A Review of Supercritical CO2 Fracturing Technology in Shale Gas Reservoirs

Abstract

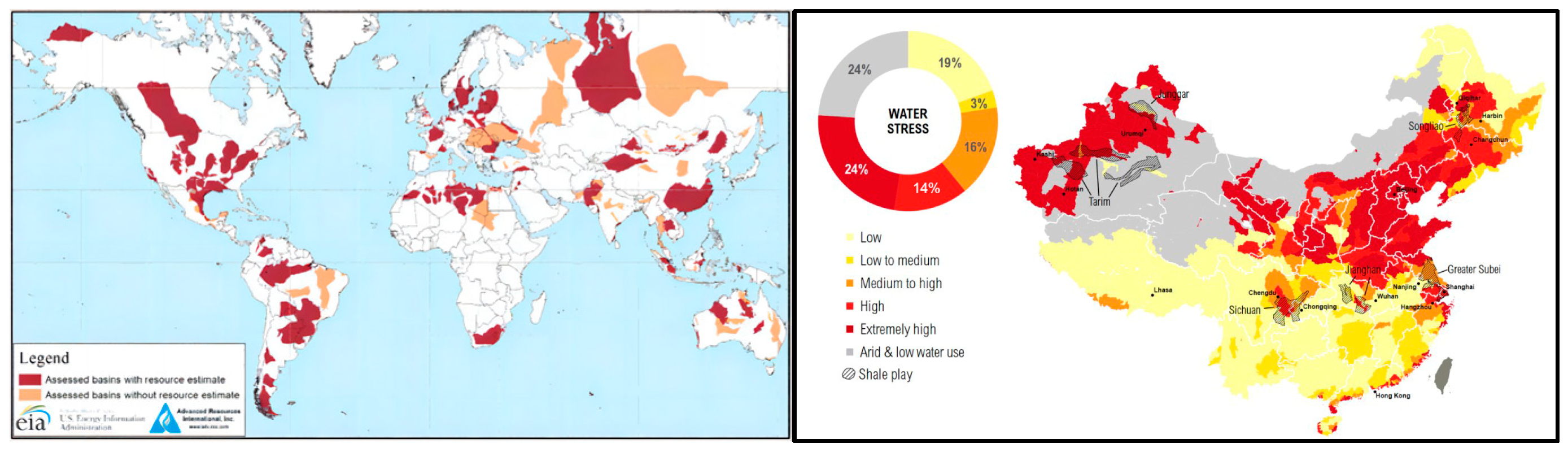

1. Introduction

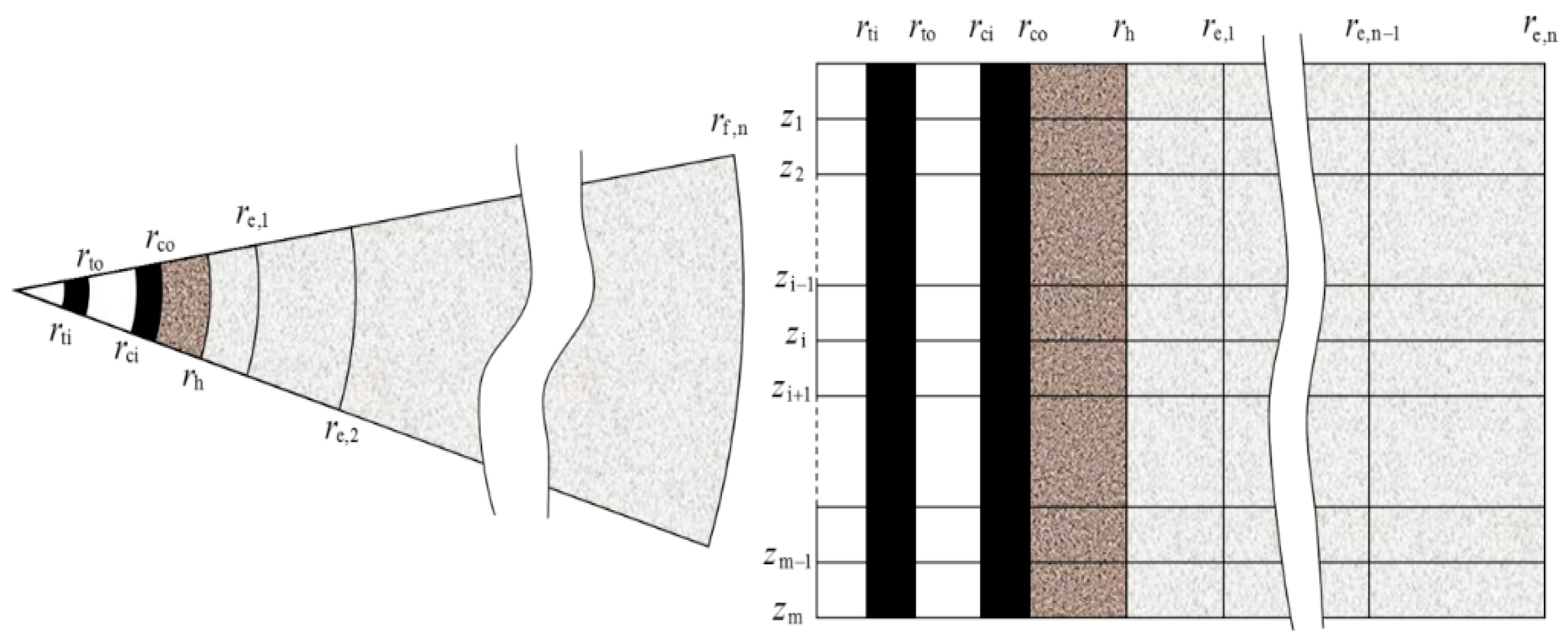

2. Supercritical CO2 Phase Control Technology

3. The System of Rock Initiation and Fracture Propagation in Supercritical CO2 Fracturing

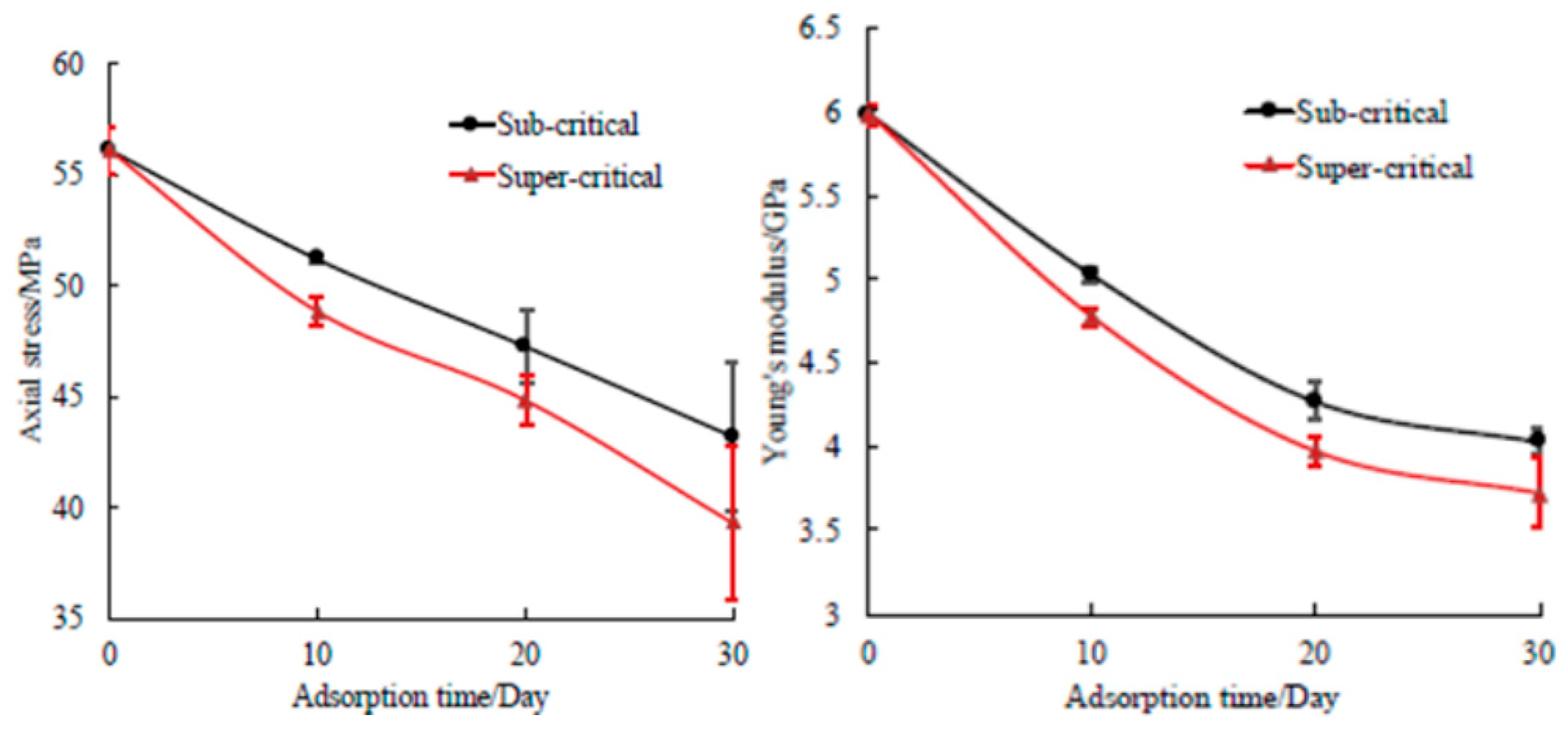

3.1. Effect of Supercritical CO2 on Rock’s Physical Properties

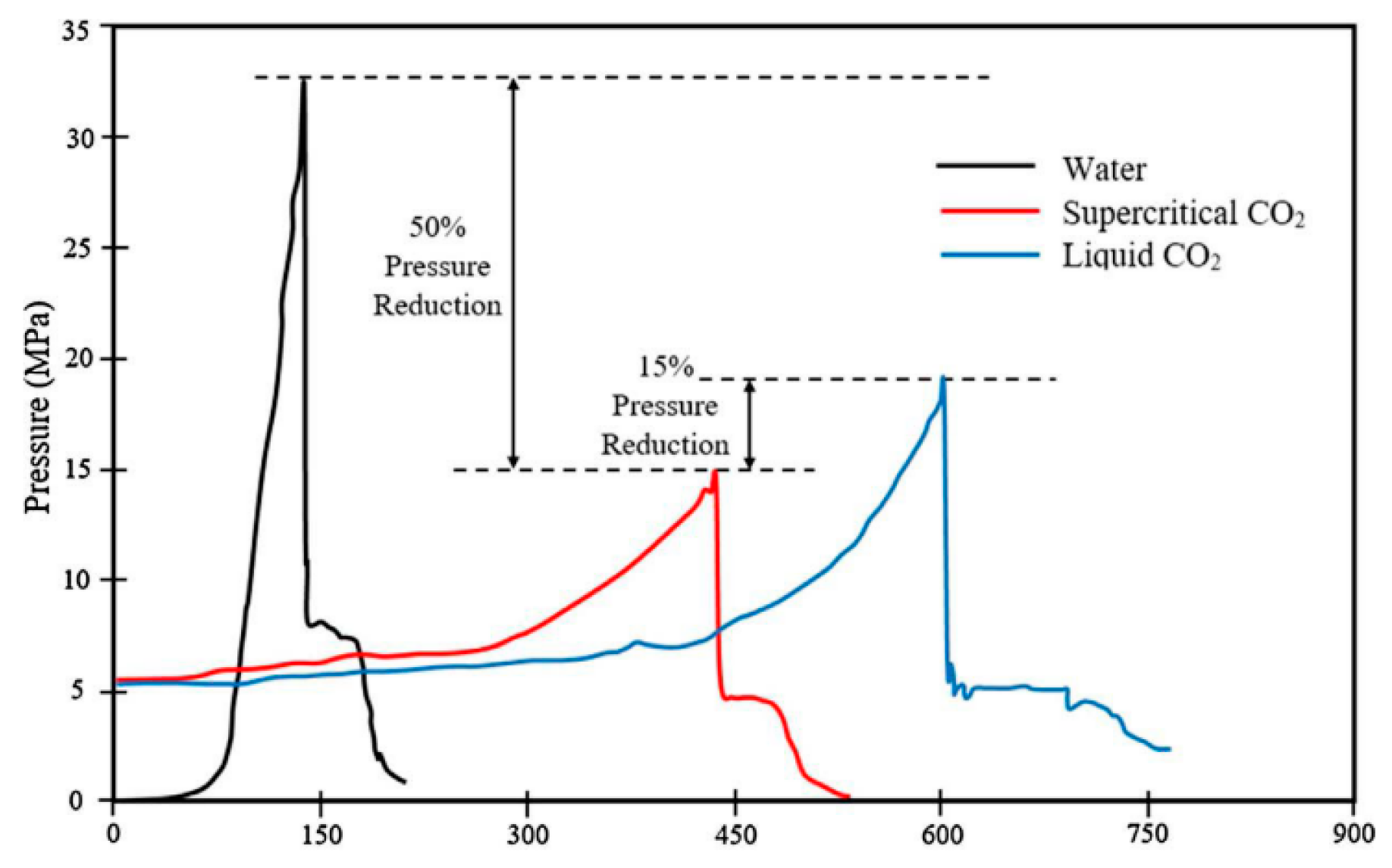

3.2. Cracking Law of Supercritical CO2 Fracturing of Rock

3.3. Crack Growth Law of Supercritical CO2 Fracturing

4. Discussion

5. Conclusions and Future Prospects

- Shale contains a variety of complex mineral components such as carbonate minerals, clay, quartz, and pyrite. Under reservoir conditions, the injected CO2 dissolves in formation water to form an acidic solution, which reacts geochemically with shale minerals, causing changes in the mineral composition and microstructure, thus weakening the mechanical properties of shale.

- Based on the chemical reaction between SC-CO2 and shale, the low viscosity of SC-CO2, and the thermophysical properties of CO2, SC-CO2 fracturing can decrease the initiation pressure and result in the formation of a more complicated fracture network.

- Although much research has been conducted on the initiation and growth of supercritical CO2 fracturing, it has focused only on the observation and analysis of surface phenomena. As a result, the interaction law of flow, temperature, and rock mechanical parameters in the process of supercritical CO2 fracturing is still unclear. In future research, it is necessary to use extended finite element, boundary element, or more advanced simulation methods to track the multi-field coupling effects during crack initiation and propagation, supplemented by experimental methods to deeply understand and reveal the mechanisms of crack initiation and propagation.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, H.Y.; Pu, X.Y.; Zhang, L.H. Beneficial development of shale gas in China: Theoretical logic, practical logic and prospect. Nat. Gas Ind. 2023, 43, 177–183. [Google Scholar]

- Wang, F.; Xu, H.; Liu, Y. Mechanism of low chemical agent adsorption by high pressure for hydraulic fracturing-assisted oil displacement technology: A study of molecular dynamics combined with laboratory experiments. Langmuir 2023, 39, 16628–16636. [Google Scholar] [CrossRef] [PubMed]

- Myers, T. Potential contaminant pathways from hydraulically fractured shale to aquifers. Groundwater 2012, 50, 872–882. [Google Scholar] [CrossRef]

- Middleton, R.S.; Carey, J.W.; Currier, R.P. Shale gas and non-aqueous fracturing fluids: Opportunities and challenges for supercritical CO2. Appl. Energy 2015, 147, 500–509. [Google Scholar] [CrossRef]

- Jiang, Z.; Quan, X.; Tian, S. Permeability-Enhancing Technology through Liquid CO2 Fracturing and Its Application. Sustainability 2022, 14, 10438. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, G. A review of mechanisms of induced fractures in SC-CO2 fracturing. Pet. Sci. Bull. 2020, 5, 239–253. [Google Scholar]

- Abedini, A.; Torabi, F. On the CO2 storage potential of cyclic CO2 injection process for enhanced oil recovery. Fuel 2014, 124, 14–27. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, M.; Li, X.; Liu, Y. Impact research of CH4 replacement with CO2 in hydrous coal under high pressure injection. Min. Miner. Depos. 2022, 16, 121–126. [Google Scholar] [CrossRef]

- Ndlovu, P.; Babaee, S.; Naidoo, P. Review on CH4-CO2 replacement for CO2 sequestration and CH4/CO2 hydrate formation in porous media. Fuel 2022, 320, 123795. [Google Scholar] [CrossRef]

- Hamza, A.; Hussein, I.A.; Al-Marri, M.J. CO2 enhanced gas recovery and sequestration in depleted gas reservoirs: A review. J. Pet. Sci. Eng. 2021, 196, 107685. [Google Scholar] [CrossRef]

- Ramey, H.J., Jr. Wellbore heat transmission. J. Pet. Technol. 1962, 14, 427–435. [Google Scholar] [CrossRef]

- Holmes, C.S.; Swift, S.C. Calculation of circulating mud temperatures. J. Pet. Technol. 1970, 22, 670–674. [Google Scholar] [CrossRef]

- Romero-Juarez, A. A simplified method for calculating temperature changes in deep wells. J. Pet. Technol. 1979, 31, 763–768. [Google Scholar] [CrossRef]

- Fontanilla, J.P.; Aziz, K. Prediction of bottom-hole conditions for wet steam injection wells. J. Can. Pet. Technol. 1982, 21, 82–88. [Google Scholar] [CrossRef]

- Gu, H.; Cheng, L.; Huang, S. Prediction of thermophysical properties of saturated steam and wellbore heat losses in concentric dual-tubing steam injection wells. Energy 2014, 75, 419–429. [Google Scholar] [CrossRef]

- Raymond, L.R. Temperature distribution in a circulating drilling fluid. J. Pet. Technol. 1969, 21, 333–341. [Google Scholar] [CrossRef]

- Eickmeier, J.R.; Ersoy, D.; Ramey, H.J. Wellbore temperatures and heat losses during production or injection operations. J. Can. Pet. Technol. 1970, 9, 115–121. [Google Scholar] [CrossRef]

- You, J.; Rahnema, H.; McMillan, M.D. Numerical modeling of unsteady-state wellbore heat transmission. J. Nat. Gas Sci. Eng. 2016, 34, 1062–1076. [Google Scholar] [CrossRef]

- Dong, W.; Shen, R.; Liang, Q. Model calculations and factors affecting wellbore temperatures during SRV fracturing. Arab. J. Sci. Eng. 2018, 43, 6475–6480. [Google Scholar] [CrossRef]

- Alves, I.N.; Alhanati, F.J.S.; Shoham, O. A unified model for predicting flowing temperature distribution in wellbores and pipelines. SPE Prod. Eng. 1992, 7, 363–367. [Google Scholar] [CrossRef]

- Sun, X.; Yao, D.; Qu, J. A novel transient hole cleaning algorithm for horizontal wells based on drift-flux model. Geoenergy Sci. Eng. 2024, 233, 212517. [Google Scholar] [CrossRef]

- Hasan, A.R.; Kabir, C.S. Aspects of wellbore heat transfer during two-phase flow. SPE Prod. Facil. 1994, 9, 211–216. [Google Scholar] [CrossRef]

- Kabir, C.S.; Hasan, A.R.; Kouba, G.E. Determining circulating fluid temperature in drilling, workover, and well control operations. SPE Drill. Complet. 1996, 11, 74–79. [Google Scholar] [CrossRef]

- Peng, D.Y.; Robinson, D.B. A new two-constant equation of state. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Wu, X.; Wang, Q.; He, Y. Temperature-pressure field coupling calculation model considering phase behavior change in CO2 injection well borehole. J. China Univ. Pet. (Ed. Nat. Sci.) 2009, 1, 73–77. [Google Scholar]

- Span, R.; Wagner, W. A new equation of state for carbon dioxide covering the fluid region from the triple-point temperature to 1100 K at pressures up to 800 MPa. J. Phys. Chem. Ref. Data 1996, 25, 1509–1596. [Google Scholar] [CrossRef]

- Li, X.; Li, G.; Wang, H. A unified model for wellbore flow and heat transfer in pure CO2 injection for geological sequestration, EOR and fracturing operations. Int. J. Greenh. Gas Control 2017, 57, 102–115. [Google Scholar] [CrossRef]

- Dou, L.B.; Li, G.S.; Shen, Z.H. Wellbore pressure and temperature prediction model and its affecting factors for CO2 injection wells. Pet. Drill. Tech. 2013, 41, 76–81. [Google Scholar]

- Singhe, A.T.; Ursin, J.R.; Henninges, J. Modeling of temperature effects in CO2 injection wells. Energy Procedia 2013, 37, 3927–3935. [Google Scholar] [CrossRef]

- Guo, J.C.; Zeng, J.; Zhang, R. A dual transient coupling model for wellbore of carbon dioxide injection well. Acta Pet. Sin. 2015, 36, 976–982. [Google Scholar] [CrossRef]

- Wang, H.; Li, X.; Sepehrnoori, K. Calculation of the wellbore temperature and pressure distribution during supercritical CO2 fracturing flowback process. Int. J. Heat Mass Transf. 2019, 139, 10–16. [Google Scholar] [CrossRef]

- Yang, Z.Z.; Yi, L.P.; Li, X.G. Model for calculating the wellbore temperature and pressure during supercritical carbon dioxide fracturing in a coalbed methane well. J. CO2 Util. 2018, 26, 602–611. [Google Scholar] [CrossRef]

- Wu, L.; Luo, Z.; Zhao, L. Transient temperature-pressure field model of supercritical CO2 fracturing wellbore with tubing and annulus co-injection. Greenh. Gases Sci. Technol. 2022, 12, 85–102. [Google Scholar] [CrossRef]

- Ruan, B.; Xu, R.; Wei, L. Flow and thermal modeling of CO2 in injection well during geological sequestration. Int. J. Greenh. Gas Control 2013, 19, 271–280. [Google Scholar] [CrossRef]

- Jiang, P.; Li, X.; Xu, R. Thermal modeling of CO2 in the injection well and reservoir at the Ordos CCS demonstration project, China. Int. J. Greenh. Gas Control 2014, 23, 135–146. [Google Scholar] [CrossRef]

- Kamphuis, H.; Davies, D.R.; Roodhart, L.P. A new simulator for the calculation of the in situ temperature profile during well stimulation fracturing treatments. J. Can. Pet. Technol. 1993, 32, PETSOC-93-05-03. [Google Scholar] [CrossRef]

- Li, X.; He, Y.; Huo, M. Model for calculating the temperature and pressure within the fracture during supercritical carbon dioxide fracturing. Int. J. Hydrogen Energy 2020, 45, 8369–8384. [Google Scholar] [CrossRef]

- Wu, L.; Luo, Z. Coupled temperature–pressure model of fracture for phase state prediction in supercritical carbon dioxide fracturing. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 3866–3882. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, B.; Sun, X. Calculation of temperature in fracture for carbon dioxide fracturing. SPE J. 2016, 21, 1491–1500. [Google Scholar] [CrossRef]

- Wang, J.; Sun, B.; Chen, W. Calculation model of unsteady temperature-pressure fields in wellbores and fractures of supercritical CO2 fracturing. Fuel 2019, 253, 1168–1183. [Google Scholar] [CrossRef]

- Friehauf, K.; Sharma, M.M. A new compositional model for hydraulic fracturing with energized fluids. SPE Prod. Oper. 2009, 24, 562–572. [Google Scholar] [CrossRef]

- Ribeiro, L.H.; Sharma, M.M. A new 3D compositional model for hydraulic fracturing with energized fluids. SPE Prod. Oper. 2013, 28, 259–267. [Google Scholar] [CrossRef]

- Yan, T.; Xu, R.; Sun, S.H.; Hou, Z.-K.; Feng, J.-Y. A real-time intelligent lithology identification method based on a dynamic felling strategy weighted random forest algorithm. Pet. Sci. 2024, 21, 1135–1148. [Google Scholar] [CrossRef]

- Wu, D.; Zhai, W.B.; Liang, B. Study on supercritical CO2 seepage and antireflection of shale injection. Nat. Gas Geosci. 2019, 30, 1406–1414. [Google Scholar]

- Luo, X.; Ren, X.; Wang, S. Supercritical CO2-water-shale interactions and their effects on element mobilization and shale pore structure during stimulation. Int. J. Coal Geol. 2019, 202, 109–127. [Google Scholar] [CrossRef]

- Edlmann, K.; Haszeldine, S.; McDermott, C.I. Experimental investigation into the sealing capability of naturally fractured shale caprocks to supercritical carbon dioxide flow. Environ. Earth Sci. 2013, 70, 3393–3409. [Google Scholar] [CrossRef]

- Yu, Z.; Liu, L.; Yang, S. An experimental study of CO2–brine–rock interaction at in situ pressure–temperature reservoir conditions. Chem. Geol. 2012, 326, 88–101. [Google Scholar] [CrossRef]

- Shiraki, R.; Dunn, T.L. Experimental study on water–rock interactions during CO2 flooding in the Tensleep Formation, Wyoming, USA. Appl. Geochem. 2000, 15, 265–279. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, K.; Tian, S. CO2-water-shale interaction induced shale microstructural alteration. Fuel 2020, 263, 116642. [Google Scholar] [CrossRef]

- Angeli, M.; Soldal, M.; Skurtveit, E. Experimental percolation of supercritical CO2 through a caprock. Energy Procedia 2009, 1, 3351–3358. [Google Scholar] [CrossRef]

- Allawzi, M.; Al-Otoom, A.; Allaboun, H.; Ajlouni, A. CO2 supercritical fluid extraction of Jordanian oil shale utilizing different co-solvents. Fuel Process. Technol. 2011, 92, 2016–2023. [Google Scholar] [CrossRef]

- Xu, T.; Apps, J.A.; Pruess, K. Mineral sequestration of carbon dioxide in a sandstone-shale system. Chem. Geol. 2005, 217, 295–318. [Google Scholar] [CrossRef]

- Babatunde, K.A.; Negash, B.M.; Mojid, M.R. Molecular simulation study of CO2/CH4 adsorption on realistic heterogeneous shale surfaces. Appl. Surf. Sci. 2021, 543, 148789. [Google Scholar] [CrossRef]

- Zhou, J.; Tian, S.; Xian, X.F. Comprehensive review of property alterations induced by CO2–shale interaction: Implications for CO2 sequestration in shale. Energy Fuels 2022, 36, 8066–8080. [Google Scholar] [CrossRef]

- Cheng, Y.; Zeng, M.; Lu, Z. Effects of supercritical CO2 treatment temperatures on mineral composition, pore structure and functional groups of shale: Implications for CO2 sequestration. Sustainability 2020, 12, 3927. [Google Scholar] [CrossRef]

- Ao, X.; Lu, Y.; Tang, J. Investigation on the physics structure and chemical properties of the shale treated by supercritical CO2. J. CO2 Util. 2017, 20, 274–281. [Google Scholar] [CrossRef]

- Yin, H.; Zhou, J.; Jiang, Y. Physical and structural changes in shale associated with supercritical CO2 exposure. Fuel 2016, 184, 289–303. [Google Scholar] [CrossRef]

- Zou, Y.; Li, S.; Ma, X. Effects of CO2–brine–rock interaction on porosity/permeability and mechanical properties during supercritical-CO2 fracturing in shale reservoirs. J. Nat. Gas Sci. Eng. 2018, 49, 157–168. [Google Scholar] [CrossRef]

- Jiang, Y.; Luo, Y.; Lu, Y. Effects of supercritical CO2 treatment time, pressure, and temperature on microstructure of shale. Energy 2016, 97, 173–181. [Google Scholar] [CrossRef]

- Masoudian, M.S.; Airey, D.W.; El-Zein, A. Experimental investigations on the effect of CO2 on mechanics of coal. Int. J. Coal Geol. 2014, 128, 12–23. [Google Scholar] [CrossRef]

- Du, Y.; Sang, S.; Pan, Z. Experimental study of supercritical CO2-H2O-coal interactions and the effect on coal permeability. Fuel 2019, 253, 369–382. [Google Scholar] [CrossRef]

- Pan, Y.; Hui, D.; Luo, P. Influences of subcritical and supercritical CO2 treatment on the pore structure characteristics of marine and terrestrial shales. J. CO2 Util. 2018, 28, 152–167. [Google Scholar] [CrossRef]

- Rani, S.; Padmanabhan, E.; Prusty, B.K. Review of gas adsorption in shales for enhanced methane recovery and CO2 storage. J. Pet. Sci. Eng. 2019, 175, 634–643. [Google Scholar] [CrossRef]

- Li, H.; Xie, L.; Ren, L. Influence of CO2–water–rock interactions on the fracture properties of sandstone from the Triassic Xujiahe Formation, Sichuan Basin. Acta Geophys. 2021, 69, 135–147. [Google Scholar] [CrossRef]

- Delle, P.C.; Sarout, J. Effects of water and supercritical CO2 on the mechanical and elastic properties of Berea sandstone. Int. J. Greenh. Gas Control 2016, 55, 209–220. [Google Scholar] [CrossRef]

- Rathnaweera, T.D.; Ranjith, P.G.; Perera, M.S.A. CO2-induced mechanical behaviour of Hawkesbury sandstone in the Gosford basin: An experimental study. Mater. Sci. Eng. A 2015, 641, 123–137. [Google Scholar] [CrossRef]

- Li, X.; Feng, Z.; Han, G. Breakdown pressure and fracture surface morphology of hydraulic fracturing in shale with H2O, CO2 and N2. Geomech. Geophys. Geo-Energy Geo-Resour. 2016, 2, 63–76. [Google Scholar] [CrossRef]

- De, J.S.M.; Spiers, C.J.; Busch, A. Development of swelling strain in smectite clays through exposure to carbon dioxide. Int. J. Greenh. Gas Control 2014, 24, 149–161. [Google Scholar]

- Roy, D.G.; Vishal, V.; Singh, T.N. Effect of carbon dioxide sequestration on the mechanical properties of Deccan basalt. Environ. Earth Sci. 2016, 75, 1. [Google Scholar]

- Tang, J.R.; Lu, Y.L.; Chen, Y.T. Experimental study of damage of shale mechanical properties under supercritical CO2. Rock Soil Mech. 2018, 39, 797–802. [Google Scholar]

- Qin, C.; Jiang, Y.D.; Luo, Y.H. Effect of Supercritical Carbon Dioxide Treatment Time, Pressure, and Temperature on Shale Water Wettability. Energy Fuels 2017, 31, 493–503. [Google Scholar] [CrossRef]

- Guo, X.; Ni, H.; Li, M. Experimental study on the influence of supercritical carbon dioxide soaking pressure on the mechanical properties of shale. Indian Geotech. J. 2018, 48, 384–391. [Google Scholar] [CrossRef]

- Ni, H.J.; Guo, X.; Ding, L. Experiment on mechanical properties of shale soaked with supercritical carbon dioxide. J. China Univ. Pet. (Ed. Nat. Sci.) 2019, 43, 77–84. [Google Scholar]

- Zhang, X.; Lu, Y.; Tang, J. Experimental study on fracture initiation and propagation in shale using supercritical carbon dioxide fracturing. Fuel 2017, 190, 370–378. [Google Scholar] [CrossRef]

- Lu, Y.; Liao, Y.; Tang, J. Experimental study on fracture initiation pressure and morphology in shale using supercritical CO2 fracturing. J. China Coal Soc. 2018, 43, 175–180. [Google Scholar]

- Verdon, J.P.; Kendall, J.M.; Maxwell, S.C. A comparison of passive seismic monitoring of fracture stimulation from water and CO2 injection. Geophysics 2010, 75, MA1–MA7. [Google Scholar] [CrossRef]

- Wang, H.; Li, G.; He, Z. Analysis of mechanisms of supercritical CO2 fracturing. Rock Soil Mech. 2018, 39, 3589–3596. [Google Scholar]

- Yan, H.; Zhang, J.; Li, B. Crack propagation patterns and factors controlling complex crack network formation in coal bodies during tri-axial supercritical carbon dioxide fracturing. Fuel 2021, 286, 119–381. [Google Scholar] [CrossRef]

- Zhang, Y.; He, J.; Li, X. Experimental study on the supercritical CO2 fracturing of shale considering anisotropic effects. J. Pet. Sci. Eng. 2019, 173, 932–940. [Google Scholar] [CrossRef]

- Jiang, Y.; Qin, C.; Kang, Z. Experimental study of supercritical CO2 fracturing on initiation pressure and fracture propagation in shale under different triaxial stress conditions. J. Nat. Gas Sci. Eng. 2018, 55, 382–394. [Google Scholar] [CrossRef]

- Hubbert, M.K.; Willis, D.G. Mechanics of hydraulic fracturing. Trans. AIME 1957, 210, 153–168. [Google Scholar] [CrossRef]

- Haimson, B.; Fairhurst, C. Initiation and extension of hydraulic fractures in rocks. Soc. Pet. Eng. J. 1967, 7, 310–318. [Google Scholar] [CrossRef]

- Hossain, M.M.; Rahman, M.K.; Rahman, S.S. Hydraulic fracture initiation and propagation: Roles of wellbore trajectory, perforation and stress regimes. J. Pet. Sci. Eng. 2000, 27, 129–149. [Google Scholar] [CrossRef]

- Ma, T.; Wu, B.; Fu, J. Fracture pressure prediction for layered formations with anisotropic rock strengths. J. Nat. Gas Sci. Eng. 2017, 38, 485–503. [Google Scholar] [CrossRef]

- Gao, Y.; Detournay, E. Fracture toughness interpretation from breakdown pressure. Eng. Fract. Mech. 2021, 243, 107518. [Google Scholar] [CrossRef]

- Zhu, H.Y.; Deng, J.G.; Liu, S.J. A prediction model for the hydraulic fracture initiation pressure in oriented perforation. Acta Pet. Sin. 2013, 34, 556. [Google Scholar]

- Chen, L.Q.; Tian, S.C.; Li, G.-S.; Fan, X. Initiation pressure models for supercritical CO2 fracturing and sensitivity analysis. Rock Soil Mech. 2015, 36, 125–131. [Google Scholar]

- Zhong, G.; Zuo, L.; Jiang, T. Fracture initiation pressure prediction for shale gas well fracturing with super-critical carbon dioxide. Fault-Block Oil Gas Field 2020, 27, 710–714. [Google Scholar]

- Xiao, C.; Ni, H.; Shi, X. A fracture initiation model for carbon dioxide fracturing considering the bottom hole pressure and temperature condition. J. Pet. Sci. Eng. 2020, 184, 106541. [Google Scholar] [CrossRef]

- Ma, J.M.; Ma, K.X.; Zhang, F.M. Prediction method of fracture initiation pressure for supercritical CO2 fracturing. Fault-Block Oil& Gas Field 2022, 29, 295–301. [Google Scholar]

- Daneshy, A.A. Experimental investigation of hydraulic fracturing through perforations. J. Pet. Technol. 1973, 25, 1201–1206. [Google Scholar] [CrossRef]

- Ye, L.; Zou, Y.S.; Zhao, Q.Y. Experiment research on the CO2 fracturing fracture propagation laws of tight sandstone. Oil Drill. Prod. Technol. 2018, 40, 361–368. [Google Scholar]

- Liu, G.J.; Xan, X.F.; Zhou, J.P. Experimental study on the supercritical CO2 fracturing of shale. J. China Coal Soc. 2017, 42, 694–701. [Google Scholar]

- Ranjith, P.G.; Zhang, C.P.; Zhang, Z.Y. Experimental study of fracturing behaviour in ultralow permeability formations: A comparison between CO2 and water fracturing. Eng. Fract. Mech. 2019, 217, 106541. [Google Scholar] [CrossRef]

- Wang, Y.L.; Li, Z.G.; Guo, H.G. Application development prospects of supercritical CO2 fracturing to increase coalbed methane production. China Min. Mag. 2021, 30, 160–167. [Google Scholar]

- Liang, W.; He, W.; Yan, J. Weakening and fracturing mechanism of mechanical properties of coal and rock caused by supercritical CO2. Meitan Xuebao/J. China Coal Soc. 2022, 47, 2557–2568. [Google Scholar]

- Li, X.; Li, G.; Yu, W. Thermal effects of liquid/supercritical carbon dioxide arising from fluid expansion in fracturing. SPE J. 2018, 23, 2026–2040. [Google Scholar] [CrossRef]

- Bennour, Z.; Ishida, T.; Nagaya, Y. Crack extension in hydraulic fracturing of shale cores using viscous oil, water, and liquid carbon dioxide. Rock Mech. Rock Eng. 2015, 48, 1463–1473. [Google Scholar] [CrossRef]

- Chen, Y.; Nagaya, Y.; Ishida, T. Observations of fractures induced by hydraulic fracturing in anisotropic granite. Rock Mech. Rock Eng. 2015, 48, 1455–1461. [Google Scholar] [CrossRef]

- Wang, L.; Yao, B.; Xie, H. CO2 injection-induced fracturing in naturally fractured shale rocks. Energy 2017, 139, 1094–1110. [Google Scholar] [CrossRef]

- Zhang, Y.; He, J.; Li, F. Characteristics of fracture propagation induced by supercritical CO2 in inter-salt-shale reservoir. Geofluids 2019, 2019, 7132843. [Google Scholar] [CrossRef]

- Deng, B.; Yin, G.; Li, M. Feature of fractures induced by hydrofracturing treatment using water and L-CO2 as fracturing fluids in laboratory experiments. Fuel 2018, 226, 35–46. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, S.; Qu, Z. Experimental study of hydraulic fracturing for shale by stimulated reservoir volume. Fuel 2014, 128, 373–380. [Google Scholar] [CrossRef]

- Liu, P.; Ju, Y.; Ranjith, P.G. Visual representation and characterization of three-dimensional hydrofracturing cracks within heterogeneous rock through 3D printing and transparent models. Int. J. Coal Sci. Technol. 2016, 3, 284–294. [Google Scholar] [CrossRef]

- Al, S.T.; Kim, T.W.; Kovscek, A.R. Investigating fracture propagation characteristics in shale using SC-CO2 and water with the aid of X-ray Computed Tomography. J. Nat. Gas Sci. Eng. 2021, 92, 103736. [Google Scholar]

- Zhou, D.; Zhang, G.; Wang, Y. Experimental investigation on fracture propagation modes in supercritical carbon dioxide fracturing using acoustic emission monitoring. Int. J. Rock Mech. Min. Sci. 2018, 110, 111–119. [Google Scholar] [CrossRef]

- Shi, X.; Xu, H.; Che, M. Investigations of fracture behavior and pore structure change in pulse fracturing for cement block. Int. J. Rock Mech. Min. Sci. 2023, 166, 105366. [Google Scholar] [CrossRef]

- Jia, Y.; Lu, Y.; Elsworth, D. Surface characteristics and permeability enhancement of shale fractures due to water and supercritical carbon dioxide fracturing. J. Pet. Sci. Eng. 2018, 165, 284–297. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, X.; He, J. A laboratory investigation of fracture propagation induced by supercritical carbon dioxide fracturing in continental shale with interbeds. J. Pet. Sci. Eng. 2018, 166, 739–746. [Google Scholar] [CrossRef]

- Zou, Y.; Li, N.; Ma, X. Experimental study on the growth behavior of supercritical CO2-induced fractures in a layered tight sandstone formation. J. Nat. Gas Sci. Eng. 2018, 49, 145–156. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, F.; Hu, Y. Propagation characteristics of supercritical carbon dioxide induced fractures under true tri-axial stresses. Energies 2019, 12, 4229. [Google Scholar] [CrossRef]

- Chen, Z.; Jeffrey, R.G.; Zhang, X. Finite-element simulation of a hydraulic fracture interacting with a natural fracture. SPE J. 2017, 22, 219–234. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, W.; Wei, C. Microcrack-based geomechanical modeling of rock-gas interaction during supercritical CO2 fracturing. J. Pet. Sci. Eng. 2018, 164, 91–102. [Google Scholar] [CrossRef]

- Wang, J.; Elsworth, D.; Wu, Y. The influence of fracturing fluids on fracturing processes: A comparison between water, oil and SC-CO2. Rock Mech. Rock Eng. 2018, 51, 299–313. [Google Scholar] [CrossRef]

- Carrier, B.; Granet, S. Numerical modeling of hydraulic fracture problem in permeable medium using cohesive zone model. Eng. Fract. Mech. 2012, 79, 312–328. [Google Scholar] [CrossRef]

- Taleghani, A.D.; Olson, J.E. How natural fractures could affect hydraulic-fracture geometry. SPE J. 2014, 19, 161–171. [Google Scholar] [CrossRef]

- Shi, F.; Wang, X.; Liu, C. An XFEM-based method with reduction technique for modeling hydraulic fracture propagation in formations containing frictional natural fractures. Eng. Fract. Mech. 2017, 173, 64–90. [Google Scholar] [CrossRef]

- Gordeliy, E.; Peirce, A. Implicit level set schemes for modeling hydraulic fractures using the XFEM. Comput. Methods Appl. Mech. Eng. 2013, 266, 125–143. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, J.; Zhou, N. Staged numerical simulations of supercritical CO2 fracturing of coal seams based on the extended finite element method. J. Nat. Gas Sci. Eng. 2019, 65, 275–283. [Google Scholar] [CrossRef]

- Feng, Y.; Gray, K.E. XFEM-based cohesive zone approach for modeling near-wellbore hydraulic fracture complexity. Acta Geotech. 2019, 14, 377–402. [Google Scholar] [CrossRef]

- Mohammadnejad, T.; Khoei, A.R. An extended finite element method for hydraulic fracture propagation in deformable porous media with the cohesive crack model. Finite Elem. Anal. Des. 2013, 73, 77–95. [Google Scholar] [CrossRef]

- Nagel, N.B.; Sanchez-Nagel, M.A.; Zhang, F. Coupled numerical evaluations of the geomechanical interactions between a hydraulic fracture stimulation and a natural fracture system in shale formations. Rock Mech. Rock Eng. 2013, 46, 581–609. [Google Scholar] [CrossRef]

- Bao, J.; Xu, Z.; Fang, Y. A coupled discrete element and finite element model for multiscale simulation of geological carbon sequestration. Greenh. Gases Sci. Technol. 2015, 5, 474–486. [Google Scholar] [CrossRef]

- Al-Busaidi, A.; Hazzard, J.F.; Young, R.P. Distinct element modeling of hydraulically fractured Lac du Bonnet granite. J. Geophys. Res. Solid Earth 2005, 110, B06302. [Google Scholar] [CrossRef]

- Yoon, J.S.; Zimmermann, G.; Zang, A. Numerical investigation on stress shadowing in fluid injection-induced fracture propagation in naturally fractured geothermal reservoirs. Rock Mech. Rock Eng. 2015, 48, 1439–1454. [Google Scholar] [CrossRef]

- Eshiet, K.I.I.; Sheng, Y. Carbon dioxide injection and associated hydraulic fracturing of reservoir formations. Environ. Earth Sci. 2014, 72, 1011–1024. [Google Scholar] [CrossRef]

- Weng, X.; Kresse, O.; Chuprakov, D. Applying complex fracture model and integrated workflow in unconventional reservoirs. J. Pet. Sci. Eng. 2014, 124, 468–483. [Google Scholar] [CrossRef]

- Long, G.; Xu, G. The effects of perforation erosion on practical hydraulic-fracturing applications. SPE J. 2017, 22, 645–659. [Google Scholar] [CrossRef]

- Peirce, A.P.P.; Bunger, A.P.P. Interference fracturing: Nonuniform distributions of perforation clusters that promote simultaneous growth of multiple hydraulic fractures. SPE J. 2015, 20, 384–395. [Google Scholar] [CrossRef]

| Minerals | Equation |

|---|---|

| Calcite | CaCO3 + H+ ⇌ Ca2+ + HCO3− |

| Dolomite | CaMg(CO3)2 + 2H+ ⇌ Ca2+ +Mg2+ +2HCO3− |

| Kaolinite | Al2Si2O5(OH)4 + 6H+ ⇌ 2Al3 + +2SiO2 + 5H2O |

| Illite | KAl2(OH)2AlSiO10 + 10H+ ⇌ 2K+ +3Al3+ +3SiO2 + 6H2O |

| Potassium feldspar | 2KAlSi3O8 + 2H+ + H2O ⇌ 2K+ + Al2Si2O5(OH)4 + 4SiO2 |

| Sodium feldspar | 2NaAlSi3O8 + CO2 + 11H2O ⇌ 2Na+ +2HCO3− + 2H4SiO4 + Al2Si2O5(OH)4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Z.; Yuan, Y.; Chen, Y.; Feng, J.; Wang, H.; Zhang, X. A Review of Supercritical CO2 Fracturing Technology in Shale Gas Reservoirs. Processes 2024, 12, 1238. https://doi.org/10.3390/pr12061238

Hou Z, Yuan Y, Chen Y, Feng J, Wang H, Zhang X. A Review of Supercritical CO2 Fracturing Technology in Shale Gas Reservoirs. Processes. 2024; 12(6):1238. https://doi.org/10.3390/pr12061238

Chicago/Turabian StyleHou, Zhaokai, Yuan Yuan, Ye Chen, Jinyu Feng, Huaishan Wang, and Xu Zhang. 2024. "A Review of Supercritical CO2 Fracturing Technology in Shale Gas Reservoirs" Processes 12, no. 6: 1238. https://doi.org/10.3390/pr12061238

APA StyleHou, Z., Yuan, Y., Chen, Y., Feng, J., Wang, H., & Zhang, X. (2024). A Review of Supercritical CO2 Fracturing Technology in Shale Gas Reservoirs. Processes, 12(6), 1238. https://doi.org/10.3390/pr12061238