Geological Evaluation and Favorable Area Optimization for In Situ Pyrolysis of Tar-Rich Coal: A Case Study from the Santanghu Basin, NW China

Abstract

1. Introduction

2. Geological Background

2.1. Regional Geological Setting

2.2. Stratigraphic Characteristics

3. Methods

3.1. Laboratory Experiments

3.1.1. Vitrinite Reflectance of Coal

3.1.2. Proximate Analysis of Coal

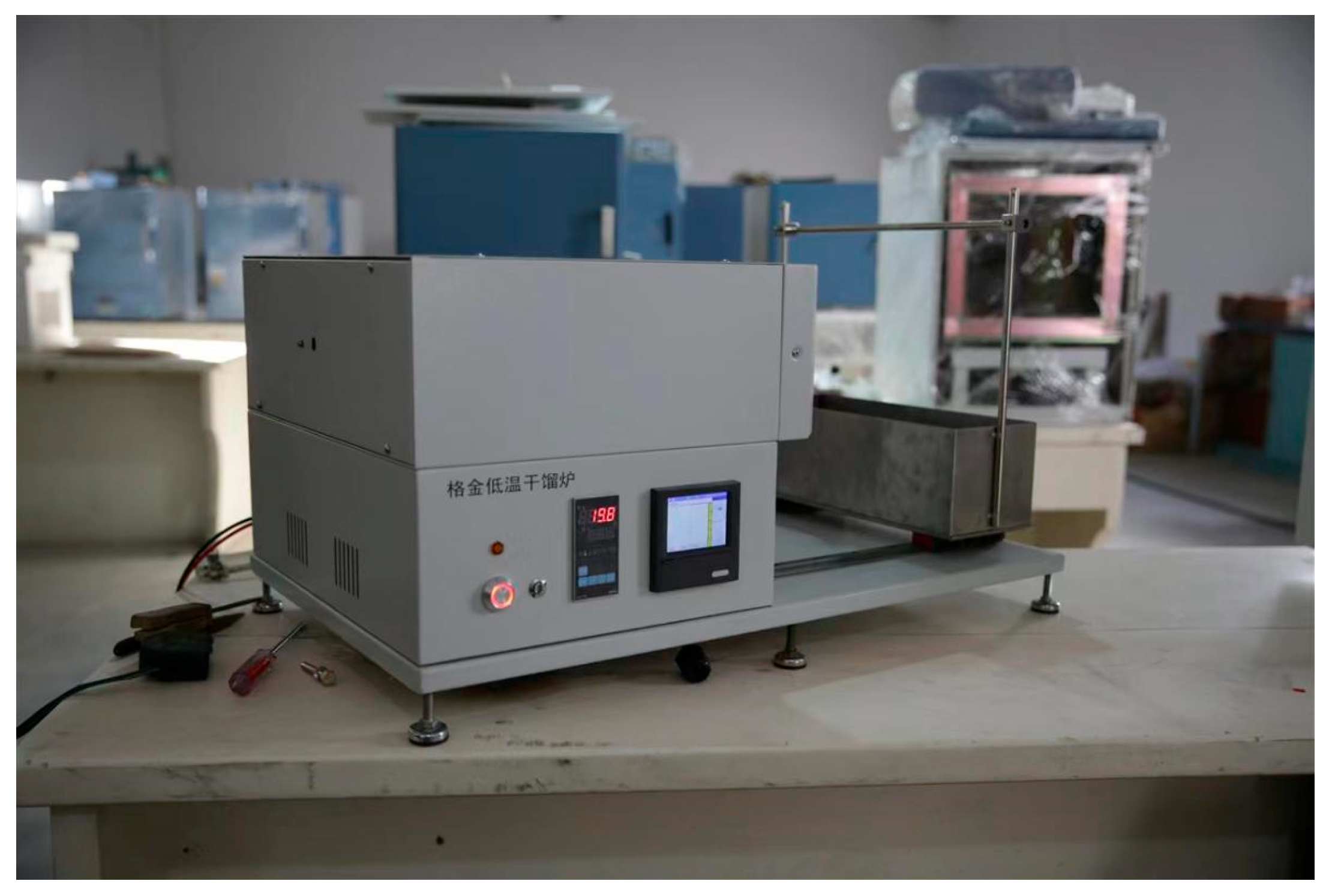

3.1.3. Tar Yield of Coal

3.1.4. Caking Index of Coal

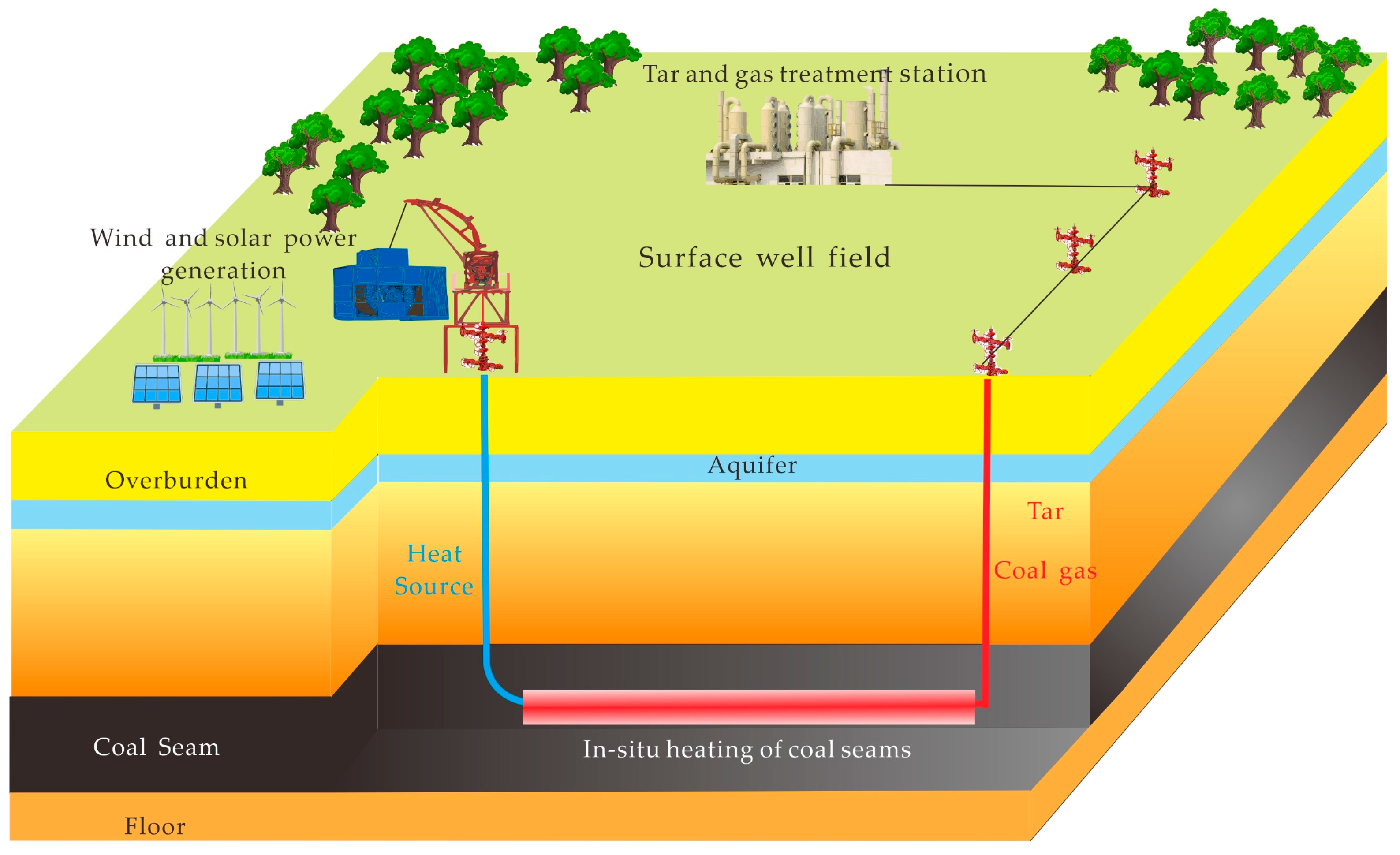

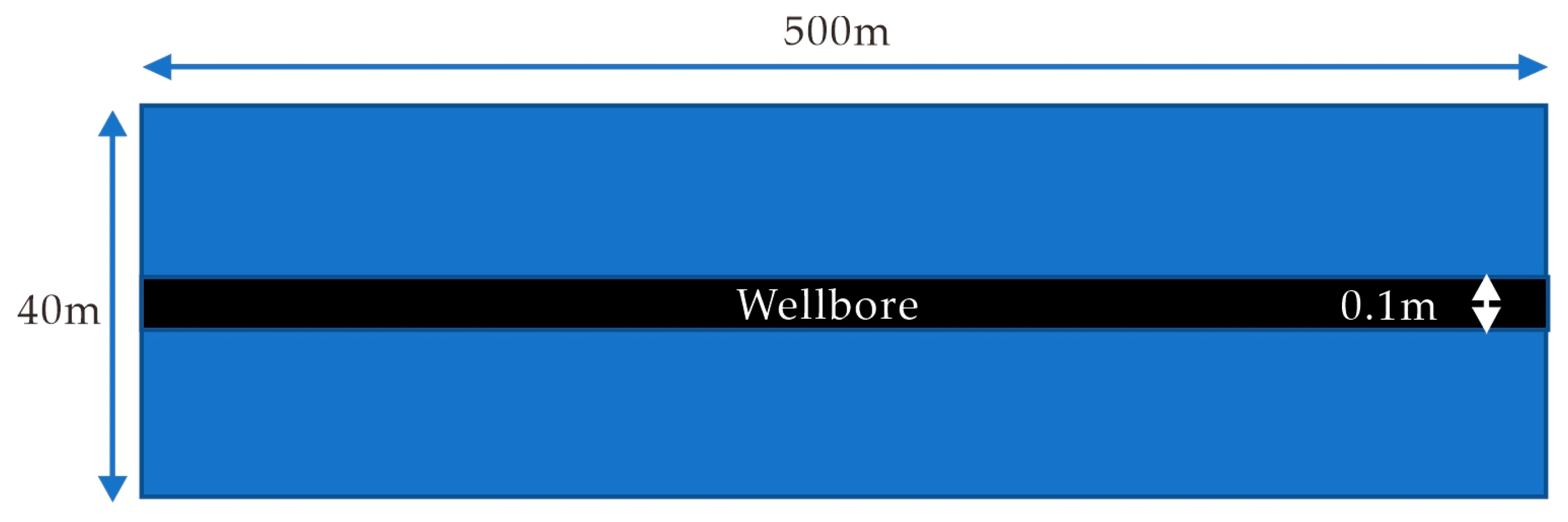

3.2. Numerical Modeling of In Situ Pyrolysis for Tar-Rich Coal

3.2.1. Mass Conservation Equation

3.2.2. Energy Conservation Equation

3.2.3. Governing Equations for Deformation

3.2.4. Physical Property Models of Coal

- Porosity and Permeability

- 2.

- Thermophysical Parameters

3.3. Geological Target Selection Evaluation

3.3.1. Evaluative Parameter Analysis

- 1.

- Resource Scale

- 2.

- Coal Seam Conditions

- (1)

- Burial Depth of Coal Seams

- (2)

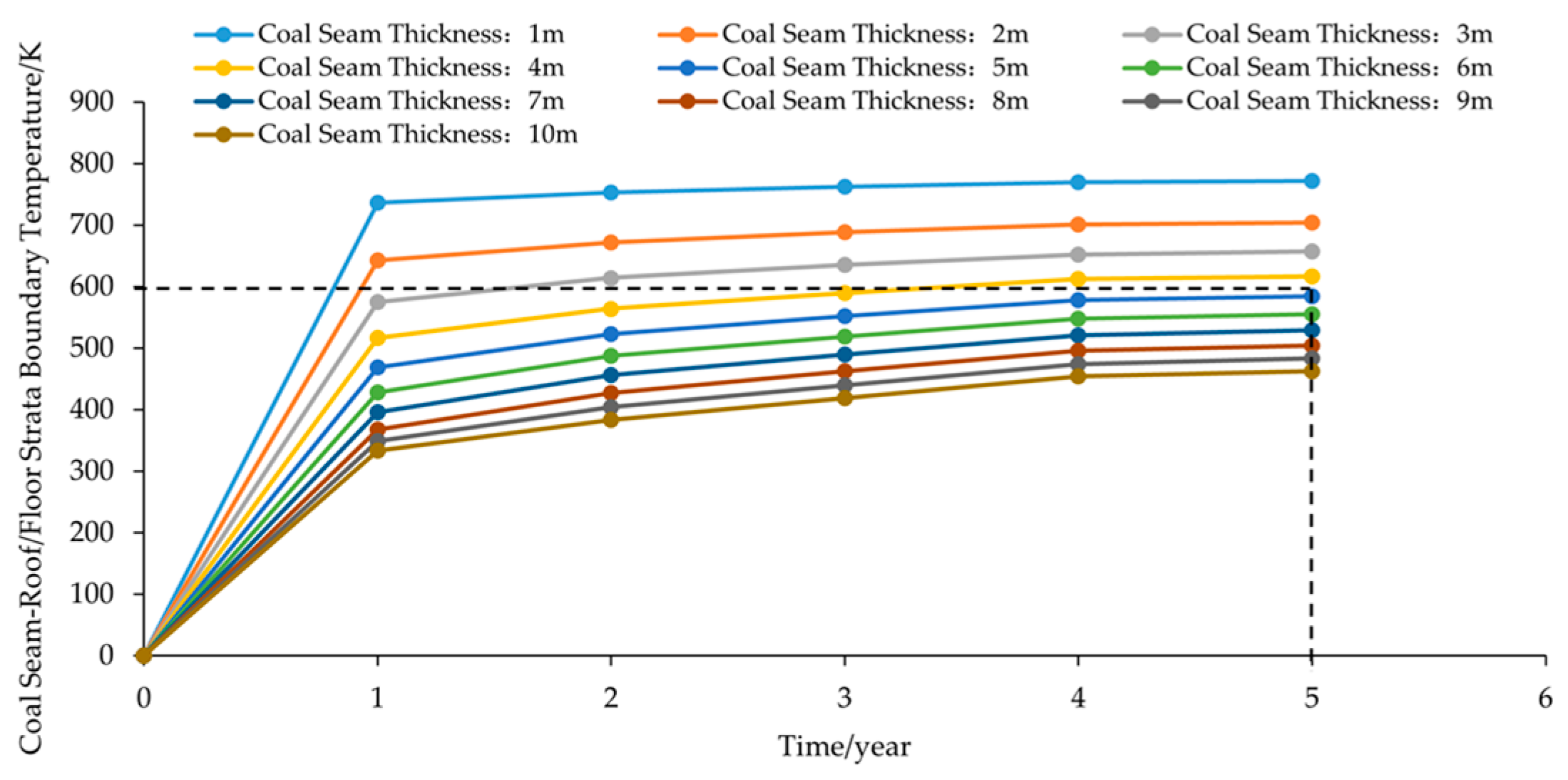

- Thickness of Coal Seams

- (3)

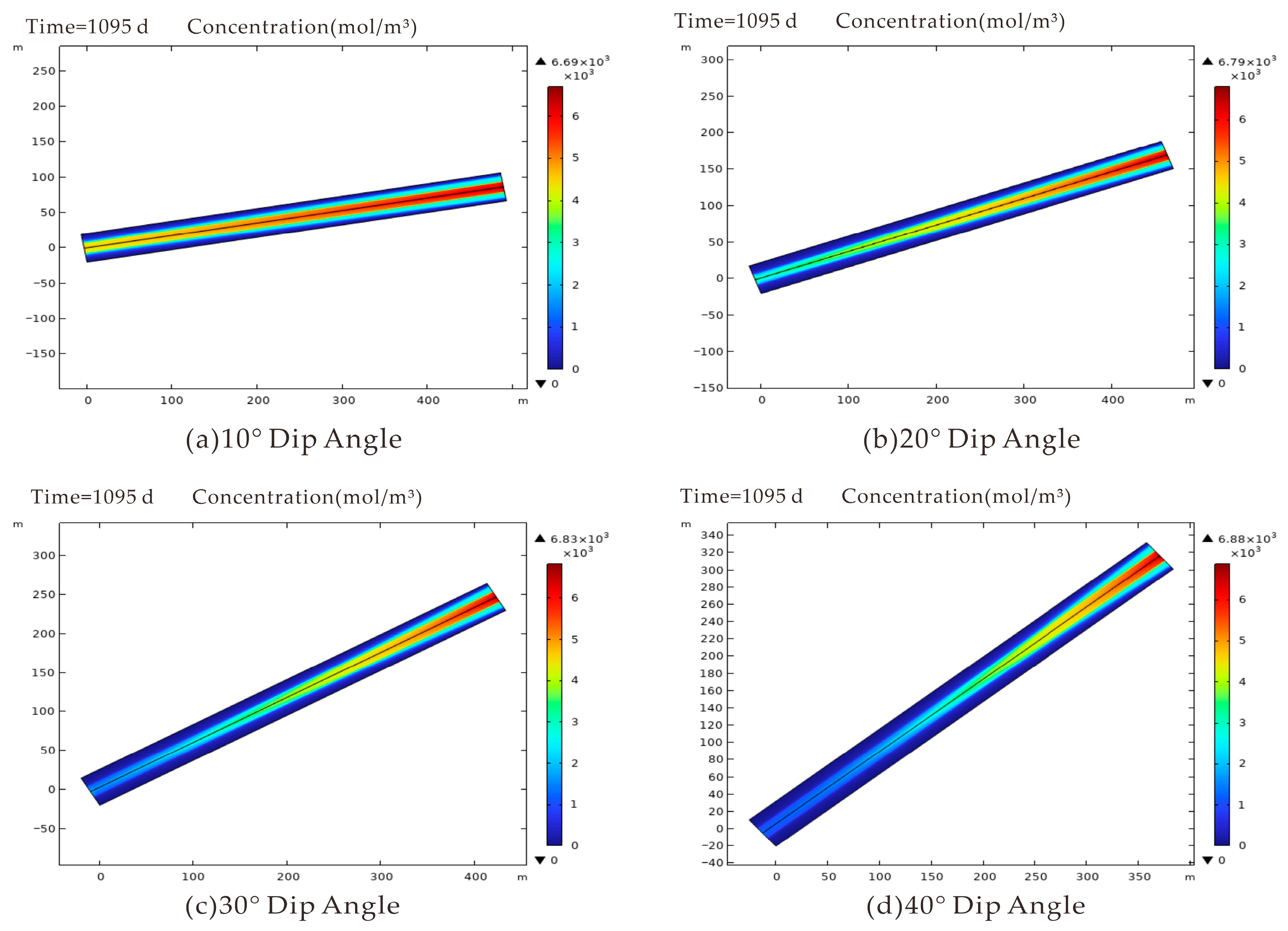

- Dip Angle of Coal Seams

- 3.

- Coal Quality

- (1)

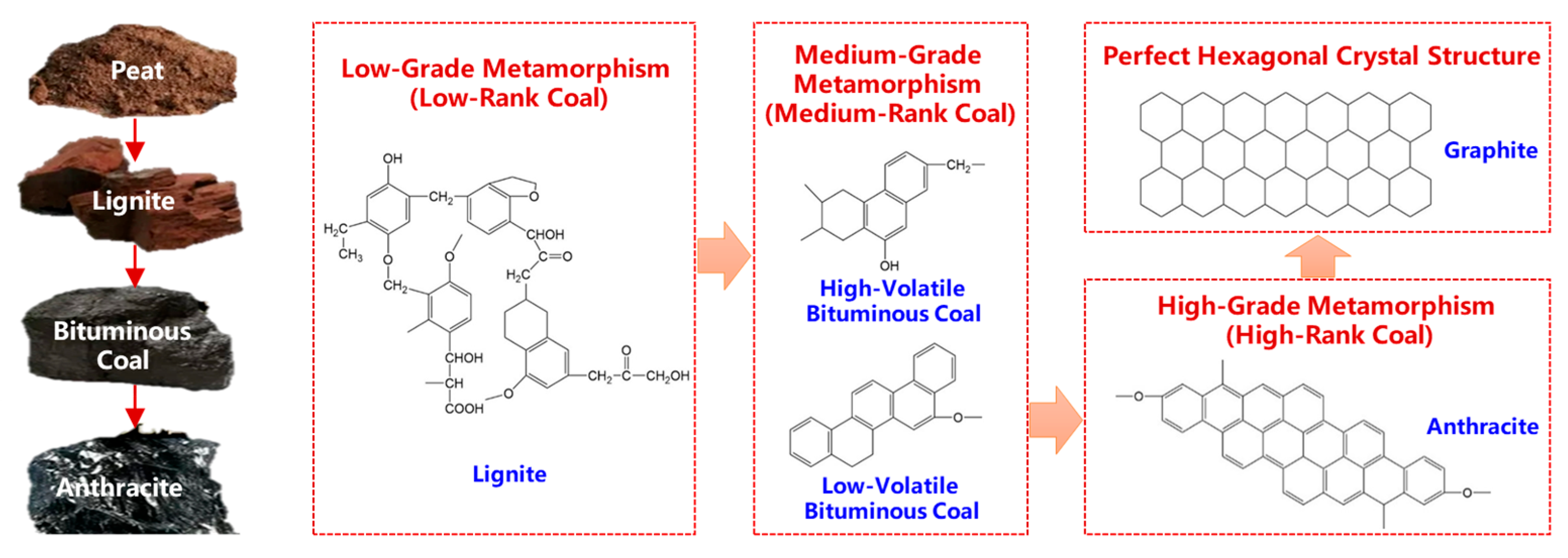

- Coal Rank

- (2)

- Moisture Content

- 4.

- Process Properties of Coal

- (1)

- Tar yield

- (2)

- Caking Index

- 5.

- Tectonic Conditions

- (1)

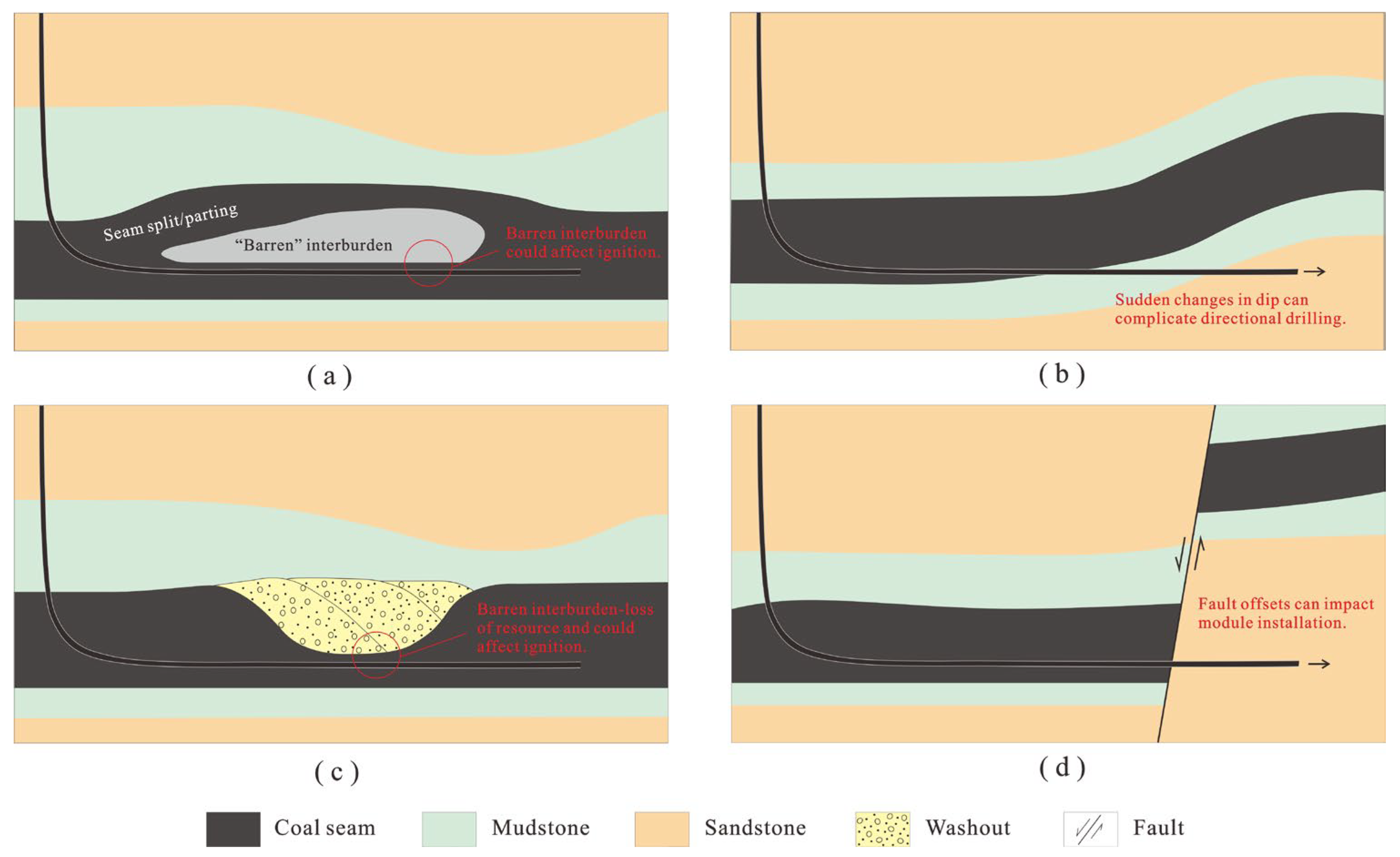

- Fracture Structures

- (2)

- Fold Structures

- 6.

- Coal Seam Partings

- 7.

- Hydrogeological Conditions

- (1)

- Groundwater Hydrological Environment

- (2)

- Aquifer Distribution

- 8.

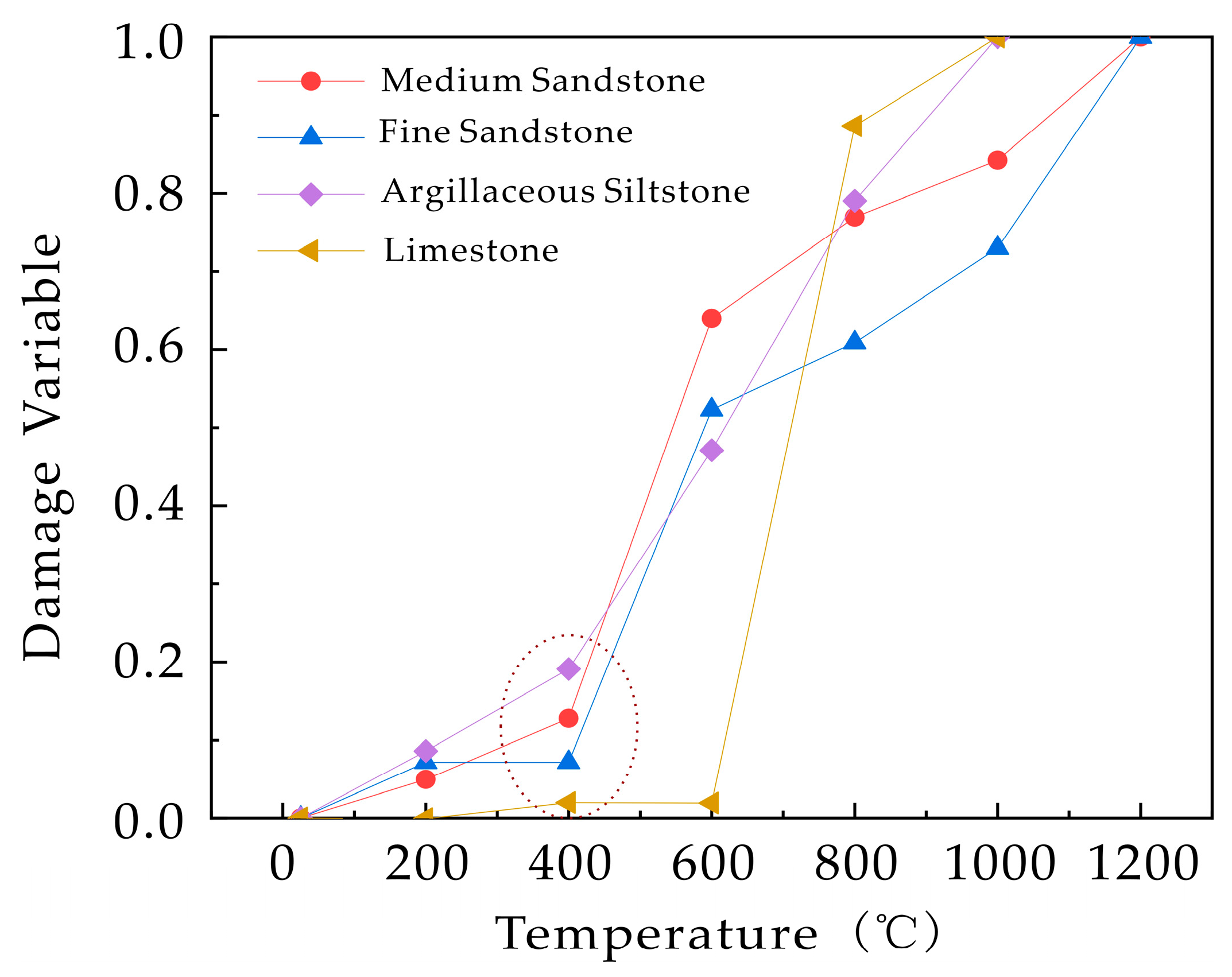

- Roof and Floor Conditions of Coal Seams

- 9.

- Surface Conditions

3.3.2. Determination of the Classification Rating

3.3.3. Establishment of a Geological Evaluation System

3.3.4. Determination of Evaluation Parameter Weights

4. Results and Discussion

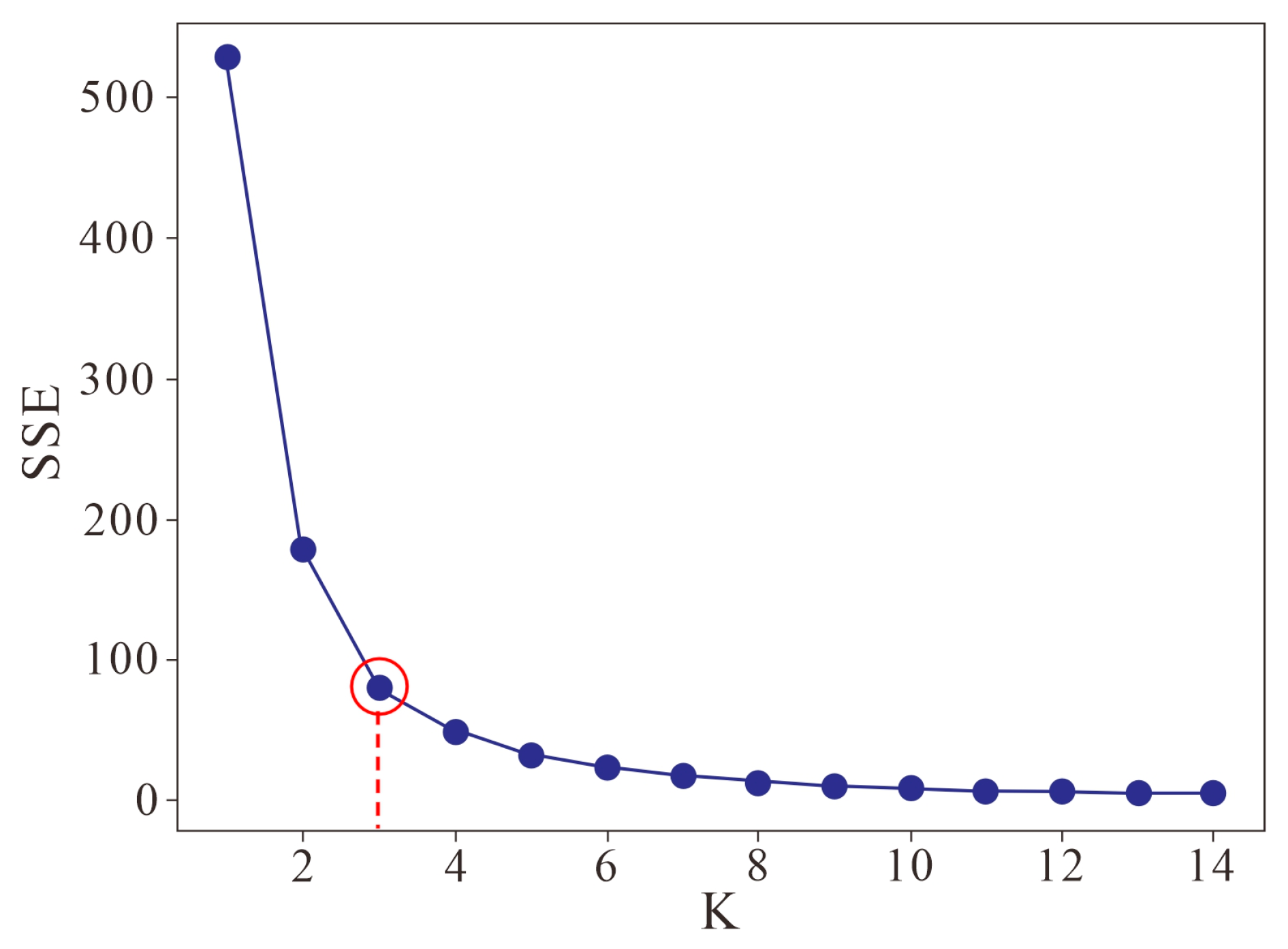

4.1. Division of Geological Assessment Units

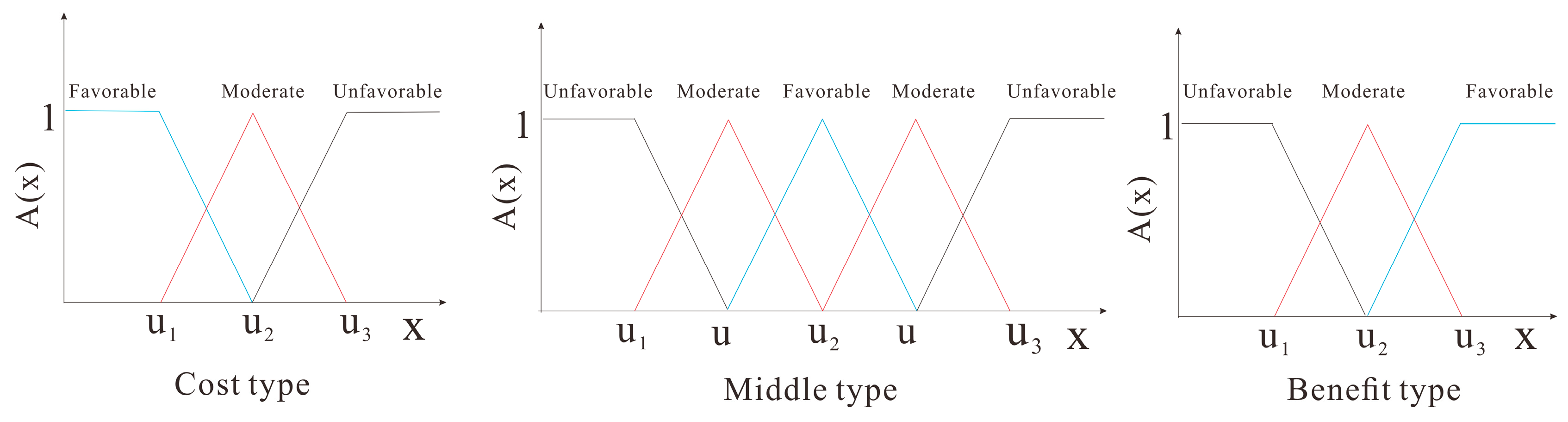

4.2. Membership Function for Geological Index

4.3. Optimization Results of Favorable Target Areas

4.3.1. Class I: Preferred Target Area

4.3.2. Class II: Alternative Target Areas

4.3.3. Class III Areas Pending Verification

5. Conclusions

- (1)

- This study systematically analyzed the main controlling factors for the geological site selection of in situ pyrolysis of tar-rich coal. Taking “geological conditions—mining conditions” as the core framework, an 8-unit evaluation system was constructed, covering resource scale, coal seam conditions, coal petrology and quality, process performance, structural conditions, hydrogeological conditions, roof–floor conditions, and surface conditions, with 16 supporting evaluation parameters, thus forming a hierarchical comprehensive evaluation system. Combined with numerical simulation and core experimental data, the quantitative division thresholds of each parameter for Class I, Class II, and Class III sites were clarified. Finally, a practically guiding evaluation standard system for the geological site selection of in situ pyrolysis of tar-rich coal was established, providing a theoretical basis and technical support for the optimization of regional development target areas.

- (2)

- To ensure the objectivity and accuracy of evaluation results, this study adopted the fuzzy comprehensive evaluation method as the core mathematical evaluation approach and used the combined weighting method to determine weights, thereby calculating the subjective weights of first-level and second-level geological indicators. For 10 numerical second-level indicators (e.g., coal seam thickness, dip angle, and burial depth), values were directly assigned based on their original units; for 6 descriptive second-level indicators (e.g., coal seam stability, coal rank and type, and roof–floor lithology), values were assigned after quantification via a 100-point scale. Combined with the weight coefficient table of geological condition evaluation factors, a multi-level fuzzy evaluation index system was built, realizing the quantification and standardization of the evaluation process.

- (3)

- By integrating the results of quantitative evaluation and qualitative classification, a general process for optimizing favorable areas for in situ pyrolysis of tar-rich coal was proposed, which enables priority ranking and comprehensive classification of site selection results: Block Tiao-IV was recommended as the preferred field test area, Blocks Tiao-I, Tiao-II, and Tiao-III as alternative areas, and Blocks Han-I and Han-III as to-be-verified areas. Thus, a complete technical system for optimizing favorable areas for in situ pyrolysis of tar-rich coal was formed, providing a referable technical process for the selection of development target areas in similar coal mining areas.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, M.; Wang, C.A.; Yuan, T.; Ning, X.; Huang, X.; Deng, L.; Che, D. Experimental investigation on gas-liquid–solid tri-phase product distributions during the simulated in-situ pyrolysis of tar-rich coal. Fuel 2025, 381, 133465. [Google Scholar] [CrossRef]

- Zhang, H.R.; Li, S.; Kelly, K.E.; Eddings, E.G. Underground in situ coal thermal treatment for synthetic fuels production. Prog. Energy Combust. Sci. 2017, 62, 1–32. [Google Scholar] [CrossRef]

- Kelly, K.E.; Wang, D.; Hradisky, M.; Silcox, G.D.; Smith, P.J.; Eddings, E.G.; Pershing, D.W. Underground coal thermal treatment as a potential low-carbon energy source. Fuel Process. Technol. 2016, 144, 8–19. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Determination of the Extent of the Rock Destruction Zones around a Gasification Channel on the Basis of Strength Tests of Sandstone and Claystone Samples Heated at High Temperatures up to 1200 °C and Exposed to Water. Energies 2021, 14, 6464. [Google Scholar] [CrossRef]

- Ju, Y.; Zhu, Y.; Zhou, H.; Ge, S.; Xie, H. Microwave pyrolysis and its applications to the in situ recovery and conversion of oil from tar-rich coal: An overview on fundamentals, methods, and challenges. Energy Rep. 2021, 7, 523–536. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, F.; Fu, D.; Ma, L.; Duan, Z.; Wang, Q.; Kang, S.; Guo, W. Economic and heating efficiency analysis of double-shell downhole electric heater for tar-rich coal in-situ conversion. Case Stud. Therm. Eng. 2023, 41, 102596. [Google Scholar] [CrossRef]

- Quan, F.; Lu, W.; Song, Y.; Sheng, W.; Qin, Z.; Luo, H. Multifractal Characterization of Heterogeneous Pore Water Redistribution and Its Influence on Permeability During Depletion: Insights from Centrifugal NMR Analysis. Fractal Fract. 2025, 9, 536. [Google Scholar] [CrossRef]

- Quan, F.; Lu, W.; Song, Y.; Wei, C.; Ma, J. Direct Quantification of Coal Pore Dynamics during Methane Depletion via Low-Field Nuclear Magnetic Resonance. Energ. Fuel 2025, 39, 12538–12550. [Google Scholar] [CrossRef]

- Jing, G.; Gao, X.; Feng, S.; Li, X.; Wang, W.; Zhang, T.; Li, C. Geological Evaluation of In-Situ Pyrolysis Development of Oil-Rich Coal in Tiaohu Mining Area, Santanghu Basin, Xinjiang, China. Energies 2025, 18, 4034. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, H.; Hou, Y.; Shi, H.; Li, J.; Yang, T.; Feng, Y.; Meng, W. Quantitative evaluation of unconsolidated sandstone heavy oil reservoirs based on machine learning. Geol. J. 2023, 58, 2321–2341. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, H.; Cai, H.; Hou, Y.; Shi, H.; Li, J.; Yang, T.; Feng, Y. Production prediction and main controlling factors in a highly heterogeneous sandstone reservoir: Analysis on the basis of machine learning. Energy Sci. Eng. 2022, 10, 4674–4693. [Google Scholar] [CrossRef]

- Wang, Z.; Tang, H.; Yang, J.; Huang, L. Reservoir Pore Characteristics Based on Depositional Microfacies Control in the Neogene Guantao Formation, Bohai Bay Basin, China. Energies 2022, 15, 2870. [Google Scholar] [CrossRef]

- Li, M.; Wang, H.; Wang, D.; Shao, Z.; He, S. Risk assessment of gas explosion in coal mines based on fuzzy AHP and bayesian network. Process Saf. Environ. Prot. 2020, 135, 207–218. [Google Scholar] [CrossRef]

- Paraskevis, N.; Roumpos, C.; Stathopoulos, N.; Adam, A. Spatial analysis and evaluation of a coal deposit by coupling AHP & GIS techniques. Int. J. Min. Sci. Technol. 2019, 29, 943–953. [Google Scholar] [CrossRef]

- Chun, Y.; Zhang, J.; Han, Y. Green development level assessment and obstacle analysis of China’s coal-resource-based regions. Heliyon 2023, 9, e22495. [Google Scholar] [CrossRef]

- Moharir, K.N.; Pande, C.B.; Gautam, V.K.; Singh, S.K.; Rane, N.L. Integration of hydrogeological data, GIS and AHP techniques applied to delineate groundwater potential zones in sandstone, limestone and shales rocks of the Damoh district, (MP) central India. Environ. Res. 2023, 228, 115832. [Google Scholar] [CrossRef]

- Xiang, W.; Sang, S.; Han, S.; Liu, S.; Zhou, X.; Wang, D. Assessment of CO2 geological sequestration potential in the Northern Jiangsu-Southern yellow Sea Basin via AHP-CRITIC methodology. Int. J. Greenh. Gas Control. 2025, 142, 104321. [Google Scholar] [CrossRef]

- Naseer, Z.; Ehsan, M.; Ali, M.; Amjad, M.R.; Latif, M.A.U.; Abdelrahman, K. Lithofacies and sandstone reservoir characterization for geothermal assessment through artificial intelligence. Results Eng. 2025, 26, 105173. [Google Scholar] [CrossRef]

- Wang, Z.; Yin, H.; Tang, H.; Hou, Y.; Yu, H.; Liu, Q.; Tang, H.; Jia, T. Damage Evaluation of Unconsolidated Sandstone Particle Migration Reservoir Based on Well–Seismic Combination. Processes 2024, 12, 2009. [Google Scholar] [CrossRef]

- Wu, B.; Xie, R.; Xiao, L.; Guo, J.; Jin, G.; Fu, J. Integrated classification method of tight sandstone reservoir based on principal component analysis– simulated annealing genetic algorithm–fuzzy cluster means. Petrol. Sci. 2023, 20, 2747–2758. [Google Scholar] [CrossRef]

- Ali, N.; Chen, J.; Fu, X.; Hussain, W.; Ali, M.; Iqbal, S.M.; Anees, A.; Hussain, M.; Rashid, M.; Thanh, H.V. Classification of reservoir quality using unsupervised machine learning and cluster analysis: Example from Kadanwari gas field, SE Pakistan. Geosyst. Geoenviron. 2023, 2, 100123. [Google Scholar] [CrossRef]

- Baouche, R.; Nabawy, B.S. Permeability prediction in argillaceous sandstone reservoirs using fuzzy logic analysis: A case study of triassic sequences, Southern Hassi R’Mel Gas Field, Algeria. J. Afr. Earth Sci. 2021, 173, 104049. [Google Scholar] [CrossRef]

- Ren, Q.; Zhang, H.; Zhang, D.; Zhao, X. Lithology identification using principal component analysis and particle swarm optimization fuzzy decision tree. J. Petrol. Sci. Eng. 2023, 220, 111233. [Google Scholar] [CrossRef]

- ARTUN, E.; KULGA, B. Selection of candidate wells for re-fracturing in tight gas sand reservoirs using fuzzy inference. Pet. Explor. Dev. 2020, 47, 413–420. [Google Scholar] [CrossRef]

- Yu, M.; Gao, G.; Liu, M.; Liang, H.; Kang, J.; Xu, X.; Zhao, X. Sedimentary environment shift and organic matter enrichment mechanism in response to volcanic ash influence: A case study of the Permian Lucaogou Formation, Santanghu Basin, NW China. J. Palaeogeogr. 2024, 13, 793–822. [Google Scholar] [CrossRef]

- Liang, H.; Li, X.; Ma, Q.; Liang, H.; Luo, Q.; Chen, X.; Bai, G.; Zhang, Q.; Meng, Y. Geological features and exploration potential of Permian Tiaohu Formation tight oil, Santanghu Basin, NW China. Pet. Explor. Dev. 2014, 41, 616–627. [Google Scholar] [CrossRef]

- Lei, X.; Sun, P.; Wang, J.; Dang, H.; Tian, X.; Luan, Z.; Wang, Z. Origin and provenance of Lower Jurassic clastic rocks in the Badaowan Formation, Dachanggou Basin, Northern Xinjiang, China: Constraints on Early Jurassic weathering and depositional processes. Palaeogeogr. Palaeoclimatol. Palaeoecol. 2025, 679, 113293. [Google Scholar] [CrossRef]

- Zhang, L.; Yan, D.; Yang, S.; Li, B.; Fu, H.; Wang, G.; Yang, X.; Zhang, B.; Liang, W.; Zhang, J. Evolution of the Middle Jurassic paleoclimate: Sedimentary evidence from coal-bearing strata in the Santanghu Basin, NW China. J. Asian Earth Sci. 2023, 242, 105495. [Google Scholar] [CrossRef]

- Shi, Q.; Geng, X.; Wang, S.; Cai, Y.; Zhao, H.; Ji, R.; Xing, L.; Miao, X. Tar yield prediction of tar-rich coal based on geophysical logging data: Comparison between semi-supervised and supervised learning. Comput. Geosci. 2025, 196, 105848. [Google Scholar] [CrossRef]

- GB/T 6948-2008; Determination of Vitrinite Reflectance of Coal by Microscope. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ) and Standardization Administration of the People’s Republic of China (SAC): Beijing, China, 2008.

- Lupoi, J.S.; Fritz, L.P.; Hackley, P.C.; Solotky, L.; Weislogel, A.; Schlaegle, S. Quantitative evaluation of vitrinite reflectance and atomic O/C in coal using Raman spectroscopy and multivariate analysis. Fuel 2018, 230, 1–8. [Google Scholar] [CrossRef]

- GB/T 212-2008; Proximate Analysis of Coal. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ) and Standardization Administration of the People’s Republic of China (SAC): Beijing, China, 2008.

- Li, Y.; Li, X.; Zhang, Y.; Deng, J.; Zhang, Y.; Guo, Q.; Zhang, X.; Li, H. Influences of surface active-groups on the exothermic properties and oxidation of coal molecules. Case Stud. Therm. Eng. 2024, 63, 105367. [Google Scholar] [CrossRef]

- GB/T 480-2000; Low-Temperature Carbonization Test of Coal by Aluminum Retort. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ) and Standardization Administration of the People’s Republic of China (SAC): Beijing, China, 2000.

- Zhao, J.; Shi, Q.; Wang, S.; Mi, Y.; Zhao, H.; Ji, R.; Cui, S. Study on molecular structural heterogeneity of tar-rich coal based on micro-FTIR. Spectrochim. Acta A 2025, 330, 125749. [Google Scholar] [CrossRef] [PubMed]

- GB/T 5447-2014; Determination of Caking Index of Bituminous Coal. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ) and Standardization Administration of the People’s Republic of China (SAC): Beijing, China, 2014.

- Kumar, D.; Kumar, D. Chapter 3-Evaluation of Coking Coal Resources and Reserves. In Management of Coking Coal Resources; Kumar, D., Kumar, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 61–112. [Google Scholar]

- Dong, G.; Zhu, C.; Li, J.; Xu, S.; Guo, W. Numerical simulation on development effect of tar-rich coal through in-situ conversion by convective heating in Huangling Mining Area. Meitiandizhi Yu Kantan/Coal Geol. Explor. 2023, 51, 57–67. [Google Scholar] [CrossRef]

- Yang, F.; Cheng, X.; Li, M.; Wu, Z.; Wei, J.; Cao, H. Numerical simulations of the evolutionary patterns of multi-physical fields during the in-situ pyrolysis of tar-rich coals. Meitiandizhi Yu Kantan/Coal Geol. Explor. 2024, 52, 25–34. [Google Scholar] [CrossRef]

- Dong, Z.; Chen, Y.; Zhang, M.; Wang, X.; Jiao, L.; Feng, S.; Ren, B.; Chen, H.; Xue, J.; Zhao, Y.; et al. Production capacity prediction of U-shaped horizontal wells for in-situ pyrolysis of tar-rich coal: Experimental and numerical simulation study. Meitan Xuebao/J. China Coal Soc. 2025, 50, 1168–1184. [Google Scholar] [CrossRef]

- Sun, W.; Fish, J. Coupling of non-ordinary state-based peridynamics and finite element method for fracture propagation in saturated porous media. Int. J. Numer. Anal. Methods Geomech. 2021, 45, 1260–1281. [Google Scholar] [CrossRef]

- Yang, F.; Cheng, X.; Li, M.; Wei, J.; Duan, Z.; Ma, L. Numerical Investigation of the Heat and Mass Transfer during the In Situ Pyrolysis Process of Oil-Rich Coal. Processes 2023, 11, 3226. [Google Scholar] [CrossRef]

- Ye, Q.; Li, M.; Hao, J.; Huang, Z.; Wei, J. Multi-Physics Simulation of Tar-Rich Coal In Situ Pyrolysis with a Multiregion Homogenization Treatment. Acs Omega 2023, 8, 32565–32579. [Google Scholar] [CrossRef] [PubMed]

- Akbarzadeh Kasani, H.; Chalaturnyk, R. Influence of High Pressure and Temperature on the Mechanical Behavior and Permeability of a Fractured Coal. Energies 2017, 10, 854. [Google Scholar] [CrossRef]

- Xie, S.; Zhou, H.; Jia, W.; Gu, Y.; Zhao, W.; Zhao, J.; Chen, W. Modeling Approaches to Permeability of Coal Based on a Variable-Order Fractional Derivative. Energ. Fuel 2023, 37, 5805–5813. [Google Scholar] [CrossRef]

- Liu, X.P. Study on High Temperature Burnt Surrounding Rock Movement and Failure Mechanism in UCG. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2019. [Google Scholar]

- Tian, H.; Li, N.; Wang, S.; Wu, H.; Feng, Z.; Wang, K.; Wang, G. A log-based method for evaluating the tar yield of tar-rich coal. Meitiandizhi Yu Kantan/Coal Geol. Explor. 2024, 52, 97–107. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.; Ning, X.; Chen, M.; Huang, X.; Xue, X.; Mao, Q.; Deng, L.; Che, D. Research progress of in-situ pyrolysis technology for tar-rich coal. Meitan Xuebao/J. China Coal Soc. 2024, 49, 3969–3984. [Google Scholar] [CrossRef]

- Dong, Z.; Chen, Y.; Xu, H.; Zhao, Y.; Ren, B.; Chen, H.; Wang, F. Thermal deformation and failure mechanism of surrounding rock in underground gasification cavity of medium-deep coal. Yanshilixue Yu Gongcheng Xuebao/Chin. J. Rock. Mech. Eng. 2025, 44, 74–88. [Google Scholar]

- Zhi, D.; Li, J.; Zhou, Z.; Jiao, L.; Fan, T.; Li, B.; Liang, H.; Wang, X. New fields, new types and resource potentials of oil-gas exploration and development in Santanghu Basin. Shiyou Xuebao/Acta Pet. Sin. 2024, 45, 115–132. [Google Scholar] [CrossRef]

- Duan, Z.; Yang, F.; Wang, Z.; Ma, L.; Duan, X.; Cao, H.; Chen, L. Pilot experiment for underground in-situ pyrolysis of tar-rich coal in the northern Shaanxi Province. Meitiandizhi Yu Kantan/Coal Geol. Explor. 2024, 52, 14–24. [Google Scholar] [CrossRef]

- Li, M.; Cheng, X.; Hao, J.; Lu, Z.; Wei, J. Experimental and numerical investigation on the heat and mass transfer performance of tar rich coal in-situ pyrolysis. Int. J. Heat Fluid Flow 2024, 107, 109412. [Google Scholar] [CrossRef]

- Shi, Q.; Zhao, B.; Wang, S.; Li, X.; Li, C.; Han, B.; Mi, Y.; He, Y.; Cai, Y.; Zhang, Z.; et al. Characteristics and sedimentary environment control of Jurassic tar-rich coal in Santanghu Basin. Shiyou Xuebao/Acta Pet. Sin. 2024, 45, 787–803. [Google Scholar] [CrossRef]

- Jiang, X.; Wu, C. A review: Geological feasibility and technological applicability of underground coal gasification. Meitiandizhi Yu Kantan/Coal Geol. Explor. 2022, 50, 2. [Google Scholar] [CrossRef]

- Sarhosis, V.; Lavis, S.; Mostade, M.; Thomas, H.R. Towards commercialising underground coal gasification in the EU. Environ. Geotech. 2016, 4, 113–122. [Google Scholar] [CrossRef]

- Yang, C.; Zheng, X.; Dai, C.; Li, D.; Liu, L.; Fang, L.; Tian, H.; Shao, T.; Zhang, J. Risk assessment of coal supply chain based on analytic hierarchy process and fuzzy comprehensive evaluation. Heliyon 2025, 11, e42629. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, S.; Lu, X.; Wu, S.; Huang, J. Residual coal distribution in China and adaptability evaluation of its resource conditions to underground coal gasification. Sustain. Energy Technol. Assess. 2022, 49, 101654. [Google Scholar] [CrossRef]

- Lozynskyi, V. Multi-criteria assessment of coal seams suitability for co-gasification using the preference selection index. Heliyon 2025, 11, e43368. [Google Scholar] [CrossRef]

| Basin | Block | Type | Area (km2) | Thickness (m) | Dip Angle (°) | Density (g/cm3) | Resource (×108 t) |

|---|---|---|---|---|---|---|---|

| Santanghu basin | Hanshuiquan | Steep Slope Zone with Moderate Oil | 109 | 8.5 | 55 | 1.35 | 12.51 |

| 161 | 9.6 | 35 | 1.34 | 20.71 | |||

| Gentle Slope Zone with Moderate Oil | 243 | 6.8 | 11 | 1.35 | 22.31 | ||

| 527 | 10.2 | 12 | 1.34 | 72.03 | |||

| Handong | Gentle Slope Zone with Moderate Oil | 321 | 13.2 | 14 | 1.35 | 57.20 | |

| Tiaohu | Forward Structural Zone with High Oil | 71 | 21.2 | 8 | 1.31 | 19.72 | |

| 258 | 18.6 | 10 | 1.35 | 64.78 | |||

| 363 | 18.3 | 10 | 1.32 | 87.69 | |||

| Negative Structural Zone with High Oil | 66 | 12.3 | 6 | 1.36 | 11.04 | ||

| Gentle Incline Zone with Moderate Oil | 192 | 11.5 | 15 | 1.35 | 29.81 | ||

| Total area | 2311 | Total resource volume | 397.80 | ||||

| Physical Parameter | Value | Data Source |

|---|---|---|

| Coal Density/kg/m3 | 1400 | [47] |

| Thermal Conductivity of Coal/W/(m·K) | 0.3 | [48] |

| Specific Heat Capacity of Coal/J (kg·K) | 1200 | [48] |

| Mudstone Density/kg/m3 | 2500 | [49] |

| Thermal Conductivity of Mudstone/W/(m·K) | 1.5 | [48] |

| Specific Heat Capacity of Mudstone/J (kg·K) | 900 | [48] |

| Specific Heat Capacity of Fluid/J (kg·K) | 1039 | NIST Chemistry WebBook |

| Gas Density/kg/m3 | 1.25 | NIST Chemistry WebBook |

| Thermal Conductivity of Gas/W/(m·K) | 0.024 | NIST Chemistry WebBook |

| Gas Viscosity/Pa·s | 1.60 × 10−5 | NIST Chemistry WebBook |

| Physical Parameter | Value | Data Source |

|---|---|---|

| Coal Seam Permeability/m2 | 1.00 × 10−15 | [50] |

| Coal Seam Porosity | 0.05 | [51] |

| Wellbore Permeability/m2 | 5.00 × 10−10 | |

| Wellbore Porosity | 0.99 | |

| Universal Gas Constant J/mol/K | 8.314 | [52] |

| Pre-exponential Factor of Pyrolysis Reaction/s−1 | 6.91 | [52] |

| Activation Energy of Pyrolysis Reaction/kJ/mol | 72.35 | [52] |

| Initial Coal Concentration/mol/m3 | 9407.3 | [52] |

| Initial Temperature of Coal Seam/K | 300 | [40] |

| High-Temperature Nitrogen Temperature/K | 923 | [40] |

| Item | Level Name | Classification Range/Mt,% |

|---|---|---|

| 1 | Specially low moisture coal | ≤6.0 |

| 2 | Low moisture coal | >6.0~8.0 |

| 3 | Medium moisture coal | >8.0~12.0 |

| 4 | Medium high moisture coal | >12.0~20.0 |

| 5 | High moisture coal | >20.0~40.0 |

| 6 | Specially high moisture coal | >40.0 |

| Item | Level Name | Caking Index/% |

|---|---|---|

| 1 | Non-caking Coal | ≤5 |

| 2 | Slightly Caking Coal | >5~20 |

| 3 | Weakly Caking coal | >20~50 |

| 4 | Medium Caking Coal | >50~80 |

| 5 | Strongly Caking Coal | >80 |

| Lithology | Temperature Range of Abrupt Thermal Damage Increase |

|---|---|

| Medium-grained sandstone | 400 °C~600 °C |

| Fine-grained sandstone | 400 °C~600 °C |

| Argillaceous siltstone | 400 °C~1000 °C |

| Limestone | 600 °C~800 °C |

| Category | First Level Indicators | Second Level Indicators | Weight Comprehensive Weight | ||

|---|---|---|---|---|---|

| I (Excellent) | II (Moderate) | III (Poor) | |||

| Geological Conditions | Resource Scale U1 | Coal resources (×108 t) U11 | ≥10 | 1~10 | ≤1 |

| Coal seam Conditions U2 | Burial depth (m) U21 | 800~1200 | 1200~1500 | 1500~2000 | |

| Coal thickness (m) U22 | >10 | 7~10 | 5~7 | ||

| Dip angle (°) U23 | ≤20 | 20~30 | ≥30 | ||

| Parting layer properties U24 | None | Few partings, single parting thickness < 0.2 m | Relatively few partings, 0.2 m < single parting thickness < 0.3 m | ||

| Coal seam stability U25 | Good Continuity | Fair Continuity | Poor Continuity | ||

| Coal Quality U3 | Coal rank U31 | Long-flame coal, gas coal, fat coal | Lignite, coking coal | Lean coal, poor coal, anthracite | |

| Moisture content (%) U32 | ≤6 | 6~8 | 8~12 | ||

| Process Properties U4 | Tar yield (%) U41 | >12 | 10~12 | 7~10 | |

| Caking index (%) U42 | ≤5 | 5~20 | 20~50 | ||

| Mining Conditions | Tectonic Conditions U5 | Distance to fault (m) U51 | >1000 | 300~1000 | 200~300 |

| Hydrologic Condition U6 | Groundwater circulation conditions U61 | Poor Recharge-Runoff-Discharge Conditions | Fair Recharge-Runoff-Discharge Conditions | Moderate Recharge-Runoff-Discharge Conditions | |

| Roof & Floor Properties U7 | Lithology U71 | Mudstone, siltstone | Fine sandstone | Middle-fine sandstone | |

| Thickness (m) U72 | >30 | 20~30 | 10~20 | ||

| Surface Conditions U8 | Distance to Mines, Residences, and Protected Areas (m) U81 | >10 | 5~10 | 3.2~5 | |

| Terrain Conditions and Infrastructure Availability (Water, Power, Chemical Supply) U82 | Favorable: Flat terrain, well-developed utilities, excellent industrial integration. | Moderate: Gently undulating terrain, moderately available utilities, fair industrial integration. | Unfavorable: Significantly rolling terrain, poorly available utilities, poor industrial integration. | ||

| Scale | Meaning |

|---|---|

| 1 | Equal importance |

| 3 | Moderate importance |

| 5 | Strong importance |

| 7 | Very strong importance |

| 9 | Extreme importance |

| 2,4,6,8 | Intermediate values |

| Indicator | Resource Scale | Coal Seam Conditions | Structure Conditions | Roof & Floor Properties | Coal Quality | Process Properties | Moisture Content | Surface Conditions |

|---|---|---|---|---|---|---|---|---|

| Resource Scale | 1 | 2 | 2 | 3 | 3 | 3 | 4 | 5 |

| Coal Seam Conditions | 1/2 | 1 | 2 | 2 | 3 | 3 | 3 | 4 |

| Structure Conditions | 1/2 | 1/2 | 1 | 2 | 2 | 3 | 3 | 4 |

| Roof & Floor Properties | 1/3 | 1/2 | 1/2 | 1 | 2 | 2 | 3 | 3 |

| Coal quality | 1/3 | 1/3 | 1/2 | 1/2 | 1 | 2 | 2 | 3 |

| Process Properties | 1/3 | 1/3 | 1/3 | 1/2 | 1/2 | 1 | 2 | 2 |

| Hydrologic condition | 1/4 | 1/3 | 1/3 | 1/3 | 1/2 | 1/2 | 1 | 2 |

| Surface Conditions | 1/5 | 1/4 | 1/4 | 1/3 | 1/3 | 1/2 | 1/2 | 1 |

| Category | First Level Indicators | Weight | Second Level Indicators | Weight | Comprehensive Weight |

|---|---|---|---|---|---|

| Geological Conditions | U1 | 0.269 | U11 | 1 | 0.269 |

| U2 | 0.203 | U21 | 0.244 | 0.050 | |

| U22 | 0.386 | 0.078 | |||

| U23 | 0.079 | 0.016 | |||

| U24 | 0.119 | 0.024 | |||

| U25 | 0.172 | 0.035 | |||

| U3 | 0.090 | U31 | 0.641 | 0.058 | |

| U32 | 0.359 | 0.032 | |||

| U4 | 0.068 | U41 | 0.552 | 0.038 | |

| U42 | 0.448 | 0.031 | |||

| Mining Conditions | U5 | 0.161 | U51 | 1 | 0.161 |

| U6 | 0.053 | U61 | 1 | 0.053 | |

| U7 | 0.118 | U71 | 0.584 | 0.069 | |

| U72 | 0.414 | 0.049 | |||

| U8 | 0.038 | U81 | 0.702 | 0.027 | |

| U82 | 0.298 | 0.011 |

| Function Type | Favorable | Moderate | Unfavorable |

|---|---|---|---|

| Benefit-type Index | |||

| Cost-type Index | |||

| Middle-type Index |

| Serial Number | Evaluation Indicator | Type Function | Graded Defined Value | Note | ||||

|---|---|---|---|---|---|---|---|---|

| u1 | U′ | u2 | u″ | u3 | ||||

| 1 | U11 | Benefit-type | 1 | 5 | 10 | A larger resource volume is preferable, with an optimal threshold of >1.0 × 109 tons | ||

| 2 | U21 | Middle-type | 800 | 1100 | 1400 | 1700 | 2000 | A burial depth of >800 m to <2000 m is recommended |

| 3 | U22 | Benefit-type | 5 | 6 | 7 | 8 | 10 | The coal seam thickness should be greater than 5 m. |

| 4 | U23 | Middle-type | 0 | 10 | 15 | 20 | 30 | A coal seam dip angle of less than 30° is recommended. |

| 5 | U24 | Cost-type | 30 | 50 | 70 | Scoring was based on the number of partings and the thickness of individual partings. | ||

| 6 | U25 | Benefit-type | 30 | 50 | 70 | Scoring was based on the continuity of the coal seam. | ||

| 7 | U31 | Cost-type | 30 | 50 | 70 | Scoring was performed based on the types of coal: lignite, bituminous coal, and anthracite. | ||

| 8 | U32 | Cost-type | 6 | 8 | 12 | A lower moisture content is preferable. | ||

| 9 | U41 | Benefit-type | 7 | 10 | 12 | A tar yield greater than 7% is required. | ||

| 10 | U42 | Cost-type | 5 | 20 | 50 | A lower caking index is preferable, with a value of ≤5 being optimal. | ||

| 11 | U51 | Cost-type | 200 | 300 | 1000 | A minimum distance of 200 m from faults should be maintained. | ||

| 12 | U61 | Cost-type | 30 | 50 | 70 | Scoring was based on the degree of confinement of the groundwater circulation system. | ||

| 13 | U71 | Benefit-type | 30 | 50 | 70 | Scoring was based on the lithology types: mudstone, siltstone, and fine sandstone. | ||

| 14 | U72 | Benefit-type | 10 | 20 | 30 | A roof/floor thickness greater than 10 m is required. | ||

| 15 | U81 | Cost-type | 3.2 | 5 | 10 | A lower number of impacted mining rights in the surrounding area is preferable for scoring. | ||

| 16 | U82 | Benefit-type | 30 | 50 | 80 | Scoring was based on terrain flatness, distance from chemical plants, and utility accessibility of water and electricity. | ||

| Block | Type | U1 | U2 | U3 | U4 | U5 | U6 | U7 | U8 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U11 | U21 | U22 | U23 | U24 | U25 | U31 | U32 | U41 | U42 | U52 | U61 | U71 | U72 | U81 | U82 | ||

| Tiao I | Value | 6.480 | 1600 | 30 | 14 | None | Good | / | 6.2 | 12~16 | 0 | >3000 | Sealing | 70 | Roof/Floor Thickness: 13 m/12 m | None | Convenient power supply; lacks integration capability (50). |

| Favorable | 0.296 | 0.333 | 1 | 0.8 | 1 | 0.5 | 1 | 0.9 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | |

| Moderately Favorable | 0.704 | 0.667 | 0 | 0.2 | 0 | 0.5 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0 | 1 | |

| Unfavorable | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.8 | 0 | 0 | |

| Tiao II | Value | 1.890 | 1500 | 10 | 14 | None | Good | / | 6.5 | 14~18 | 0 | >1000 | Sealing | 70 | Roof/Floor Thickness: 13 m/12 m | None | Convenient power supply; lacks inte-gration capability (50). |

| Favorable | 0 | 0.667 | 1 | 0.8 | 1 | 0.5 | 1 | 0.75 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | |

| Moderately Favorable | 0.223 | 0.333 | 0 | 0.2 | 0 | 0.5 | 0 | 0.25 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0 | 1 | |

| Unfavorable | 0.778 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.8 | 0 | 0 | |

| Tiao III | Value | 4.320 | 1250 | 20 | 11 | None | Better | / | 5.8 | 16~18 | 0 | >1000 | Sealing | 60 | Roof/Floor Thickness: 13 m/7 m | None | Convenient power supply; lacks inte-gration capability (50). |

| Favorable | 0 | 0.5 | 1 | 0.2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.5 | 0 | 1 | 0 | |

| Moderately Favorable | 0.830 | 0.5 | 0 | 0.8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.5 | 0 | 0 | 1 | |

| Unfavorable | 0.170 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | |

| Tiao IV | Value | 7.690 | 1200 | 30 | 6 | None | Better | 0.41 | 5.45 | 15.4 | 0 | >2000 | Sealing | 90 | Roof/Floor Thickness: 20 m/21 m | None | Favorable integration: Coal chemical plant (S), Wind farm (E) (95). |

| Favorable | 0.538 | 0.333 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | |

| Moderately Favorable | 0.462 | 0.667 | 0 | 0.6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | |

| Unfavorable | 0 | 0 | 0 | 0.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Han I | Value | 5.270 | 1700 | 15 | 10 | None | Average | / | 7.3 | 14~16 | 0 | >2000 | Sealing | / | / | None | Poor power supply; no integration potential (20). |

| Favorable | 0.054 | 0 | 1 | 0 | 1 | 0 | 1 | 0.35 | 1 | 1 | 1 | 1 | 0.5 | 0 | 1 | 0 | |

| Moderately Favorable | 0.946 | 1 | 0 | 1 | 0 | 1 | 0 | 0.65 | 0 | 0 | 0 | 0 | 0.5 | 1 | 0 | 0 | |

| Unfavorable | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | |

| Han III | Value | 2.700 | 1750 | 25 | 8 | None | Average | / | 7.1 | 14~16 | 0 | >1000 | Sealing | 40 | Roof/Floor Thickness: 20 m/30 m | None | Poor power supply; no integration potential (20). |

| Favorable | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0.45 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | |

| Moderately Favorable | 0.425 | 0.833 | 0 | 0.8 | 0 | 1 | 0 | 0.55 | 0 | 0 | 0 | 0 | 0.5 | 1 | 0 | 0 | |

| Unfavorable | 0.575 | 0.167 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.5 | 0 | 0 | 1 | |

| Block | Favorable | Moderate | Unfavorable |

|---|---|---|---|

| Tiao I | 0.693 | 0.268 | 0.039 |

| Tiao II | 0.625 | 0.126 | 0.249 |

| Tiao III | 0.598 | 0.307 | 0.095 |

| Tiao IV | 0.777 | 0.216 | 0.006 |

| Han I | 0.529 | 0.460 | 0.011 |

| Han III | 0.483 | 0.305 | 0.212 |

| Block | Xinjiang Uygur Autonomous Region | Shaanxi Province | |

|---|---|---|---|

| Target Coal Seam | Badaowan Formation of Jurassic System | Yanan Formation of Jurassic System | |

| Ro (%) | 0.41 | 0.58 | |

| Proximate Components of Coal | Volatile Matter (%) | 48.66 | 37.56 |

| Moisture (%) | 5.37 | 8.04 | |

| Ash (%) | 5.46 | 4.46 | |

| Maceral of Coal | Vitrinite (%) | 64.4 | 54.9 |

| Liptinite (%) | 22.8 | 0.8 | |

| Inertinite (%) | 12.8 | 42.2 | |

| Burial Depth of Coal Seam (m) | 1000–1500 | 1000–1500 | |

| Thickness of Coal Seam (m) | 31.8 | 31.8 | |

| Tar Yield (%) | 15.4 | 15.4 | |

| TOC (%) | 61.8 | 61.8 | |

| Physical Properties of Coal Seam | Porosity (%) | 3.34 | 5.8 |

| Permeability (mD) | 0.05 | 4.21 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Dong, Z.; Chen, Y.; Zhao, Y.; Wang, X.; Cao, Z.; Xue, J.; Chen, H. Geological Evaluation and Favorable Area Optimization for In Situ Pyrolysis of Tar-Rich Coal: A Case Study from the Santanghu Basin, NW China. Processes 2025, 13, 3575. https://doi.org/10.3390/pr13113575

Zhang M, Dong Z, Chen Y, Zhao Y, Wang X, Cao Z, Xue J, Chen H. Geological Evaluation and Favorable Area Optimization for In Situ Pyrolysis of Tar-Rich Coal: A Case Study from the Santanghu Basin, NW China. Processes. 2025; 13(11):3575. https://doi.org/10.3390/pr13113575

Chicago/Turabian StyleZhang, Mengyuan, Zhen Dong, Yanpeng Chen, Yufeng Zhao, Xinggang Wang, Zhixiong Cao, Junjie Xue, and Hao Chen. 2025. "Geological Evaluation and Favorable Area Optimization for In Situ Pyrolysis of Tar-Rich Coal: A Case Study from the Santanghu Basin, NW China" Processes 13, no. 11: 3575. https://doi.org/10.3390/pr13113575

APA StyleZhang, M., Dong, Z., Chen, Y., Zhao, Y., Wang, X., Cao, Z., Xue, J., & Chen, H. (2025). Geological Evaluation and Favorable Area Optimization for In Situ Pyrolysis of Tar-Rich Coal: A Case Study from the Santanghu Basin, NW China. Processes, 13(11), 3575. https://doi.org/10.3390/pr13113575