Abstract

Leveraging machine learning applications for predictive process control signifies a decisive advancement in manufacturing quality management, transitioning from traditional descriptive to predictive capability indices. This review highlights the growing importance of predictive process control, essential for quality assurance and the dynamic adaptability of production lines, which is paramount in satisfying stringent quality standards and evolving consumer demands. The investigation into the integration of comprehensive sensor networks and sophisticated algorithmic analytics enriches continuous improvement strategies, markedly enhancing the accuracy and efficiency of production quality monitoring and control mechanisms. By moving beyond the limits of statistical process control to predictive methods enabled by machine learning algorithms, the study presents a transformative leap in manufacturing processes. The presented findings illustrate the critical role of predictive algorithms in navigating the complexities of process variability, thereby ensuring consistent adherence to established quality specifications. This approach not only facilitates immediate and accurate product quality categorization, increasing overall operational efficiency, but also equips manufacturers to swiftly respond to the variable nature of manufacturing requirements. Furthermore, this research delves into the multifaceted impacts of predictive process control on the manufacturing ecosystem. The ability to predict process quality decrease before it occurs, the optimization of resource allocation, and the anticipation of production bottlenecks before they impact output are among the notable benefits of this technological evolution. These developments to predictive process control is instrumental in propelling the manufacturing industry toward a more agile, sustainable, and customer-centric future. This shift not only complements the industry’s drive toward comprehensive digitization but also promises significant strides in achieving superior process improvements and maintaining a competitive edge on the global market.

1. Introduction

The digital era has profoundly reshaped the landscape of manufacturing industries. At the core of these changes is the imperative for businesses to adapt to escalating consumer demands and to the principles of continuous improvement management. The challenge that arises for manufacturers is the establishment of production processes that are both robust and efficient [1]. When the stringent requirements of these processes are not met, there often is a necessity for physical intervention which can compromise the stability of these processes. Central to the decision making in process adjustments is the Process Capability Indicator (PCI). The PCI functions as an analytical benchmark, facilitating the evaluation of a process’s ability to produce output within predefined quality limits. It is a crucial determinant of whether a production process conforms to specific numerical quality thresholds, aiding in the assertion of quality adherence [2]. The evaluation of process capability necessitates a sequential documentation of the inherent quality criteria of products during their manufacturing stage. This implies that continuous measurements must be integrated within the production process, capturing data in a temporal sequence. Such data are then analyzed using Statistical Process Control (SPC) methodologies to compute the PCI. By examining the statistical positional parameters of a sample, a metric is developed, from which inferences regarding the defect rate and overall process quality can be extrapolated [3].

The rise of advanced data processing methods, particularly in the domain of Machine Learning (ML), has had a substantial impact on this landscape. ML, a subset of artificial intelligence, refers to the development of algorithms that enable computers to learn patterns and make decisions based on data. Unlike traditional programming, where explicit instructions are coded, ML algorithms learn from data inputs and can improve their performance over time. This ability to learn and adapt makes ML particularly effective in enhancing predictive decision making by leveraging large datasets. As the volume and quality of data grow, so does the accuracy of statistical prediction algorithms, thereby enabling a more refined approach to quality control and process optimization [4]. Furthermore, technological advancements are not limited to data acquisition; they also encompass data transmission, enabling real-time data processing and facilitating immediate data analysis for advanced decision making [5]. The implementation of such technologies plays a pivotal role in ensuring ongoing monitoring of process quality and adherence to customer specifications, thereby driving sustainable improvements in process reliability and efficiency [6]. This method will hereafter be referred to as Predictive Process Control (PPC), which involves the prediction of critical quality attributes for process control.

The structure of the paper is as follows: Section 2 presents a detailed review of existing literature on PPC, emphasizing the integration of ML applications for enhancing manufacturing quality management. In Section 3, the methodology adopted for the systematic literature analysis (SLA) is discussed, including the selection criteria, data sources, and analytical approaches employed. Section 4 delves into the findings of the review, categorizing the applications of ML in PPC and highlighting key trends and gaps in the current research landscape. In Section 5, we engage in a critical discussion of the results, exploring the implications for industry practice and future research directions. Section 6 concludes the paper by summarizing the key insights and offering recommendations for leveraging ML in PPC to achieve greater operational efficiency and product quality in manufacturing.

2. Background

The implementation of process quality key figures is being contradicted by these advancements. Thus, the deployment of SPC, especially in the early stages of machine operation subsequent to the conclusion of the design phase, to configure machine parameters, represents a substantial instrument. This facilitates the continuous monitoring of quality requirements after the start of serial production (SOP). After this indicated time step, only statistically significant statements regarding the past can be made due to the descriptive characteristics and the utilization of randomized samples [7].

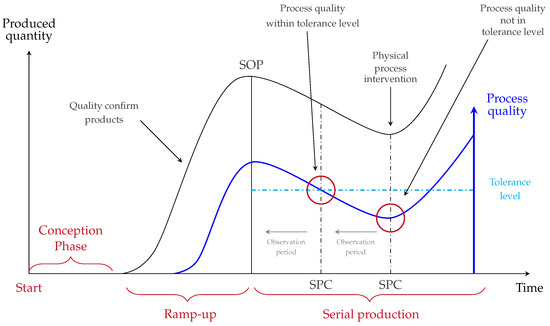

Figure 1 illustrates the chronological arrangement of the SPC and the impact associated with a decreasing number of acceptable parts, which directly influences the PCI and process quality, respectively. During the start-up phase, the process quality gradually improves to reach the desired tolerance level. At this juncture, series production begins, along with the collection of samples for the SPC. During the second iteration of the SPC, the backlog of acceptable parts falls within a range that causes the PCI to drop below the desired tolerance level. This realization prompts physical intervention in the process, resulting in an increase in the number of acceptable parts and, consequently, the process quality. However, it is evident that due to the retrospective observation period, the SPC leads to a reactive decision-making process, thus resulting in the production of avoidable missing parts. This avoidability is primarily attributed to the utilization of industrial ML-applications, which facilitate the advancement of decision support through the utilization of sensor data. However, it enables targeted statements to be made regarding future product and process quality. For instance, predictive algorithms are employed to make forecasts about production processes or to classify products into different quality groups. As a result, sustainable support processes are established to ensure compliance with the required quality criteria [8,9].

Figure 1.

Chronological arrangement of the SPC in serial production.

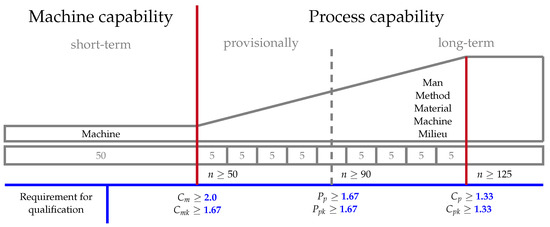

Since the primary purpose of SPC is to provide statistically significant evidence of the entire production process based on an inherent quality criterion, specific characteristics related to the process are defined to calculate the quality of the process. The quality criterion is associated with individual tolerance limits, namely the upper tolerance limit (UTL) and the lower tolerance limit (LTL), which determine whether the manufactured workpiece should be classified as rework or scrap if it exceeds or falls short of these limits [10]. To avoid the cost-intensive measure of 100% quality control in series production, descriptive indices such as process potential () and process performance () are computed based on random samples drawn to assess the quality characteristic of the products produced. This allows for statistically significant conclusions to be drawn regarding compliance with the tolerance limits for the entire population. Moreover, by using different sample sizes, adjusted assessments of the influences of factors such as human, material, method, and environment on the process can be made [11]. When a sample size of 50 is used for the calculation, the defined metrics are machine capability () and machine potential (), which assumes a less powerful statement about the capability. Herein, only 1 M (Machine) is under control, whereas a higher sample size assumes more influence (5 M) is under control (in addition to Machine: Man, Method, Material, and Milieu). In each case, the potential is interpreted by comparing the tolerance limits to the spread. The capability indices further relate the scatter width to statistical position parameters, enabling the determination of both the process variation and the quantity of defective parts produced [2].

According to Dietrich and Conrad [12], the distinctive characteristic of the determined indicator resides in both the temporal sampling of the sample and its size. Figure 2 presents a temporal relationship between the indicators and the level of confidence in their enablement.

Figure 2.

Classification and characterization of capability indices, following Dietrich and Conrad [12].

For the determination of the capability indices, only single measured quality attributes are utilized. Similarly, ML algorithms are designed with a single dependent variable, which enables the transformation of previous descriptive capability indices into predictive capability indices. Supervised algorithms, which leverage historical data to adapt to the past behavior of dependent variables, can optimize learning behavior by expanding the descriptive variables with sensor values. However, autoregressive models also allow for univariate predictions. Unsupervised algorithms, predominantly used for pattern recognition, enable classifications based on defined clusters. Nonetheless, these classifications do not establish a concrete affiliation and may indicate other dependencies within a cluster [13]. This interpretive limitation restricts the application of PPC. Given the diverse outcomes of ML algorithms and the multilevel execution of SPC, supervised prediction algorithms serve as the foundation for addressing the challenge of PPC.

In the context of digitized industries, various forecasting methods have been developed and applied to enhance process control and quality management. Table 1 provides an overview of some of these existing forecasting methods, along with their descriptions and relevant citations:

Table 1.

Existing forecasting methods which can be used for PPC.

These forecasting methods represent a blend of traditional statistical techniques and modern machine learning approaches, each offering distinct advantages depending on the specific requirements of the manufacturing environment.

2.1. Interpretation of ML Applications in the Context of PPC

As a consequence of the predominant focus of applied ML technologies on optimizing decision processes and their outcomes, the interpretation and causation of predictive elements have been increasingly overlooked [16]. This characterization has led to the inclination to develop intricate algorithms known as black-box models, which only permit limited inferences about algorithmic decision making. Only in recent years have endeavors to develop interpretable models become discernible. These efforts are encompassed by the comprehensive term “explainable Artificial Intelligence” (xAI) [17]. Given the importance of interpreting the results, xAI methods contribute to an increase in information within the context of process quality. In order to situate industrial ML applications in a suitable environment, companies must consider not only information gains and knowledge transfer but also various concepts for the industrial application of decision-supporting ML in quality management for operational integration [18]. The primary focus lies in functionality, although the economic benefit can only be partially measured and the integration costs are a critical determinant of the technology’s success. With the shift towards digitized corporate environments, production companies are confronted with the decision of which decision-making processes should be supported by ML and what requirements should be met by the application [19].

In order to be able to place industrial ML applications in an appropriate environment, not only information gains and knowledge transfer play a decisive role for companies. Therefore, a variety of concepts for the industrial application of decision-supporting ML in quality management for operational integration is available [18]. The main focus is on functionality, whereby the economic benefit can only be measured to a limited extent and the integration costs are a decisive factor in the success of the technology. Due to the industrial adaptation to a digitized corporate environment, production companies are faced with the decision as to which decision-making processes are to be supported with the help of ML and which requirements are to be met by the application [19].

2.2. Scope and Aim of the Study

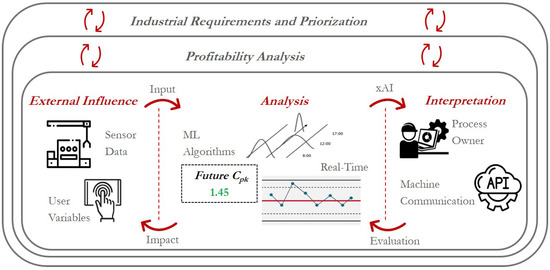

The ultimate goal of an ML application is to continuously supervise the quality of the production process by incorporating predictive elements. This empowers process managers to make well-informed decisions prior to the occurrence of production errors, leading to numerous advantages for the company. The decrease in defective parts not only reduces production costs by minimizing the need for rework, but also optimizes the utilization of resources that can be reassigned. Nonetheless, the deployment of ML applications in the production setting involves multiple funtional units, including both employees and machines. As depicted in Figure 3, the thematic relationships are visually presented.

Figure 3.

Operational relationships of PPC.

In the area of manufacturing, the utilization of interpretable methods is of paramount importance in order to fulfill the requisites for interactive prediction systems. To provide recommendations to process owners, it is imperative to compare the interpretive capabilities of ML methods for flexible designed models. Thus, the primary research question (RQ1) pertains to the utilization of ML methods in the field of interactive prediction systems in manufacturing and their interpretive capabilities for numerical, binary, and multiclass predictions in contrast to descriptive models.

Moreover, the accuracy of predictive algorithms plays a pivotal role in ensuring the high quality of models for numerical, binary, and multiclass prediction of the process quality, as it directly affects the intervention decision. This raises the question as to whether contemporary prediction algorithms, such as reinforcement learning and neural networks such as Long Short-Term Memory (LSTM), offer advantages over other methods in this regard. Hence, the second research question (RQ2) focuses on whether predictive algorithms can exhibit high model quality and accuracy in numerical, binary, and multiclass prediction of the value, and whether modern prediction algorithms such as reinforcement learning and LSTM provide advantages over alternative methods.

The configuration of user variables and the nature of user input are critical factors that shape the effectiveness of ML systems, especially in process qualification assessment. These factors necessitate flexible evaluation criteria that can adapt to different user-defined settings for learning and prediction intervals, as well as to the complexities introduced by handling multiple classes for predictions within each category of the qualification process. Accordingly, the third research question (RQ3) examines how the user interface design of ML systems can accommodate the diverse requirements introduced by varying user inputs, such as changes in learning and prediction timeframes, classifications within multi-class prediction scenarios, and the adjustment of intervention thresholds. This exploration is vital to ensure that ML models remain robust and accurate when faced with the dynamic conditions posed by end-user interactions and their individual needs during the process qualification assessments.

Conclusively, the objective of this study is to examine the capabilities of ML methods for interactive prediction systems in process quality assessment and compare them to interpretable models. In addition, it seeks to assess the accuracy of predictive algorithms for value prediction and compare contemporary prediction algorithms with alternative methods. Finally, it aims to investigate the alterations in evaluation criteria for ML models in response to changes in learning and prediction horizons, multi-class prediction per class, and intervention boundaries.

3. Methodology

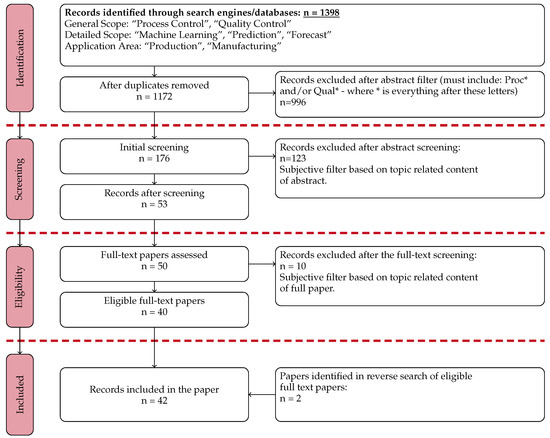

Reviewing literature systematically, according to Okoli and Schabram [20], is used as a methodology for the successive development of relevant information (Figure 4). For this purpose, the authors define a workflow that explicitly refers to SLA in information systems research.

Figure 4.

Sequence of the SLA in accordance to Okoli and Schabram [20].

The pre-selected online libraries, namely Google Scholar, Web of Science, and Scopus, encompass the majority of the literature that is generally accessible, as stated by [21]. However, it cannot be disregarded that relevant literature may have been published beyond the confines of the selected libraries. Nevertheless, the proportion of literature that is not typically found in the selected online libraries is relatively small. To ensure that no relevant works have been overlooked, a reverse search was conducted by examining the references of the filtered works. This process involves reviewing the cited references within each selected paper to identify any additional relevant studies that may not have appeared in the initial search, thereby enhancing the comprehensiveness and accuracy of the literature review.

The search itself is conducted based on various combinations of terms, which are within the context of PPC. However, prior to this, Vom Brocke et al. [22] highlighted the impact of selecting predefined search terms on the outcomes. In order to ensure a more unbiased search, blocks are categorized using keywords and all combinations from these blocks are inputted as search patterns. This methodology serves to minimize the error rate in terms of identifying relevant work. For this particular study, the search terms are divided into three combination blocks. Each block is assigned to a category that holds significance for the process index. The first block focuses on fundamental topics, such as “Process Control” and “Quality Control”. This is followed by a secondary determination of the specific focus of the research. Given the distinct characteristics, two blocks are utilized for this purpose—one describing the application and the other categorizing the type, thus thematically classifying the application. The first subordinate block employs the terms “machine learning”, “prediction”, and “forecast”. The final block completes the search with the terms “production” and “manufacturing”. Consequently, a total of twelve different combinations are generated. The search encompasses publications from the past ten years. The quantitative outcome of the literature search reveals a total of 1398 papers retrieved.

4. Results

Due to the research work already carried out on the use of ML in the context of product and process quality, a broad body of knowledge can be drawn upon. The objective of the SLA is the elaboration of relevant literature to describe the current findings of PPC. Furthermore, research gaps related to the dependencies (Figure 2) of PPC are subsequently identified. Specifically, categories are defined to describe the industrial application of the research. These target the production engineering background, the applied statistical methodology, the experimental setup, and the data used.

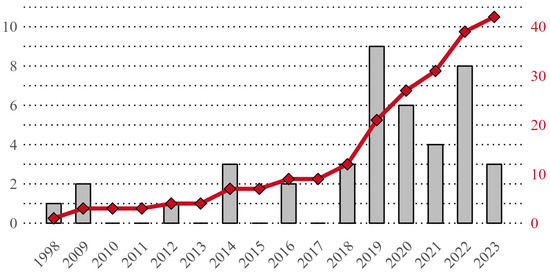

To emphasize the current relevance and significance of the research endeavor, it is worth noting that Figure 5 provides a comprehensive illustration of the quantity of pertinent publications that have emerged in recent years. This visual representation clearly demonstrates the substantial concentration of scholarly works focusing on the same subject matter since 2018, which in turn underscores the unwavering commitment and fervor exhibited by the research community in their pursuit of various inquiries pertaining to PPC. It is of particular interest to note that a substantial proportion, specifically approximately 65%, of the articles identified in the SLA were disseminated during this specific timeframe, thereby affirming the heightened level of scholarly discourse.

Figure 5.

Periodic development of relevant papers by year and cumulated.

4.1. Industries

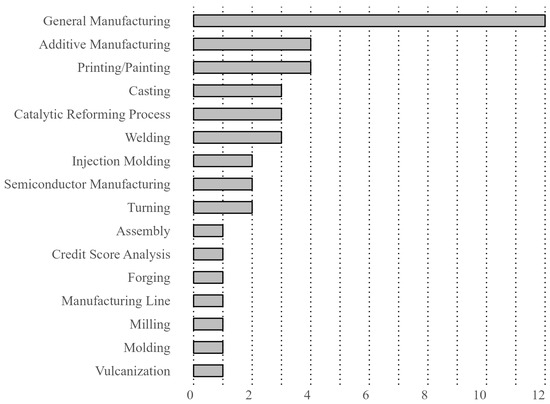

Cheng et al. [23] delved into the Catalytic Reforming Processes, which play a pivotal role in the production of high-octane fuels, thus making a significant stride towards addressing the conundrum of energy sustainability. Schäfer et al. [24] shed light on the Printing/Painting industry, ambitiously seeking avenues to enhance efficiency and sustainability. Equally significant is the examination of Casting processes by Mishra and Rane [14], a process of paramount importance in ensuring the manufacturing of high-quality components across various sectors.

In the field of injection molding, which is a crucial component of plastics manufacturing, significant advancements have been made by researchers such as Ke and Huang [25]. Their work focuses on enhancing efficiency and promoting sustainability within plastic production processes. Additionally, the transformative potential of additive manufacturing, particularly in sectors such as aerospace and healthcare, has been widely explored. Key contributions in this area have been made by Ismail et al. [26], Krauß et al. [27], and Zhang et al. [28], whose research is instrumental in advancing the capabilities and applications of 3D printing technologies.

The complex and diverse field of general manufacturing has been thoroughly analyzed by scholars such as Viharos and Jakab [29], Teinemaa et al. [30], Abbasi [31], and Nalbach et al. [32]. Their research provides valuable insights into a wide range of manufacturing techniques and technologies, offering significant contributions that impact various industrial sectors. The semiconductor manufacturing industry, which is critical to the electronics sector, has also seen groundbreaking advancements through the work of Schrunner et al. [33].

In the domain of welding technologies, essential to industries such as construction and aerospace, important progress has been made by Escobar et al. [34]. Additionally, related fields have benefited from the research on credit score analysis by Boaventura et al. [35], which paves the way for more accurate risk evaluation models. Finally, the review highlights the contributions of Köksal et al. [36] to molding technologies, particularly in advanced polymer processing, with implications for the automotive, medical, and consumer goods industries. Figure 6 presents a visual summary of the industries examined in the review, highlighting the diverse areas where significant advancements have been made through research. The figure showcases the breadth of industries impacted by PPC and relevant studies.

Figure 6.

Occurence of different industries found in the relevant literature.

4.2. Data

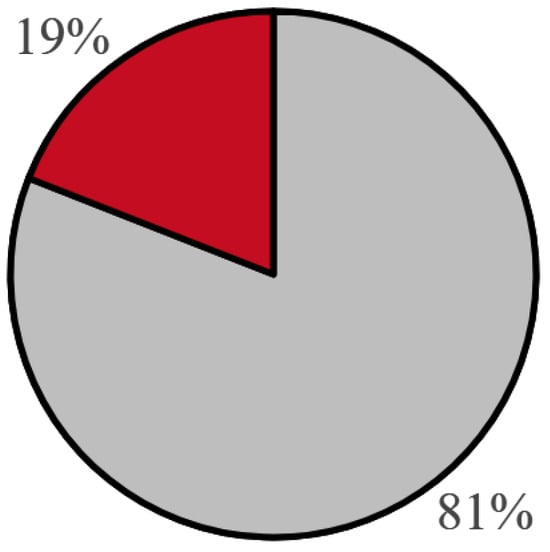

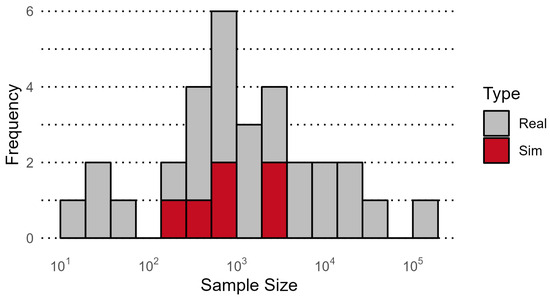

In the context of PPC, the comparison of datasets from diverse case studies is essential for understanding the robustness and generalizability of findings. These studies have been conducted by various researchers and teams, each bringing unique expertise and perspectives to the analysis. Notably, approximately 19% of the analyzed datasets are synthetic. Synthetic data hold particular value in scenarios where real-world data are limited or when specific conditions must be replicated for analysis, offering a flexible and controlled alternative for testing and validation purposes (Figure 7). The data utilized in these studies originate from a range of sources, including real-world observations, controlled experiments, surveys, and synthesized datasets differing in their size (Figure 8).

Figure 7.

Proportion of simulated and real data.

Figure 8.

Distribution of sample size in a logarithmic scale.

The choice of data type depends on research goals and data accessibility. These datasets have varying sample sizes, based on the research domain and methodology. One challenge for researchers is ensuring the integrity, dependability, and representativeness of the data. Data collection, validation, and preprocessing are rigorously emphasized. Additionally, ethical, privacy, and legal concerns require careful management and safeguarding of sensitive data. In the context of PPC, the data from case studies are invaluable for scientific breakthroughs and knowledge in various fields. These data facilitate replication and validation of research, highlighting the importance of transparency and responsibility in science.

4.3. Design of Experiments

The studies encompass a broad spectrum of experiments within the realm of manufacturing and quality control. For instance, Afrasiab and Khodaygan [37] measured control points and employed Monte Carlo Simulation to relate them to workpieces, calculating Capability Ratios for quality assessment. Meanwhile, Schäfer et al. [24] focused on predicting maintenance needs for grippers and failure forecasting systems within an electronics production cell. On the other hand, Ke and Huang [25] conducted a two-factor full-factorial experiment to explore correlations between process parameters and quality indicators for injection molding, using MLP neural networks for prediction.

Several experiments emphasized the importance of ML and predictive modeling. Li et al. [38] compared ensemble learners with traditional algorithms for predicting steel quality, while Zan et al. [39] utilized Bi-LSTM to analyze historical data patterns in histograms and line charts. Khoza and Grobler [40] evaluated various ML algorithms for multivariate SPC. Similarly, Teinemaa et al. [30] and Jeereddy et al. [41] employed ML techniques for event log evaluation and unit production prediction, respectively.

In addition to quality control and predictive modeling, some experiments concentrated on optimizing manufacturing processes. Cheng et al. [23] employed an individual adjusted simple linear regression to improve manufacturing processes, while Wuest et al. [9] used process state information to adjust parameters during manufacturing, reducing quality deviations and enhancing product quality.

Furthermore, experiments by Demircioglu Diren et al. [42] and Viharos and Jakab [29] involved process monitoring and control, using Hotellings T⌃2 control charts and reinforcement learning agents to identify and rectify faults in production processes. Lastly, various studies emphasized data-driven approaches for quality prediction, such as the work by Kahya et al. [43], Mabunda and Mashamba [44], and Qiu and Xie [45].

These diverse experiments collectively contribute to advancing quality assurance, predictive maintenance, and process optimization in the manufacturing sector.

4.4. Methodologies

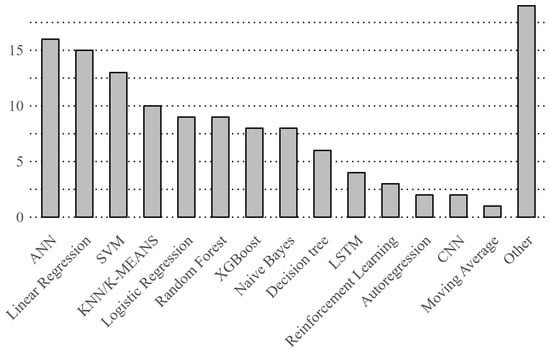

In the field of SPC, researchers from diverse backgrounds have applied ML principles to address both classification and regression challenges, employing a variety of predictive algorithms (Figure 9). For instance, some researchers, such as Afrasiab and Khodaygan [37], have utilized the Monte Carlo method specifically for regression tasks, contributing significantly to predictive modeling and forecasting within SPC. Others, such as Li et al. [38], have tackled regression problems using ensemble learning techniques, including methods such as Linear Regression, Support Vector Machines (SVM), Random Forests, and Gradient Boosting, to derive comprehensive insights. Additionally, some studies, exemplified by Abbasi [31], focus exclusively on regression by employing Artificial Neural Networks (ANNs), a versatile tool in ML. In contrast, Pheng et al. [46] leveraged LSTM networks, which are particularly well-suited for forecasting tasks. Moreover, Li et al. [47] combined Convolutional Neural Networks (CNNs) with SVMs to address regression problems, aiming to enhance predictive accuracy by integrating the strengths of these algorithms. Further diversifying the approaches, researchers such as Jeereddy et al. [41] employed a range of algorithms, including XGBoost and LSTM, to tackle regression challenges across different application domains. These efforts contribute to the broader advancement of predictive analytics and the refinement of forecasting models. Finally, Li et al. [47] continued to explore regression methodologies, seeking to deepen the understanding of predictive capabilities within their specific fields of study, thereby advancing the field of SPC.

Figure 9.

Frequency of predictive algorithms found in the relevant literature.

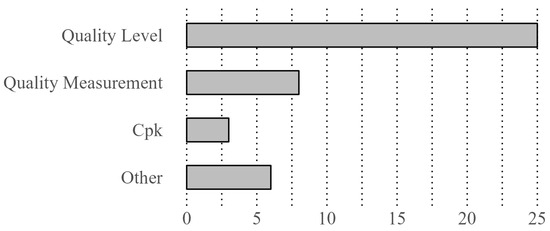

4.5. Dependent Variables

Within the field of quality control and process monitoring, researchers have examined a broad spectrum of dependent variables to improve our understanding of industrial processes and product quality. This review compiles and analyzes key findings from studies published between 2008 and 2023, offering a detailed overview of the progress and emerging trends in this area (Figure 10). Several studies have focused on the geometric aspects of industrial processes. Afrasiab and Khodaygan [37] examined the importance of six geometrical control points, while Ke and Huang [25] explored the geometric width of products. These investigations shed light on how geometric factors contribute to product quality and process control. Quality assessment and control are integral to manufacturing and production processes. Researchers such as Li et al. [38] and Kahya et al. [43] have examined product quality through parameters such as yield strength, tensile strength, elongation, and impact work, providing valuable insights into the factors influencing steel quality. Additionally, the studies by Schäfer et al. [24] and Mahadevan and Theocharous [48] delved into negative pressure and inventory levels as indicators of product quality and process stability. Process monitoring and control are crucial in maintaining efficiency and minimizing defects. Various studies have explored control chart patterns [23,39,45,49], Hotellings T⌃2 [42], and abnormal wave profiles [50] to detect deviations and anomalies. These investigations provide insights into the detection and mitigation of process variations. Furthermore, researchers have undertaken significant effort of predictive process modeling. Mishra and Rane [14] investigated the probability of achieving a global benchmark quality level, while Abbasi [31] delved into the prediction of PCI for distributions. Similarly, the study by Kabasakal et al. [51] focused on binary predictions for fault detection, highlighting the importance of reliable modelling structures in quality management. Multiclass and multilabel classification have also been explored in quality control and process monitoring in their study. In addition, Demircioglu Diren et al. [42] investigated different types of faults and critical events, respectively, while Pheng et al. [46] explored multiclass classification models to enhance process monitoring.

Figure 10.

Categories and frequency of dependent variables in the observed literature.

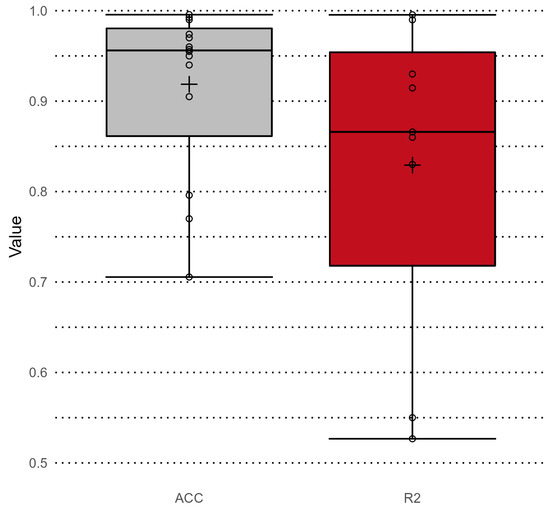

4.6. Model Performance

The performance of the models in these case studies varies, demonstrating the versatility and complexity of real-world industrial challenges (Figure 11). Some studies have achieved high accuracy or R-squared values, such as the classification models in Escobar et al. [34] and Li et al. [52], which both exhibit accuracy scores of 0.99. On the other hand, some regression models, such as those in Schäfer et al. [24] and Xiao et al. [53], have achieved relatively high R-squared values of 0.83 and 0.99, showcasing their effectiveness in predicting outcomes.

Figure 11.

Comparison of algorithmic performance (Accuracy and ) regarding classification and regression.

It is important to note that the performance of these models often depends on various factors, including the quality of data preprocessing, feature engineering, and the suitability of the chosen algorithms for the specific problem at hand. Overall, this dataset provides valuable insights into the application of data analytics and ML techniques in industrial settings, showcasing the potential for improved process control, quality monitoring, and predictive maintenance.

5. Analysis of Results

Due to the extensive investigation of ML algorithms, the existing body of knowledge can be leveraged for the practical implementation of PPC in industrial settings. However, it is worth noting that only a limited number of scrutinized algorithms have been employed for the prediction of Cpk value. Consequently, a combination of interpretable (descriptive) and advanced (black-box) models is utilized for the purpose of process quality prediction. Moreover, no experiments have been identified that integrate quality criteria with reinforcement learning. As a result, there is room for expanding the scope of this study due to the scarcity of independent variables and the absence of xAI methods. By examining the derivations of the SLA and the localization of application areas in PPC, it becomes possible to identify the pertinent research gaps that exist in the related domains.

5.1. RQ1: Interpretation Domain—Humans

The imperative for human-centered interpretability in manufacturing prediction systems is becoming increasingly evident as the industry forges ahead in the digital age [54]. In direct response to this evolution, the research outcomes elucidate the profound necessity for explainable artificial intelligence (xAI) techniques that stand superior to classical models, particularly in their ability to elucidate complex ML algorithms for end users. xAI techniques bridge the cognitive gap between sophisticated ML predictions and pragmatic decision making by elucidating the underlying logic of numerical, binary, and multiclass predictions. This cognitive bridge is not merely a convenience but a catalyst for enhancing productivity and ensuring quality in production processes. It enables process owners and operators to garner transparent insights and fosters an environment where informed decisions are the norm rather than the exception. However, only few case studies show the direct relationship of PPC and interpretable results, as can be seen in Boaventura et al. [35], Qiu and Xie [45], Kabasakal et al. [51], and Kim et al. [49].

Within digitization, there has been a growing demand for more intuitive and user-friendly interactive prediction systems in production. As the complexity of manufacturing processes increases, it becomes essential for end users to have access to accurate, reliable, and timely information [55]. Given the preceding information, factors that contribute to the successful implementation of these systems must be explored and requirements need to be derived for the end user.

First and foremost, the accessibility of the interactive prediction system is paramount. For end users to effectively harness the benefits of PPC, the system must be easy to understand, navigate, and operate. This means that the user interface should be designed with simplicity and usability in mind, ensuring that the learning curve is minimal for operators who may not have advanced technical expertise. In addition to being user-friendly, the system should also be customizable and adaptable to the specific needs of the production environment [56,57]. This involves taking into consideration the unique challenges and requirements of each manufacturing process, and tailoring the interactive prediction system accordingly. By offering a high degree of customization, the system becomes more relevant and valuable to the end user. Moreover, the interactive prediction system should be equipped with advanced algorithms and artificial intelligence capabilities, enabling it to learn from historical data and continuously improve its predictions. This self-learning ability is crucial in adapting to changing production conditions and maintaining a high level of accuracy and reliability. Furthermore, seamless integration with existing production systems and equipment is essential for maximizing the potential of the interactive prediction system. By ensuring compatibility and interoperability with other production elements, end users can harness the full power of PPC without disrupting their current operations [58].

In the quest to optimize the performance of interactive prediction systems in production for end users, interpretability emerges as a crucial factor in ensuring transparency, trust, and informed decision making. Addressing these requirements calls for a comprehensive comparison between xAI methods and classical interpretable models in terms of their ability to provide actionable recommendations to process owners. xAI methods, with their capacity to unravel the inner workings of complex ML models, exhibit a distinct advantage over traditional interpretable models by facilitating a more nuanced understanding of the underlying decision-making process [15]. This advantage enables stakeholders to better comprehend the rationale behind predictions, ensuring a more informed and context-sensitive adoption of recommendations. As such, the integration of xAI techniques in interactive prediction systems is paramount in fostering a transparent and effective decision-making landscape for end users, ultimately enhancing the practicality and adaptability of these systems in real-world applications.

5.2. RQ1: Interpretation Domain—Machines

Since PPC relies on the timely acquisition and analysis of sensor data, gathered from various points throughout the production process, automated decision processes rely reversely on data quality and stable connections [59]. Sensors detect fluctuations in temperature, pressure, humidity, and other essential factors, providing valuable insight into the behavior of the system. These data serve as the foundation for building predictive models, enabling real-time monitoring, and identifying potential issues before they escalate [60]. As more sensors are integrated into the production process, the complexity of managing this data increases. This poses a significant challenge in creating an environment that can efficiently process, analyze, and communicate the information. Effective data management solutions and communication tools are needed to filter, store, and transmit the data to appropriate channels for analysis and decision making [33,42].

One solution lies in edge computing, a decentralized approach to data processing that pushes computation to the edge of the network, closer to the source of the data. Edge computing can significantly reduce the latency and bandwidth required to transmit data to centralized servers, allowing for real-time analysis and decision making [61]. Implementing edge computing systems can be complex and costly, especially for small- and medium-sized enterprises [62].

Another challenge in creating a PPC environment is ensuring seamless communication between different devices, software, and systems involved in the production process. The Industrial Internet of Things (IIoT) aims to address this issue by providing a standardized framework for device-to-device communication [63]. However, interoperability between devices from different manufacturers remains a challenge, as there is no universally accepted standard for IIoT communication. Moreover, cybersecurity is an increasingly critical concern as the use of connected devices and sensors in manufacturing processes expands. Ensuring the confidentiality, integrity, and availability of production data is paramount to maintain trust and prevent unauthorized access.

5.3. RQ2: Analysis Domain

Modern algorithms such as LSTMs and Reinforcement Learning have demonstrated substantial superiority in predictive accuracy, robustness, and model quality when compared to traditional predictive methods [29,39]. The predictive performance of these algorithms is contingent on several factors, including the underlying process distribution, noise characteristics, and model complexity [64]. Consequently, it becomes imperative to assess the predictive power of these algorithms across various process distributions, in order to ascertain their robustness and generalizability to a wide range of industrial applications.

These algorithms are designed to facilitate accurate, timely, and efficient decision making by predicting future behavior and events in a given system, thereby enhancing the overall performance of process control systems. As industrial processes become increasingly complex and interconnected, the need for dynamic and adaptive control strategies has never been greater [65]. Consequently, a burgeoning body of research has emerged, seeking to explore and quantify the advantages offered by modern predictive algorithms in comparison to traditional control methodologies. The efficacy of these algorithms hinges upon their ability to construct accurate and reliable predictive models, which can be derived from historical and real-time data, enabling process engineers to implement proactive adjustments in response to anticipated changes in process conditions [66]. By doing so, these algorithms can effectively mitigate undesirable fluctuations, reduce the incidence of disturbances, and optimize operational efficiency.

Central to the success of modern predictive algorithms is their inherent adaptability, which arises from their ability to learn and evolve in response to changes in process dynamics, system characteristics, and environmental conditions [67]. Hence, this flexibility allows these algorithms to be applied across a wide range of processes. Furthermore, the availability of high-performance computing resources and the proliferation of low-cost, high-quality sensors have facilitated the generation and processing of massive volumes of data, thereby enhancing the accuracy and precision of predictive models.

Despite these promising advancements, it is crucial to recognize that the efficacy of predictive algorithms is contingent upon various factors, including the quality of the input data, the appropriateness of the selected modeling technique, and the ability to account for uncertainties and non-linearities in the system. As such, the accurate quantification of the advantages offered by these algorithms necessitates a comprehensive evaluation of their performance across a diverse array of process control applications, in order to establish their relative superiority over traditional control methodologies [68]. Moreover, it is imperative to consider the potential limitations and challenges associated with the implementation of predictive algorithms, including the need for robust data preprocessing techniques, the management of computational complexity, and the establishment of effective feedback mechanisms to ensure the stability and robustness of the control system [52].

In light of these considerations, it is crucial to systematically investigate the extent to which modern predictive algorithms enhance process control. Such an investigation is essential to fully understand the potential of these algorithms across various industrial applications and to identify opportunities for future research and development in PPC. By exploring these avenues, industries can effectively harness the power of AI and ML technologies to drive substantial improvements in the efficiency, safety, and sustainability of industrial processes, thereby fostering innovation and progress across a broad spectrum of scientific and engineering domains.

5.4. RQ3: Domain of External Influence

A primary challenge in the interface of ML systems for process qualification assessment is the continuous evolution of user inputs and the associated production conditions. These conditions necessitate the adaptation of predictive models to reflect user-driven changes [69]. This challenge calls for the implementation of adaptive ML algorithms capable of modifying model parameters and the weights of features based on dynamic user interactions and changes within the production framework. To tackle this issue, researchers have introduced methods for the ongoing assessment and real-time adjustment of ML models within live user environments. One prevalent method involves the application of online learning algorithms that adopt incremental learning practices to refine model weights with each new piece of user data. Another method is the utilization of a hybrid learning model, merging offline and online learning to strike an optimal balance between model consistency and adaptability [70,71,72].

Beyond these technical considerations, the practical deployment of predictive controls through user interfaces in production settings also presents numerous challenges. A significant hurdle is ensuring the availability and reliability of data derived from user interactions, which, if incomplete or noisy, can adversely affect model predictions. Furthermore, the complexity of industrial systems often hampers the interpretability of models, especially when the link between user inputs and outcomes is obscured [73]. Overcoming these obstacles necessitates a dual approach that marries technical innovation with practical solutions.

Additionally, understanding which user inputs or variables have a pivotal role in the predictive accuracy of ML models in process qualification is an area of active research with far-reaching consequences for production efficiency [74]. By persistently refining these models in response to the changing landscape of user engagement, it becomes feasible to cultivate a more resilient and adaptive system for PPC, thus enabling the handling of disruptions and promoting optimal production results.

6. Conclusions

This study provides a comprehensive investigation into the application of ML in PPC, emphasizing its practical implementation across various industrial scenarios. The analysis reveals the significant potential of ML to enhance accuracy and decision-making processes in manufacturing. By examining a diverse range of case studies and applications, the research illustrates the versatility of ML in addressing complex industrial challenges and optimizing operational strategies [20]. The findings highlight how ML models, such as supervised learning and neural networks, have been particularly effective in overcoming the reactive characteristics of traditional SPC, enabling more precise predictions and informed decision making [14,15]. These models have demonstrated their capability in synthesizing large volumes of data to predict potential issues before they occur, thus improving both the efficiency and reliability of manufacturing processes [22,59]. For instance, ANNs have shown significant promise in estimating process capability for non-normal processes, contributing to more accurate and reliable quality control measures [31]. Additionally, ensemble learning techniques have been effective in improving the quality control of multistage manufacturing systems by leveraging data-driven insights for real-time process adjustments [32,73]. Moreover, the integration of ML into PPC not only enhances predictive accuracy but also facilitates the development of adaptive control mechanisms that respond dynamically to changes in the manufacturing environment. This proactive approach enables manufacturers to anticipate and mitigate operational challenges, ensuring a more resilient and responsive production process [8,27]. Thus, PPC underscores the transformative potential of ML in revolutionizing manufacturing paradigms by augmenting analytical capabilities and providing real-time process control. These advancements have contributed to sustained improvements in process quality and efficiency, marking a significant step forward in the field of industrial manufacturing [14,28].

However, it is crucial to recognize various limitations inherent in this study. Firstly, the research may not encompass all possible confounding variables, a restriction that could incorporate hidden biases and subsequently distort the accuracy of the results. These variables could arise from overlooked factors during the analysis, such as disparities in equipment, operator expertise, or prevailing environmental conditions. Addressing these potential biases requires a more comprehensive approach, integrating a diverse range of variables to better understand the intricate relationships between ML techniques and advancements in process quality.

Another significant limitation is the potential absence of reproducibility in the study, which can have an impact on the level of certainty regarding the resulting outcomes. The lack of independent replications has the potential to undermine the strength and generalizability of the results across different industries and settings. This suggests that the benefits of ML techniques may be specific to certain contexts or that the methods applied may not be universally applicable across diverse manufacturing environments. It is essential to encourage further research and independent verification of these findings in order to strengthen the foundational knowledge of ML applications in PPC.

The use of self-reported data in this study introduces biases and inaccuracies due to its susceptibility to factors such as errors in recall, the desire for social approval, or intentional misreporting. These biases can distort the perceived impact of ML techniques on process quality and decision-making processes, either exaggerating or underestimating the actual influence. Therefore, future research should focus on incorporating more objective and diverse data sources, such as direct measurements or sensor data, to enhance the reliability and validity of the findings and provide a more authentic representation of the effectiveness of ML techniques in PPC.

Addressing these limitations and developing more robust methodologies will be crucial in establishing conclusive evidence and drawing more reliable conclusions regarding the effectiveness of ML techniques in PPC, specifically within the steel industry and other industrial processes. The considerations highlighted in this conclusion aim to promote a more refined approach to future research efforts in this field, fostering advancements in industrial process optimization and contributing to the existing body of knowledge on the intersection of ML and industrial applications.

Author Contributions

Conceptualization, J.M. and R.J.; methodology, J.M.; validation, J.M. and R.J.; formal analysis, J.M.; investigation, J.M.; resources, J.M.; data curation, J.M.; writing—original draft preparation, J.M.; writing—review and editing, R.J.; visualization, J.M.; supervision, R.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Goshime, Y.; Kitaw, D.; Jilcha, K. Lean manufacturing as a vehicle for improving productivity and customer satisfaction: A literature review on metals and engineering industries. Int. J. Lean Six Sigma 2019, 10, 691–714. [Google Scholar] [CrossRef]

- Kane, V.E. Process capability indices. J. Qual. Technol. 1986, 18, 41–52. [Google Scholar] [CrossRef]

- Tsung, F.; Li, Y.; Jin, M. Statistical process control for multistage manufacturing and service operations: A review and some extensions. Int. J. Serv. Oper. Inform. 2008, 3, 191–204. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, D.; Kim, Y.S. The quality management ecosystem for predictive maintenance in the Industry 4.0 era. Int. J. Qual. Innov. 2019, 5, 4. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, G.; Wang, J.; Sun, S.; Si, S.; Yang, T. Real-time information capturing and integration framework of the internet of manufacturing things. Int. J. Comput. Integr. Manuf. 2015, 28, 811–822. [Google Scholar] [CrossRef]

- Das, A.; Mondal, S.; Thakkar, J.; Maiti, J. A methodology for modeling and monitoring of centrifugal casting process. Int. J. Qual. Reliab. Manag. 2015, 32, 718–735. [Google Scholar] [CrossRef]

- Dombrowski, U.; Wullbrandt, J.; Krenkel, P. Industrie 4.0 in production ramp-up management. Procedia Manuf. 2018, 17, 1015–1022. [Google Scholar] [CrossRef]

- Guh, R.S. Integrating artificial intelligence into on-line statistical process control. Qual. Reliab. Eng. Int. 2003, 19, 1–20. [Google Scholar] [CrossRef]

- Wuest, T.; Irgens, C.; Thoben, K.D. An approach to monitoring quality in manufacturing using supervised machine learning on product state data. J. Intell. Manuf. 2014, 25, 1167–1180. [Google Scholar] [CrossRef]

- Lee, S.; Amin, R.W. Process tolerance limits. Total Qual. Manag. 2000, 11, 267–280. [Google Scholar] [CrossRef]

- Sharma, G.; Rao, P.S. A DMAIC approach for process capability improvement an engine crankshaft manufacturing process. J. Ind. Eng. Int. 2014, 10, 65. [Google Scholar] [CrossRef]

- Dietrich, E.; Conrad, S. Statistische Verfahren zur Maschinen-und Prozessqualifikation; Carl Hanser Verlag GmbH Co. KG: München, Germany, 2021; ISBN 978-3-446-46447-6. [Google Scholar]

- Hastie, T.; Tibshirani, R.; Friedman, J.; Hastie, T.; Tibshirani, R.; Friedman, J. Unsupervised learning. In The Elements of Statistical Learning; Springer: New York, NY, USA, 2009. [Google Scholar] [CrossRef]

- Mishra, N.; Rane, S.B. Prediction and improvement of iron casting quality through analytics and Six Sigma approach. Int. J. Lean Six Sigma 2019, 10, 189–210. [Google Scholar] [CrossRef]

- Senoner, J.; Netland, T.; Feuerriegel, S. Using explainable artificial intelligence to improve process quality: Evidence from semiconductor manufacturing. Manag. Sci. 2022, 68, 5704–5723. [Google Scholar] [CrossRef]

- Rehse, J.R.; Mehdiyev, N.; Fettke, P. Towards explainable process predictions for industry 4.0 in the dfki-smart-lego-factory. KI-Künstliche Intell. 2019, 33, 181–187. [Google Scholar] [CrossRef]

- Rudin, C.; Radin, J. Why are we using black box models in AI when we do not need to? A lesson from an explainable AI competition. Harv. Data Sci. Rev. 2019, 1, 1–9. [Google Scholar] [CrossRef]

- Hyun Park, S.; Seon Shin, W.; Hyun Park, Y.; Lee, Y. Building a new culture for quality management in the era of the Fourth Industrial Revolution. Total Qual. Manag. Bus. Excell. 2017, 28, 934–945. [Google Scholar] [CrossRef]

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A. Implementing challenges of artificial intelligence: Evidence from public manufacturing sector of an emerging economy. Gov. Inf. Q. 2022, 39, 101624. [Google Scholar] [CrossRef]

- Okoli, C.; Schabram, K. A guide to conducting a systematic literature review of information systems research. Commun. Assoc. Inf. Syst. 2015, 37, 879–910. [Google Scholar] [CrossRef]

- Gusenbauer, M. Google Scholar to overshadow them all? Comparing the sizes of 12 academic search engines and bibliographic databases. Scientometrics 2019, 118, 177–214. [Google Scholar] [CrossRef]

- Vom Brocke, J.; Simons, A.; Riemer, K.; Niehaves, B.; Plattfaut, R.; Cleven, A. Standing on the shoulders of giants: Challenges and recommendations of literature search in information systems research. Commun. Assoc. Inf. Syst. 2015, 37, 9. [Google Scholar] [CrossRef]

- Cheng, W.K.; Azman, A.F.; Hamdan, M.H.; Mansa, R.F. Application of Six Sigma in oil and gas industry: Converting operation data into business value for process prediction and quality control. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, 9–12 December 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 148–153. [Google Scholar] [CrossRef]

- Schäfer, F.; Schwulera, E.; Otten, H.; Franke, J. From descriptive to predictive six sigma: Machine learning for predictive maintenance. In Proceedings of the 2019 Second International Conference on Artificial Intelligence for Industries (AI4I), Laguna Hills, CA, USA, 25–27 September 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 35–38. [Google Scholar] [CrossRef]

- Ke, K.C.; Huang, M.S. Quality classification of injection-molded components by using quality indices, grading, and machine learning. Polymers 2021, 13, 353. [Google Scholar] [CrossRef] [PubMed]

- Ismail, M.; Mostafa, N.A.; El-assal, A. Quality monitoring in multistage manufacturing systems by using machine learning techniques. J. Intell. Manuf. 2021, 33, 2471–2486. [Google Scholar] [CrossRef]

- Krauß, J.; Pacheco, B.M.; Zang, H.M.; Schmitt, R.H. Automated machine learning for predictive quality in production. Procedia CIRP 2020, 93, 443–448. [Google Scholar] [CrossRef]

- Zhang, S.; Gao, J.G.; Wang, H.; Zhang, X.Q. Position Tolerance Process Capability Prediction under Maximum Material Condition. Adv. Mater. Res. 2014, 945, 107–110. [Google Scholar] [CrossRef]

- Viharos, Z.J.; Jakab, R. Reinforcement learning for statistical process control in manufacturing. Measurement 2021, 182, 109616. [Google Scholar] [CrossRef]

- Teinemaa, I.; Dumas, M.; Rosa, M.L.; Maggi, F.M. Outcome-oriented predictive process monitoring: Review and benchmark. ACM Trans. Knowl. Discov. Data (TKDD) 2019, 13, 1–57. [Google Scholar] [CrossRef]

- Abbasi, B. A neural network applied to estimate process capability of non-normal processes. Expert Syst. Appl. 2009, 36, 3093–3100. [Google Scholar] [CrossRef]

- Nalbach, O.; Linn, C.; Derouet, M.; Werth, D. Predictive quality: Towards a new understanding of quality assurance using machine learning tools. In Proceedings of the Business Information Systems: 21st International Conference, BIS 2018, Berlin, Germany, 18–20 July 2018; pp. 30–42. [Google Scholar] [CrossRef]

- Schrunner, S.; Scheiber, M.; Jenul, A.; Zernig, A.; Kästner, A.; Kern, R. Towards a General Framework to Embed Advanced Machine Learning in Process Control Systems. arXiv 2021, arXiv:2103.13058. [Google Scholar] [CrossRef]

- Escobar, C.A.; Morales-Menendez, R.; Macias, D. Process-monitoring-for-quality—A machine learning-based modeling for rare event detection. Array 2020, 7, 100034. [Google Scholar] [CrossRef]

- Boaventura, L.L.; Ferreira, P.H.; Fiaccone, R.L. On flexible statistical process control with artificial intelligence: Classification control charts. Expert Syst. Appl. 2022, 194, 116492. [Google Scholar] [CrossRef]

- Köksal, G.; Batmaz, I.; Testik, M.C. A review of data mining applications for quality improvement in manufacturing industry. Expert Syst. Appl. 2011, 38, 13448–13467. [Google Scholar] [CrossRef]

- Afrasiab, H.; Khodaygan, S. Capability Prediction of Machining Processes Based on Uncertainty Analysis. Int. J. Mech. Mechatron. Eng. 2016, 10, 1262–1269. [Google Scholar] [CrossRef]

- Li, F.; Wu, J.; Dong, F.; Lin, J.; Sun, G.; Chen, H.; Shen, J. Ensemble machine learning systems for the estimation of steel quality control. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 2245–2252. [Google Scholar] [CrossRef]

- Zan, T.; Liu, Z.; Su, Z.; Wang, M.; Gao, X.; Chen, D. Statistical process control with intelligence based on the deep learning model. Appl. Sci. 2019, 10, 308. [Google Scholar] [CrossRef]

- Khoza, S.C.; Grobler, J. Comparing machine learning and statistical process control for predicting manufacturing performance. In EPIA Conference on Artificial Intelligence; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Jeereddy, S.; Kennedy, K.; Duffy, E.; Walker, A.; Vorster, B. Machine learning use cases for smart manufacturing kpis. In Proceedings of the 2019 IEEE International Conference on Big Data (Big Data), Los Angeles, CA, USA, 9–12 December 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 4375–4380. [Google Scholar] [CrossRef]

- Demircioglu Diren, D.; Boran, S.; Cil, I. Integration of machine learning techniques and control charts in multivariate processes. Sci. Iran. 2020, 27, 3233–3241. [Google Scholar] [CrossRef]

- Kahya, A.S.; Şişmanoğlu, S.; Erçin, Z.; Akdağ, H.C. Total Quality Management through Defect Detection in Manufacturing Processes Using Machine Learning Algorithms. In Proceedings of the International Symposium for Production Research 2019; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Mabunda, M.R.; Mashamba, A. Predictive Process Control Framework for Online Quality Control in a Hot Rolling Mill. J. Hum. Earth Future 2022, 3, 263–279. [Google Scholar] [CrossRef]

- Qiu, P.; Xie, X. Transparent sequential learning for statistical process control of serially correlated data. Technometrics 2022, 64, 487–501. [Google Scholar] [CrossRef]

- Pheng, T.; Chuluunsaikhan, T.; Ryu, G.; Kim, S.H.; Nasridinov, A.; Yoo, K.H. Prediction of process quality performance using statistical analysis and long short-term memory. Appl. Sci. 2022, 12, 735. [Google Scholar] [CrossRef]

- Li, B.H.; Zhao, L.P.; Yao, Y.Y. Multiconditional machining process quality prediction using deep transfer learning network. Adv. Manuf. 2023, 11, 329–341. [Google Scholar] [CrossRef]

- Mahadevan, S.; Theocharous, G. Optimizing production manufacturing using reinforcement learning. In Proceedings of the FLAIRS Conference, Sanibel Island, FL, USA, 18–20 May 1998; Volume 372, p. 377, ISBN 978-1-57735-051-4. [Google Scholar]

- Kim, S.B.; Jitpitaklert, W.; Park, S.K.; Hwang, S.J. Data mining model-based control charts for multivariate and autocorrelated processes. Expert Syst. Appl. 2012, 39, 2073–2081. [Google Scholar] [CrossRef]

- Chou, S.H.; Chang, S.; Tsai, T.R.; Lin, D.K.; Xia, Y.; Lin, Y.S. Implementation of statistical process control framework with machine learning on waveform profiles with no gold standard reference. Comput. Ind. Eng. 2020, 142, 106325. [Google Scholar] [CrossRef]

- Kabasakal, İ.; Keskin, F.D.; Koçak, A.; Soyuer, H. A prediction model for fault detection in molding process based on logistic regression technique. In Proceedings of the International Symposium for Production Research 2019, Vienna, Austria, 28–30 August 2019; Springer International Publishing: Cham, Switzerland, 2020; pp. 351–360. [Google Scholar] [CrossRef]

- Li, J.; Liu, L.; Le, T.D.; Liu, J. Accurate data-driven prediction does not mean high reproducibility. Nat. Mach. Intell. 2020, 2, 13–15. [Google Scholar] [CrossRef]

- Xiao, X.; Waddell, C.; Hamilton, C.; Xiao, H. Quality prediction and control in wire arc additive manufacturing via novel machine learning framework. Micromachines 2022, 13, 137. [Google Scholar] [CrossRef] [PubMed]

- Crankshaw, D.; Gonzalez, J. Prediction-Serving Systems: What happens when we wish to actually deploy a machine learning model to production? Queue 2018, 16, 83–97. [Google Scholar] [CrossRef]

- Denkena, B.; Dittrich, M.A.; Wilmsmeier, S. Automated production data feedback for adaptive work planning and production control. Procedia Manuf. 2019, 28, 18–23. [Google Scholar] [CrossRef]

- Ziegler, D.; Peissner, M. Enabling Accessibility through Model-Based User Interface Development. In Proceedings of the AAATE Conference, Sheffield, UK, 11–15 September 2017; pp. 1067–1074. [Google Scholar] [CrossRef]

- Knowles, R.; Sanchez-Torron, M.; Koehn, P. A user study of neural interactive translation prediction. Mach. Transl. 2019, 33, 135–154. [Google Scholar] [CrossRef]

- Gupta, P.K.; Tyagi, V.; Singh, S.K. Predictive Computing and Information Security; Springer: Singapore, 2017. [Google Scholar] [CrossRef]

- Sadati, N.; Chinnam, R.B.; Nezhad, M.Z. Observational data-driven modeling and optimization of manufacturing processes. Expert Syst. Appl. 2018, 93, 456–464. [Google Scholar] [CrossRef]

- Chen, W.; Liu, H.; Qi, E. Discrete event-driven model predictive control for real-time work-in-process optimization in serial production systems. J. Manuf. Syst. 2020, 55, 132–142. [Google Scholar] [CrossRef]

- Tulkinbekov, K.; Kim, D.H. Blockchain-enabled approach for big data processing in edge computing. IEEE Internet Things J. 2022, 9, 18473–18486. [Google Scholar] [CrossRef]

- Ganapathy, A. Edge computing: Utilization of the internet of things for time-sensitive data processing. Asian Bus. Rev. 2021, 11, 59–66. [Google Scholar] [CrossRef]

- Qi, Q.; Xu, Z.; Rani, P. Big data analytics challenges to implementing the intelligent Industrial Internet of Things (IIoT) systems in sustainable manufacturing operations. Technol. Forecast. Soc. Chang. 2023, 190, 122401. [Google Scholar] [CrossRef]

- Rajagopal, R.; Del Castillo, E.; Peterson, J.J. Model and distribution-robust process optimization with noise factors. J. Qual. Technol. 2005, 37, 210–222. [Google Scholar] [CrossRef]

- Vilalta, R.; Apte, C.V.; Hellerstein, J.L.; Ma, S.; Weiss, S.M. Predictive algorithms in the management of computer systems. IBM Syst. J. 2002, 41, 461–474. [Google Scholar] [CrossRef][Green Version]

- Ławryńczuk, M. Explicit nonlinear predictive control algorithms with neural approximation. Neurocomputing 2014, 129, 570–584. [Google Scholar] [CrossRef]

- Warriach, E.U.; Ozcelebi, T.; Lukkien, J.J. A comparison of predictive algorithms for failure prevention in smart environment applications. In Proceedings of the 2015 International Conference on Intelligent Environments, Prague, Czech Republic, 15–17 July 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 33–40. [Google Scholar] [CrossRef]

- Malyuta, D.; Açikmeşe, B.; Cacan, M. Robust model predictive control for linear systems with state and input dependent uncertainties. In Proceedings of the 2019 American Control Conference (ACC), Philadelphia, PA, USA, 10–12 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1145–1151. [Google Scholar] [CrossRef]

- Angione, C.; Lió, P. Predictive analytics of environmental adaptability in multi-omic network models. Sci. Rep. 2015, 5, 15147. [Google Scholar] [CrossRef]

- Muhr, D.; Tripathi, S.; Jodlbauer, H. An adaptive machine learning methodology to determine manufacturing process parameters for each part. Procedia Comput. Sci. 2021, 180, 764–771. [Google Scholar] [CrossRef]

- Wu, Z.; Rincon, D.; Christofides, P.D. Real-time adaptive machine-learning-based predictive control of nonlinear processes. Ind. Eng. Chem. Res. 2019, 59, 2275–2290. [Google Scholar] [CrossRef]

- Shahbazi, Z.; Byun, Y.C. Smart manufacturing real-time analysis based on blockchain and machine learning approaches. Appl. Sci. 2021, 11, 3535. [Google Scholar] [CrossRef]

- Kozłowski, E.; Mazurkiewicz, D.; Żabiński, T.; Prucnal, S.; Sęp, J. Machining sensor data management for operation-level predictive model. Expert Syst. Appl. 2020, 159, 113600. [Google Scholar] [CrossRef]

- Moldovan, D.; Cioara, T.; Anghel, I.; Salomie, I. Machine learning for sensor-based manufacturing processes. In Proceedings of the 2017 13th IEEE International Conference on Intelligent Computer Communication and Processing (ICCP), Cluj-Napoca, Romania, 7–9 September 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 147–154. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).