The Impact of Product Environmental Innovation in Process Industries: Evidence from Innovation Efficiency and Performance

Abstract

1. Introduction

2. Literature Review

2.1. Product Environmental Innovation

2.2. Innovation Efficiency

3. Methodology

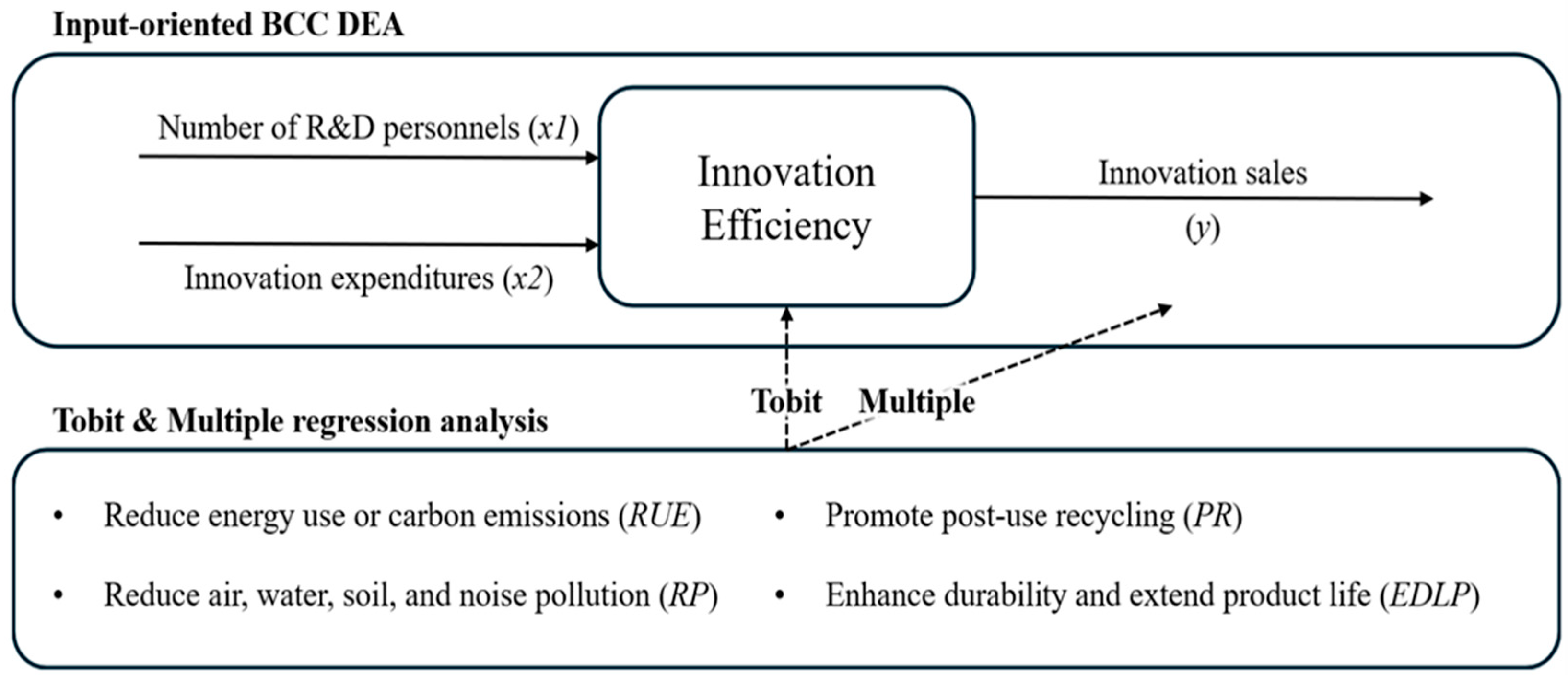

3.1. Data Envelopment Analysis (DEA) Approach

3.2. Data Collection and Variable Definition

3.3. Research Model

4. Results Analysis

4.1. Regression Analysis Results for the Entire Industry

4.2. Regression Analysis Results for the Chemical Industry

4.3. Regression Analysis Results for the Electronic Industry

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kuwashima, K.; Fujimoto, T. Redefining the characteristics of process-industries: A design theory approach. J. Eng. Technol. Manag. 2023, 68, 101748. [Google Scholar] [CrossRef]

- Hwang, J.; Lim, J.; Seong, J.; Hwang, J.; Lee, R.; Song, S.; Song, Y. Korea’s Next S-Curve: A New Economic Growth Model for 2040; McKinsey & Company: Seoul, Republic of Korea, 2023; Available online: https://www.mckinsey.com/featured-insights/future-of-asia/koreas-next-s-curve-a-new-economic-growth-model-for-2040 (accessed on 15 September 2025).

- Gabrielli, P.; Rosa, L.; Gazzani, M.; Meys, R.; Bardow, A.; Mazzotti, M.; Sansavini, G. Net-zero emissions chemical industry in a world of limited resources. One Earth 2023, 6, 682–704. [Google Scholar] [CrossRef]

- Yin, Y.; Yang, Y. Sustainable Transition of the Global Semiconductor Industry: Challenges, Strategies, and Future Directions. Sustainability 2025, 17, 3160. [Google Scholar] [CrossRef]

- Deng, M.; Fang, X.; Tian, Z.; Luo, W. The impact of environmental uncertainty on corporate innovation: Evidence from Chinese listed companies. Sustainability 2022, 14, 4902. [Google Scholar] [CrossRef]

- Yi, D.; Hu, J.; Yang, J. Climate policy uncertainty, environmental regulation, and corporate green innovation. Front. Environ. Sci. 2025, 13, 1570848. [Google Scholar] [CrossRef]

- Shin, J.; Kim, Y.; Kim, C. Firm Performance and Innovation Efficiency by Innovation Type in the Korean Logistics Industry. Int. J. Transp. Econ. 2025, 1/2, 9–24. [Google Scholar]

- Shin, J.; Kim, Y.; Yang, H.; Kim, C. What is the right innovation type for your industry? evidence from chemical firms in Korea. Processes 2019, 7, 643. [Google Scholar] [CrossRef]

- Eder, P. Expert inquiry on innovation options for cleaner production in the chemical industry. J. Clean. Prod. 2003, 11, 347–364. [Google Scholar] [CrossRef]

- Benner, M.J.; Tushman, M. Process management and technological innovation: A longitudinal study of the photography and paint industries. Adm. Sci. Q. 2002, 47, 676–707. [Google Scholar] [CrossRef]

- Chang, S.; Yue, J.; Wang, X.; Yu, B. Managerial strategies for process innovation through the perspective of competition among supply chain members. J. Clean. Prod. 2021, 296, 126532. [Google Scholar] [CrossRef]

- Aliasghar, O.; Kanani Moghadam, V. Selective search and new-to-market process innovation. J. Manuf. Technol. Manag. 2022, 33, 1301–1318. [Google Scholar] [CrossRef]

- Aibar-Guzmán, C.; Somohano-Rodríguez, F.M. Do consumers value environmental innovation in product? Adm. Sci. 2021, 11, 33. [Google Scholar] [CrossRef]

- Jean, G. Green Product Innovation and Market Performance. Preprint 2024. submitted. [Google Scholar]

- Eusebio, E.J.G. How eco-innovation affects sustainable performance: A systematic review. Multidiscip. Rev. 2025, 8, 2025166. [Google Scholar] [CrossRef]

- Stundziene, A.; Pilinkiene, V.; Vilkas, M.; Grybauskas, A.; Lukauskas, M. The challenge of measuring innovation types: A systematic literature review. J. Innov. Knowl. 2024, 9, 100620. [Google Scholar] [CrossRef]

- Lee, J.; Kim, C.; Choi, G. Exploring data envelopment analysis for measuring collaborated innovation efficiency of small and medium-sized enterprises in Korea. Eur. J. Oper. Res. 2019, 278, 533–545. [Google Scholar] [CrossRef]

- De Marchi, V. Environmental innovation and R&D cooperation: Empirical evidence from Spanish manufacturing firms. Res. Policy 2012, 41, 614–623. [Google Scholar] [CrossRef]

- Paunov, C.; Rochell, C.; Labrue, L.; Planes-Satorra, S. What Is Unique About Green Innovation?: Evidence from Green Hydrogen, Green Steel, Batteries and Electric Vehicles; OECD Publishing: Paris, France, 2025. [Google Scholar]

- Manjunatheshwara, K.J.; Vinodh, S. Sustainable electronics product design and manufacturing: State of art review. Int. J. Sustain. Eng. 2021, 14, 541–551. [Google Scholar] [CrossRef]

- Sudarshan, C.C.; Matkar, N.; Vrudhula, S.; Sapatnekar, S.S.; Chhabria, V.A. Eco-chip: Estimation of carbon footprint of chiplet-based architectures for sustainable vlsi. In Proceedings of the 2024 IEEE on HPCA 2024, Edinburgh, UK, 2–6 March 2024; pp. 671–685. [Google Scholar]

- Olatunde, T.M.; Okwandu, A.C.; Akande, D.O. Reviewing the impact of energy-efficient appliances on household consumption. Int. J. Sci. Technol. 2024, 6, 1–11. [Google Scholar]

- Schieweck, A.; Bock, M.C. Emissions from low-VOC and zero-VOC paints–Valuable alternatives to conventional formulations also for use in sensitive environments? Built Environ. 2015, 85, 243–252. [Google Scholar] [CrossRef]

- Bae, B.; Tamura, S.; Imanaka, N. Novel environmentally friendly inorganic yellow pigments based on gehlenite-type structure. Ceram. Int. 2016, 42, 15104–15106. [Google Scholar] [CrossRef]

- Köhler, J. Detergent phosphates: An EU policy assessment. J. Bus. Chem. 2006, 3, 15–30. [Google Scholar]

- Andrae, A.S. Does the Restriction of Hazardous Substances (RoHS) Directive Help Reduce Environmental Impacts? Int. J. Green Technol. 2020, 6, 25. [Google Scholar]

- Sabet, M. Sustainable halogen-free polymer composites for next-generation flexible electronics. J. Nanopart. Res. 2025, 27, 33. [Google Scholar] [CrossRef]

- Samir, A.; Ashour, F.H.; Hakim, A.A.; Bassyouni, M. Recent advances in biodegradable polymers for sustainable applications. npj Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- Köpman, J.; Majava, J. The role of product design in advancing the circular economy of electric and electronic equipment. RCR Adv. 2024, 21, 200207. [Google Scholar] [CrossRef]

- Miteva, A.; Hodjaoglu, G. Applications of Recycled Aluminum in the Modern Food Industry. RCR Adv. 2024, 114, 18–31. [Google Scholar]

- Hossain, R.; Sahajwalla, V. Current recycling innovations to utilize e-waste in sustainable green metal manufacturing. Philos. Trans. R. Soc. A 2024, 382, 20230239. [Google Scholar] [CrossRef] [PubMed]

- Firoozi, A.; Firoozi, A.; Oyejobi, D.O.; Avudaiappan, S.; Flores, E. Enhanced durability and environmental sustainability in marine infrastructure: Innovations in anti-corrosive coating technologies. Results Eng. 2025, 26, 105144. [Google Scholar] [CrossRef]

- Frigione, M. Assessment of the Ageing and Durability of Polymers. Polymers 2022, 14, 1934. [Google Scholar] [CrossRef] [PubMed]

- Lee, P.; Calugar-Pop, C.; Bucaille, A.; Raviprakash, S. Making Smartphones Sustainable: Live Long and Greener. Deloitte Insights, 1 December 2021. Available online: https://www.deloitte.com/us/en/insights/industry/technology/technology-media-and-telecom-predictions/2022/environmental-impact-smartphones.html (accessed on 17 August 2025).

- Arsad, S.R.; Hannan, M.A.; Ker, P.J.; Wong, R.T.; Begum, R.A.; Hossain, M.J.; Jang, G. Longevity of lithium-ion batteries in EV applications: Techno-economic and environmental impact considerations toward sustainability. J. Energy Storage 2025, 131, 117551. [Google Scholar]

- Pode, R. Organic light emitting diode devices: An energy efficient solid state lighting for applications. Renew. Sustain. Energy Rev. 2020, 133, 110043. [Google Scholar] [CrossRef]

- Shin, J.; Kim, Y.; Son, J.; Kim, C. Is there a difference in innovation performance depending on the investment in each stage of development process? Evidence from medical device industry. IEEE Access 2023, 11, 92092–92099. [Google Scholar] [CrossRef]

- Zhang, T.; Li, S.; Li, Y.; Wang, W. Evaluation of technology innovation efficiency for the listed NEV enterprises in China. Econ. Anal. Policy 2023, 80, 1445–1458. [Google Scholar] [CrossRef]

- Shin, J.; Kim, Y.J.; Jung, S.; Kim, C. Product and service innovation: Comparison between performance and efficiency. J. Innov. Knowl. 2022, 7, 100191. [Google Scholar] [CrossRef]

- Park, J.H. Open innovation of small and medium-sized enterprises and innovation efficiency. Asian J. Technol. Innov. 2018, 26, 115–145. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Tobin, J. Estimation of relationships for limited dependent variables. Econometrica 1958, 26, 24–36. [Google Scholar] [CrossRef]

- Castellacci, F. Technological paradigms, regimes and trajectories: Manufacturing and service industries in a new taxonomy of sectoral patterns of innovation. Res. Policy 2008, 37, 978–994. [Google Scholar] [CrossRef]

- Lööf, H.; Heshmati, A. Knowledge capital and performance heterogeneity: A firm-level innovation study. Int. J. Prod. Econ. 2002, 76, 61–85. [Google Scholar] [CrossRef]

- Griliches, Z. R&D and Productivity: The Econometric Evidence; National Bureau of Economic Research Book Series; University of Chicago Press: Chicago, IL, USA, 2007. [Google Scholar]

- Autio, E.; Sapienza, H.J.; Almeida, J.G. Effects of age at entry, knowledge intensity, and imitability on international growth. Acad. Manag. J. 2000, 43, 909–924. [Google Scholar] [CrossRef]

- Cohen, W.M.; Klepper, S. Firm size and the nature of innovation within industries: The case of process and product R&D. Rev. Econ. Stat. 1996, 78, 232–243. [Google Scholar] [CrossRef]

- Padel, S.; Foster, C. Exploring the gap between attitudes and behaviour: Understanding why consumers buy or do not buy organic food. Br. Food J. 2005, 107, 606–625. [Google Scholar] [CrossRef]

- Joshi, Y.; Rahman, Z. Factors affecting green purchase behaviour and future research directions. Int. Strateg. Manag. Rev. 2015, 3, 128–143. [Google Scholar] [CrossRef]

- Riva, F.; Magrizos, S.; Rubel, M.R.B.; Rizomyliotis, I. Green consumerism, green perceived value, and restaurant revisit intention: Millennials’ sustainable consumption with moderating effect of green perceived quality. Bus. Strategy Environ. 2022, 31, 2807–2819. [Google Scholar] [CrossRef]

- Munten, P.; Vanhamme, J. To reduce waste, have it repaired! The quality signaling effect of product repairability. J. Bus. Res. 2023, 156, 113457. [Google Scholar] [CrossRef]

- Han, S.H.; Yun, M.H.; Kwahk, J.; Hong, S.W. Usability of consumer electronic products. Int. J. Ind. Ergon. 2001, 28, 143–151. [Google Scholar] [CrossRef]

- van Kuijk, J.; Kanis, H.; Christiaans, H.; van Eijk, D. Barriers to and enablers of usability in electronic consumer product development: A multiple case study. Hum. Comput. Interact. 2017, 32, 1–71. [Google Scholar] [CrossRef]

- Sun, J.J.; Bellezza, S.; Paharia, N. Buy less, buy luxury: Understanding and overcoming product durability neglect for sustainable consumption. J. Mark. 2021, 85, 28–43. [Google Scholar] [CrossRef]

- Jacobs, K. Driven by personal or environmental gains? Investigating consumer motives behind purchasing long-lasting products. J. Clean. Prod. 2023, 383, 135505. [Google Scholar] [CrossRef]

- Lin, P.C.; Huang, Y.H. The influence factors on choice behavior regarding green products based on the theory of consumption values. J. Clean. Prod. 2012, 22, 11–18. [Google Scholar] [CrossRef]

- Riva, F. Eco-Friendly Marketing Strategy and Performance Outcome: The Role of Learning. Ph.D. Thesis, University of Leeds, Leeds, UK, 4 July 2025. [Google Scholar]

- Luchs, M.G.; Kumar, M. “Yes, but this other one looks better/works better”: How do consumers respond to trade-offs between sustainability and other valued attributes? J. Bus. Ethics 2017, 140, 567–584. [Google Scholar] [CrossRef]

| Researcher | DMUs | Input Variable | Output Variable | Method |

|---|---|---|---|---|

| Shin et al. [37] | 743 medical device companies | R&D expenditure, Employees | Sales | BCC DEA |

| Zhang et al. [38] | 45 new energy vehicle companies | R&D employee, R&D expenditure, Sales expenses | Patent, Intangible assets, Operating income | Slack-based DEA, Meta-frontier model |

| Shin et al. [39] | 902 manufacturing companies | R&D employee, Innovation cost | Innovation sales | Bootstrapped DEA |

| Shin et al. [8] | 64 chemical companies | R&D employee, Innovation cost | Sales | Bootstrapped DEA |

| Park [40] | 1778 manufacturing companies | R&D employee, R&D expenditure, | Innovation sales | BCC DEA |

| Variable | Max | Min | Mean | St.dev | |

|---|---|---|---|---|---|

| Output | Innovation sales | 9,590,000.000 | 11.000 | 204,651.149 | 811,873.116 |

| Input | R&D personnel | 2202.000 | 1.000 | 54.890 | 170.497 |

| Innovation expenditure | 637,249.000 | 20.000 | 8579.890 | 43,789.490 | |

| Control | ln (Firm age) | 4.331 | 1.099 | 3.068 | 0.637 |

| ln (Employees) | 9.358 | 2.303 | 5.132 | 1.407 | |

| Dependent | RUE | 1.000 | 0.000 | 0.512 | 0.500 |

| RP | 1.000 | 0.000 | 0.473 | 0.499 | |

| PR | 1.000 | 0.000 | 0.456 | 0.498 | |

| EDEL | 1.000 | 0.000 | 0.558 | 0.497 | |

| Model | Model 1 (Tobit) | Model 2 (OLS) | ||

|---|---|---|---|---|

| Dependent Variable | Innovation Efficiency | Innovation Efficiency | ||

| Independent Variable | Coefficient | Std. Error | Coefficient | Std. Error |

| RUE | 0.216 | 0.232 | 0.531 | 0.330 |

| RP | −0.360 | 0.263 | 0.145 | 0.357 |

| PR | −0.012 | 0.266 | −1.449 *** | 0.365 |

| EDEL | 0.413 ** | 0.174 | 1.829 *** | 0.255 |

| Firm age | −0.075 | 0.096 | −0.141 | 0.145 |

| Firm size | −0.289 | 0.044 | 1.329 *** | 0.065 |

| Log-likelihood | 176.155 | |||

| Wald-statistics | 114.595 | |||

| 0.696 | ||||

| F-statistics | 93.299 *** | |||

| Model | Model 1 (Tobit) | Model 2 (OLS) | ||

|---|---|---|---|---|

| Dependent Variable | Innovation Efficiency | Innovation Efficiency | ||

| Independent Variable | Coefficient | Std. Error | Coefficient | Std. Error |

| RUE | 0.856 *** | 0.308 | 1.516 *** | 0.428 |

| RP | −0.165 | 0.341 | −0.014 | 0.474 |

| PR | −0.024 | 0.434 | −1.289 ** | 0.604 |

| EDEL | −0.097 | 0.389 | 1.353 ** | 0.541 |

| Firm age | −0.152 | 0.123 | 0.026 | 0.171 |

| Firm size | −0.190 *** | 0.064 | 1.440 *** | 0.089 |

| Log-likelihood | 31.371 | |||

| Wald-statistics | 26.098 | |||

| 0.750 | ||||

| F-statistics | 70.335 *** | |||

| Model | Model 1 (Tobit) | Model 2 (OLS) | ||

|---|---|---|---|---|

| Dependent Variable | Innovation Efficiency | Innovation Efficiency | ||

| Independent Variable | Coefficient | Std. Error | Coefficient | Std. Error |

| RUE | −1.062 *** | 0.370 | −0.978 ** | 0.480 |

| RP | 0.303 | 0.402 | 0.890 | 0.503 |

| PR | −0.026 | 0.412 | −1.264 *** | 0.434 |

| EDEL | 0.905 *** | 0.273 | 1.833 *** | 0.266 |

| Firm age | −0.030 | 0.200 | −0.333 | 0.188 |

| Firm size | 0.000 | 0.063 | 1.130 *** | 0.076 |

| Log-likelihood | 59.606 | |||

| Wald-statistics | 20.568 | |||

| 0.663 | ||||

| F-statistics | 47.458 *** | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; Seong, J.; Kim, C. The Impact of Product Environmental Innovation in Process Industries: Evidence from Innovation Efficiency and Performance. Processes 2025, 13, 3227. https://doi.org/10.3390/pr13103227

Kim Y, Seong J, Kim C. The Impact of Product Environmental Innovation in Process Industries: Evidence from Innovation Efficiency and Performance. Processes. 2025; 13(10):3227. https://doi.org/10.3390/pr13103227

Chicago/Turabian StyleKim, Yeongjun, Jiyun Seong, and Changhee Kim. 2025. "The Impact of Product Environmental Innovation in Process Industries: Evidence from Innovation Efficiency and Performance" Processes 13, no. 10: 3227. https://doi.org/10.3390/pr13103227

APA StyleKim, Y., Seong, J., & Kim, C. (2025). The Impact of Product Environmental Innovation in Process Industries: Evidence from Innovation Efficiency and Performance. Processes, 13(10), 3227. https://doi.org/10.3390/pr13103227