Properties of Binderless Insulating Boards Made from Canary Island Date Palm and Cork Particles

Abstract

1. Introduction

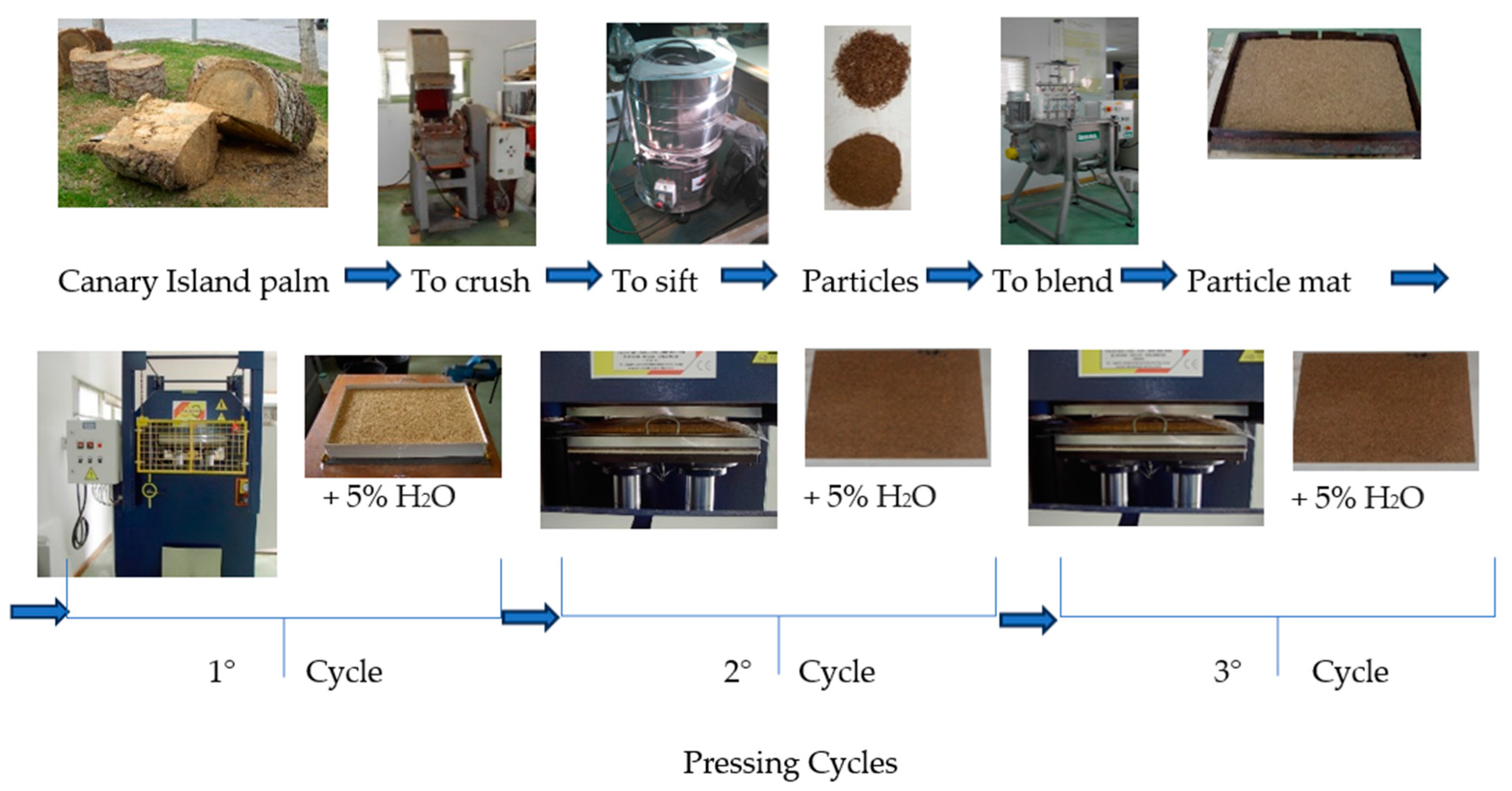

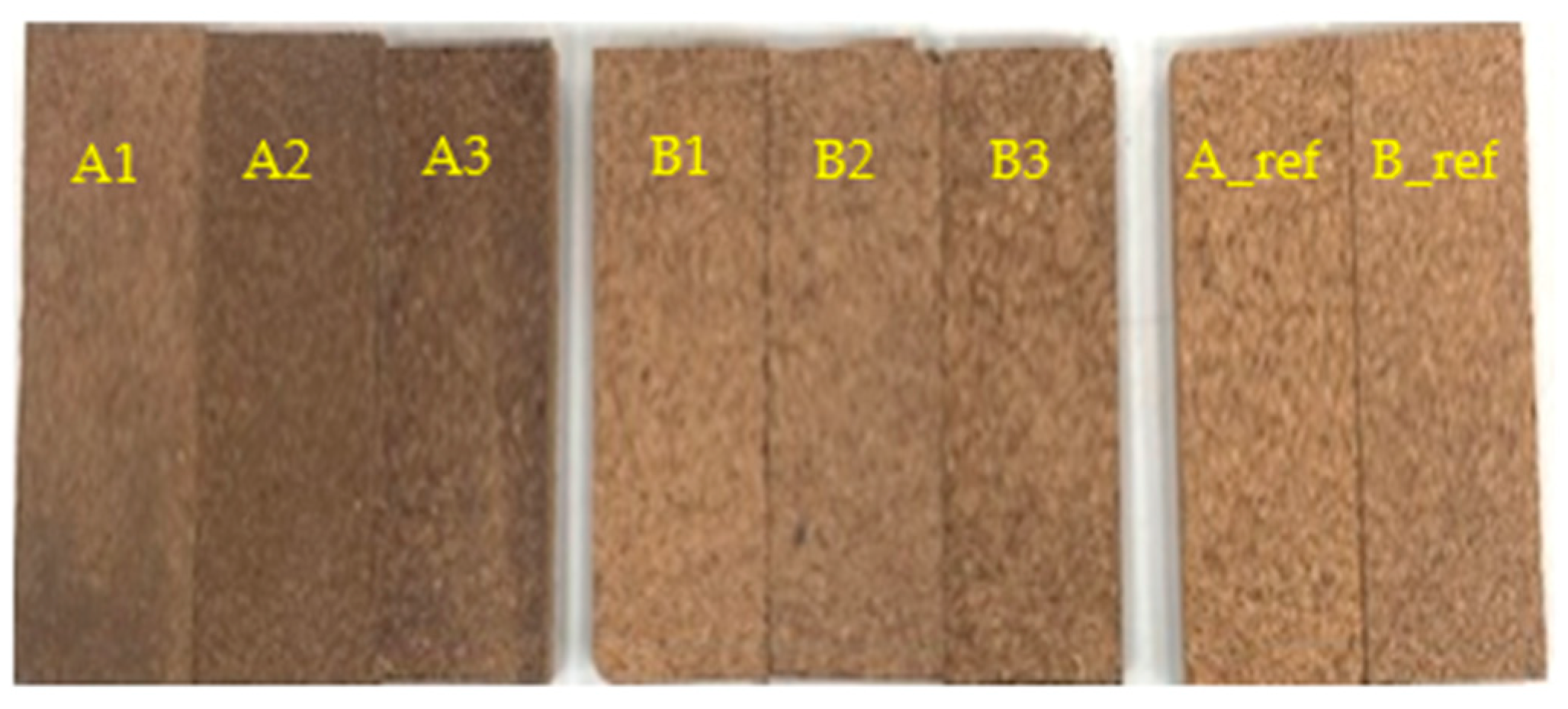

2. Materials and Methods

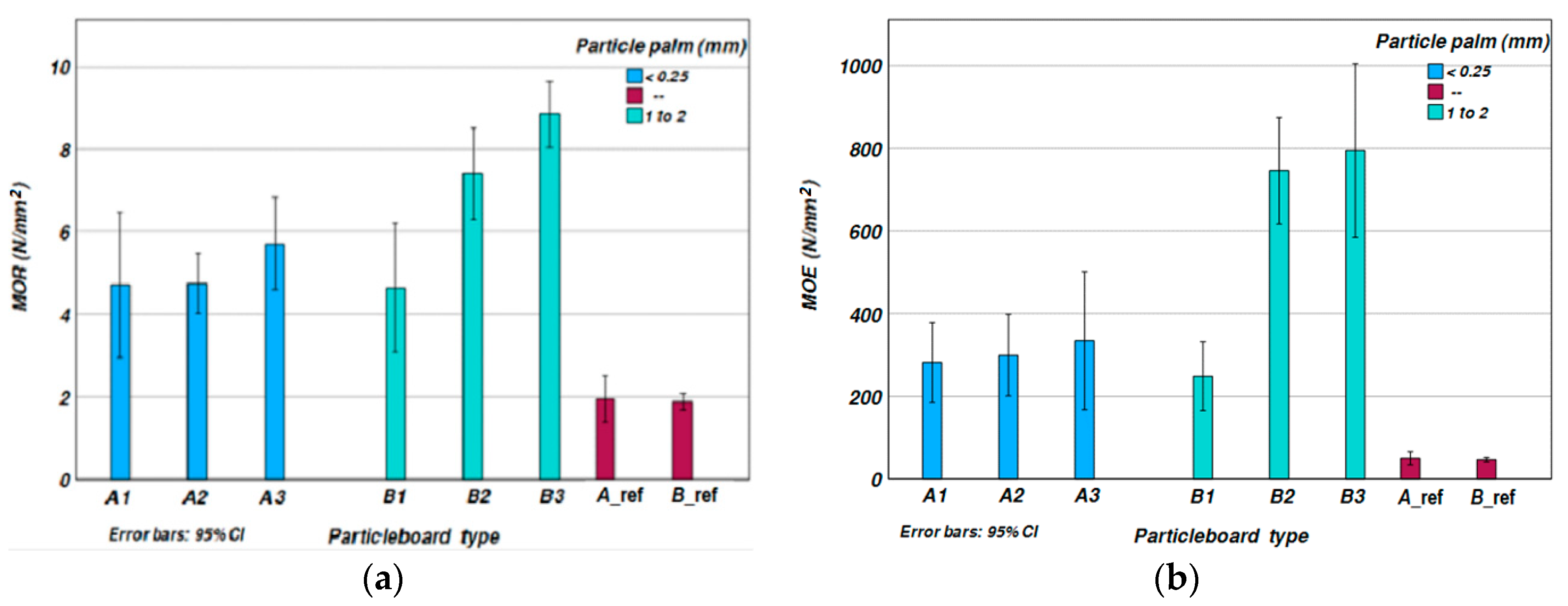

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Silvestre, J.D.; Pargana, N.; De Brito, J.; Pinheiro, M.D.; Durão, V. Insulation cork boards—Environmental life cycle assessment of an organic construction material. Materials 2016, 9, 394. [Google Scholar] [CrossRef]

- Sierra-Pérez, J.; Boschmonart-Rives, J.; Gabarrell, X. Production and trade analysis in the Iberian cork sector: Economic characterization of a forest industry. Resour. Conserv. Recycl. 2015, 98, 55–66. [Google Scholar] [CrossRef]

- Pereira, H. Cork: Biology, Production and Uses, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2017; p. 336. ISBN 13: 978-0-444-52967-1. [Google Scholar]

- Gil, L. Cork composites: A review. Materials 2009, 2, 776–789. [Google Scholar] [CrossRef]

- Yay, Ö.; Hasanzadeh, M.; Diltemiz, S.F.; Kuşhan, M.C.; Gürgen, S. Thermal Insulation with Cork-Based Materials. In Cork-Based Materials in Engineering: Design and Applications for Green and Sustainable Systems; Springer Nature: Cham, Switzerland, 2024; pp. 3–15. [Google Scholar] [CrossRef]

- Jardin, R.T.; Fernandes, F.A.O.; Pereira, A.B.; Alves de Sousa, R.J. Static and dynamic mechanical response of different cork agglomerates. Mater. Des. 2015, 68, 121–126. [Google Scholar] [CrossRef]

- Knapic, S.; Oliveira, V.; Machado, J.S.; Pereira, H. Cork as a building material: A review. Eur. J. Wood Prod. 2016, 74, 775–791. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Correlo, V.M.; Mano, J.F.; Reis, R.L. Cork–polymer biocomposites: Mechanical, structural and thermal properties. Mater. Des. 2015, 82, 282–289. [Google Scholar] [CrossRef]

- Carvalho, R.; Fernandes, M.; Fangueiro, R. The influence of cork on the thermal insulation properties of home textiles. Procedia Eng. 2017, 200, 252–259. [Google Scholar] [CrossRef]

- Lakreb, N.; Şen, U.; Toussaint, E.; Amziane, S.; Djakab, E.; Pereira, H. Physical properties and thermal conductivity of cork-based sandwich panels for building insulation. Constr. Build. Mater. 2023, 368, 130420. [Google Scholar]

- Sarasini, F.; Tirillò, J.; Lampani, L.; Sasso, M.; Mancini, E.; Burgstaller, C.; Calzolari, A. Static and dynamic characterization of agglomerated cork and related sandwich structures. Compos. Struct. 2019, 212, 439–451. [Google Scholar] [CrossRef]

- Boria, S.; Raponi, E.; Sarasini, F.; Tirillò, J.; Lampani, L. Green sandwich structures under impact: Experimental vs numerical analysis. Procedia Struct. Integrity 2018, 12, 317–329. [Google Scholar] [CrossRef]

- Reis, L.; Silva, A. Mechanical behavior of sandwich structures using natural cork agglomerates as core materials. J. Sandw. Struct. Mater. 2009, 11, 487–500. [Google Scholar] [CrossRef]

- Simões, I.; Simões, N.; Tadeu, A. Thermal delay simulation in multilayer systems using analytical solutions. Energy Build. 2012, 49, 631–639. [Google Scholar] [CrossRef]

- Malanho, S.; Veiga, R.; Farinha, C.B. Global performance of sustainable thermal insulating systems with cork for building facades. Buildings 2021, 11, 83. [Google Scholar] [CrossRef]

- Gil, L. New Cork-Based Materials and Applications. Materials 2015, 8, 625–637. [Google Scholar] [CrossRef]

- Sajdak, M.; Velázquez-Martí, B.; López-Cortés, I. Quantitative and qualitative characteristics of biomass derived from pruning Phoenix canariensis hort. ex Chabaud and Phoenix dactilifera L. Renew. Energy 2014, 71, 545–552. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, M.T.; Ferrandez-Garcia, A.; Garcia-Ortuño, T.; Ferrandez-Garcia, C.E.; Ferrandez-Villena, M. Influence of particle size on the properties of boards made from Washingtonia palm rachis with citric acid. Sustainability 2020, 12, 4841. [Google Scholar] [CrossRef]

- Mawardi, I.; Aprilia, S.; Faisal, M.; Rizal, S. Characterization of thermal bio-insulation materials based on oil palm wood: The effect of hybridization and particle size. Polymers 2021, 13, 3287. [Google Scholar] [CrossRef]

- Ali, M.; Alabdulkarem, A.; Nuhait, A.; Al-Salem, K.; Iannace, G.; Almuzaiqer, R. Characteristics of agro waste fibers as new thermal insulation and sound absorbing materials: Hybrid of date palm tree leaves and wheat straw fibers. J. Nat. Fibers 2022, 19, 6576–6594. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, B.E.; Garcia-Ortuño, T.; Ferrandez-Villena, M.; Ferrandez-Garcia, M.T. Evaluation of the Properties and Reaction-to-Fire Performance of Binderless Particleboards Made from Canary Island Palm Trunks. Fire 2024, 7, 193. [Google Scholar] [CrossRef]

- EN 323; Wood-Based Panels. Determination of Density. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 317; Particleboards and Fiberboards. Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 310; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319; Particleboards and Fiberboards. Determination of Tensile Strength Perpendicular to the Plane of de Board. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 12667; Thermal Performance of Building Materials and Products: Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods: Products of High and Medium Thermal Resistance. Committee for Standardization: Brussels, Belgium, 2001.

- Zhou, X.Y.; Zheng, F.; Li, H.G.; Lu, C.L. An environment-friendly thermal insulation material from cotton stalk fibers. Energy Build. 2010, 42, 1070–1074. [Google Scholar] [CrossRef]

- Xu, J.; Sugawara, R.; Widyorini, R.; Han, G.; Kawai, S. Manufacture and properties of low-density binderless particleboard from kenaf core. J. Wood Sci. 2004, 50, 62–67. [Google Scholar] [CrossRef]

- Liao, R.; Xu, J.; Umemura, K. Low density sugarcane bagasse particleboard bonded with citric acid and sucrose: Effect of board density and additive content. BioResources 2016, 11, 2174–2185. [Google Scholar]

- Ferrández-García, C.E.; Ferrández-García, A.; Ferrández-Villena, M.; Hidalgo-Cordero, J.F.; García-Ortuño, T.; Ferrández-García, M.T. Physical and mechanical properties of particleboard made from palm tree prunings. Forests 1018, 9, 755. [Google Scholar] [CrossRef]

- Peleteiro, S.; Rivas, S.; Alonso, J.L.; Santos, V.; Parajó, J.C. Furfural production using ionic liquids: A review. Bioresour. Technol. 2016, 202, 181–191. [Google Scholar] [CrossRef]

- Anglès, M.N.; Reguant, J.; Montané, D.; Ferrando, F.; Salvadó, J. Binderless composites from pretreated residual softwood. J. Appl. Polym. Sci. 1999, 73, 2485–2491. [Google Scholar] [CrossRef]

- Pintiaux, T.; Viet, D.; Vandenbossche, V.; Rigal, L.; Rouilly, A. Binderless Materials Obtained by Thermo-Compressive Processing of Lignocellulosic Fibers: A Comprehensive Review. BioResources 2015, 10, 1915–1963. [Google Scholar] [CrossRef]

- Ferrández-García, A.; Ferrández-Villena, M.; Ferrández-García, C.E.; García-Ortuño, T.; Ferrández-García, M.T. Potential use of Phoenix canariensis biomass in binderless particleboards at low temperature and pressure. BioResources 2017, 12, 6698–6712. [Google Scholar] [CrossRef]

| Type | Particle Size (mm) | % Cork | % Canary Island Palm | Binder | Temperature (°C) | Pressure (MPa) | Time (min) | No. of Boards |

|---|---|---|---|---|---|---|---|---|

| A1 | <0.25 | 50 | 50 | No | 130 | 2.6 | 15 | 4 |

| A2 | <0.25 | 50 | 50 | No | 130 | 2.6 | 15 + 15 | 4 |

| A3 | <0.25 | 50 | 50 | No | 130 | 2.6 | 15 + 15 + 15 | 4 |

| B1 | 0.25 to 1 | 50 | 50 | No | 130 | 2.6 | 15 | 4 |

| B2 | 0.25 to 1 | 50 | 50 | No | 130 | 2.6 | 15 + 15 | 4 |

| B3 | 0.25 to 1 | 50 | 50 | No | 130 | 2.6 | 15 + 15 + 15 | 4 |

| A_ref | - | 100 | 0 | UF 8% | 130 | 2.6 | 6 | 4 |

| B_ref | - | 100 | 0 | UF 8% | 130 | 2.6 | 15 | 4 |

| Type of Board | Thickness (mm) | Density (kg/m3) | TS 2 h (%) | TS 24 h (%) | WA 2 h (%) | WA 24 h (%) |

|---|---|---|---|---|---|---|

| A1 | 10.81 (0.11) | 676.56 (9.52) | 4.59 (1.45) | 13.30 (2.58) | 25.42 (8.06) | 43.3 (7.06) |

| A2 | 10.71 (0.47) | 718.66 (16.12) | 7.82 (3.20) | 14.00 (2.66) | 31.44 (6.97) | 49.96 (7.13) |

| A3 | 10.66 (0.94) | 708.74 (24.39) | 7.70 (3.39) | 12.02 (1.99) | 34.92 (7.09) | 49.18 (10.32) |

| B1 | 10.63 (0.24) | 698.37 (35.97) | 13.87 (3.39) | 19.71 (3.00) | 47.20 (6.40) | 63.15 (13.96) |

| B2 | 10.49 (0.15) | 794.74 (52.24) | 10.28 (2.53) | 18.01 (3.40) | 31.58 (7.49) | 41.51 (10.93) |

| B3 | 9.98 (0.26) | 850.13 (28.90) | 2.77 (3.00) | 13.04 (1.36) | 18.27 (3.97) | 24.64 (8.92) |

| A_ref | 11.39 (0.47) | 330.96 (10.54) | 0.68 (0.35) | 1.61 (0.13) | 29.71 (5.74) | 54.50 (10.95) |

| B_ref | 11.03 (0.84) | 331.36 (3.64) | 0.69 (0.20) | 1.62 (0.30) | 27.90 (4.11) | 45.64 (4.82) |

| Sum of Squares | DF | Mean Square | F | Sig. | ||

|---|---|---|---|---|---|---|

| Type of board | Thickness | 43.142 | 7 | 6.163 | 12.707 | <0.001 |

| Density | 1,446,845.1 | 7 | 206,692.1 | 242.17 | <0.001 | |

| TS 2 h | 621.224 | 7 | 88.746 | 12.156 | <0.001 | |

| TS 24 h | 1258.783 | 7 | 179.826 | 25.490 | <0.001 | |

| WA 2 h | 2192.856 | 7 | 313.265 | 4.205 | 0.004 | |

| WA 24 h | 3496.046 | 7 | 499.435 | 4.749 | 0.002 | |

| MOR | 160.975 | 7 | 22.996 | 48.788 | <0.001 | |

| MOE | 2,216,122.6 | 7 | 316,588.9 | 55.834 | <0.001 | |

| IB | 0.179 | 7 | 0.026 | 19.505 | <0.001 | |

| (λ) | 0.008 | 7 | 0.001 | 14.106 | <0.001 | |

| Pressing time | Thickness | 31.413 | 3 | 10.471 | 12.546 | <0.001 |

| Density | 961,465.5 | 3 | 320,488.5 | 17.739 | <0.001 | |

| TS 2 h | 193.789 | 3 | 64.596 | 3.001 | 0.047 | |

| TS 24 h | 562.92 | 3 | 187.643 | 6.073 | 0.199 | |

| WA 2 h | 500.97 | 3 | 166.992 | 1.344 | 0.280 | |

| WA 24 h | 1208.76 | 3 | 402.921 | 2.345 | 0.094 | |

| MOR | 106.44 | 3 | 35.482 | 15.089 | <0.001 | |

| MOE | 1,264,661.6 | 3 | 421,553.8 | 10.853 | <0.001 | |

| IB | 0.030 | 3 | 0.010 | 1.528 | 0.229 | |

| λ | 0.006 | 3 | 0.002 | 17.000 | <0.001 | |

| Density | TS 2 h | TS 24 h | WA 2 h | WA 24 h | MOR | MOE | IB | λ | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Type | Pearson Correlation | −0.378 * | −0.444 * | −0.017 | −0.112 | −0.017 | −0.254 | −0.102 | −0.507 ** | −0.507 ** |

| Sig. | 0.033 | 0.011 | 0.928 | 0.541 | 0.928 | 0.161 | 0.578 | 0.003 | 0.003 | |

| N | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | |

| Time | Pearson Correlation | 0.747 ** | 0.163 | −0.337 | −0.337 | −0.444 * | 0.773 ** | 0.696 ** | −0.193 | 0.799 ** |

| Sig. | <0.001 | 0.374 | 0.059 | 0.059 | 0.011 | <0.001 | <0.001 | 0.289 | <0.001 | |

| N | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | |

| Name | Density (kg/m3) | Thermal Conductivity (W/m K) | Source |

|---|---|---|---|

| Cotton | 150–300 | 0.059 to 0.074 | [27] |

| Kenaf | 150–250 | 0.051 to 0.058 | [28] |

| Sugar cane | 350–500 | 0.079 to 0.098 | [29] |

| Palm rachis | 797–841 | 0.053 to 0.061 | [30] |

| Cork + polyurethane | 170 | 0.037 | [5] |

| Cork–Canary Island Palm | 676–850 | 0.068 to 0.096 | This study |

| Cork + UF | 321 | 0.052 | This study |

| Specimen | Total Sugars (%) | Xylose (%) | Arabinose (%) | Acetic Acid (%) | Starch g/100 g |

|---|---|---|---|---|---|

| Canary Island date palm trunk | 1.19 | - | - | 3.96 | <0.5 |

| Canary Island date palm and cork | < 0.1 | 0.35 | 0.48 | 1.29 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrandez-Garcia, B.E.; Garcia-Ortuño, T.; Ferrandez-Villena, M.; Ferrandez-Garcia, M.T. Properties of Binderless Insulating Boards Made from Canary Island Date Palm and Cork Particles. Processes 2024, 12, 1245. https://doi.org/10.3390/pr12061245

Ferrandez-Garcia BE, Garcia-Ortuño T, Ferrandez-Villena M, Ferrandez-Garcia MT. Properties of Binderless Insulating Boards Made from Canary Island Date Palm and Cork Particles. Processes. 2024; 12(6):1245. https://doi.org/10.3390/pr12061245

Chicago/Turabian StyleFerrandez-Garcia, Berta Elena, Teresa Garcia-Ortuño, Manuel Ferrandez-Villena, and Maria Teresa Ferrandez-Garcia. 2024. "Properties of Binderless Insulating Boards Made from Canary Island Date Palm and Cork Particles" Processes 12, no. 6: 1245. https://doi.org/10.3390/pr12061245

APA StyleFerrandez-Garcia, B. E., Garcia-Ortuño, T., Ferrandez-Villena, M., & Ferrandez-Garcia, M. T. (2024). Properties of Binderless Insulating Boards Made from Canary Island Date Palm and Cork Particles. Processes, 12(6), 1245. https://doi.org/10.3390/pr12061245