A Study on the Residual Oil Distribution in Tight Reservoirs Based on a 3D Pore Structure Model

Abstract

1. Introduction

2. Modeling of 3D Pore Structure in Tight Reservoirs

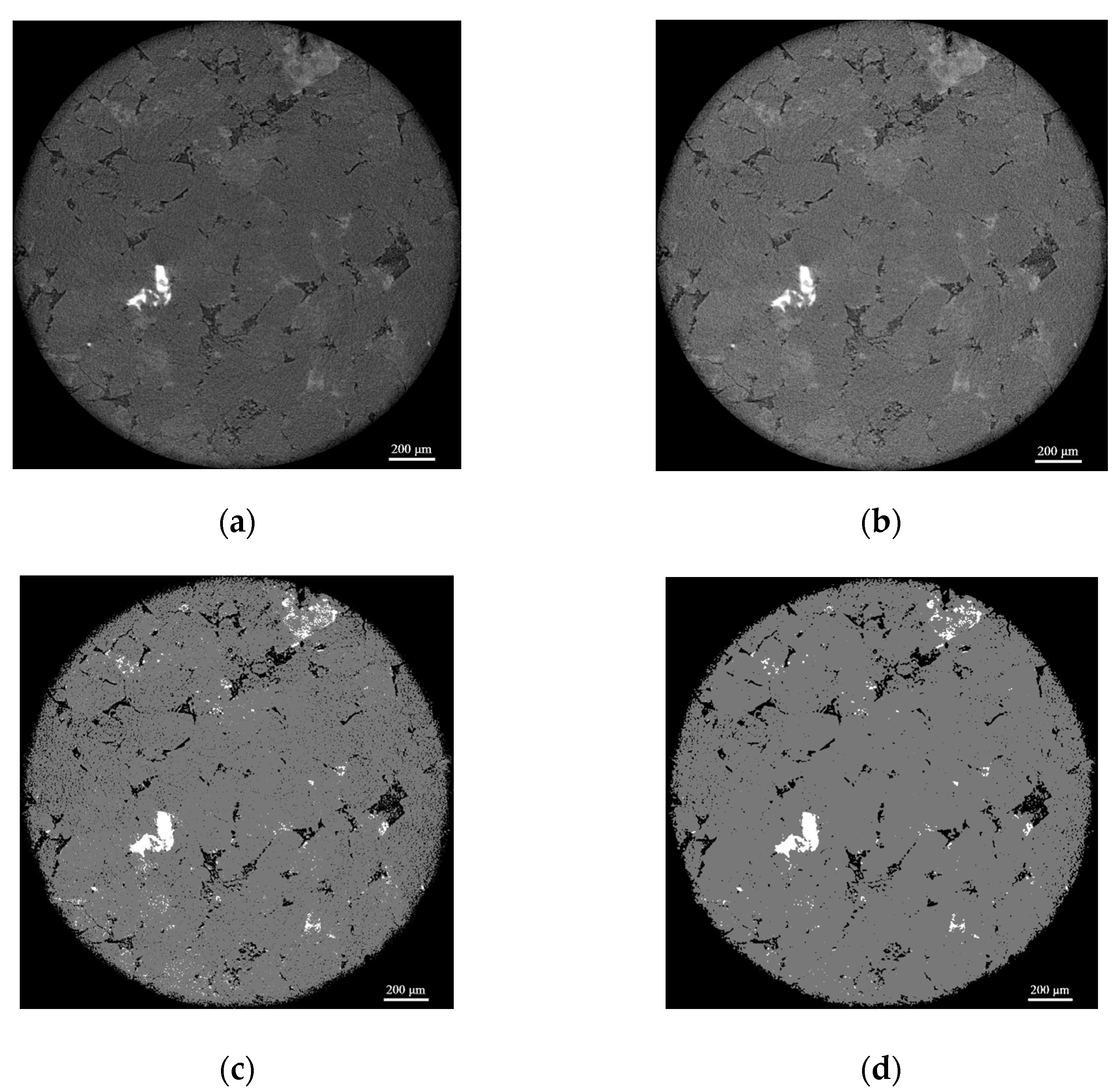

2.1. Micro-CT Scanning Test

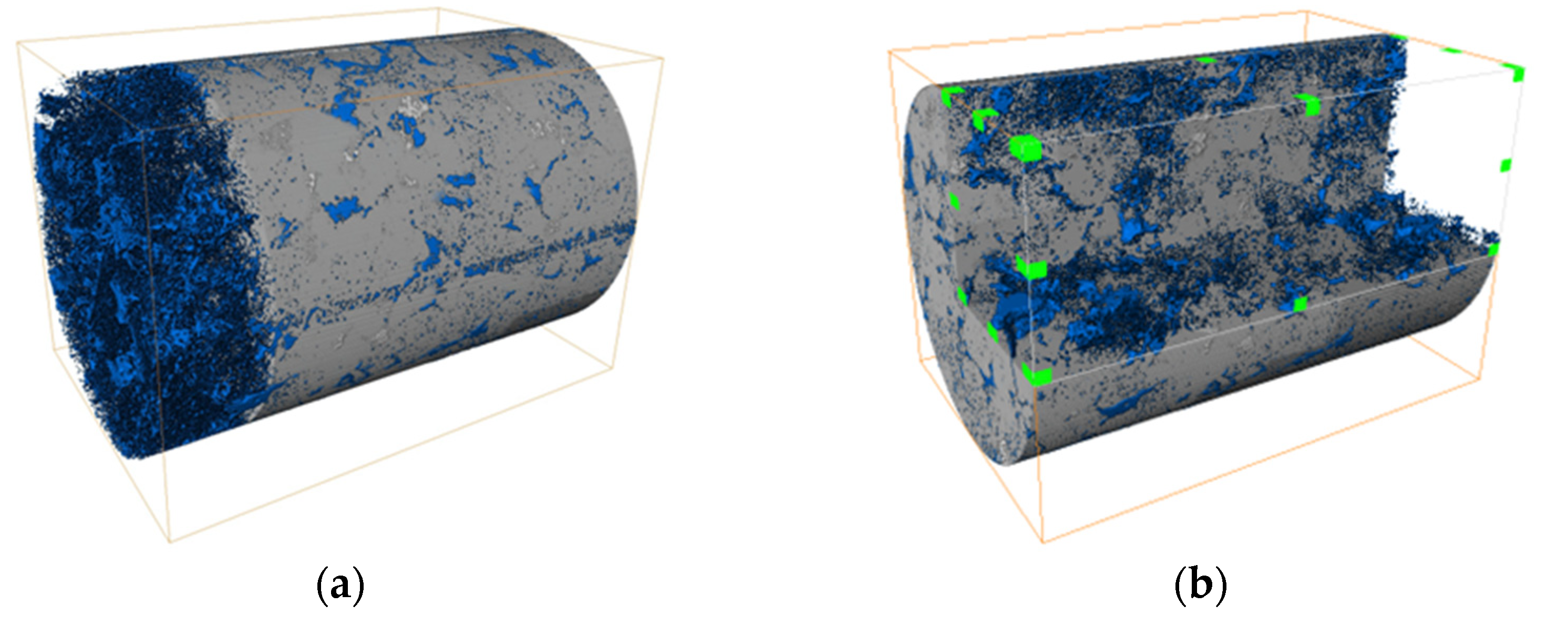

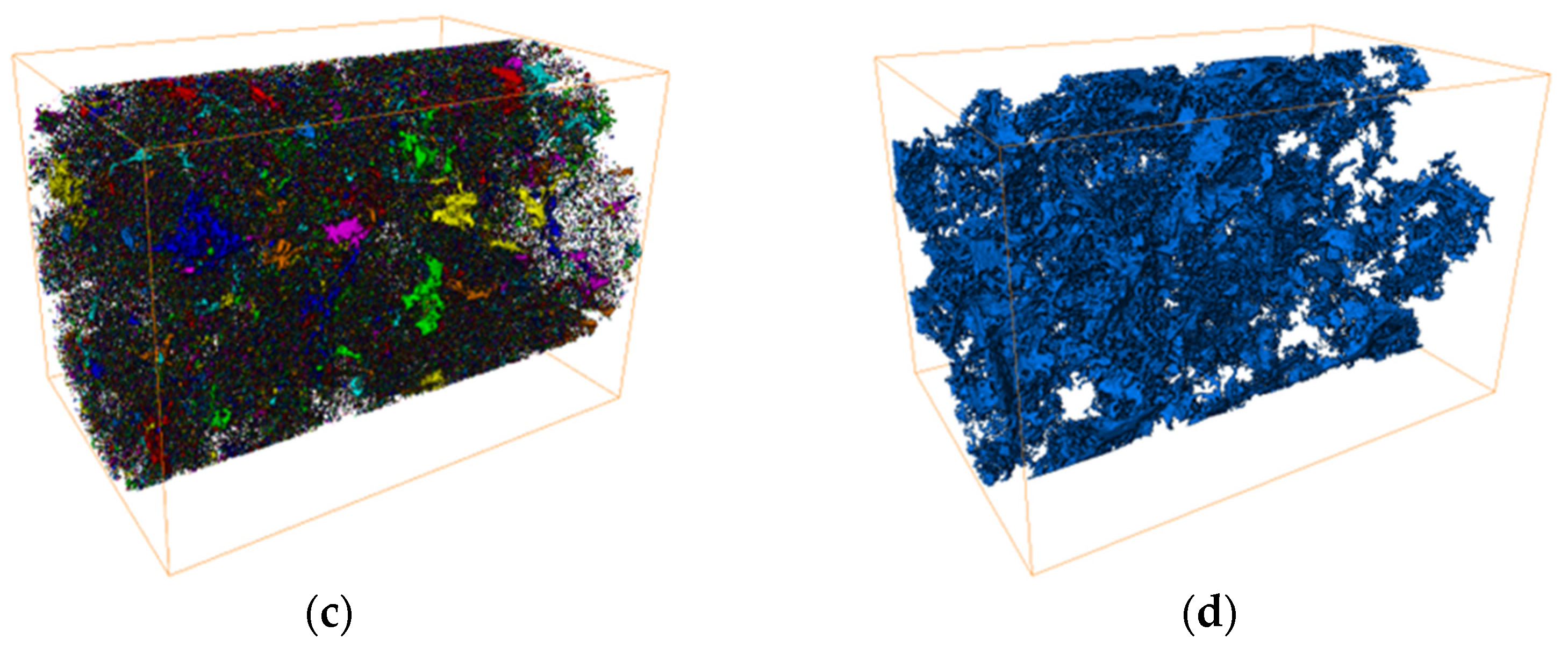

2.2. Three-Dimensional Pore Structure Reconstruction

2.3. Three-Dimensional Pore Structure Finite Element Modeling

3. Phase Field Method Control Equations

4. Research on the Distribution of Micro Residual Oil

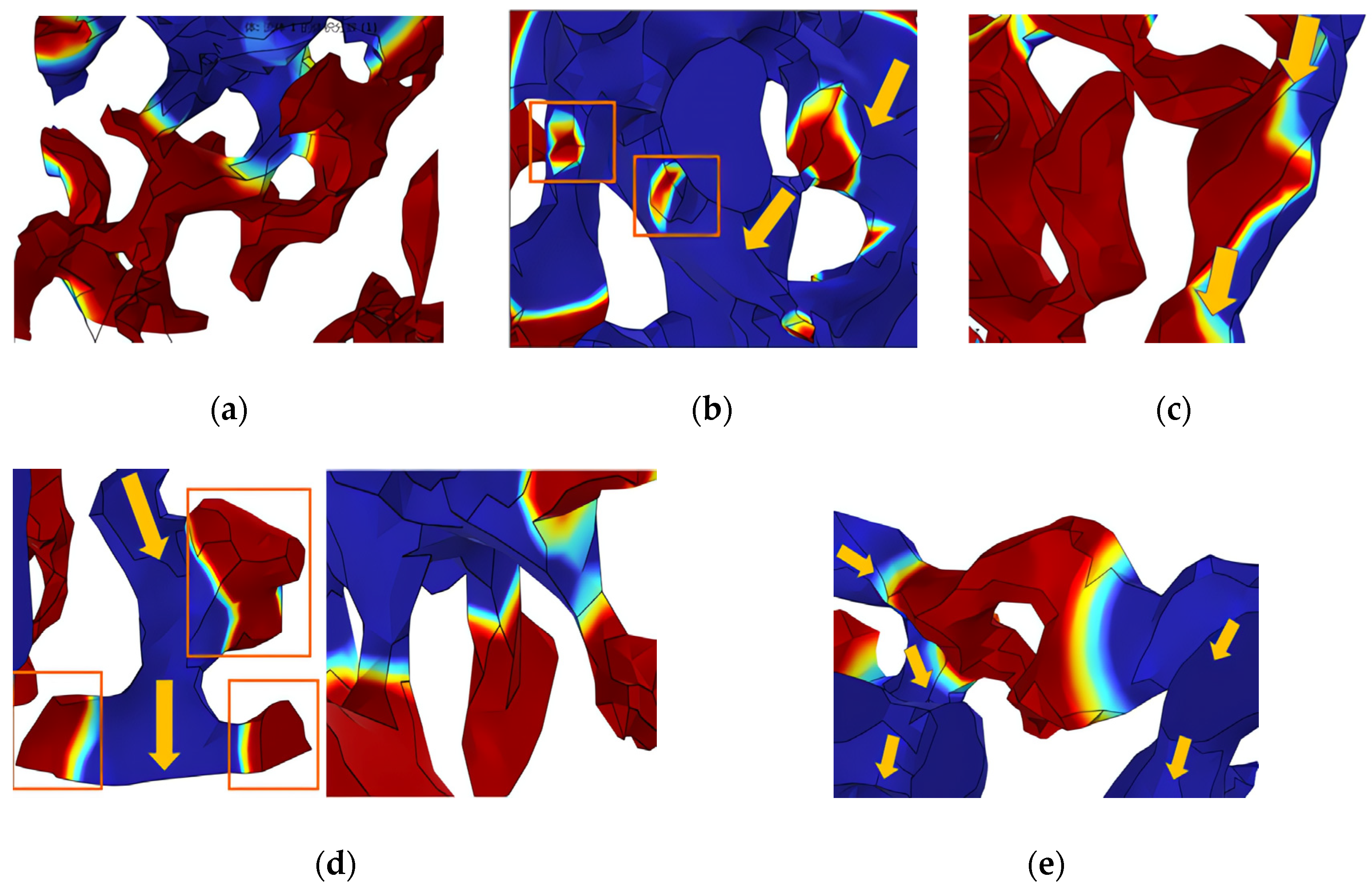

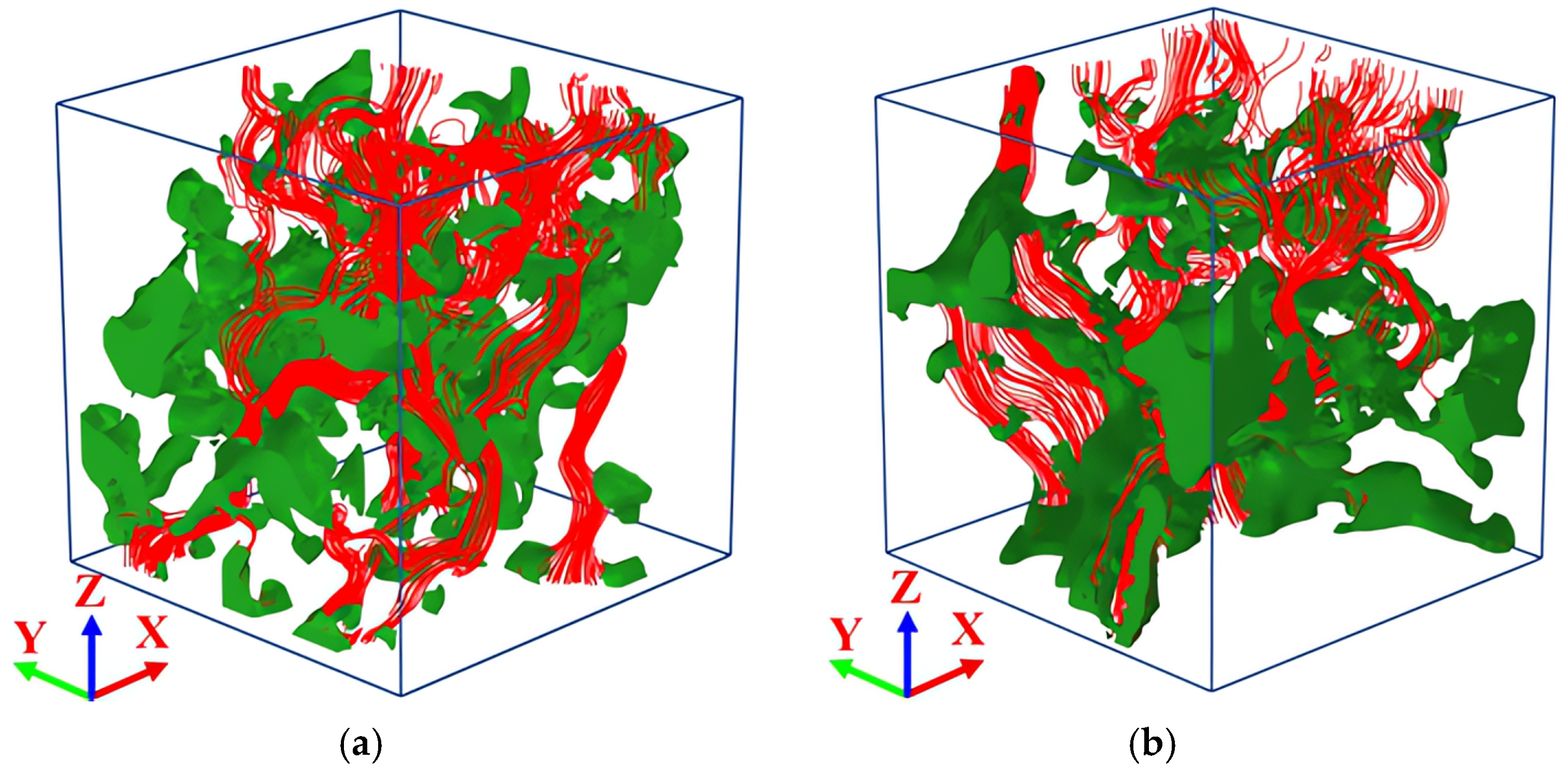

4.1. Distribution of Residual Oil Under Different Pore Structure

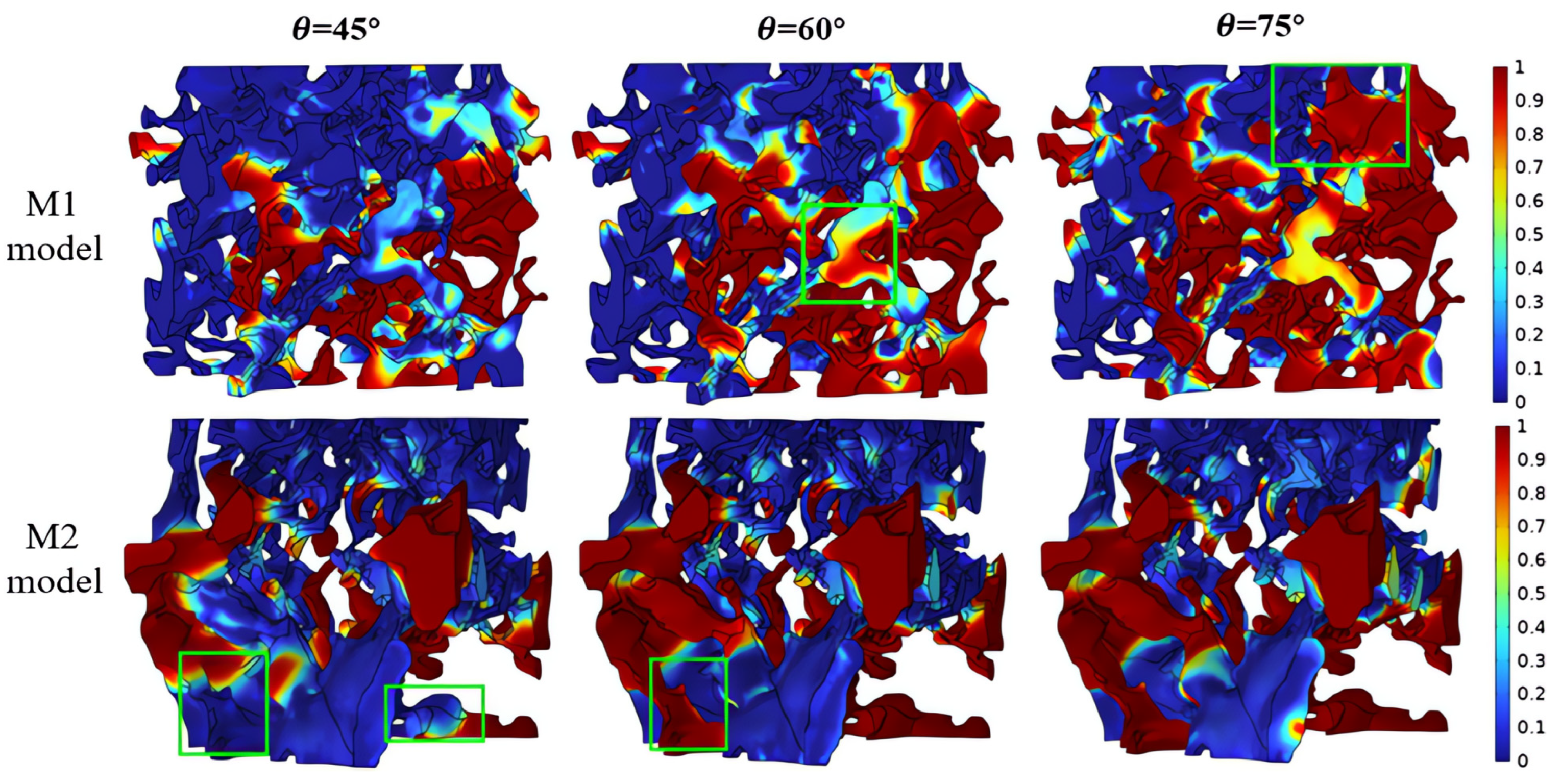

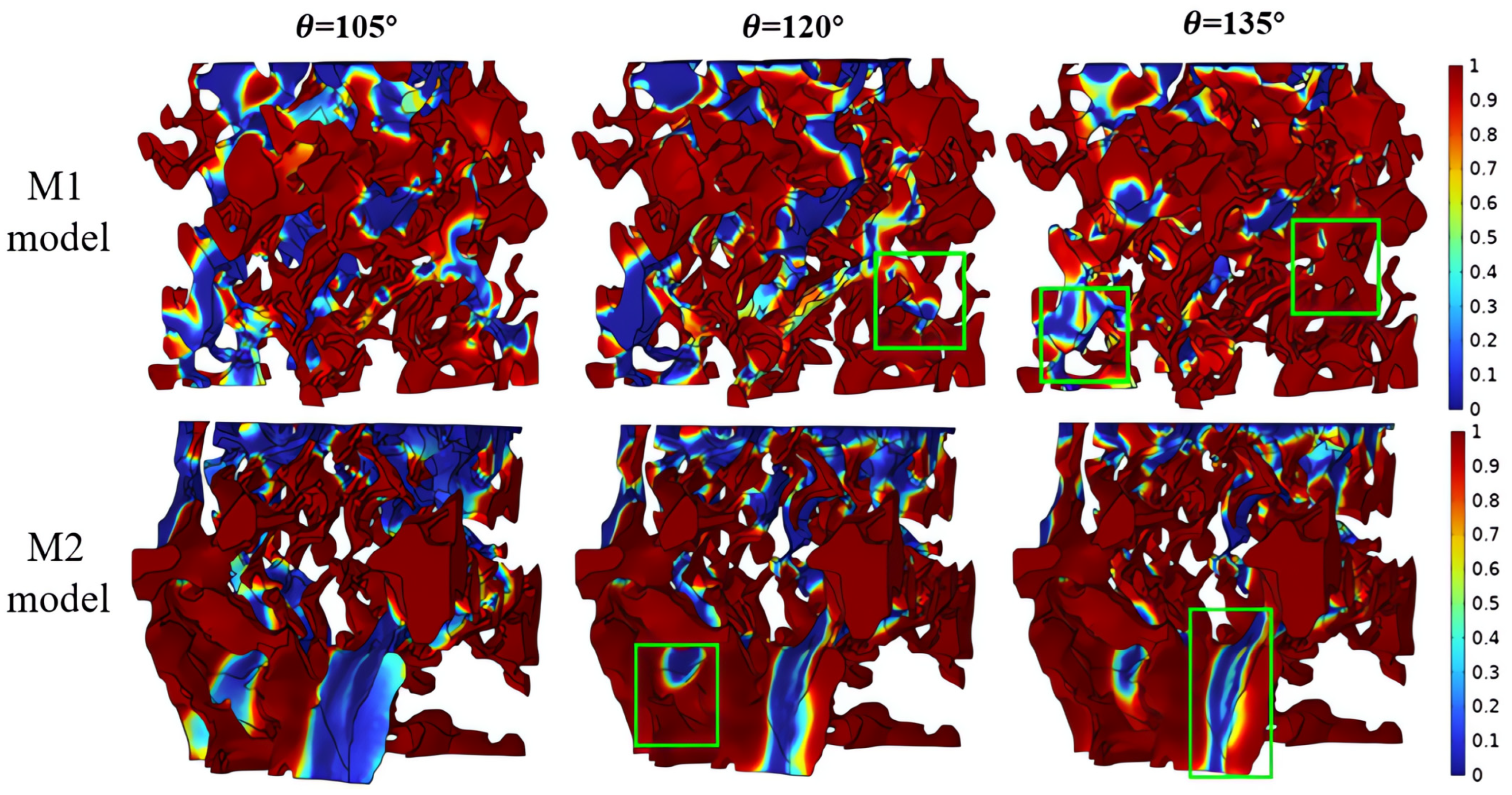

4.2. Influence of Rock Wettability on Residual Oil Distribution

4.3. Distribution of Residual Oil Under Different Displacement Methods

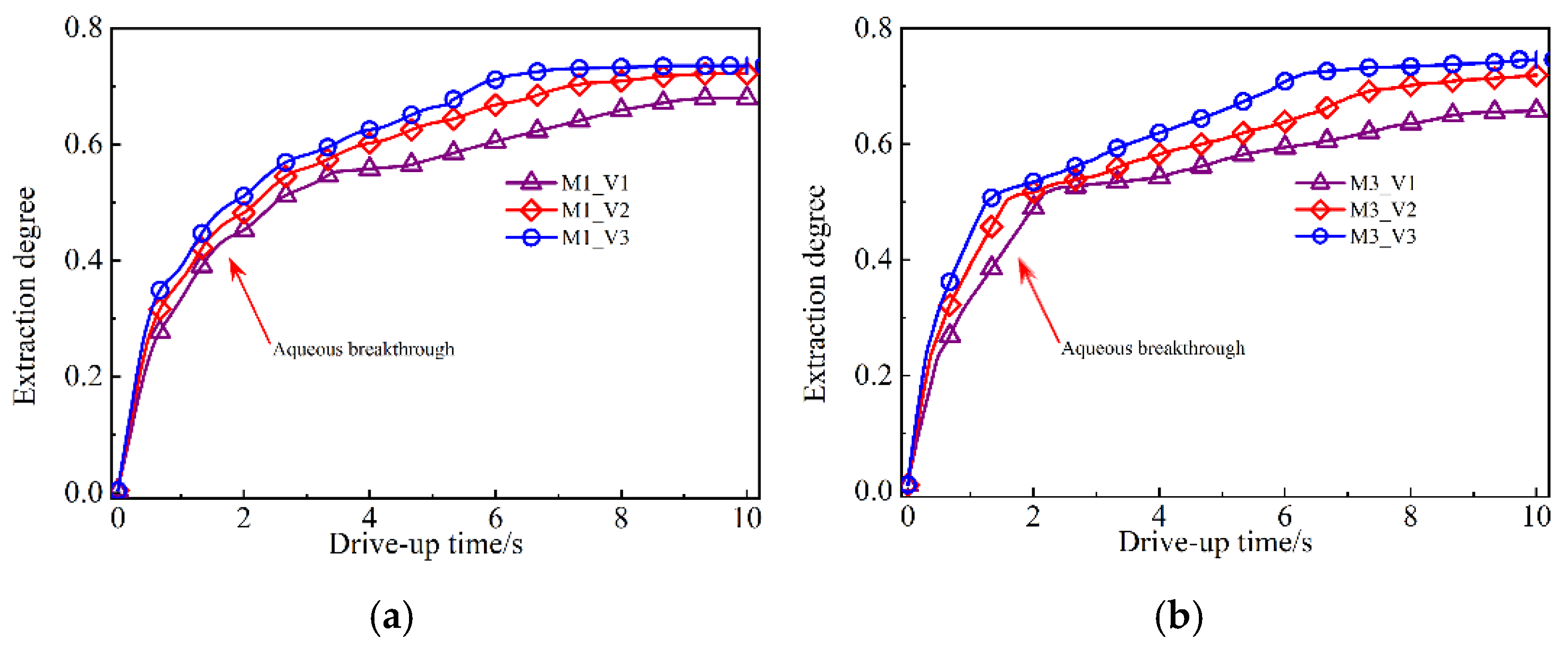

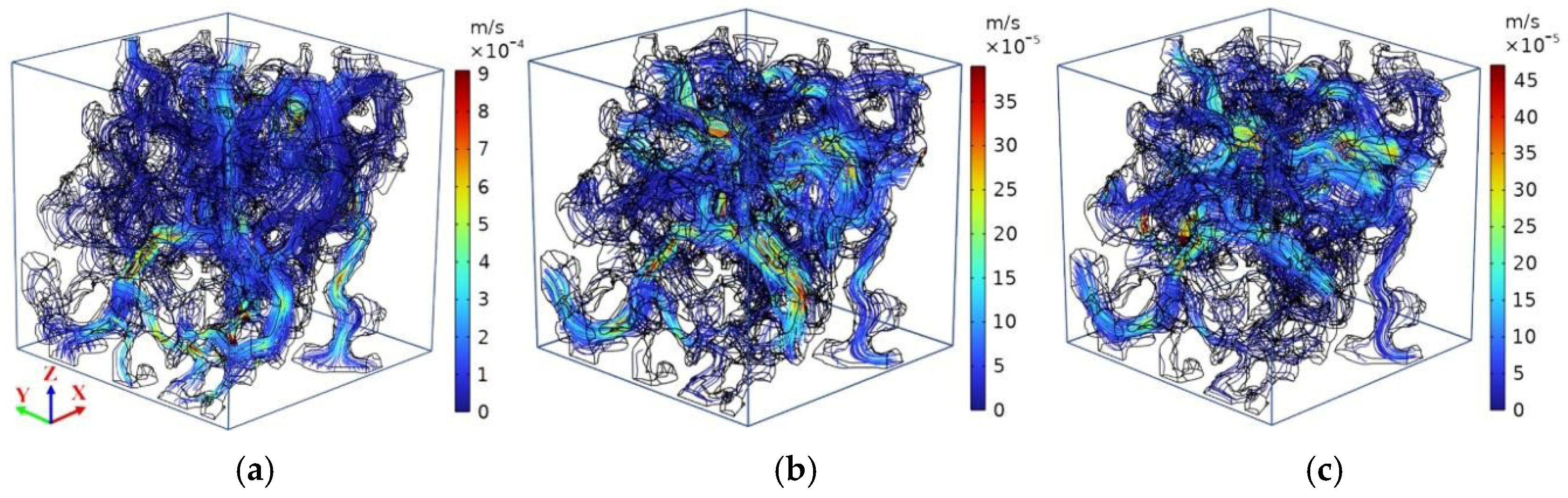

4.3.1. Distribution Pattern of Residual Oil at Different Displacement Rates

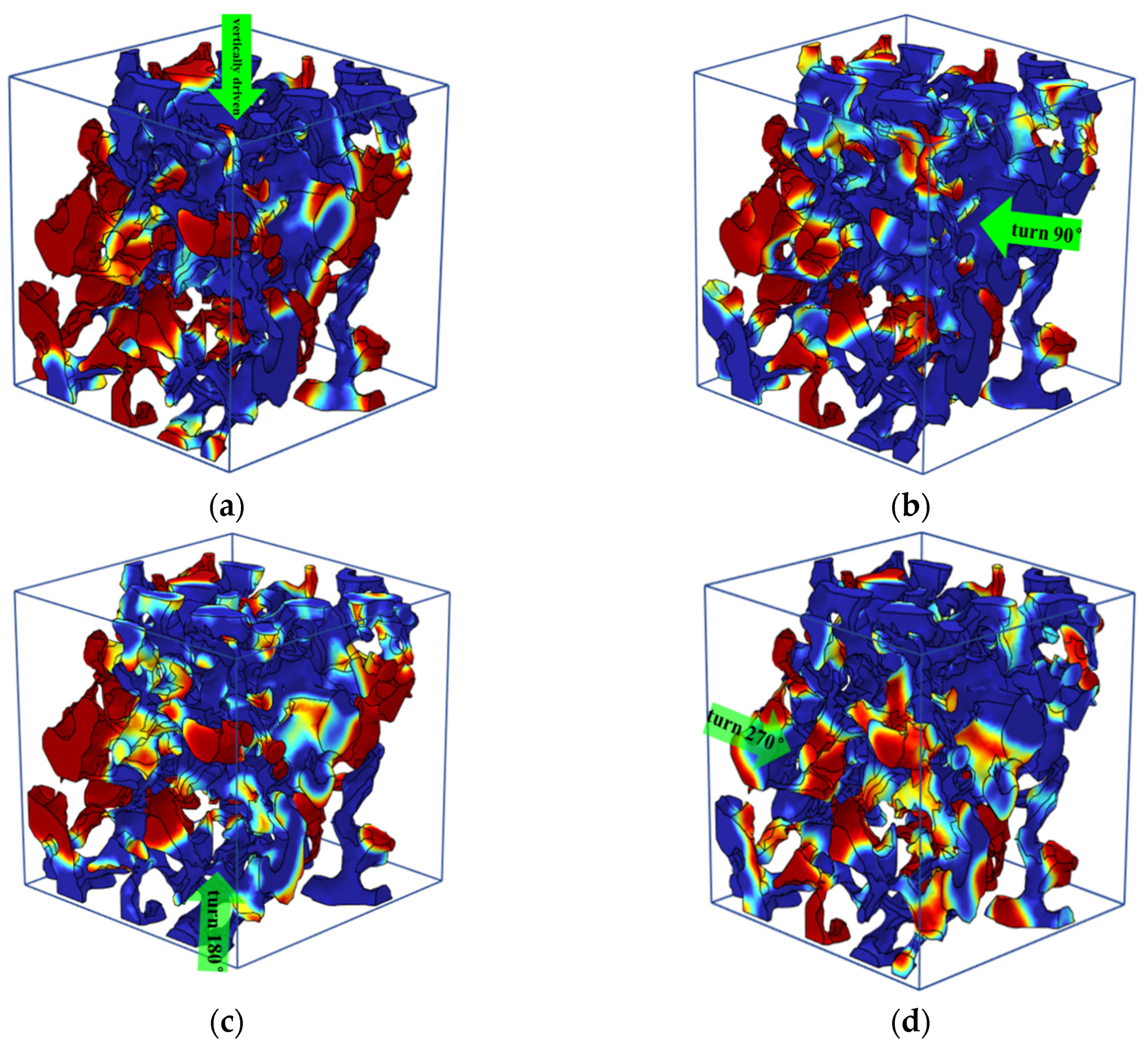

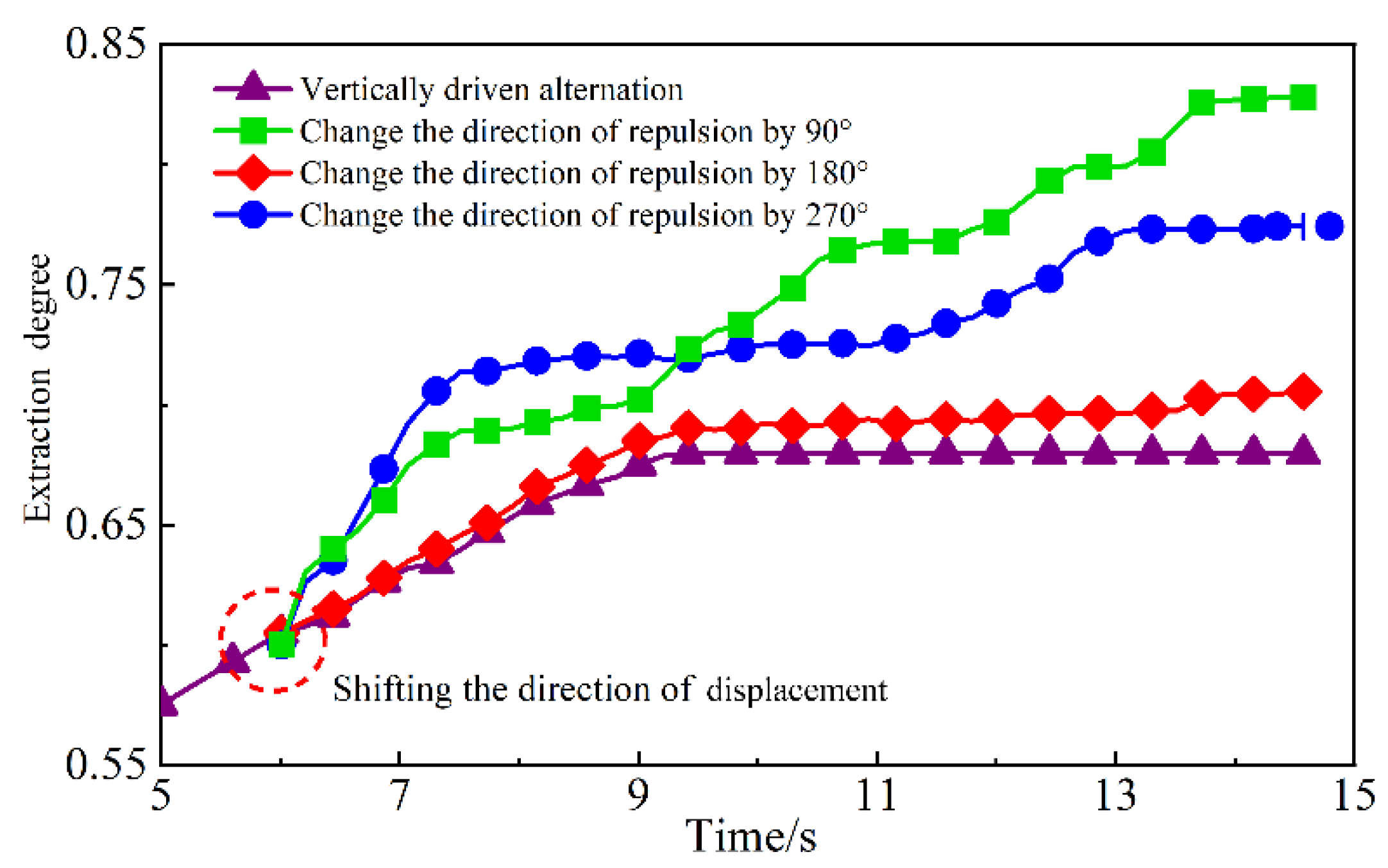

4.3.2. Distribution Pattern of Residual Oil at Different Displacement Directions

5. Discussion

6. Conclusions

- (1)

- The micro residual oil after water flooding was divided into five discontinuous phases: porous (sheet-like), membranous, corner, droplet, and columnar phases. The content was mainly composed of porous and membranous micro residual oil. The residual oil exhibited characteristics of overall high dispersion but local relative distribution.

- (2)

- Under water-wet conditions, water can easily strip the oil phase along the pore wall, resulting in a significant reduction in the distribution of residual oil. Under oil-wet conditions, the adsorption capacity of the pore wall for the oil phase was enhanced. There was a large amount of porous and membranous residual oil within the pore, resulting in a decreased recovery rate.

- (3)

- Increasing the displacement speed expands the range of water flooding and improves the mobility of residual oil near the dominant flow channels. However, there is no significant change in the main distribution area of residual oil or the dominant flow channels. The final recovery rates are 67.97%, 72.15%, and 73.56% at the displacement velocities of V1, V2, and V3, respectively. Furthermore, there is a limited improvement in the recovery rate by increasing the displacement velocity.

- (4)

- When the displacement direction changed to counter displacement after reaching the high-water stage, there was a certain improvement in the recovery degree. However, due to no fundamental changes in the dominant channels, injected water still flowed out along the original dominant channels with lower resistance, resulting in ineffective water circulation. On the other hand, lateral displacement during the high-water stage can effectively change the distribution position and type of residual oil, resulting in a better recovery rate. The final recovery rates for displacement directions are 90°, 180°, and 270° are 82.79%, 70.55%, and 77.43%, respectively, which are increases of 22.12%, 4.07%, and 14.22% compared to the vertical displacement.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, P.; Ou, Y.; Chen, H.; Li, Q.; Zhao, L.; Yan, J. Pore throat distributions and movable fluid occurrences in different diagenetic facies of tight sandstone reservoirs in the Triassic Chang 6 reservoirs, Wuqi Area, Ordos Basin, China. J. Pet. Explor. Prod. Technol. 2024, 14, 1783–1797. [Google Scholar] [CrossRef]

- Mohammed, S.; Anumah, P.; Sarkodie-kyeremeh, J.; Acheaw, E. A production-based model for a fractured well in unconventional reservoirs. J. Pet. Sci. Eng. 2021, 201, 109036. [Google Scholar] [CrossRef]

- Xie, Y.T.; Li, J.; Liu, H.; Zhang, K.; Li, J.; Liu, C.; Zhu, R. Study on hydro-mechanical-damage coupling seepage in digital shale cores: A case study of shale in Bohai Bay Basin. Energy 2023, 268, 123759. [Google Scholar] [CrossRef]

- Aguilera, R. Flow units: From conventional to tight-gas to shale-gas to tight-oil to shale-oil reservoirs. SPE Reserv. Eval. Eng. 2014, 17, 190–208. [Google Scholar] [CrossRef]

- Li, J.; Yang, L.; Gao, B.; Cheng, B.; Meng, F.; Xu, H. Effects of microscopic pore structure heterogeneity on the distribution and morphology of remaining oil. Pet. Explor. Dev. 2018, 45, 1112–1122. [Google Scholar] [CrossRef]

- Mustafa, A.; Mahmoud, M.; Abdulraheem, A. A review of pore structure characterization of unconventional tight reservoirs. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019. [Google Scholar] [CrossRef]

- Wang, J.; Song, L.; Song, K. The reasonable development technology policy in sweet spot of tight gas reservoir. J. Pet. Explor. Prod. Technol. 2018, 8, 1235–1241. [Google Scholar] [CrossRef]

- Gao, J.; Wang, X.; Zhang, D.; Wang, J. The Formation Mechanism of Residual Oil and Methods of Enhanced Oil Recovery in a Fractured Low-Permeability Metamorphic Rock Reservoir in Bohai Bay. Processes 2024, 12, 2281. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Wang, Z.; Chen, J.; Pang, X.; Wang, S.; Zhou, Z.; He, Z.; Qin, Z.; Fan, X. A review on pore structure characterization in tight sandstones. Earth-Sci. Rev. 2017, 177, 436–457. [Google Scholar] [CrossRef]

- Jiang, N.; Zhang, Z.; Qu, G.; Zhi, J.; Zhang, R. Distribution Characteristics of Micro Remaining Oil of Class III Reservoirs after Fracture Flooding in Daqing Oilfield. Energies 2022, 15, 3385. [Google Scholar] [CrossRef]

- Yue, M.; Zhu, W.; Han, H.; Song, H.; Long, Y.; Lou, Y. Experimental research on remaining oil distribution and recovery performances after nano-micron polymer particles injection by direct visualization. Fuel 2018, 212, 506–514. [Google Scholar] [CrossRef]

- Shi, L.; Jin, Z.; Yan, W.; Zhu, X.; Xu, X.; Peng, B. Influences of overpressure on reservoir compaction and cementation: A case from northwestern subsag, Bozhong sag, Bohai Bay Basin, East China. Pet. Explor. Dev. 2015, 42, 339–347. [Google Scholar] [CrossRef]

- Wang, W.-Y.; Pang, X.-Q.; Wang, Y.-P.; Chen, Z.-X.; Jiang, F.-J.; Chen, Y. Quantitative prediction model for the depth limit of oil accumulation in the deep carbonate rocks: A case study of Lower Ordovician in Tazhong area of Tarim Basin. Pet. Sci. 2024, 21, 115–124. [Google Scholar] [CrossRef]

- Zhou, R.; Wu, C. 3D reconstruction of digital rock guided by petrophysical parameters with deep learning. Geoenergy Sci. Eng. 2023, 231, 212320. [Google Scholar] [CrossRef]

- Wang, E.; Liu, G.; Pang, X.; Wu, Z.; Li, C.; Bai, H.; Zhang, Z. Sedimentology, diagenetic evolution, and sweet spot prediction of tight sandstone reservoirs: A case study of the third member of the Upper Paleogene Shahejie Formation, Nanpu Sag, Bohai Bay Basin, China. J. Pet. Sci. Eng. 2020, 186, 106718. [Google Scholar] [CrossRef]

- Teng, Y.; Liu, Y.; Jiang, L.; Song, Y.; Zhao, J.; Zhang, Y.; Wang, D. A visualization study on two-phase gravity drainage in porous media by using magnetic resonance imaging. Magn. Reson. Imaging 2016, 34, 855–863. [Google Scholar] [CrossRef]

- Jungreuthmayer, C.; Steppert, P.; Sekot, G.; Zankel, A.; Reingruber, H.; Zanghellini, J.; Jungbauer, A. The 3D pore structure and fluid dynamics simulation of macroporous monoliths: High permeability due to alternating channel width. J. Chromatogr. 2015, 1425, 141–149. [Google Scholar] [CrossRef] [PubMed]

- Jia, P.; Guo, H.; Wang, Y.; Peng, C.; Cheng, L.; Ke, X. COMSOL-based investigation of the characteristics of microscopic water flooding and residual oil distribution in carbonate reservoirs. Front. Earth Sci. 2022, 10, 1016941. [Google Scholar] [CrossRef]

- Xia, H.; Wang, L.; Han, P.; Cao, R.; Zhang, S.; Sun, X. Microscopic residual oil distribution characteristics and quantitative characterization of producing degree based on core fluorescence analysis technology. Geofluids 2021, 2021, 8827721. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, L.; Zhu, G.; Yao, J.; Sun, H.; Song, W.; Yang, Y.; Zhao, J. A pore-scale investigation of residual oil distributions and enhanced oil recovery methods. Energies 2019, 12, 3732. [Google Scholar] [CrossRef]

- Iglauer, S.; Fernø, M.A.; Shearing, P.; Blunt, M.J. Comparison of residual oil cluster size distribution, morphology and saturation in oil-wet and water-wet sandstone. J. Colloid Interface Sci. 2012, 375, 187–192. [Google Scholar] [CrossRef] [PubMed]

- Ekechukwu, G.K.; Khishvand, M.; Kuang, W.; Piri, M.; Masalmeh, S. The effect of wettability on waterflood oil recovery in carbonate rock samples: A systematic multi-scale experimental investigation. Transp. Porous Media 2021, 138, 369–400. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, S. Multiscale pore structure characterization based on SEM images. Fuel 2021, 289, 119915. [Google Scholar] [CrossRef]

- Li, J.; Liu, D.; Yao, Y.; Cai, Y.; Guo, X. Physical characterization of the pore-fracture system in coals, Northeastern China. Energy Explor. Exploit. 2013, 31, 267–285. [Google Scholar] [CrossRef]

- Jacqmin, D. Calculation of two-phase Navier–Stokes flows using phase-field modeling. J. Comput. Phys. 1999, 155, 96–127. [Google Scholar] [CrossRef]

- Wang, Z.; Dong, S.; Triantafyllou, M.S.; Constantinides, Y.; Karniadakis, G.E. A stabilized phase-field method for two-phase flow at high Reynolds number and large density/viscosity ratio. J. Comput. Phys. 2019, 397, 108832. [Google Scholar] [CrossRef]

- Cai, J.; Wei, W.; Hu, X.; Liu, R.; Wang, J. Fractal characterization of dynamic fracture network extension in porous media. Fractals 2017, 25, 1750023. [Google Scholar] [CrossRef]

- Badalassi, V.E.; Ceniceros, H.D.; Banerjee, S. Computation of multiphase systems with phase field models. J. Comput. Phys. 2003, 190, 371–397. [Google Scholar] [CrossRef]

- Gudala, M.; Govindarajan, S.K. Numerical investigations on two-phase fluid flow in a fractured porous medium fully coupled with geomechanics. J. Pet. Sci. Eng. 2021, 199, 108328. [Google Scholar] [CrossRef]

- Zhang, Z.; Nemcik, J.; Ma, S. Micro-and macro-behavior of fluid flow through rock fractures: An experimental study. Hydrogeol. J. 2013, 21, 1717. [Google Scholar] [CrossRef]

- Zhou, C.; Yue, P.; Feng, J.; Ollivier-Gooch, C.F.; Hu, H. 3D phase-field simulations of interfacial dynamics in Newtonian and viscoelastic fluids. J. Comput. Phys. 2010, 229, 498–511. [Google Scholar] [CrossRef]

- Glowinski, R.; Pironneau, O. Finite element methods for Navier-Stokes equations. J. Pet. Sci. Eng. 1992, 24, 167–204. [Google Scholar] [CrossRef]

- Alpak, F.; Samardžić, A.; Frank, F. A distributed parallel direct simulator for pore-scale two-phase flow on digital rock images using a finite difference implementation of the phase-field method. J. Pet. Sci. Eng. 2017, 166, 806–824. [Google Scholar] [CrossRef]

- Hirasaki, G.J.; Huang, C.C.; Zhang, G.Q. Interpretation of wettability in sandstones with NMR analysis. Petrophysics-SPWLA J. Form. Eval. Reserv. Descr. 2000, 41, SPWLA-2000-v41n3a1. [Google Scholar]

- Roshan, H.; Al-Yaseri, A.Z.; Sarmadivaleh, M.; Iglauer, S. On wettability of shale rocks. J. Colloid Interface Sci. 2016, 475, 104–111. [Google Scholar] [CrossRef] [PubMed]

- Hiraga, T.; Nishikawa, O.; Nagase, T.; Akizuki, M. Morphology of intergranular pores and wetting angles in politic schists studied by transmission electron microscopy. Contrib. Mineral. Petrol. 2001, 141, 613–622. [Google Scholar] [CrossRef]

- Biberg, D. An explicit approximation for the wetted angle in two-Phase stratified pipe flow. Can. J. Chem. Eng. 2009, 77, 1221–1224. [Google Scholar] [CrossRef]

- Kholodov, V.A.; Yaroslavtseva, N.V.; Yashin, M.A.; Frid, A.S.; Lazarev, V.I.; Tyugai, Z.N.; Milanovskiy, E.Y. Contact angles of wetting and water stability of soil structure. Eurasian Soil Sci. 2015, 48, 600–607. [Google Scholar] [CrossRef]

- Drummond, C.; Israelachvili, J. Surface forces and wettability. J. Pet. Sci. Eng. 2002, 33, 123–133. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Zhang, Y.; Sun, C.; Li, J.; Meng, X.; Yang, C.; Chen, Z. A Study on the Residual Oil Distribution in Tight Reservoirs Based on a 3D Pore Structure Model. Processes 2025, 13, 203. https://doi.org/10.3390/pr13010203

Wang R, Zhang Y, Sun C, Li J, Meng X, Yang C, Chen Z. A Study on the Residual Oil Distribution in Tight Reservoirs Based on a 3D Pore Structure Model. Processes. 2025; 13(1):203. https://doi.org/10.3390/pr13010203

Chicago/Turabian StyleWang, Rujun, Yintao Zhang, Chong Sun, Jing Li, Xiaoyu Meng, Chengqiang Yang, and Zhaoyang Chen. 2025. "A Study on the Residual Oil Distribution in Tight Reservoirs Based on a 3D Pore Structure Model" Processes 13, no. 1: 203. https://doi.org/10.3390/pr13010203

APA StyleWang, R., Zhang, Y., Sun, C., Li, J., Meng, X., Yang, C., & Chen, Z. (2025). A Study on the Residual Oil Distribution in Tight Reservoirs Based on a 3D Pore Structure Model. Processes, 13(1), 203. https://doi.org/10.3390/pr13010203