Temperature Profile from Parts Produced by Fused Filament Fabrication (FFF) Measured by In Situ Infrared Thermography

Abstract

1. Introduction

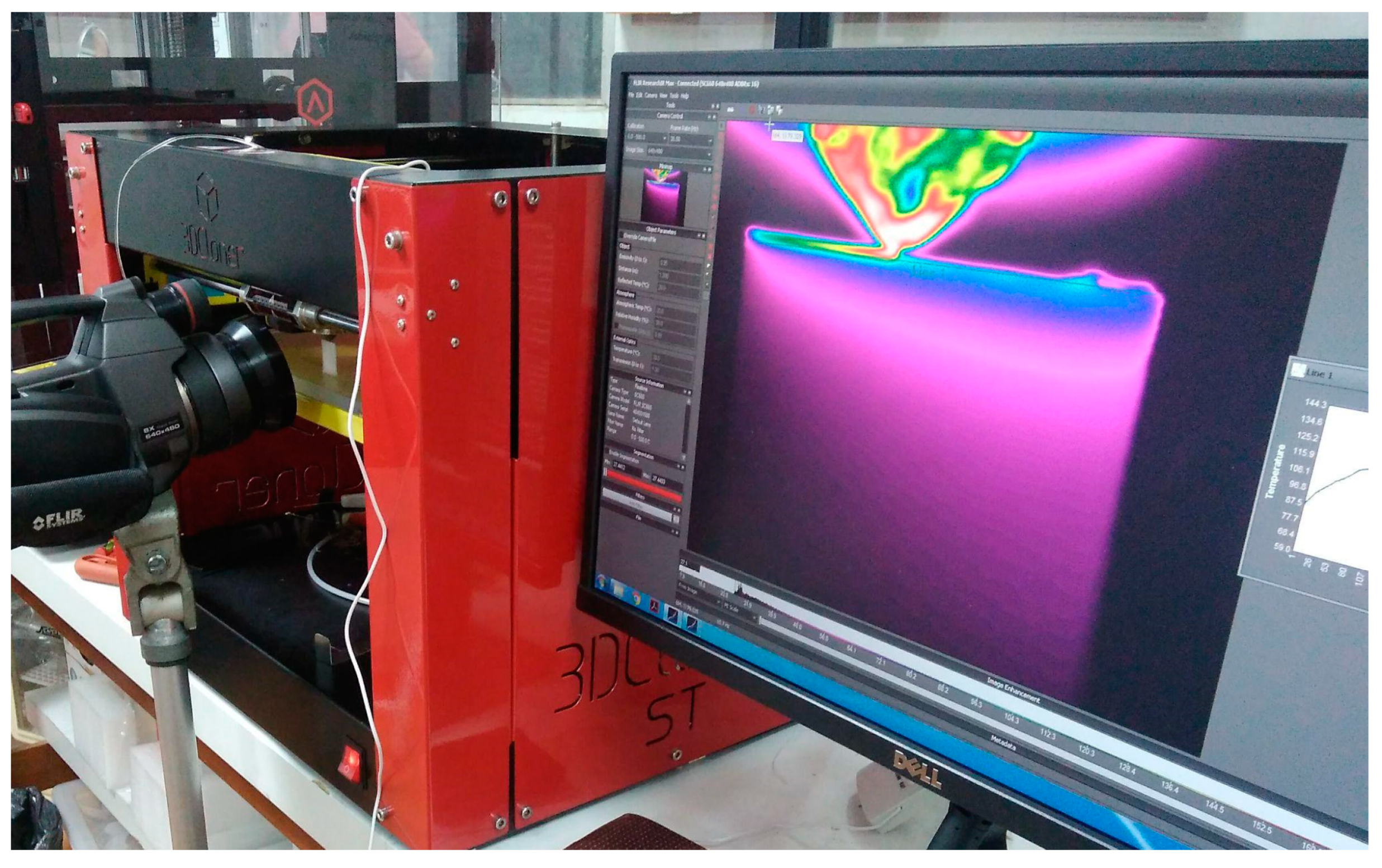

2. Materials and Methods

Static and Dynamic Thermographic Analysis

3. Results

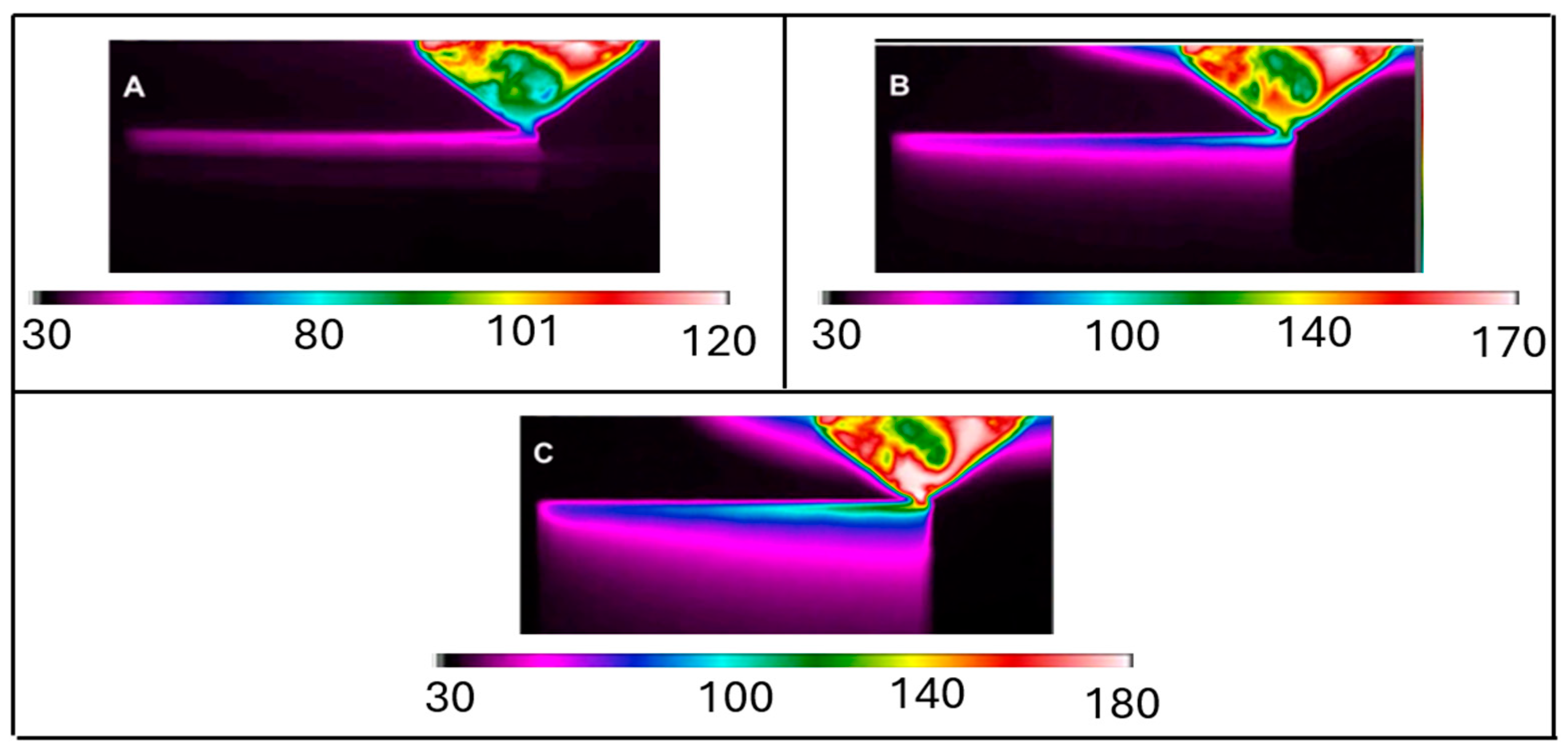

3.1. Qualitative Thermographic Analysis

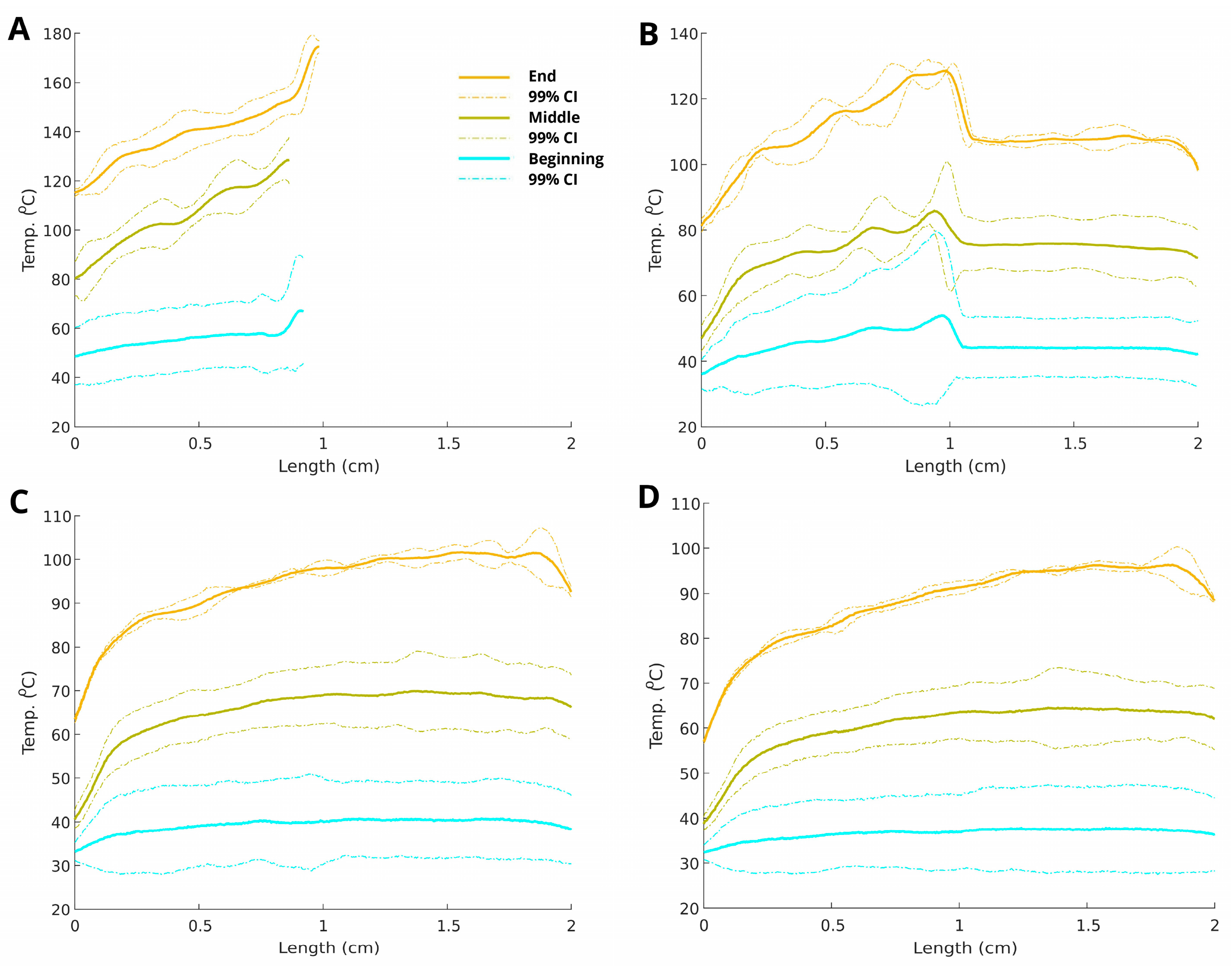

3.2. Static Thermographic Analysis

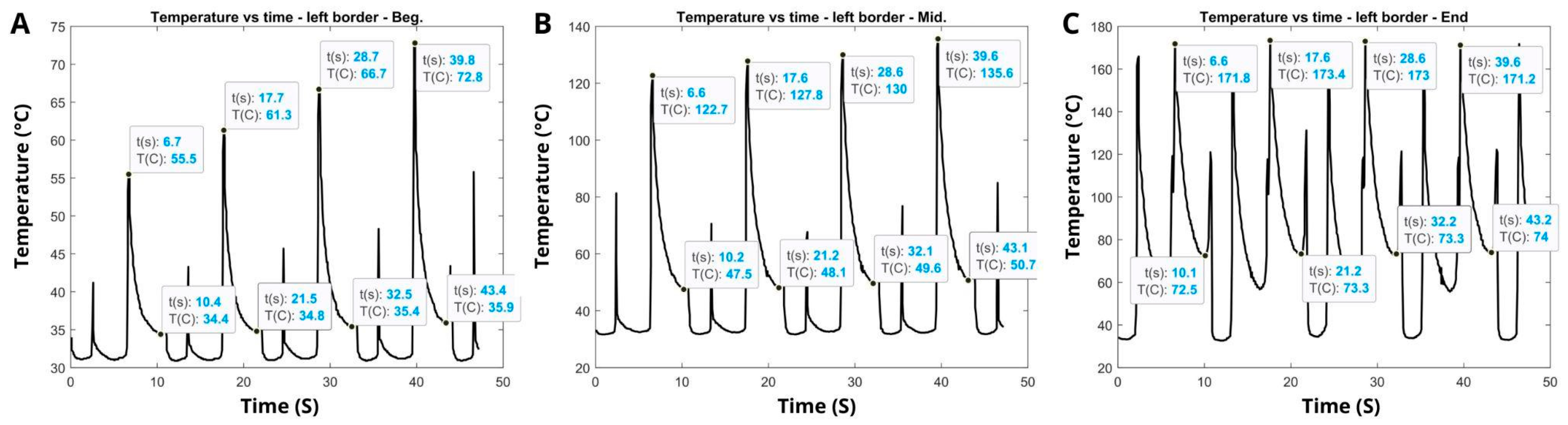

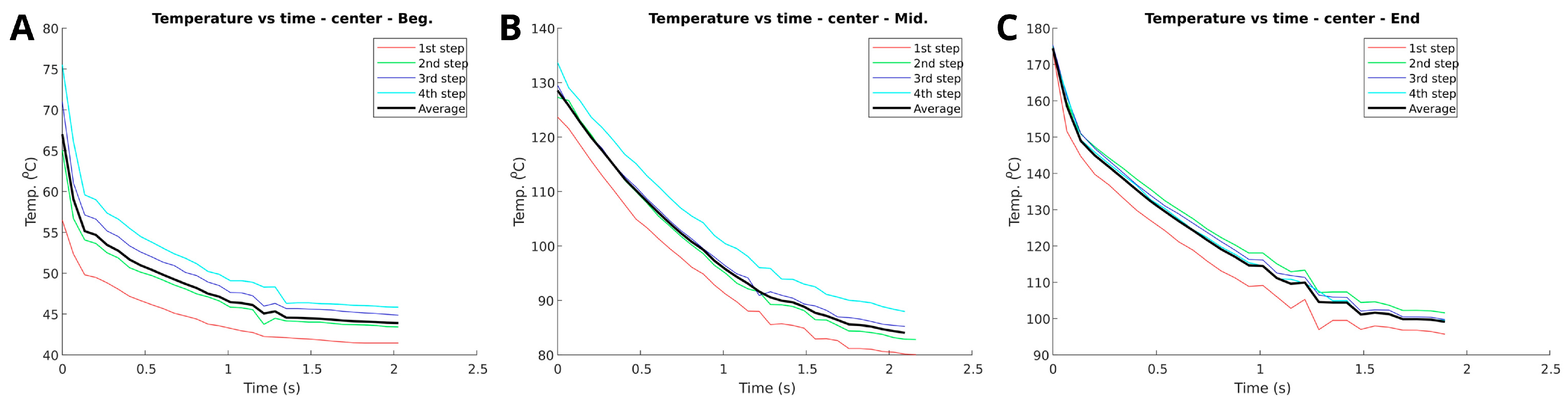

3.3. Dynamic Thermographic Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Balderrama-Armendariz, C.O.; MacDonald, E.; Espalin, D.; Cortes-Saenz, D.; Wicker, R.; Maldonado-Macias, A. Torsion analysis of the anisotropic behavior of FDM technology. Int. J. Adv. Manuf. Technol. 2018, 96, 307–317. [Google Scholar] [CrossRef]

- Montalvo Navarrete, J.I.; Hidalgo-Salazar, M.A.; Nunez, E.E.; Arciniegas, A.J.R. Thermal and mechanical behavior of biocomposites using additive manufacturing. Int. J. Interact. Des. Manuf. (IJIDeM) 2018, 12, 449–458. [Google Scholar] [CrossRef]

- Kollamaram, G.; Croker, D.M.; Walker, G.M.; Goyanes, A.; Basit, A.W.; Gaisford, S. Low temperature fused deposition modeling (FDM) 3D printing of thermolabile drugs. Int. J. Pharm. 2018, 545, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Tan, D.K.; Maniruzzaman, M.; Nokhodchi, A. Advanced Pharmaceutical Applications of Hot-Melt Extrusion Coupled with Fused Deposition Modelling (FDM) 3D Printing for Personalised Drug Delivery. Pharmaceutics 2018, 10, 203. [Google Scholar] [CrossRef] [PubMed]

- Bandinelli, F.; Peroni, L.; Morena, A. Elasto-Plastic Mechanical Modeling of Fused Deposition 3D Printing Materials. Polymers 2023, 15, 234. [Google Scholar] [CrossRef] [PubMed]

- Parker, M.; Inthavong, A.; Law, E.; Waddell, S.; Ezeokeke, N.; Matsuzaki, R.; Arola, D. 3D printing of continuous carbon fiber reinforced polyphenylene sulfide: Exploring printability and importance of fiber volume fraction. Addit. Manuf. 2022, 54, 102763. [Google Scholar] [CrossRef]

- Storck, J.L.; Ehrmann, G.; Güth, U.; Uthoff, J.; Homburg, S.V.; Blachowicz, T.; Ehrmann, A. Investigation of Low-Cost FDM-Printed Polymers for Elevated-Temperature Applications. Polymers 2022, 14, 2826. [Google Scholar] [CrossRef] [PubMed]

- Mogan, J.; Harun, W.S.W.; Kadirgama, K.; Ramasamy, D.; Foudzi, F.M.; Sulong, A.B.; Tarlochan, F.; Ahmad, F. Fused Deposition Modelling of Polymer Composite: A Progress. Polymers 2023, 15, 28. [Google Scholar] [CrossRef]

- Crump, S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent No. 5,121,329, 9 June 1992. [Google Scholar] [CrossRef]

- Menczel, J.D.; Prime, R.B. Thermal Analysis of Polymers: Fundamentals and Applications; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar] [CrossRef]

- Costa, S.F.; Duarte, F.M.; Covas, J.A. Thermal conditions affecting heat transfer in FDM/FFE: A contribution towards the numerical modelling of the process. Virtual Phys. Prototyp. 2015, 10, 35–46. [Google Scholar] [CrossRef]

- Zhang, J.; Vasiliauskaite, E.; De Kuyper, A.; De Schryver, C.; Vogeler, F.; Desplentere, F.; Ferraris, E. Temperature Analyses in Fused Filament Fabrication: From Filament Entering the Hot-End to the Printed Parts. 3D Print. Addit. Manuf. 2022, 9, 132–142. [Google Scholar] [CrossRef] [PubMed]

- Coogan, T.J.; Kazmer, D.O. Healing simulation for bond strength prediction of FDM. Rapid Prototyp. J. 2017, 23, 551–561. [Google Scholar] [CrossRef]

- Zhou, Y.; Nyberg, T.; Xiong, G.; Liu, D. Temperature Analysis in the Fused Deposition Modeling Process. In Proceedings of the 2016 3rd International Conference on Information Science and Control Engineering, ICISCE 2016, Beijing, China, 8–10 July 2016; pp. 678–682. [Google Scholar] [CrossRef]

- D’Elia, C.R.; Hill, M.R.; Stender, M.E.; San Marchi, C.W. Residual Stresses at Critical Locations in Additively-Manufactured Components. In Residual Stress, Thermomechanics & Infrared Imaging and Inverse Problems; Conference Proceedings of the Society for Experimental Mechanics Series; Springer: Cham, Switzerland, 2020; Volume 6, pp. 49–57. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, M.; Kang, Y.; Tian, X.; Ding, J.; Li, D. Material extrusion 3D printing of polyether ether ketone in vacuum environment: Heat dissipation mechanism and performance. Addit. Manuf. 2023, 62, 103390. [Google Scholar] [CrossRef]

- Kousiatza, C.; Chatzidai, N.; Karalekas, D. Temperature Mapping of 3D Printed Polymer Plates: Experimental and Numerical Study. Sensors 2017, 17, 456. [Google Scholar] [CrossRef]

- Compton, B.G.; Post, B.K.; Duty, C.E.; Love, L.; Kunc, V. Thermal analysis of additive manufacturing of large-scale thermoplastic polymer composites. Addit. Manuf. 2017, 17, 77–86. [Google Scholar] [CrossRef]

- Yardimci, M.A.; Guceri, S.I.; Agarwala, M.; Danforth, S.C. Part Quality Prediction Tools For Fused Deposition Processing. In Proceedings of the Solid Freeform Fabrication Proceedings, Austin, TX, USA, 12–14 August 1996; pp. 539–548. [Google Scholar]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Dinwiddie, R.B.; Love, L.J.; Rowe, J.C. Real-Time Process Monitoring and Temperature Mapping of a 3D Polymer Printing Process. In Proceedings of the Thermosense: Thermal Infrared Applications XXXV, Baltimore, MD, USA, 29 April–3 May 2013; SPIE Digital Library: Bellingham, WA, USA, 2013; Volume 8705. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Tavitov, A.; Urzhumtsev, O.; Vakulik, A. Increasing strength of FFF three-dimensional printed parts by influencing on temperature-related parameters of the process. Rapid Prototyp. J. 2020, 26, 107–121. [Google Scholar] [CrossRef]

- Hossain, R.E.N.; Lewis, J.; Moore, A.L. In situ infrared temperature sensing for real-time defect detection in additive manufacturing. Addit. Manuf. 2021, 47, 102328. [Google Scholar] [CrossRef]

- Tang, C.-L.; Seeger, S.; Röllig, M. Improving the comparability of FFF-3D printing emission data by adjustment of the set extruder temperature. Atmos. Environ. X 2023, 18, 100217. [Google Scholar] [CrossRef]

- Vanaei, H.R.; Deligant, M.; Shirinbayan, M.; Raissi, K.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. A comparative in-process monitoring of temperature profile in fused filament fabrication. Polym. Eng. Sci. 2021, 61, 68–76. [Google Scholar] [CrossRef]

- Bauriedel, N.; Albuquerque, R.Q.; Utz, J.; Geis, N.; Ruckdäschel, H. Monitoring of fused filament fabrication (FFF): An infrared imaging and machine learning approach. J. Polym. Sci. 2024, 62, 5633–5641. [Google Scholar] [CrossRef]

- Malekipour, E.; Attoye, S.; El-Mounayri, H. Investigation of Layer Based Thermal Behavior in Fused Deposition Modeling Process by Infrared Thermography. Procedia Manuf. 2018, 26, 1014–1022. [Google Scholar] [CrossRef]

- D’andrea, D.; Risitano, G.; Raffaele, M.; Cucinotta, F.; Santonocito, D. Damage assessment of different FDM-processed materials adopting Infrared Thermography. Frat. Integrita Strutt. 2022, 16, 75–90. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Zayas-Figueras, E.E. Comparative study about dimensional accuracy and form errors of FFF printed spur gears using PLA and Nylon. Polym. Test. 2023, 117, 107862. [Google Scholar] [CrossRef]

- Slejko, E.A.; Sesto Gorella, N.; Makaya, A.; Gallina, P.; Scuor, N.; Seriani, S. Vacuum 3D printing of highly filled polymeric matrix composites. Acta Astronaut. 2023, 204, 25–33. [Google Scholar] [CrossRef]

- Nycz, A.; Kishore, V.; Lindahl, J.; Duty, C.; Carnal, C.; Kunc, V. Controlling substrate temperature with infrared heating to improve mechanical properties of large-scale printed parts. Addit. Manuf. 2020, 33, 101068. [Google Scholar] [CrossRef]

- Kishore, V.; Ajinjeru, C.; Nycz, A.; Post, B.; Lindahl, J.; Kunc, V.; Duty, C. Infrared preheating to improve interlayer strength of big area additive manufacturing (BAAM) components. Addit. Manuf. 2017, 14, 7–12. [Google Scholar] [CrossRef]

- Ravi, A.K.; Deshpande, A.; Hsu, K.H. An in-process laser localized pre-deposition heating approach to inter-layer bond strengthening in extrusion based polymer additive manufacturing. J. Manuf. Process. 2016, 24, 179–185. [Google Scholar] [CrossRef]

- Luo, M.; Tian, X.; Zhu, W.; Li, D. Controllable interlayer shear strength and crystallinity of PEEK components by laser-assisted material extrusion. J. Mater. Res. 2018, 33, 1632–1641. [Google Scholar] [CrossRef]

- Ravoori, D.; Salvi, S.; Prajapati, H.; Qasaimeh, M.; Adnan, A.; Jain, A. Void reduction in fused filament fabrication (FFF) through in situ nozzle-integrated compression rolling of deposited filaments. Virtual Phys. Prototyp. 2021, 16, 146–159. [Google Scholar] [CrossRef]

- Oleff, A.; Küster, B.; Stonis, M.; Overmeyer, L. Process monitoring for material extrusion additive manufacturing: A state-of-the-art review. Prog. Addit. Manuf. 2021, 6, 705–730. [Google Scholar] [CrossRef]

- Seppala, J.E.; Hoon Han, S.; Hillgartner, K.E.; Davis, C.S.; Migler, K.B. Weld formation during material extrusion additive manufacturing. Soft Matter 2017, 13, 6761–6769. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Hsieh, S.-J. Thermal Analysis Of Fused Deposition Modeling Process Using Infrared Thermography Imaging And Finite Element Modeling. In Proceedings of the Thermosense: Thermal Infrared Applications XXXIX, Anaheim, CA, USA, 10–13 April 2017; Volume 10214, p. 1021409. [Google Scholar] [CrossRef]

- Hartmann, S.; Müller-Lohse, L.; Tröger, J.-A. Temperature Gradient Determination with Thermography and Image Correlation in Curved Surfaces with Application to Additively Manufactured Components. Exp. Mech. 2023, 63, 43–61. [Google Scholar] [CrossRef]

- Wolszczak, P.; Lygas, K.; Paszko, M.; Wach, R.A. Heat distribution in material during fused deposition modelling. Rapid Prototyp. J. 2018, 24, 615–622. [Google Scholar] [CrossRef]

- Seppala, J.E.; Migler, K.D. Infrared thermography of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2016, 12, 71–76. [Google Scholar] [CrossRef]

- Traxler, G.; Köpplmayr, T. Process Monitoring By Thermography During Fused Deposition Modeling. In Proceedings of the 32nd International Conference of the Polymer Processing Society, Lyon, France, 25–29 July 2016. [Google Scholar]

- Micalizzi, S.; Lantada, A.D. Shape-memory actuators manufactured by dual extrusion multimaterial 3d printing of conductive and non-conductive fi laments. Smart Mater. Struct. 2019, 28, 105025. [Google Scholar] [CrossRef]

- Yardimci, M.A.; Güçeri, S. Conceptual framework for the thermal process modelling of fused deposition. Rapid Prototyp. J. 1996, 2, 26–31. [Google Scholar] [CrossRef]

- Thomas, J.; Rodriguez, J. Modeling The Fracture Strength Between Fused-Deposition Extruded Roads. In Proceedings of the Solid Freeform and Additive Fabrication, San Francisco, CA, USA, 24–26 April 2000; pp. 16–23. [Google Scholar] [CrossRef]

- Bellini, A.; Güçeri, S. Mechanical characterization of parts fabricated using fused deposition modeling. Rapid Prototyp. J. 2003, 9, 252–264. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mech. Work. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Cox, J.R.; Kipling, I.; Gibbons, G.J. Ensuring supply chain integrity for material extrusion 3D printed polymer parts. Addit. Manuf. 2023, 62, 103403. [Google Scholar] [CrossRef]

- Zhou, X.; Hsieh, S.-J.; Sun, Y. Experimental and numerical investigation of the thermal behaviour of polylactic acid during the fused deposition process. Virtual Phys. Prototyp. 2017, 12, 221–233. [Google Scholar] [CrossRef]

- Pooladvand, K.; Salerni, A.D.; Furlong, C. In-Situ Thermal Monitoring of Printed Components During Rapid Prototyping by Fused Deposition Modeling. In Residual Stress, Thermomechanics & Infrared Imaging and Inverse Problems, Volume 6; Conference Proceedings of the Society for Experimental Mechanics Series; Springer: Cham, Switzerland, 2020; Volume 6, pp. 131–140. [Google Scholar] [CrossRef]

- Vaes, D.; Coppens, M.; Goderis, B.; Zoetelief, W.; Van Puyvelde, P. Assessment of Crystallinity Development during Fused Filament Fabrication through Fast Scanning Chip Calorimetry. Appl. Sci. 2019, 9, 2676. [Google Scholar] [CrossRef]

- Srinivas, V.; van Hooy-Corstjens, C.S.; Harings, J.A. Correlating molecular and crystallization dynamics to macroscopic fusion and thermodynamic stability in fused deposition modeling; a model study on polylactides. Polymer 2018, 142, 348–355. [Google Scholar] [CrossRef]

- Costa, S.F.; Duarte, F.M.; Covas, J.A. Estimation of filament temperature and adhesion development in fused deposition techniques. J. Mech. Work. Technol. 2017, 245, 167–179. [Google Scholar] [CrossRef]

- Kousiatza, C.; Karalekas, D. In-situ monitoring of strain and temperature distributions during fused deposition modeling process. Mater. Des. 2016, 97, 400–406. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Printability and Tensile Performance of 3D Printed Polyethylene Terephthalate Glycol Using Fused Deposition Modelling. Polymers 2019, 11, 1220. [Google Scholar] [CrossRef] [PubMed]

- Gudadhe, A.; Bachhar, N.; Kumar, A.; Andrade, P.; Kumaraswamy, G. Three-Dimensional Printing with Waste High-Density Polyethylene. ACS Appl. Polym. Mater. 2019, 1, 3157–3164. [Google Scholar] [CrossRef]

- Hu, B.; Duan, X.; Xing, Z.; Xu, Z.; Du, C.; Zhou, H.; Chen, R.; Shan, B. Improved design of fused deposition modeling equipment for 3D printing of high-performance PEEK parts. Mech. Mater. 2019, 137, 103139. [Google Scholar] [CrossRef]

- Dinwiddie, R.B.; Kunc, V.; Lindal, J.M.; Post, B.; Smith, R.J.; Love, L.; Duty, C.E. Infrared Imaging of the Polymer 3D-Printing Process. In Proceedings of the Thermosense: Thermal Infrared Applications XXXVI, Baltimore, MD, USA, 5–9 May 2014. [Google Scholar] [CrossRef]

- Eyercioğlu, Ö.; Aladağ, M.; Sever, S. Temperature Evaluation and Bonding Quality of Large Scale Additive Manufacturing Thin Wall Parts. Sigma J. Eng. Nat. Sci. 2018, 36, 645–654. [Google Scholar]

- Rodríguez, J.F.; Thomas, J.P.; Renaud, J.E. Mechanical behavior of acrylonitrile butadiene styrene fused deposition materials modeling. Rapid Prototyp. J. 2003, 9, 219–230. [Google Scholar] [CrossRef]

- Rodriguez, J.F.; Thomas, J.P.; Renaud, J.E. Characterization of the mesostructure of fused-deposition acrylonitrile-butadiene-styrene materials. Rapid Prototyp. J. 2000, 6, 175–186. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conceição, M.d.N.d.; Fonseca, H.M.d.; Thiré, R.M.S.M. Temperature Profile from Parts Produced by Fused Filament Fabrication (FFF) Measured by In Situ Infrared Thermography. Processes 2025, 13, 60. https://doi.org/10.3390/pr13010060

Conceição MdNd, Fonseca HMd, Thiré RMSM. Temperature Profile from Parts Produced by Fused Filament Fabrication (FFF) Measured by In Situ Infrared Thermography. Processes. 2025; 13(1):60. https://doi.org/10.3390/pr13010060

Chicago/Turabian StyleConceição, Marceli do N. da, Henrique M. da Fonseca, and Rossana M. S. M. Thiré. 2025. "Temperature Profile from Parts Produced by Fused Filament Fabrication (FFF) Measured by In Situ Infrared Thermography" Processes 13, no. 1: 60. https://doi.org/10.3390/pr13010060

APA StyleConceição, M. d. N. d., Fonseca, H. M. d., & Thiré, R. M. S. M. (2025). Temperature Profile from Parts Produced by Fused Filament Fabrication (FFF) Measured by In Situ Infrared Thermography. Processes, 13(1), 60. https://doi.org/10.3390/pr13010060