The Technological Quality of New Wheat Varieties Grown in the Southern Region of the Central Andes in Perú

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Process of Obtaining Flour

2.3. Proximate Composition of Flour

2.4. Amylographic and Farinographic Properties

2.5. The Determination of the Thermal Stability of the Flours

2.6. Structural Analysis of Flours

2.7. Determination of Functional Groups by Infrared Spectrophotometry

2.8. Statistical Analysis

3. Results and Discussion

3.1. Proximate Analysis

3.2. Rheological Properties Associated with Amylographies and Farinography

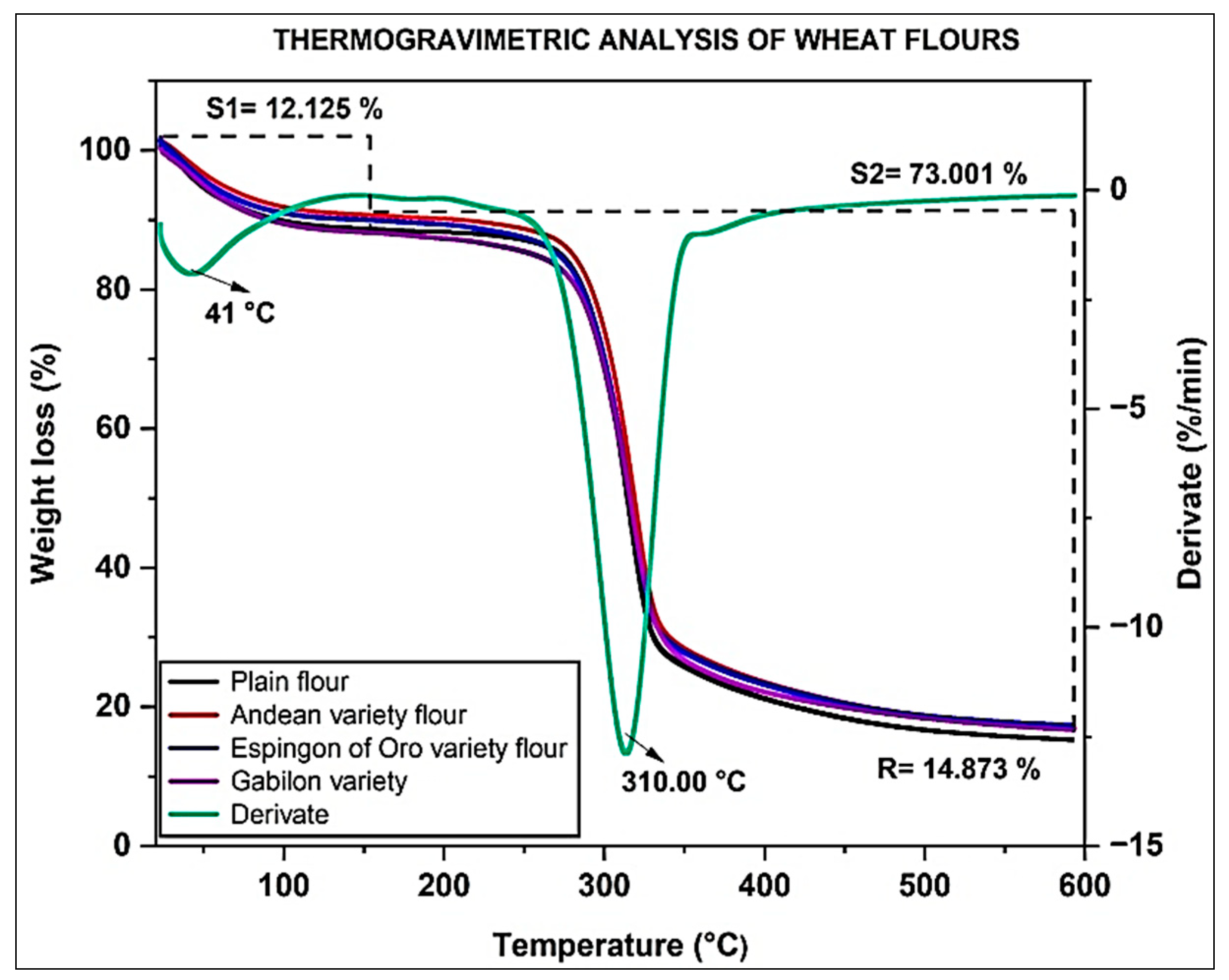

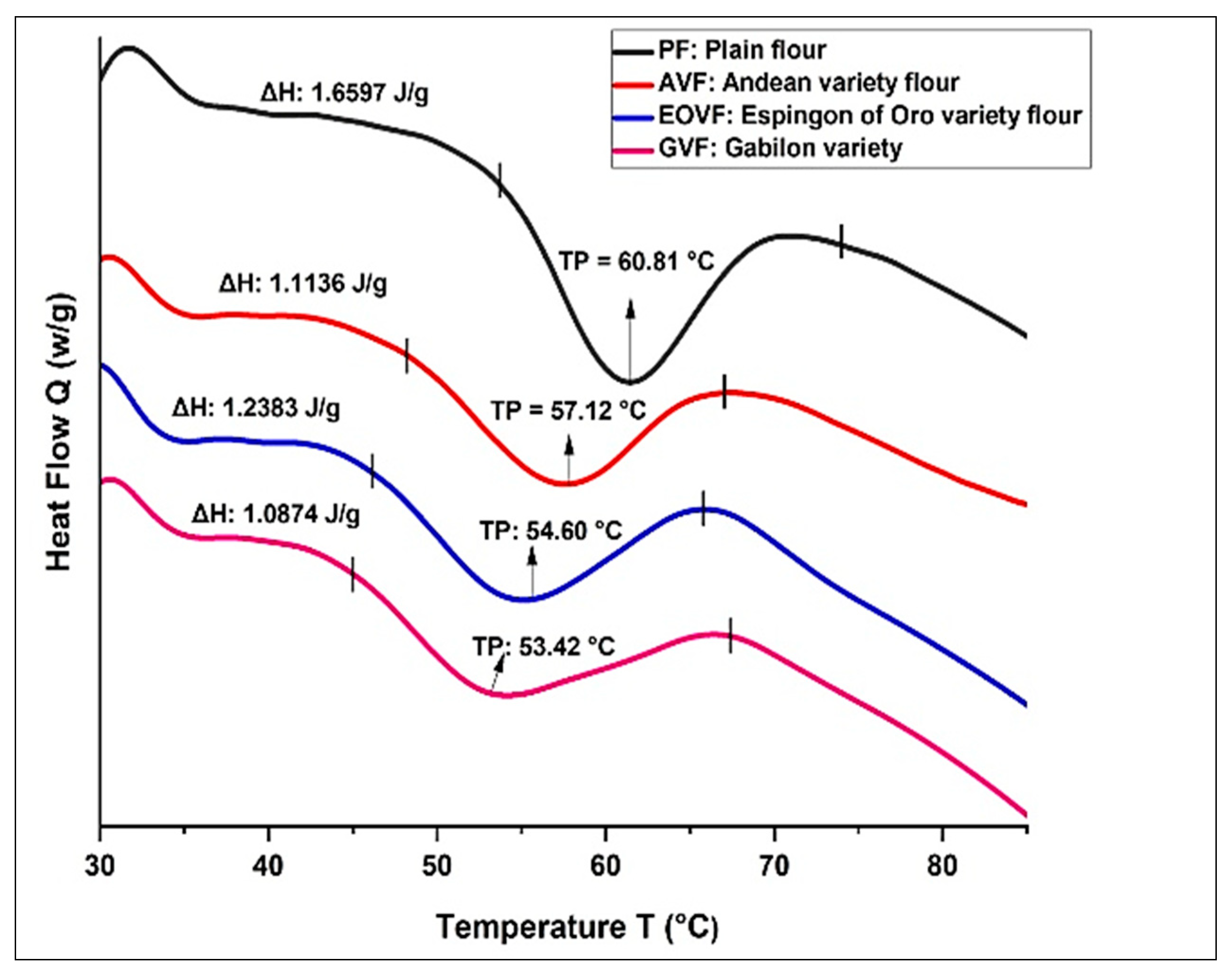

3.3. Thermal Characteristics and Gelatinization Degree of Flour

3.4. Structural Properties of Flour Particles

Surface Analysis of Flour by SEM-EDS

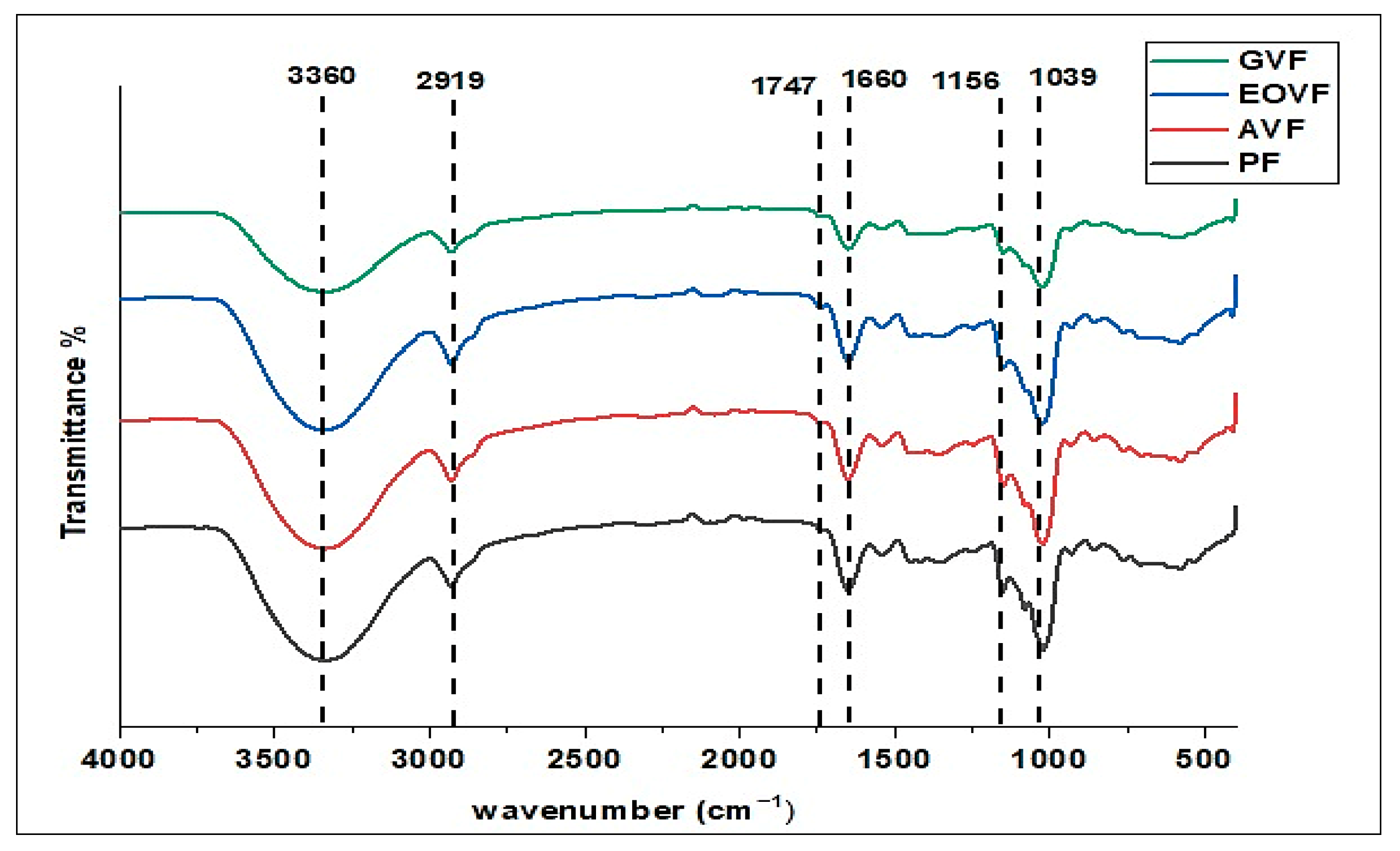

3.5. Analysis of Functional Groups

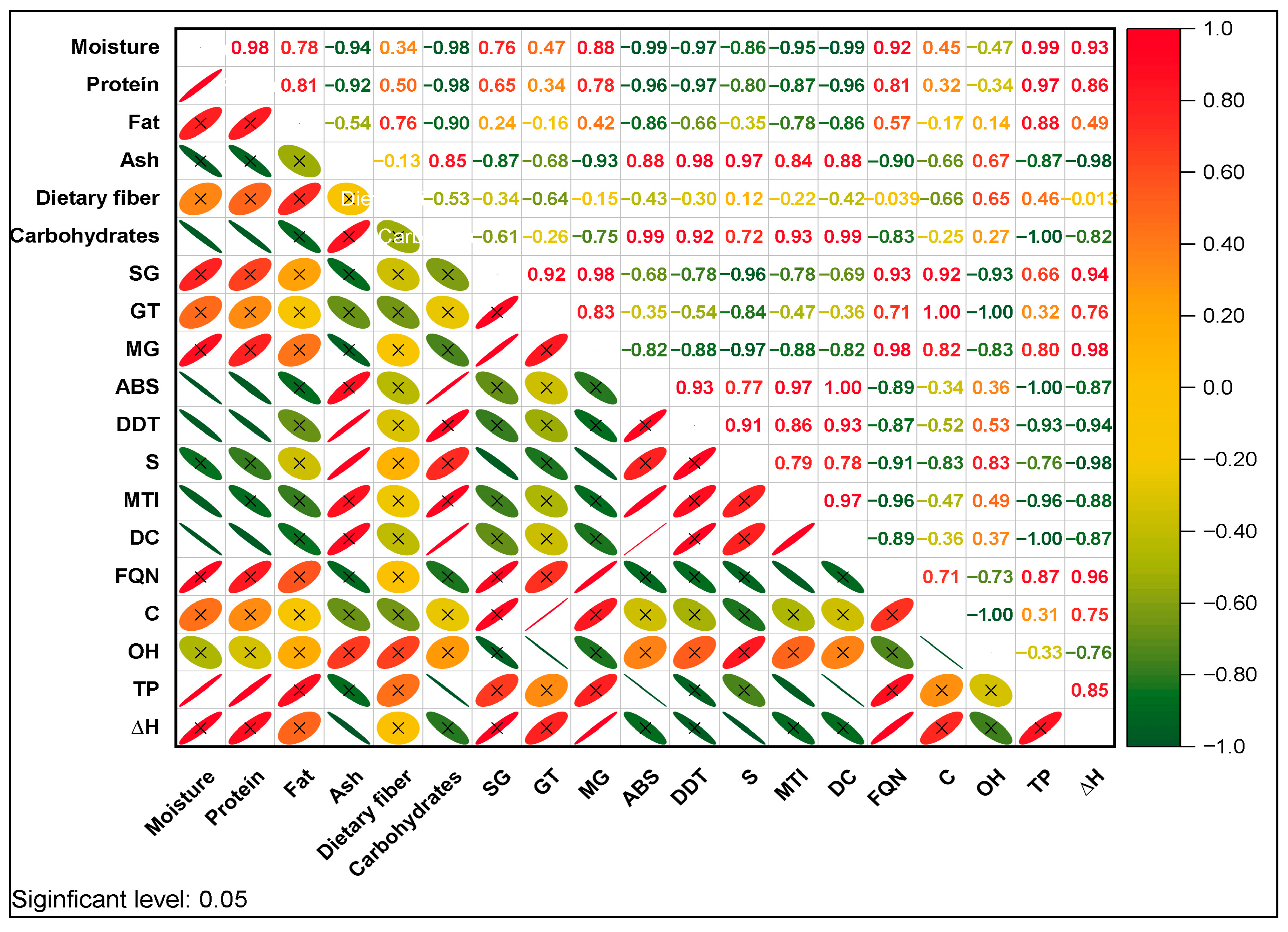

3.6. Pearson Correlation

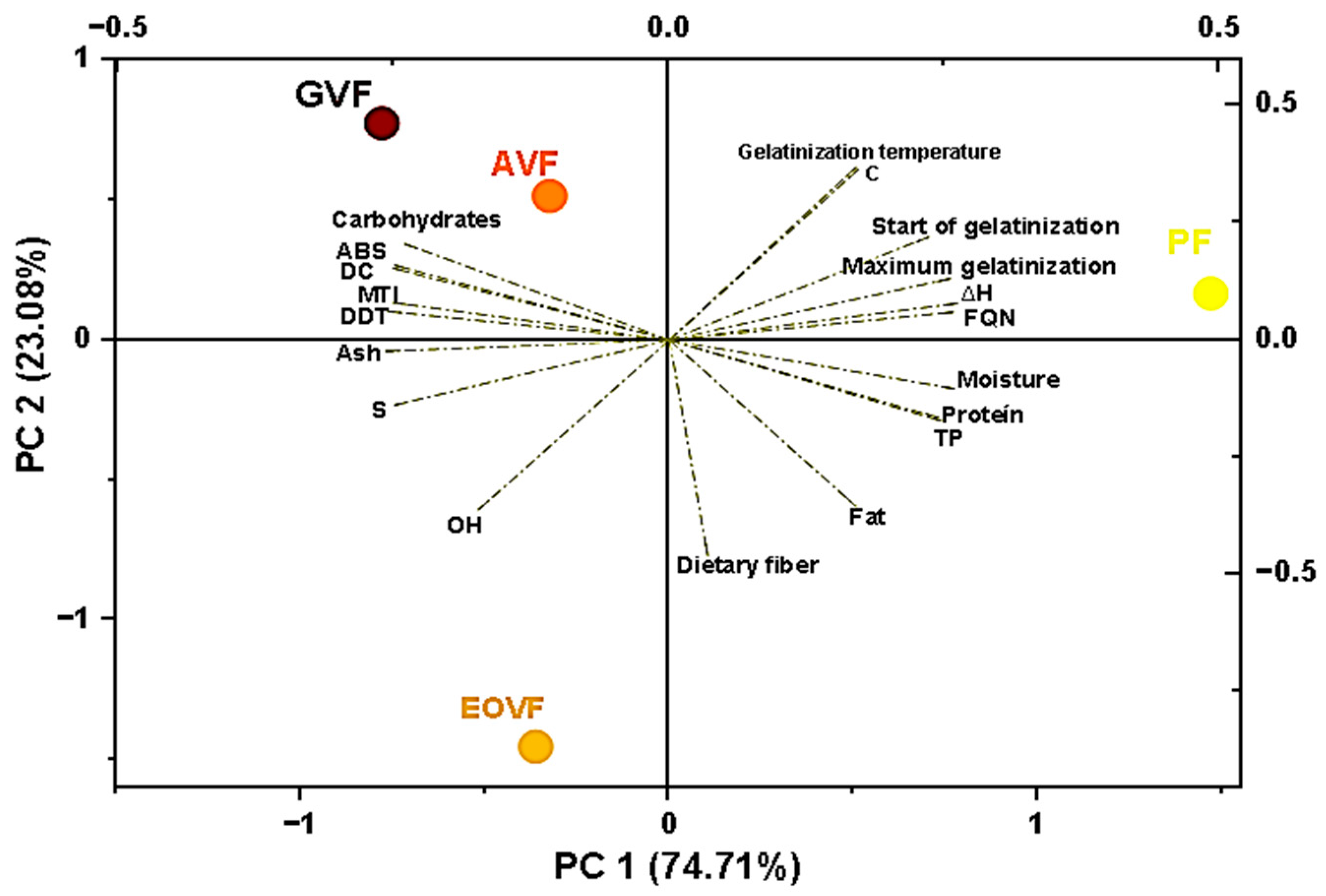

3.7. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ATR | Attenuated Total Reflectance |

| AVF | Andino Variety flour |

| DSC | Differential Scanning Calorimetry |

| EDS | Energy Dispersive X-ray Spectroscopy |

| EOVF | Espigon de Oro variety flour |

| FTIR | Fourier transform infrared spectroscopy |

| GVF | Gavilon variety flour |

| PF | Plain flour |

| TGA | Thermogravimetric Analysis |

| SEM | Scanning Electron Microscopy |

References

- Borghi, E.; Domínguez, G.G.; Humphreys, A. The State of Food Security and Nutrition in the World 2022; FAO: Rome, Italy, 2022. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, P.; Yue, Y. Prediction of global wheat cultivation distribution under climate change and socioeconomic development. Sci. Total Environ. 2024, 919, 170481. [Google Scholar] [CrossRef]

- McCloud, N. What has inflation targeting done for household consumption? Int. Rev. Financ. Anal. 2024, 95, 103499. [Google Scholar] [CrossRef]

- Gracia, B. Diseño de Harinas a Partir de Variedades de Trigo (Triticum aestivum), Para la Industria Panificadora, Zaragoza, España. 2015. Available online: https://zaguan.unizar.es/record/31749?ln=eshttps://zaguan.gpt.c (accessed on 20 August 2025).

- Marti, A.; Ulrici, A.; Foca, G.; Quaglia, L.; Pagani, M.A. Characterization of common wheat flours (Triticum aestivum L.) through multivariate analysis of conventional rheological parameters and gluten peak test indices. LWT-Food Sci. Technol. 2015, 64, 95–103. [Google Scholar] [CrossRef]

- De la Horra, A.E.; Seghezzo, M.L.; Molfese, E.; Ribotta, P.D.; León, A.E. Indicadores de calidad de las harinas de trigo: Índice de calidad industrial y su relación con ensayos predictivos. Agriscientia 2012, 29, 81–89. [Google Scholar] [CrossRef]

- Cuniberti, M.B.; Menella, D. Requerimientos Industriales de Trigo en la Argentina. IDIA 2004, 21, 16–20. [Google Scholar]

- Zhou, S.; Reddy, C.K.; Du, B.; Xu, B. Pasting, thermal, and functional properties of wheat flour and rice flour formulated with chestnut flour. Bioact. Carbohydrates Diet. Fibre 2021, 26, 100290. [Google Scholar] [CrossRef]

- Shewry, P.R.; Halford, N.G.; Belton, P.S.; Tatham, A.S. The structure and properties of gluten: An elastic protein from wheat grain. Philos. Trans. R. Soc. B Biol. Sci. 2002, 357, 133–142. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.-H.; Kim, J.-Y. Understanding Wheat Starch Metabolism in Properties, Environmental Stress Condition, and Molecular Approaches for Value-Added Utilization. Plants 2021, 10, 2282. [Google Scholar] [CrossRef]

- Chan, H.-W.; Pong, V.; Tam, K.-P. Cross-National Variation of Gender Differences in Environmental Concern: Testing the Sociocultural Hindrance Hypothesis. Environ. Behav. 2017, 51, 81–108. [Google Scholar] [CrossRef]

- AOAC. Solids (Total) and Moisture in Flour, Method 925.10. In Official Methods of Analysis, 18th ed.; AOAC International: Rockville, MD, USA, 2005; p. 800. [Google Scholar]

- AOAC. Official Methods of Analysis, 22nd Edition 2023; Association of Official Analytical Chemists AOAC: Washington, DC, USA, 1990. [Google Scholar]

- McCleary, B.V. Measurement of Dietary Fiber: Which AOAC Official Method of AnalysisSM to Use. J. AOAC Int. 2023, 106, 917–930. [Google Scholar] [CrossRef]

- AOAC. Official Method 942.05/90 Ash of Animal Feed. Official methods of analysis of the Association of Official Analytical Chemists. Assoc. Off. Anal. Chem. 1990, 857, 2000. [Google Scholar]

- Owheruo, J.O.; Edo, G.I.; Makia, R.S.; Gaaz, T.S.; Okolie, M.C.; Nwaogu, M.U.; Faturoti, A.O.; Akpoghelie, P.O.; Yousif, E.; Isoje, E.F.; et al. Nutritional qualities of cookies made from wheat/cashew nut composite flour. Food Humanit. 2024, 3, 100452. [Google Scholar] [CrossRef]

- AACC, American Association of Cereal Chemestry. (Ed.) St Paul, MN, USA, 2000; p. 4000. Available online: https://www.cerealsgrains.org/resources/Methods/tools/Pages/ArchivedMethods.aspx (accessed on 20 August 2025).

- Jhan, F.; Shah, A.; Gani, A.; Ahmad, M.; Noor, N. Nano-reduction of starch from underutilised millets: Effect on structural, thermal, morphological and nutraceutical properties. Int. J. Biol. Macromol. 2020, 159, 1113–1121. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, H.; Xu, Q.; Zhang, H.; Yang, Y.Y. Thermal, Rheological, Structural and Adhesive Properties of Wheat Starch Gels with Different Potassium Alum Contents. Molecules 2023, 28, 6670. [Google Scholar] [CrossRef]

- Mir, S.A.; Farooq, M.; Naseem, Z.; Mugabi, R. Techno-functional, nutritional, antioxidant and prebiotic potential of underutilized buck wheat flour from Western Himalayas of Jammu and Kashmir. Appl. Food Res. 2025, 5, 100723. [Google Scholar] [CrossRef]

- Tharise, N.; Julianti, E.; Nurminah, M. Evaluation of physico-chemical and functional properties of composite flour from cassava, rice, potato, soybean and xanthan gum as alternative of wheat flour. Int. Food Res. J. 2014, 21, 1641–1649. [Google Scholar]

- Jahn, N.; Konradl, U.; Fleissner, K.; Geisslitz, S.; Scherf, K.A. Protein composition and bread volume of German common wheat landraces grown under organic conditions. Curr. Res. Food Sci. 2024, 9, 100871. [Google Scholar] [CrossRef] [PubMed]

- Siddiqi, R.A.; Singh, T.P.; Rani, M.; Sogi, D.S.; Bhat, M.A. Diversity in Grain, Flour, Amino Acid Composition, Protein Profiling, and Proportion of Total Flour Proteins of Different Wheat Cultivars of North India. Front. Nutr. 2020, 7, 141. [Google Scholar] [CrossRef]

- Skendi, A.; Papageorgiou, M.; Varzakas, T. High protein substitutes for gluten in gluten-free bread. Foods 2021, 10, 1997. [Google Scholar] [CrossRef]

- Al-Marazeeq, K.; Saleh, M.; Angor, M.; Lee, Y. Cookie dough functional properties of partially replaced all-purpose wheat flour with powdered fruit skins and the hedonic perception of the resulting cookies. Front. Sustain. Food Syst. 2024, 8, 1445206. [Google Scholar] [CrossRef]

- Montiel, N.I.A.; Lira, B.M.R.; Ortega, J.A.A.; Moreno, E.R. Alternativas nutricionales y beneficios a la salud: Harinas de trigo (Triticum) y avena (Avena sativa L.) en contraste con polvos de chapulín (Sphenarium purpurascens) y huitlacoche (Ustilago maydis) Nutritional alternatives and health benefits. South Fla. J. Dev. 2024, 5, e4825. [Google Scholar] [CrossRef]

- Sujka, K.; Koczoń, P.; Ceglińska, A.; Reder, M.; Ciemniewska-Żytkiewicz, H. The Application of FT-IR Spectroscopy for Quality Control of Flours Obtained from Polish Producers. J. Anal. Methods Chem. 2017, 2017, 4315678. [Google Scholar] [CrossRef]

- Tripathi, A.; Iswarya, V.; Singh, N.; Rawson, A. Chapter 4—Chemistry of pulses—Micronutrients. In Pulse Foods, 2nd ed.; Tiwari, B.K., Gowen, A., McKenna, B., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 61–86. [Google Scholar]

- Tsegay, N.; Admassu, H.; Zegale, B.; Gosu, A. Nutritional and functional potentials of wheat, cowpea, and yam composite flours on bread formulations: Effect of blending ratio and baking parameters. J. Agric. Food Res. 2024, 18, 101294. [Google Scholar] [CrossRef]

- Stellingwerff, T.; Cox, G.R. Systematic review: Carbohydrate supplementation on exercise performance or capacity of varying durations. Appl. Physiol. Nutr. Metab. 2014, 39, 998–1011. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ou, X.; Al-Maqtari, Q.A.; He, H.-J.; Othman, N. Evaluation of amylose content: Structural and functional properties, analytical techniques, and future prospects. Food Chem. X 2024, 24, 101830. [Google Scholar] [CrossRef]

- Delcour, J.A.; Bruneel, C.; Derde, L.J.; Gomand, S.V.; Pareyt, B.; Putseys, J.A.; Wilderjans, E.; Lamberts, L. Fate of starch in food processing: From raw materials to final food products. Annu. Rev. Food Sci. Technol. 2010, 1, 87–111. [Google Scholar] [CrossRef]

- Wang, K.; Li, M.; Wang, Y.; Liu, Z.; Ni, Y. Effects of extraction methods on the structural characteristics and functional properties of dietary fiber extracted from kiwifruit (Actinidia deliciosa). Food Hydrocoll. 2021, 110, 106162. [Google Scholar] [CrossRef]

- Cui, C.; Caporaso, N.; Chen, J.; Fearn, T. Farinograph characteristics of wheat flour predicted by near infrared spectroscopy with an ensemble modelling method. J. Food Eng. 2023, 359, 111689. [Google Scholar] [CrossRef]

- Cairano, M.D.; Condelli, N.; Caruso, M.C.; Marti, A.; Cela, N.; Galgano, F. Functional properties and predicted glycemic index of gluten free cereal, pseudocereal and legume flours. LWT 2020, 133, 109860. [Google Scholar] [CrossRef]

- Wrigley, C.W.; Tömösközi, S.; Békés, F.; Bason, M. The Farinograph: Its origins. In The Farinograph Handbook; Advances in Technology, Science, and Applications; Woodhead Publishing: Cambridge, UK, 2022; pp. 3–21. [Google Scholar] [CrossRef]

- Sarker, Z.I.; Yamauchi, H.; Kim, S.-J.; Matsumura-Endo, C.; Takigawa, S.; Hashimoto, N.; Noda, T. A farinograph study on dough characteristics of mixtures of wheat flour and potato starches from different cultivars. Food Sci. Technol. Res. 2008, 14, 211–216. [Google Scholar] [CrossRef]

- Wrigley, C.W.; Corke, H.; Seetharaman, K.; Faubion, J. Encyclopedia of Food Grains. 2015. Available online: https://books.google.com/books?hl=es&lr=&id=ce7tBgAAQBAJ&oi=fnd&pg=PP1&ots=Lk-gbvyFW6&sig=nOW5InoTFtBNUdApDWrDBsHAvu8 (accessed on 20 August 2025).

- Aydogan, S.; Sahin, M.; Akcacik, A.G.; Hamzaoglu, S.; Taner, S. Relationships between Farinograph Parameters and Bread Volume, Physicochemical Traits in Bread Wheat Flours. Bahri Dağdaş Bitkisel Araştırma Derg. J. Bahri Dagdas Crop Res. 2015, 3, 2148–3205. Available online: https://api.semanticscholar.org/CorpusID:237158064 (accessed on 20 August 2025).

- Zhang, H.; Zhang, W.; Xu, C.; Zhou, X. Studies on the rheological and gelatinization characteristics of waxy wheat flour. Int. J. Biol. Macromol. 2014, 64, 123–129. [Google Scholar] [CrossRef]

- Deng, L.; Hou, G. Farinograph Applications for Whole Wheat Flour: Exploring the Influence of Circulating Water Temperature and Mixing Speed on Dough Mixing Properties in the Farinograph, 4th ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Shevkani, K.; Katyal, M.; Singh, N. A comparative review of protein and starch characteristics and end-use quality of soft and hard wheat. Food Chem. Adv. 2024, 4, 100613. [Google Scholar] [CrossRef]

- Ktenioudaki, A.; Crofton, E.; Scannell, A.G.; Hannon, J.A.; Kilcawley, K.N.; Gallagher, E. Sensory properties and aromatic composition of baked snacks containing brewer’s spent grain. J. Cereal Sci. 2013, 57, 384–390. [Google Scholar] [CrossRef]

- Hruskova, I.S.M. Characteristics of Bread and Biscuit Made With Wheat and Rice Flour Composites. J. Food Technol. Res. 2014, 1, 156–163. [Google Scholar] [CrossRef]

- Badjona, A.; Bradshaw, R.; Millman, C.; Howarth, M.; Dubey, B. Structural, thermal, and physicochemical properties of ultrasound-assisted extraction of faba bean protein isolate (FPI). J. Food Eng. 2024, 377, 112082. [Google Scholar] [CrossRef]

- Ballesteros-Vivasaa, D.; Ibáñezbb, E.; Cifuentesbb, A.; Parada-Alfonsoa, F. Aprovechamiento de Subproductos Agroalimentarios y de Biomasas no Convencionales en América Latina; Centro de Formación de la Cooperación Española: La Antigua, Spain, 2020. [Google Scholar]

- Dominici, F.; Luzi, F.; Benincasa, P.; Torre, L.; Puglia, D. Biocomposites based on plasticized wheat Flours: Effect of bran content on thermomechanical behavior. Polymers 2020, 12, 2248. [Google Scholar] [CrossRef]

- van Rooyen, J.; Simsek, S.; Oyeyinka, S.A.; Manley, M. Holistic View of Starch Chemistry, Structure and Functionality in Dry Heat-Treated Whole Wheat Kernels and Flour. Foods 2022, 11, 207. [Google Scholar] [CrossRef] [PubMed]

- Osorio-Ruiz, A.; Avena-Bustillos, R.J.; Chiou, B.-S.; Rodríguez-González, F.; Martinez-Ayala, A.-L. Mechanical and Thermal Behavior of Canola Protein Isolate Films As Improved by Cellulose Nanocrystals. ACS Omega 2019, 4, 19172–19176. [Google Scholar] [CrossRef]

- Carvajal, E.Á.; Castaño, V.D.Q.; Aguirre, J.C.L. Determinación de las propiedades térmicas y composicionales de la harina y almidón de chachafruto (erytina edulis triana ex micheli). Temas Agrar. 2013, 18, 21–35. [Google Scholar] [CrossRef]

- Badjona, A.; Bradshaw, R.; Millman, C.; Howarth, M. Faba Bean Processing: Thermal and Non-Thermal Processing on Chemical, Antinutritional Factors, and Pharmacological Properties. Molecules 2023, 28, 5431. [Google Scholar] [CrossRef]

- Saho, V.T.N.; Njintang, Y.N. Morphological, textural analysis and freeze-thaw stability of starches from legume grow in Cameroon. Braz. J. Biol. 2024, 84, e269844. [Google Scholar] [CrossRef] [PubMed]

- Ranathunga, R.A.A.; Suwannaporn, P. Young cereal grains as a new source of healthy and hypoallergenic foods: A review. J. Food Sci. Technol. 2022, 59, 3336–3348. [Google Scholar] [CrossRef] [PubMed]

- Sissons, M. Durum Wheat Products—Recent Advances; MDPI AG: Basel, Switzerland, 2024; pp. 11–13. [Google Scholar] [CrossRef]

- Lappi, J.; Selinheimo, E.; Schwab, U.; Katina, K.; Lehtinen, P.; Mykkänen, H.; Kolehmainen, M.; Poutanen, K. Sourdough fermentation of wholemeal wheat bread increases solubility of arabinoxylan and protein and decreases postprandial glucose and insulin responses. J. Cereal Sci. 2010, 51, 152–158. [Google Scholar] [CrossRef]

- Fernández-Canto, M.N.; García-Gómez, M.B.; Boado-Crego, S.; Vázquez-Odériz, M.L.; Muñoz-Ferreiro, M.N.; Lombardero-Fernández, M.; Pereira-Lorenzo, S.; Romero-Rodríguez, M.Á. Element Content in Different Wheat Flours and Bread Varieties. Foods 2022, 11, 3176. [Google Scholar] [CrossRef]

- Lin, J.; Gu, Y.; Bian, K. Bulk and Surface Chemical Composition of Wheat Flour Particles of Different Sizes. J. Chem. 2019, 2019, 5101684. [Google Scholar] [CrossRef]

- Czaja, T.; Sobota, A.; Szotak, R. Quantification of Ash and Moisture in Wheat Flour by. Foods 2020, 9, 280. [Google Scholar] [CrossRef]

- Chen, L.; Wang, J.; Huang, J.; Tu, T.; Li, L. Cost-trivial material contributes greatly: A review of the application of starch in energy storage systems. J. Energy Storage 2023, 73, 109060. [Google Scholar] [CrossRef]

- Golea, C.M.; Codină, G.G.; Oroian, M. Prediction of wheat flours composition using fourier transform infrared spectrometry (FT-IR). Food Control. 2023, 143, 109318. [Google Scholar] [CrossRef]

- Gunarathne, R.; Marikkar, N.; Yalegama, C.; Mendis, E. FTIR spectral analysis combined with chemometrics in evaluation of composite mixtures of coconut testa flour and wheat flour. J. Food Meas. Charact. 2022, 16, 1796–1806. [Google Scholar] [CrossRef]

- Chinma, C.E.; Abu, J.O.; Adedeji, O.E.; Aburime, L.C.; Joseph, D.G.; Agunloye, G.F.; Adebo, J.A.; Oyeyinka, S.A.; Njobeh, P.B.; Adebo, O.A. Nutritional composition, bioactivity; starch characteristics, thermal and microstructural properties of germinated pigeon pea flour. Food Biosci. 2022, 49, 101900. [Google Scholar] [CrossRef]

- Pasqualone, A.; Summo, C. Qualitative and nutritional improvement of cereal-based foods and beverages. Foods 2021, 10, 338. [Google Scholar] [CrossRef]

- AACC. Farinograph Method for Flour. In AACC Approved Methods of Analysis; AACC International: St. Paul, MN, USA, 2009; pp. 1–7. [Google Scholar] [CrossRef]

- Cerezal, P.M.; Urtuvia, V.G.; Ramírez, V.Q.; Arcos, R.Z. Desarrollo de producto sobre la base de harinas de cereales y leguminosa para niños celíacos entre 6 y 24 meses; II: Propiedades de las mezclas. Nutr. Hosp. 2011, 26, 161–169. [Google Scholar] [CrossRef]

- Bravo, A.P.M. Valoración de la Cáscara de Vicia Faba (Haba) Para la Obtención de una Lámina de Plástico Biodegradable Para el uso en Alimentos. Bachelor’s Thesis, Escuela Superior Técnica de Chimborazo, Riobamba, Ecuador, 2021. Available online: http://dspace.espoch.edu.ec/handle/123456789/15310 (accessed on 20 August 2025).

- Kaur, G.; Sharma, S.; Singh, B.; Dar, B.N. Comparative Study on Functional, Rheological, Thermal, and Morphological Properties of Native and Modified Cereal Flours. Int. J. Food Prop. 2016, 19, 1949–1961. [Google Scholar] [CrossRef]

- Badia-Olmos, C.; Laguna, L.; Haros, C.M.; Tárrega, A. Techno-Functional and Rheological Properties of Alternative Plant-Based Flours. Foods 2023, 12, 1411. [Google Scholar] [CrossRef] [PubMed]

- Hrušková, M.; Švec, I.; Jurinová, I. Chemometrics of wheat composites with hemp, teff, and chia flour: Comparison of rheological features. Int. J. Food Sci. 2013, 2013, 30–32. [Google Scholar] [CrossRef]

- Tapia, M.S. Contribución al Concepto de Actividad del Agua (aw) y su Aplicación en la Ciencia y Tecnología de Alimentos en Lati-noamérica y Venezuela. Boletín la Acad. Ciencias Físicas, Matemáticas y Nat., Volume LXXX, pp. 18–40. 2020. Available online: https://acfiman.org/boletines_articulos/contribucion-al-concepto-de-actividad-del-agua-aw-y-su-aplicacion-en-la-ciencia-y-tecnologia-de-alimentos-en-latinoamerica-y-venezuela/ (accessed on 20 August 2025).

- Scott, G.; Awika, J.M. Effect of protein–starch interactions on starch retrogradation and implications for food product quality. Compr. Rev. Food Sci. Food Saf. 2023, 22, 2081–2111. [Google Scholar] [CrossRef] [PubMed]

| Sample | Moisture (%) | Protein (%) | Fat (%) | Ash (%) | Dietary Fiber (%) | Carbohydrates % |

|---|---|---|---|---|---|---|

| PF | 10.78 ± 0.09 a | 9.10 ± 0.04 a | 1.26 ± 0.06 a | 0.68 ± 0.12 c | 0.92 ± 0.03 b | 78.16 ± 0.03 c |

| GVF | 9.70 ± 0.11 d | 8.39 ± 0.04 d | 1.25 ± 0.04 a | 1.32 ± 0.14 a | 0.82 ± 0.03 b | 79.32 ± 0.25 a |

| EOVF | 10.12 ± 0.03 b | 8.78 ± 0.03 b | 1.26 ± 0.03 a | 1.18 ± 0.06 ab | 1.05 ± 0.12 a | 78.65 ± 0.03 b |

| AVF | 9.95 ± 0.06 c | 8.67 ± 0.04 c | 1.25 ± 0.01 a | 1.05 ± 0.04 b | 0.90 ± 0.06 b | 79.07 ± 0.12 b |

| LSD | 0.0001 | 0.0001 | 0.96 | 0.0003 | 0.0241 | 0.0001 |

| Samples | Start of Gelatinization (°C) | Gelatinization Temperature (°C) | Maximum Gelatinization (AU) |

|---|---|---|---|

| PF | 65.13 ± 0.49 c | 90.20 ± 0.55 c | 1284.67 ± 8.50 d |

| GVF | 61.10 ± 0.30 b | 85.26 ± 0.30 b | 431.33 ± 4.16 b |

| EOVF | 59.40 ± 0.46 a | 78.56 ± 0.15 a | 314.33 ± 4.72 a |

| AVF | 61.46 ± 0.40 b | 86.20 ± 0.55 b | 526.33 ± 3.51 c |

| LSD | 0.0011 | 0.0011 | 0.0001 |

| Type of Flour | ABS (%) | DDT (min) | S (min) | MTI (BU) | DC (FE) | FQN (min) |

|---|---|---|---|---|---|---|

| PF | 58.67 ± 0.15 a | 2.3 ± 0.02 a | 0.00 ± 0.00 a | 14.67 ± 2.08 a | 611.00 ± 2.64 a | 167.00 ± 2.64 b |

| GVF | 72.00 ± 0.36 d | 4.15 ± 0.04 c | 2.32 ± 0.02 c | 267.67 ± 3.51 c | 1133.00 ± 4.58 d | 48.66 ± 2.51 a |

| EOVF | 65.73 ± 0.21 b | 3.46 ± 0.03 b | 2.42 ± 0.02 d | 204.66 ± 6.03 b | 893.67 ± 4.04 b | 44.67 ± 2.08 a |

| AVF | 70.06 ± 0.21 c | 3.36 ± 0.75 b | 1.45 ± 0.03 b | 293.33 ± 4.04 d | 1057.00 ± 3.00 c | 43.00 ± 3.60 a |

| LSD | 0.0001 | 0.0011 | 0.0001 | 0.0012 | 0.0011 | 0.0001 |

| Variety of Wheat Flour | GVF | AVF | EOVF | PF | ||||

|---|---|---|---|---|---|---|---|---|

| Element | C | OH | C | OH | C | OH | C | OH |

| Atómic (%) | 51.9 | 47.8 | 52.2 | 47.6 | 47.9 | 51.5 | 54.6 | 45.2 |

| Atomic error (%) | 0.1 | 0.1 | 0.1 | 0.2 | 0.1 | 0.2 | 0.1 | 0.1 |

| Weight (%) | 44.6 | 54.7 | 44.9 | 54.5 | 40.5 | 58 | 47.4 | 52.2 |

| Weight error (%) | 0.1 | 0.1 | 0.1 | 0.2 | 0.1 | 0.2 | 0.1 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taipe-Pardo, F.; Obregón-Yupanqui, M.E.; Arone-Palomino, H.; Terán-Hilares, F.; Núñez-Espinoza, B.; Ramos-Quispe, I. The Technological Quality of New Wheat Varieties Grown in the Southern Region of the Central Andes in Perú. Processes 2025, 13, 3577. https://doi.org/10.3390/pr13113577

Taipe-Pardo F, Obregón-Yupanqui ME, Arone-Palomino H, Terán-Hilares F, Núñez-Espinoza B, Ramos-Quispe I. The Technological Quality of New Wheat Varieties Grown in the Southern Region of the Central Andes in Perú. Processes. 2025; 13(11):3577. https://doi.org/10.3390/pr13113577

Chicago/Turabian StyleTaipe-Pardo, Fredy, Mirian E. Obregón-Yupanqui, Herson Arone-Palomino, Félix Terán-Hilares, Beatriz Núñez-Espinoza, and Isaias Ramos-Quispe. 2025. "The Technological Quality of New Wheat Varieties Grown in the Southern Region of the Central Andes in Perú" Processes 13, no. 11: 3577. https://doi.org/10.3390/pr13113577

APA StyleTaipe-Pardo, F., Obregón-Yupanqui, M. E., Arone-Palomino, H., Terán-Hilares, F., Núñez-Espinoza, B., & Ramos-Quispe, I. (2025). The Technological Quality of New Wheat Varieties Grown in the Southern Region of the Central Andes in Perú. Processes, 13(11), 3577. https://doi.org/10.3390/pr13113577