | In Situ Porosity (%) | In Situ Permeability (mD) |

|---|---|---|---|---|---|

| Matrix Cores | BZ-1 | 3.08 | 2.55 | 2.85 | 0.00256 |

| DB-1 | 5.54 | 2.55 | 2.68 | 0.00077 | |

| KS-1 | 3.52 | 2.52 | 6.27 | 0.00174 | |

| Fractured Cores | BZ-2 | 3.11 | 2.54 | 3.05 | 1.18417 |

| DB-2 | 5.58 | 2.54 | 2.82 | 1.01876 | |

| KS-2 | 5.02 | 2.55 | 5.17 | 2.00046 |

| Block | Gas Type | Simulated Gas Composition |

|---|---|---|

| Keshen | Dry gas | 100% CH4 |

| Dabei | Wet gas | 100% CH4 |

| Bozi | Condensate gas | 86.7% Methane (CH4) + 13.3% Ethane (C2H6) |

| Block | Temperature (°C) | Inlet Pressure (MPa) | Outlet Pressure (MPa) | Confining Pressure (MPa) |

|---|---|---|---|---|

| BZ | 121.0 | 92.5 | 92.5 | 133.1 |

| DB | 147.5 | 111.9 | 111.9 | 158.2 |

| KS | 170.0 | 120.0 | 120.0 | 152.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, L.; Zhang, Y.; Chen, X.; Zhang, Q.; Chen, M.; Pei, X.; Kang, Y.; Zhang, Y.; Tang, X.; Zhou, B.; et al. Multiscale Gas Flow Mechanisms in Ultra-Deep Fractured Tight Sandstone Reservoirs with Water Invasion. Processes 2025, 13, 3596. https://doi.org/10.3390/pr13113596

Tang L, Zhang Y, Chen X, Zhang Q, Chen M, Pei X, Kang Y, Zhang Y, Tang X, Zhou B, et al. Multiscale Gas Flow Mechanisms in Ultra-Deep Fractured Tight Sandstone Reservoirs with Water Invasion. Processes. 2025; 13(11):3596. https://doi.org/10.3390/pr13113596

Chicago/Turabian StyleTang, Liandong, Yongbin Zhang, Xueni Chen, Qihui Zhang, Mingjun Chen, Xuehao Pei, Yili Kang, Yiguo Zhang, Xingyu Tang, Bihui Zhou, and et al. 2025. "Multiscale Gas Flow Mechanisms in Ultra-Deep Fractured Tight Sandstone Reservoirs with Water Invasion" Processes 13, no. 11: 3596. https://doi.org/10.3390/pr13113596

APA StyleTang, L., Zhang, Y., Chen, X., Zhang, Q., Chen, M., Pei, X., Kang, Y., Zhang, Y., Tang, X., Zhou, B., Li, J., Tian, P., & Wu, D. (2025). Multiscale Gas Flow Mechanisms in Ultra-Deep Fractured Tight Sandstone Reservoirs with Water Invasion. Processes, 13(11), 3596. https://doi.org/10.3390/pr13113596