1. Introduction

Multiphase flow is the term used to describe a mixture of fluids that has two or more phases. This type of flow is commonly observed in the petroleum industry. The system can encompass gas-oil, gas-water, oil-water two-phase flow, or even more intricate oil-gas-water three-phase flow. The intricate nature of this flow condition renders the research and implementation of multiphase flow a crucial discipline in the petroleum industry. Since the 1980s, with the increasing complexity of offshore oil extraction tasks, non-straight well drilling techniques have become prevalent. Horizontal and directional wells provide substantial benefits compared to conventional straight well drilling methods. The most notable advantage is the capacity to effectively decrease the overall cost of oilfield development while substantially enhancing the recovery rate. The implementation of non-straight well technology increases the productivity of wells by providing greater access to the reservoir, resulting in a substantial improvement in the overall development efficiency of the field. Compared to traditional straight well drilling, these methods result in a significant alteration in fluids’ flow patterns within the wellbore due to the well slope [

1,

2]. The main factor causing this alteration is gravity, leading to significant differences in the distribution and movement of fluids in nonlinear wells compared to straight wells. The technical disparities not only impact the flow characteristics but also have a direct impact on the design of related equipment, the choice of instruments, and the implementation of extraction methods.

In recent years, with the development of the petroleum industry, significant progress has been made by scholars both domestically and internationally in the research of multiphase flow patterns. The topic is challenging because flow states are impacted by multiple elements, and the behavior of flow patterns changes under different conditions. Therefore, accurately predicting flow patterns is both theoretically significant and practically valuable. In order to tackle this difficulty, researchers have employed a range of methods, including experimental studies and modeling, to systematically investigate the properties of multiphase flow. In 1995, Trallero proposed a systematic classification method approach to characterize the flow patterns of oil-water two-phase flows in horizontal wells [

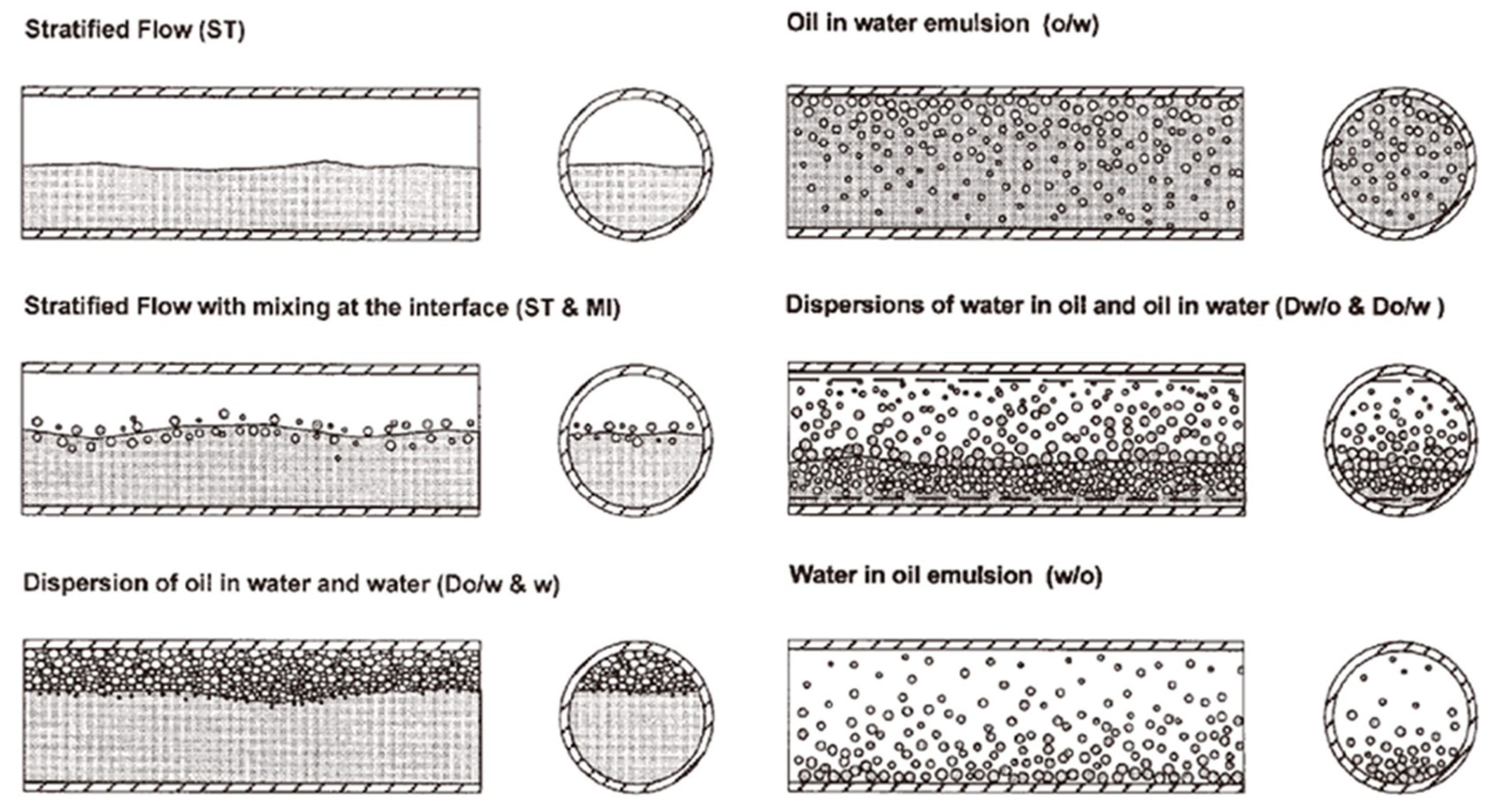

3]. He classified flow patterns into six unique types: stratified flow (ST), interfacially mixed stratified flow (ST&MI), the dispersed flow of oil and water in water (Do/w&w), oil in water emulsion flow (o/w), the dispersed flow of oil in water and water in oil (Do/w&o/w), and water in oil emulsion flow (w/o). This categorization offers a theoretical foundation for comprehending the complex behavior of oil-water flow in horizontal wellbores and has been extensively embraced in subsequent research and practical monitoring. Research has shown that the development of flow patterns is impacted by a multitude of elements. The main parameters that directly impact the flow condition of the oil-water mixture in a wellbore are the slope of the well, the rate at which the fluid flows, and the amount of water present. Secondary elements, such as fluid density, temperature, pressure, viscosity, and tubing wall roughness, can have significant influences on the formation and development of flow patterns. In 2007, Keskin conducted physical experiments to study the different patterns of multiphase flow. Using a simulated wellbore and advanced camera technology, he precisely documented the distribution of flow pattern at different total flows. This experimental study yielded valuable data for comprehending the behavior of oil-water two-phase flow in actual wellbores and established a strong basis for subsequent modeling [

4]. In 2010, Reza Ettehadi Osgouei developed a gas-liquid multiphase flow regime model applicable to horizontal annular geometries using second-order discriminant analysis. The model examined the apparent velocities of the liquid and gas phases, formulated appropriate generalized expressions [

5], and was compared to the classical Beggs and Brill and Beggs and Brill flow models [

6,

7]. The results indicated that the new model offers superior accuracy in predicting two-phase flow in horizontal annuli, hence offering a more precise tool for predicting oil and gas two-phase flow. In 2015, A.S. Izwan Ismail conducted experimental investigations to investigate variations in pressure drop and liquid content in oil-water two-phase flow at varied flow rates. He discovered that the occurrence of the oil-water slide phenomena is greatly influenced by the lowest flow rate, which is a crucial insight for comprehending the intricate flow dynamics of oil and water in horizontal wells [

8].

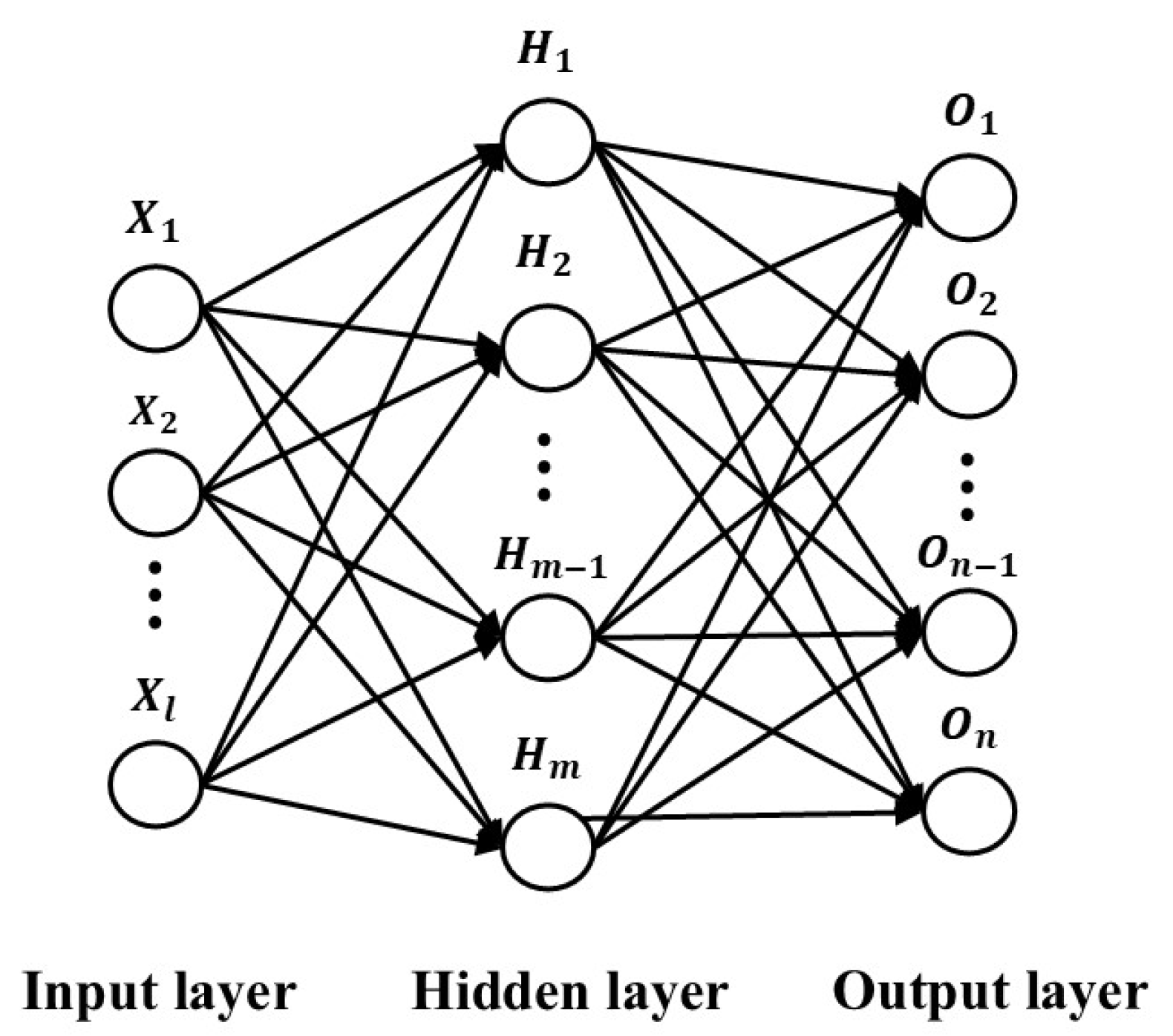

The precision of forecasting flow patterns has been a crucial concern in the initial phases of multiphase flow investigations. Early research approaches faced challenges in effectively capturing and predicting the complicated flow patterns of multiphase flow regimes due to their increasing complexity. These investigations commonly depended on visual observation and measurement, which were not only labor-intensive and tedious but also prone to subjectivity, leading to the poor reliability of the prediction outcomes. Furthermore, the technological constraints in that period resulted in a lack of adequate theoretical support and experimental validation for the classification and identification of flow patterns. As a result, early research faced challenges in meeting practical application requirements. In 2015, a method was developed by G.H. Roshan et al. for identifying gas-liquid multiphase flow models and predicting porosity. This method relies on gamma-ray attenuation and artificial neural networks [

9]. This approach utilizes three characteristics offered by two gamma-ray detectors to identify gas-liquid multiphase flow regimes using a multilayer perceptron network. It effectively improves the accuracy of flow pattern identification. It significantly enhances the precision of identifying flow patterns and provides a novel method for predicting multiphase flow in intricate conditions. In 2017, Hanafizad P. et al. performed an empirical investigation on fluid flow patterns in a simulated wellbore by employing a high-speed camera [

10]. They conducted a thorough analysis of flow behavior in non-straight wells by examining the variations in flow patterns at different well inclination degrees and total oil flows. The implementation of high-speed camera technology has enhanced the intuitive and exact monitoring of flow patterns, thereby establishing a strong experimental basis for gaining a deeper comprehension of the intricate flow phenomena in wellbores. In 2019, Wen Qingsong et al. developed an image-processing-based method for identifying the characteristics of oil and water two-phase distributions in wellbores that slope upwards [

11]. While this method did address the issue of flow pattern recognition to some extent, there is still room for improvement in terms of accuracy. This is because there is a loss of feature information during the process of picture processing. This study indicates that although image processing algorithms have the capacity to recognize flow patterns, their application still needs to be further optimized and enhanced. In 2021, Song et al. and Liu et al. combined laboratory tests with computational simulations to thoroughly examine the velocity, composition, and spatial regimes of oil-water two-phase flow. The researchers utilized Doppler sensors and conductivity sensors to enhance the classification of flow patterns, offering a novel instrument for the comprehensive examination of oil-water two-phase flow. These investigations not only enhance the comprehension of the behavior of oil-water two-phase flow, but also provide more accurate technical approaches for future research on multiphase flow [

12,

13]. To summarize, physical simulation and numerical simulation are two commonly used research methodologies in the investigation of oil-water two-phase flow behavior: (1) The physical simulation method accurately recreates the actual conditions within a flow loop by adjusting different experimental parameters to mimic the real behavior of oil-water multiphase flow in a wellbore. This method has the ability to accurately replicate flow phenomena, but its effectiveness is restricted because it requires a significant amount of work and has a limited number of data points. In addition, physical simulation incurs expensive costs and necessitates strict equipment and operating conditions. On the other hand, the numerical simulation method uses computational fluid dynamics software to simulate flow under various conditions on a computer. This approach is cost-effective and enables the production of substantial quantities of simulation data within a brief timeframe. Nevertheless, numerical simulations frequently diverge from actual flow conditions, especially in intricate multiphase flows, where the simulation outcomes may not precisely correspond to the genuine flow characteristics. These deviations need to be rectified and confirmed by thorough experimental data.

Due to the swift advancement of artificial intelligence (AI) technology, researchers have progressively utilized AI algorithms in the domain of multiphase flow pattern prediction to improve the precision and effectiveness of flow pattern identification. This development highlights the significant potential of AI algorithms in tackling intricate multiphase flow difficulties. In 2004, Osman utilized artificial neural networks (ANNs) to analyze the properties of gas-liquid multiphase flow in horizontal wells using a database, achieving successful predictions of flow patterns and liquid content rates. This study showcased the ability of artificial neural networks (ANNs) to accurately capture intricate flow properties. This achievement serves as a foundation for future endeavors in predicting flow patterns [

14]. In 2013, Li et al. carried out a thorough examination of the characteristics of oil-water multiphase flow in nearly horizontal wells and accurately predicted the transitions between different flow regimes under different viscosity conditions. This research is crucial for accurately predicting pressure drops in the wellbore, providing valuable insights for well design and optimization [

15]. In 2016, Al-Naser applied artificial neural networks to identify fluid flow pattern. They used three dimensionless input variables (liquid Reynolds number, gas Reynolds number, and pressure drop multiplier) to establish an effective flow pattern classification model [

16]. The model demonstrated an impressive accuracy of 97% in identifying flow patterns, highlighting the robust capabilities of AI algorithms in predicting multiphase flow. In 2019, Gene Mask explored the characteristics of gas-water flow. The study utilized a dimensionless approach derived from a dataset and evaluated the effectiveness of several deep learning algorithms in forecasting gas-liquid flow patterns. According to the study, deep learning algorithms offer notable benefits in dealing with intricate multiphase flow issues, resulting in more precise forecasts of flow patterns [

17]. In 2020, Mayadah Alhashem utilized the Stanford multiphase flow dataset to pinpoint critical parameters of gas-liquid multiphase flow in horizontal wells and evaluated the effectiveness of five machine learning algorithms in forecasting flow patterns. The work showcased the superior performance of machine learning algorithms in predicting flow patterns, providing a novel technical tool for the real-time monitoring of multiphase flow [

18]. In 2022, Wu et al. obtained 60 sets of sample data through multiphase flow physical experiments and developed the Mamdani fuzzy model to forecast oil-water multiphase flow patterns. This work emphasized the benefits of using fuzzy logic to handle uncertainty and complexity, providing a new method for predicting multiphase flow patterns [

19]. In 2023, Shi et al. combined Genetic Algorithm (GA) and BP neural networks to learn and predict experimental data on multiphase flow. The efforts resulted in the development of prediction models for four distinct experimental flow patterns [

20]. Although the studies stated above are important in both theory and practice, they frequently depend on experimental data driven by databases. This type of datum may not be able to visually examine the dynamic changes in fluid flow patterns or may lack confirmation from sample well data.

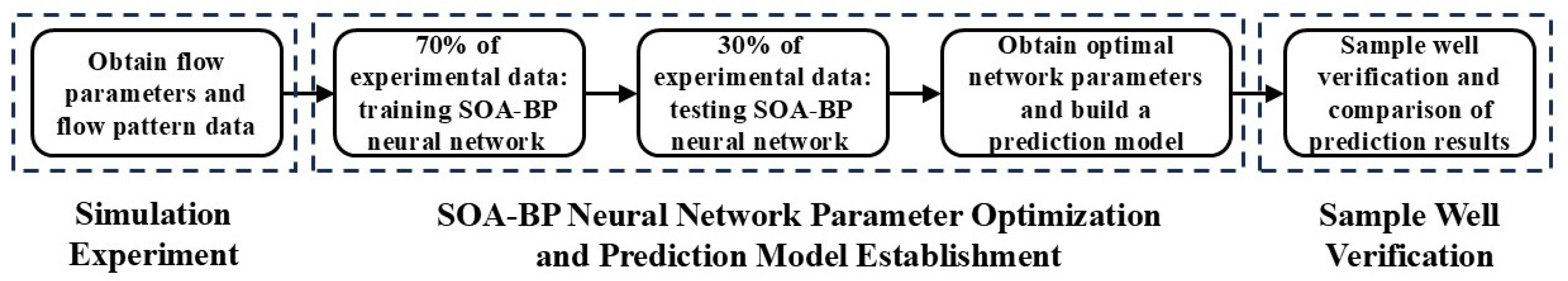

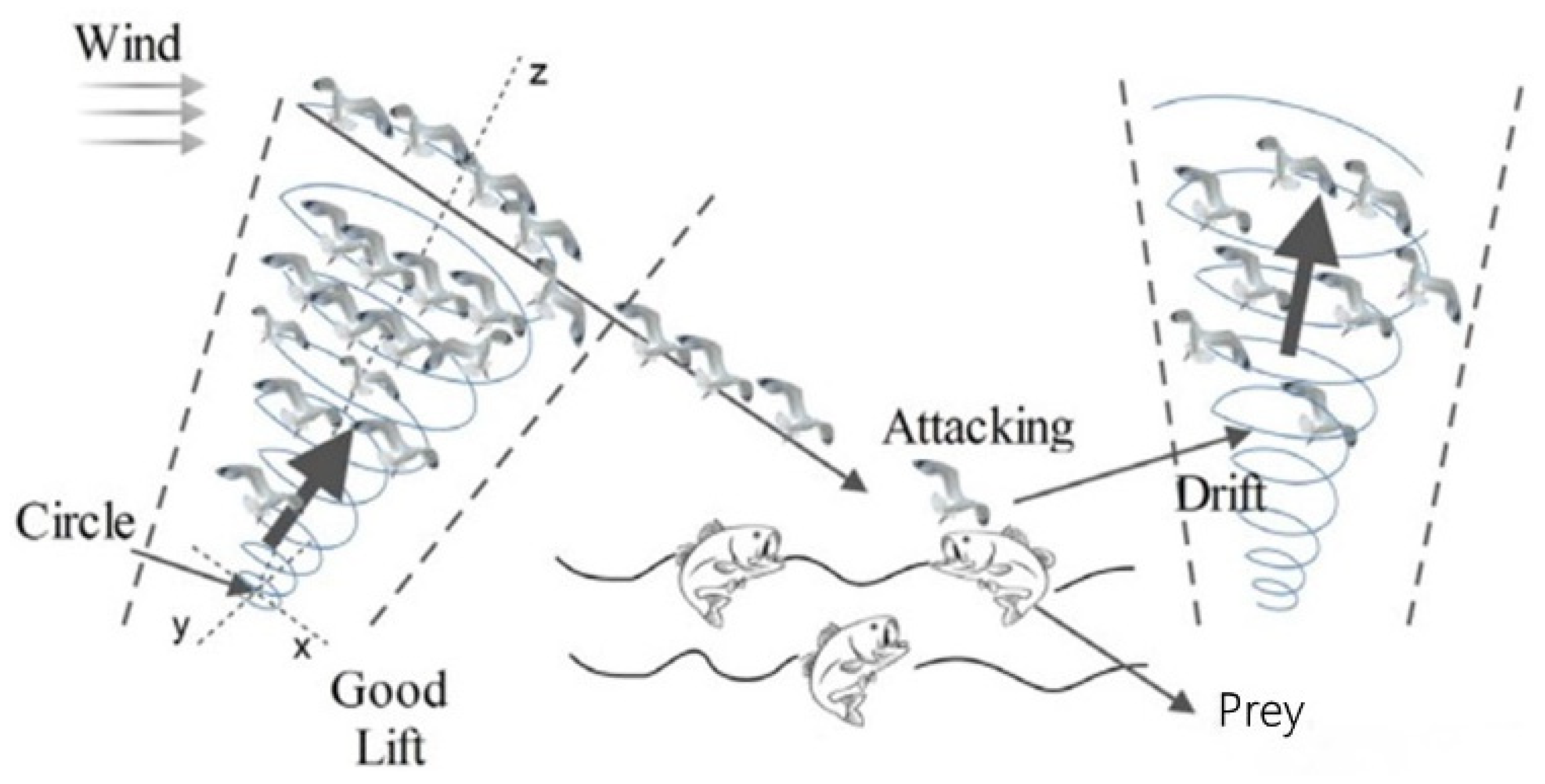

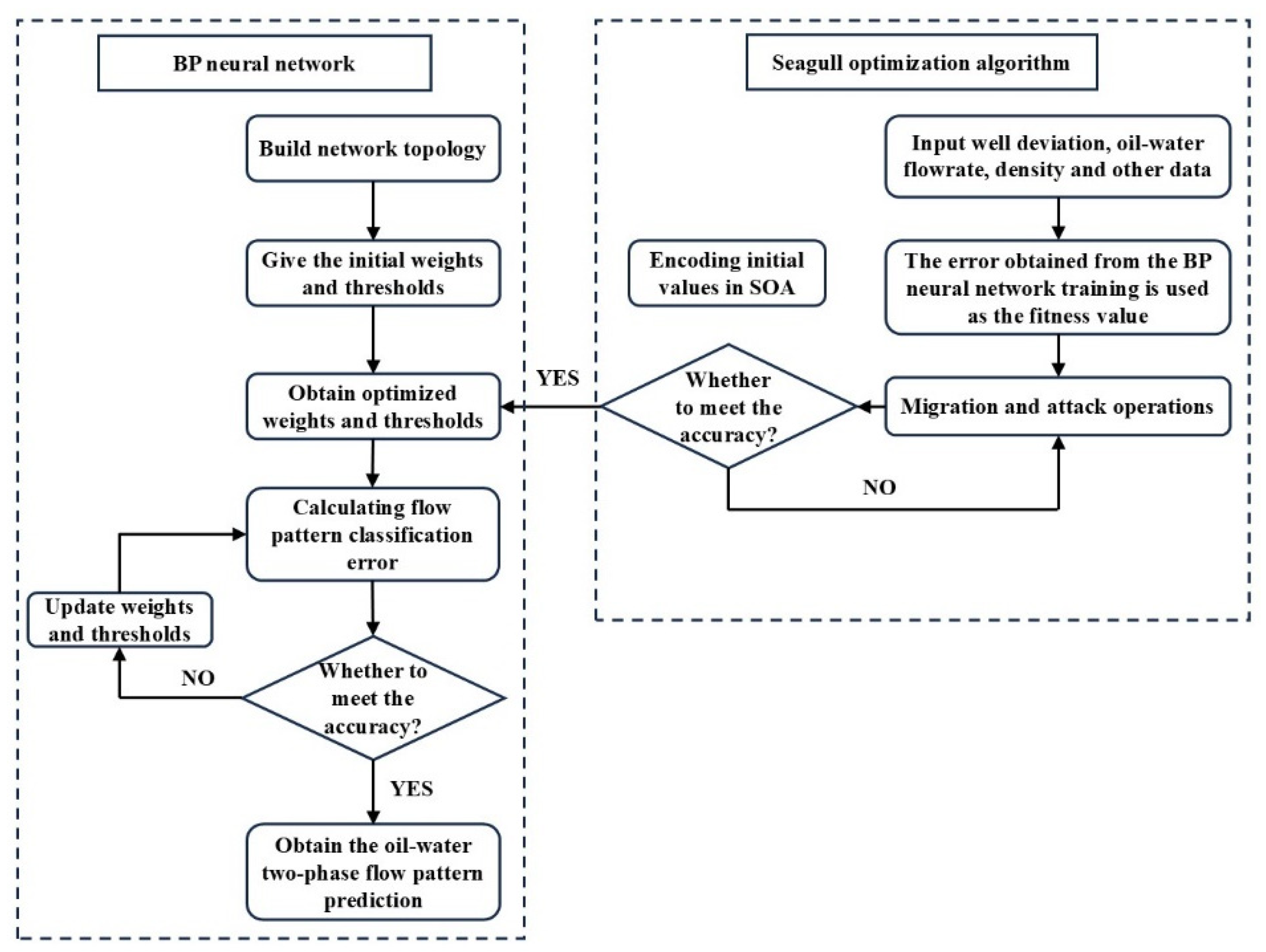

The variability in flow conditions in horizontal wells adds layers of complexity to the characteristics of oil-water two-phase flow. This flow is not only affected by factors such as well slope angle, total flow, and water cut. Additionally, it displays various flow patterns as a result of the intricate geological and physical conditions in the downhole. The accurate prediction of these flow patterns is crucial for the dynamic monitoring of production logging and the accurate processing and interpretation of logging data. This paper employed a multiphase flow simulation experimental device to recreate the oil-water multiphase flow patterns in a wellbore. The experimental equipment was designed to mimic an actual wellbore in terms of size. By adjusting the experimental parameters, such as well inclination angles, flow rates, and water contents, the researchers were able to investigate different multiphase flow regimes. Data on the oil-water two-phase flow state were collected and captured using video during the trials. The main benefit of this experimental technique is its simulation apparatus, which accurately replicates actual downhole conditions, resulting in more precise flow parameters and flow pattern data. Compared with small-well-size multiphase flow simulation experiments, numerical simulations, and studies that depend on multiphase flow databases, this method offers higher realism and accuracy, resulting in a dependable data foundation for subsequent modeling. Based on the experimental data obtained, a flow pattern prediction model for oil-water two-phase flow was constructed by combining the Seagull Optimization Algorithm (SOA) with the BP neural network. The SOA-BP neural network model leverages the global search capabilities of the SOA to optimize the initial weights and biases of the BP neural network, hence improving the model’s learning capacity. This approach enables the model to learn and interpolate flow pattern data for predictions based on limited physical experimental data. The SOA-BP neural network has the advantage of efficiently capturing the intricate nonlinear connections among various flow parameters (such as well inclination angle, flow rate, and water content) and the flow pattern. Additionally, the optimization algorithm reduces the likelihood of overfitting, thereby enhancing the model’s ability to generalize. In order to validate the effectiveness of the prediction model, this study randomly selected data points from sample wells with varying well inclination angles, flow rates, and water content conditions, which were then used in the forecasting model for validation, and the outcomes indicate that the SOA-BP neural network model achieves a high level of accuracy in predicting outcomes under various working conditions.

The prediction model utilizing the SOA-BP neural network exhibits extensive potential for practical applications. By inputting downhole fluid parameters, the model can accurately identify the oil-water two-phase flow pattern in horizontal wells. This provides strong support for the dynamic monitoring of production logging. Compared with traditional methods, this AI-based prediction model not only enhances the accuracy of logging data processing and interpretation but also adapts to the complex and changing downhole conditions, providing more precise technical support for oilfield development.

The paper is organized as follows:

Section 2 summarizes the experimental procedure.

Section 3 analyzes the oil-water two-phase flow patterns.

Section 4 discusses the prediction of oil-water two-phase flow patterns using the SOA-BP neural network.

Section 5 validates the prediction model with sample well data. Finally, conclusions and suggestions are presented.

2. Experimental Summary

This study conducted an oil-water multiphase flow experiment in the multiphase flow laboratory of the Key Laboratory of the Ministry of Education for Oil and Gas Resource Exploration Technology at Yangtze River University in order to replicate the oil-water flow dynamics in a wellbore and evaluate the distribution of flow patterns. The experiment replicated the behavior of oil-water two-phase flow while adjusting the well slopes, flow rates, and water contents.

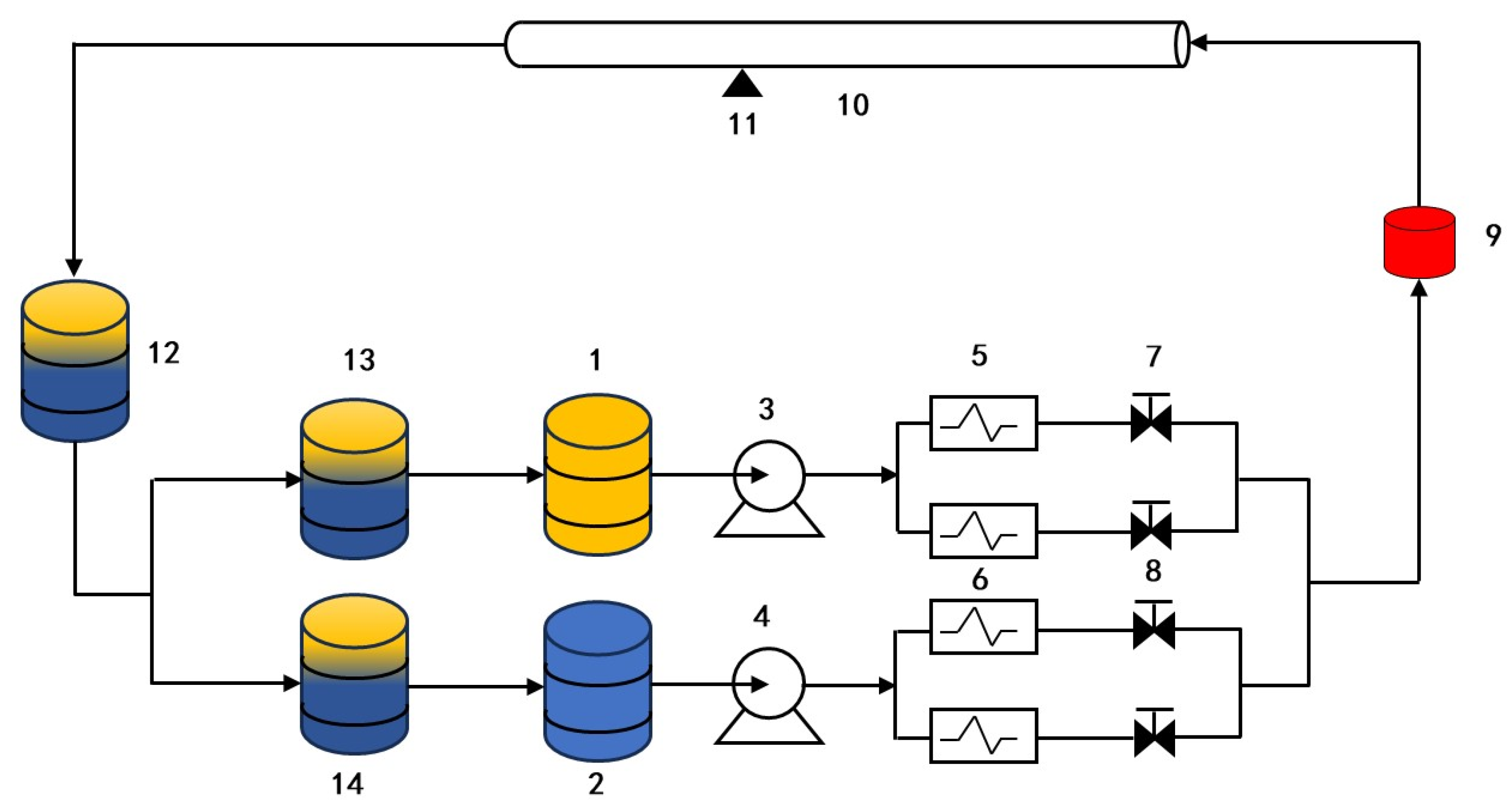

Figure 1 displays a schematic diagram of the laboratory equipment. To realistically replicate the downhole conditions, a transparent Plexiglas wellbore with an outer diameter of 156 mm (similar to the actual wellbore size) and a length of 12 m was used. The transparent wellbore design not only facilitated the observation and recording of the flow state but also allowed real-time monitoring of changes in the flow pattern. Under ambient temperature and pressure conditions (20 °C, 95.89 kPa), industrial white oil (No. 10) with a density of 826.3 kg/m

3 and a viscosity of 2.92 mPa∙s, coupled with tap water (988.4 kg/m

3 and 1.16 mPa∙s), was utilized to simulate subsurface crude oil and reservoir water, respectively. The properties of the downhole fluids closely resembled those of real fluids, which guaranteed the correctness and reliability of the experimental results.

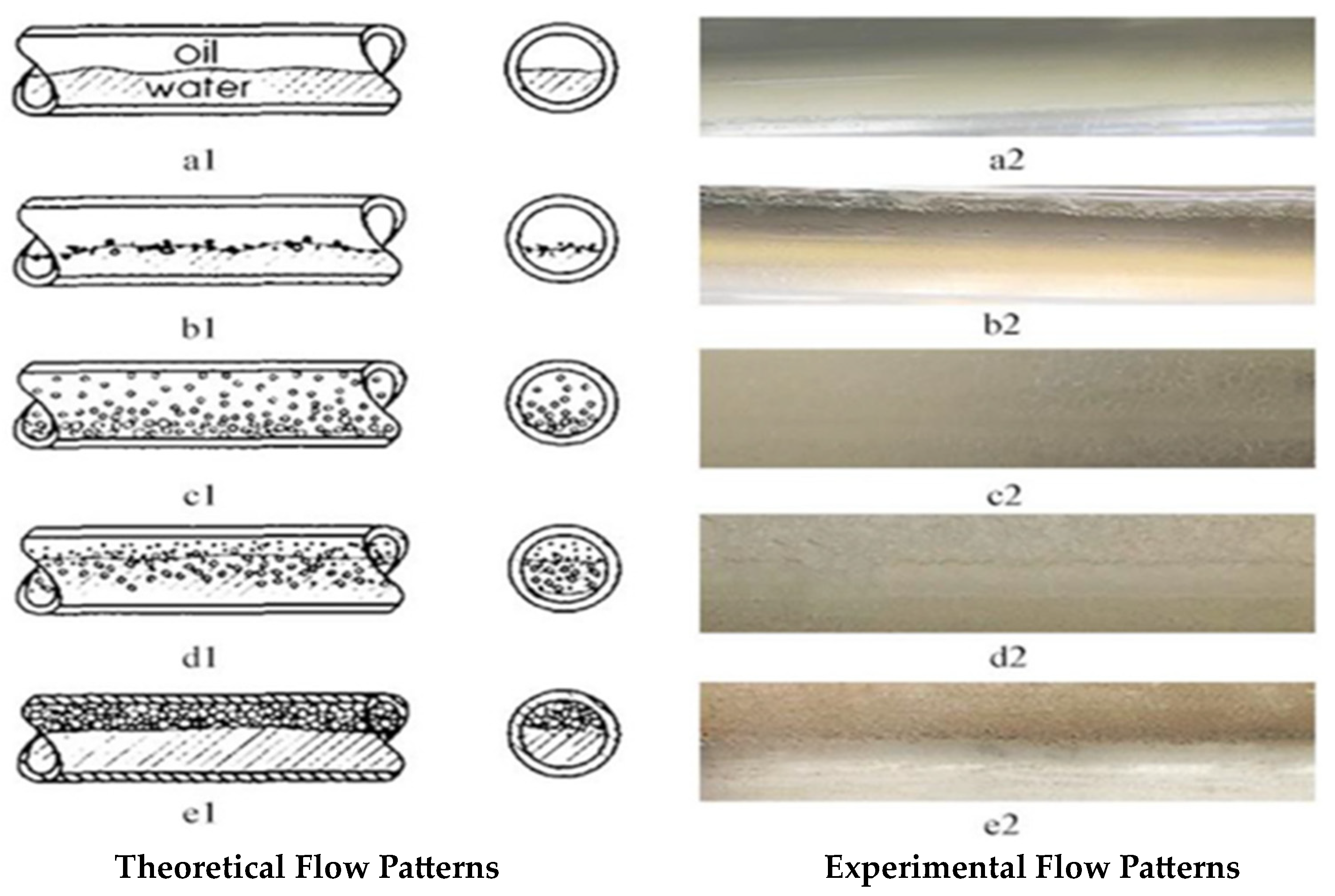

The fluid storage component of the experimental arrangement comprised a white oil tank, a tap water tank, and an oil-water separation tank. These tanks had a crucial function in the overall experimental configuration, since they were responsible for storing and reusing fluids. During the experiment, the oil storage tank and water storage tank stored white oil and tap water, respectively. These substances were crucial for the simulation experiment. The fluids in question were the authentic crude oil and formation water extracted from the well. It was of utmost importance to store and handle them correctly in order to ensure the experiment ran smoothly. The oil-water separation tank was used to separate the mixed fluids after the experiment, facilitating the reversion of oil and water to their respective tanks for the purpose of recycling. During the experiment, the oil and water were initially manipulated by pumps and flow meters to ensure that each fluid entered the oil-water mixer at a precise flow rate. The primary function of the oil-water mixer was to uniformly blend the two fluids in a predetermined proportion, replicating the oil-water two-phase flow conditions experienced downhole. The emulsion of oil and water was subsequently injected into the simulated wellbore, where it circulated internally. As the fluid was introduced, the interface between oil and water gradually stabilized due to gravity and the flow characteristics of the fluid itself. This stable state had a substantial impact on the establishment and evolution of the flow pattern. In order to thoroughly examine the distribution of the oil-water interface, the experimental setup incorporated an observation point located at two-thirds of the length of the simulated wellbore. At this point, a camera recorded real-time video footage of the changes occurring in the oil-water interface during the experiment.

This configuration enabled the capturing of temporary flow conditions and simplified the examination and evaluation of the complete experimental procedure, offering useful visual information to support the investigation of flow patterns. Once the oil-water mixture had flowed through the simulated wellbore and completed the flow, it was directed into the oil-water separation tank. The main purpose of this tank was to efficiently segregate the oil and water in the fluid, guaranteeing the separate recovery of pure oil and pure water.

After being separated, the uncontaminated oil was sent back to the oil storage tank, while the purified water was sent to the water storage tank. This procedure not only guaranteed the smooth flow of fluid but also reduced fluid wastage during the experiment.

As shown in

Table 1, the experiments were designed with total flow rates of 60, 80, 100, 120, 140, 160, 180, 200, 300, and 600 m

3/d, with water content varying from 0% to 100%, specifically at 20%, 40%, 60%, 80%, and 90%. The well inclination angles were set at 0°, 60°, 85°, and 90°, covering vertical, inclined, large inclined, and horizontal wells. A total of 200 sets of experimental data were collected during the experiment.

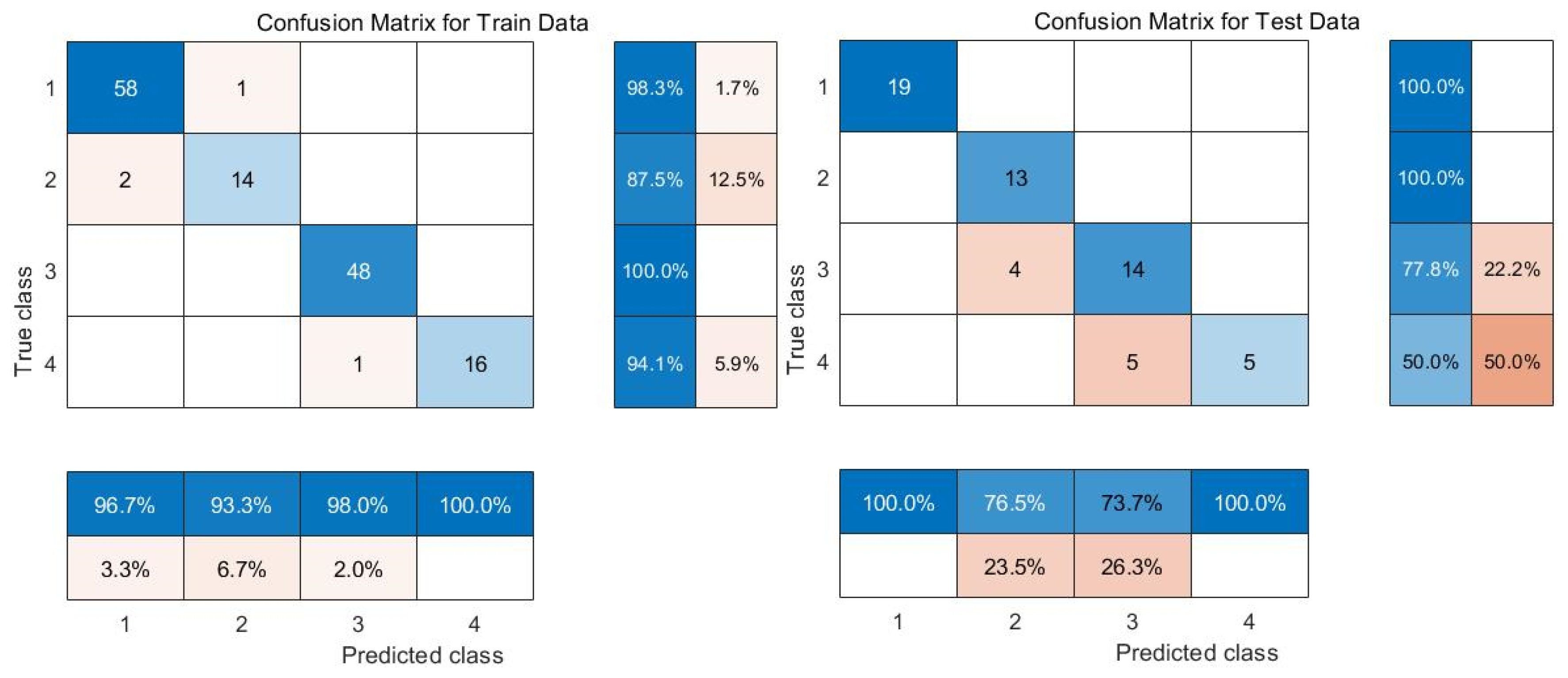

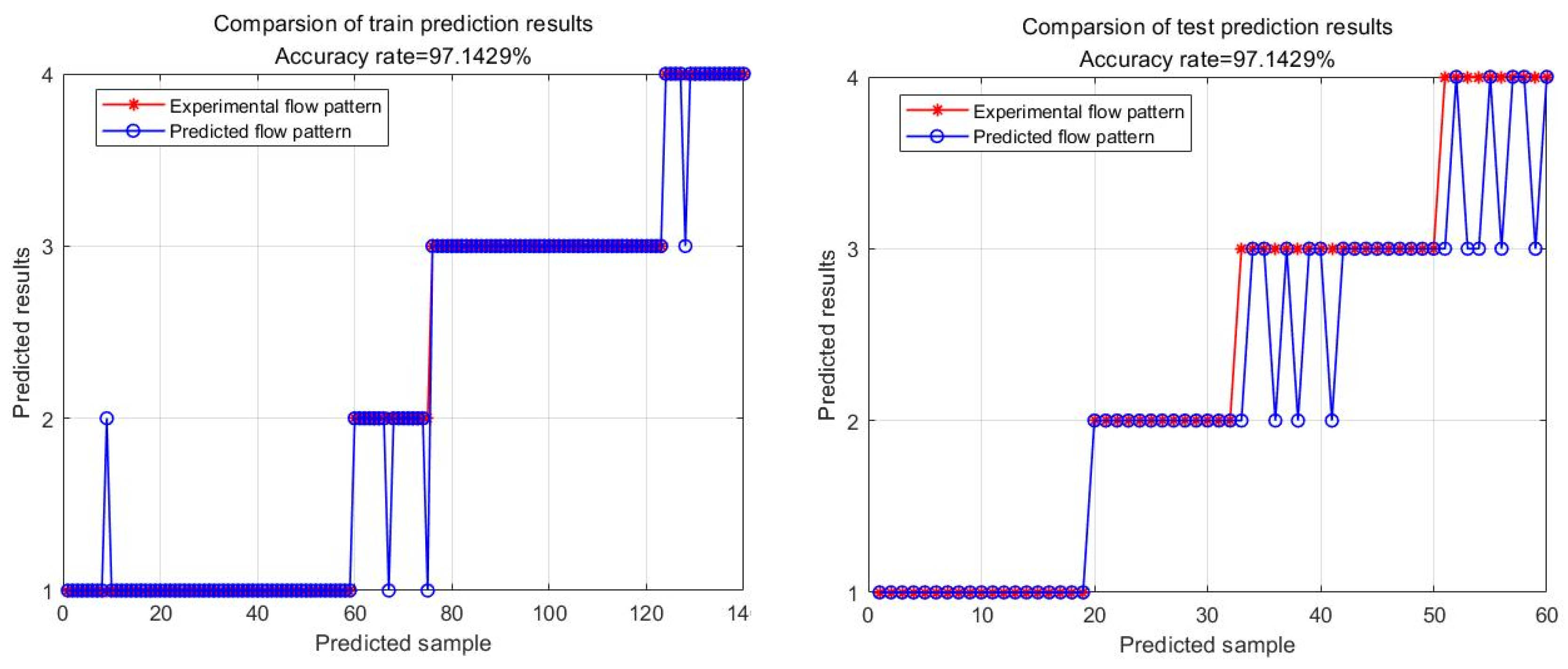

5. Model Verification

This research successfully developed a model to forecast oil-water two-phase flow patterns, leveraging the training and testing outcomes of the SOA-BP neural network. By conducting a thorough examination of the experimental data, the weights and thresholds of the neural network were fine-tuned to ensure that the model precisely captured the intricate flow features of oil-water two-phase flow. In order to evaluate the effectiveness of the model in practical situations, data from a representative well were selected to forecast flow patterns, and these forecasts were subsequently compared with the actual well logging data. The Resistive Array Tool (RAT) and the Capacitive Array Tool (CAT) were used to obtain oil-water flow pattern information in the wellbore. The RAT is a high-precision measurement tool designed to address the challenge of identifying fluid phases in oil-water two-phase flow. The RAT features a very compact structural design, consisting of twelve miniature sensors secured in a bow spring, as shown in

Figure 12. These sensors precisely assess various flow properties in the wellbore. The RAT is capable of precisely measuring fluid resistivity values at various locations within the wellbore. Since water has low resistivity and high conductivity, while oil has high resistivity and low conductivity, the RAT can accurately determine the oil-to-water ratio in the wellbore by measuring these resistivity differences.

The Capacitive Array Tool (CAT) is a logging tool specifically designed to identify the flow pattern of two-phase oil and water streams. The assembly of the device comprises twelve small capacitive sensors that are installed on a bow spring plate, as depicted in

Figure 13. The CAT provides critical information about the flow pattern of oil and water by accurately measuring the capacitance signal inside the wellbore. The CAT operates based on the differences in dielectric constants among fluids; gas, water, and oil have distinct dielectric constants—gas has a dielectric constant of 1, water has a dielectric constant as high as 80, and oil has a dielectric constant between that of gas and water. The significant disparity in dielectric constants enables the CAT to identify fluid phases by sensing alterations in capacitance within the wellbore. The detection principle indicates that gas and water exhibit low and high values, respectively, in CAT measurements, while oil readings are typically closer to those of gas. By detecting the circuit frequency signal corresponding to the phase state around the sensor, the CAT can accurately determine the fluid composition in the wellbore and identify the flow pattern of oil and water.

Measurement data from the RAT and CAT provide comprehensive fluid information within the wellbore. By carrying out thorough analysis of these data, it is possible to accurately deduce the distribution of oil and water in the wellbore, as well as identify different kinds of flow patterns. The measurements are essential for verifying the accuracy of the SOA-BP neural network flow pattern prediction model.

To further verify the effectiveness of the oil-water two-phase flow pattern prediction model proposed in this paper, multiple data points featuring various well inclinations and oil-water flow rates from Well A were randomly chosen for flow pattern forecasting. These forecasts were derived from real wellhead production data and interpretations of production profiles. The forecast outcomes were subsequently juxtaposed with the measurement outcomes acquired from logging equipment (RAT and CAT). The results of the prediction are displayed in

Table 3.

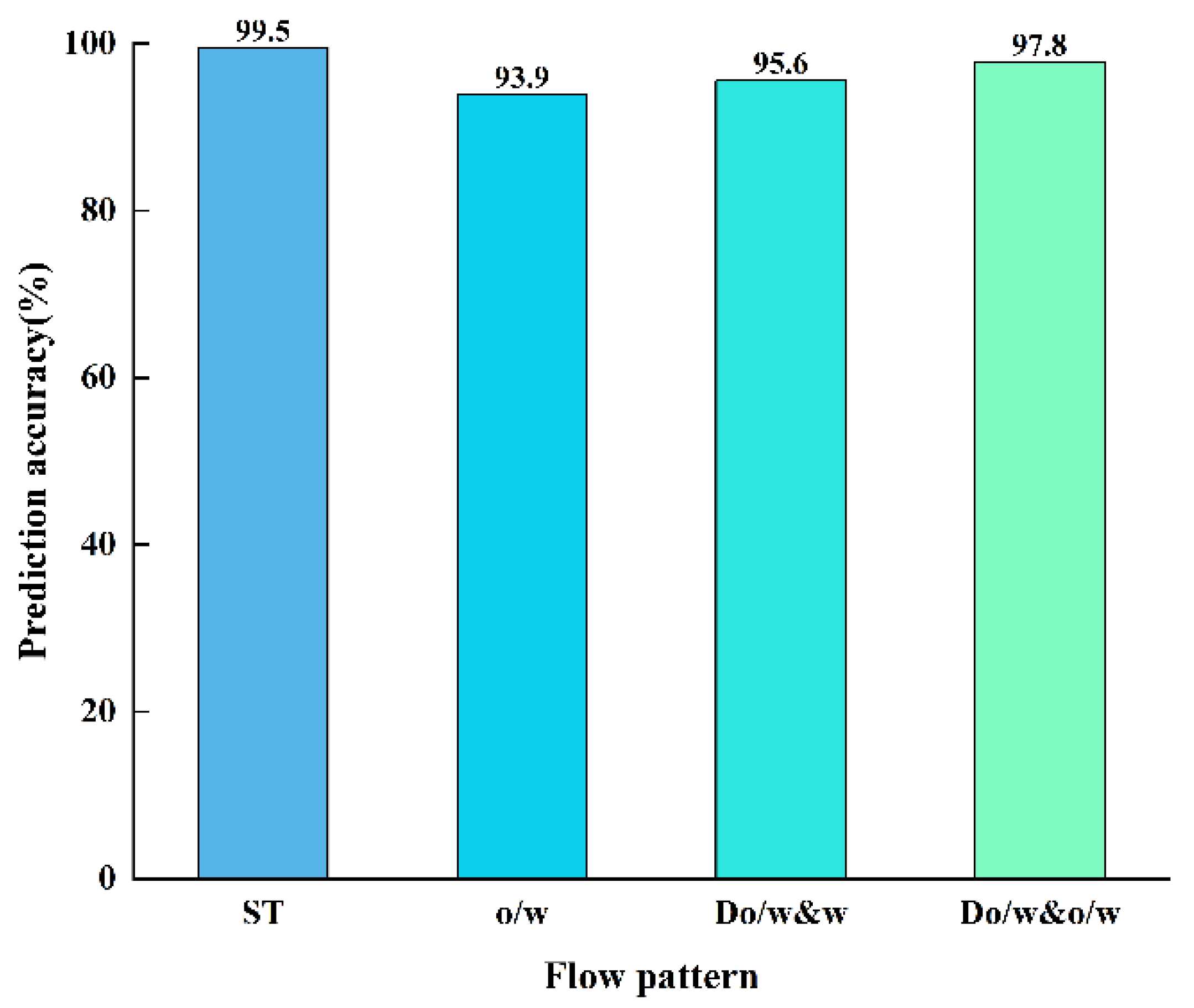

Table 3 presents a compilation of 15 data points that were measured, along with the outcomes of both the observed and predicted flow patterns. The forecasting model shows the best performance for the ST and Do/w&o/w flow patterns, achieving an accuracy of 100%. However, there is a certain degree of inaccuracy in predicting the o/w and Do/w&w flow patterns. The overall prediction accuracy is 86.67%, which essentially meets the accuracy requirements for production dynamic monitoring. In the validation results for Well A, two flow pattern prediction errors were identified. Three potential reasons that could lead to these inaccuracies were (1) only 200 sets of data were used to train and test the prediction model, and the limited amount of data may have resulted in insufficient prediction accuracy; (2) differences in parameters such as temperature, pressure, and fluid viscosity between the simulated wellbore in the physical experiments and the actual conditions in Well A could have led to variations in the downhole flow pattern; (3) the measurement data from the logging instruments may not have accurately reflected the actual fluid flow pattern in the wellbore.