1. Introduction

With the advancement of the global economy, the demand for oil and gas continues to rise, accompanied by a rapidly escalating energy demand. As a key material for pipeline networks, pipeline steel has garnered increasing research attention [

1]. Nevertheless, non-renewable energy sources such as coal, oil, and natural gas still account for 85% of the world’s total energy consumption [

2]. The “Opinions of the Central Committee of the Communist Party of China and the State Council on Fully and Accurately Implementing the New Development Concept and Promoting Carbon Peak and Carbon Neutrality” (2021) emphasize the need to advance the comprehensive green transformation of economic and social development and accelerate the construction of a clean, low-carbon, safe, and efficient energy system [

3]. Natural gas, as a critical energy source for societal development, maintains substantial demand [

4,

5]. However, due to China’s relatively limited and unevenly distributed oil and gas resources, coupled with asymmetric resource-market distributions and increasing annual dependence on foreign natural gas, long-distance oil and gas transportation has become essential [

6]. Most natural gas pipelines are constructed using welded steel, with their base materials commonly referred to as pipeline steel [

7]. Among these, X70 pipeline steel remains the most widely applied material in oil and gas pipeline infrastructure [

8].

With the advancement of the “double carbon” strategy, China’s demand for natural gas is increasing daily, accompanied by a gradual rise in foreign natural gas dependence. To ensure stable imports of natural gas, an analysis of vulnerabilities in its transportation system is imperative [

9]. As a green, clean, and efficient energy source, natural gas represents a strategic choice for global energy structure optimization [

10]. China’s external dependence on natural gas stands at approximately 40.9%, with domestic production reaching 248.3 billion cubic meters, imported pipeline gas 76.6 billion cubic meters, and total imported LNG 105.6 billion cubic meters [

11]. China’s natural gas market is concentrated in the east, while resources are primarily located in the west; imported natural gas resources originate mainly from Russia and Central Asia [

12]. The extensive utilization of natural gas across production, daily life, industry, and manufacturing necessitates stable and efficient transportation to ensure operational stability and safety [

13]. Although existing pipeline steels have achieved relatively high stress levels, the application of pipelines in harsher environments and the demand for increased transport capacity pose new challenges—requiring the development of specialized properties in pipeline steel [

14,

15]. Due to various defects and management inadequacies in the early construction and subsequent operation of long-distance natural gas pipeline girth welds, a series of major safety accidents have sequentially occurred, causing significant harm and adverse impacts on national security and public life and property [

16].

In China, the issue of weld-induced pipeline failures is particularly pronounced [

17]. The welding process can result in degraded performance of welded joints and the generation of welding defects [

18,

19,

20]. With the rapid growth of China’s oil and gas storage and transportation industry, the application of pipeline steel has steadily increased, driving stricter requirements for structural performance evaluation and operational monitoring [

21]. In the context of hydrogen-blended natural gas transportation, the integrity of welded joints becomes even more critical. Gao et al. [

22] and Ll et al. [

23] investigated the microstructures and crack initiation in automated welds of sloped pipelines, highlighting the critical influence of welding quality. LI et al. [

24] and Wu et al. [

25] focused on the distribution and control of residual stress in girth welds, a key factor affecting pipeline safety. Furthermore, PENG et al. [

26] investigated hydrogen diffusion behavior in plastically deformed pipeline steel, Zhang et al. [

27] examined microstructure-dependent toughness variations in X70 girth welds, and HUANG et al. [

28] analyzed welding residual stress distributions in high-strength pipeline steel. Collectively, these studies have addressed critical aspects of weld quality and environmental interaction. However, they primarily focus on isolated factors or single-scale analyses. A significant research gap remains in the multi-scale coupling analysis of mechanical performance degradation and the establishment of a Comprehensive Degradation Rate (CDR) metric for X70 steel welds under hydrogen-blended natural gas environments, which warrants further exploration.

This study systematically investigates X70 pipeline steel’s mechanical behavior in Sichuan-Chongqing high-pressure natural gas systems. Using SSRT tests on weld joints and SEM characterization, a multiscale method links macroscopic responses with microscopic damage mechanisms, enabling analysis of multi-factor effects on welding performance. Quantitative analysis of stress–strain curves and key mechanical parameters, combined with microstructural analysis, reveals weldment degradation mechanisms. A “deterioration rate” concept, derived from experimental data, quantifies the correlation between mechanical performance and environmental variables. The results support pipeline integrity management in the region. The deterioration rate framework offers a new approach for predicting weld life in hydrogen-blended gas transmission. Integrating macro-micro analyses, this research creates an optimization framework for materials and engineering.

2. Experimental Materials and Methods

2.1. Materials

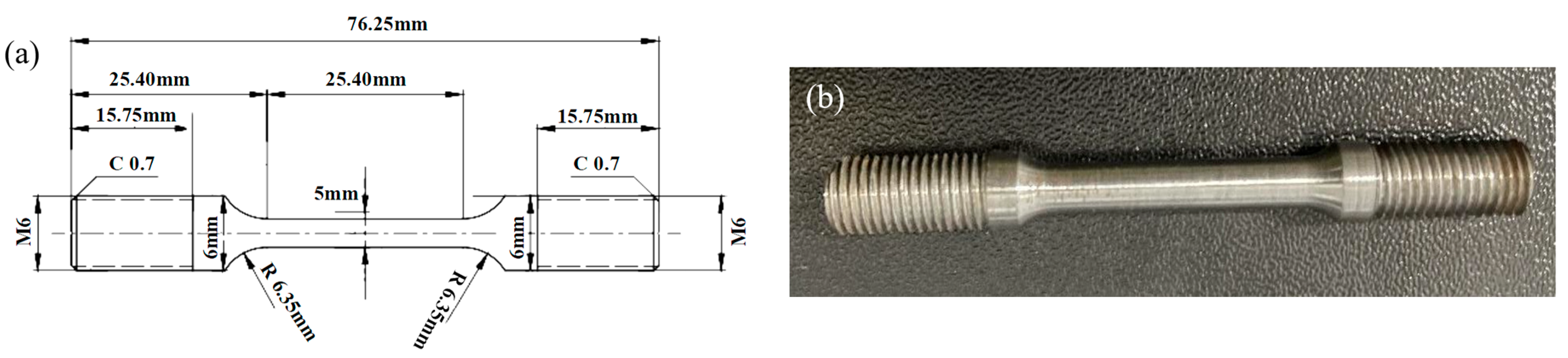

This study employed twenty-five specimens prepared from in-service X70 natural gas pipelines in the Sichuan-Chongqing region, with fifteen fabricated from the weld metal and ten from the base metal. The term ‘material regions’ refers to these two types of specimens machined from different zones of the pipeline: base metal and weld metal, as illustrated in

Figure 1. Their specific illustrations and fundamental chemical compositions are provided in

Figure 1 and

Table 1, respectively. To ensure the reliability of the experimental data, multiple replicates were tested for each condition. Specifically, for the tests investigating the effect of material regions and gas media, a minimum of two valid replicates (

n ≥ 2) were conducted for each combination. For the pressure gradient tests, each pressure level was tested with two replicates (

n = 2). The stress–strain curves and key mechanical properties showed good repeatability across these replicates. The test gases employed in this study were supplied from high-pressure gas cylinders containing nitrogen and methane. These cylinders have a capacity of 40 L, gas pressure of 13 MPa (±0.5 MPa), and gas purity ≥ 99.999%.

The tensile testing protocol strictly adheres to ASTM G142-98 Standard Test Method for Determination of Susceptibility to Embrittlement of Metallic Materials in High-Pressure, High-Temperature, or Both, Hydrogen-Containing Environments. This specification mandates the use of smooth cylindrical tensile specimens, prepared in accordance with the dimensional requirements depicted in

Figure 1a. Representative specimen morphology is presented in

Figure 1b.

The experimental system, as shown in

Figure 2, consists of three main parts: 40 L high-pressure gas cylinders (13 MPa working pressure), a gas pressurization system with a 10:1 compression ratio and ±0.2 MPa pressure control accuracy, and a servo-electromechanical slow strain rate tensile (SSRT) testing machine. Dual 316L stainless steel gas supply lines (10 mm OD) for N

2 and CH

4 connect the cylinders to the pressurization system, each equipped with Swagelok SS-4BMG precision needle valves and 0.25% FS accuracy bourdon tube pressure gauges. (Bourdon tube pressure gauges with 0.25% FS accuracy, manufactured by Swagelok (Shanghai, China) Fluid Systems Technology Co., Ltd.) The SSRT testing machine uses full-digital microcomputer control technology, with a servo motor and drive system, loading drive mechanisms, load and displacement sensors, and an industrial computer. High-precision sensors, measurement amplifiers, and a high-speed data acquisition card enable accurate display and processing of load, deformation, and displacement parameters. A closed-loop control strategy supports displacement, large deformation, and force control modes for loading and constant-holding control.

2.2. Experimental Methods

The experimental protocol was executed through the following sequential stages:

(1) Specimens polishing to ensure uniform surface roughness. The specimens was secured to the lower fixture inside the autoclave using threaded connections after opening the autoclave cover.

(2) System Purging and Leak Check: The autoclave was pressurized with nitrogen to the test pressure and purged three times with 1 MPa nitrogen to remove impurities (e.g., O2, H2O vapor). Leakage was checked at all connections. After confirming no leaks and a 30 min hold, the cooling water circulation was activated, the target temperature was set, and the heating furnace was ignited.

(3) Tensile Testing: The specimen was subjected to a load at a constant strain rate of 3.5 × 10−4 s−1. Stress–strain data and test duration were recorded using the extensometer technique and load sensors. Ultimate tensile stress, percentage reduction in area, and elongation were calculated.

(4) Post-test Depressurization and Specimen Retrieval: Following fracture, the autoclave gas was slowly vented and purged with nitrogen. After cooling to room temperature and full depressurization, the cover was opened, and the specimen was removed. The fracture surface was cleaned to remove contaminants and stored in a vacuum-sealed container.

(5) Sample Replication: The above procedures (steps 1–4) were repeated for subsequent samples.

(6) Fractography: Fracture surfaces were analyzed using Scanning Electron Microscopy (SEM) and Energy-Dispersive X-ray Spectroscopy (EDS) (The Scios 2 Hiva environmental scanning electron microscope (FEI, Hillsboro, OR, USA) was equipped with an Energy-Dispersive X-ray Spectroscopy (EDS) detector from Thermo Fisher Scientific, Waltham, MA, USA).

2.3. Evaluation Parameters

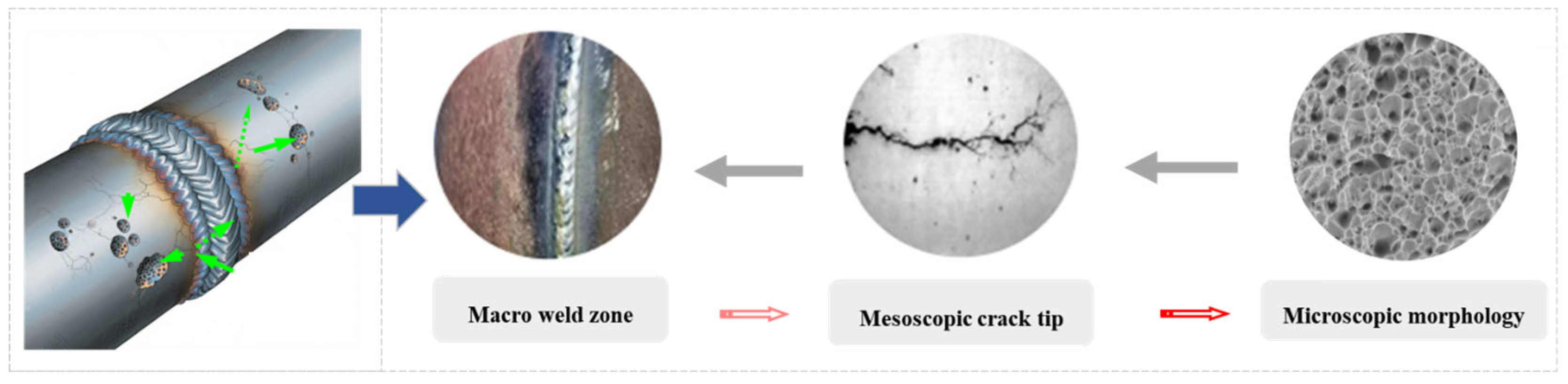

Figure 3 illustrates multiscale structural characteristics of the welded joint. At the macroscale (left), potential defects in the weld zone are indicated by green arrows. Transitioning to the mesoscale weld region reveals the overall weld morphology and fusion boundary integrity. Further magnification at the mesoscopic crack tip highlights this stress concentration zone where crack initiation typically occurs. Microscopic features disclose material microstructural details, including grain morphology and defect distribution. These multiscale characteristics provide critical insights for evaluating mechanical properties, predicting fatigue life, and preventing failures, thereby offering multidimensional perspectives for weld integrity assessment and optimized design.

The plastic behavior of X70 pipeline steel welds under multiphysics environments was comprehensively characterized through the coupling analysis of critical mechanical parameters, including yield strength (distinguishing proof vs. flow yield modes), tensile strength, post-fracture elongation, and reduction in area. Among these, the calculation formula for elongation after fracture is as follows [

29]:

Among them, L0 is the original length of the sample, and L is the distance difference in the tensile direction after the tensile fracture of the sample.

The calculation formula of reduction in area is as follows [

29]:

Among them, S0 is the original cross-sectional area of the sample, and S represents the minimum cross-sectional area after sample fracture. Typically, the fracture width is measured using a fracture measurement instrument or microscope, and then the section shrinkage is calculated based on the sample’s cross-sectional area.

The Yield-to-Tensile Ratio (

Y/T) is a key parameter in material mechanical properties, denoting the ratio of material yield stress to tensile stress. The calculation formula is [

30]:

The standard properties of X70 steel (reference API 5L specification) dictate a minimum yield stress of 483 MPa (actual production typically ranges from 485 to 605 MPa) and a minimum tensile stress of 570 MPa (actual production usually reaches 650 MPa to satisfy yield ratio specifications). The yield ratio (Yield-to-Tensile Ratio) is generally required to be ≤0.93 to ensure material plastic deformation capacity. A lower yield ratio (e.g., ≤0.8) indicates that the material retains significant plastic deformation ability after yielding, enhancing safety. Conversely, a higher yield ratio (e.g., ≥0.9) implies the material rapidly reaches tensile stress post-yielding, increasing susceptibility to brittle fracture.

3. Results and Discussion

3.1. Effect of Material Regions on Differences in X70 Steel Behaviour

Under 10 MPa methane (CH

4) environment, the plastic deformation behavior of X70 steel may be affected. As shown in

Figure 4a, the yield and tensile stress of base metal specimens generally exceed those of weld joints. For instance, Base Metal 1# exhibits yield stress of 567 MPa and tensile stress of 745 MPa, while Weld Joint 3# demonstrates reduced values of 548 MPa and 619 MPa, respectively. This stress degradation in weld zones likely originates from microstructural alterations induced by welding thermal cycles, which compromise mechanical properties.

Figure 4b reveals relatively minor differences in reduction in area between weld and base metal, though the weld joint shows slightly lower elongation after fracture (7.03% for Weld Joint 3# vs. 8% for Base Metal 2#). This indicates moderate ductility reduction in welded regions while maintaining comparable contraction characteristics. The stress–strain curves in

Figure 4c demonstrate distinct deformation characteristics through their initial slopes (reflecting elastic modulus) and inflection points (A1–A4 for yielding, B1–B4 for necking initiation). Base metals exhibit prominent yield points (A1, A2) compared to attenuated yielding behavior in welds (A3, A4). Earlier necking initiation in welds (B3, B4 vs. B1, B2) further confirms differential elastic-plastic deformation responses and reduced plastic deformation capacity in welded regions.

In summary, welding-induced microstructural heterogeneity and stress concentration predispose weld zones to delayed crack initiation through brittle fracture mechanisms under load, followed by ductile crack propagation [

31]. These metallurgical alterations significantly degrade mechanical performance, manifesting as reduced plasticity and stress attenuation in welded components.

3.2. Effect of Gas Medium on Differences in X70 Steel Behaviour

The influence of 10 MPa nitrogen (N

2) and methane (CH

4) environments on the plastic deformation behavior of X70 pipeline steel weld joints is summarized in

Figure 5. As shown in

Figure 5a, the yield stress under CH

4 exposure decreases by approximately 8% compared to the N

2 environment (from 618 MPa to 568 MPa), with a slight reduction in tensile stress (725 MPa vs. 741 MPa). This mechanical degradation supports the hypothesis that CH

4 adsorption or phase transformation may weaken grain boundaries and impede dislocation motion. Notably, the addition of 10% hydrogen (H

2) does not further degrade stress, indicating limited synergistic embrittlement effects.

Figure 5b reveals an 11.8% increase in reduction in area under CH

4 compared to N

2, though post-fracture elongation remains unchanged. In contrast, the 10% H

2-blended environment exhibits a 34.1% surge in elongation, attributed to the dual mechanisms of CH

4-induced crack propagation suppression and hydrogen-enhanced dislocation mobility at low concentrations. The stress–strain curves in

Figure 5c demonstrate comparable initial slopes across environments, implying minimal gas-induced variations in elastic modulus. While yielding initiates at slightly lower strains under CH

4 and H

2-blended conditions (points A1–A3), the subdued yield points and similar necking progression across all curves suggest that gaseous environments exert limited macroscopic impact on the overall mechanical performance of the pipeline steel, with negligible macroscopic effects on elastic modulus and necking behavior.

3.3. Effect of Pressure Gradient on Differences in X70 Steel Behaviour

In

Figure 6a,c, the stress–strain curves of X70 pipeline steel welds in a pure nitrogen environment at different elastic deformation stages under varying pressures show little variation. Within the 0.1 MPa to 10 MPa range, yield stress and tensile stress increase monotonically with rising pressure (yield stress increases from 547 MPa to 618 MPa, and tensile stress increases from 716 MPa to 741 MPa), indicating the material retains high load-bearing capacity under high pressure without reaching its tensile or yield limits.

Figure 6b reveals a significant decrease in fracture elongation at 8 MPa—dropping from 7.42% to 5.67%, a 26.74% reduction—signifying a notable decline in material ductility near 8 MPa, which may approach the critical point for plastic deformation or fracture. The section shrinkage surges to 74.73% at 8 MPa (31.76% higher than at 4 MPa) but reverts to 58.81% at 10 MPa, suggesting the material undergoes local necking or plastic instability at 8 MPa, followed by fracture. Under 0.1 MPa, 4 MPa, and 10 MPa pressures, the rates of change in fracture elongation and section shrinkage remain minimal; however, abnormal fluctuations occur in these parameters at 8 MPa, potentially attributable to inherent material characteristics.

In addition, the abrupt decline in fracture elongation and drastic variation in section shrinkage at 8 Mpa, as consistently observed in repeated tests, indicate severe compromise of material ductility, potentially signaling a transition into the plastic failure stage. In practical engineering applications, when ductility or fracture resistance serve as design criteria, 8 MPa may approach the material’s service limit. Conversely, if tensile stress is the governing standard, the ultimate pressure tolerance could be higher. For scenarios requiring the pipeline steel to withstand dynamic loads or impacts, 8 MPa may be defined as a safety threshold; however, if only static load tensile capacity is considered, higher-pressure performance remains viable for exploration. Notably, the variation curves of various parameters across different pressures exhibit minimal fluctuation. Therefore, it can be concluded that under a pure nitrogen environment, varying pressures exert negligible effects on the differences in X70 pipeline steel welds.

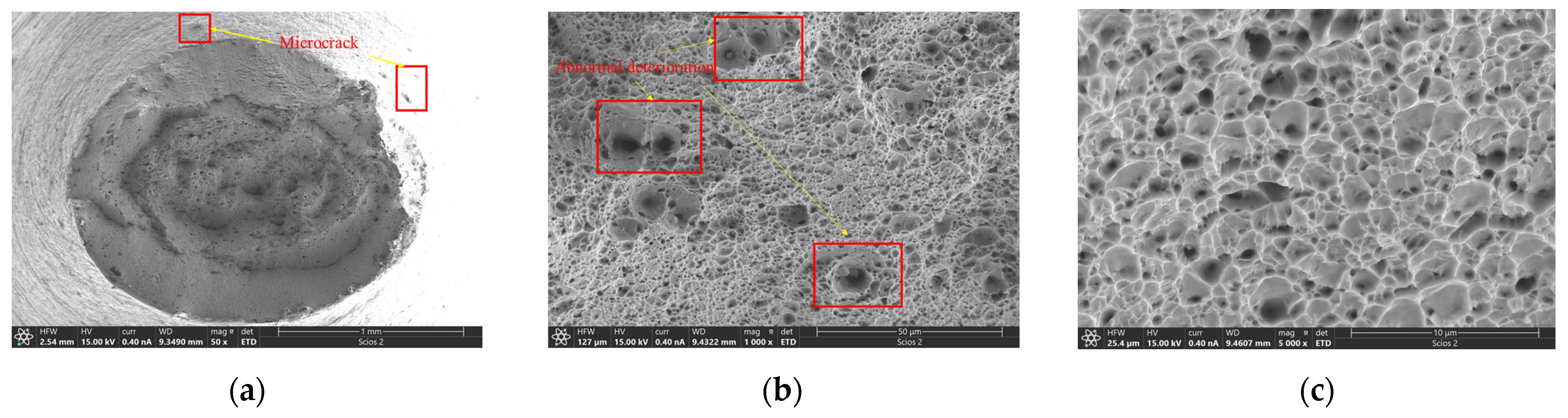

3.4. Fracture Mechanisms

According to

Figure 7 and

Figure 8, the fracture morphology of X70 steel base metal and weld in the methane environment exhibits a certain number of microcracks, indicating localized hydrogen embrittlement in the material under this environment. The fiber zone and shear lip region constitute a significant proportion of the fracture surface, which indicates excellent plastic deformation capacity of the material [

29].

In

Figure 7a, distinct dimple features are evident, with deep and uniformly distributed dimples indicating that the material undergoes substantial plastic deformation prior to fracture, displaying typical signs of plastic deformation and suggesting a predominantly ductile fracture process.

Figure 7b shows a small number of fine micro-cracks on the surface, potentially associated with local stress concentration; however, the microcrack density remains low.

Figure 7c exhibits a typical ductile fracture mode. Overall, the methane environment imposes minimal influence on the microstructure of the bulk region, with no obvious traces of environmental embrittlement observed. Consequently, the X70 steel base metal demonstrates good plastic deformation capacity in the methane environment, with the fracture mode dominated by ductile fracture. Methane gas does not significantly degrade the toughness of the base material.

According to

Figure 8a, the fracture surface exhibits characteristics of a quasi-cleavage morphology. Substantial weld misalignment and discontinuous geometry at the weld root induce stress concentration [

32], indicating that the fracture mode in the weld region transitions toward brittle fracture. The dimples are shallow and unevenly distributed, reflecting reduced plastic properties in the weld compared to the base metal.

Figure 8b reveals numerous traces of microcrack initiation and propagation, which may be attributed to microstructural inhomogeneities—such as grain coarsening and residual stress—induced by the welding thermal cycle. Localized tearing ridges observed in

Figure 8c suggest that the weld region’s resistance to brittle fracture in the methane environment is weaker than that of the base metal, with environmental methane potentially exacerbating the weld’s embrittlement tendency. In the methane environment, the fracture mode of the X70 steel weld zone is primarily brittle with partial ductile characteristics. Microstructural defects and stress concentration in the weld zone render it more sensitive to the methane environment, resulting in inferior performance compared to the base metal.

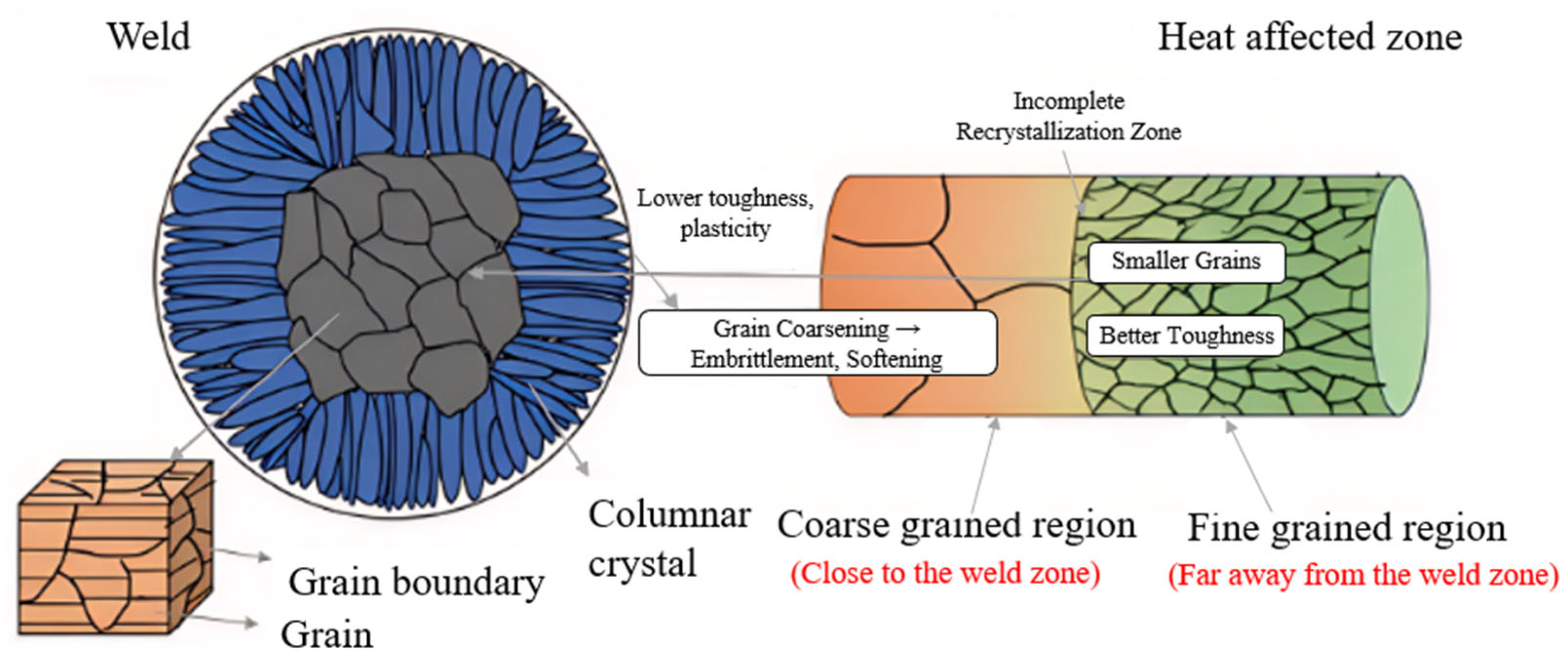

Figure 9 depicts the microstructure of the weld zone in the pipe in relation to mechanical properties. The discrepancy in mechanical properties between the weld and base metal in the in-service pipeline primarily arises from differences in material microstructure and stress distribution. Various welding defects—such as pores, cracks, slag inclusions, and incomplete penetration—may emerge during the welding process, potentially initiating structural failure and compromising product performance and reliability [

33]. Owing to the material characteristics of high-stress pipeline steel, the welding heat-affected zone (HAZ) is susceptible to grain coarsening during welding, leading to varying degrees of embrittlement and softening in this zone [

34], which degrades the overall mechanical properties of the ring welded joint [

35]. Welding residual stress represents a critical factor influencing the initiation and propagation of welding cracks, as well as the service performance and failure behavior of pipelines [

36,

37]. The high-temperature melting and rapid cooling during welding cause the weld region to develop a microstructure distinct from the base metal. Such microstructures typically exhibit lower toughness and plasticity, resulting in reduced elongation and impact resistance in the weld compared to the base metal. The heat-affected zone is the most inhomogeneous and crack-prone region within the welded joint, with its thermal effects classified into the coarse-grain zone, fine-grain zone, and incomplete recrystallization zone [

38,

39]. The elevated temperature in the heat affected zone induces significant grain growth, with distinct original austenite grain boundaries visible, and granular bainite along with a small amount of massive ferrite present within the grains [

40]. Additionally, the high temperature during welding induces residual stress. Under the influence of welding heat input, the coarse grain zone of the cover surface exhibits a higher proportion of acicular ferrite compared to root welding, hot welding, and filling processes [

41]. Particularly at the interface between the weld and base metal (heat affected zone), these stresses may further facilitate crack initiation and propagation under external loading. Therefore, the discrepancy in mechanical properties of the weld zone arises from the combined influence of multiple factors: microstructural formation, stress state, and compositional differences between the weld metal and base metal.

3.5. Quantitative Analysis of Stress Deterioration in X70 Steel

Based on the macro-scale and micro-scale analyses of the mechanical properties of X70 pipeline steel, this study proposes the concept of “Degradation Rate” to quantify the performance attenuation of materials/structures under specific service environments, defined as the relative loss rate of key mechanical parameters. Using slow strain rate tensile testing, the synergistic effects of gas media (N

2, CH

4, H

2), pressure (0.1–10 MPa), and material zones (base metal, weld) on X70 pipeline steel stress degradation were investigated. Results show that multi-physics coupling in in-service X70 pipeline weld zones, involving welding-induced macro-morphology, microstructural evolution, and service conditions, significantly affects weld stress, toughness, and fatigue resistance. Yield-to-tensile ratios were calculated via Equation (3), and degradation rate indices under different conditions were characterized by Equation (4) (

Table 2).

A Comprehensive Degradation Rate (CDR) was developed as a quantitative evaluation system for multi-factor synergistic effects. CDR integrates the independent degradation rates of gas media, pressure gradients, and material zones, considering their nonlinear interactions, to assess overall performance degradation. Weights were assigned based on a systematic analysis of the experimental results presented in

Section 3.1,

Section 3.2 and

Section 3.3: 0.5 for material zones, reflecting their dominant role in mechanical degradation as evidenced by the most significant yield strength reduction (15.2–18.7%) and fracture mode transition; 0.3 for gas media, accounting for their substantial influence on embrittlement susceptibility and ductility; and 0.2 for pressure gradients, consistent with their relatively minor and non-monotonic impact on mechanical properties within the tested range. This metric improves the multi-physics coupling analysis framework for in-service pipeline welds, supporting engineering integrity assessments.

The yield-to-tensile ratios under different variables reveal that, in high-pressure methane environments, both the yield stress and tensile stress of the base metal comply with the API 5L specification, with a yield-to-tensile ratio of 0.76, indicating favorable plastic deformation capability. In contrast, the weld zone exhibits a yield-to-tensile ratio of 0.89, which, while meeting the standard, is significantly higher than that of the base metal, reflecting plastic performance degradation in the weld zone due to microstructural heterogeneity and residual stresses. Using the base metal as the benchmark under varying material zones, the degradation rate of the weld zone reaches 17.10%, primarily attributed to welding defects and residual stresses. With pure methane as the reference under different gas media, the degradation rates are 9.21% in nitrogen and 2.63% at 10% hydrogen blending, both contributing to reduced weld performance. Additionally, under pressure gradients (with 0.1 MPa as the baseline), increasing pressure exacerbates degradation, with the degradation rate rising to 9.21% at 10 MPa, demonstrating deteriorated mechanical performance in welds under elevated pressure. By integrating the comprehensive degradation rates (CDR) across these three variable groups, the material zone variation exerts the most substantial influence on the degradation rate of X70 pipeline steel, with a CDR of 8.55%, and also dominates the impact on mechanical properties. The effects of gas media and pressure gradients are comparatively secondary.

3.6. Inspiration for High-Pressure Pipeline Transportation

In high-pressure natural gas transmission, in-service X70 pipeline steel—a high-stress low-alloy steel—exhibits high yield and tensile stress, enabling it to withstand the internal pressures encountered during natural gas transportation. Meanwhile, its excellent corrosion and fatigue resistance allow effective resistance to corrosive media erosion and delay crack propagation in complex environments, ensuring stable pipeline operation [

42]. Over time, pipelines may suffer from corrosion, fatigue damage, and other factors, leading to degradation of mechanical properties and compressive stress; however, the superior characteristics of X70 pipeline steel can effectively mitigate these degradation rates.

In-service X70 pipeline steel significantly differs from new pipes in mechanical properties. Long-term use increases the yield ratio of in-service pipelines, indicating a safety gap. New pipes, optimized via alloy composition and thermomechanical processing, reduce microscopic defects (pores, inclusions) and enhance performance stability, suitable for high-pressure (≤10 MPa) and high-hydrogen-blending (≤20%) conditions, while in-service pipelines require pressure limits (≤8 MPa). For hydrogen-doped natural gas transportation, X70 high-stress low-alloy steel’s high yield and tensile stresses enable it to withstand internal pressures. Its corrosion and fatigue resistance also ensure stable operation by resisting corrosion and retarding crack propagation [

43]. To advance China’s hydrogen pipeline development, systematic study on the relationship between X70 steel’s hydrogen embrittlement resistance/hydrogen compatibility and its microstructure/chemical composition is essential.

This study underpins high-pressure natural gas pipeline safety assessment and design, guiding material development. Future research on X70 pipeline steel could focus on two areas. First, analyze durability degradation by factoring in long-term service conditions, including temperature, humidity, and geological stress. Second, optimize welding processes, adjust material compositions, and apply post-weld treatments to boost weld zone properties and hydrogen embrittlement resistance. Leveraging advanced simulations and intelligent monitoring can create accurate mechanical behavior prediction models, enabling real-time safety evaluations and early warnings for pipeline operation. These efforts will support pipeline lifecycle management and advance high-pressure pipeline material development.

4. Conclusions

In this study, the mechanical behavior and degradation mechanisms of in-service X70 pipeline steel welds from the Sichuan-Chongqing region were systematically investigated under multiphysics environments. The following conclusions are drawn:

(1) The weld zone, due to its inherent microstructural inhomogeneity and residual stresses, constitutes the most critical region for performance degradation. Its mechanical properties are markedly inferior to the base metal, exhibiting a substantial yield stress reduction of 15.2–18.7%. Fracture morphology confirms a distinct transition towards brittle fracture in the welds, characterized by prominent quasi-cleavage features.

(2) The gaseous environment significantly modulates embrittlement susceptibility. The 10% hydrogen-blended environment presented the highest risk of brittle fracture. While a methane atmosphere reduced the tensile stress of the weld by 6.07%, a pure nitrogen environment demonstrated the least detrimental effect on material ductility.

(3) A critical pressure threshold of 8 MPa was identified, where a sharp 26.74% decrease in fracture elongation, coupled with anomalous section shrinkage fluctuations, indicates the onset of plastic instability. This pressure is proposed as a vital safety design threshold for in-service pipelines.

(4) The newly introduced “degradation rate” metric quantitatively corroborates that the material region (weld vs. base metal) is the dominant factor governing performance loss, with the highest comprehensive degradation rate (CDR) of 8.55%. The influence of the gas medium and pressure gradient is secondary, establishing a clear hierarchy of influencing factors for pipeline integrity assessment.