A Comparison of the Carbon Footprints of Different Digested Sludge Post-Treatment Routes: A Case Study in China

Abstract

1. Introduction

2. Materials and Methods

2.1. Sludge Testing

2.2. Carbon Footprint Boundary

2.3. Accounting Method of Indirect Emissions

2.4. Monitoring Method for Direct N2O and CH4 Emissions

2.4.1. N2O and CH4 Monitoring While Composting Digested Sludge

2.4.2. N2O Emissions from the Application of Digested and Composted Sludge on Land

2.5. Accounting of Carbon Emission Reduction

3. Results and Discussion

3.1. Sludge Characteristics

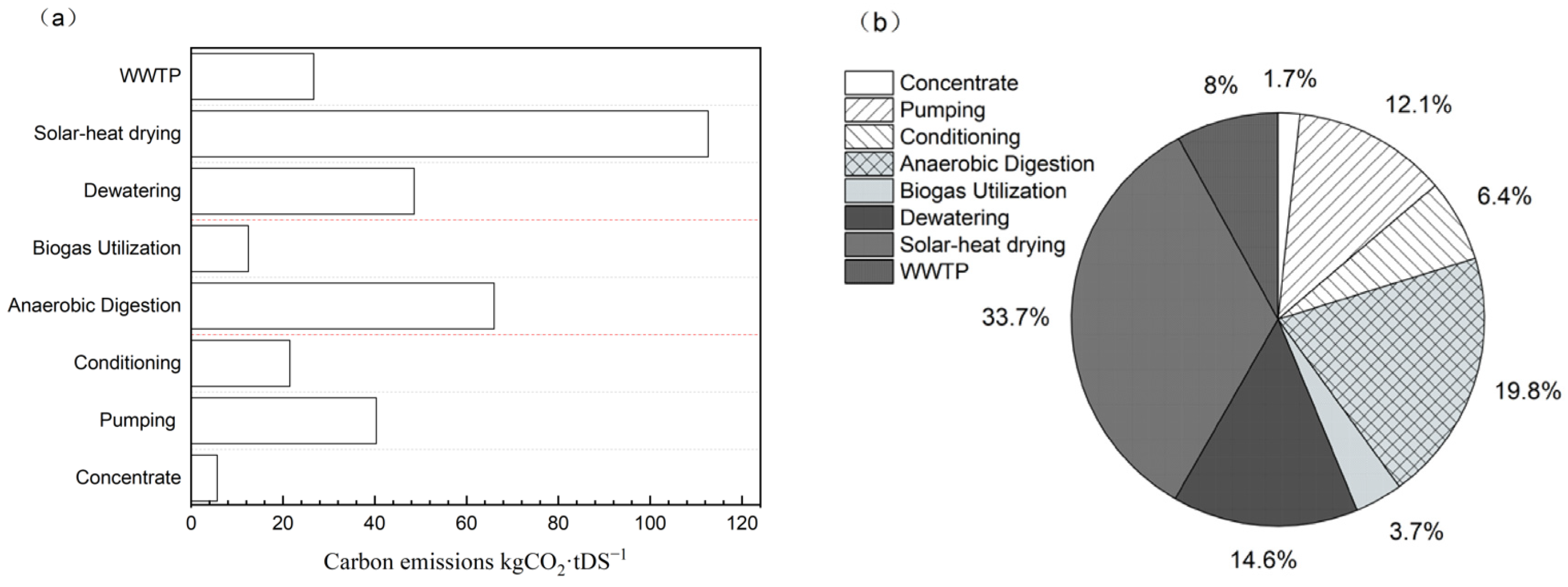

3.2. Carbon Emission Analysis of Anaerobic Digestion

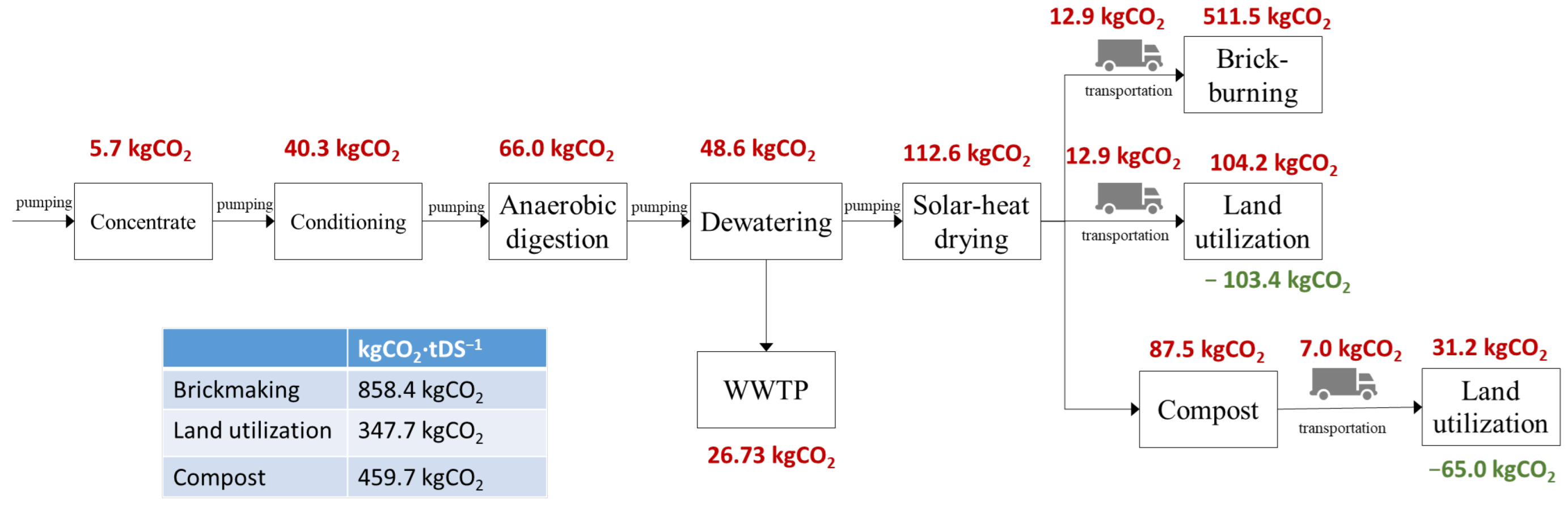

3.3. Carbon Emission Analysis of Digested Sludge Disposal

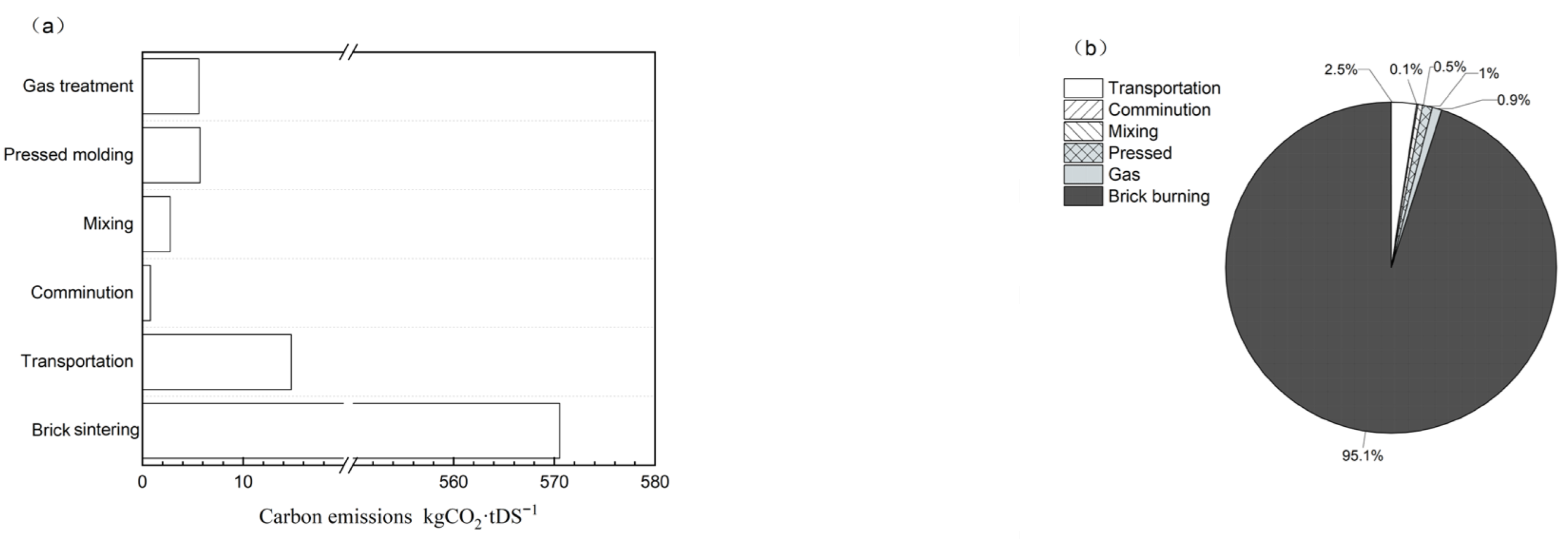

3.3.1. Brickmaking

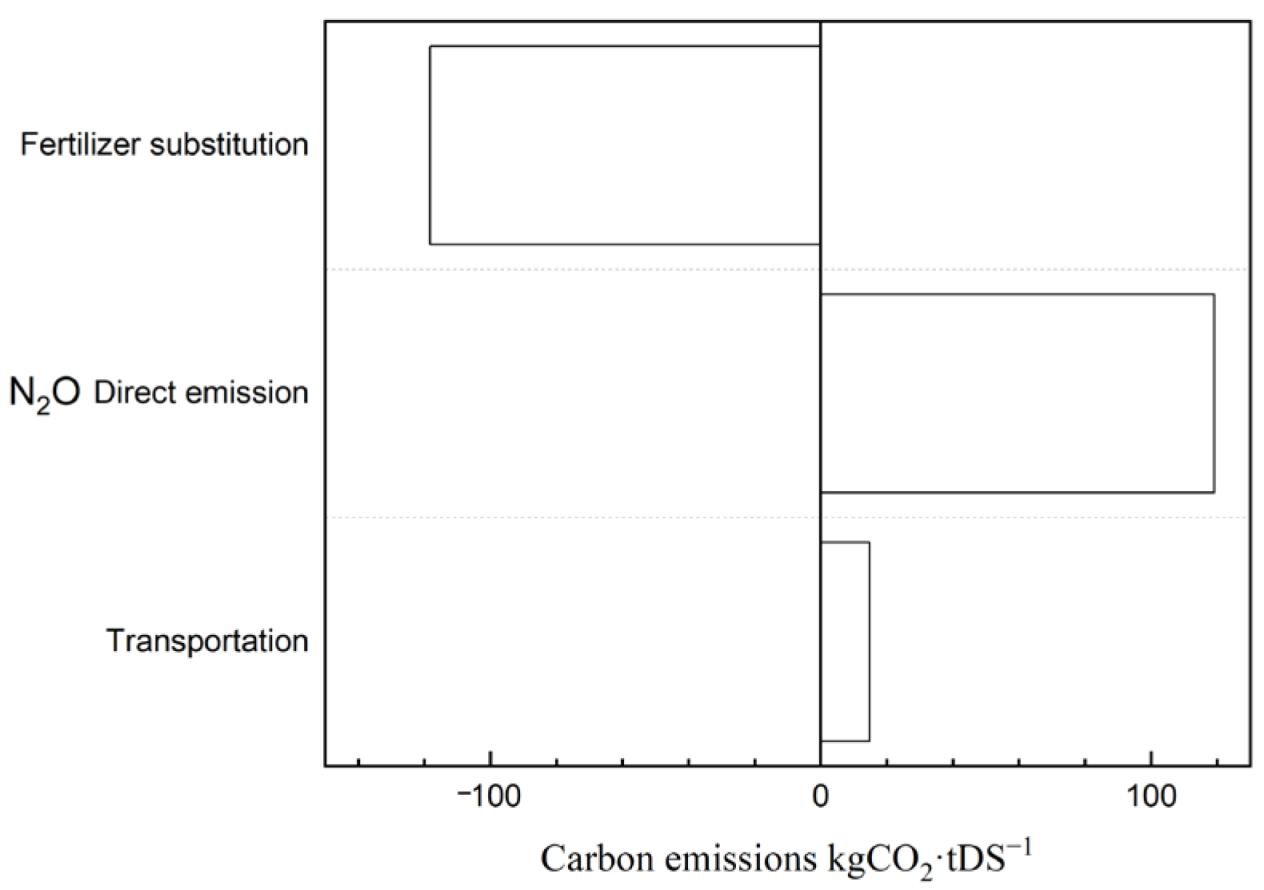

3.3.2. Land Application

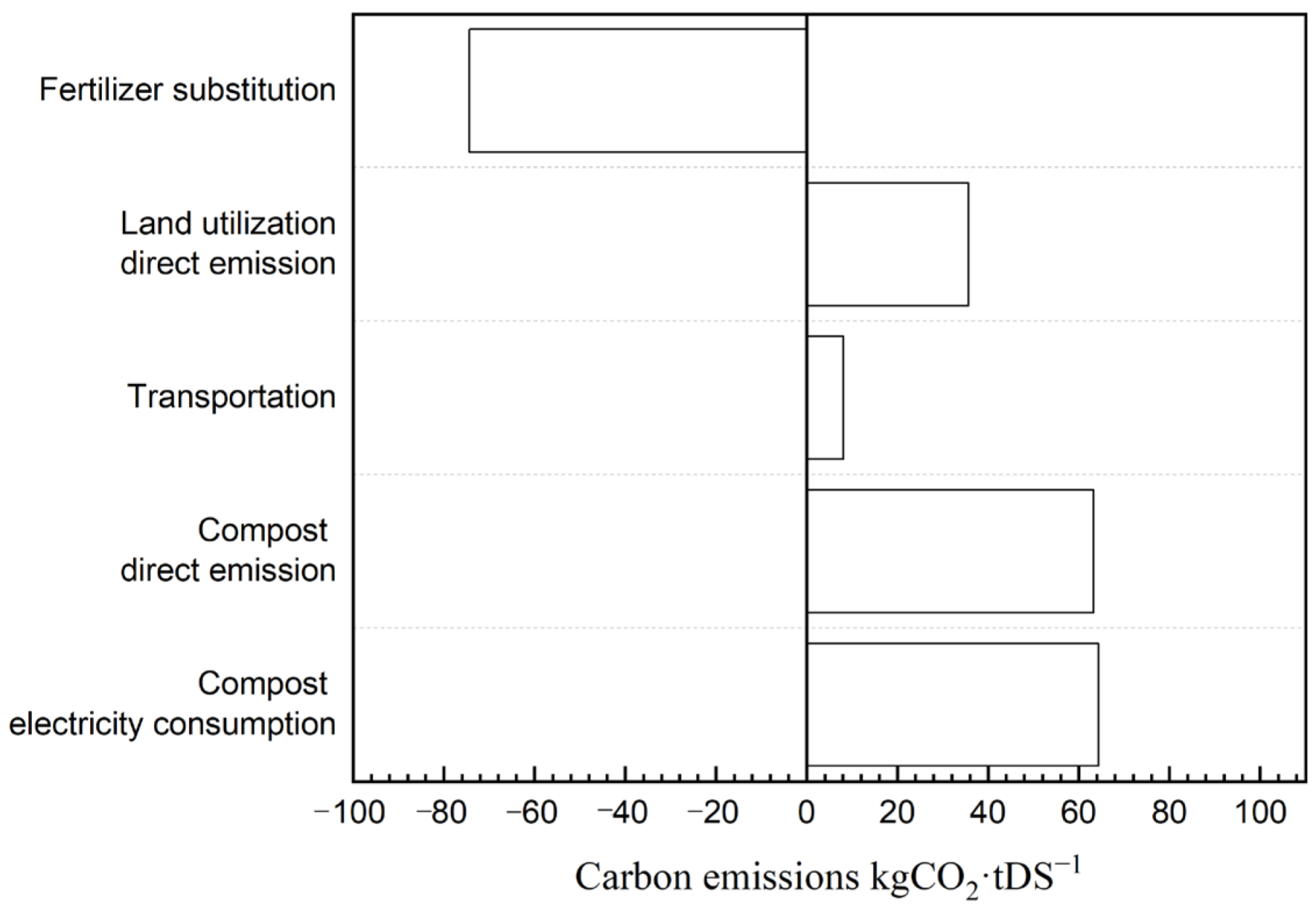

3.3.3. Composting

3.3.4. Comparison of Different Digested Sludge Post-Treatment Routes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ritchie, H.R.P.; Roser, M. Breakdown of carbon dioxide, methane and nitrous oxide emissions by sector. Our World Data 2020. Available online: https://ourworldindata.org/emissions-by-sector (accessed on 2 July 2024).

- Zhao, G.; Liu, W.; Xu, J.; Huang, X.; Lin, X.; Huang, J.; Li, G. Greenhouse Gas Emission Mitigation of Large-Scale Wastewater Treatment Plants (WWTPs): Optimization of Sludge Treatment and Disposal. Pol. J. Environ. Stud. 2020, 30, 955–964. [Google Scholar] [CrossRef] [PubMed]

- Chu, X.; Fei, Z.; Chu, Z.; Huang, W.-C. Decarbonizing the sludge treatment industry: Assessing the feasibility of achieving carbon reduction from carbon peaking to carbon neutrality. J. Clean. Prod. 2024, 434, 140023. [Google Scholar] [CrossRef]

- Wei, L.; Zhu, F.; Li, Q.; Xue, C.; Xia, X.; Yu, H.; Zhao, Q.; Jiang, J.; Bai, S. Development, current state and future trends of sludge management in China: Based on exploratory data and CO2-equivaient emissions analysis. Environ. Int. 2020, 144, 106093. [Google Scholar] [CrossRef] [PubMed]

- Karki, R.; Chuenchart, W.; Surendra, K.C.; Shrestha, S.; Raskin, L.; Sung, S.; Hashimoto, A.; Khanal, S.K. Anaerobic co-digestion: Current status and perspectives. Bioresour. Technol. 2021, 330, 125001. [Google Scholar] [CrossRef] [PubMed]

- Van Fan, Y.; Klemeš, J.J.; Lee, C.T.; Perry, S. Anaerobic digestion of municipal solid waste: Energy and carbon emission footprint. J. Environ. Manag. 2018, 223, 888–897. [Google Scholar] [CrossRef]

- Lijó, L.; González-García, S.; Bacenetti, J.; Fiala, M.; Feijoo, G.; Lema, J.M.; Moreira, M.T. Life Cycle Assessment of electricity production in Italy from anaerobic co-digestion of pig slurry and energy crops. Renew. Energy 2014, 68, 625–635. [Google Scholar] [CrossRef]

- Chai, B.-H.; Li, W.-T.; Qi, W.; Ran, L.-F.; Wang, Q.; Wang, M.-J.; Lu, Y. Status of municipal sludge treatment and disposal in China. Adv. New Renew. Energy 2023, 11, 38–44. [Google Scholar] [CrossRef]

- Cartes, J.; Neumann, P.; Hospido, A.; Vidal, G. Life cycle assessment of management alternatives for sludge from sewage treatment plants in Chile: Does advanced anaerobic digestion improve environmental performance compared to current practices? J. Mater. Cycles Waste Manag. 2018, 20, 1530–1540. [Google Scholar] [CrossRef]

- Yang, H.; Guo, Y.; Fang, N.; Dong, B. Life cycle assessment of sludge anaerobic digestion combined with land application treatment route: Greenhouse gas emission and reduction potential. J. Environ. Chem. Eng. 2023, 11, 111255. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, Z.; Liu, B.; He, H.; Peng, S.; Zhang, Y.; Li, L.; Ai, J.; Yu, J.; Zhang, W. Regional heterogeneity of sustainable wastewater sludge management in China. Resour. Conserv. Recycl. 2024, 209, 107755. [Google Scholar] [CrossRef]

- Chojnacka, K.; Moustakas, K. Anaerobic digestate management for carbon neutrality and fertilizer use: A review of current practices and future opportunities. Biomass Bioenergy 2024, 180, 106991. [Google Scholar] [CrossRef]

- Zeng, Q.; Zhen, S.; Liu, J.; Ni, Z.; Chen, J.; Liu, Z.; Qi, C. Impact of solid digestate processing on carbon emission of an industrial-scale food waste co-digestion plant. Bioresour. Technol. 2022, 360, 127639. [Google Scholar] [CrossRef]

- Guo, D.; Li, B.; Yu, W.; Baroutian, S.; Young, B.R. A system engineering perspective for net zero carbon emission in wastewater and sludge treatment industry: A review. Sustain. Prod. Consum. 2024, 46, 369–381. [Google Scholar] [CrossRef]

- Czekała, W.; Nowak, M.; Piechota, G. Sustainable management and recycling of anaerobic digestate solid fraction by composting: A review. Bioresour. Technol. 2023, 375, 128813. [Google Scholar] [CrossRef]

- Hobson, A.M.; Frederickson, J.; Dise, N.B. CH4 and N2O from mechanically turned windrow and vermicomposting systems following in-vessel pre-treatment. Waste Manag. 2005, 25, 345–352. [Google Scholar] [CrossRef]

- Gurmessa, B.; Cocco, S.; Ashworth, A.J.; Udawatta, R.P.; Cardelli, V.; Ilari, A.; Serrani, D.; Fornasier, F.; Del Gatto, A.; Pedretti, E.F.; et al. Short term effects of digestate and composted digestate on soil health and crop yield: Implications for sustainable biowaste management in the bioenergy sector. Sci. Total Environ. 2024, 906, 167208. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Wang, M.; Chen, H.; Wang, Q.; Zhao, J.; Ren, X.; Li, D.-S.; Awasthi, S.K.; Shen, F.; Li, R.; et al. Heterogeneity of biochar amendment to improve the carbon and nitrogen sequestration through reduce the greenhouse gases emissions during sewage sludge composting. Bioresour. Technol. 2017, 224, 428–438. [Google Scholar] [CrossRef]

- Piippo, S.; Lauronen, M.; Postila, H. Greenhouse gas emissions from different sewage sludge treatment methods in north. J. Clean. Prod. 2018, 177, 483–492. [Google Scholar] [CrossRef]

- Liu, B.; Wei, Q.; Zhang, B.; Bi, J. Life cycle GHG emissions of sewage sludge treatment and disposal options in Tai Lake Watershed, China. Sci. Total Environ. 2013, 447, 361–369. [Google Scholar] [CrossRef]

- Zhu-Barker, X.; Bailey, S.K.; Paw U, K.T.; Burger, M.; Horwath, W.R. Greenhouse gas emissions from green waste composting windrow. Waste Manag. 2017, 59, 70–79. [Google Scholar] [CrossRef]

- González, D.; Guerra, N.; Colón, J.; Gabriel, D.; Ponsá, S.; Sánchez, A. Characterization of the Gaseous and Odour Emissions from the Composting of Conventional Sewage Sludge. Atmosphere 2020, 11, 211. [Google Scholar] [CrossRef]

- He, Y.; Inamori, Y.; Mizuochi, M.; Kong, H.; Iwami, N.; Sun, T. Nitrous Oxide Emissions from Aerated Composting of Organic Waste. Environ. Sci. Technol. 2001, 35, 2347–2351. [Google Scholar] [CrossRef] [PubMed]

- GB 4284; Control Standards of Pollution in Sludge for Agricultural Use. Ministry of Ecology and Evironment: Beijing, China, 1985. (In Chinese)

- GBT 23486; The Disposal of Sludge from Municipal Wastewater Treatment Plant—The Quality of Sludge Used in Gardens or Parks. National Standards of People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Ronga, D.; Setti, L.; Salvarani, C.; De Leo, R.; Bedin, E.; Pulvirenti, A.; Milc, J.; Pecchioni, N.; Francia, E. Effects of solid and liquid digestate for hydroponic baby leaf lettuce (Lactuca sativa L.) cultivation. Sci. Hortic. 2019, 244, 172–181. [Google Scholar] [CrossRef]

- Yang, H.; Guo, Y.; Fang, N.; Dong, B.; Wu, X. Greenhouse gas emissions of sewage sludge land application in urban green space: A field experiment in a Bermuda grassland. Sci. Total Environ. 2024, 926, 172106. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Dai, X. Analysis on carbon dioxide emission reduction during the anaerobic synergetic digestion technology of sludge and kitchen waste: Taking kitchen waste synergetic digestion project in Zhenjiang as an example. Waste Manag. 2017, 69, 360–364. [Google Scholar] [CrossRef] [PubMed]

- Malet, N.; Pellerin, S.; Girault, R.; Nesme, T. Does anaerobic digestion really help to reduce greenhouse gas emissions? A nuanced case study based on 30 cogeneration plants in France. J. Clean. Prod. 2023, 384, 135578. [Google Scholar] [CrossRef]

- Ju, X.T.; Zhang, C. The Principles and Indicators of Rational N Fertilization. Acta Pedol. Sin. 2021, 58, 1–13. [Google Scholar]

- Díaz, M.A.; Bown, H.E.; Fuentes, J.P.; Martínez, A.M. Soils act as sinks or sources of CH4 depending on air-filled porosity in sclerophyllous ecosystems in semiarid central Chile. Appl. Soil Ecol. 2018, 130, 13–20. [Google Scholar] [CrossRef]

- Pampillón-González, L.; Luna-Guido, M.; Ruíz-Valdiviezo, V.M.; Franco-Hernández, O.; Fernández-Luqueño, F.; Paredes-López, O.; Hernández, G.; Dendooven, L. Greenhouse Gas Emissions and Growth of Wheat Cultivated in Soil Amended with Digestate from Biogas Production. Pedosphere 2017, 27, 318–327. [Google Scholar] [CrossRef]

- Parravicini, V.; Svardal, K.; Krampe, J. Greenhouse Gas Emissions from Wastewater Treatment Plants. Energy Procedia 2016, 97, 246–253. [Google Scholar] [CrossRef]

- Li, Y.; Lv, C.; Yang, N.; Liu, H.; Liu, Z. A study of high temporal-spatial resolution greenhouse gas emissions inventory for on-road vehicles based on traffic speed-flow model: A case of Beijing. J. Clean. Prod. 2020, 277, 122419. [Google Scholar] [CrossRef]

- Guidelines for Carbon Emission Accounting and Reporting of Industrial Enterprises in Chongqing (Trial). (In Chinese). Available online: http://fzggw.cq.gov.cn/zwxx/tzgg/202002/t20200212_5169344.html (accessed on 7 June 2024).

- Cai, B.F.; Cao, D.; Liu, L.C.; Zhang, Z.S. Analysis of lime production and energy consumption in china. Environ. Eng. 2012, 30, 124–127. [Google Scholar]

- The Norm of Carbon Emissions Caps per Unit Product of Caustic Soda. (In Chinese). Available online: https://www.1clicktong.com/LawWeb/attached_prod/file/20190510/20190510222530_112.pdf (accessed on 2 July 2024).

- Zhang, C. Study on Carbon Emission of Urban Wastewater Treatment System in Chongqing. Ph.D. Thesis, Chongqing University, Chongqing, China, 2011. [Google Scholar]

- Chong, Y.; Li, H.; Pan, T.; You, L.; Du, H.; Yu, B.; Chen, J.; Ren, N.; Lu, L. More applicable quantification of non-CO2 greenhouse gas emissions from wastewater treatment plants by on-site plant-integrated measurements. Sci. Total Environ. 2024, 929, 172598. [Google Scholar] [CrossRef] [PubMed]

- Shcherbak, I.; Millar, N.; Robertson, G.P. Global metaanalysis of the nonlinear response of soil Nitrous oxide (N2O) emissions to fertilizer nitrogen. Proc. Natl. Acad. Sci. USA 2014, 111, 9199–9204. [Google Scholar] [CrossRef] [PubMed]

- Millar, N.; Urrea, A.; Kahmark, K.; Shcherbak, I.; Robertson, G.P.; Ortiz-Monasterio, I. Nitrous oxide (N2O) flux responds exponentially to nitrogen fertilizer in irrigated wheat in the Yaqui Valley, Mexico. Agric. Ecosyst. Environ. 2018, 261, 125–132. [Google Scholar] [CrossRef]

- Miao, Y.L.; Liang, F.; Xie, J.; Zhang, Q.; Liu, Y.R.; Zhao, X.M. Effects of Long-term Organic Fertilizer Instead of Chemical Fertilizer on Organic Carbon Stability of Paddy Soil. Acta Pedol. Sin. 2023, 60, 512–522. [Google Scholar]

- Hou, H.Q.; Ji, J.H.; Liu, X.; Lv, Z.; Lan, X.J.; Liu, Y.R. Effect of Long-Term Combined Application of Organic and Inorganic Fertilizers on Rice Yield, Nitrogen Uptake and Utilization in Red Soil Area of China. Soils 2020, 52, 758–765. [Google Scholar]

- Gao, Y.; Serrenho, A.C. Greenhouse gas emissions from nitrogen fertilizers could be reduced by up to one-fifth of current levels by 2050 with combined interventions. Nat. Food 2023, 4, 170–178. [Google Scholar] [CrossRef]

- Chen, S.; Lu, F.; Wang, X. Estimation of greenhouse gases emission factors for China’s nitrogen, phosphate, and potash fertilizers. Acta Ecol. Sin. 2015, 35, 6371–6383. [Google Scholar] [CrossRef]

- Cayuela, M.L.; Aguilera, E.; Sanz-Cobena, A.; Adams, D.C.; Abalos, D.; Barton, L.; Ryals, R.; Silver, W.L.; Alfaro, M.A.; Pappa, V.A.; et al. Direct nitrous oxide emissions in Mediterranean climate cropping systems: Emission factors based on a meta-analysis of available measurement data. Agric. Ecosyst. Environ. 2017, 238, 25–35. [Google Scholar] [CrossRef]

- Dietrich, M.; Fongen, M.; Foereid, B. Anaerobic digestion affecting nitrous oxide and methane emissions from the composting process. Bioresour. Technol. Rep. 2021, 15, 100752. [Google Scholar] [CrossRef]

- Font, X.; Artola, A.; Sánchez, A. Detection, Composition and Treatment of Volatile Organic Compounds from Waste Treatment Plants. Sensors 2011, 11, 4043–4059. [Google Scholar] [CrossRef] [PubMed]

- Nag, M.; Shimaoka, T.; Komiya, T. Nitrous oxide production during nitrification from organic solid waste under temperature and oxygen conditions. Environ. Technol. 2016, 37, 2890–2897. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.-C.; Kuo, J. Potential of greenhouse gas emissions from sewage sludge management: A case study of Taiwan. J. Clean. Prod. 2016, 129, 196–201. [Google Scholar] [CrossRef]

- Guan, D.; Zhao, J.; Wang, Y.; Fu, Z.; Zhang, D.; Zhang, H.; Xie, J.; Sun, Y.; Zhu, J.; Wang, D. A critical review on sustainable management and resource utilization of digestate. Process Saf. Environ. Prot. 2024, 183, 339–354. [Google Scholar] [CrossRef]

| Process Description | GHG Emissions (kgCO2/t Dry Solid (DS)) | References |

|---|---|---|

| Thickening→AD→dewatering→land application | −5.36 | [9] |

| Thickening→AD→dewatering→land application | −26.33 | [10] |

| Thickening→AD→dewatering→land application | −178~106 | [11] |

| Thermal hydrolysis→AD→dewatering→land application | −627~−202 | [11] |

| Emission Factor | |

|---|---|

| PAM | 2.62 kg CO2·kg−1 [33] |

| Electricity | 0.5703 kg CO2·kg−1 |

| Diesel Fuel | 1.45 kg·kg−1 Standard coal |

| Coal Transportation | 0.665 kg CO2/km [34] |

| Coal Gangue | 0.807 kgCO2/kg [35] |

| Limestone | 0.43 kgCO2/kg [36] |

| Caustic Soda | 1.912 kgCO2/kg [37] |

| Wastewater Treatment | 3.3 kgCO2/t [38] |

| Activity Data | ||

|---|---|---|

| Anaerobic Digestion | Power Consumption—Thickening | 10 kWh·tDS−1 |

| Power Consumption—Pumping | 70.71 kWh·tDS−1 | |

| Power Consumption—Conditioning | 37.71 kWh·tDS−1 | |

| Power Consumption—Anaerobic Digestion | 106.29 kWh·tDS−1 | |

| Power Consumption—Centrifugal Dewatering | 77.14 kWh·tDS−1 | |

| PAM Consumption—Centrifugal Dewatering | 2 kg·tDS−1 | |

| Power Consumption—Solar Drying | 49.37·tDS−1 | |

| Biogas Slurry Treatment Capacity | 226.8 t·d−1 | |

| Power Consumption—Biogas Boilers | 21.85 kWh·tDS−1 | |

| Direction Emissions—Biogas Production | 1200 m3·d−1 | |

| Direction Emissions—Methane Ratio | 60% | |

| Amount of Digested Effluent Produced | 8.10 t water·tDS−1 | |

| Brickmaking | Power Consumption—Material Grinding and Transport | 233.31 kWh·d−1 |

| Power Consumption—Material Mixing and Transport | 837 kWh·d−1 | |

| Power Consumption—Compression Molding | 1756.8 kWh·d−1 | |

| Power Consumption—Baking Bricks | 2320 kWh·d−1 | |

| Limestone Consumption—Waste Gas Treatment | 119.53 kg·d−1 | |

| Caustic Soda Consumption—Waste Gas Treatment | 24.15 kg·d−1 | |

| Composting | Power Consumption—Compost | 112.8 kWh·tDS−1 |

| Transport Distance | 50 km |

| Emission Factor | |

|---|---|

| Synthetic Nitrogen Fertilizer | 4.42 kg CO2·kg N−1 [44] |

| Phosphorus Fertilizer | 0.636 kg CO2·kg P2O5−1 [45] |

| Potassium Fertilizer | 0.180 kg CO2·kg K2O−1 [45] |

| Organic Matter | Moisture | Total Organic Carbon | Total Nitrogen | Total Phosphorus | Total Potassium | |

|---|---|---|---|---|---|---|

| Raw Sludge | 42.0% | 92.0% | 32.5% | 3.2% | 1.9% | 0.5% |

| Digested Sludge | 30.6% | 67.1% | 29.8% | 3.4% | 2.8% | 0.5% |

| Composted Sludge | 38.3% | 45.6% | 22.2% | 2.1% | 2.1% | 0.06% |

| GI | Sludge Usage (Dry Basis) 200 kg N ha−1 Input | Sludge Usage (80% Moisture Content) 200 kg N ha−1 Input | |

|---|---|---|---|

| Digested Sludge | 42~53% | 5.88 t·ha−1 | 29.40 t·ha−1 |

| Composted Sludge | 81~92% | 9.52 t·ha−1 | 47.60 t·ha−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ci, H.; Fang, N.; Yang, H.; Guo, Y.; Mei, X.; Zhao, X. A Comparison of the Carbon Footprints of Different Digested Sludge Post-Treatment Routes: A Case Study in China. Processes 2024, 12, 1444. https://doi.org/10.3390/pr12071444

Ci H, Fang N, Yang H, Guo Y, Mei X, Zhao X. A Comparison of the Carbon Footprints of Different Digested Sludge Post-Treatment Routes: A Case Study in China. Processes. 2024; 12(7):1444. https://doi.org/10.3390/pr12071444

Chicago/Turabian StyleCi, Hanlin, Ning Fang, Hang Yang, Yali Guo, Xiaojie Mei, and Xiaolei Zhao. 2024. "A Comparison of the Carbon Footprints of Different Digested Sludge Post-Treatment Routes: A Case Study in China" Processes 12, no. 7: 1444. https://doi.org/10.3390/pr12071444

APA StyleCi, H., Fang, N., Yang, H., Guo, Y., Mei, X., & Zhao, X. (2024). A Comparison of the Carbon Footprints of Different Digested Sludge Post-Treatment Routes: A Case Study in China. Processes, 12(7), 1444. https://doi.org/10.3390/pr12071444