Effect of Primary Fracture Orientation on CO2 Fracturing in Coal Seam Stress Relief

Abstract

1. Introduction

2. Experiments and Results

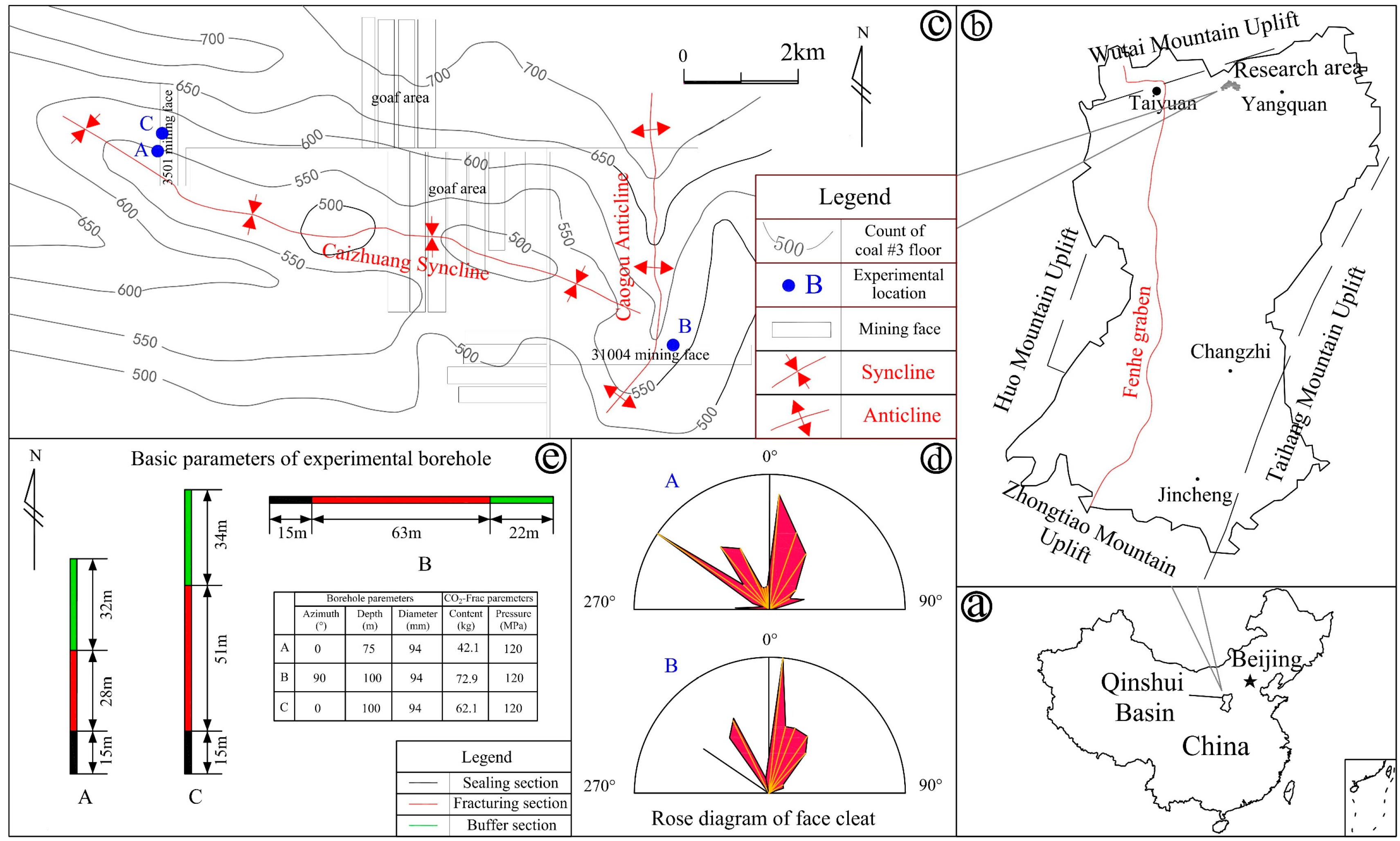

2.1. Geologic Setting

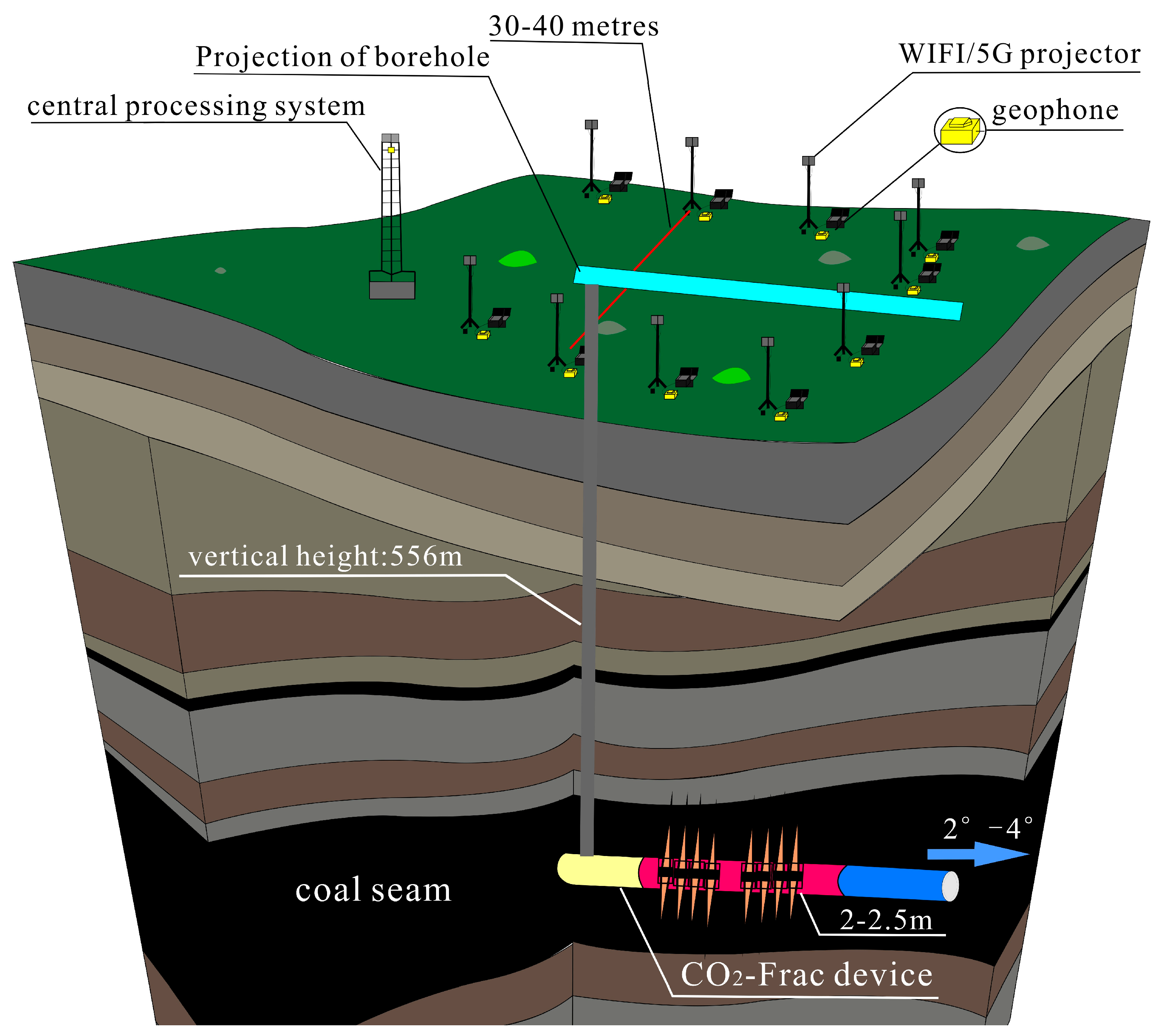

2.2. CO2 Fracturing

2.3. Microseismic Monitoring

3. Methods

3.1. Stress Drop

3.2. Description of the Distribution of Stress Drop

4. Results and Discussions

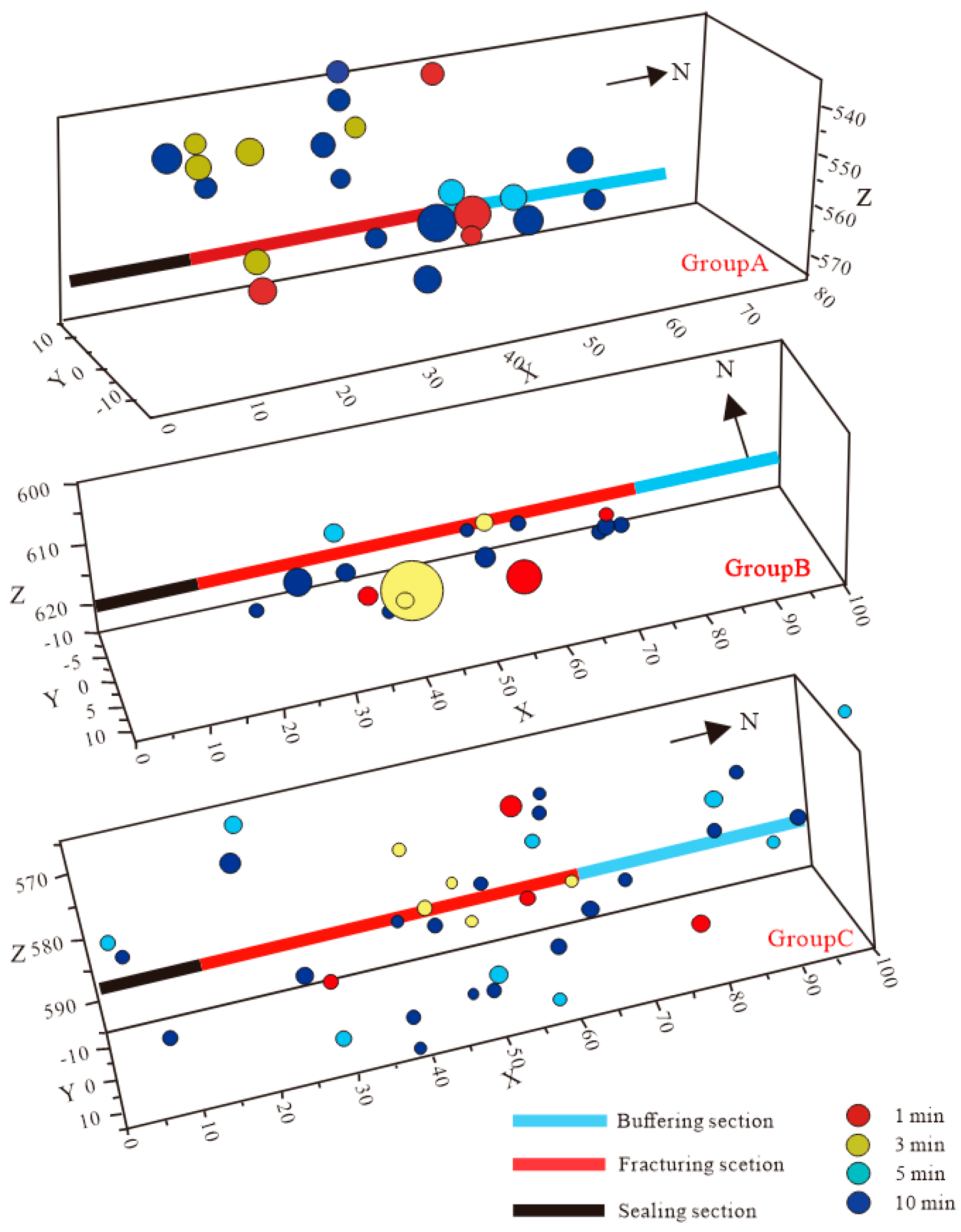

4.1. Spatiotemporal Distribution of Microseismic Events

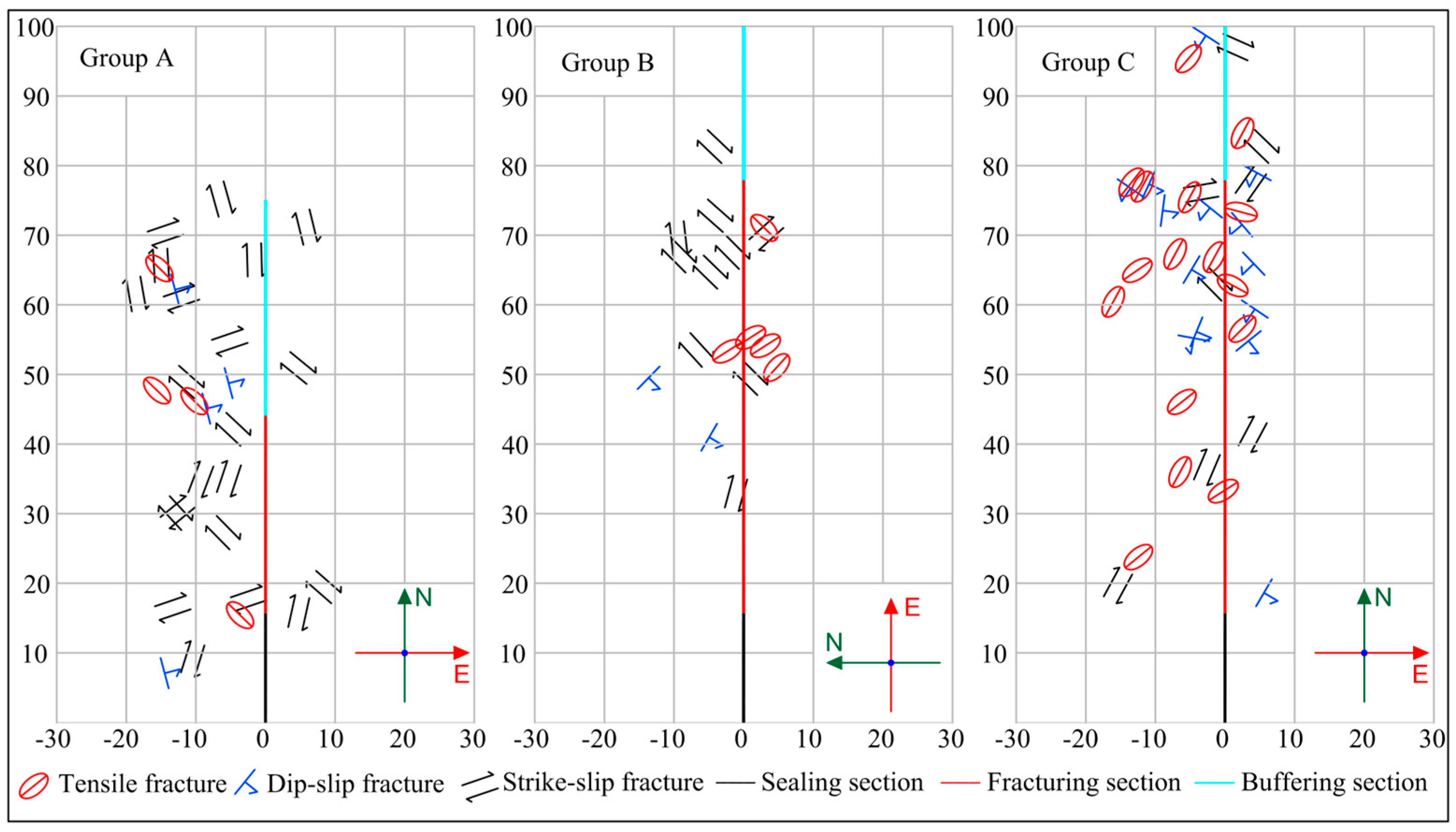

4.2. Shape of the Stress Relief Zone Formed by CO2-Frac

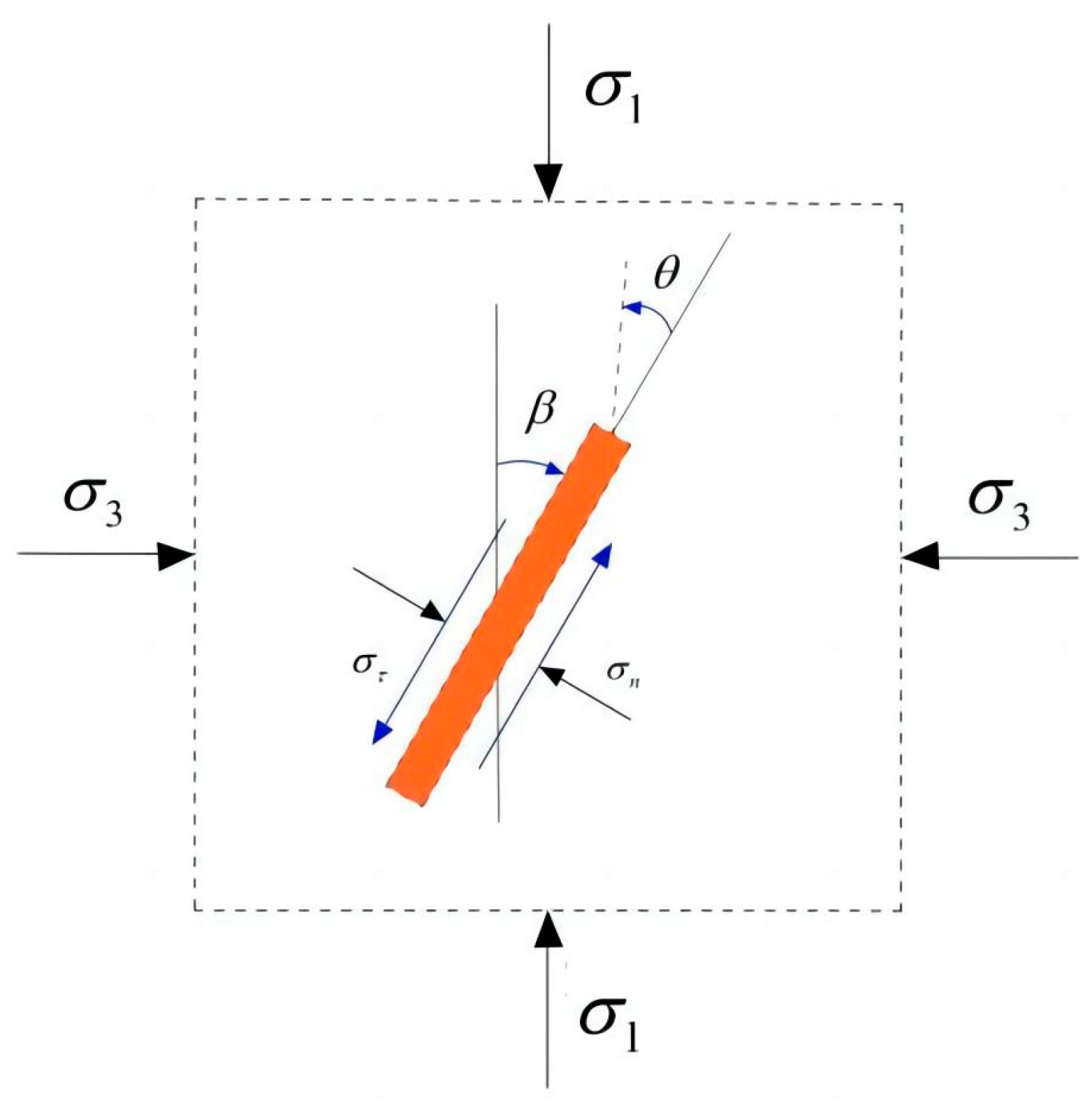

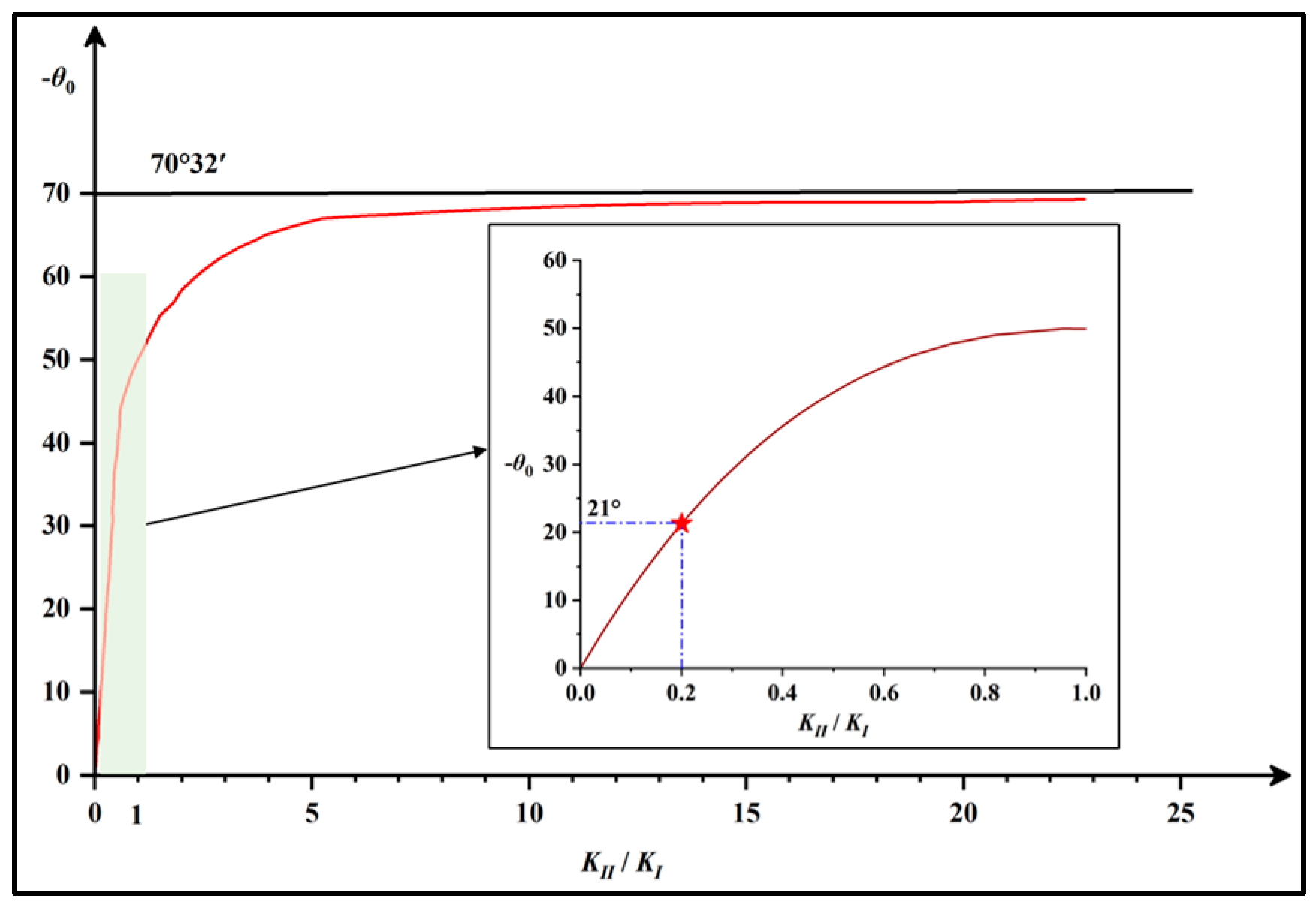

4.3. Effect of the Orientation of Primary Fractures on Stress Relief and Its Rationality

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cao, Y.; Zhang, J.; Zhai, H.; Fu, G.; Tian, L.; Liu, S. CO2 gas fracturing: A novel reservoir stimulation technology in low permeability gassy coal seams. Fuel 2017, 203, 197–207. [Google Scholar] [CrossRef]

- Liu, X.; Nie, B.; Guo, K.; Zhang, C.; Wang, Z.; Wang, L. Permeability enhancement and porosity change of coal by liquid carbon dioxide phase change fracturing. Eng. Geol. 2021, 287, 106106. [Google Scholar] [CrossRef]

- Hou, L.; Zhang, S.; Elsworth, D. Review of fundamental studies of CO2 fracturing: Fracture propagation, propping and permeating. J. Pet. Sci. Eng. 2021, 205, 108823. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Bi, C. Assessment of in-situ CO2 Sequestration Potential and Enhanced Coalbed Methane (ECBM) Production of Continental Coal-bearing Basins in China. Acta Geol. Sin.-Engl. Ed. 2024, 98, 1602–1614. [Google Scholar] [CrossRef]

- Ugwele, F.O.; Chime, T.O. Comparative Study of The Different Methods of Purifying Used Mobil Oil Using Different Acids as Washing Agents. Int. J. Nov. Res. Eng. Sci. 2019, 6, 1–6. [Google Scholar]

- Hughes, R.V.; Pfister, R.J. Advantages of brines in secondary recovery of petroleum by water-flooding. Trans. AIME 1947, 170, 187–201. [Google Scholar] [CrossRef]

- Tai, L.; Li, C.; Hu, Y.; Yu, X.; Xu, Z.; Zhang, X.; Chai, S.; Zhang, P.; Lu, S. Experimental study on the significance of pressure relief effect and crack extension law under uniaxial compression of rock-like materials containing drill holes. Sci. Rep. 2024, 14, 1104. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.; Zhang, S.; Feng, G.; Wang, Y.; Li, S.; Wang, Q.; Wang, B.; Zhao, L. Study on the Influence of Drilling Parameters on the Mechanical Properties and Pressure Relief Effect of Coal Rock. Processes 2025, 13, 993. [Google Scholar] [CrossRef]

- Liu, H.; Hao, W. Application research of liquid CO2 fracturing in coal seam penetration. Earth Environ. Sci. 2020, 526, 12095. [Google Scholar] [CrossRef]

- Shang, Z.; Wang, H.; Li, B.; Cheng, Y.; Zhang, X.; Zhao, F.; Zhang, X.; Hao, C.; Wang, Z. Fracture processes in coal measures strata under liquid CO2 phase transition blasting. Eng. Fract. Mech. 2020, 254, 107902. [Google Scholar] [CrossRef]

- Sampath, K.H.S.M.; Perera, M.S.A.; Elsworth, D.; Ranjith, P.G.; Matthai, S.K.; Rathnaweera, T.; Zhang, G. Effect of coal maturity on co2-based hydraulic fracturing process in coal seam gas reservoirs. Fuel 2019, 236, 179–189. [Google Scholar] [CrossRef]

- Jiang, Y.; Qin, C.; Kang, Z. Experimental study of supercritical CO2 fracturing on initiation pressure and fracture propagation in shale under different triaxial stress conditions. J. Nat. Gas Sci. Eng. 2018, 55, 382–394. [Google Scholar] [CrossRef]

- Zhou, W.; Shi, G.; Wang, J.; Liu, J.; Xu, N.; Liu, P. The influence of bedding planes on tensile fracture propagation in shale and tight sandstone. Rock Mech. Rock Eng. 2022, 55, 1111–1124. [Google Scholar] [CrossRef]

- Kursunoglu, N.; Onder, M. Application of structural equation modeling to evaluate coal and gas outbursts. Tunn. Undergr. Space Technol. 2019, 88, 63–72. [Google Scholar] [CrossRef]

- Li, W.; Ren, T.; Busch, A.; Hartog, S.A.M.D.; Cheng, Y.; Qiao, W.; Li, B. Architecture, stress state and permeability of a fault zone in Jiulishan coal mine, China: Implication for coal and gas outbursts. Int. J. Coal Geol. 2018, 198, 1–13. [Google Scholar] [CrossRef]

- Li, L.; Tan, J.; Tan, Y.; Pan, X.; Zhao, Z. Microseismic analysis to aid gas reservoir characterization. Sustain. Geosci. Nat. Gas Subsurf. Syst. 2022, 2, 219–242. [Google Scholar]

- Tan, Y.; Wang, J.; Rijken, P.; Zhang, Z.; Fang, Z.; Wu, R.; Ning, I.L.C.; Liu, X. Mechanism of microseismic generation during hydraulic fracturing. In Proceedings of the Unconventional Resources Technology Conference (URTeC), Houston, TX, USA, 26–28 July 2021; pp. 1146–1161. [Google Scholar] [CrossRef]

- Li, L.; Tan, J.; Wood, D.A.; Zhao, Z.; Becker, D.; Lyu, Q.; Shu, B.; Cheng, H. A review of the current status of induced seismicity monitoring for hydraulic fracturing in unconventional tight oil and gas reservoirs. Fuel 2019, 242, 195–210. [Google Scholar] [CrossRef]

- Tian, L.; Cao, Y.; Liu, S.; Shi, B.; Elsworth, D. Coalbed methane reservoir fracture evaluation through the novel passive microseismic survey and its implications on permeable and gas production. J. Nat. Gas Sci. Eng. 2020, 76, 103181. [Google Scholar] [CrossRef]

- Tian, L.; Li, Z.; Cao, Y.; Liu, S.; Song, Y. In situ stress distribution and variation monitored by microseismic tracking on a fractured horizontal well: A case study from the Qinshui Basin. Acs Omega 2022, 7, 14363–14370. [Google Scholar] [CrossRef] [PubMed]

- Besedina, A.N.; Kishkina, S.B.; Kocharyan, G.G. Source parameters of microseismic swarm events induced by the explosion at the Korobkovskoe Iron Ore deposit. Izv. Phys. Solid Earth 2021, 57, 348–365. [Google Scholar] [CrossRef]

- Duncan, P.M. Is there a future for passive seismic? First Break 2005, 23, 111–115. [Google Scholar] [CrossRef]

- Wojtecki, U.; Konicek, P.; Mendecki, M.J.; Goda, I.; Zuberek, W.M. Geophysical evaluation of effectiveness of blasting for roof caving during longwall mining of coal seam. Pure Appl. Geophys. 2020, 177, 905–917. [Google Scholar] [CrossRef]

- Urbancic, T.I.; Trifu, C.I. Microseismic identification of stress transfer as related to rockburst occurrences. In Series on Rock and Soil Mechanics; Trans Tech Publications: Clausthal-Zellerfeld, Germany, 1998; pp. 357–369. [Google Scholar]

- Cao, Y.; Tian, L.; Fan, Y.; Liu, J.; Zhang, S. Study on cracking ring form of carbon dioxide gas phase fracturing in low permeability coal seam. Coal Sci. Technol. 2018, 46, 46–51. [Google Scholar]

- Cao, T.; Yang, Z.; Qin, Y.; Li, C. Characteristics of modern geo-stress and removability of no.15 coal reservoir, Yangquan mining area, China. Nat. Resour. Res. 2021, 30, 2211–2223. [Google Scholar] [CrossRef]

- Lyu, S.; Wang, S.; Chen, X.; Wang, S.; Wang, T.; Shi, X.; Dong, Q.; Li, J. Natural fractures in soft coal seams and their effect on hydraulic fracture propagation: A field study. J. Pet. Sci. Eng. 2020, 192, 107255. [Google Scholar] [CrossRef]

- Al-Attar, H.H.; Barkhad, F.A. A review of unconventional natural gas resources. J. Nat. Sci. Sustain. Technology. 2019, 12, 263–288. [Google Scholar]

- Maxwell, S. Microseismic: Growth born from success. Lead. Edge 2010, 29, 338–343. [Google Scholar] [CrossRef]

- Maxwell, S.C.; Urbancic, T.I. The role of passive microseismic monitoring in the instrumented oil field. Lead. Edge 2001, 20, 636–640. [Google Scholar] [CrossRef]

- Baltay, A.; Ide, S.; Prieto, G.; Beroza, G. Variability in earthquake stress drop and apparent stress. Geophys. Res. Lett. 2011, 38, L06303. [Google Scholar] [CrossRef]

- Cotton, F.; Archuleta, R.; Causse, M. What is sigma of the stress drop? Seism. Res. Lett. 2013, 84, 42–48. [Google Scholar] [CrossRef]

- Huang, Y.; Beroza, G.C.; Ellsworth, W.L. Stress drop estimates of potentially induced earthquakes in the guy-greenbrier sequence. J. Geophys. Res. Solid Earth 2016, 121, 6597–6607. [Google Scholar] [CrossRef]

- Lengliné, O.; Lamourette, L.; Vivin, L.; Cuenot, N.; Schmittbuhl, J. Fluid-induced earthquakes with variable stress drop. J. Geophys. Res. Solid Earth 2014, 119, 8900–8913. [Google Scholar] [CrossRef]

- Noda, H.; Lapusta, N.; Kanamori, H. Comparison of average stress drop measures for ruptures with heterogeneous stress change and implications for earthquake physics. Geophys. J. Int. 2013, 193, 1691–1712. [Google Scholar] [CrossRef]

- Klinger, A.G.; Werner, M.J. Stress drops of hydraulic fracturing induced microseismicity in the horn river basin: Challenges at high frequencies recorded by borehole geophones. Geophys. J. Int. 2022, 228, 2018–2037. [Google Scholar] [CrossRef]

- Li, H.; Chang, X. A review of the microseismic focal mechanism research. Sci. China Earth Sci. 2021, 64, 351–363. [Google Scholar] [CrossRef]

- Li, Z.; Chang, X.; Yao, Z.; Wang, Y. Fracture monitoring and reservoir evaluation by micro-seismic method. Chin. J. Geophys. 2019, 62, 707–719. (In Chinese) [Google Scholar]

- Shao, S.; Chen, K.; Ding, W.; Yang, G.; Tang, J. Stress field analytic model and stress perturbation analysis around hydraulic cracks. China Pet. Mach. 2018, 46, 108–114. [Google Scholar] [CrossRef]

- Sneddon, I.N. The distribution of stress in the neighborhood of a crack in an elastic solid. Proc. R. Soc. A Math. Phys. Eng. Sci. 1946, 1009, 229–260. [Google Scholar] [CrossRef]

- Su, S.; Stephansson, O. Effect of a fault on in situ stresses studied by the distinct element method. Int. J. Rock Mech. Min. 1999, 36, 1051–1056. [Google Scholar] [CrossRef]

- Su, S.; Zhu, H.; Wang, S.; Stephansson, O. Effect of physical and mechanical properties of rocks on stress field in the vicinity of fractures. Chin. Int. J. Rock Mech. Min. 2003, 22, 370–377. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, M.; Jin, Y.; Zhang, G. Analysis of fracture propagation behavior and fracture geometry using a tri-axial fracturing system in naturally fractured reservoirs. Int. J. Rock Mech. Min. Sci. 2008, 45, 1143–1152. [Google Scholar] [CrossRef]

- Jia, J.; Wang, D.; Li, B.; Tian, X. Study of the influencing factors of the liquid CO2 phase change fracturing effect in coal seams. PLoS ONE 2021, 16, 254996. [Google Scholar] [CrossRef] [PubMed]

- Brune, J.N. Tectonic stress and the spectra of seismic shear waves from earthquakes. J. Geophys. Res. 1970, 75, 4997–5009. [Google Scholar] [CrossRef]

- Zeng, W.; Mi, Q. Skin coefficient decomposition calculation of horizontal well after perforation. Drill. Fluid Complet. Fluid 2005, 22, 105–106. [Google Scholar]

- Irwin, G.R. Analysis of stresses and strains near end of a crack traversing a plate. J. Appl. Mech. 1956, 24, 361–364. [Google Scholar] [CrossRef]

- Li, S.Y.; He, T.; Yin, X. Introduction of Rock Fracture Mechanics; University of Science and Technology of China Press: Hefei, China, 2010. [Google Scholar]

- Hu, Q.; Liu, L.; Li, Q.; Wu, Y.; Wu, X. Experimental investigation on crack competitive extension during hydraulic fracturing in coal measures strata. Fuel 2020, 265, 117003. [Google Scholar] [CrossRef]

- Liang, X.; Hou, P.; Xue, Y.; Gao, Y.; Gao, F.; Liu, J.; Dang, F. Role of fractal effect in predicting crack initiation angle and its application in hydraulic fracturing. Rock Mech. Rock Eng. 2022, 55, 5491–5512. [Google Scholar] [CrossRef]

- Liu, Q.; Zhao, Y.; Tang, L.; Liao, J.; Wang, X.; Tan, T.; Chang, L.; Luo, S.; Wang, M. Mechanical characteristics of single cracked limestone in compression-shear fracture under hydro-mechanical coupling. Theor. Appl. Fract. Mech. 2022, 119, 103371. [Google Scholar] [CrossRef]

- Pan, J.; Li, D.; Cai, S.; Luo, X. A pure complex variable enrichment method for modeling progressive fracture of orthotropic functionally gradient materials. Eng. Fract. Mech. 2023, 277, 108984. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, L.; Wang, W.; Pu, C.; Wan, W.; Tang, J. Cracking and stress–strain behavior of rock-like material containing two flaws under uniaxial compression. Rock Mech. Rock Eng. 2016, 49, 2665–2687. [Google Scholar] [CrossRef]

- Zhao, X.; Huang, B.; Xu, J. Experimental investigation on the characteristics of fractures initiation and propagation for gas fracturing by using air as fracturing fluid under true triaxial stresses. Fuel 2019, 236, 1496–1504. [Google Scholar] [CrossRef]

- Tan, Y.; Fang, Z.; Liu, X.; Fradelizio, G.; John, E. The impact of in-situ shear stress on microseismic temporal-magnitude patterns. In Proceedings of the 56th US Rock Mechanics/Geomechanics Symposium, Santa Fe, NM, USA, 26–29 June 2022. [Google Scholar] [CrossRef]

| Test Serial | Seismic Dots | Focal Mechanism | Fracture Scale (m) | Stress Drop (kPa) | ||

|---|---|---|---|---|---|---|

| Tensile | Dip–Slip | Strike–Slip | ||||

| Group A | 23 | 4 | 4 | 15 | 16.21–34.22 | 0.24–569.81 |

| Group B | 16 | 5 | 2 | 9 | 10.81–48.63 | 1.53–1469.57 |

| Group C | 38 | 16 | 14 | 8 | 10.81–18.01 | 24.62–992.72 |

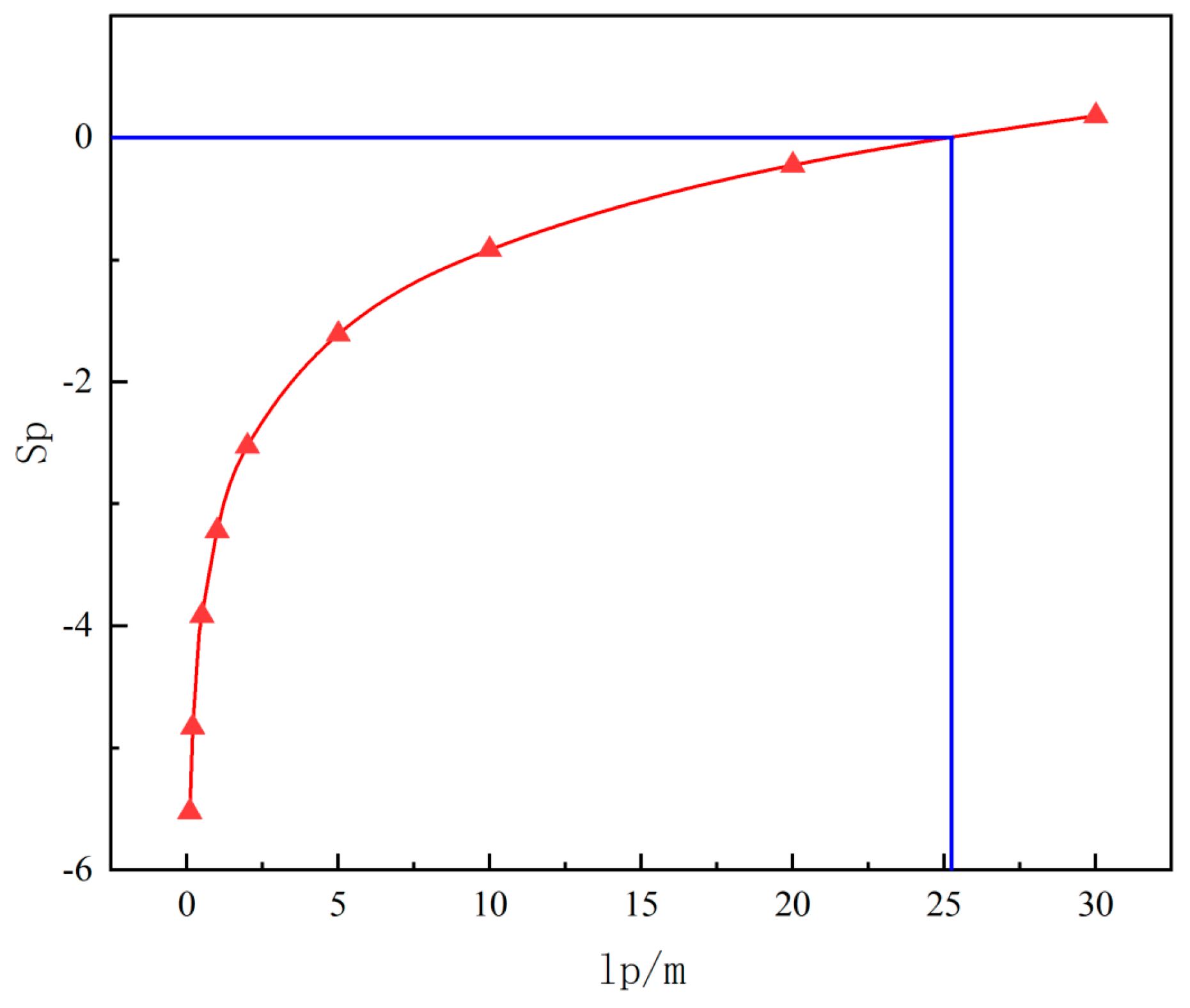

| 0.1 | 25 | 0.06 | 15 | 0.375 | 0.0005 | 3 | −5.5215 | 0.0015 | −5.5199 |

| 0.2 | 25 | 0.06 | 7.5 | 0.230769 | 0.0005 | 3 | −4.8283 | 0.0010 | −4.8273 |

| 0.5 | 25 | 0.06 | 3 | 0.107143 | 0.0005 | 3 | −3.9120 | 0.0007 | −3.9113 |

| 1 | 25 | 0.06 | 1.5 | 0.056604 | 0.0005 | 3 | −3.2189 | 0.0006 | −3.2183 |

| 2 | 25 | 0.06 | 0.75 | 0.029126 | 0.0005 | 3 | −2.5257 | 0.0005 | −2.5252 |

| 5 | 25 | 0.06 | 0.3 | 0.011858 | 0.0005 | 3 | −1.6094 | 0.0005 | −1.6089 |

| 10 | 25 | 0.06 | 0.1 | 0.005964 | 0.0005 | 3 | −0.9163 | 0.0005 | −0.9158 |

| 20 | 25 | 0.06 | 0.075 | 0.002991 | 0.0005 | 3 | −0.2231 | 0.0005 | −0.2226 |

| 30 | 25 | 0.06 | 0.05 | 0.001996 | 0.0005 | 3 | 0.1823 | 0.0005 | 0.1828 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Zhang, D.; Wang, Z.; Han, W.; Tian, L. Effect of Primary Fracture Orientation on CO2 Fracturing in Coal Seam Stress Relief. Processes 2025, 13, 3523. https://doi.org/10.3390/pr13113523

Li P, Zhang D, Wang Z, Han W, Tian L. Effect of Primary Fracture Orientation on CO2 Fracturing in Coal Seam Stress Relief. Processes. 2025; 13(11):3523. https://doi.org/10.3390/pr13113523

Chicago/Turabian StyleLi, Peng, Di Zhang, Zhirong Wang, Wenbin Han, and Lin Tian. 2025. "Effect of Primary Fracture Orientation on CO2 Fracturing in Coal Seam Stress Relief" Processes 13, no. 11: 3523. https://doi.org/10.3390/pr13113523

APA StyleLi, P., Zhang, D., Wang, Z., Han, W., & Tian, L. (2025). Effect of Primary Fracture Orientation on CO2 Fracturing in Coal Seam Stress Relief. Processes, 13(11), 3523. https://doi.org/10.3390/pr13113523