Wellbore Temperature Prediction Model and Influence Law of Ultra-Deep Wells in Shunbei Field, China

Abstract

1. Introduction

2. Model Development

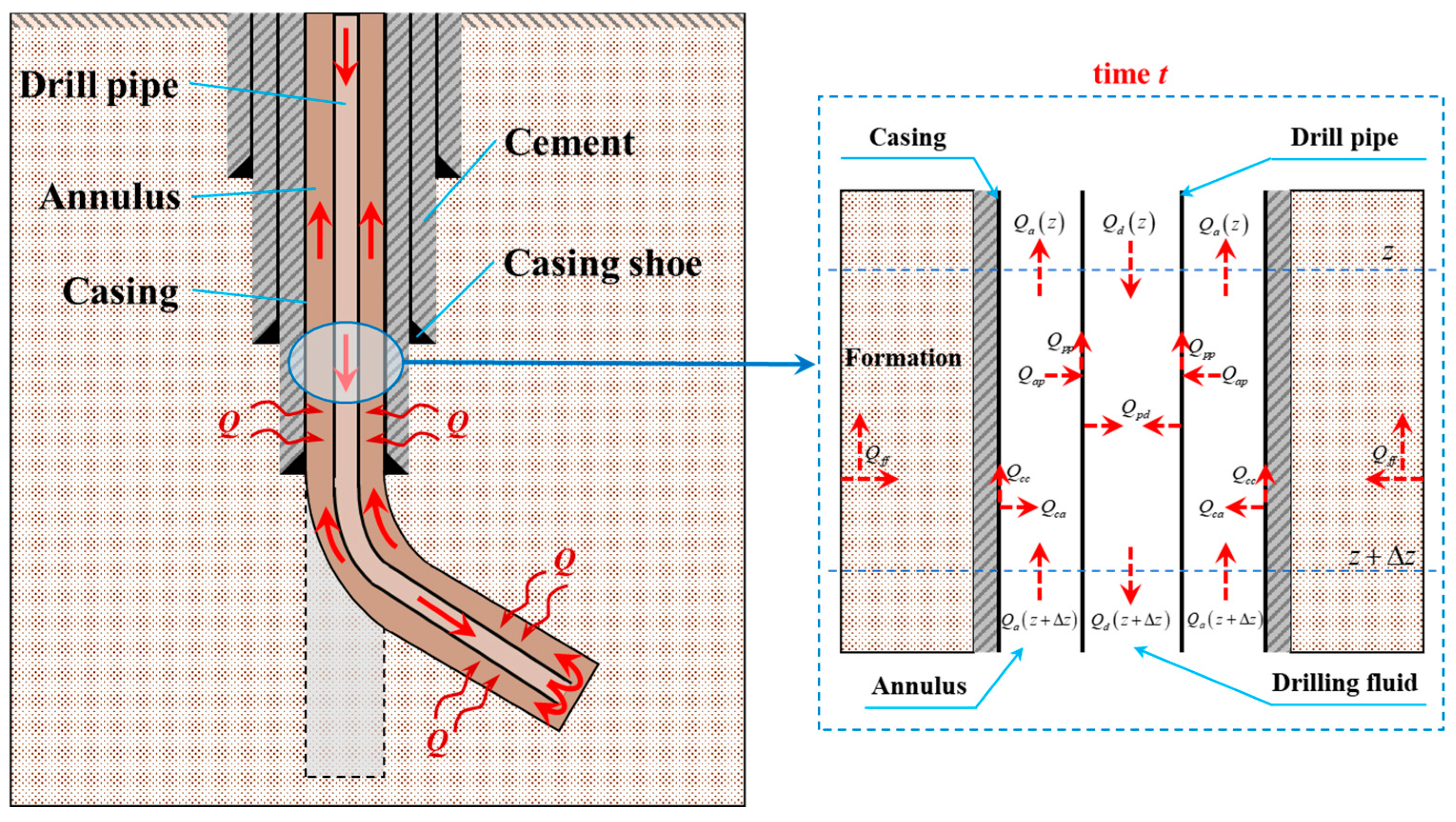

2.1. Physical Model

2.2. Basic Assumption

- Only radial heat conduction and convective heat transfer between the fluid and the solid are considered [23].

- The borehole trajectory and wall shape are regular, and there is no flexing or eccentricity of the drill pipe throughout the well section.

- At a certain distance from the well wall, the formation temperature is not affected by the heat transfer from the wellbore and is the static formation temperature [23].

2.3. Mathematical Model

- (1)

- Heat transfer model of drilling fluids in drill pipe

- (2)

- Heat transfer model of drill pipe wall

- (3)

- Heat transfer model of drilling fluids in the annulus

- (4)

- Heat transfer model of casing

- (5)

- Heat transfer model of cement

- (6)

- Heat transfer model of the formation

2.4. Convective Heat Transfer Coefficient

2.5. Initial and Boundary Conditions

- (1)

- Initial condition

- (2)

- Boundary conditions

3. Model Solution and Validation

3.1. Model Solution

3.2. Application Cases of Shunbei Block

- (1)

- SHB X Well

- (2)

- SHB Y Well

4. Impact Factors and Regularities Analysis

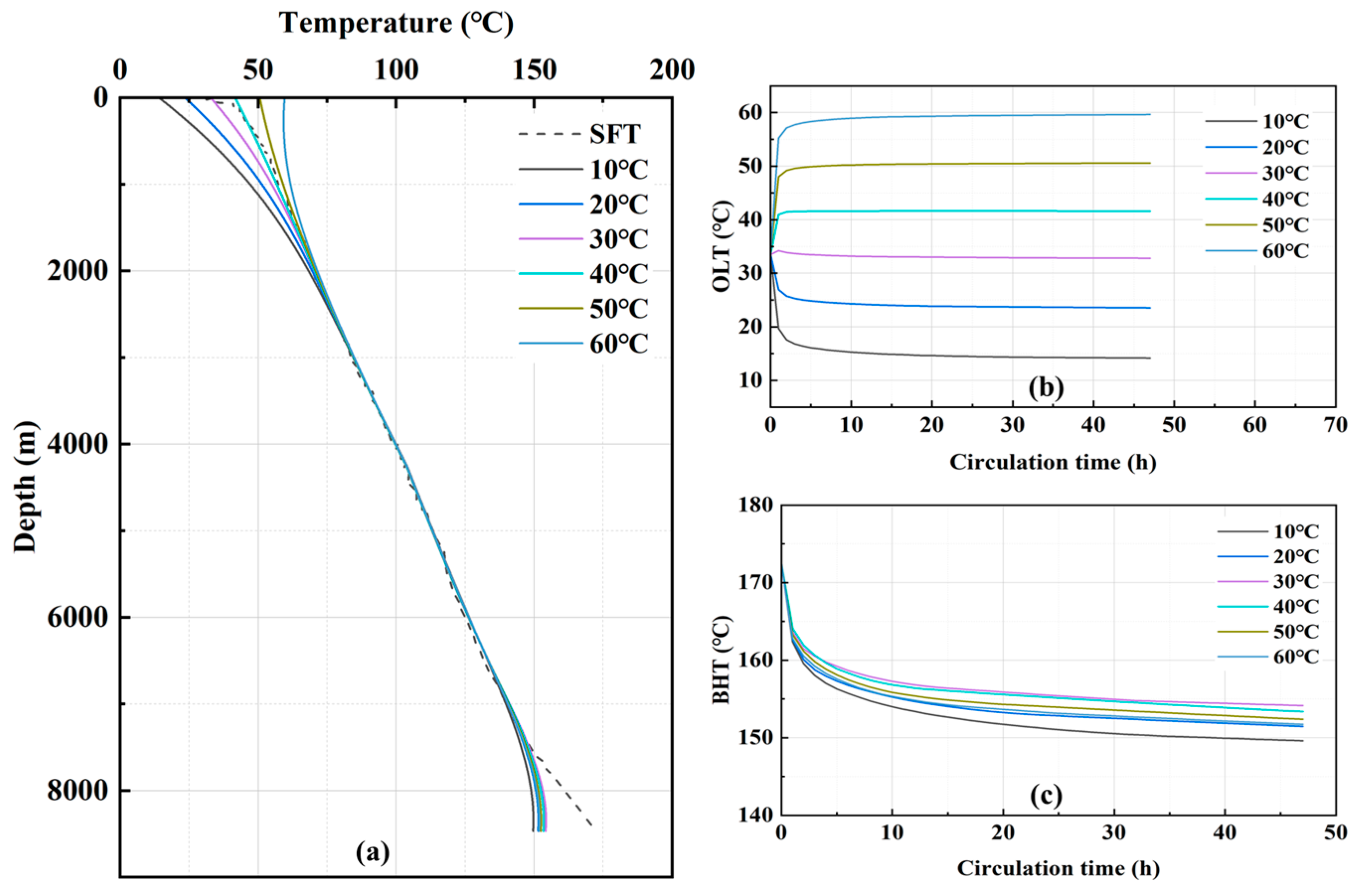

4.1. Inlet Temperature

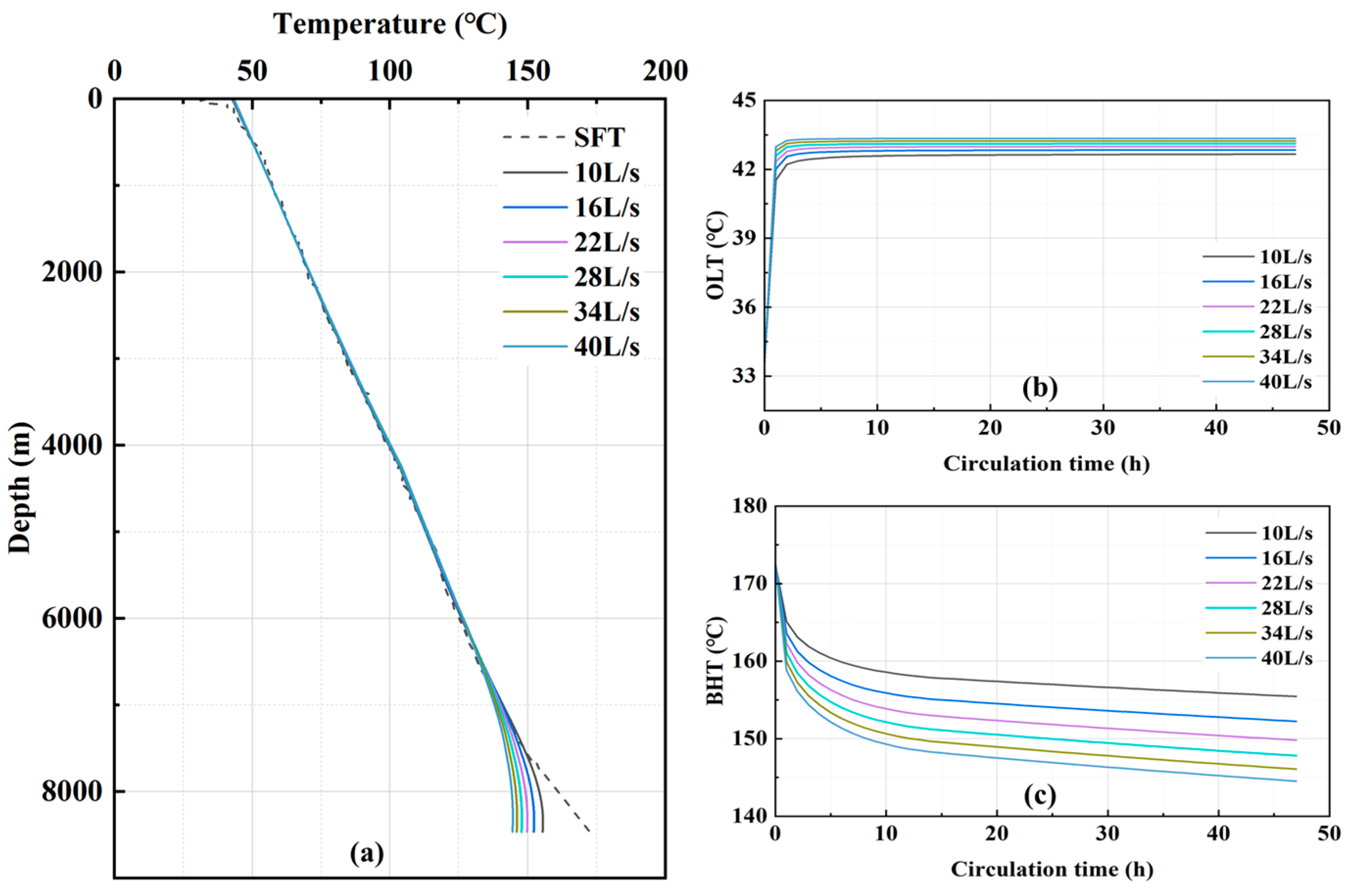

4.2. Flow Rate

4.3. Drilling Fluid Properties

- (1)

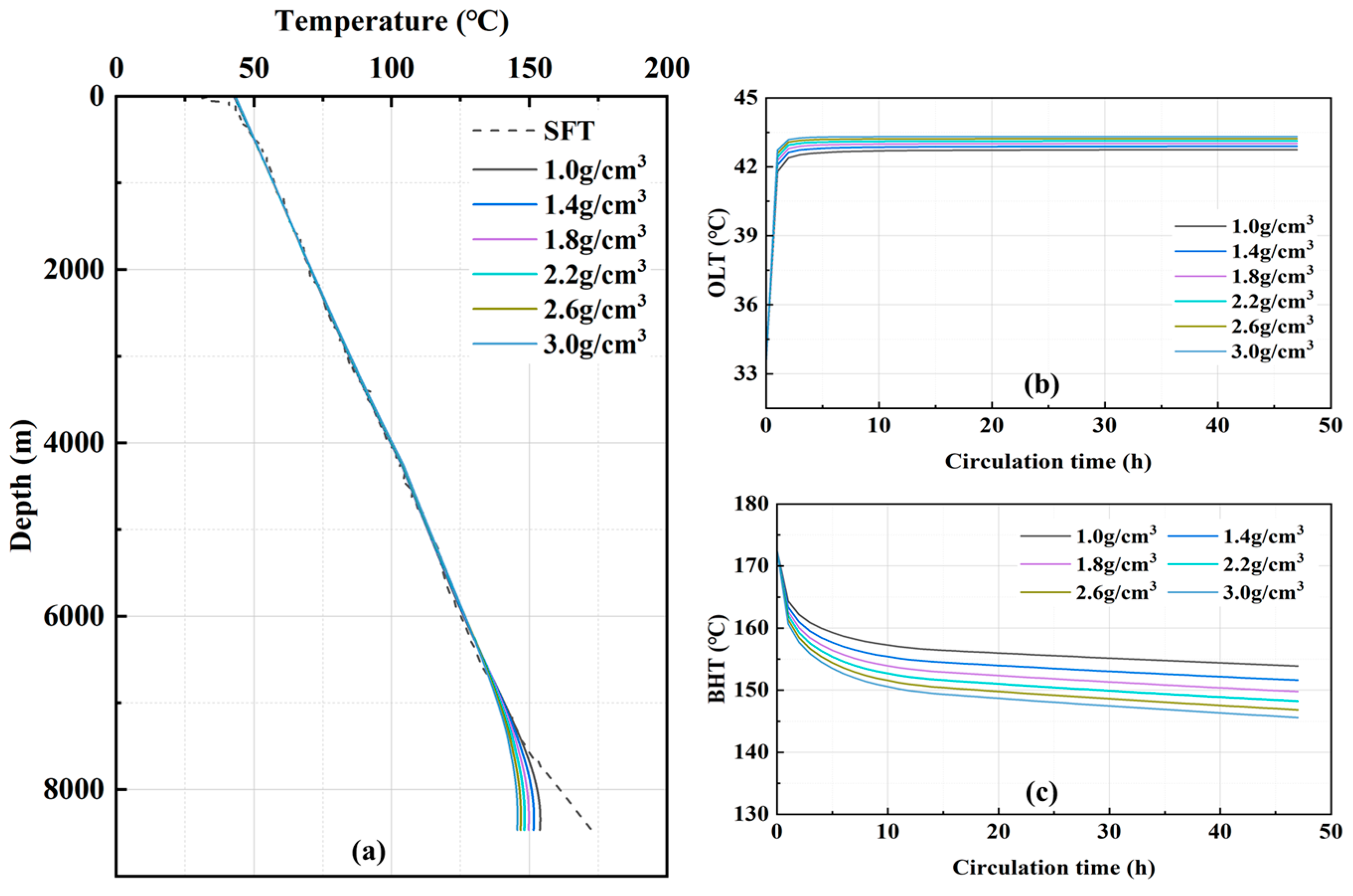

- Density of the drilling fluid

- (2)

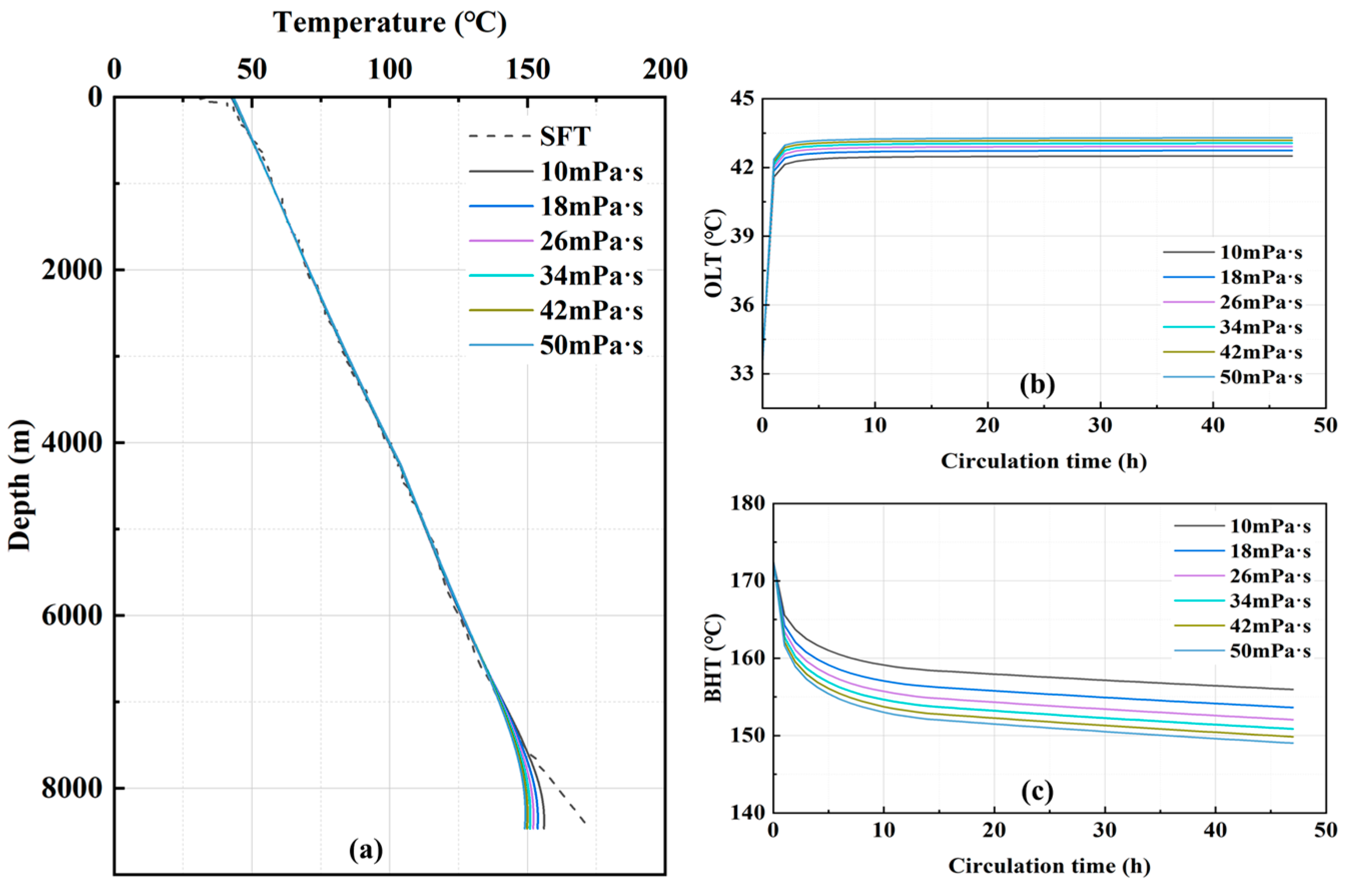

- Viscosity of the drilling fluid

- (3)

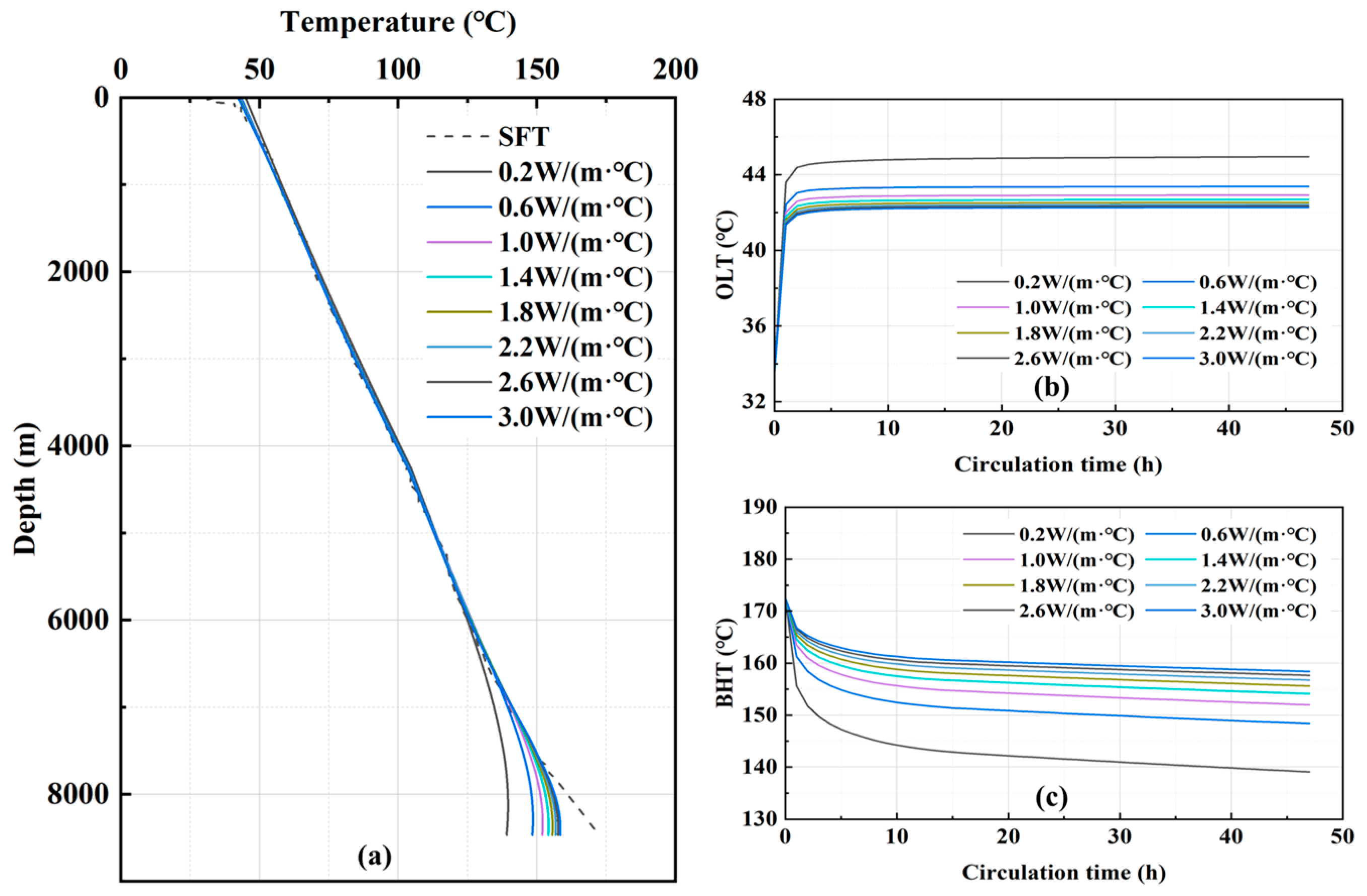

- Thermal conductivity of the drilling fluid

- (4)

- Specific heat capacity of the drilling fluid

4.4. Drill Pipe Thermophysical Properties

- (1)

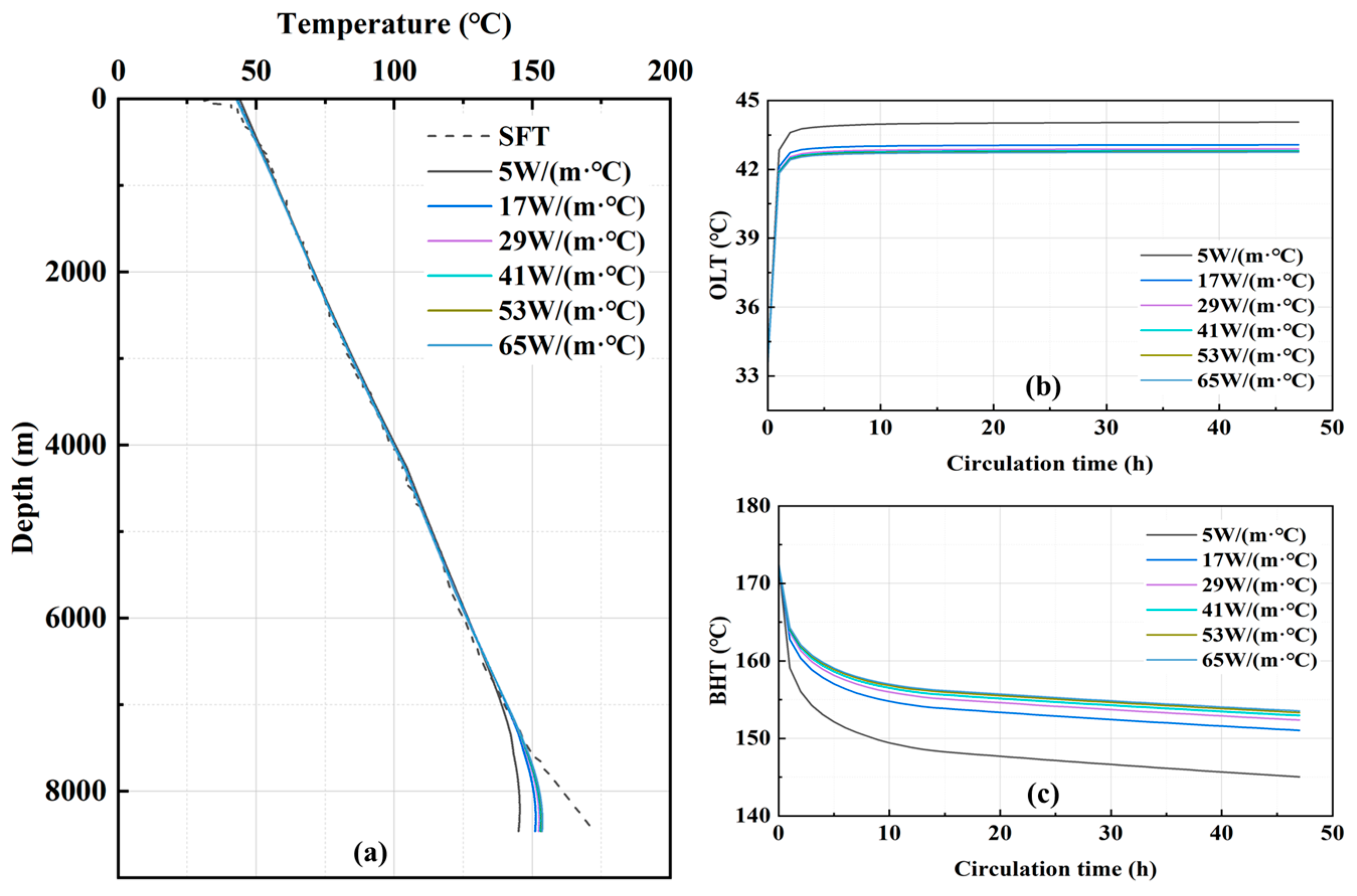

- Thermal conductivity of the drill pipe

- (2)

- Specific heat capacity of the drill pipe

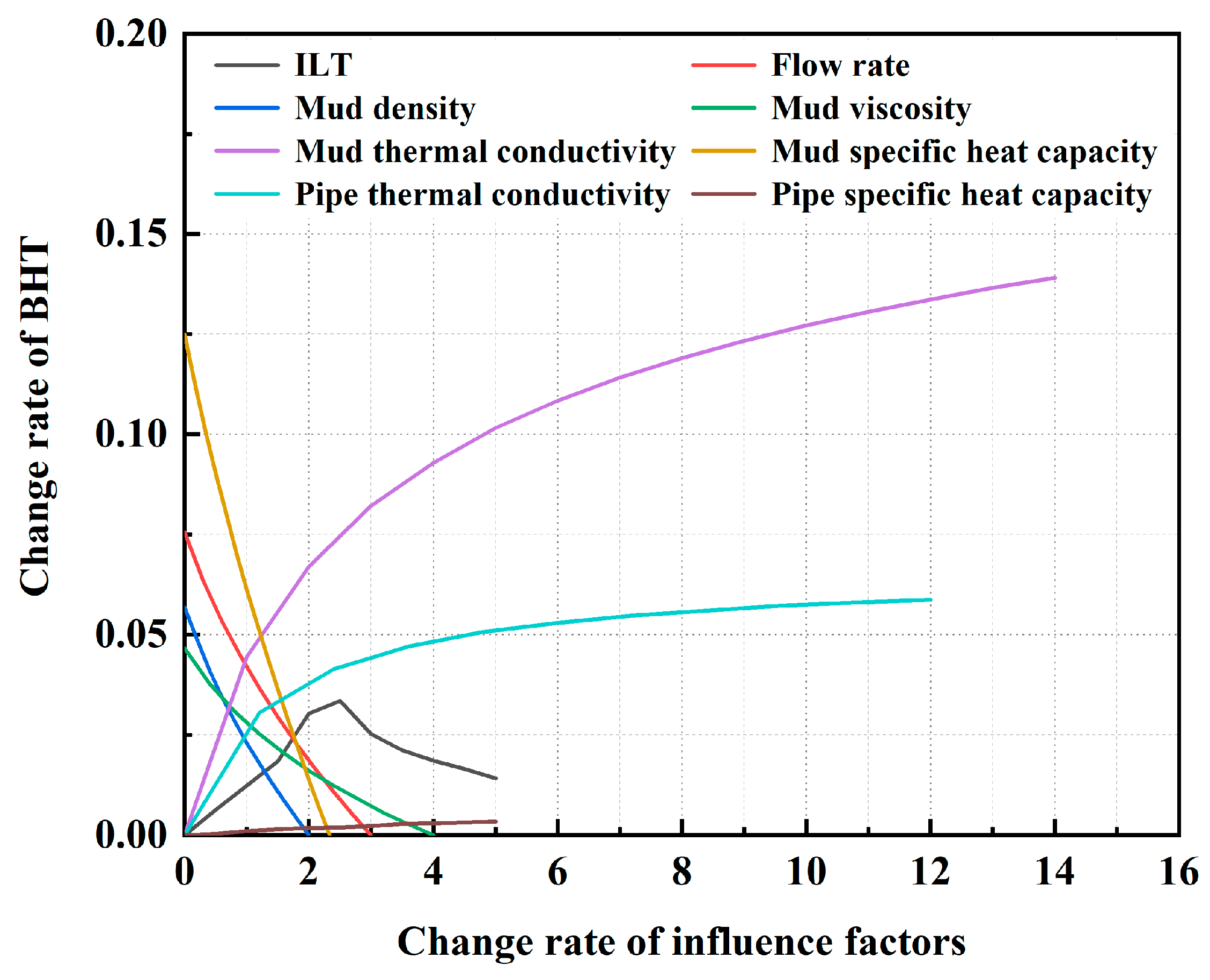

4.5. The Key Factors Impact Level

5. Conclusions

- (1)

- Based on the principle of energy conservation, a wellbore-formation transient heat transfer model with one-dimensional wellbore and two-dimensional formation has been established by considering the effects of casing program, drilling string assembly, flow channel structure and drilling fluid flow pattern on convective heat transfer coefficients;

- (2)

- Data from two actual wells in the Shunbei block are used to further validate the applicability and reliability of the model developed in this paper. The prediction error of BHCT in SHB X well is 1.35%, and the prediction error of OLT is 1.08%. The prediction error of BHCT of SHB Y well is 1.1%, and the prediction error of OLT is 5.89%. The results show that the model established in this paper is applicable to the prediction of wellbore temperature in ultra-deep directional wells in the Shunbei block, and the prediction error of BHT is about 2%;

- (3)

- The key influencing factors and laws of wellbore annular temperature were analyzed, among which the flow rate, drilling fluid density, drilling fluid viscosity, drilling fluid thermal conductivity, drilling fluid specific heat, and drill pipe thermal conductivity have a greater influence on the BHT, the ILT has the greatest influence on the OLT, while the drill pipe specific heat has no influence on the wellbore annular temperature.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zongqi, C.; Xianghua, L.; Binzhen, B.; Hao, Y. Technical Progress and Development Consideration of Drilling and Completion Engineering for Ultra-deep Wells in the Shunbei Oil & Gas Field. Pet. Drill. Tech. 2022, 50, 1–10. [Google Scholar]

- Lixin, Q.; Lu, Y.; Zicheng, C.; Haiying, L.; Cheng, H. Geological Reserves Assessment and Petroleum Exploration Targets in Shunbei Oil & Gas Field. Xinjiang Pet. Geol. 2021, 42, 127. [Google Scholar]

- Yongsheng, M.; Xunyu, C.; Lu, Y.; Zongjie, L.; Huili, L.; Shang, D.; Peirong, Z. Practice and Theoretical and Technical Progress in Exploration and Development of Shunbei Ultra-deep Carbonate Oil and Gas Field, Tarim Basin, NW China. Pet. Explor. Dev. 2022, 49, 1–20. [Google Scholar]

- Xiong, S.; Minghe, Y.; Weifeng, C.; Jun, Z. Study and Application of Wellbore Temperature Field Characteristics in the Ultra-deep Slim-hole Wells in the Shunbei No. 1 Area. Pet. Drill. Tech. 2021, 49, 67–74. [Google Scholar]

- Xianghua, L.; Huan, D.; Biao, L.; Hongning, Z.; Rong, S. Key Technology of Directional Drilling in the Ultra-deep High-temperature IV Belt, the Shunbei Oilfield. Oil Drill. Prod. Technol. 2022, 44, 665–670. [Google Scholar]

- Kabir, C.; Hasan, A.; Kouba, G.; Ameen, M. Determining Circulating Fluid Temperature in Drilling, Workover, and Well Control Operations. SPE Drill. Complet. 1996, 11, 74–79. [Google Scholar] [CrossRef]

- Cunxi, W.; Yingfeng, M.; Wei, J.; Hu, D. Hole Temperature Variation and Its Effects on Gas Injection Rate During Gas Drilling. Nat. Gas Ind. 2007, 27, 67. [Google Scholar]

- Willhite, G.P. Over-all Heat Transfer Coefficients in Steam and Hot Water Injection Wells. J. Pet. Technol. 1967, 19, 607–615. [Google Scholar] [CrossRef]

- Ruiyao, Z.; Jun, L.; Gonghui, L.; Hongwei, Y.; Hailong, J. Analysis of Coupled Wellbore Temperature and Pressure Calculation Model and Influence Factors under Multi-pressure System in Deep-water Drilling. Energies 2019, 12, 3533. [Google Scholar] [CrossRef]

- Chuanjun, H.; Wenkang, C.; Liangliang, D.; Qiang, Z. A New Two-dimensional Transient Forecast Model of Wellbore Temperature Based on Precise Time Step Integration Method. J. Pet. Sci. Eng. 2022, 215, 110708. [Google Scholar]

- Hongwei, Y.; Jun, L.; Hui, Z.; Jiwei, J.; Boyun, G.; Geng, Z. Numerical Analysis of Heat Transfer Rate and Wellbore Temperature Distribution under Different Circulating Modes of Reel-well Drilling. Energy 2022, 254, 124313. [Google Scholar]

- Kutasov, I.; Targhi, A. Better Deep-hole BHTC Estimations Possible. Oil Gas J. 1987, 85, 6340860. [Google Scholar]

- Holmes, C.S.; Swift, S.C. Calculation of Circulating Mud Temperatures. J. Pet. Technol. 1970, 22, 670–674. [Google Scholar] [CrossRef]

- Raymond, L. Temperature Distribution in a Circulating Drilling Fluid. J. Pet. Technol. 1969, 21, 333–341. [Google Scholar] [CrossRef]

- Hasan, A.R.; Kabir, C. Aspects of Wellbore Heat Transfer During Two-phase Flow. SPE Prod. Facil. 1994, 9, 211–216. [Google Scholar] [CrossRef]

- Marshall, D.W.; Bentsen, R.G. A Computer Model to Determine the Temperature Distributions in a Wellbore. J. Can. Pet. Technol. 1982, 21, 5. [Google Scholar] [CrossRef]

- Shiming, H. Prediction and Distribution of Liquid Temperature in Well; Southwest Petroleum Institute: Nanchong, China, 1998. [Google Scholar]

- Shiming, H.; Cheng, Y.; Bihua, X.; Jun, C.; Zhoucheng, S. Mathematical Model of Determining Borehole Circulating Temperatures in Cementing and Drilling Processes. Nat. Gas Ind. 2002, 22, 42–45. [Google Scholar]

- Bing, Z.; Duo, F.; Taihe, S. Sensibility Analysis of the Factors Affecting Temperature in Well Bore. Nat. Gas Ind. 2000, 20, 57–60. [Google Scholar]

- Abdelhafiz, M.M.; Hegele, L.A., Jr.; Oppelt, J.F. Numerical Transient and Steady State Analytical Modeling of the Wellbore Temperature During Drilling Fluid Circulation. J. Pet. Sci. Eng. 2020, 186, 106775. [Google Scholar] [CrossRef]

- Youzhi, Z.; Tao, G.; Gang, S.; Mou, Y.; Jiang, Y. A Mathematical Model of Wellbore Transient Temperature of High-temperature Directional Wells and its Application. Nat. Gas Ind. 2021, 41, 119–126. [Google Scholar]

- Xiangyang, Z.; Cong, Z.; Peng, W.; Xiaoyang, L.; Mou, Y. A Comparative Study on the Calculation Accuracy of Numerical and Analytical Models for Wellbore Temperature in Ultra-Deep Wells. Pet. Drill. Tech. 2022, 50, 69–75. [Google Scholar]

- Mou, Y.; Yingfeng, M.; Gao, L.; Jianmin, D.; Lin, Z.; Sihong, T. Effects of the Radial Temperature Gradient and Axial Conduction of Drilling Fluid on the Wellbore Temperature Distribution. Acta Phys. Sin. 2013, 62, 537–546. [Google Scholar]

- Mou, Y.; Yingfeng, M.; Gao, L.; Jianmin, D.; Xiangyang, Z. A transient heat transfer model of wellbore and formation during the whole drilling process. Acta Pet. Sin. 2013, 34, 366. [Google Scholar]

- Pengcheng, W.; Chengxu, Z.; Juntao, Y.; Xiumei, W.; Ye, C.; Mou, Y. Well-formation Transient Heat Transfer Model During Drilling of Deep Shale Gas Horizontal Wells. Oil Drill. Prod. Technol. 2022, 44, 1–8. [Google Scholar]

- Zheng, D.; Ozbayoglu, E.; Miska, S.Z.; Liu, Y.; Li, Y. Cement Sheath Fatigue Failure Prediction by ANN-Based Model. In Proceedings of the Offshore Technology Conference, Rio de Janeiro, Brazil, 28–30 October 2022. [Google Scholar]

- Zheng, D.; Ozbayoglu, E.M.; Miska, S.Z.; Liu, Y. Cement Sheath Fatigue Failure Prediction by Support Vector Machine Based Model. In Proceedings of the SPE Eastern Regional Meeting, Wheeling, WV, USA, 18–20 October 2022. [Google Scholar]

- Incropera, F.P.; DeWitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer; Wiley: New York, NY, USA, 1996; Volume 6. [Google Scholar]

- Gnielinski, V. Neue Gleichungen für den Wärme-und den Stoffübergang in turbulent durchströmten Rohren und Kanälen. Forsch. Ingenieurwesen A 1975, 41, 8–16. [Google Scholar] [CrossRef]

- Gnielinski, V. Heat Transfer Coefficients for Turbulent Flow in Concentric Annular Ducts. Heat Transf. Eng. 2009, 30, 431–436. [Google Scholar] [CrossRef]

- Wenlong, L.; Deli, G.; Jin, Y.; Zhenxiang, Z. Prediction of the Borehole Temperature Profile in Ultra-deep Drilling under Ocean Deepwater Conditions. Oil Drill. Prod. Technol. 2020, 42, 558–563. [Google Scholar]

| Type | Bit Diameter (mm) | Depth (m) | Casing Outer Diameter (mm) | Wall Thickness (mm) |

|---|---|---|---|---|

| Surface casing | 660.4 | 110 | 508 | 11.13 |

| Intermediate casing | 444.5 | 1201 | 365.1 | 13.88 |

| Intermediate casing | 333.4 | 4834 | 273.1 | 12.57 |

| Intermediate casing | 241.3 | 7821 | 193.7 | 12.7 |

| Open hole section | 165.1 | 8**9 | / | / |

| Medium | Density (kg/m3) | Specific Heat (J/kg/°C) | Thermal Conductivity (W/m/°C) |

|---|---|---|---|

| Drilling fluid | 1110 | 1600 | 1.2 |

| Drill pipe | 7800 | 500 | 48 |

| Casing | 7800 | 500 | 48 |

| Cement | 2140 | 2000 | 0.7 |

| Formation rock | 2655 | 985 | 2.021 |

| Type | Bit Diameter (mm) | Depth (m) | Casing Outer Diameter (mm) | Wall Thickness (mm) |

|---|---|---|---|---|

| Surface casing | 660.4 | 100 | 508 | 12.7 |

| Intermediate casing | 444.5 | 1507 | 339.72 | 13.88 |

| Intermediate casing | 311.2 | 5382 | 250.8 | 15.83 |

| Intermediate casing | 215.9 | 7528 | 177.8 | 12.65 |

| Open hole section | 149.2 | 8**7 | / | / |

| Medium | Density (kg/m3) | Specific Heat (J/kg/°C) | Thermal Conductivity (W/m/°C) |

|---|---|---|---|

| Drilling fluid | 1290 | 1600 | 1.2 |

| Drill pipe | 7800 | 500 | 48 |

| Casing | 7800 | 500 | 48 |

| Cement | 2140 | 2000 | 0.7 |

| Formation rock | 2655 | 985 | 2.021 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dang, Z.; Chen, X.; Yao, X.; Xu, Z.; Zhou, M.; Yang, W.; Song, X. Wellbore Temperature Prediction Model and Influence Law of Ultra-Deep Wells in Shunbei Field, China. Processes 2024, 12, 1715. https://doi.org/10.3390/pr12081715

Dang Z, Chen X, Yao X, Xu Z, Zhou M, Yang W, Song X. Wellbore Temperature Prediction Model and Influence Law of Ultra-Deep Wells in Shunbei Field, China. Processes. 2024; 12(8):1715. https://doi.org/10.3390/pr12081715

Chicago/Turabian StyleDang, Zhigang, Xiuping Chen, Xuezhe Yao, Zhengming Xu, Mengmeng Zhou, Weixing Yang, and Xianzhi Song. 2024. "Wellbore Temperature Prediction Model and Influence Law of Ultra-Deep Wells in Shunbei Field, China" Processes 12, no. 8: 1715. https://doi.org/10.3390/pr12081715

APA StyleDang, Z., Chen, X., Yao, X., Xu, Z., Zhou, M., Yang, W., & Song, X. (2024). Wellbore Temperature Prediction Model and Influence Law of Ultra-Deep Wells in Shunbei Field, China. Processes, 12(8), 1715. https://doi.org/10.3390/pr12081715