Abstract

The width of a stop-mining coal pillar is of great significance to the stability of the surrounding rock of the main roadway and the safety of production in the mine. This paper focuses on the west panel of Sihe Coal Mine as the engineering background, analyzes the evolution characteristics of front abutment pressure in the mining area under conditions of rapid advancement and large mining height and its sensitivity to influencing factors, explores the coupling mechanism between the width of the stop-mining coal pillar and the surrounding rock of the main roadway, and analyzes the differences in mining pressure characteristics such as internal stress of the coal pillar, vertical stress, deformation, and failure of the main roadway’s surrounding rock under different coal pillar widths with the influence of mining. The comprehensive results indicate that the influence range of front abutment pressure on the working face is 65 m, and the significance ranking of different mining factors acting on it is as follows: mining height > working face length > advancing speed. The rational width of the stop-mining coal pillar is determined to be 80 m while the stress field of the surrounding rock in the main roadway is in a critical state of mining disturbance. Industrial tests have shown that the relative displacements between the roof and floor as well as the ribs of the main roadway are relatively small, at 105 and 260 mm, respectively, which can effectively maintain the stability of the surrounding rock of the main roadway. The research results can provide a scientific basis and engineering reference for the design of stop-mining coal pillars in mines with similar geological conditions.

1. Introduction

A stop-mining coal pillar (SMCP) is crucial to maintain the stability of the main roadway surrounding rock (MRSR). Narrower coal pillars cause the roadway to be under the influence of mining stress, which is vulnerable to coal pillar instability and roadway deformation [1,2,3], while wide coal pillars will reduce the recovery rate, resulting in serious loss of coal resources [4]. Therefore, a reasonable width of the SMCP is essential for safe and efficient production in the mine [5,6].

To date, domestic and foreign scholars have conducted extensive research on coal pillar stability and reasonable size design. Frith, Das, and Kumar et al. have analyzed the stability of coal pillars of different shapes and explored the limitations of empirical methods applied to the analysis of strength and stress of coal pillars [7,8,9]. Lu et al. analyzed the deformation and damage mechanism of irregular SMCPs [10,11]. Liu et al. analyzed the coal rock body damage characteristics from the rock specimen scale with different loading and unloading rates to represent the advancing speed [12,13]. Sinha, Klemetti, and Zhang et al. used borehole pressure cells to monitor coal pillar stresses and used them to design coal pillar sizes [14,15,16]. Xiang, Zhai, and Li et al. studied the front abutment pressure (FAP) characteristics and determined the width of SMCPs under different mining geological conditions [17,18,19,20]. Feng et al. explored the reasonable width of SMCPs based on the internal stress of the coal pillar, vertical stress of the MRSR, and abutment pressure characteristics under different overburden-type conditions in extra-thick coal seams [21,22]. Bai et al. determined the location of the stopping line of the double-panel mining face based on the range of mining influence, the deformation law of the surrounding rock, and the peak coefficient of vertical stress of the coal pillar in the main road group [23,24,25]. Summarizing the above research results, the FAP is the main influencing factor on the width of SMCPs. For the FAP, Shavarskyi and Trung Vu et al. analyzed the deformation damage and stress evolution characteristics of coal pillars under different advancing speeds [26,27]. Song et al. studied the characteristics of FAP under high mining height conditions [28]. However, the current research results mainly focus on the characteristics of the stress distribution under a single mining factor, and the sensitivity of different mining factors to the influence factors of FAP is not clear.

Based on the engineering background of the large mining height in the west panel of Sihe Coal Mine, this paper analyzes the evolution characteristics of the FAP under the rapid advancement of the working face through theoretical calculations, numerical simulations, and field measurements. It clarifies the main control factors of the front abutment pressure and proposes a method to determine the rational width of the SMCP in a large mining height working face. The rationality of the width of the SMCP is evaluated through industrial tests. The research results will provide theoretical and technical support for the width of the SMCP in a large mining height working face, which is of great significance for promoting the coordinated development of mine production safety and efficient utilization of resources. At the same time, it can also provide scientific basis and engineering reference for the setting of SMCPs in mines with similar geological conditions.

2. Study Area

The mining stopping line of the working face is the position where the longwall working face stops coal mining and withdraws the supports. The SMCP in the east panel of Sihe Coal Mine is observed to be 68 m based on the length of equipment such as belts, transfer crushers, and Martin conveyors during the final mining period, while those in the west well panel are determined to be 100 m based on experience, as there is a lack of systematic and meticulous research. Therefore, how to optimize the rational location of the stopping line, maintain the stability of the roadway, and maximize the recycling of coal resources are important issues to be solved in realizing the security and high efficiency of mining in the Sihe Mine.

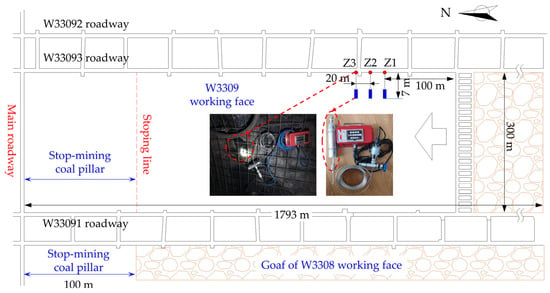

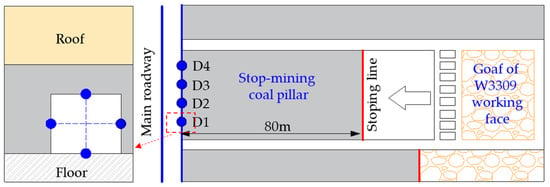

The mine operates with strike longwall integrated mechanized one-time full-height coal mining at W3309. W3309 is 6.0 m thick, 300 m wide, and 1793 m long, having a cover depth of about 412 m. The immediate roof of the coal seam is composed of soft to semi-hard sandy mudstone. The immediate floor is mainly composed of sandy mudstone. The roadway in the panel is arranged perpendicular to the working face along the east–west direction. Figure 1 shows the location of the main roadway in relation to W3309.

Figure 1.

Layout of W3309 positions and stress monitoring points.

3. Characteristics of FAP in Large Height Working Face

To more accurately reflect the dynamic evolution characteristics of the FAP, borehole stress meters were installed to continuously monitor the FAP under the conditions of large mining height and rapid advancement. Three stress monitoring points were arranged within 100 m in the W33093 gateway, with an interval of 20 m between each stress monitoring point. Borehole stress gauges were installed 1.5 m from the bottom plate parallel to the bottom plate into the coal body at a depth of 7 m (Figure 1).

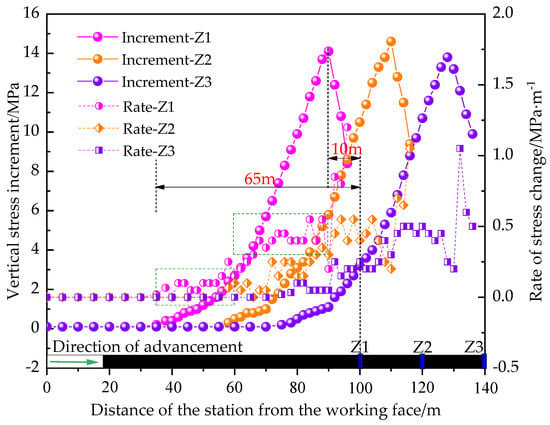

Figure 2 shows the characteristics of the FAP during mining. The maximum stress increments of the abutment pressure at measuring points Z1 to Z3 are 14.1 MPa, 14.6 MPa, and 13.8 MPa, respectively, with an average of 14.17 MPa. Taking measuring point Z1 as an example, the abutment pressure starts to show stress appreciation at 65 m from the working face. In the front range of 40~65 m from the working face, the stress increment increases slowly with the advance of the working face, and the average growth rate is 0.095 MPa/m, with an incremental value of 2.7 Mpa. In the front range of 10~45 m from the working face, the stress increment increases rapidly with the advance of the working face, and the average growth rate is 0.366 MPa/m, with an incremental value of 2.7 Mpa. The stress increment peaked at 14.1 MPa at a location 10 m in front of the working face. The stress increment in the range of 4~10 m from the working face to the measuring station shows a decreasing trend with the advancement of the mining face, and it is reduced to 9.9 MPa at a position of 4 m from the working face. Field measurement data indicate that the influence range of the FAP is 0~65 m.

Figure 2.

Distribution curve of the FAP.

4. Determination of Rational Width of SMCP

4.1. Theoretical Calculation

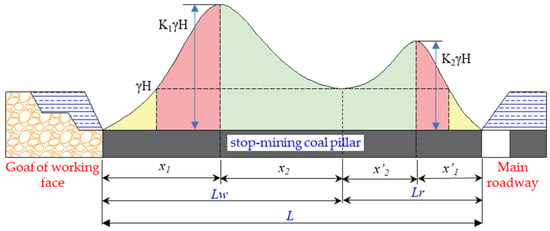

The rational width of the SMCP is an essential guarantee for maintaining the long-term stability of the main roadway. The SMCP undergoes three main stress stages during its service life: the main roadway excavation stress stage, the stress stage during working face mining, and the stabilized stress stage after the end of mining. After the main roadway is excavated, the original rock stress is redistributed and balanced to form a certain area of the stress field, which is not influenced by the pre-mining of the quarry. Compared with the excavation period, the SMCP is more strongly disturbed by the disturbance stress from working face mining. The deterioration in the surrounding rock conditions caused by mining stress is the fundamental cause of main roadway rock disasters. As the mining field continues to advance, the impact range of the FAP moves forward, and the range of the in situ stress between the mining field and the main roadway gradually decreases, thus disturbing the pressure field of the MRSR. Based on the limit equilibrium theory and engineering practice [29,30], when the main roadway has just been disturbed, the width of the SMCP is the sum of the excavation stress field range Lr of the main roadway and the range Lw of the FAP (Figure 3).

Figure 3.

Calculation model for the width of the SMCP.

The range of FAP includes the widths of the plastic zone x1 and the elastic zone x2, which can be calculated using the following formulas [31,32].

In the formulas, M represents the mining height, taken as 6 m; φ represents the friction angle, taken as 30°; f represents the friction coefficient, taken as 0.12; c0 represents the cohesion, taken as 2.68 MPa; H represents the depth of the coal seam, taken as 412 m; γ represents the average bulk density of the overlying strata, taken as 25 kN/m3; K represents the maximum stress concentration factor, taken as 3.5; λ represents the lateral pressure coefficient, taken as 1.5. By substituting the parameters, we obtain x1 = 11.30 m and x2 = 46.98 m. Therefore, the impact distance of the mining-induced FAP Lw is 58.28 m.

The stress influence zone of the MRSR is calculated based on 6 times the radius of the roadway cross-section, and for non-circular roadways, the radius of the circumcircle is considered as the radius of a circular roadway [21]. The main roadway is a rectangular shape with a net width of 5 m and a height of 4 m. Therefore, the stress influence range of the MRSR Lr is calculated to be 19.21 m. Consequently, when the main roadway has just been disturbed, the width of the SMCP L is equal to the sum of Lw and Lr, which is 77.49 m.

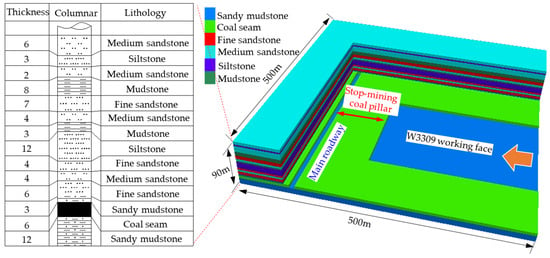

4.2. Numerical Analysis

Figure 4 shows the numerical modeling using FLAC 3D 5.0 based on the geological conditions of the west panel of the Sihe Mine. The model dimensions are 500 m × 500 m × 90 m (length × width × height), and the sizes of the main roadway are 5 m × 4 m (width × height). Displacement constraints were used for the model bottom and surrounding nodes, and the top part of the model was a free boundary, and a vertical stress of 8.18 MPa was implemented to simulate the loading of the unmodeled overlying strata. The rock’s physical and mechanical parameters are shown in Table 1, and the rock’s mechanical behavior is in accordance with the Mohr–Coulomb constitutive criterion.

Figure 4.

Numerical model.

Table 1.

Mechanical parameters of rocks.

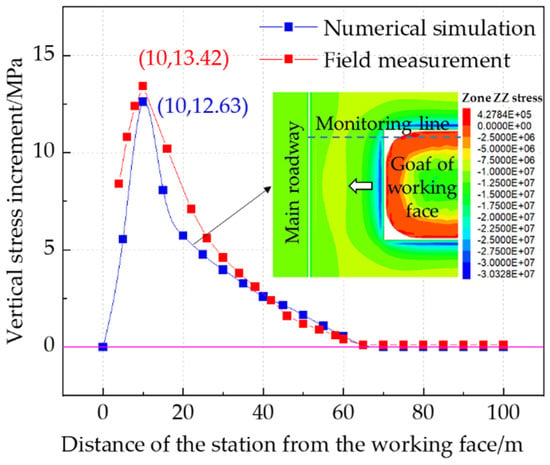

To improve the precision of the constructed numerical model, the actual mining parameters in the field were used to simulate the working face advancement. The extraction and processing to obtain the characteristics of the FAP increment at the same location as measured in the field are shown in Figure 5. The trend of the FAP curves obtained from both research methods, field measurement and numerical simulation, is consistent. The stress increments all peaked at 10 m in front of the working face and were 13.42 MPa and 12.63 MPa, respectively, with a difference of 0.7 MPa. The fact that the difference in stress increment at the same position is kept between 0 and 1 MPa indicates the rationality and reliability of the constructed numerical model.

Figure 5.

Correction results of FAP.

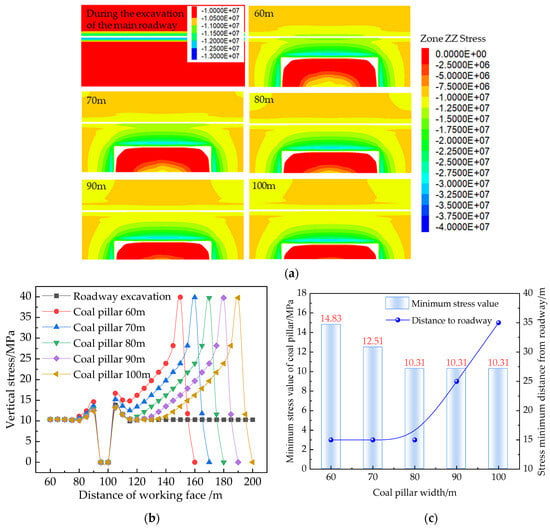

Figure 6a shows the vertical stress clouds obtained from the numerical excavation model for different widths of the SMCP. The cloud map data were extracted to obtain the front abutment pressure distribution curve shown in Figure 6b. And it shows that during the main roadway excavation, a stress concentration area within 15 m was formed on two sides of the roadway, the peak stress value of 13.23 MPa was reached at a distance of 5 m from the roadway, and the largest vertical stress concentration coefficient (VSCC) was 1.28.

Figure 6.

Stress characteristics of SMCPs at different widths: (a) stress cloud map; (b) stress distribution curve of SMCPs; (c) distribution characteristics of the lowest stress point in the elastic zone of coal pillars.

Figure 6c shows the lowest stress point characteristics of the elastic zone of the SMCP with different widths. When the width of the SMCP is more than 80 m, the stress field on the side of the main roadway is not affected by mining activities, and the lowest stress in the elastic zone of the coal pillar is 10.31 MPa. When the SMCP width is 80 m, the stress field on the side of the main roadway is in the critical state of being disturbed by mining, and the lowest stress point from the location of the main roadway is reduced from 35 m to 15 m, but the stress value does not change. When the SMCP width is 70 m, the stress field of the main roadway overlaps with the mining stress field of the working face, and the stress at the lowest point increases significantly to 12.51 MPa. As the width of the SMCP decreases, the disturbance of the main roadway by the overrunning support pressure gradually increases, and the overall stress of the SMCP gradually increases. The lowest stress point is 14.13 MPa, reaching 1.37 times the original rock stress, with an SMCP width of 60 m.

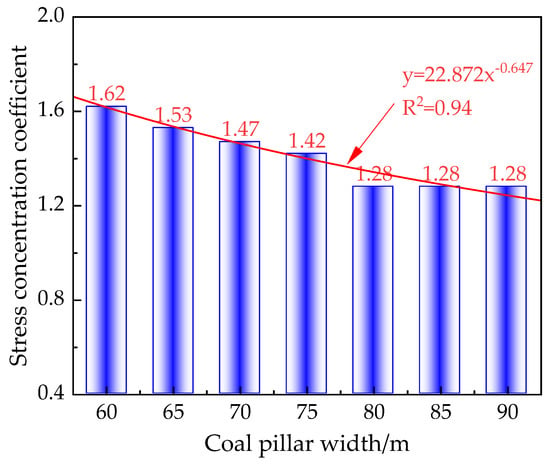

The relationship between the maximum VSCC of the main roadway disturbed by mining and the SMCP width is shown in Figure 7. When the width of the SMCP is lower than 80 m, the maximum VSCC of the main roadway increases gradually with the decrease in the SMCP width. When the width of the SMCP decreases to 60 m, the maximum VSCC increases from 1.28 to 1.62, showing that the stress field of the MRSR is enhanced gradually by the influence of FAP, and the MRSR is going to become unstable gradually.

Figure 7.

Maximum VSCC of the MRSR under different widths of the SMCP.

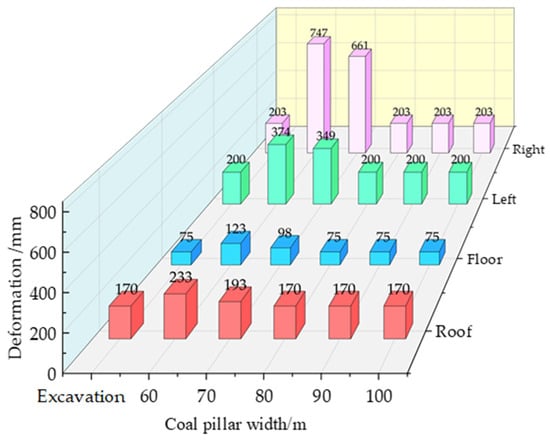

The deformation features of the main roadway under the influence of excavation and mining are shown in Figure 8. After the main roadway was excavated, the damage of the SRMR was dominated by the movement of the two sides, and the deformations of the roof and floor and the two sides were 170, 75, 200, and 203 mm, respectively. When the coal pillar width exceeds 80 m, the deformation amount of the roadway is basically the same as that after the stabilization of the excavation, and working face mining has no impact on the roadway. As the coal pillar width decreases to 70 m, the deformation of the roadway increases sharply. At this time, the deformations of the roof, floor, and two sides were 193 mm, 98 mm, 349 mm, and 661 mm, with increases of 14%, 30%, 74%, and 229%, respectively, indicating that the working face mining at this time had a significant impact on the main roadway. When the SMCP width continued to decrease to 60 m, the deformation of the MRSR continued to increase.

Figure 8.

Deformation characteristics of MRSR at different SMCP widths.

To summarize, the width of the SMCP calculated by the limit equilibrium theory is 77.49 m. According to the numerical analysis, the coal pillar width is not less than 80 m based on the internal stress of the pillar, vertical stress, and deformation characteristics of the main roadway. Combining the results of theoretical calculation and numerical analysis, it is determined that the rational width of the SMCP in the W3309 working face is 80 m.

5. Field Application

To assess the reasonableness of coal pillar retention, four measuring stations (D1~D4) were arranged at intervals of 60 m in the main roadway, and the cross-point method was used to continuously monitor the deformation of MRSR after the end of mining. The monitoring station arrangement is shown in Figure 9.

Figure 9.

Arrangement of monitoring stations for deformation of the MRSR.

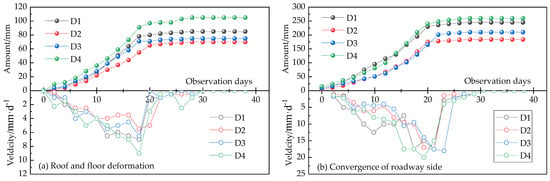

The deformation characteristics of the MRSR after the working face stopped mining are shown in Figure 10. During the monitoring period, the continuous deformation of the MRSR lasted for approximately 28 days, which can be divided into three distinct periods. Taking the D1 measuring point as an example, in the first time period of 0~10 days for the slow deformation stage, the roof-to-floor and side-to-side convergences are 18 mm and 75 mm, and the maximum movement rates were 3 mm/d and 10 mm/d, respectively. The second time period of 10~20 days is the rapid deformation stage; the roof-to-floor convergence is 62 mm, the convergence of the two sides is 155 mm, and the maximum movement rates were 7 mm/d and 17.5 mm/d, respectively. The third time period from 20 to 28 days is the slow deformation stage; the roof-to-floor convergence is 7 mm, the convergence of the two sides is 15 mm, and the maximum movement rates were 0.5 mm/d and 1 mm/d, respectively. After that, the deformation of the MRSR stabilized, and the amount of displacement no longer increased. The maximum roof-to-floor and side-to-side convergences of the main roadway are 105 mm and 260 mm, and the overall deformation of the surrounding rock is small, which indicates that the width of the SMCP must be 80 m to meet the needs of safe production.

Figure 10.

Observation results of main roadway surface deformation.

6. Discussion

The front abutment pressure is a major factor influencing the retention of the stop-mining coal pillar width. Under intense mining activities, the peak stress and the impact scale of the front abutment pressure are different, resulting in different stress environments and instability characteristics for the SMCP and the MRSR. Based on the established numerical model, three factors are selected: mining height (M), with values of 2 m, 4 m, 6 m, and 8 m; working face length (L), with values of 200 m, 250 m, 300 m, and 350 m; and advancing speed (V), with values of 4 m/d, 7 m/d, 10 m/d, and 13 m/d. Using the orthogonal experimental method, 16 numerical simulation scenarios are established with three factors and four levels each. The effect of these factors on the FAP is studied using the impact scale of the front abutment pressure (Lw) and the peak stress (σzz) as indicators. The specific scenarios and results are presented in Table 2. The results of range analysis and variance analysis based on the orthogonal test calculations are shown in Table 3 and Table 4.

Table 2.

Orthogonal test program (L1643) and results.

Table 3.

Range analysis.

Table 4.

Analysis of variance.

Based on the range analysis (Table 3), when considering peak stress as the metric, the factors’ influence on peak stress can be ranked as follows: M > L > V. Specifically, the range value of mining height is 23.51 and 27.79 times larger than that of face length and advancing speed, respectively, indicating that the influence of mining height is significantly greater than that of face length and advancing speed. The relatively small range difference between working face length and advancing speed suggests that they have a similar level of influence on peak stress. When considering the influence range as the metric, the ranking of the factors’ influence is also M > L > V. Here, the range value of mining height is 6.55 and 10.29 times larger than that of face length and advancing speed, respectively, further highlighting the preponderance of mining height’s influence compared to the other two factors.

Based on the variance analysis results (Table 4), the mining height has a great effect on the characteristics of the FAP, while the working face length and advancing speed have insignificant effects. The significance ranking of the factors’ influence on the characteristics of the FAP is M > L > V, which in agreement with the results of the range analysis.

In summary, the mining height has a significant effect on the overrunning support pressure, which is consistent with the findings of Ren, et al. [33,34]. Therefore, the mining height is the main controlling factor in determining the width of the stop-mining coal pillar. Under the condition of constant face length, during the final mining stage, it is advisable to appropriately reduce the mining height or slow down the advancing speed to minimize the impact of dynamic pressure in the mining area and protect the stability of the coal pillar.

In order to realize the green and sustainable development of mines, with the continuous progress of mining technology, narrow coal pillars are gradually being implemented in mines. Zhang et al. reduced the width of the stop-mining coal pillar by reducing the abutment pressure peaks and the surrounding rock stresses in the roadway through blasting and roof-cutting techniques [30,35,36]. Zhang replaced some of the stop-mining coal pillars with concrete fillers in the withdrawal tunnel, which improved the recovery rate of coal resources [37]. In addition, Malashkevych et al. effectively reduced the roof stress intensity by leaving waste rocks in the mined-out space, which also provided a new idea for reducing the width of the SMCP [38,39]. However, the influence of the wide coal pillar left by the mining of the upper group of coal and the waste rock left by the mining-out area on the lower group of coal when mining may need to be further studied.

7. Conclusions

The paper takes W3309 in the west panel of Sihe Mine as a case study. Through on-site measurement, theoretical calculation, and numerical simulation methods, the characteristics of FAP in a large height working face are studied, and a design method for stop-mining coal pillar width in a strong mining working face is proposed.

- (1)

- The characteristics of FAP in a large height working face and its influence factors’ sensitivity are analyzed. The results show that the influence of FAP ranges from 0 to 65 m. Mining height has a significant effect on the FAP, and the significance ranking of the factors’ influence is mining height > working face length > advancing speed.

- (2)

- The method of determining the width of SMCPs by taking the internal stress of the coal pillar, the vertical stress, and the deformation characteristics of the MRSR as the indexes is proposed. The results show that when the SMCP width is 80 m, the main roadway is in a critical state of mining disturbance.

- (3)

- The SMCP width was determined to be 80 m, and its reasonableness was evaluated by industrial tests. On-site application indicates that the maximum value of roof-to-floor convergence of the main roadway is 105 mm, and the maximum value of side-to-side convergence is 260 mm. The overall deformation of the MRSR is small, which means it can effectively maintain the stability of the roadway and meet the needs of safety operation.

Author Contributions

Conceptualization, W.Y. and G.F.; methodology, S.Z.; software, W.Y. and Z.F.; validation, W.Y., W.G. and W.Z.; formal analysis, W.Y.; investigation, W.Y. and W.G.; data curation, W.G. and W.Z.; writing—original draft preparation, W.Y. and Z.F.; writing—review and editing, D.Z. and Z.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by the Shanxi Province Unveils Bidding Project (grant no. 20201101009), the National Natural Science Foundation of China (no. 52204161), the Jiangsu Funding Program for Excellent Postdoctoral Talent (nos. 2022ZB511; 2023ZB517), and the Fundamental Research Funds for the Central Universities (nos. 2022QN1008; 2021ZDPY0226).

Data Availability Statement

Data are contained within this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bu, Q.; Tu, M.; Fu, B. Research on the Redistribution Law of Lateral Mining Stress and the Bearing Characteristics of Section Coal Pillar in Extra-Thick Fully Mechanized Top-Coal Caving Mining. Shock Vib. 2021, 2021, 4355977. [Google Scholar] [CrossRef]

- He, X.; He, S.; Cai, Y.; Xu, R.Y.; Yang, K. Investigation on rational width of coal pillar and roadway support in isolated panel of extra-thick coal seam. Front. Earth Sci. 2023, 11, 1125678. [Google Scholar] [CrossRef]

- Zhao, S.; Zuo, J.; Liu, L.; Wu, K. Study on the Retention of Large Mining Height and Small Coal Pillar under Thick and Hard Roof of Bayangaole Coal. Adv. Civ. Eng. 2021, 2021, 8837189. [Google Scholar] [CrossRef]

- He, W.; He, F.; Zhao, Y. Field and simulation study of the rational coal pillar width in extra-thick coal seams. Energy Sci Eng. 2020, 8, 627–646. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, Y.; Han, P.; Bai, Q. Coal pillar failure analysis and instability evaluation methods: A short review and prospect. Eng. Fail. Anal. 2022, 138, 106344. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, S.; Wang, Z.; Li, J. Research and Application of Prefilled Concrete Wall to Reduce the Size of Stopping Mining Coal Pillar. Geofluids 2022, 2022, 8526755. [Google Scholar] [CrossRef]

- Frith, R.; Reed, G. Limitations and potential design risks when applying empirically derived coal pillar strength equations to real-life mine stability problems. Int. J. Min. Sci. Technol. 2019, 29, 17–25. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Paul, P.S.; Sinha, R.K. Generalised Analytical Models for the Strength of the Inclined as well as the Flat Coal Pillars using Rock Mass Failure Criterion. Rock Mech. Rock Eng. 2019, 52, 3921–3946. [Google Scholar] [CrossRef]

- Kumar, R.; Mandal, P.K.; Ghosh, N.; Das, A.J.; Banerjee, G. Design of Stable Parallelepiped Coal Pillars Considering Geotechnical Uncertainties. Rock Mech. Rock Eng. 2023, 56, 6581–6602. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, C.; Wang, H.; Guo, Y.; Xiao, Z.; Xia, L.; Wang, C. Moment tensor inversion study on deformation andfailure mechanism of the irregular coal pillar. J. Min. Saf. Eng. 2023, 40, 1201–1209. [Google Scholar] [CrossRef]

- Song, C.; Lu, C.; Zhang, X.; Wang, C.; Xie, H.; Yan, X.; Yang, H. Moment Tensor Inversion and Stress Evolution of Coal Pillar Failure Mechanism. Rock Mech. Rock Eng. 2022, 55, 2371–2383. [Google Scholar] [CrossRef]

- Nie, B.; Zhang, H.; Liu, X.; Li, Y.; Deng, B.; He, H.; Liu, P. Experimental Study on the Mechanical Stability and Mesoscopic Damage Characteristics of Coal Under Different Mining Disturbance Rates. Rock Mech. Rock Eng. 2024, 57, 3841–3861. [Google Scholar] [CrossRef]

- Liu, W.; Cheng, W.; Liu, X.; Zhang, Z.; Yue, Z.; Yang, L.; Shen, A. Effects of Loading Rate and Notch Geometry on Dynamic Fracture Behavior of Rocks Containing Blunt V-Notched Defects. Rock Mech. Rock Eng. 2024, 57, 2501–2521. [Google Scholar] [CrossRef]

- Sinha, S.; Walton, G. Investigation of longwall headgate stress distribution with an emphasis on pillar behavior. Int. J. Rock Mech. Min. Sci. 2019, 121, 104049. [Google Scholar] [CrossRef]

- Klemetti, T.M.; Van Dyke, M.A.; Tulu, I.B.; Tuncay, D. A case study of the stability of a non-typical bleeder entry system at a U.S. longwall mine. Int. J. Min. Sci. Technol. 2020, 30, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Wang, X.; Fan, G.; Zhang, D.; Cui, J. Pillar size optimization design of isolated island panel gob-side entry driving in deep inclined coal seam-case study of Pingmei No. 6 coal seam. J. Geophys. Eng. 2018, 15, 816–828. [Google Scholar] [CrossRef]

- Xiang, X.; Yang, X.; Ma, C.; Ren, Q.; Zhang, C.; Fang, P.; Luo, B.; Sun, Y. Determination of Reasonable Stopping Line Position in Weakly Cemented Soft Rock Face under Influence of Fault. Coal Technol. 2022, 41, 29–33. [Google Scholar] [CrossRef]

- Zhai, W.; He, F.; Li, L.; Song, J.; Xu, X.; Lv, K.; Wang, D.; Ma, Q. Study on deflection of principal stress and deformation characteristics of roadway surrounding rock under mining action in close-distance coal seams. Geomat. Nat. Hazards Risk 2023, 14, 2227327. [Google Scholar] [CrossRef]

- Wang, D.; He, F.; Wu, Y.; Xu, X.; Zhang, J.; Lv, K.; Li, L.; Zhai, W.; Song, J. Study on surrounding rock failure mechanism and rational coal pillar width of the gob-side coal roadway under influence of intense dynamic pressure. Energy Sci. Eng. 2023, 11, 1716–1733. [Google Scholar] [CrossRef]

- He, F.; Li, L.; Lv, K.; Qin, B.; Xu, X.; Ma, Q.; Chen, Y. Study on Evolution of Front Abutment Pressure at Working Face in Repeated Mining of Close-Distance Coal Seams. Sustainability 2022, 14, 12399. [Google Scholar] [CrossRef]

- Feng, G.; Wang, G.; Wang, P.; Guo, J.; Yan, Y.; Ren, Y. Study on rational width of the end-mining coal pillar of extra-thickmining panel in permo-carboniferous igneous rock intrusion area. J. Min. Saf. Eng. 2019, 36, 87–94. [Google Scholar] [CrossRef]

- Guo, J.; Feng, G.; Wang, P.; Qi, T.; Zhang, X.; Yan, Y. Roof Strata Behavior and Support Resistance Determination for Ultra-Thick Longwall Top Coal Caving Panel: A Case Study of the Tashan Coal Mine. Energies 2018, 11, 1041. [Google Scholar] [CrossRef]

- Yu, Y.; Bai, J.; Zhang, S.; Guo, Y.; Zhang, L. Disaster mechanism of surrounding rock withdouble wing mining roadway group and its repairand reinforcement system. J. Min. Saf. Eng. 2020, 37, 1133–1141. [Google Scholar] [CrossRef]

- Sun, Y.; Bi, R.; Chang, Q.; Taherdangkoo, R.; Zhang, J.; Sun, J.; Huang, J.; Li, G. Stability Analysis of Roadway Groups under Multi-Mining Disturbances. Appl. Sci. 2021, 11, 7953. [Google Scholar] [CrossRef]

- Yang, S.; Li, G.; Bi, R.; Yao, B.; Feng, R.; Sun, Y. The Stability of Roadway Groups under Rheology Coupling Mining Disturbance. Sustainability 2021, 13, 2300. [Google Scholar] [CrossRef]

- Vu, T.T. Solutions to prevent face spall and roof falling in fully mechanized longwall at underground mines, Vietnam. Min. Miner. Depos. 2022, 16, 127–134. [Google Scholar] [CrossRef]

- Shavarskyi, I.; Falshtynskyi, V.; Dychkovskyi, R.; Akimov, O.; Sala, D.; Buketov, V. Management of the longwall face advance on the stress-strain state of rock mass. Min. Miner. Depos. 2022, 16, 78–85. [Google Scholar] [CrossRef]

- Song, B.; Zhang, S.; Zhang, D.; Fan, G.; Yu, W.; Zhao, Q.; Liang, S. Inorganic Cement Grouting for Reinforcing Triangular Zone of Highly Gassy Coal Face with Large Mining Height. Energies 2018, 11, 2549. [Google Scholar] [CrossRef]

- Zhou, H.; Qu, C.; Huang, J.; Zhang, C.; Hu, M.; Tang, J. Analysis of rational shape of stop line in deep coal seam based on model test. Chin. J. Rock Mech. Eng. 2017, 36, 2373–2382. [Google Scholar] [CrossRef]

- Gong, P.; Chen, Y.; Ma, Z.; Cheng, S. Study on Stress Relief of Hard Roof Based on Presplitting and Deep Hole Blasting. Adv. Civ. Eng. 2020, 2020, 8842818. [Google Scholar] [CrossRef]

- Liu, C.; Wang, F.; Zhang, Z.; Zhu, D.; Hao, W.; Tang, T.; Zhang, X.; Zhu, C. Surrounding Rock Deformation Mechanism and Control Technology for the Roadway in the Fault-Disturbed Zone under Special-Shaped Coal Pillars. Processes 2023, 11, 3264. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, Y.; Li, Z.; Zheng, Y.; Song, G.; Hu, L. The Optimized Roadway Layouts and Surrounding Rock Control Technology of the Fully Mechanized Mining Surface with Large Mining Heights in High-Gas Mines. Processes 2022, 10, 2657. [Google Scholar] [CrossRef]

- Ren, W.T.; Chen, J.T.; Liu, W.Z. Study on Mine Zoning Based on lmpact Index of Advanced Abutment Pressure. Min. Res. Dev. 2019, 39, 71–75. [Google Scholar] [CrossRef]

- Jin, Z.P.; Qin, T.; Zhang, J.W. Analysis of abutment pressure distribution characteristics and influencing factors of deep mining height face. Coal Sci. Technol. 2018, 46, 97–99+134. [Google Scholar] [CrossRef]

- Xie, S.; Wu, Y.; Ma, X.; Chen, D.; Guo, F.; Jiang, Z.; Li, H.; Zou, H.; Liu, R.; Zhang, X. Reasonable stopping method and retracement channel support at fully mechanized top coal caving working face of 15 m extra-thick coal seam: A case study. Energy Sci. Eng. 2022, 10, 4336–4357. [Google Scholar] [CrossRef]

- Zhang, X.; Li, X.; Tong, Z.; Gao, Y.; Zhao, X. Enhancing recovery efficiency during the final mining phase offully mechanized caving mining under thick-coal hard-roofconditions: Countermeasures and strategies. J. Min. Saf. Eng. 2024, 41, 295–304. [Google Scholar] [CrossRef]

- Ren, X.; Hao, B.; Wang, H.; Zhao, J.; Zhang, J.; Zhang, C. Roadway Protection by Roof-Cutting in the Support Removing Channel of the Long-Wall Mining Face. Shock Vib. 2022, 2022, 8116399. [Google Scholar] [CrossRef]

- Malashkevych, D.; Petlovanyi, M.; Sai, K.; Zubko, S. Research into the coal quality with a new selective mining technology of the waste rock accumulation in the mined-out area. Min. Miner. Depos. 2022, 16, 103–114. [Google Scholar] [CrossRef]

- Smoli’nski, A.; Malashkevych, D.; Petlovanyi, M.; Rysbekov, K.; Lozynskyi, V.; Sai, K. Research into Impact of Leaving Waste Rocks in the Mined-Out Space on the Geomechanical State of the Rock Mass Surrounding the Longwall Face. Energies 2022, 15, 9522. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).