Analyzing the Smart Industry Readiness Index in Adopting Industry 4.0 Technologies

Abstract

1. Introduction

- In defining Industry 4.0 technologies in relation to manufacturing organizations, this research contributes to a deeper understanding of the Fourth Industrial Revolution.

- In terms of SIRI improvement, this article empirically examines the connection between I4.0 and SIRI.

- To counter global competition, manufacturing organizations can choose the right I4.0 technologies thanks to this research.

2. Research Methodology

- ▪

- With an emphasis on integrating cutting-edge technologies such as IoT, AI, robotics, and automation across business and manufacturing processes, SIRI is a structured tool for mapping readiness and guiding Industry 4.0 transformation.

- ▪

- Businesses can customize their Industry 4.0 journeys with strategic, phased roadmaps created using the SIRI framework.

- ▪

- To guarantee competitive and future-ready manufacturing, SIRI serves as a comprehensive guide for Industry 4.0 transformation, closely tying operational and process maturity to technological breakthroughs.

- ▪

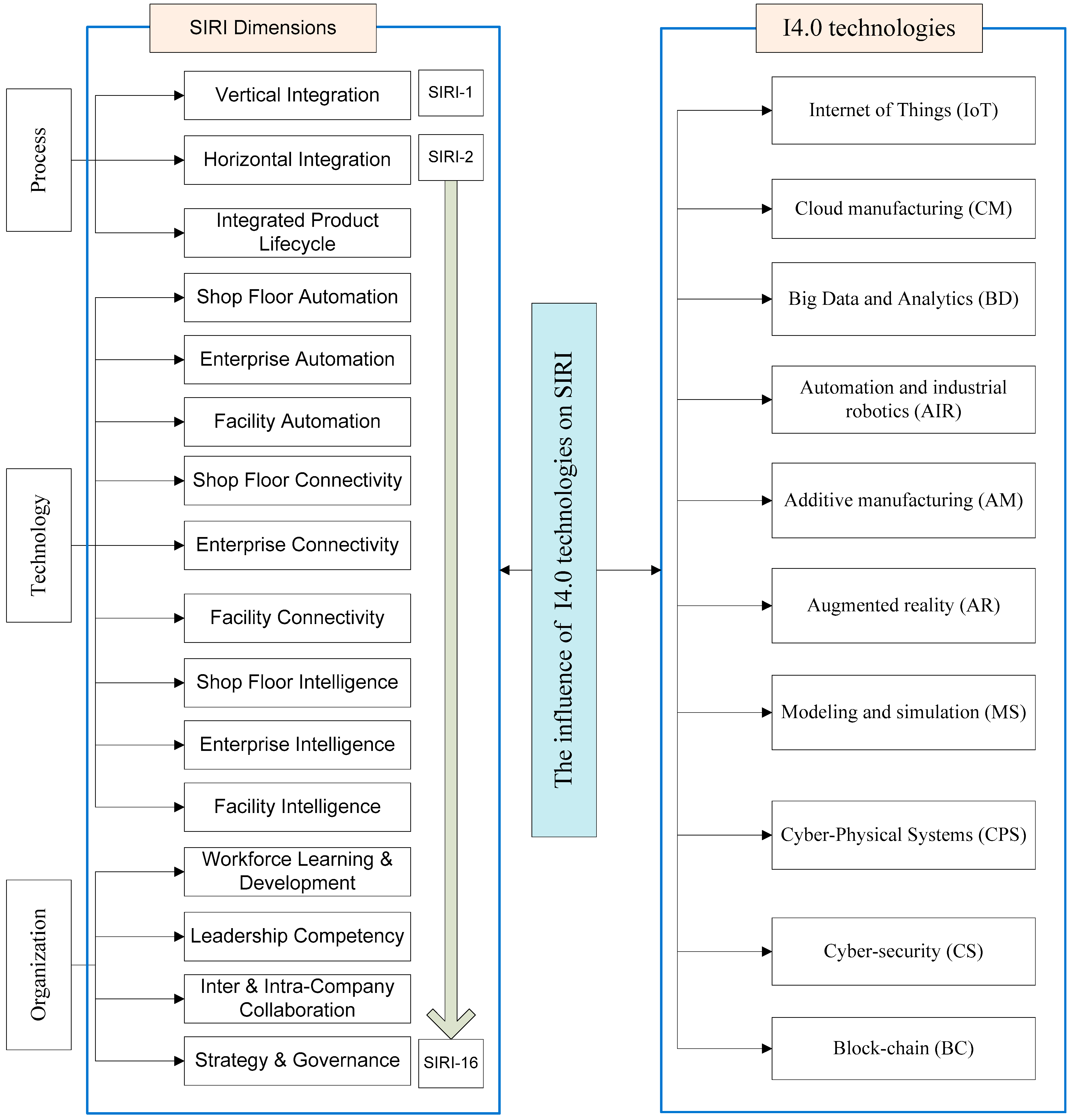

- Internet of things (loT): Through the Internet of Things, physical objects can exchange information, coordinate decisions, and communicate with one another [32,33,34]. It creates a network of humans to humans and things to things. IoT applications in manufacturing systems reduce the size of product recalls, identify defective products early, modify product designs, and improve product performance.

- ▪

- Cloud manufacturing (CM) is a business model that leverages the sharing of cloud-based manufacturing capabilities and resources. Cloud manufacturing is ideal for contemporary manufacturers due to its cloud-based software, web-based management dashboards, and cloud-based collaboration capabilities. Despite their disparate locations, distributed manufacturing resources can be integrated to form a scalable platform [35].

- ▪

- Big Data and Analytics (BD): It is characterized by vast amounts of diverse data that are moving in real time, coming from a range of sources, and taking many different forms [36]. This system and technology demonstrate how companies can gain a competitive edge by discovering, processing, and analyzing vast amounts of diverse data [37].

- ▪

- Automation and industrial robotics (AIR): AIR is undoubtedly increasing, especially in business and, to a greater extent, in daily life [27]. Advanced robot technology (gluing, coating, laser-based processes, precision assembly, and fiber material processing) will be required for manufacturing processes and services in rapidly growing industries (such as electronics, food, logistics, and the life sciences).

- ▪

- Additive manufacturing (AM): In additive manufacturing (AM), materials are joined, usually layer by layer, to create objects from three-dimensional (3D) model data [38,39]. It reduces waste and streamlines on-demand manufacturing, mass customization, and production procedures. Additionally, producing close to the end user increases supply chain flexibility.

- ▪

- ▪

- Modeling and simulation (MS): Designing, implementing, testing, and controlling a manufacturing system in real time should be made easier by modeling and simulation technologies [42]. Saving money, reducing development time, and improving product quality are all benefits of modeling and simulation.

- ▪

- Cyber-Physical Systems (CPS): These provide and consume internet-based data-access and data-processing services, and are systems of cooperating computational entities closely connected to the real world and its activities [43]. Increased efficiency and greater manufacturing flexibility are two key advantages of distributed manufacturing systems made possible by CPS [44].

- ▪

- Cybersecurity (CS): Cybersecurity makes CS a new paradigm for extremely secure information systems that can be utilized in manufacturing across the entire IoT ecosystem. “Cybersecurity” (CS) is the umbrella term for the set of tools used to prevent, detect, and respond to hackers [45].

- ▪

- Blockchain (BC): Blockchain is a technology that enables a specific industry to have a decentralized, transparent financial transaction platform. Transparency, process integrity, stability, and adaptability are the attributes of BC technology [46]. With BC technology, any digital knowledge can be shared. BC has been adopted by numerous industries, including design, manufacturing, banking, supply chain management, and social networks [46].

2.1. Proposed Model

2.2. Constricting the MCDM Model

2.3. Fuzzy TOPSIS Method

3. Results and Discussion

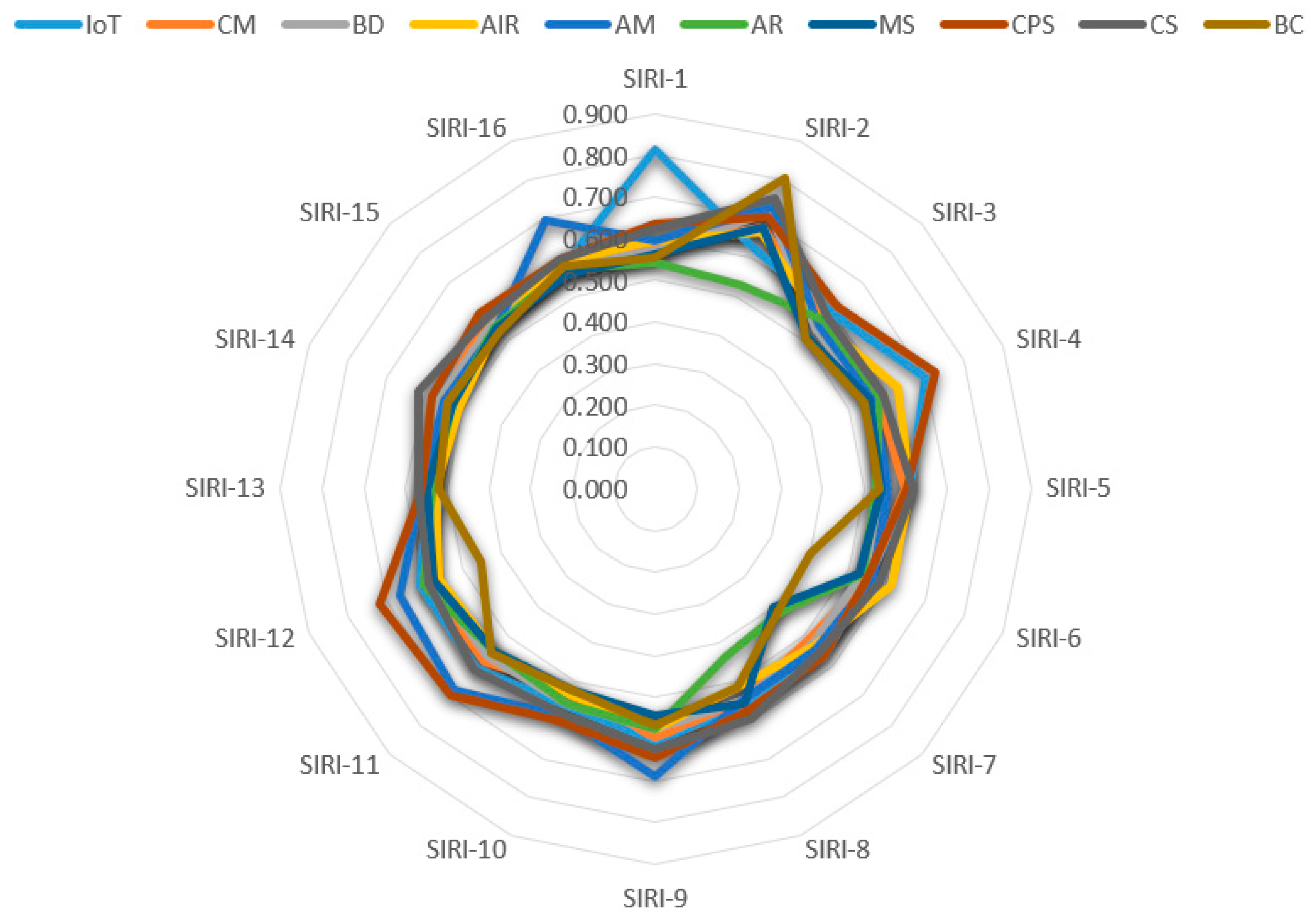

The Ranking of I4 Technologies According to Each SIRI

4. Sensitivity Analysis

5. Implications

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Machado, C.G.; Winroth, M.P.; Ribeiro da Silva, E.H.D. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Boareto, P.A.; Rocha Loures, E.d.F.; Deschamps, F.; Santos, E.A.P. Genesis-I4. 0: A Generative Ai Framework for Democratizing Digital Twins in Industry 4.0. Machines 2024, 12, 584. [Google Scholar]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; Policy Brief; European Commission, Directorate-General for Research and Innovation: Luxembourg, 2021; pp. 1–44. [Google Scholar]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Li, L. China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0”. Technol. Forecast. Soc. Change 2018, 135, 66–74. [Google Scholar] [CrossRef]

- Sony, M.J.P.; Research, M. Industry 4.0 and lean management: A proposed integration model and research propositions. Prod. Manuf. Res. 2018, 6, 416–432. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industrie 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Sung, T.K. Industry 4.0: A Korea perspective. Technol. Forecast. Soc. Change 2018, 132, 40–45. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0; Acatech—National Academy of Science and Engineering: Munich, Germany, 2013. [Google Scholar]

- Öberg, C.; Graham, G. How smart cities will change supply chain management: A technical viewpoint. Prod. Plan. Control. 2016, 27, 529–538. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Subramanian, N.; Ngai, W.T.E. Quality Management in the 21st Century Enterprises: Research Pathway Towards Industry 4.0; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Vaidya, S.; Ambad, P.; Bhosle, S.J. Industry 4.0—A glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Salkin, C.; Oner, M.; Ustundag, A.; Cevikcan, E. A conceptual framework for Industry 4.0. In Industry 4.0: Managing the Digital Transformation; Springer: Cham, Switzerland, 2018; pp. 3–23. [Google Scholar]

- Lin, W.; Low, M.Y.; Chong, Y.; Teo, C. Application of SIRI for industry 4.0 maturity assessment and analysis. In Proceedings of the 2019 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macao, China, 15–18 December 2019; pp. 1450–1454. [Google Scholar]

- Schuh, G.; Anderl, R.; Gausemeier, J.; ten Hompel, M.; Wahlster, W. Industrie 4.0 Maturity Index. Manag. Digit. Transform. companies. 2017. Munich Herbert Utz 61. Available online: https://www.acatech.de/wp-content/uploads/2018/03/acatech_STUDIE_Maturity_Index_eng_WEB.pdf (accessed on 1 October 2025).

- Govindan, K.; Kannan, D.; Mathiyazhagan, K.; Jabbour, A.B.L.d.S.; Jabbour, C.J.C.J. Analysing green supply chain management practices in Brazil’s electrical/electronics industry using interpretive structural modelling. Int. J. Environ. Stud. 2013, 70, 477–493. [Google Scholar] [CrossRef]

- Wu, C.; Barnes, D.J. An integrated model for green partner selection and supply chain construction. J. Clean. Prod. 2016, 112, 2114–2132. [Google Scholar] [CrossRef]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Jafarian, A.; Diabat, A. Integrated fuzzy multi criteria decision making method and multi-objective programming approach for supplier selection and order allocation in a green supply chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Beikkhakhian, Y.; Javanmardi, M.; Karbasian, M.; Khayambashi, B. The application of ISM model in evaluating agile suppliers selection criteria and ranking suppliers using fuzzy TOPSIS-AHP methods. Expert Syst. Appl. 2015, 42, 6224–6236. [Google Scholar] [CrossRef]

- Onat, N.C.; Gumus, S.; Kucukvar, M.; Tatari, O. Application of the TOPSIS and intuitionistic fuzzy set approaches for ranking the life cycle sustainability performance of alternative vehicle technologies. Sustain. Prod. Consum. 2016, 6, 12–25. [Google Scholar] [CrossRef]

- Yu, X.; Suntrayuth, S.; Su, J. A comprehensive evaluation method for industrial sewage treatment projects based on the improved entropy-topsis. Sustainability 2020, 12, 6734. [Google Scholar] [CrossRef]

- Trung, D.; Nhu-Tung, N. Applying Cocoso, Mabac, Mairca, Eamr, Topsis and weight determination methods for multi-criteria decision making in hole turning process. Stroj. Časopis J. Mech. Eng. 2022, 72, 15–40. [Google Scholar]

- Yin, S.; Zhang, N.; Ullah, K.; Gao, S.J.S. Enhancing Digital Innovation for the Sustainable Transformation of Manufacturing Industry: A Pressure-State-Response System Framework to Perceptions of Digital Green Innovation and Its Performance for Green and Intelligent Manufacturing. Systems 2022, 10, 72. [Google Scholar] [CrossRef]

- Hund, A.; Wagner, H.T.; Beimborn, D.; Weitzel, T. Digital innovation: Review and novel perspective. J. Strateg. Inf. Syst. 2021, 30, 101695. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V.J. Scanning the industry 4.0: A literature review on technologies for manufacturing systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Ghobakhloo, M.J. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Ko, M.; Kim, C.; Lee, S.; Cho, Y.J. An assessment of smart factories in Korea: An exploratory empirical investigation. Appl. Sci. 2020, 10, 7486. [Google Scholar] [CrossRef]

- Parhi, S.; Joshi, K.; Akarte, M.M. Smart manufacturing: A framework for managing performance. Int. J. Comput. Integr. Manuf. 2021, 34, 227–256. [Google Scholar] [CrossRef]

- Dohale, V.; Gunasekaran, A.; Akarte, M.M.; Verma, P.J. 52 Years of manufacturing strategy: An evolutionary review of literature (1969–2021). Int. J. Prod. Res. 2022, 60, 569–594. [Google Scholar] [CrossRef]

- Abdullah, F.M.; Al-Ahmari, A.M.; Anwar, S. Analyzing Interdependencies among Influencing Factors in Smart Manufacturing. Sustainability 2023, 15, 3864. [Google Scholar] [CrossRef]

- Al-Fuqaha, A.; Guizani, M.; Mohammadi, M.; Aledhari, M.; Ayyash, M.J. Internet of things: A survey on enabling technologies, protocols, and applications. IEEE Commun. Surv. Tutor. 2015, 17, 2347–2376. [Google Scholar] [CrossRef]

- Abdullah, F.M.; Saleh, M.; Al-Ahmari, A.M.; Anwar, S.J. The Impact of Industry 4.0 Technologies on Manufacturing Strategies: Proposition of Technology-Integrated Selection. IEEE Access 2022, 10, 21574–21583. [Google Scholar] [CrossRef]

- Savaglio, C.; Mazzei, P.; Fortino, G. Edge intelligence for industrial iot: Opportunities and limitations. Procedia Comput. Sci. 2024, 232, 397–405. [Google Scholar] [CrossRef]

- Xu, X. From cloud computing to cloud manufacturing. Robot. Comput.-Integr. Manuf. 2012, 28, 75–86. [Google Scholar] [CrossRef]

- Mabkhot, M.M.; Ferreira, P.; Maffei, A.; Podržaj, P.; Mądziel, M.; Antonelli, D.; Lanzetta, M.; Barata, J.; Boffa, E.; Finžgar, M.J. Mapping Industry 4.0 Enabling Technologies into United Nations Sustainability Development Goals. Sustainability 2021, 13, 2560. [Google Scholar] [CrossRef]

- LaValle, S.; Lesser, E.; Shockley, R.; Hopkins, M.S.; Kruschwitz, N.J. Big data, analytics and the path from insights to value. MIT Sloan Manag. Rev. 2011, 52, 21–32. [Google Scholar]

- Esmaeilian, B.; Behdad, S.; Wang, B.J. The evolution and future of manufacturing: A review. J. Manuf. Syst. 2016, 39, 79–100. [Google Scholar] [CrossRef]

- Abdullah, F.M.; Anwar, S.; Al-Ahmari, A. Thermomechanical simulations of residual stresses and distortion in electron beam melting with experimental validation for Ti-6Al-4V. Metals 2020, 10, 1151. [Google Scholar] [CrossRef]

- Yew, A.; Ong, S.; Nee, A.Y.J. Towards a griddable distributed manufacturing system with augmented reality interfaces. Robot. Comput.-Integr. Manuf. 2016, 39, 43–55. [Google Scholar] [CrossRef]

- Palmirini, R.; Erkoyuncu, J.A.; Roy, R.J. An innovative process to select Augmented Reality (AR) technology for maintenance. Procedia CIRP 2017, 59, 23–28. [Google Scholar] [CrossRef]

- Kocian, J.; Tutsch, M.; Ozana, S.; Koziorek, J. Application of modeling and simulation techniques for technology units in industrial control. In Frontiers in Computer Education; Springer: Cham, Switzerland, 2012; pp. 491–499. [Google Scholar]

- Monostori, L.J. Cyber-physical production systems: Roots, expectations and R&D challenges. Procedia CIRP 2014, 17, 9–13. [Google Scholar]

- Adamson, G.; Wang, L.; Moore, P.J. Feature-based control and information framework for adaptive and distributed manufacturing in cyber physical systems. J. Manuf. Syst. 2017, 43, 305–315. [Google Scholar] [CrossRef]

- Piedrahita, A.F.M.; Gaur, V.; Giraldo, J.; Cardenas, A.A.; Rueda, S.J. Virtual incident response functions in control systems. Comput. Netw. 2018, 135, 147–159. [Google Scholar] [CrossRef]

- Abeyratne, S.A.; Monfared, R.P. Blockchain ready manufacturing supply chain using distributed ledger. Int. J. Res. Eng. Technol. 2016, 5, 1–10. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Pradhan, N.; Macias de Anda, E.; Trevino Martinez, S.; Sawhney, R.; Kumar, M. Designing lean value streams in the fourth industrial revolution era: Proposition of technology-integrated guidelines. Int. J. Prod. Res. 2020, 58, 5020–5033. [Google Scholar] [CrossRef]

- Baker, J.; Lovell, K.; Harris, N. How expert are the experts? An exploration of the concept of ‘expert’ within Delphi panel techniques. Nurse Res. 2006, 14, 59–70. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fettermann, D.J. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Jumarni, R.F.; Zamri, N. An integration of fuzzy TOPSIS and fuzzy logic for multi-criteria decision making problems. Int. J. Eng. Technol. 2018, 7, 102–106. [Google Scholar] [CrossRef][Green Version]

- Basahel, A.; Taylan, O. Using fuzzy AHP and fuzzy TOPSIS approaches for assessing safety conditions at worksites in construction industry. Int. J. Saf. Secur. Eng. 2016, 6, 728–745. [Google Scholar] [CrossRef]

- Chen, C.-T. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst. 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Carnero, M.C. Developing a fuzzy TOPSIS model combining MACBETH and fuzzy shannon entropy to select a gamification App. Mathematics 2021, 9, 1034. [Google Scholar] [CrossRef]

- Sanislav, T.; Miclea, L. Cyber-physical systems-concept, challenges and research areas. J. Control. Eng. Appl. Inform. 2012, 14, 28–33. [Google Scholar]

- Nwankwo, C.O.; Chikwendu, O.C.; Igbokwe, N.C. Enhancing smart manufacturing supply chains through cybersecurity measures. Int. J. Eng. Invent. 2024, 13, 1–6, NISTIR 8107. [Google Scholar]

- Lu, Y.; Morris, K.C.; Frechette, S. Current standards landscape for smart manufacturing systems. National Institute of Standards and Technology, NISTIR 2016, 8107, 1–39. [Google Scholar]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Sezer, O.B.; Dogdu, E.; Ozbayoglu, A.M. Context-Aware Computing, Learning, and Big Data in Internet of Things: A Survey. IEEE Internet Things J. 2017, 5, 1–27. [Google Scholar] [CrossRef]

| SIRI | Dimensions | Rep. | Definition |

|---|---|---|---|

| Process | Vertical Integration | SIRI-1 | Vertical integration is the process of creating a connected, end-to-end data thread within a facility by integrating systems and processes at all hierarchical levels of the automation pyramid. |

| Horizontal Integration | SIRI-2 | Enterprise processes are integrated horizontally with stakeholders along the value chain and throughout the organization. | |

| Integrated Product Lifecycle | SIRI-3 | Integrated Product Cycle is the process of integrating people, processes, and systems throughout the product lifecycle, including design and development, engineering, production, customer use, service, and disposal. In this section, we will explore some of the more common questions that arise in the field of e-commerce, including how to use e-commerce in a sustainable manner. | |

| Technology | Shop Floor Automation | SIRI-4 | The use of technology to oversee, manage, and carry out the production and delivery of goods and services within the site where these activities are conducted is known as shop floor automation. |

| Enterprise Automation | SIRI-5 | Enterprise automation refers to the use of technology in the administrative work environment to monitor, control, and carry out processes. Demand planning, procurement, sales and marketing, and human resource management and planning are a few examples of these procedures. | |

| Facility Automation | SIRI-6 | The application of technology to the physical building and/or premises where the production area is located, in order to monitor, control, and automate processes, is known as facility automation. These procedures cover the control of lighting, security, HVAC, and chiller systems, among others. | |

| Shop Floor Connectivity | SIRI-7 | The process of connecting machinery, equipment, and computer-based systems to facilitate communication and smooth data exchange within the area where goods are produced and managed is known as shop floor connectivity. | |

| Enterprise Connectivity | SIRI-8 | The interconnection of machinery, computers, and other equipment to facilitate communication and smooth data exchange within the facility where administrative tasks are performed is known as enterprise connectivity. | |

| Facility Connectivity | SIRI-9 | The process of connecting machinery, equipment, and computer-based systems within the actual building and/or the plot of land where the production area is situated, in order to facilitate communication and smooth data exchange, is known as facility connectivity. | |

| Shop Floor Intelligence | SIRI-10 | Shop floor intelligence refers to the processing and analysis of data in the area where goods are produced and managed, to optimize current procedures and develop new applications, goods, and services. | |

| Enterprise Intelligence | SIRI-11 | The processing and analysis of data to develop new applications, goods, and services, as well as optimize current administrative procedures, is known as enterprise intelligence. | |

| Facility Intelligence | SIRI-12 | The processing and analysis of data within the actual building and grounds where the production area is situated, in order to optimize current processes and develop new applications, goods, and services, is known as facility intelligence. | |

| Organization | Workforce Learning & Development | SIRI-13 | The system of procedures and initiatives known as “workforce learning and development,” or “L&D,” aims to enhance the workforce’s competencies, abilities, and skills, ultimately achieving organizational excellence. |

| Leadership Competency | SIRI-14 | The ability of the management core to use the newest trends and technologies to maintain the organization’s relevance and competitiveness is referred to as leadership competency. | |

| Inter- & Intra-Company Collaboration | SIRI-15 | The process of cooperating with external partners and cross-functional teams to accomplish a common goal is known as intra- and inter-company collaboration. | |

| Strategy & Governance | SIRI-16 | The creation and implementation of a plan of action to accomplish several long-term objectives is known as strategy and governance. To convert a vision into business value, it entails setting priorities, creating a roadmap, and creating a set of guidelines, procedures, and practices. |

| Scale | The Extent of the Influence | Fuzzy Triangular Number |

|---|---|---|

| VH | Very high influence | 7.00 9.00 9.00 |

| H | High influence | 5.00 7.00 9.00 |

| M | Medium influence | 3.00 5.00 7.00 |

| L | Low influence | 1.00 3.00 5.00 |

| VL | Very Low influence | 1.00 1.00 3.00 |

| I4.0 | SIRI-1 | SIRI-2 | SIRI-3 | SIRI-4 | SIRI-5 | SIRI-6 | SIRI-7 | SIRI-8 | SIRI-9 | SIRI-10 | SIRI-11 | SIRI-12 | SIRI-13 | SIRI-14 | SIRI-15 | SIRI-16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IoT | VH | H | H | VH | H | VH | VH | VH | VH | VH | H | H | M | M | H | H |

| CM | H | VH | H | M | VH | H | H | VH | H | M | VH | H | H | H | VH | VH |

| BD | H | H | VH | M | H | M | H | H | H | VH | VH | VH | H | VH | H | VH |

| AIR | H | M | H | VH | H | VH | H | M | H | H | M | H | H | M | M | H |

| AM | M | H | VH | H | M | H | M | M | M | H | H | M | VH | H | H | H |

| AR | M | L | H | H | M | H | M | M | M | H | M | H | VH | H | H | M |

| MS | H | H | VH | H | H | H | M | H | M | VH | VH | H | H | H | H | H |

| CPS | VH | VH | VH | VH | H | VH | VH | VH | VH | VH | VH | VH | H | H | H | VH |

| CS | H | H | M | H | VH | H | VH | VH | VH | H | VH | H | VH | VH | H | VH |

| BC | M | VH | H | L | M | L | M | H | M | L | H | L | H | H | VH | H |

| I4.0 | SIRI-1 | SIRI-2 | SIRI-3 | SIRI-4 | SIRI-5 | SIRI-6 | SIRI-7 | SIRI-8 | SIRI-9 | SIRI-10 | SIRI-11 | SIRI-12 | SIRI-13 | SIRI-14 | SIRI-15 | SIRI-16 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IoT | 0.000 | 0.385 | 0.035 | 0.047 | 0.012 | 0.093 | 0.000 | 0.058 | 0.146 | 0.070 | 0.130 | 0.141 | 0.035 | 0.082 | 0.035 | 0.152 | 1.421 |

| CM | 0.292 | 0.261 | 0.082 | 0.181 | 0.035 | 0.093 | 0.093 | 0.082 | 0.152 | 0.140 | 0.146 | 0.159 | 0.070 | 0.105 | 0.035 | 0.173 | 2.100 |

| BD | 0.304 | 0.166 | 0.128 | 0.208 | 0.105 | 0.128 | 0.070 | 0.082 | 0.173 | 0.082 | 0.159 | 0.166 | 0.082 | 0.093 | 0.070 | 0.152 | 2.167 |

| AIR | 0.282 | 0.266 | 0.093 | 0.133 | 0.012 | 0.000 | 0.058 | 0.140 | 0.173 | 0.117 | 0.181 | 0.190 | 0.070 | 0.187 | 0.093 | 0.141 | 2.136 |

| AM | 0.282 | 0.152 | 0.105 | 0.199 | 0.105 | 0.082 | 0.047 | 0.082 | 0.047 | 0.023 | 0.023 | 0.093 | 0.012 | 0.117 | 0.093 | 0.000 | 1.461 |

| AR | 0.332 | 0.423 | 0.082 | 0.173 | 0.152 | 0.128 | 0.181 | 0.199 | 0.173 | 0.082 | 0.181 | 0.146 | 0.058 | 0.152 | 0.082 | 0.159 | 2.702 |

| MS | 0.311 | 0.217 | 0.175 | 0.208 | 0.128 | 0.140 | 0.208 | 0.070 | 0.217 | 0.140 | 0.181 | 0.173 | 0.035 | 0.152 | 0.093 | 0.173 | 2.621 |

| CPS | 0.261 | 0.257 | 0.000 | 0.000 | 0.023 | 0.105 | 0.000 | 0.035 | 0.128 | 0.000 | 0.000 | 0.000 | 0.012 | 0.058 | 0.000 | 0.137 | 1.015 |

| CS | 0.266 | 0.137 | 0.058 | 0.166 | 0.000 | 0.047 | 0.023 | 0.000 | 0.133 | 0.035 | 0.129 | 0.159 | 0.000 | 0.000 | 0.035 | 0.137 | 1.324 |

| BC | 0.317 | 0.082 | 0.187 | 0.226 | 0.140 | 0.266 | 0.190 | 0.140 | 0.181 | 0.140 | 0.173 | 0.269 | 0.082 | 0.128 | 0.117 | 0.152 | 2.790 |

| I4.0 | SIRI-1 | SIRI-2 | SIRI-3 | SIRI-4 | SIRI-5 | SIRI-6 | SIRI-7 | SIRI-8 | SIRI-9 | SIRI-10 | SIRI-11 | SIRI-12 | SIRI-13 | SIRI-14 | SIRI-15 | SIRI-16 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IoT | 0.332 | 0.163 | 0.152 | 0.190 | 0.140 | 0.190 | 0.208 | 0.159 | 0.105 | 0.070 | 0.105 | 0.190 | 0.047 | 0.105 | 0.082 | 0.035 | 2.271 |

| CM | 0.070 | 0.181 | 0.105 | 0.058 | 0.117 | 0.190 | 0.146 | 0.146 | 0.093 | 0.000 | 0.058 | 0.166 | 0.012 | 0.082 | 0.082 | 0.000 | 1.506 |

| BD | 0.047 | 0.266 | 0.058 | 0.023 | 0.047 | 0.166 | 0.159 | 0.146 | 0.058 | 0.058 | 0.035 | 0.159 | 0.000 | 0.093 | 0.047 | 0.035 | 1.397 |

| AIR | 0.093 | 0.166 | 0.093 | 0.152 | 0.140 | 0.266 | 0.166 | 0.129 | 0.058 | 0.023 | 0.000 | 0.141 | 0.012 | 0.000 | 0.023 | 0.058 | 1.521 |

| AM | 0.093 | 0.273 | 0.082 | 0.035 | 0.047 | 0.199 | 0.173 | 0.146 | 0.181 | 0.117 | 0.166 | 0.210 | 0.070 | 0.070 | 0.023 | 0.173 | 2.058 |

| AR | 0.000 | 0.000 | 0.105 | 0.070 | 0.000 | 0.166 | 0.035 | 0.000 | 0.058 | 0.058 | 0.000 | 0.181 | 0.023 | 0.035 | 0.035 | 0.023 | 0.790 |

| MS | 0.035 | 0.257 | 0.012 | 0.023 | 0.023 | 0.159 | 0.000 | 0.152 | 0.000 | 0.000 | 0.000 | 0.152 | 0.047 | 0.035 | 0.023 | 0.000 | 0.918 |

| CPS | 0.163 | 0.217 | 0.187 | 0.226 | 0.128 | 0.181 | 0.208 | 0.173 | 0.175 | 0.140 | 0.181 | 0.269 | 0.070 | 0.128 | 0.117 | 0.070 | 2.634 |

| CS | 0.140 | 0.287 | 0.128 | 0.082 | 0.152 | 0.226 | 0.190 | 0.199 | 0.140 | 0.105 | 0.117 | 0.166 | 0.082 | 0.187 | 0.082 | 0.070 | 2.351 |

| BC | 0.023 | 0.396 | 0.000 | 0.000 | 0.012 | 0.000 | 0.023 | 0.129 | 0.047 | 0.000 | 0.012 | 0.000 | 0.000 | 0.058 | 0.000 | 0.035 | 0.735 |

| I4.0 T. | Rank | |||

|---|---|---|---|---|

| IoT | 1.421 | 2.271 | 0.6150 | 3 |

| CM | 2.100 | 1.506 | 0.4177 | 5 |

| BD | 2.167 | 1.397 | 0.3919 | 7 |

| AIR | 2.136 | 1.521 | 0.4158 | 6 |

| AM | 1.461 | 2.058 | 0.5849 | 4 |

| AR | 2.702 | 0.790 | 0.2263 | 9 |

| MS | 2.621 | 0.918 | 0.2593 | 8 |

| CPS | 1.015 | 2.634 | 0.7218 | 1 |

| CS | 1.324 | 2.351 | 0.6398 | 2 |

| BC | 2.790 | 0.735 | 0.2085 | 10 |

| Process | Technology | Organization | |

|---|---|---|---|

| Scenario#1 | Every weight is the same: 1/n can complete this one, where n is the number of dimensions. | ||

| Scenario#2 | 33.33% of the total weight is assigned for process dimensions (33.33/3) | 33.33% of the total weight is assigned for Technology dimensions (33.33/9) | 33.33% of the total weight is assigned for Organization dimensions (33.33/9) |

| Scenario#3 | 20% | 50% | 30% |

| Scenario#4 | 25% | 40% | 35% |

| I4.0 tech. | Scenario#1 | Scenario#2 | Scenario#3 | Scenario#4 | ||||

|---|---|---|---|---|---|---|---|---|

| Closeness Coefficients | Rank | Closeness Coefficients | Rank | Closeness Coefficients | Rank | Closeness Coefficients | Rank | |

| IoT | 0.6150 | 3 | 0.5962 | 3 | 0.6075 | 3 | 0.5976 | 3 |

| CM | 0.4177 | 5 | 0.3879 | 5 | 0.4097 | 5 | 0.3961 | 5 |

| BD | 0.3919 | 7 | 0.3792 | 6 | 0.3871 | 7 | 0.3806 | 6 |

| AIR | 0.4158 | 6 | 0.3676 | 7 | 0.4000 | 6 | 0.3764 | 7 |

| AM | 0.5849 | 4 | 0.5455 | 4 | 0.5792 | 4 | 0.5636 | 4 |

| AR | 0.2263 | 9 | 0.1887 | 10 | 0.2197 | 9 | 0.2042 | 10 |

| MS | 0.2593 | 8 | 0.2648 | 9 | 0.2579 | 8 | 0.2590 | 8 |

| CPS | 0.7218 | 1 | 0.6485 | 1 | 0.7076 | 1 | 0.6768 | 1 |

| CS | 0.6398 | 2 | 0.6187 | 2 | 0.6387 | 2 | 0.6313 | 2 |

| BC | 0.2085 | 10 | 0.2699 | 8 | 0.2168 | 10 | 0.2409 | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdullah, F.M.; Al-Ahmari, A.M. Analyzing the Smart Industry Readiness Index in Adopting Industry 4.0 Technologies. Processes 2025, 13, 3172. https://doi.org/10.3390/pr13103172

Abdullah FM, Al-Ahmari AM. Analyzing the Smart Industry Readiness Index in Adopting Industry 4.0 Technologies. Processes. 2025; 13(10):3172. https://doi.org/10.3390/pr13103172

Chicago/Turabian StyleAbdullah, Fawaz M., and Abdulrahman M. Al-Ahmari. 2025. "Analyzing the Smart Industry Readiness Index in Adopting Industry 4.0 Technologies" Processes 13, no. 10: 3172. https://doi.org/10.3390/pr13103172

APA StyleAbdullah, F. M., & Al-Ahmari, A. M. (2025). Analyzing the Smart Industry Readiness Index in Adopting Industry 4.0 Technologies. Processes, 13(10), 3172. https://doi.org/10.3390/pr13103172