Based on practical operational experience, four key control parameters—lance gas flow rate, lance height, hot metal charge mass, and flux addition amount—are known to significantly influence the mass transfer coefficients in the kinetic reactions of element removal during BOF steelmaking [

26]. Therefore, to improve the prediction accuracy of the theoretical decarburization kinetic model and enhance its applicability to real-world production conditions, this study integrates these operational control parameters into the existing two-zone decarburization model. This integration enables the model to better reflect actual process dynamics, effectively avoid abnormal operating conditions and product quality issues, and significantly improve production efficiency [

27].

4.1. Revised Kinetic Model for the Jet Impact Zone

Fitting analysis of actual plant data reveals that the hot metal charge mass (

M0) directly affects the physicochemical characteristics of the molten bath—such as temperature distribution and fluid flow behavior—thereby altering the thickness of the mass transfer boundary layer and the diffusion pathways of elements [

28]. As

M0 increases, the thermal capacity of the bath rises, leading to changes in jet penetration depth and energy distribution during blowing. To account for this effect, the mass transfer coefficient is dynamically corrected using

M0. To enhance model robustness [

29] and improve its adaptability to variations in raw material inputs, the hot metal mass

M0 is introduced as a scaling factor to quantify the impact of different hot metal batches on mass transfer efficiency.

In addition, during actual operation, lance height (

h) is frequently adjusted in response to bath level changes and different blowing stages, significantly influencing the decarburization kinetics. The lance height fundamentally governs the momentum transfer from the oxygen jet to the molten bath, directly affecting the size and stability of the impact crater, emulsion formation, and interfacial area between metal and slag. A higher lance reduces penetration depth, promoting slag foaming and reducing iron oxidation, while a lower lance intensifies jet penetration, enhancing carbon-oxygen reaction rates in the emulsion zone. These hydrodynamic and interfacial effects critically determine the decarburization rate and must be captured in the kinetic model for accurate process representation. Therefore, incorporating the lance height parameter into the kinetic theoretical model is essential. Operators can use real-time lance height measurements to dynamically update model parameters, enabling adaptive simulation across varying operational conditions [

30]. The correction functions for

M0 and

h are formulated in power-law form based on dimensional analysis and analogy to turbulent jet penetration and mass transfer scaling laws in multiphase reactors. The exponents aa and b are determined through regression on industrial data, but their physical interpretability is preserved:

a > 0 reflects increased mixing intensity with larger bath mass (up to saturation), while

b < 0 aligns with reduced jet penetration and interfacial area at higher lance positions. This semi-empirical approach ensures both model accuracy and consistency with underlying fluid dynamic principles.

By introducing correction factors for calibration, the revised mass transfer coefficient in the jet impact zone is expressed as:

where

DC: diffusion coefficient of carbon in metal droplets (unit: m

2/s);

ul: circulation renewal velocity of molten steel under top-blowing (unit: m/s);

Q: lance gas flow rate (unit: Nm

3/h); g: gravitational acceleration (unit: m/s

2);

Hbath: bath depth (unit: m);

rcm: impact crater radius (unit: m);

M0: hot metal charge mass (unit: kg);

a: empirical exponent for hot metal mass correction;

:calibration coefficient for the jet impact zone;

h: lance height above the bath (unit: m);

b: empirical constant for lance height adjustment.

A sensitivity analysis was conducted by varying M0 (±15% around nominal value) and h (±20%) while holding other inputs constant. Results show that a 10% increase in M0 leads to a 6.2% increase, consistent with enhanced bath mixing at larger charges. In contrast, a 10% increase in h by 8.5%, reflecting diminished jet penetration and interfacial area. These trends confirm that the model responds physically to operational changes, with lance height exerting a stronger influence than hot metal mass, which aligns with industrial observation.

4.2. Revised Kinetic Model for the Emulsion Zone

Based on slag-metal reaction thermodynamics and mass transfer principles [

31], the lime addition mass (

MLime) is introduced as a dynamic correction factor. Lime (CaO), as the primary flux, directly determines the slag basicity (R = CaO/SiO

2) [

32], which in turn influences key interfacial properties:

Interfacial tension: Lower interfacial tension enhances wettability and increases the effective slag-metal contact area;

Slag viscosity: Reduced viscosity facilitates mass transfer and element diffusion across phases.

By incorporating

MLime into the model, the dynamic impact of flux addition on the mass transfer process can be quantified, thereby addressing the discrepancy between the traditional assumption of constant basicity and the actual operational fluctuations observed in industrial practice [

33].

Combining analysis of industrial trial data, a revised mass transfer coefficient model considering the synergistic effect of stirring energy is established:

where

: mass transfer coefficient of carbon in the emulsion zone (unit: m/s);

DC: diffusion coefficient of carbon in the steel phase (unit: m

2/s);

u: velocity of metal droplets (unit: m/s);

d: average diameter of metal droplets (unit: m);

MLime: mass of lime flux added (unit: ton);

a: empirical exponent for lime addition, used as a calibration parameter.

While MLime serves as a practical proxy for basicity evolution, its effect is implicitly linked to measured or estimated SiO2 content from hot metal analysis, ensuring RR remains within a physically meaningful range. Temperature dependence is accounted for through the temperature-sensitive terms in the base mass transfer coefficient. In industrial applications, real-time temperature measurements (via sub-lance or estimation models) are used to update these parameters dynamically, ensuring the model captures the combined influence of slag chemistry and thermal state on decarburization kinetics.

4.3. Model Parameter Calibration and Accuracy Evaluation

The predicted end-point TSO from a machine learning-coupled model, along with other kinetic parameters, is used as input to the process prediction model. Through continuous comparison with actual BOF operational data, the kinetic model parameters are iteratively optimized, and the prediction accuracy is evaluated.

The iterative algorithm serves as the core of the process simulation, enabling self-adjustment during computation to progressively reduce prediction error. In this study, the forest_minimize function [

34] is employed, which uses a random forest-based surrogate model to locate the minimum of the objective function (e.g., weighted mean squared error). The optimization process demonstrates stable convergence, typically reaching a plateau within 150 iterations, with less than 0.5% improvement in the objective function thereafter. Robustness was assessed through 10 independent optimization runs, which yielded consistent optimal parameter sets, with a coefficient of variation (CV) of less than 2% across runs. These results confirm that the algorithm is both convergent and robust under stochastic variations. The 9199 cleaned samples from the training set are used for parameter optimization of the control-parameter-integrated kinetic model, while the 2300 samples in the test set are used to assess the final model accuracy.

Through iterative searching, the optimal parameter set that minimizes the prediction error is identified. Combined with the physical parameters listed in

Table 9,

Table 12 (presented below) summarizes the calibrated control-parameter-integrated kinetic parameters for each reaction zone, obtained through cyclic fitting of the decarburization kinetic model.

The calibrated parameters in the control-parameter-integrated kinetic model, while optimized using data-driven methods, are not merely empirical fitting constants but carry clear physical and metallurgical significance rooted in the underlying process dynamics. The hot metal charge mass exponent of 0.75 reflects the sub-linear enhancement of mass transfer with increasing bath size, consistent with turbulent jet penetration theory—larger charges improve thermal stability and promote deeper oxygen jet penetration, yet wall effects and reduced relative momentum at excessive masses lead to diminishing returns in mixing efficiency. The lance height coefficient (0.0005) captures the inverse relationship between lance elevation and jet momentum, where higher positions reduce impingement energy, weaken bath agitation, and decrease interfacial reaction area, with the calibrated value aligning with observed reductions in decarburization rate during soft-blowing practices. Similarly, the correction coefficient for the jet impact zone (1.9 × 10−6) serves as a lumped parameter representing effective surface renewal frequency and boundary layer dynamics under top-blowing conditions, scaling the diffusion-limited flux to match realistic mass transfer intensities observed in high-energy gas-stirred systems. The inclusion of lime addition as a proxy for slag basicity further links operational practice to interfacial phenomena, as increased fluxing lowers slag viscosity and interfacial tension, thereby enhancing slag-metal contact and mass transfer rates. By constructing the correction functions based on dimensional analysis and hydrodynamic scaling laws, the model preserves mechanistic interpretability, ensuring that the optimized parameters represent measurable physical effects—such as mixing intensity, jet penetration depth, and emulsion stability—rather than arbitrary adjustments, thus bridging the gap between theoretical kinetics and industrial operational variability.

The optimized correction parameters obtained from the parameter tuning process are incorporated into the control-parameter-integrated decarburization kinetic model. Equations (8) and (9) below represent the kinetic models for the jet impact zone and emulsion zone during the BOF steelmaking process, respectively.

where

M0: hot metal charge mass (unit: t);

Q: lance gas flow rate (unit: Nm

3/min);

h: lance height above the bath (unit: m);

MLime: mass of flux added (unit: kg).

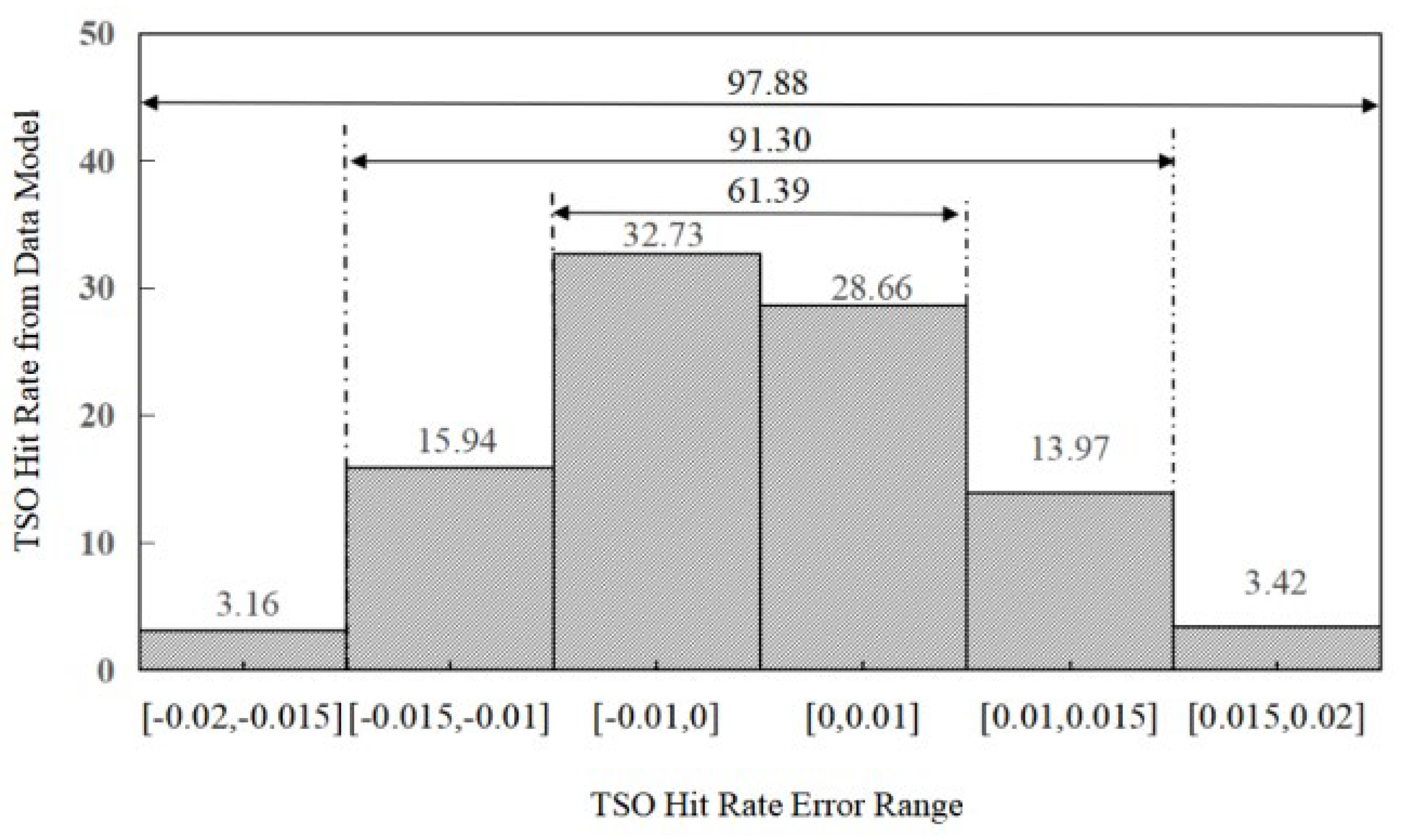

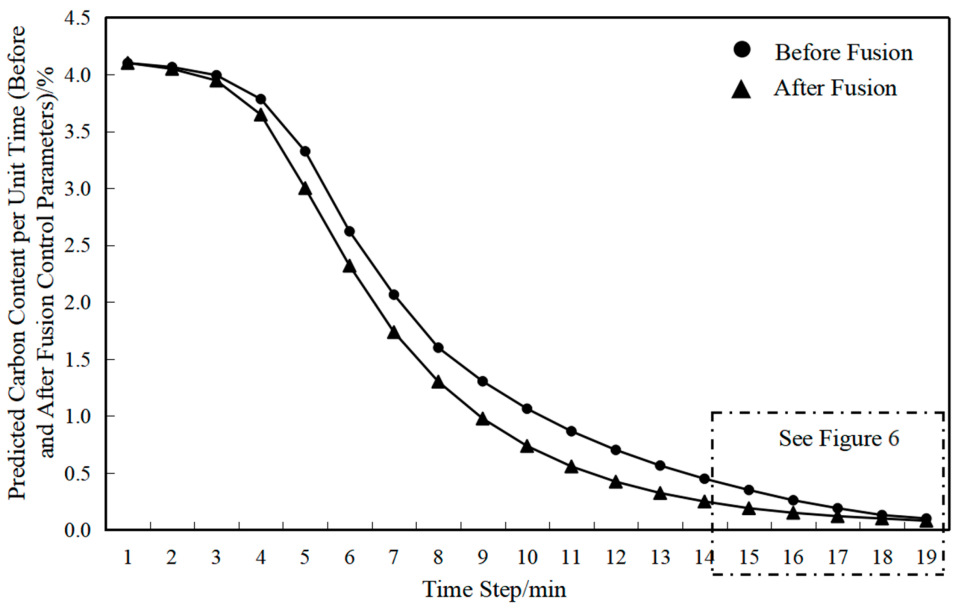

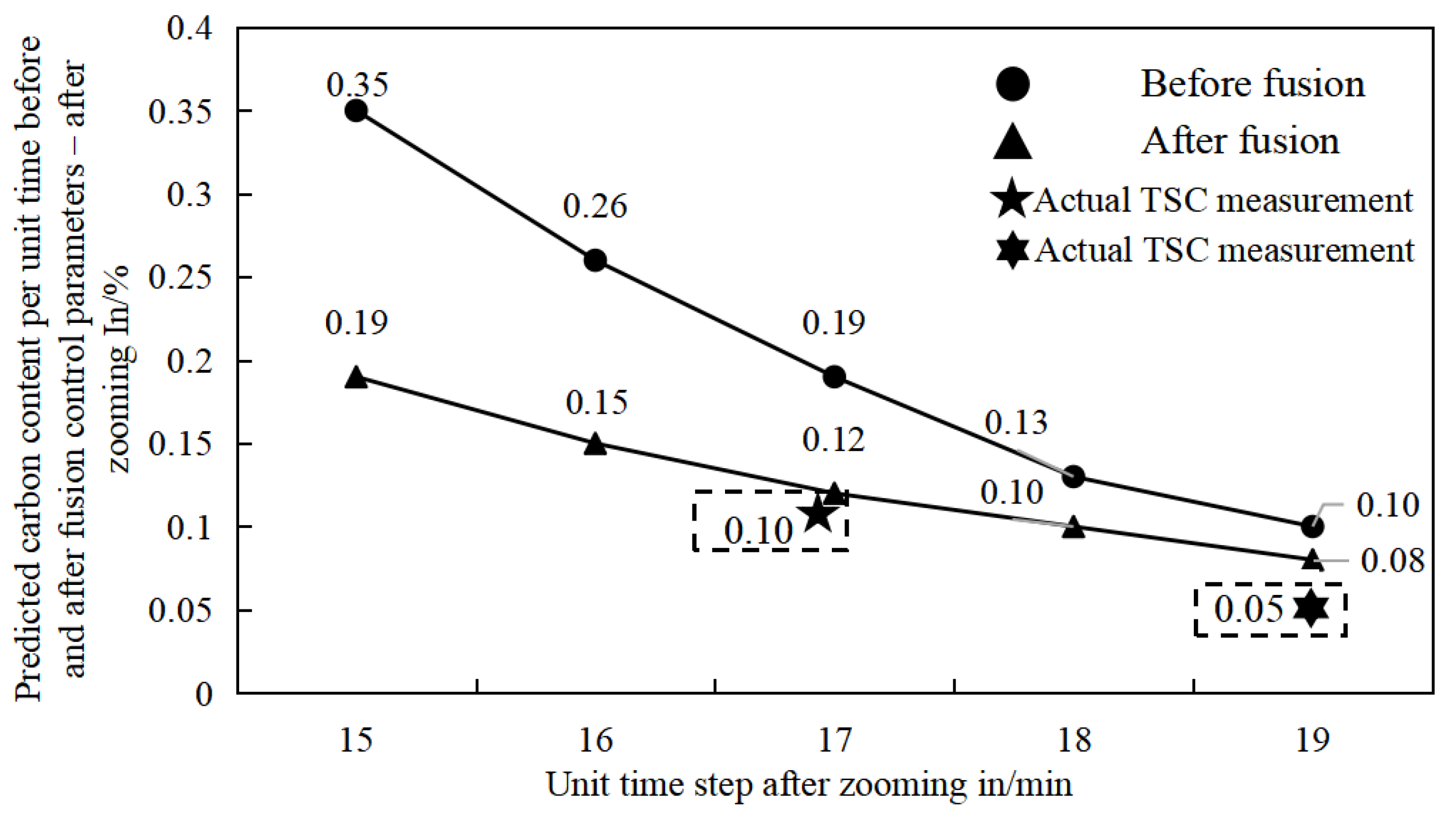

To evaluate the predictive capability of the control-parameter-integrated kinetic model, the dual-point hit rate at the mid-blowing stage (TSC, Tapping Sample Carbon before tapping) and at the end-point (TSO, final carbon content) is adopted as the core performance metric. The model’s prediction accuracy is systematically analyzed across different error tolerance bands. Taking a real production heat as an example, the following control parameter values are set: Hot metal charge mass: 220 t, Lance height range: 1.5–1.8 m, Lance flow rate: 282 Nm

3/min, Flux addition: 6500 kg. A comparison of the predicted carbon content (mass%) with and without integrated control parameters is presented in

Figure 5, with a close-up view of the mid- and end-point regions shown in

Figure 6.

At the TSC (mid-blowing carbon measurement) stage, the prediction error of the decarburization kinetic model with integrated control parameters is reduced by 0.07 wt% compared to the model without parameter integration. At the TSO (end-point carbon measurement) stage, the prediction error is reduced by 0.02 wt%. In the complex and dynamic industrial environment, appropriate parameter adjustment helps overcome the limitations of traditional models and provides more reliable predictions.

To ensure a rigorous evaluation of model performance, an independent validation dataset consisting of 2300 heats from a distinct time period (one month of production data not included in the training phase) was used to assess prediction accuracy. This temporal split ensures no data leakage and provides a realistic assessment of model generalization under industrial operating conditions. The reported hit rates and error reductions for TSC and TSO are computed on this held-out test set, rather than the training or calibration data. Furthermore, the consistency of performance improvements across multiple consecutive validation periods confirms the robustness of the proposed approach.

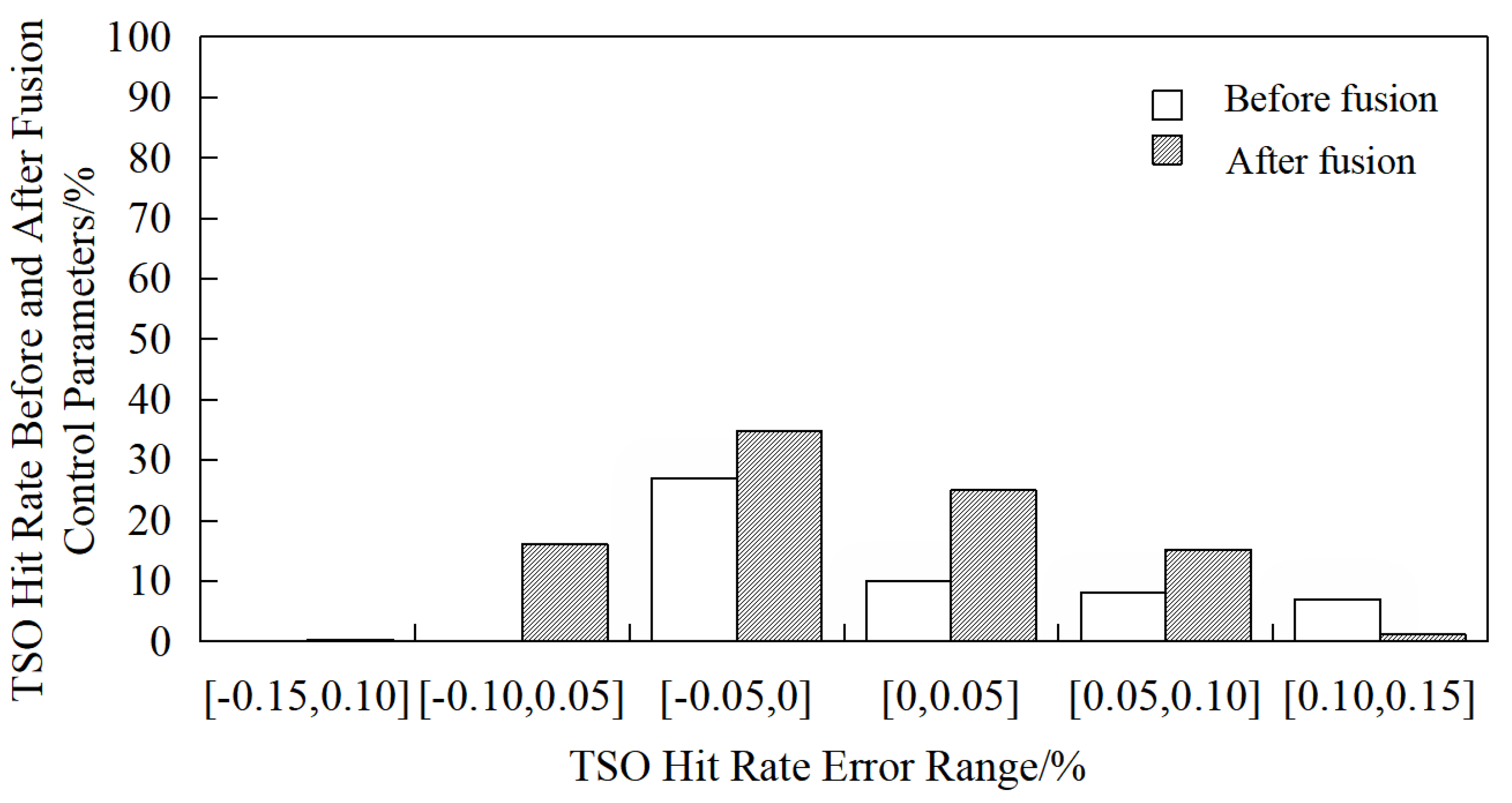

To evaluate the performance of the optimized model, the predicted TSO and TSC contents from the validation set are compared with actual production data, and the hit rates are calculated based on the absolute deviations. By inputting the actual process parameters for each heat, the hit rates for TSO and TSC before and after optimization are obtained. The comparative results are presented in

Figure 7 and

Figure 8, respectively.

The model achieves a 6.26% improvement in TSC hit rate within the error band of [−0.2, +0.2] wt%, and significant improvements in TSO hit rate: 21.30% increase within [−0.05, +0.05] wt%, 19.51% increase within [−0.15, +0.15] wt%. These results demonstrate the model’s enhanced capability in controlling and predicting end-point carbon content. This improvement is attributed to the synergistic optimization of mass transfer coefficients in both the jet impact zone and emulsion zone by the parameter tuning algorithm, particularly through the accurate calibration of the hot metal charge mass exponent and diffusion coefficient.