Analysis of Influencing Factors on Water Use of Mechanical Draft Cooling Towers in China

Abstract

1. Introduction

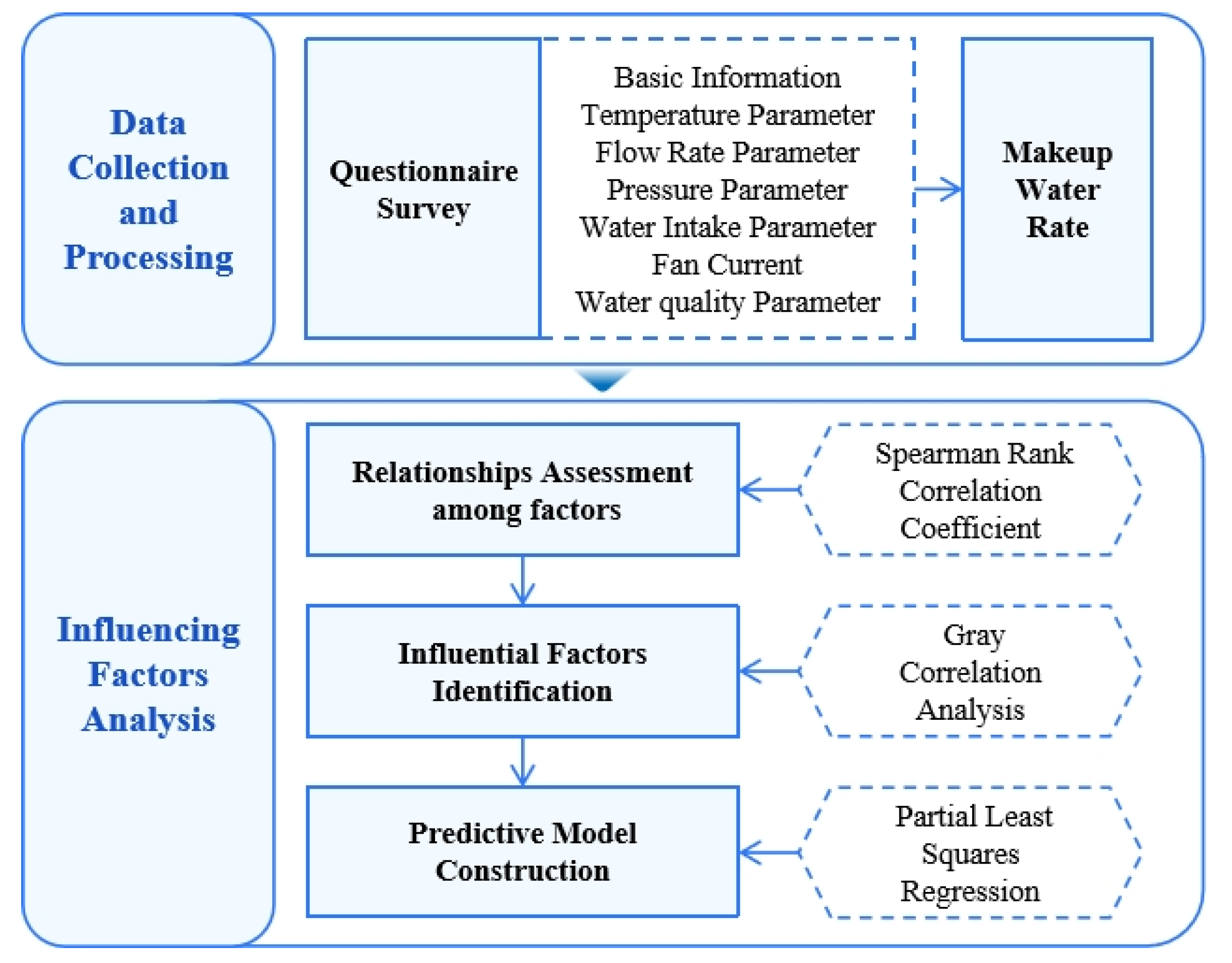

2. Materials and Methods

2.1. Data Collection and Processing

2.2. Calculation Method for the Indicator Characterizing Cooling Towers Water Use

2.3. Methods for Influencing Factors Analysis

2.3.1. Spearman’s Rank Correlation Coefficient

2.3.2. Gray Correlation Analysis

2.3.3. Partial Least Squares Regression (PLSR)

3. Results and Discussion

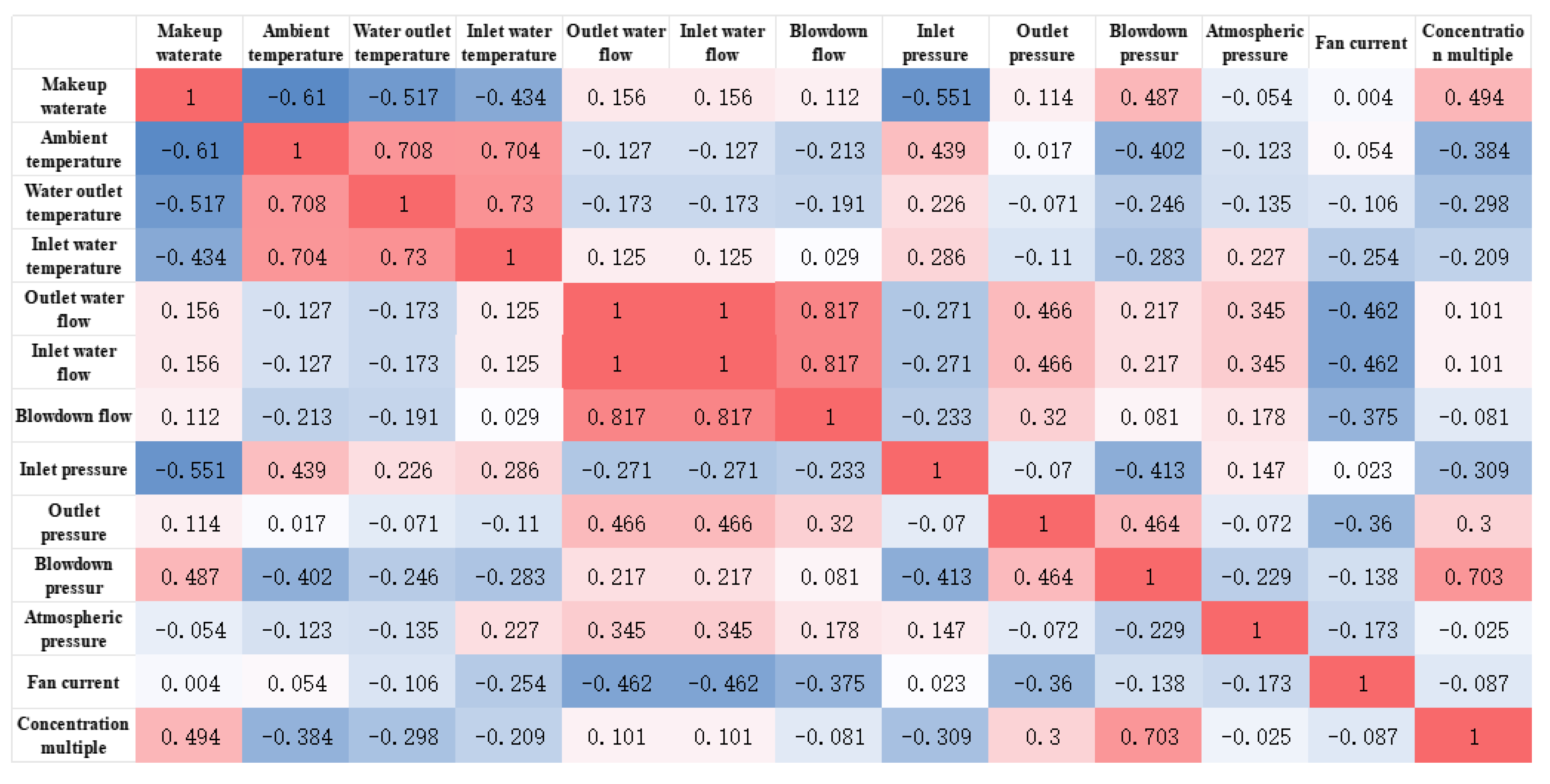

3.1. The Quantitative Correlations Among Influencing Factors

3.2. The Importance of Various Influencing Factors on Water Use of Cooling Towers

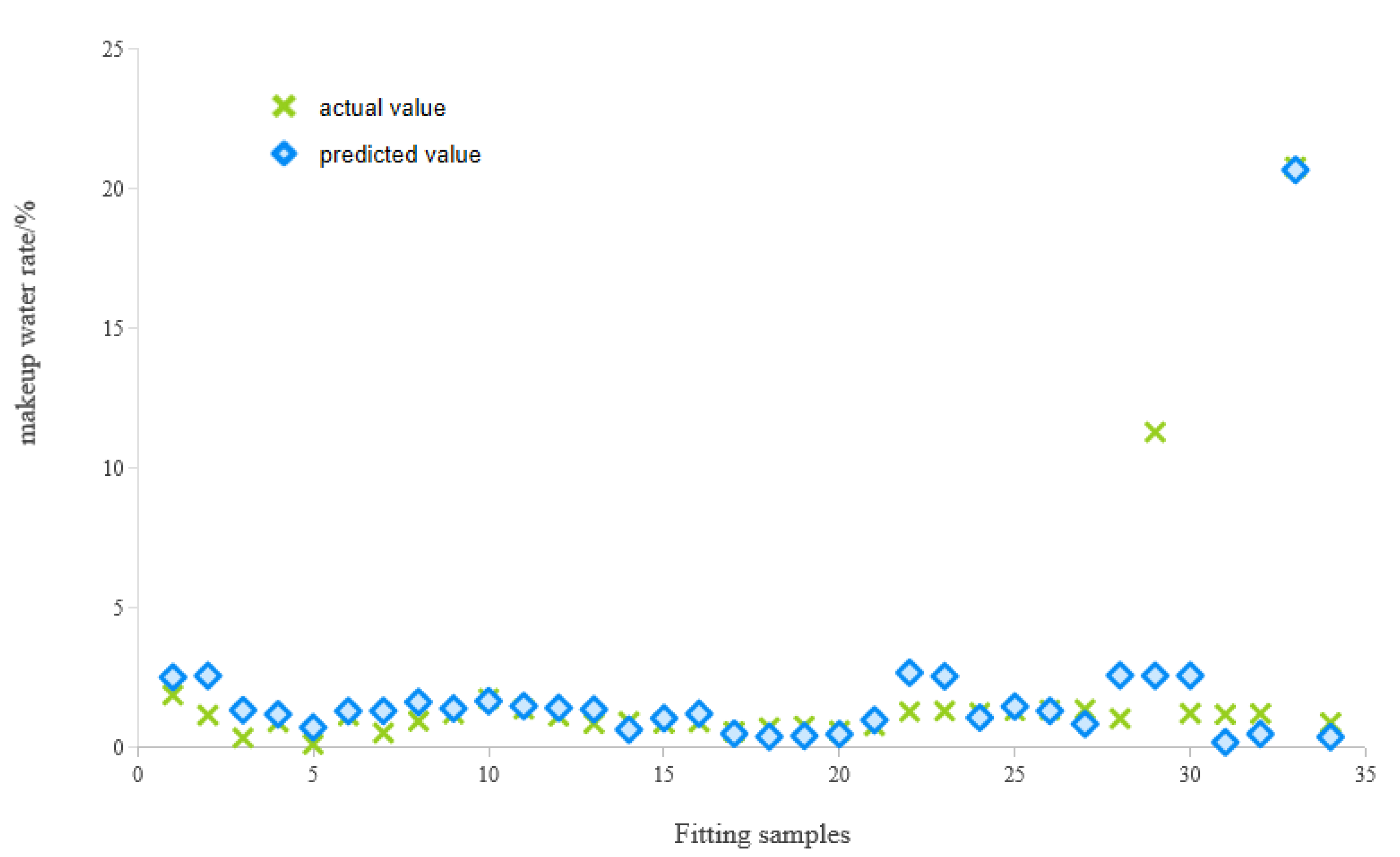

3.3. The Validation of the Prediction Model

4. Conclusions

- Key influencing factors were identified through Spearman’s correlation analysis, confirming that ambient temperature, outlet water temperature, and inlet pressure were significantly negatively correlated with the makeup water rate, whereas blowdown pressure and concentration multiples were significantly positively correlated. Variables such as the inlet water flow showed no significant correlation with the makeup water rate;

- Gray correlation analysis was used to quantify the importance of the influencing factors, revealing that blowdown pressure, concentration multiple, and inlet water temperature are the core drivers of the makeup water rate, with correlation degrees of 0.923, 0.897, and 0.897, respectively, which were significantly higher than those of external parameters, such as ambient temperature. Therefore, by directly regulating blowdown volume, the blowdown pressure is the primary target for water-saving optimization;

- The PLSR-based prediction model for the makeup water rate of mechanical draft cooling towers had a cumulative explanatory power of 80.6%, verifying the effectiveness of the multifactor synergistic effects. The consistent trend between the predicted and observed values validates the reliability of the model. Notably, the positive coefficient of blowdown pressure was significantly higher than those of the other variables, further highlighting its critical role.

- Reducing the blowdown pressure and reasonably controlling the concentration multiple are the key strategies for lowering the makeup water rate, which can be synergistically managed using water temperature parameters.

5. Limitation

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Structure and Core Content of the Questionnaire

- (1)

- Basic information

- -

- Enterprise details: Name, unified social credit code, address, contact person, and telephone number.

- -

- Cooling tower specifications: Number of installed towers, number of daily operating towers, brand/model, processing capacity, and filler type.

- -

- Metering configuration: Whether separate water and energy metering instruments are equipped.

- -

- Operational parameters: Daily operation duration (hours/day) and annual operation days (days/year).

- (2)

- Water use information

- -

- Statistical period: Start and end dates for water use data recording.

- -

- Makeup water volume: Broken down by water source (conventional water, reclaimed water, rainwater, purchased water, and others), with units in m3.

- -

- Circulating water volume (m3), leakage volume (m3), reuse volume (m3), and blowdown volume (m3).

- -

- Other water losses: Evaporation volume and drift loss volume (to be filled based on on-site records or calculations).

- (3)

- Remarks

Appendix A.2. Survey Implementation Notes

| No. | Geographic Regions | Circulating Water Volume (m3) | Makeup Water Volume (m3) |

|---|---|---|---|

| 1 | Central South China | 4,079,232 | 47,232 |

| 2 | East China | 17,280,000 | 332,400 |

| 3 | East China | 82,080,000 | 970,040 |

| 4 | North China | 30,908,304 | 318,888 |

| 5 | East China | 190,080,000 | 674,125 |

| 6 | East China | 176,462,873 | 1,536,882 |

| 7 | East China | 166,449,254 | 1,341,594 |

| 8 | East China | 119,935,862 | 889,375 |

| 9 | Central South China | 8000 | 1020 |

| 10 | East China | 9,760,000 | 91,000 |

| 11 | Southwestern China | 21,084,307 | 90,390 |

| 12 | Southwestern China | 126,853,760 | 1,102,536 |

| 13 | Central South China | 3,183,665 | 284,395 |

| 14 | Northwestern China | 251,813,539 | 2,539,461 |

| 15 | Central South China | 88,704,000 | 674,866 |

| 16 | East China | 7,118,496 | 58,599 |

| 17 | East China | 5,581,224 | 48,083 |

| 18 | East China | 25,200,000 | 298,735 |

| 19 | East China | 7,200,000 | 21,440 |

| 20 | East China | 13,180,240 | 107,701.2 |

| 21 | East China | 108,000,000 | 1,294,230 |

| 22 | East China | 60,480,000 | 707,200 |

| 23 | East China | 125,280,000 | 674,125 |

| 24 | East China | 82,080,000 | 674,125 |

| 25 | East China | 59,616,000 | 814,120 |

| 26 | East China | 38,880,000 | 489,650 |

| 27 | East China | 73,440,000 | 879,000 |

| 28 | East China | 34,560,000 | 437,200 |

| 29 | East China | 60,480,000 | 584,125 |

| 30 | East China | 54,780,000 | 674,125 |

| 31 | East China | 38,880,000 | 695,346 |

| 32 | East China | 34,560,000 | 484,841 |

| 33 | East China | 26,352,000 | 386,640 |

| 34 | East China | 64,080,000 | 734,984 |

| 35 | East China | 82,080,000 | 721,033 |

| 36 | East China | 111,600,000 | 1,048,000 |

| 37 | East China | 33,984,000 | 303,000 |

| 38 | East China | 98,496,000 | 920,160 |

| 39 | East China | 3,860,000 | 22,600 |

| 40 | East China | 1,560,000 | 11,300 |

| 41 | East China | 420,000 | 3295 |

| 42 | East China | 640,000 | 3900 |

| 43 | East China | 350,000 | 2800 |

| 44 | East China | 20,427,747 | 267,747 |

| 45 | East China | 20,442,847 | 272,847 |

| 46 | East China | 53,964,785 | 684,785.8 |

| 47 | East China | 34,664,473 | 464,473 |

| 48 | East China | 35,042,304 | 482,304 |

| 49 | East China | 37,238,479 | 518,479.2 |

| 50 | East China | 34,201,695 | 361,695 |

| 51 | North China | 7,300,373 | 100,373 |

| 52 | North China | 11,362,211 | 142,211 |

| 53 | North China | 946,524 | 10,524 |

| 54 | East China | 8,208,000 | 137,930 |

| 55 | North China | 5,616,567 | 72,567 |

| 56 | North China | 947,880 | 120,650 |

| 57 | North China | 15,310,838 | 190,838 |

| 58 | North China | 5,834,302 | 74,302 |

| 59 | North China | 14,589,276 | 189,726 |

| 60 | North China | 16,092,000 | 149,760 |

| 61 | East China | 34,482,643 | 284,395 |

| 62 | Central South China | 141,000,612 | 1,463,845 |

| 63 | East China | 203,040,000 | 3,014,425 |

| 64 | East China | 97,200,000 | 1,037,940 |

| 65 | East China | 99,360,000 | 1,154,125 |

| 66 | Northeastern China | 45,360,000 | 547,842 |

| 67 | East China | 60,480,000 | 750,000 |

| 68 | North China | 15,312,780 | 193,887 |

| 69 | Southwestern China | 54,927,835 | 526,883 |

| 70 | East China | 70,000 | 815 |

| 71 | East China | 34,560,000 | 220,000 |

| 72 | East China | 44,640,000 | 405,000 |

| 73 | East China | 316,000,000 | 3,190,000 |

References

- Jiang, F.; Chen, B.; Wang, H.; Duan, C. Mitigating China’s prefecture-level economic risk of water scarcity: The role of water conservation and carbon neutrality policies. Resour. Conserv. Recycl. 2025, 215, 108140. [Google Scholar] [CrossRef]

- Li, G. Establish and Improve the Water-Saving Institutional and Policy System. Guangming Daily, 18 December 2024. Available online: https://news.gmw.cn/2024-12/18/content_37743527.htm (accessed on 8 July 2025). (In Chinese).

- Guerras, L.S.; Martín, M. On the water footprint in power production: Sustainable design of wet cooling towers. Appl. Energy 2020, 263, 114620. [Google Scholar] [CrossRef]

- Ministry of Water Resources of the People’s Republic of China. Water Resources Bulletin; China Water Resources and Hydropower Press: Beijing, China, 2023. [Google Scholar]

- Yu, Z.; Wu, W.; Huang, S.; Zhang, X. Review on Application and Optimization of Cooling Technology for Cooling Tower. J. Refrig. 2024, 45, 50–62. [Google Scholar]

- Cortinovis, G.F.; Ribeiro, M.T.; Paiva, J.L.; Song, T.W.; Pinto, J.M. Integrated analysis of cooling water systems: Modeling and experimental validation. Appl. Therm. Eng. 2009, 29, 3124–3131. [Google Scholar] [CrossRef]

- Serna-González, M.; Ponce-Ortega, J.M.; Jiménez-Gutiérrez, A. MINLP optimization of mechanical draft counter flow wet-cooling towers. Chem. Eng. Res. Des. 2010, 88, 614–625. [Google Scholar] [CrossRef]

- Singh, K.; Das, R. Simultaneous optimization of performance parameters and energy consumption in induced draft cooling towers. Chem. Eng. Res. Des. 2017, 123, 1–13. [Google Scholar] [CrossRef]

- Yu, J.; Qu, Z.; Zhang, J.; Hu, S.; Song, J.; Chen, Y. A comprehensive energy efficiency assessment indicator and grading criteria for natural draft wet cooling towers. Energy 2022, 254, 124375. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Q.; Wang, Z.; Li, S.; Wei, F.; Liu, J.; Yu, D. Thermal performance model of cooling towers for operational optimization: An equivalent temperature difference coefficient-based approach. Appl. Therm. Eng. 2024, 252, 123595. [Google Scholar] [CrossRef]

- Ma, K.; Liu, M.; Zhang, J. A method for determining the optimum state of recirculating cooling water system and experimental investigation based on heat dissipation efficiency. Appl. Therm. Eng. 2020, 176, 115398. [Google Scholar] [CrossRef]

- Jin, G.-Y.; Cai, W.-J.; Lu, L.; Lee, E.L.; Chiang, A. A simplified modeling of mechanical cooling tower for control and optimization of HVAC systems. Energy Convers. Manag. 2007, 48, 355–365. [Google Scholar] [CrossRef]

- Ma, K.; Liu, M.; Zhang, J. Online optimization method of cooling water system based on the heat transfer model for cooling tower. Energy 2021, 231, 120896. [Google Scholar] [CrossRef]

- Hosoz, M.; Ertunc, H.; Bulgurcu, H. Performance prediction of a cooling tower using artificial neural network. Energy Convers. Manag. 2007, 48, 1349–1359. [Google Scholar] [CrossRef]

- Bueso, M.C.; de Nicolás, A.P.; Vera-García, F.; Molina-García, Á. Cooling tower modeling based on machine learning approaches: Application to Zero Liquid Discharge in desalination processes. Appl. Therm. Eng. 2024, 242, 122522. [Google Scholar] [CrossRef]

- Henry, C.L.; Pratson, L.F. Differentiating the Effects of Climate Change-Induced Temperature and Streamflow Changes on the Vulnerability of Once-Through Thermoelectric Power Plants. Environ. Sci. Technol. 2019, 53, 3969–3976. [Google Scholar] [CrossRef] [PubMed]

- Coffel, E.D.; Mankin, J.S. Thermal power generation is disadvantaged in a warming world. Environ. Res. Lett. 2021, 16, 024043. [Google Scholar] [CrossRef]

- Ayoub, A.; Gjorgiev, B.; Sansavini, G. Cooling towers performance in a changing climate: Techno-economic modeling and design optimization. Energy 2018, 160, 1133–1143. [Google Scholar] [CrossRef]

- Lavasani, A.M.; Baboli, Z.N.; Zamanizadeh, M.; Zareh, M. Experimental study on the thermal performance of mechanical cooling tower with rotational splash type packing. Energy Convers. Manag. 2014, 87, 530–538. [Google Scholar] [CrossRef]

- Singla, R.K.; Singh, K.; Das, R. Tower characteristics correlation and parameter retrieval in wet-cooling tower with expanded wire mesh packing. Appl. Therm. Eng. 2016, 96, 240–249. [Google Scholar] [CrossRef]

- Handayani, K.; Filatova, T.; Krozer, Y.; Anugrah, P. Seeking for a climate change mitigation and adaptation nexus: Analysis of a long-term power system expansion. Appl. Energy 2020, 262, 114485. [Google Scholar] [CrossRef]

- Trautman, N.; Razban, A.; Chen, J. Overall chilled water system energy consumption modeling and optimization. Appl. Energy 2021, 299, 117166. [Google Scholar] [CrossRef]

- Pontes, R.F.; Yamauchi, W.M.; Silva, E.K. Analysis of the effect of seasonal climate changes on cooling tower efficiency, and strategies for reducing cooling tower power consumption. Appl. Therm. Eng. 2019, 161, 114148. [Google Scholar] [CrossRef]

- Shiqi, L.; Xiaobo, L.; Guoyu, Z.; Like, T.; Qing, Y. A novel flexible analysis approach of recirculating cooling water system integrated cooling tower and cooling water network. Appl. Therm. Eng. 2025, 265, 125628. [Google Scholar] [CrossRef]

- Agarwal, N.K.; Biswas, P.; Shirke, A. Novel model predictive control by hypothetical stages to improve energy efficiency of industrial cooling tower. Appl. Therm. Eng. 2022, 215, 118899. [Google Scholar] [CrossRef]

- Nedjah, N.; Mourelle, L.d.M.; Lizarazu, M.S.D. Swarm Intelligence-Based Multi-Objective Optimization Applied to Industrial Cooling Towers for Energy Efficiency. Sustainability 2022, 14, 11881. [Google Scholar] [CrossRef]

- Wenzel, P.M.; Fensterle, E.; Radgen, P. Catalyzing Cooling Tower Efficiency: A Novel Energy Performance Indicator and Functional Unit including Climate and Cooling Demand Normalization. Sustainability 2023, 15, 15454. [Google Scholar] [CrossRef]

- Yuan, W.; Sun, F.; Liu, R.; Chen, X.; Li, Y. Effect of chance factors on evaporation loss based on cold end system in natural draft counter-flow wet fooling towers. J. Therm. Sci. Technol. 2021, 16, JTST0015. [Google Scholar] [CrossRef]

- Soliman, M.; Eljack, F.; Kazi, M.-K.; Almomani, F.; Ahmed, E.; El Jack, Z. Treatment Technologies for Cooling Water Blowdown: A Critical Review. Sustainability 2022, 14, 376. [Google Scholar] [CrossRef]

- Long, G.; Zhang, G.; Zhang, Q.; Zhao, C.; He, S.; Sun, F. Experimental Study on the Resistance and Splash Performances of Water Collecting Devices for Mechanical Draft Cooling Towers. Fluid Dyn. Mater. Process. 2023, 19, 1789–1801. [Google Scholar] [CrossRef]

- Jiang, Y. Study on Influencing Factors and Prediction Models of Water Consumption in Typical Public Buildings. Master’s Thesis, Chongqing University, Chongqing, China, 2021. [Google Scholar] [CrossRef]

- Deng, J. Grey Theory; Huazhong University of Science and Technology Publishing Agency: Wuhan, China, 2002. [Google Scholar]

- Song, X.; Zhang, W.; Ge, Z.; Huang, S.; Huang, Y.; Xiong, S. A Study of the Influencing Factors on the Carbon Emission Trading Price in China Based on the Improved Gray Relational Analysis Model. Sustainability 2022, 14, 8002. [Google Scholar] [CrossRef]

- Wang, F.; Wang, T.; Zhang, W.; Liu, J.; Zhang, Q. Gray Relational Analysis of Influencing Factors on Safety Performance of HTPB Propellant Slurry and Finished Products. Chin. J. Energetic Mater. 2025, 33, 367–373. [Google Scholar] [CrossRef]

- Peng, S.; Li, C.; Huang, J.; Wang, F. Study on Soil Moisture Content Prediction Model Based on Partial Least Squares Regression. J. Agric. Mech. Res. 2010, 32, 45–49. (In Chinese) [Google Scholar] [CrossRef]

- Deng, W.; Sun, F.; Wang, R.; He, K. Influence mechanism of the louver on the thermal performance of the mechanical draft wet cooling tower. Appl. Therm. Eng. 2023, 230, 120640. [Google Scholar] [CrossRef]

- Wang, W.; Li, L.; Gao, M.; Zhang, M.; Xu, Q.; Wang, J. Water-saving performance study of water conservation and plume abatement device in wet mechanical draft cooling towers. Case Stud. Therm. Eng. 2024, 56, 104188. [Google Scholar] [CrossRef]

| Indicator | Range | Mean Values | Standard Deviations |

|---|---|---|---|

| Makeup water rate | 0.3–12.75 | 0.15 | 0.021 |

| Ambient temperature | −24–38 | 20.32 | 13.99 |

| Outlet water temperature | 10–39 | 27.62 | 5.25 |

| Inlet water temperature | 18–43.8 | 34.15 | 5.12 |

| Outlet water flow | 406–94,000 | 21,064.55 | 19,377 |

| Inlet water flow | 406–94,000 | 21,926.11 | 19,112 |

| Blowdown flow | 40–6780 | 217 | 760 |

| Inlet pressure | 0.1–0.57 | 0.27 | 0.086 |

| Outlet pressure | 0.1–0.67 | 0.47 | 0.121 |

| Blowdown pressure | 0.1–0.36 | 0.28 | 0.043 |

| Atmospheric pressure | 85.4–102.5 | 99.11 | 3.94 |

| Fan current | 12–390 | 77.63 | 97 |

| Concentration multiple | 1.3–7.6 | 4.39 | 1.24 |

| Indicator | Makeup Water Rate | Ambient Temperature | Outlet Water Temperature | Inlet Water Temperature | Outlet Water Flow | Inlet Water Flow | Blowdown Flow | Inlet Pressure | Outlet Pressure | Blowdown Pressure | Atmospheric Pressure | Fan Current | Concentration Multiple |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Makeup water rate | 1 *** (0.000) | −0.61 *** (0.000) | −0.517 *** (0.002) | −0.434 ** (0.010) | 0.156 (0.378) | 0.156 (0.378) | 0.112 (0.528) | −0.551 (0.001 ***) | 0.114 (0.520) | 0.487 *** (0.003) | −0.054 (0.762) | 0.004 (0.981) | 0.494 *** (0.003) |

| Ambient temperature | −0.61 *** (0.000) | 1 *** (0.000) | 0.708 *** (0.000) | 0.704 *** (0.000) | −0.127 (0.475) | −0.127 (0.475) | −0.213 (0.226) | 0.439 *** (0.009) | 0.017 (0.925) | −0.402 ** (0.018) | −0.123 (0.489) | 0.054 (0.763) | −0.384 ** (0.025) |

| Water outlet temperature | −0.517 *** (0.002) | 0.708 *** (0.000) | 1 *** (0.000) | 0.73 *** (0.000) | −0.173 (0.327) | −0.173 (0.327) | −0.191 (0.280) | 0.226 (0.200) | −0.071 (0.689) | −0.246 (0.162) | −0.135 (0.447) | −0.106 (0.552) | −0.298 (0.087 *) |

| Inlet water temperature | −0.434 ** (0.010) | 0.704 *** (0.000) | 0.73 *** (0.000) | 1 *** (0.000) | 0.125 (0.482) | 0.125 (0.482) | 0.029 (0.872) | 0.286 (0.102) | −0.11 (0.534) | −0.283 (0.105) | 0.227 (0.196) | −0.254 (0.147) | −0.209 (0.235) |

| Outlet water flow | 0.156 (0.378) | −0.127 (0.475) | −0.173 (0.327) | 0.125 (0.482) | 1 *** (0.000) | 1 *** (0.000) | 0.817 *** (0.000) | −0.271 (0.121) | 0.466 *** (0.005) | 0.217 (0.218) | 0.345 ** (0.046) | −0.462 *** (0.006) | 0.101 (0.570) |

| Inlet water flow | 0.156 (0.378) | −0.127 (0.475) | −0.173 (0.327) | 0.125 (0.482) | 1 *** (0.000) | 1 *** (0.000) | 0.817 *** (0.000) | −0.271 (0.121) | 0.466 *** (0.005) | 0.217 (0.218) | 0.345 ** (0.046) | −0.462 *** (0.006) | 0.101 (0.570) |

| Blowdown flow | 0.112 (0.528) | −0.213 (0.226) | −0.191 (0.280) | 0.029 (0.872) | 0.817 *** (0.000) | 0.817 *** (0.000) | 1 *** (0.000) | −0.233 (0.185) | 0.32 (0.065 *) | 0.081 (0.649) | 0.178 (0.314) | −0.375 ** (0.029) | −0.081 (0.647) |

| Inlet pressure | −0.551 *** (0.001) | 0.439 *** (0.009) | 0.226 (0.200) | 0.286 (0.102) | −0.271 (0.121) | −0.271 (0.121) | −0.233 (0.185) | 1 *** (0.000) | −0.07 (0.695) | −0.413 ** (0.015) | 0.147 (0.405) | 0.023 (0.897) | −0.309 (0.076 *) |

| Outlet pressure | 0.114 (0.520) | 0.017 (0.925) | −0.071 (0.689) | −0.11 (0.534) | 0.466 *** (0.005) | 0.466 *** (0.005) | 0.32 * (0.065) | −0.07 (0.695) | 1 *** (0.000) | 0.464 *** (0.006) | −0.072 (0.684) | −0.36 ** (0.037) | 0.3 * (0.085) |

| Blowdown pressure | 0.487 *** (0.003) | −0.402 ** (0.018) | −0.246 (0.162) | −0.283 (0.105) | 0.217 (0.218) | 0.217 (0.218) | 0.081 (0.649) | −0.413 ** (0.015) | 0.464 *** (0.006) | 1 *** (0.000) | −0.229 (0.193) | −0.138 (0.436) | 0.703 *** (0.000) |

| Atmospheric pressure | −0.054 (0.762) | −0.123 (0.489) | −0.135 (0.447) | 0.227 (0.196) | 0.345 ** (0.046) | 0.345 ** (0.046) | 0.178 (0.314) | 0.147 (0.405) | −0.072 (0.684) | −0.229 (0.193) | 1 *** (0.000) | −0.173 (0.328) | −0.025 (0.890) |

| Fan current | 0.004 (0.981) | 0.054 (0.763) | −0.106 (0.552) | −0.254 (0.147) | −0.462 *** (0.006) | −0.462 *** (0.006) | −0.375 ** (0.029) | 0.023 (0.897) | −0.36 ** (0.037) | −0.138 (0.436) | −0.173 (0.328) | 1 *** (0.000) | −0.087 (0.627) |

| Concentration multiple | 0.494 *** (0.003) | −0.384 ** (0.025) | −0.298 * (0.087) | −0.209 (0.235) | 0.101 (0.570) | 0.101 (0.570) | −0.081 (0.647) | −0.309 * (0.076) | 0.3 * (0.085) | 0.703 *** (0.000) | −0.025 (0.890) | −0.087 (0.627) | 1 *** (0.000) |

| Evaluation Item | Correlation Degree | Rank |

|---|---|---|

| Blowdown Pressure | 0.923 | 1 |

| Concentration Multiple | 0.897 | 2 |

| Inlet Water Temperature | 0.897 | 3 |

| Outlet Water Temperature | 0.896 | 4 |

| Inlet Pressure | 0.895 | 5 |

| Ambient Temperature | 0.860 | 6 |

| Indicator | Makeup Water Rate |

|---|---|

| Constant term | 1.919 |

| Blowdown Pressure | 3.056 |

| Concentration Multiple | −0.026 |

| Outlet Water Temperature | 0.163 |

| Inlet Water Temperature | −0.089 |

| Inlet Pressure | −0.251 |

| Ambient Temperature | −0.529 |

| R2 | 0.806 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, R.; Kong, L.; Hu, M.; Bai, X. Analysis of Influencing Factors on Water Use of Mechanical Draft Cooling Towers in China. Processes 2025, 13, 3465. https://doi.org/10.3390/pr13113465

Cai R, Kong L, Hu M, Bai X. Analysis of Influencing Factors on Water Use of Mechanical Draft Cooling Towers in China. Processes. 2025; 13(11):3465. https://doi.org/10.3390/pr13113465

Chicago/Turabian StyleCai, Rong, Lingsi Kong, Mengting Hu, and Xue Bai. 2025. "Analysis of Influencing Factors on Water Use of Mechanical Draft Cooling Towers in China" Processes 13, no. 11: 3465. https://doi.org/10.3390/pr13113465

APA StyleCai, R., Kong, L., Hu, M., & Bai, X. (2025). Analysis of Influencing Factors on Water Use of Mechanical Draft Cooling Towers in China. Processes, 13(11), 3465. https://doi.org/10.3390/pr13113465