A New Method for Predicting the Dynamic Coal Consumption of Coal-Fired Dual Heating Systems

Abstract

1. Introduction

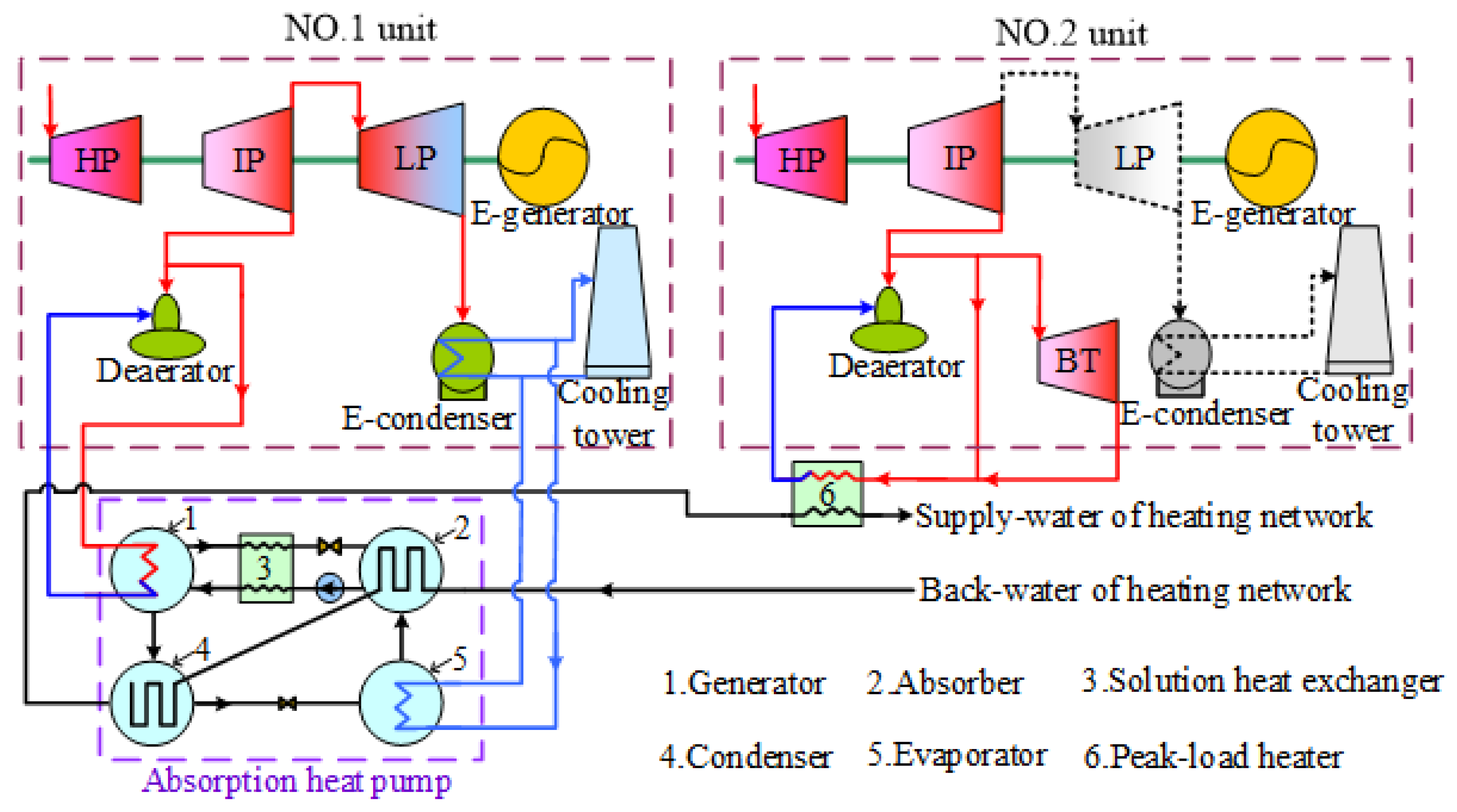

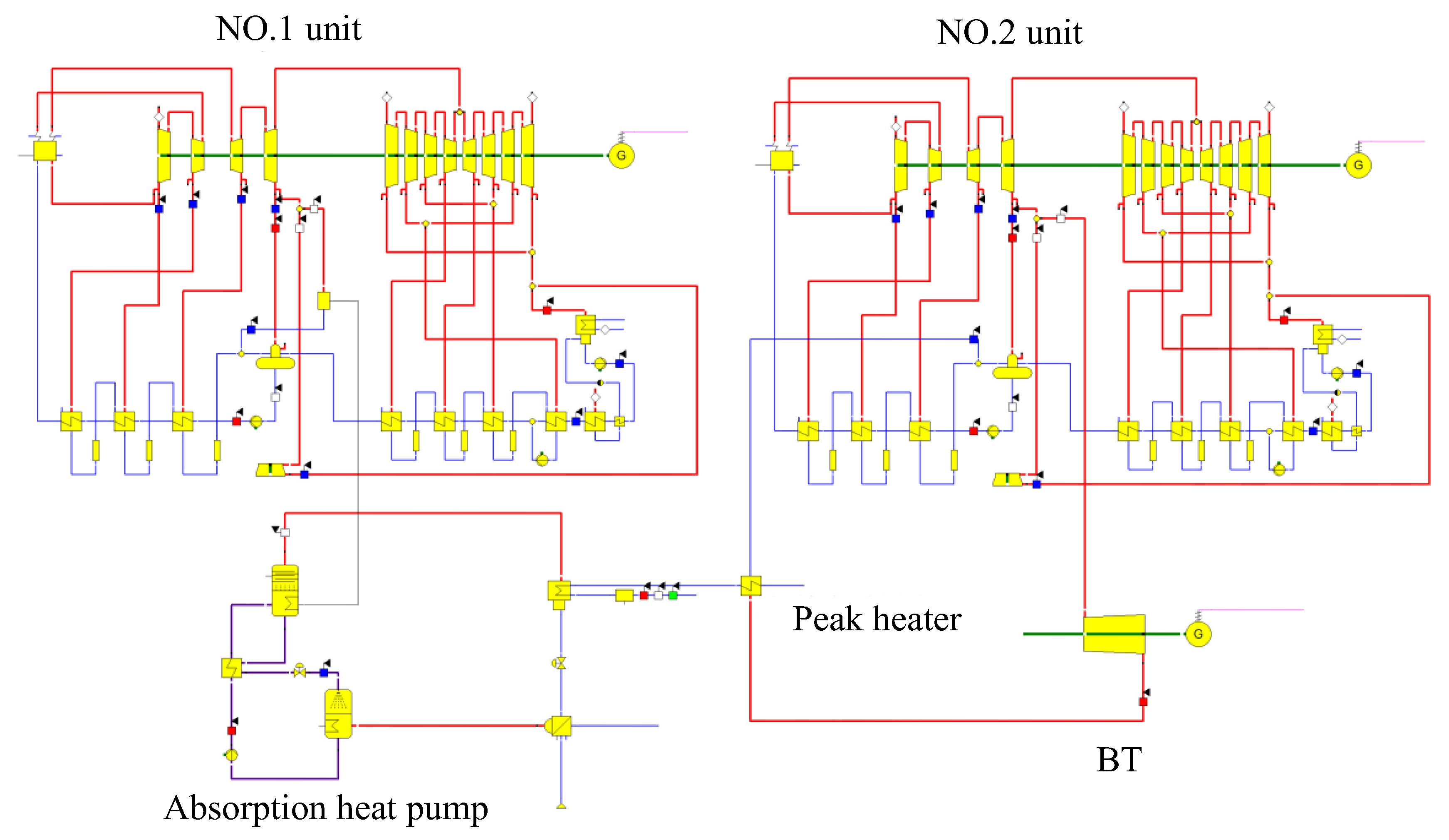

2. System Introduction

2.1. Heating System

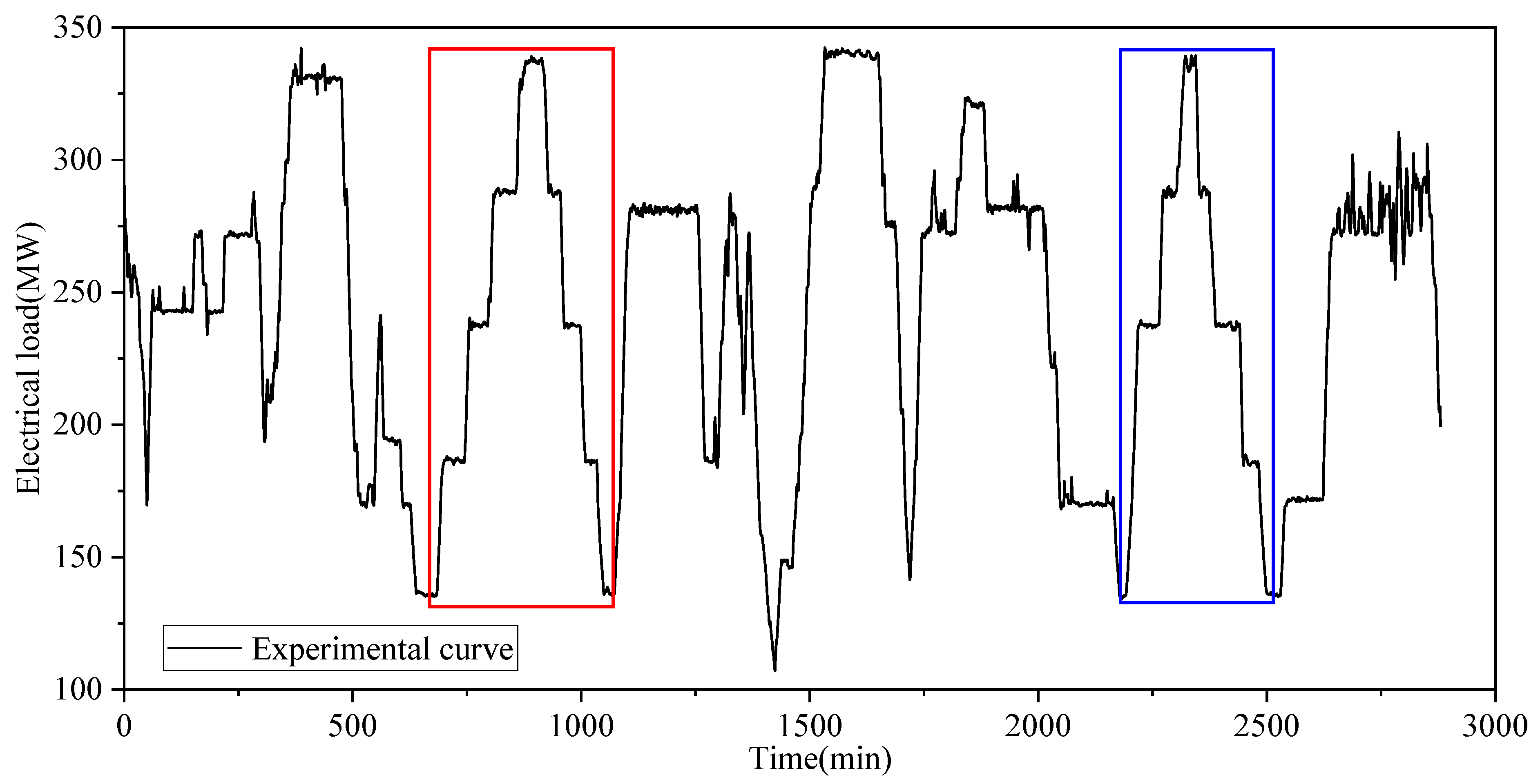

2.2. Steady State and Dynamic Testing

3. Model Construction and Regulation Domain

3.1. Heat Pump System

3.2. Back-Pressure Turbine

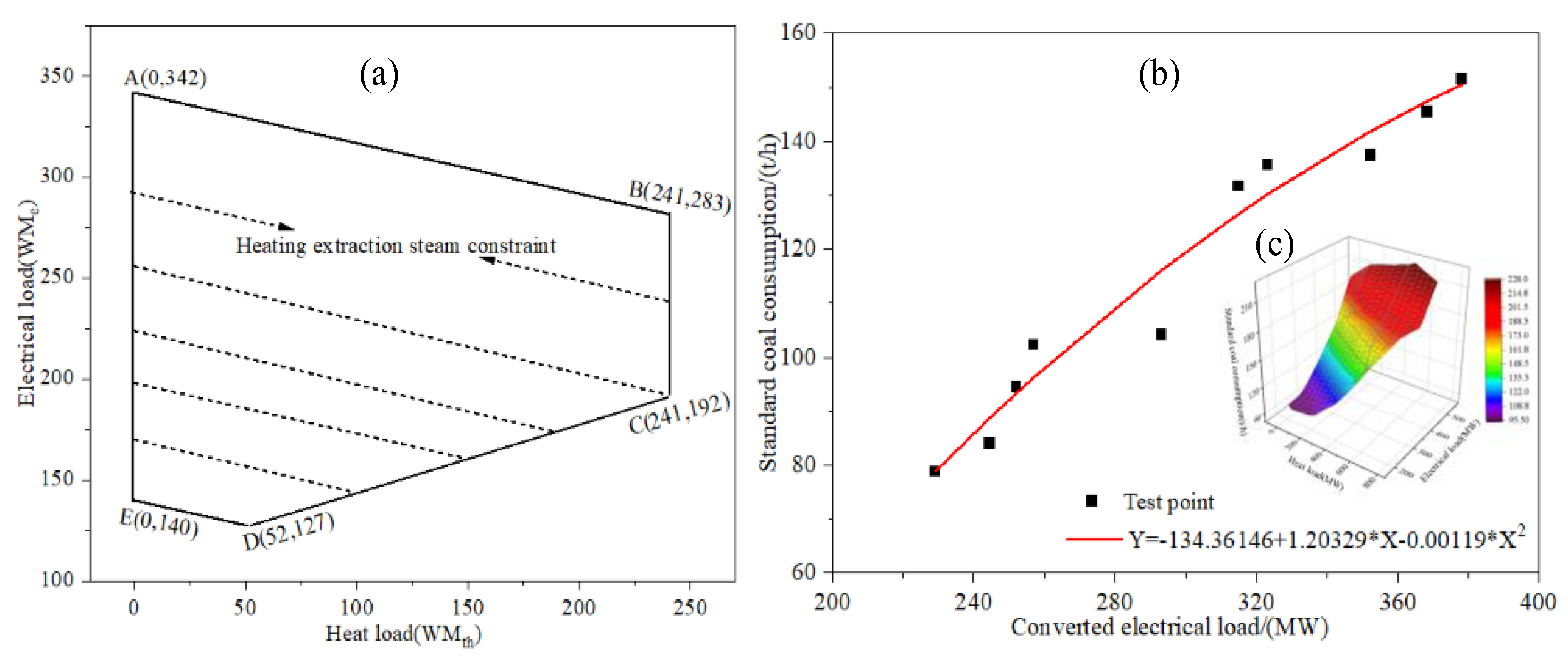

3.3. Condensing Unit

3.4. Low-Pressure Turbine Zero-Output Unit

4. Characteristic Parameters

4.1. Heat Pump System

4.2. Back-Pressure Turbine

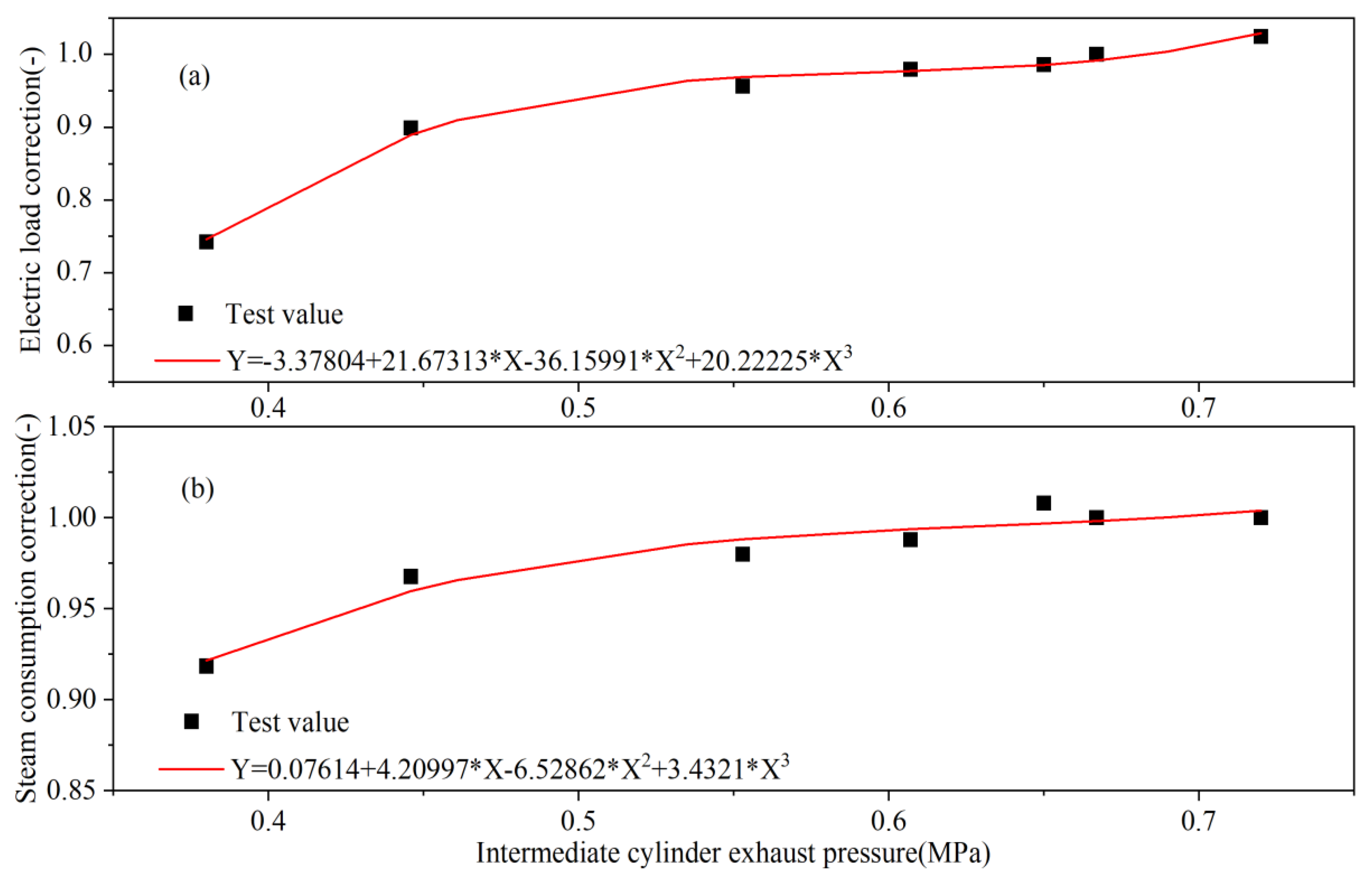

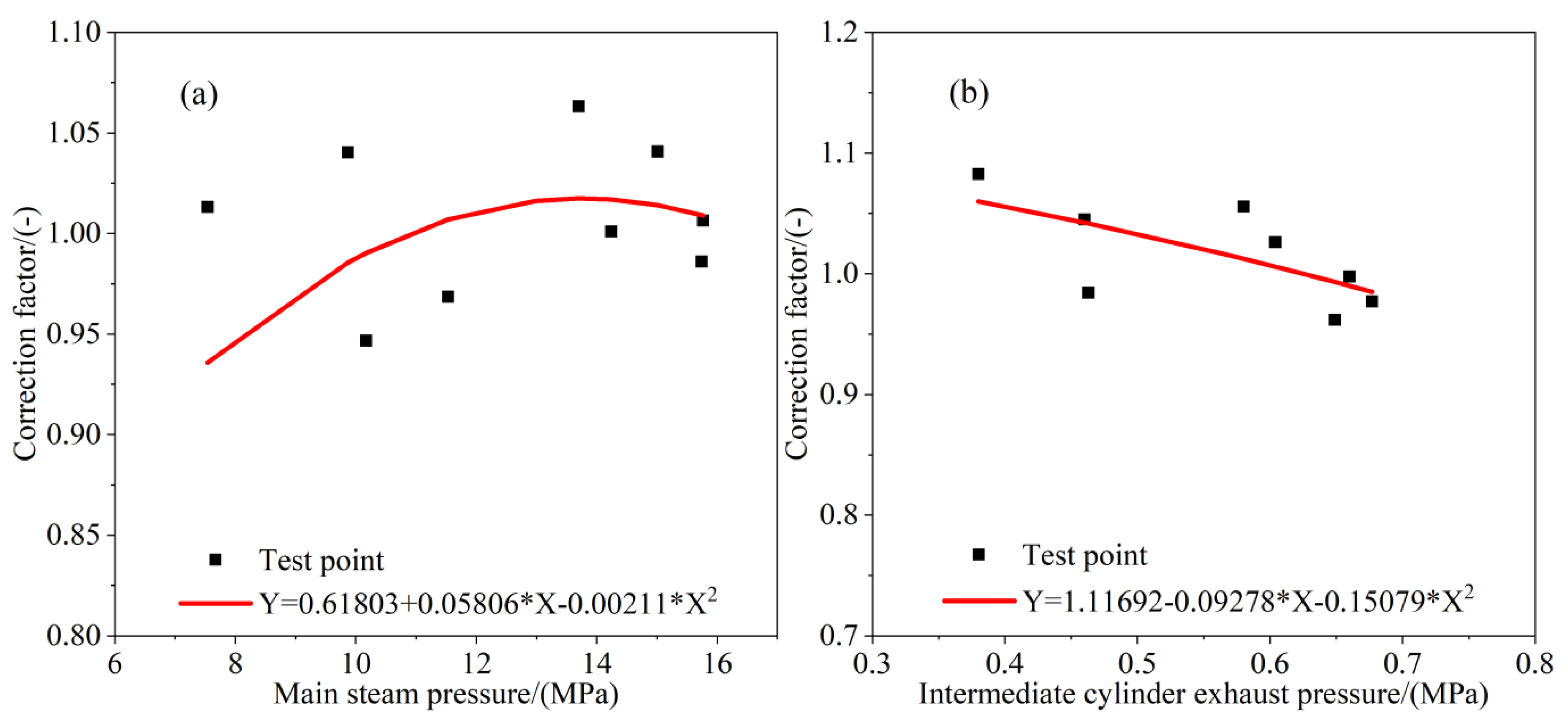

4.3. Condensing Unit

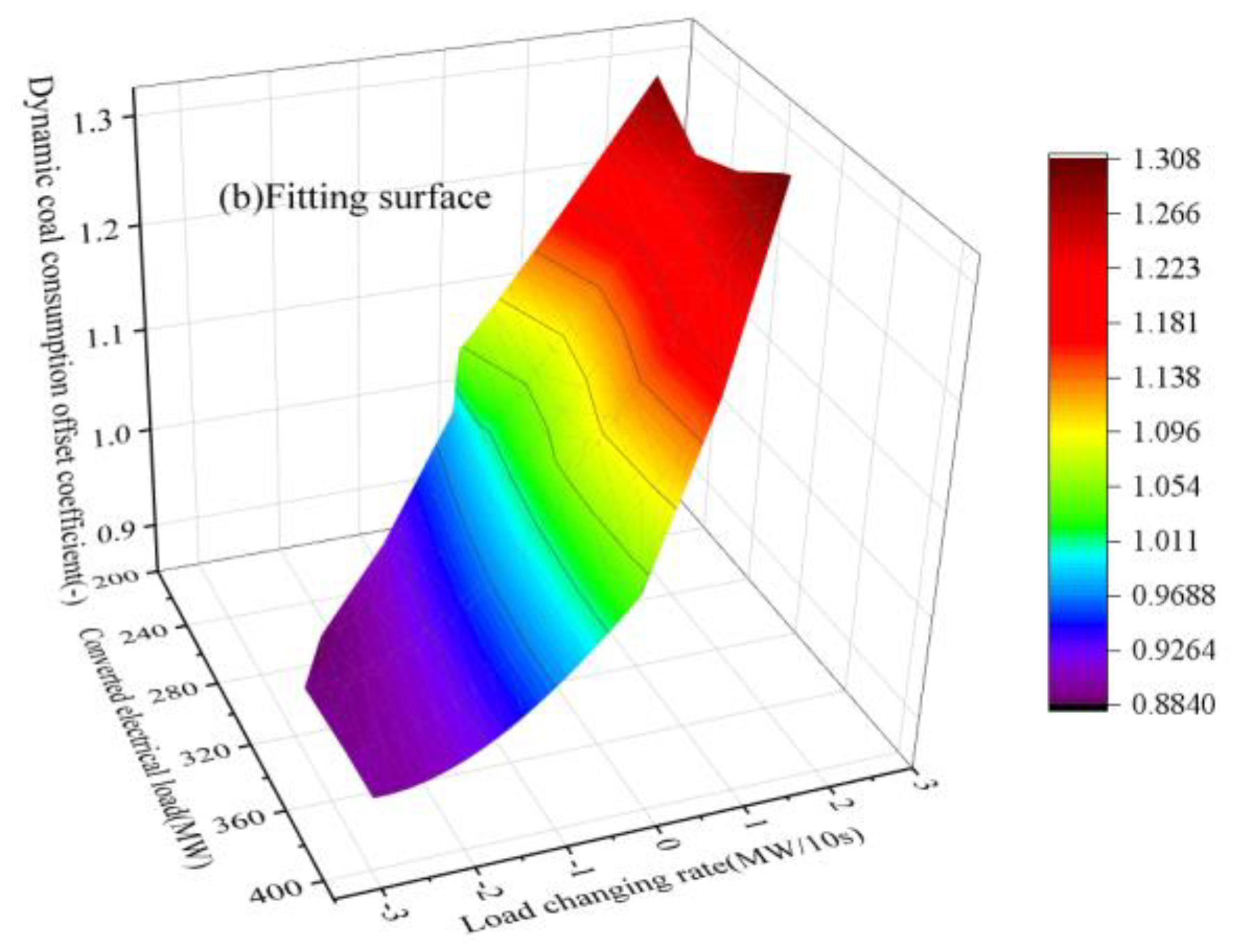

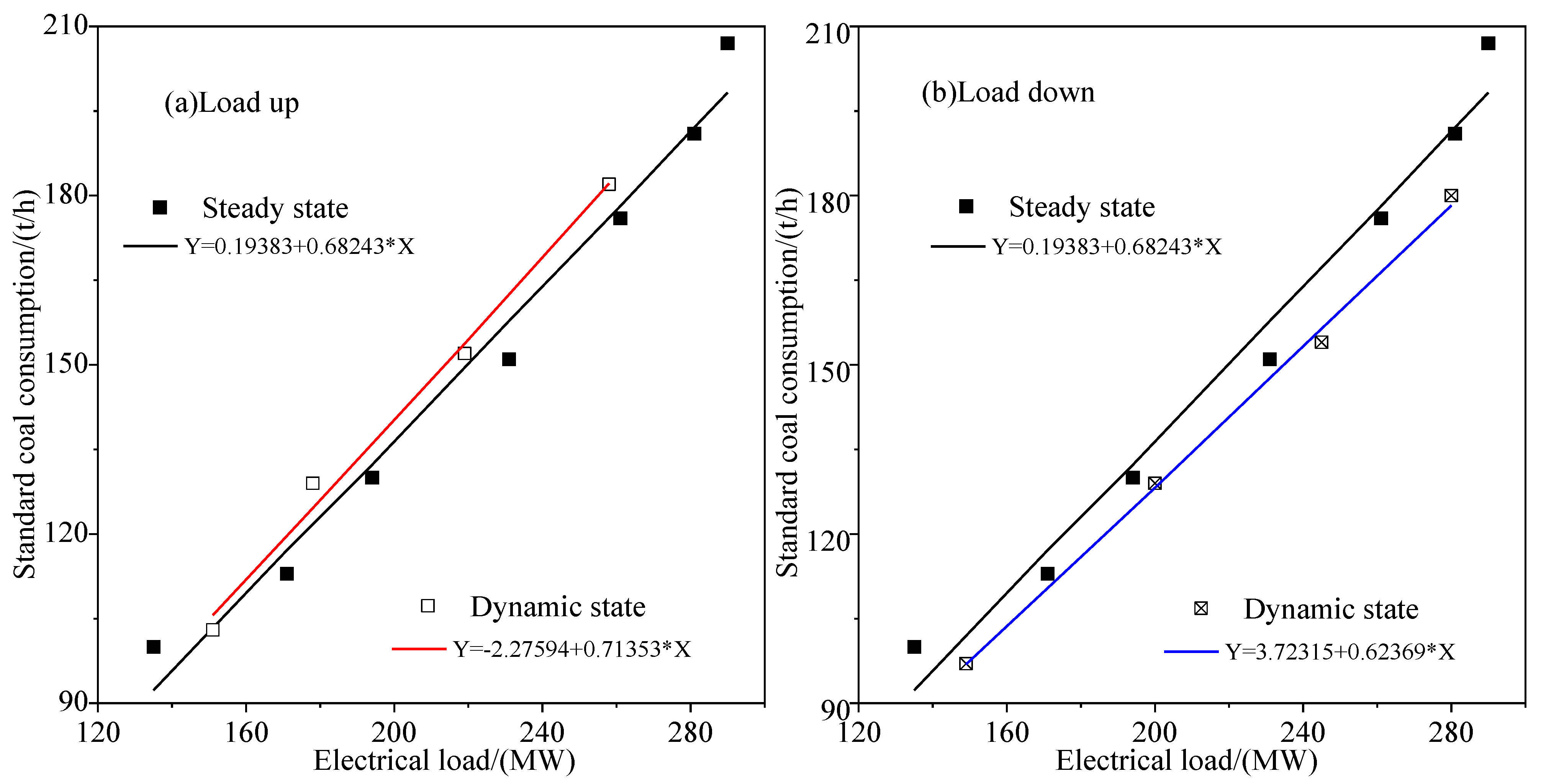

4.4. Dynamic Coal Consumption Analysis

5. Results and Discussion

5.1. Dynamic Coal Consumption

5.2. Accuracy Verification

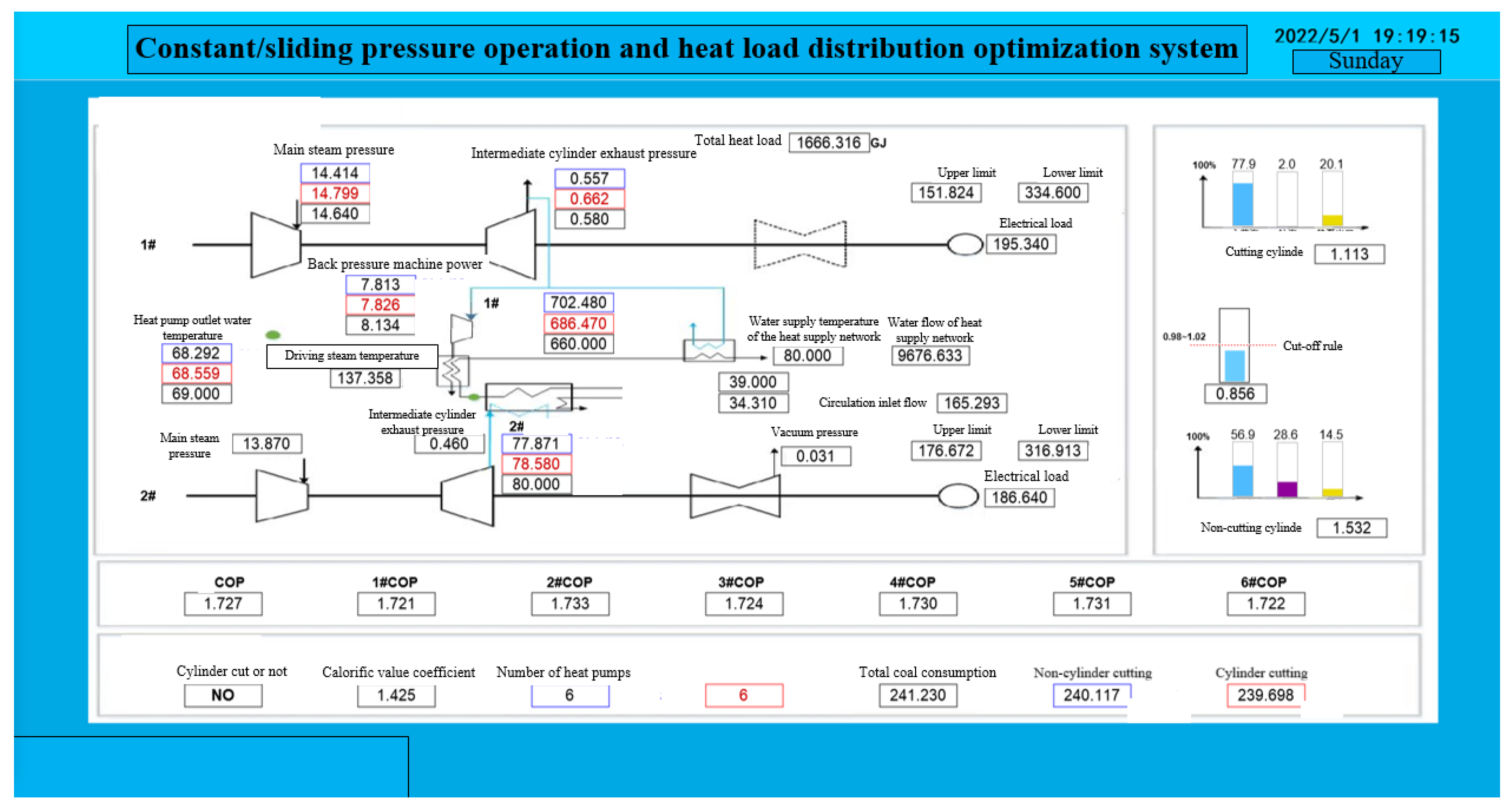

5.3. Online Software Development

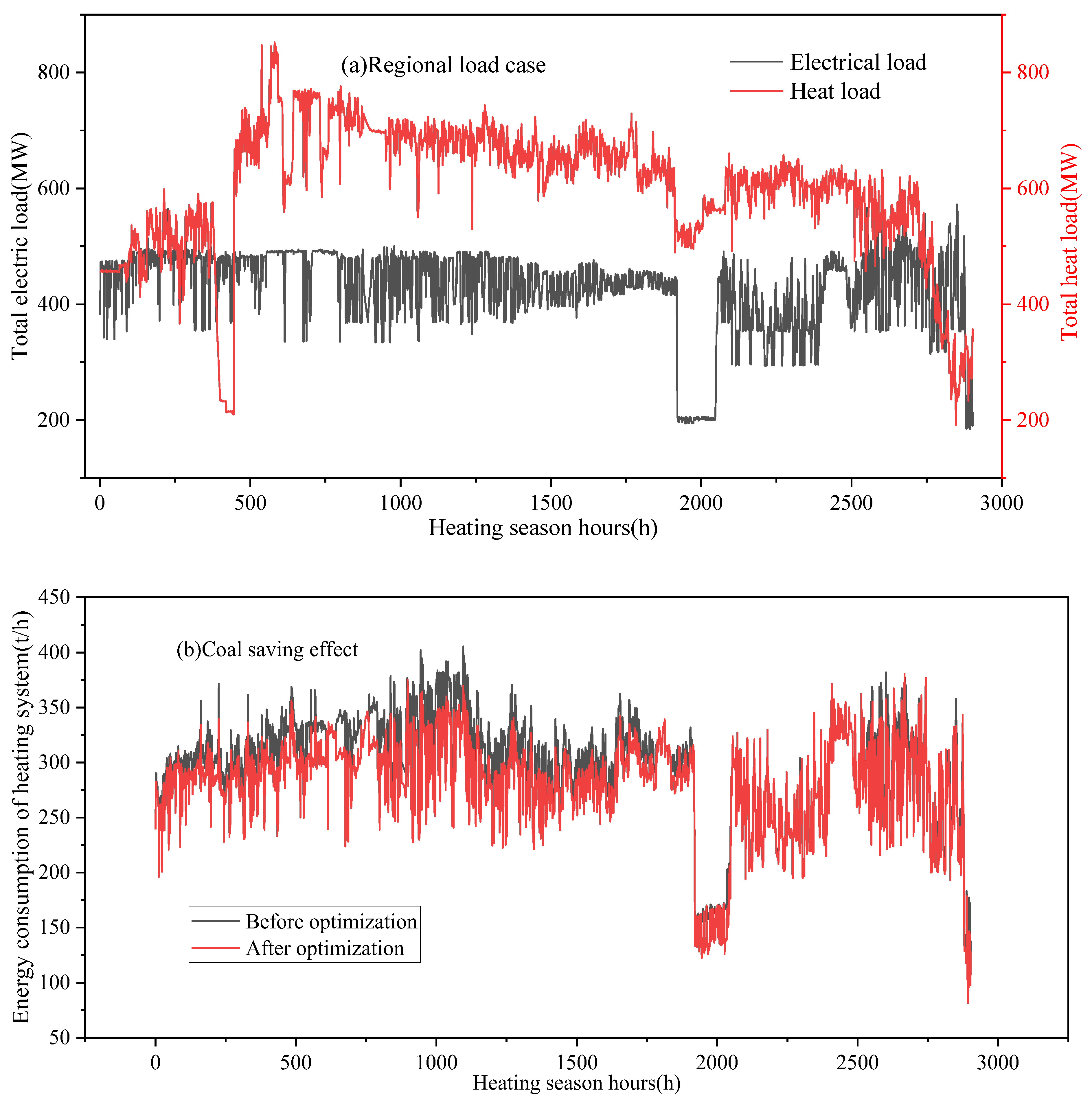

5.4. Total Coal-Saving Amount in Heating Season

6. Conclusions

- (1)

- Separate fittings were conducted to account for the impact of converted electric load during the load increase and decrease processes. Furthermore, area delineation and surface fitting techniques were applied to establish the relationship among load change rate, converted electric load, and dynamic coal consumption offset coefficient under the cutter head mode.

- (2)

- For the cylinder unloading mode, the coal consumption will increase compared with the steady operating condition. When the unit load change rate is greater than 1, the offset coefficient is also greater than 1; conversely, the offset coefficient is less than 1 when the load is reduced for the reason that the coal consumption is lower than under stable operating conditions; frequent changes in operating conditions will increase the unit’s coal consumption.

- (3)

- The relationship among the load change rate, converted electric load, and dynamic coal consumption offset coefficient for the two operating modes was ultimately obtained after the adjustment range was further defined based on the correlation diagrams of converted electric load versus load change rate for both the cylinder unloading mode and the non-cylinder unloading mode. The heating season case study verified that total coal savings reached 841.5 tons of standard coal.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | Abbreviations |

| Heat pump | HP |

| Coefficient of performance | COP |

| Back-pressure turbine | BT |

| Low-pressure | LP |

| Intermediate cylinder | MP |

References

- Shan, Z.; Tan, Q.; Dong, H.; Ding, Y. Optimization model of low-carbon technology adoption timing for coal power under decarbonization and flexibility demand: Empirical study in Beijing-Tianjin-Hebei region, China. Appl. Energy 2024, 358, 122647. [Google Scholar] [CrossRef]

- Verbruggen, A.; Klemes, J.; Rosen, M.A. Assessing Cogeneration Activity in Extraction-Condensing Steam Turbines: Dissolving the Issues by Applied Thermodynamics. J. Energy Resour. Technol. 2016, 138, 052005. [Google Scholar] [CrossRef]

- Xu, C.; Bai, P.; Xin, T.; Hu, Y.; Xu, G.; Yang, Y. A novel solar energy integrated low-rank coal fired power generation using coal pre-drying and an absorption heat pump. Appl. Energy 2017, 200, 170–179. [Google Scholar] [CrossRef]

- Ma, L.; Ge, Z.; Zhang, F.; Wei, H. A novel super high back pressure cascade heating scheme with multiple large-scale turbine units. Energy 2020, 201, 117469. [Google Scholar] [CrossRef]

- Wei, S.; Wang, J.; Song, H.; Zhou, X. Technical and economic evaluation on the integrated heating system with coupled heat pump and backpressure turbine. J. Energy Resour. Technol. 2022, 144, 035001. [Google Scholar] [CrossRef]

- Xu, X.; Hu, W.; Cao, D.; Huang, Q.; Chen, C.; Chen, Z. Optimized sizing of a standalone PV-wind-hydropower station with pumped-storage installation hybrid energy system. Renew. Energy 2020, 147, 1418–1431. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, Y.; Dong, H.; Tao, Y.; Xu, C. Proposal and comprehensive analysis of gas-wind-photovoltaic-hydrogen integrated energy system considering multi-participant interest preference. J. Clean. Prod. 2020, 265, 121679. [Google Scholar] [CrossRef]

- Shang, J.; Gao, J.; Jiang, X.; Liu, M.; Liu, D. Optimal configuration of hybrid energy systems considering power to hydrogen and electricity-price prediction: A two-stage multi-objective bi-level framework. Energy 2023, 263, 126023. [Google Scholar] [CrossRef]

- Jiang, K.; Zhang, G.; Liu, H.; Mu, Z.; Wang, Q.; Qin, T.; Niu, Y.; Wang, X.; Zhang, Q. Design and dynamic simulation of flue gas-molten salt heat exchanger in flexible operation coal-fired power plant. J. Energy Storage 2024, 93, 112227. [Google Scholar] [CrossRef]

- Yan, H.; Wang, Z.; Ding, Y.; Liu, M.; Otitoju, O.; Wang, M.; Chong, D. Efficiency enhancement of solar-aided coal-fired power plant integrated with thermal energy storage under varying power loads and solar irradiances. J. Energy Storage 2024, 94, 112372. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, Y.; Zhong, Z.; Xu, C.; Ke, Y.; Gao, J. Modeling and configuration optimization of the natural gas-wind-photovoltaic-hydrogen integrated energy system: A novel deviation satisfaction strategy. Energy Convers. Manag. 2021, 243, 114340. [Google Scholar] [CrossRef]

- Wang, Y.; Zou, Z.; Lu, K.; Li, Q.; Li, L. Probing of operation economy for coal-fired unit under low loads with two fixed boundary conditions. Energy 2024, 288, 129710. [Google Scholar] [CrossRef]

- Wang, H.; Ouyang, Z.; Ding, H.; Su, K.; Zhang, J.; Hu, Y. Experimental study on the flexible peak shaving with pulverized coal self-preheating technology under load variability. Energy 2024, 289, 129830. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, L.; Zhang, X.; Wei, H.; Du, X. Energy consumption during transient operation of coal-fired generating units with cold end system back pressure regulation. Appl. Therm. Eng. 2024, 248, 123188. [Google Scholar] [CrossRef]

- Li, J.; Cheng, K. Research on Energy Comprehensive Utilization of Coupled Heating System Based on Heat Pump. Turbine Technol. 2023, 65, 214–218. [Google Scholar]

- Li, Y.; Chen, X.; Jiang, S.; Lu, G. Thermodynamics of Cascaded Waste Heat Utilization from Flue Gas and Circulating Cooling Water. J. Therm. Sci. 2023, 32, 2166–2178. [Google Scholar] [CrossRef]

- Antar, E.; Robert, E. Thermodynamic analysis of small-scale polygeneration systems producing natural gas, electricity, heat, and carbon dioxide from biomass. Energy 2024, 290, 130278. [Google Scholar] [CrossRef]

- Fu, Y.; Huang, Y.; Xin, H.; Liu, M.; Wang, L.; Yan, J. The pressure sliding operation strategy of the carbon capture system integrated within a coal-fired power plant: Influence factors and energy saving potentials. Energy 2024, 307, 132737. [Google Scholar] [CrossRef]

| Parameter | Unit | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 |

|---|---|---|---|---|---|---|

| Load | % | 100 | 90 | 80 | 70 | 60 |

| Steam outlet flow | t/h | 194 | 177 | 163 | 139 | 116 |

| Steam inlet temperature | °C | 170 | 154 | 149 | 142 | 131 |

| Hydrophobic temperature | °C | 60.8 | 58.7 | 56.7 | 53.3 | 47.2 |

| Driving steam pressure | Mpa | 0.32 | 0.30 | 0.26 | 0.17 | 0.06 |

| Inlet water temperature of heating network | °C | 39.2 | 41.8 | 41.9 | 42.1 | 37.6 |

| Outlet water temperature of heating network | °C | 76.4 | 70.6 | 67.9 | 65.3 | 62.3 |

| Inlet water temperature of waste heat water | °C | 31.4 | 35.4 | 32.2 | 32.0 | 31.7 |

| Outlet water temperature of waste heat water | °C | 22.8 | 18.4 | 17.1 | 18.5 | 25.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, G.; Xu, X.; Wang, D.; Li, X.; Liu, T.; Wang, J. A New Method for Predicting the Dynamic Coal Consumption of Coal-Fired Dual Heating Systems. Processes 2025, 13, 3492. https://doi.org/10.3390/pr13113492

Xing G, Xu X, Wang D, Li X, Liu T, Wang J. A New Method for Predicting the Dynamic Coal Consumption of Coal-Fired Dual Heating Systems. Processes. 2025; 13(11):3492. https://doi.org/10.3390/pr13113492

Chicago/Turabian StyleXing, Gang, Xianlong Xu, Dongxu Wang, Xiaolong Li, Tianhao Liu, and Jinxing Wang. 2025. "A New Method for Predicting the Dynamic Coal Consumption of Coal-Fired Dual Heating Systems" Processes 13, no. 11: 3492. https://doi.org/10.3390/pr13113492

APA StyleXing, G., Xu, X., Wang, D., Li, X., Liu, T., & Wang, J. (2025). A New Method for Predicting the Dynamic Coal Consumption of Coal-Fired Dual Heating Systems. Processes, 13(11), 3492. https://doi.org/10.3390/pr13113492