A Study of Particle Motion and Separation Characteristics in a Vibrating Airflow Composite Force Field

Abstract

1. Introduction

2. Materials and Methods

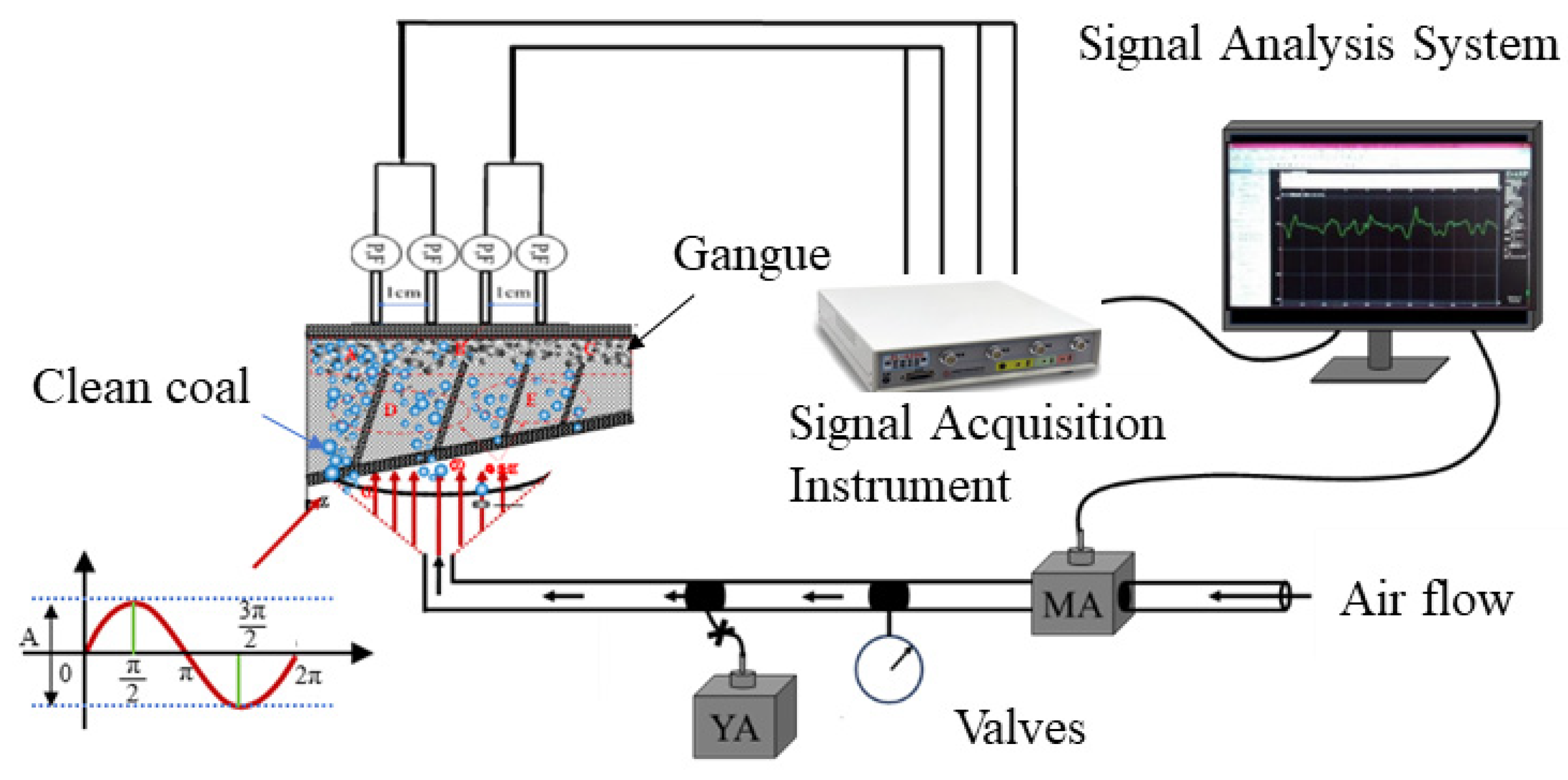

2.1. Setup

2.2. Materials

2.3. Evaluation Index

3. Results

3.1. Analysis of Forces Acting on Particles in Vibrating Airflow Composite Force Field

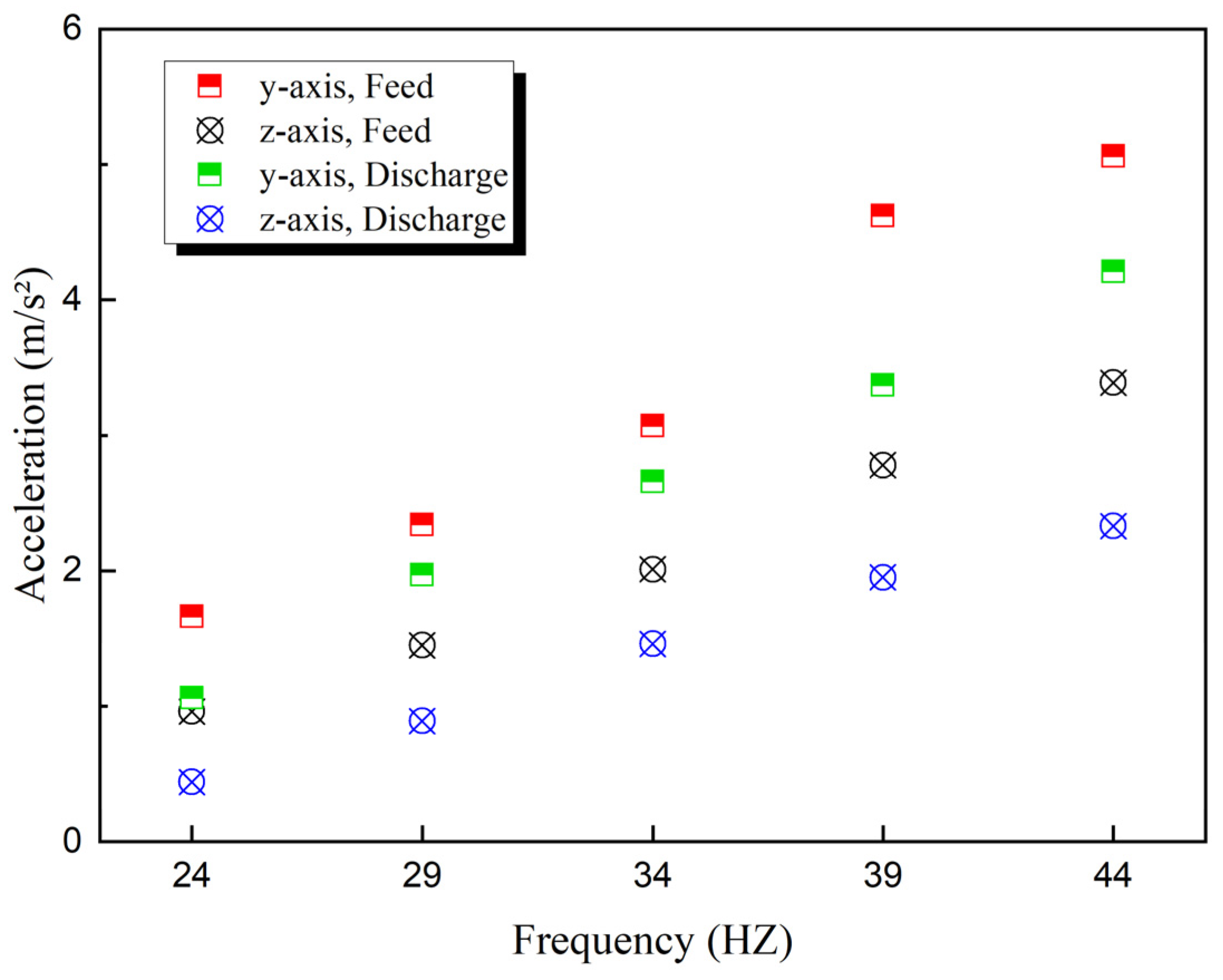

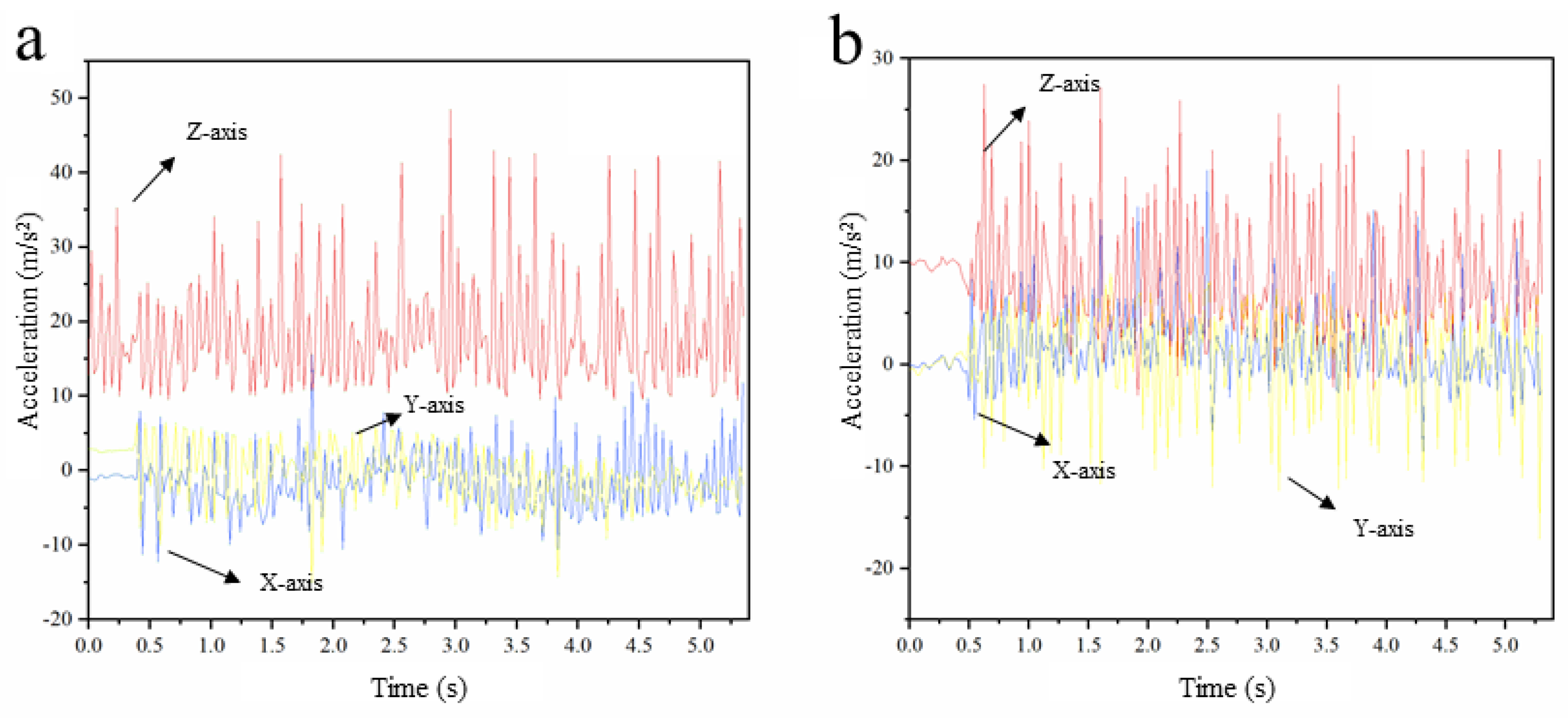

3.2. Vibration Characteristics of Particles at Different Positions in the Bed

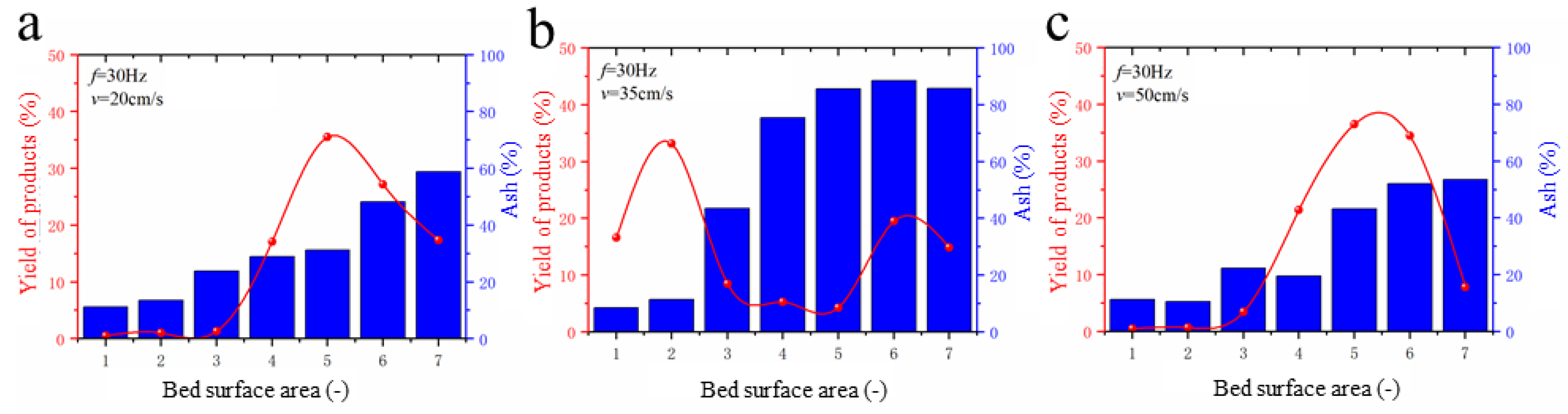

3.3. Ash Content and Mass Fraction of Selected Products Under Varying Operational Parameters

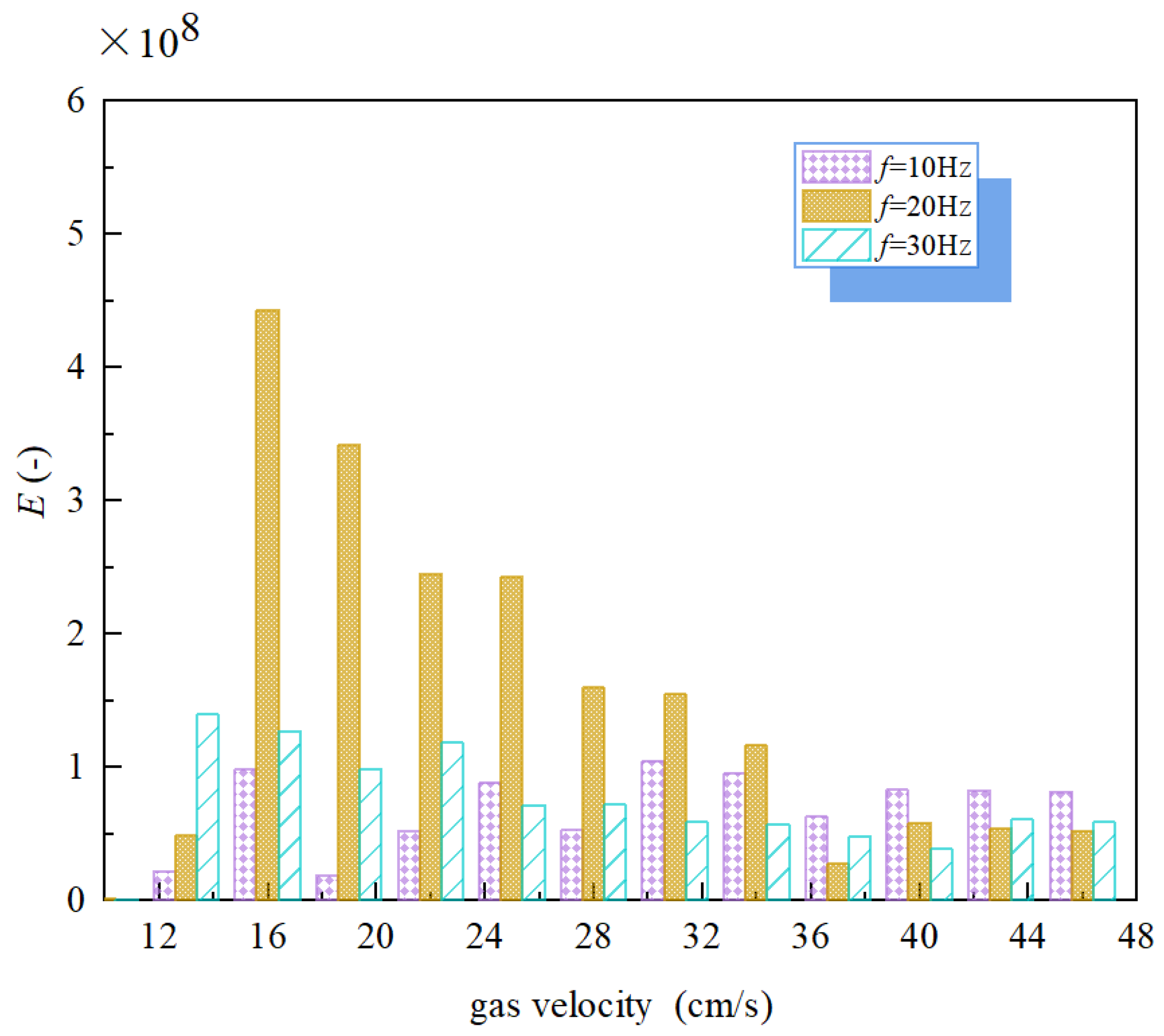

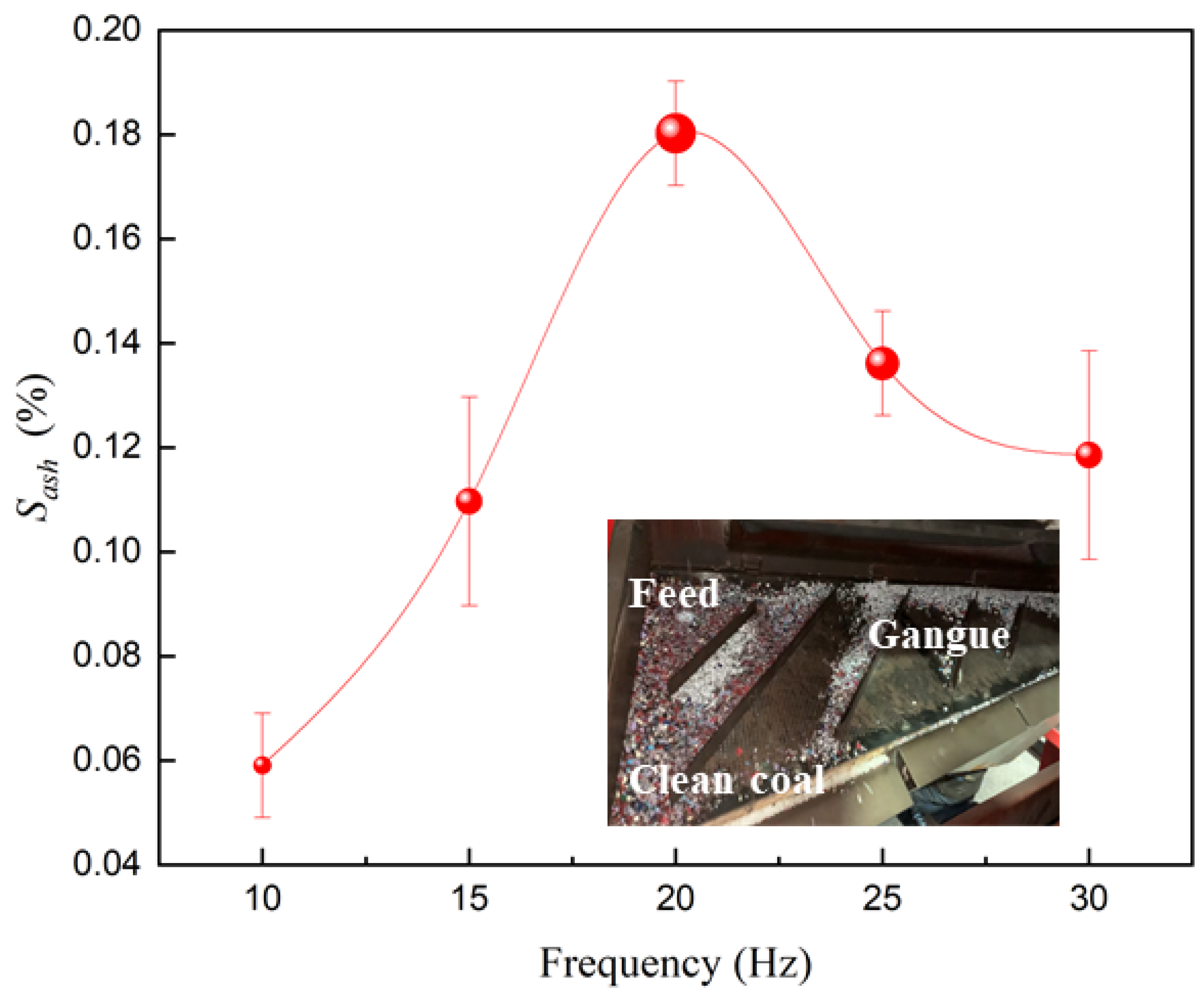

3.4. Effectiveness of Vibration Airflow Composite Force Field in Separation of Fine Coal

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| A0 | ash content of raw coal, % |

| Ai | average ash content of each product in a partition, % |

| d | particle diameter, m |

| f | vibration frequency, Hz |

| G | particle gravity, N |

| dh | length of microelement, m |

| k | thermal conductivity coefficient |

| m | particle quality, kg |

| n | number of partitions along the separation bed |

| np | particle number per unit volume |

| P | pressure, Pa |

| Q | energy of particles within the bed, J |

| Qin | input energy of the bed, J |

| Qout | output energy of the bed, J |

| dQ | net energy exchange within the bed, J·s−1 |

| Sash | ash separation degree |

| dS | area of microelement, m2 |

| T | particle temperature, J |

| v | airflow velocity, cm/s |

| vp | pulsation velocity of particle motion, m/s |

| V | velocity of bed movement, m/s |

| average value of the square of the bed’s movement velocity | |

| λ | energy dissipation rate caused by particle collisions within the bed, J·m−3·s−1 |

| η | volume fraction of bed particles |

References

- Chen, R.; Dong, X.; Feng, Z.; Fan, Y.; Ma, X. Effect of Froth on the Interaction Between Coal Particles and Cake Structures in the Dewatering Process of Clean Coal. Processes 2024, 12, 2738. [Google Scholar] [CrossRef]

- Zhao, Y.M.; Li, G.M.; Luo, Z.F.; Zhang, B.; Dong, L.; Liang, C.C.; Duan, C.L. Industrial application of a modularized dry-coal-beneficiation technique based on a novel air dense medium fluidized bed. Int. J. Coal Prep. Util. 2017, 37, 44–57. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, Y.D.; Zhao, Y.M.; Duan, C.L. Fluidization characteristics and fine coal separation in a gas-solid vibrated fluidized bed. J. China Coal Soc. 2021, 46, 2664–2672. [Google Scholar]

- Chen, Z.Q.; Pan, M.; Deng, H.; Cao, Y.W.; Zhao, S.Z.; Zhou, E.H.; Duan, C.L. Effect of vibration and airflow on separation of 6–1 mm fine coal in compound dry separation bed. Chem. Eng. Res. Des. 2024, 207, 350–360. [Google Scholar] [CrossRef]

- Xu, X.; Chen, J.M.; Luo, Z.F.; Tang, L.G.; Zhao, Y.M.; Lv, B.; Fu, Y.H.; Chen, C.S. Fluidization characteristics of air dense medium agitated separation fluidized bed with different distributors. Miner. Process. Extr. Metall. Rev. 2019, 40, 299–306. [Google Scholar] [CrossRef]

- Luo, Z.F.; Zhu, J.F.; Fan, M.M.; Zhao, Y.M.; Tao, X.X. Low Density Dry Coal Beneficiation Using an Air Dense Medium Fluidized Bed. J. China Univ. Min. Technol. 2007, 17, 306–309. [Google Scholar] [CrossRef]

- Fu, Z.J.; Zhao, Y.M.; Yang, X.L.; Luo, Z.F.; Zhao, J. Fine Coal Beneficiation via Air-Dense Medium Fluidized Beds with Improved Magnetite Powders. Int. J. Coal Prep. Util. 2016, 36, 55–68. [Google Scholar] [CrossRef]

- Zhu, R.; Zhao, Y.M.; Zhao, P.F.; Luo, Z.F.; Wang, H.K.; He, L.H.; Tan, M.B.; Wang, H.; Zhang, Y.F. Bed fluidization characteristics and separating effect offine coal in an air dense medium fluidized bed. J. China Coal Soc. 2016, 41, 727–734. [Google Scholar]

- Xu, X.; Zhang, G.; Chen, Z.; Zhang, Z.; Dong, L. Experimental investigation on the bubble characteristics in a gas-solid sound-assisted separation fluidized bed. Chem. Eng. Res. Des. 2025, 214, 1–17. [Google Scholar] [CrossRef]

- Akbari, H.; Ackah, L.; Mohanty, M. Performance Optimization of a New Air Table and Flip-flow Screen for Fine Particle Dry Separation. Int. J. Coal Prep. Util. 2020, 40, 581–603. [Google Scholar] [CrossRef]

- Jin, H.B.; Tong, Z.M.; Zhang, J.Y.; Zhang, B.J. Homogeneous Fluidization Characteristics of Vibrating Fluidized Beds. Can. J. Chem. Eng. 2008, 82, 1048–1053. [Google Scholar] [CrossRef]

- Cano-Pleite, E.; Hernandez-Jimenez, F.; Acosta-Iborraa, A.; Tsuji, T.; Müller, C.R. Segregation of equal-sized particles of different densities in a vertically vibrated fluidized bed. Powder Technol. 2017, 316, 101–110. [Google Scholar] [CrossRef]

- Cano-Pleite, E.; Hernandez-Jimenez, F.; Acosta-Iborra, A. Vibration augmentation of the solids volume dragged by the wake of a bubble rising in a fluidized bed. Powder Technol. 2020, 380, 574–583. [Google Scholar] [CrossRef]

- Macpherson, G.K.P.; Galvin, K.P. The effect of vibration on dry coal beneficiation in the reflux classifier. Int. J. Coal Prep. Util. 2010, 30, 283–294. [Google Scholar] [CrossRef]

- Su, D.; Luo, Z.F. Gas-solid two-phase flow model and its application invibrated fluidized bed of fine coal. Coal Sci. Technol. 2018, 46, 209–216. [Google Scholar]

- Zhang, Y.D.; Wang, X.Y.; Dong, H.X.; Yang, Y.; Zhao, Y.M.; Jiang, Y.; Zhu, R.; Yang, X.L. Study on key factors affecting separation of fine coalvibrated fluidized bed. Coal Prep. 2016, 41, 3128–3135. [Google Scholar]

- Liang, X.Z.; Zhou, Y.M.; Zou, L.X.; Kong, J.R.; Wang, J.; Zhou, T. Fluidization behavior of binary iron-containing nanoparticle mixtures in a vibro-fluidized bed. Powder Technol. 2016, 304, 101–107. [Google Scholar] [CrossRef]

- Diego, B.; Paola, R.; Massimo, P. Dynamic response of a vibrated fluidized bed of fine and cohesive powders. Powder Technol. 2013, 237, 276–285. [Google Scholar] [CrossRef]

- Luo, Z.; Fan, M.; Zhao, Y.; Tao, X.; Chen, Q.; Chen, Z. Density-dependent separation of dry fine coal in a vibrated fluidized bed. Powder Technol. 2008, 187, 119–123. [Google Scholar] [CrossRef]

- Luo, Z.; Chen, Q.; Tao, Q.X. Formation Mechanism of Vibrated Fluidized Bed (VFB). J. China Univ. Min. Technol. 2000, 29, 11–18. [Google Scholar]

- Yang, X.L.; Zhou, E.H.; Fu, Z.J.; Dong, L.; Jiang, H.S. Kinematic properties and beneficiation performance of fine coal in a continuous vibrated gas-fluidized bed separator. Fuel 2015, 162, 281–287. [Google Scholar] [CrossRef]

- Wei, L.B.; Liang, S.H.; Wei, R.H.; Wang, X.H.; Zeng, M. Characteristics of separation with a new-style air-densemedium fluidized bed. J. China Univ. Min. Technol. 2011, 40, 733–736. [Google Scholar]

- Sun, Z.; Yao, Q.W.; Jin, H.Q.; Xu, Y.J.; Hang, W.; Chen, H.Y.; Li, K.; Shi, L.; Gu, J.P.; Zhang, Q.J.; et al. A novel in-situ sensor calibration method for building thermal systems based on virtual samples and autoencoder. Energy 2024, 297, 131314. [Google Scholar] [CrossRef]

- Li, L.; Xu, P.; Li, Q.H.; Yin, Z.C.; Zheng, R.Y.; Wu, J.F.; Bao, J.J.; Bai, W.Y.; Qi, H.; Tan, D.P. Multi-field coupling particle flow dynamic behaviors of the microreactor and ultrasonic control method. Powder Technol. 2025, 454, 120731. [Google Scholar] [CrossRef]

- Li, Y.J.; Li, D.Q.; Jiang, H.; Dong, Y.S.; Gao, Z.L.; Hong, K.; Dong, L. Prediction of fluidization state in a pulsed gas-solid fluidized bed. Chem. Eng. J. 2025, 517, 164471. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, Z.Q.; Zhao, Y.M.; Yang, X.Y.; Fu, Z.J. Study on separation stability of fine coal with vibrating fluidized bed. Min. Process. Equip. 2015, 43, 85–90. [Google Scholar]

- Liu, C.P.; Wang, L.; Zhang, F.W. Energy transfer and dissipation in vibrational granular bed. Acta Phys. Sin. 2014, 63, 044502. [Google Scholar] [CrossRef]

- Viswanathan, H.; Wildman, R.D.; Huntley, J.M.; Martin, T.W. Comparison of kinetic theory predictions with experimental results for a vibrated three-dimensional granular bed. Phys. Fluids 2006, 18, 113302. [Google Scholar] [CrossRef]

- Wildman, R.D.; Huntley, J.M. Scaling exponents for energy transport and dissipation in binary vibro-fluidized granular beds. Phys. Fluids 2003, 15, 3090–3098. [Google Scholar] [CrossRef]

| Density (g/cm3) | Ratio (%) | Ash (%) |

|---|---|---|

| <1.3 | 46.48 | 6.97 |

| 1.3–1.4 | 14.43 | 9.82 |

| 1.4–1.5 | 1.17 | 10.34 |

| 1.5–1.6 | 3.14 | 17.95 |

| 1.6–1.7 | 2.32 | 25.55 |

| 1.7–1.8 | 7.03 | 39.71 |

| >1.8 | 25.43 | 61.77 |

| Total | 100.00 | 24.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Qi, J.; Yang, W.; Xu, B.; Xu, X.; Zhou, N.; Ma, B. A Study of Particle Motion and Separation Characteristics in a Vibrating Airflow Composite Force Field. Processes 2025, 13, 3501. https://doi.org/10.3390/pr13113501

Li K, Qi J, Yang W, Xu B, Xu X, Zhou N, Ma B. A Study of Particle Motion and Separation Characteristics in a Vibrating Airflow Composite Force Field. Processes. 2025; 13(11):3501. https://doi.org/10.3390/pr13113501

Chicago/Turabian StyleLi, Kesheng, Jian Qi, Wenhai Yang, Bao Xu, Xuan Xu, Nan Zhou, and Bingbing Ma. 2025. "A Study of Particle Motion and Separation Characteristics in a Vibrating Airflow Composite Force Field" Processes 13, no. 11: 3501. https://doi.org/10.3390/pr13113501

APA StyleLi, K., Qi, J., Yang, W., Xu, B., Xu, X., Zhou, N., & Ma, B. (2025). A Study of Particle Motion and Separation Characteristics in a Vibrating Airflow Composite Force Field. Processes, 13(11), 3501. https://doi.org/10.3390/pr13113501