Abstract

As enterprises look forward to new market share and supply chain opportunities, innovative strategies and sustainable manufacturing play important roles for micro-, small, and mid-sized enterprises worldwide. Sustainable manufacturing is one of the practices aimed towards deploying green energy initiatives to ease climate change, presenting three main pillars—economic, social, and environmental. The issue of how to reach sustainability goals within the sustainable manufacturing of pillars is a less-researched area. This paper’s main purpose and novelty is two-fold. First, it aims to provide a hierarchy of the green energy indicators and their measurements through a multi-criteria decision-making point of view to implement them as an alliance strategy towards sustainable manufacturing. Moreover, we aim to provide researchers and practitioners with a forecasting method to re-prioritize green energy indicators through a linearity factor model. The CODAS–Hamming–Mahalanobis method is used to obtain preference scores and rankings from a 50-item list. The resulting top 10 list shows that enterprises defined nine items within the economic pillar as more important and one item on the environmental pillar; items from the social pillar were less important. The implication for MSMEs within the manufacturing sector represents an opportunity to work with decision makers to deploy specific initiatives towards sustainable manufacturing, focused on profit and welfare while taking care of natural resources. In addition, we propose a continuous predictive analysis method, the linearity factor model, as a tool for new enterprises to seek a green energy hierarchy according to their individual needs. The resulting hierarchy using the predictive analysis model presented changes in the items’ order, but it remained within the same two sustainable manufacturing pillars: economic and environmental.

1. Introduction

Innovation is seen as an activity that encourages growth, development, and continuous improvement in each department of an enterprise [1]. It is considered a business strategy that enhances the organizational structure for the development of new ideas and the creation or improvement of products, services, and processes for acquiring a competitive advantage [2]. Enterprises must define, develop, and maintain their supply chain to guarantee an innovative and disruptive product.

Disruption presents uncertainty and a ripple effect in the supply chain long after the event has passed [3]. As Ref. [2] describes, innovation and disruption offer great opportunities for enterprises to achieve competitive advantage and growth for the company itself. Decision makers need to focus on strategies for innovative and disruptive events. As described in [3], a disruptive supply chain involves a number of factors such as information sharing and interconnected physical and cyber infrastructure, or, as suggested in [4], horizontal collaboration strategies to design and develop joint projects in different areas such as logistics, R&D, and knowledge transfer, among others.

The industrial sector is one sector with a rapidly changing challenge and has been identified as the main participant in green energy consumption [5]. For micro-, small, and mid-sized enterprises (MSMEs), the new challenge lies in creating a motivated environment where human capital can increase their abilities and knowledge [6] in order to use their actual resources effectively and efficiently to obtain aggregated value in their offered products and services [7]. The academic literature has identified specific elements to increase the use of innovation and disruption as an enterprise’s business strategy, from implementation changes like costs, technology diffusion, intellectual property protection, finance performance, investments, and commercialization through alliances and collaboration ventures where R&D activities, human capital, and knowledge transfer and sources are taken into account to deliver firms’ innovation and disruption [1,8,9,10].

To enable sustainable manufacturing, enterprises must consider environmental and economic implications within the supply chain. As explained by [11], enterprises focus on strategies to increase the efficiency of manufacturing processes, the use of raw materials, or the use of recovered or reused materials, as well as horizontal collaboration business models to engage in innovative projects for sustainable value creation in manufacturing [12]. Key factors include the involvement of decision makers in the considerable number of factors that need to be taken into account, from production planning, manufacturing processes, and innovation to supply chain design and products. Other factors include the selection of raw materials from the perspective of recycling, reusing, or re-furbishing materials, integrating or collaborating with processes that use energy effectively, and working with a logistics strategy that uses low fossil fuel.

Deploying innovation and disruption goes hand-in-hand with green energy initiatives. Faced with the challenge of changing climate damages, countries are working towards several development goals, strategies, and agreements, from the Sustainable Development Goals of the United Nations 2030 Agenda with 17 sustainable goals, to the Paris Agreement, a treaty with the objective of economic and social transformation to be achieved through collaboration in financial assistance, technology development and transfer, and capacity building [13,14,15,16]. These strategies aim to incentivize countries towards a green energy change, from production to consumption, and replace the use of fossil fuels [17,18,19].

To the best of our knowledge, there is no research on existing studies that outline the main green initiatives used to enhance sustainable manufacturing pillars. Furthermore, there is no literature review on the green indicators and measurements that could enhance the sustainable manufacturing pillars—economic, social, and environmental.

Given the importance of achieving sustainable manufacturing considering climate change, the current paper presents an in-depth literature review focused on the sustainable manufacturing pillars, also known as the triple bottom line [13,20]. Overall, recent studies do not provide a comprehensive review of how green energy indicators and their measurements and items can be matched with the three pillars of sustainable manufacturing. The investigation allows for companies in industrial activities to deploy specific actions to enhance sustainable manufacturing, as well as adopt a predictive analytic model for new hierarchization of the items for future research, promoting green energy indicators in sustainable manufacturing. Thus, this review was conducted to fill the gaps in the importance of these indicators and to answer the following questions:

- How can the green energy indicators be implemented within sustainable manufacturing pillars?

- Which are the green energy indicators identified as of higher priority from a comparative correlation from the MCDM methodology?

- How can new enterprises determine the hierarchy of green energy indicators?

This paper’s main purpose is to provide a hierarchy of green energy indicators, their measurements, and items aligned with the three pillars of sustainable manufacturing. This is completed from the perspective of the MCDM to implement it as an alliance strategy towards sustainable manufacturing. Moreover, it provides researchers and practitioners with a forecasting method to reprioritize green energy indicators through a linearity factor model. To answer the above research questions, the following objectives are set:

- Present the proposed CODAS–Hamming–Mahalanobis method developed by [12].

- Present the proposed green energy indicators, their measurements, and items identified by [21].

- Develop a green energy matrix with a Likert scale, including the green energy indicators within the three sustainable manufacturing pillars.

- Provide a linearity factor model to forecast the hierarchy of green energy indicators from an additional business’ opinion.

This paper is organized as follows: Section 2 presents the results of the literature review of sustainable manufacturing pillars and green energy indicators. Section 3 contains the methodology, followed by the discussion of the empirical findings in Section 4. Section 5 concludes and outlines the theoretical contributions. Finally, Section 6 presents and discusses the practical implications, limitations, and future research.

2. Literature Review

As a result of the above, this paper focuses on green energy indicators that firms can use efficiently and effectively toward sustainable manufacturing. Green energy can have a significant effect on the operational costs and performance achievements in manufacturing processes, among others, but the initiative can fail due to several challenges and barriers [22]. To gain an understanding, the authors retrieved contributions from green energy indicators, specifically those suggested by [21]. Then, a literature analysis of sustainable manufacturing pillars is presented.

2.1. Green Energy Indicators, Measurements and Their Items

Manufacturing businesses are considered responsible for 36% of carbon dioxide emissions and consume approximately a third of global energy production [17]. For this matter, decision makers are aiming for sustainable development because stakeholders and end customers are from developed, developing, and emerging economies. To make better decisions in implementing sustainable factors, managers must pay attention to a more comprehensive approach integrating economic, social, and environmental aspects [23,24]. Riosvelasco et al. [21] present a literature review to identify green energy indicators, measurements, and their items for manufacturing applications towards sustainability, as shown in Table 1. The authors applied the PRISMA 2020 methodology to analyze previous research and identify green energy indicators to ease Mexican companies in the industrial sector to deploy green energy sustainable practices.

Table 1.

Green energy indicators, measurements and items [21].

Table 1 shows six indicators: (1) technology and innovation, (2) geographical aspects, (3) investment, (4) government regulations, (5) emissions, and (6) sustainable practices. Within these six indicators, each encompasses a total of 18 measurements, and the latter accumulate a total of 50 items. These indicators and their measurements and items are identified to promote actions for Mexican companies to adapt and create a sustainable manufacturing environment. As enterprises look forward to new market shares and supply chain opportunities, innovation plays an important role for MSMEs worldwide. As described by [25], innovative enterprises must create or find a business model that balances everyday activities, innovative strategies, and sustainable manufacturing.

2.2. Sustainable Manufacturing

For enterprises, reaching sustainability goals is an everyday challenge because of the fine decisions entrepreneurs have to make every day. Managers have difficulty selecting and working on strategies for implementing sustainable manufacturing because sustainability presents a variety of factors [17,24]. The path to stabilize the disruptive relationship between industry and the negative impact on the 3Ps (people, planet, and profit) involves a holistic approach relying on economic operational efficiency, environmental compliance, communication, and legal regulations [24].

A literature review was conducted according to the following criteria: (a) year range from 2020 to 2024; (b) article type as review articles; (c) keywords such as “sustainable manufacturing pillars”, “triple bottom line” AND “sustainable manufacturing”, “sustainability” AND “manufacturing”; and (d) access type as open access. For exclusion criteria, the following were taken into account: keywords must be in title, abstract, and keywords. The results obtained ranged from systematic reviews to identify drivers and motives for sustainable manufacturing [26]; a framework for analyzing the product life cycle regarding product design and manufacturing system selection [27] to the identification of several enablers for the adoption of sustainable manufacturing [28].

For manufacturing businesses to work and implement a direct strategy towards sustainable manufacturing, research has been focusing on sustainability measurement that follows activities as the backbone within the supply chain [20], where decision makers have to pay attention to the interaction between society, environment, and companies [29]. Sustainable manufacturing presents three pillars which are: (1) economic, which includes criteria that take into account costs; (2) social, which takes into account the human elements in terms of employees and community; and (3) environmental, criteria that involve reducing emissions, waste, and spike energy, among others [20,24,27,28,30,31], as shown in Table 2.

Table 2.

Sustainable manufacturing pillars [20,27,28,30].

From this point forward, the authors present a match between the green energy indicators and the three sustainable manufacturing pillars. This decision-making matrix has been designed by considering three sustainable manufacturing pillars, selected for its approach of an innovation perspective from which enterprises can transition towards green energy usage. For the matching process, the three pillars are taken into account. (1) Economic: all firm’s costs, repairs, and enhancements, among other factors in different departments; (2) social: factors contributing to personnel, stakeholders, and government; and (3) environmental: factors regarding emissions, consumption and management systems. Table 3 shows the items that involve criteria within each sustainable manufacturing pillar.

Table 3.

Design of decision-making matrix.

3. Methodology

3.1. Research Model

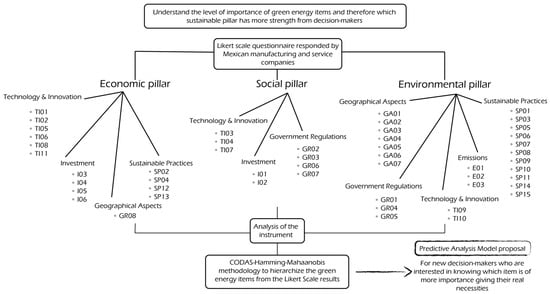

Contributing to the academic literature on sustainable manufacturing towards the use of green energy indicators, measurements, and items, this paper presents a hybrid analysis for hierarchizing green energy indicators using CODAS techniques with distinct distance equations—Hamming and Mahalanobis distances. These center data from an enterprise’s evaluation survey whose experience in different productive and service sectors enhances green energy indicators in multi-criteria decision making. Additionally, we present a linearity factor model for predicting green energy indicators from future enterprise panels. Figure 1 conceptualizes the research model followed to reach this paper’s main objective, taking into account the assigned Likert Scale, the CODAS–Hamming–Mahalanobis method, and the predictive analysis model.

Figure 1.

Research model.

3.2. Instrument for Data Collection

The instrument for data collection was then designed from the decision-making matrix, shown in Table 3, that served as a basis for the questionnaire. Table 4 presents the questionnaire, which consisted of 17 questions, divided into 7 sections: (1) demographic data, (2) technology and innovation, (3) geographic aspects, (4) investment, (5) government regulations, (6) emissions, and (7) sustainable practices. The instrument was designed to be answered by a businessperson, manager, supervisor, or person appointed from micro, small, mid-size, or big enterprises.

Table 4.

Instrument for data collection.

To give certainty to the questionnaire for the fulfillment of the objectives outlined, a validation process was carried out. Expert judgment was used—a process that requires an accurate, efficient, methodological, and statistical interpretation of the results. The expert panel selection was performed by taking into account the experience and knowledge of sustainability practices, manufacturing processes, and energy efficiency strategies. The expert panel was grouped by three experts, thus obtaining an average Cohen’s Kappa equal to 0.95 with perfect agreement between the raters.

Afterward, the questionnaire was made on Limesurvey online software so it could be in a more user-friendly form to be answered by the survey respondents. The questionnaire can be filled out at the following URL: https://energiasverdes.limesurvey.net/686967?lang=es (accessed on 21 May 2024) (it is available in Spanish, but will be made available in English to obtain responses from a broader sample).

3.3. Data Collection Process

The instrument for data collection was made available from August 2023 to March 2024, through a digital platform known as Limesurvey. A Likert scale was used to measure the level of interest of each enterprise’s decision maker towards each green energy indicator, their measurements and items, with the meanings totally agree (5), in agreement (4), indifferent (3), disagree (2), and strongly disagree (1), as shown in Table 4.

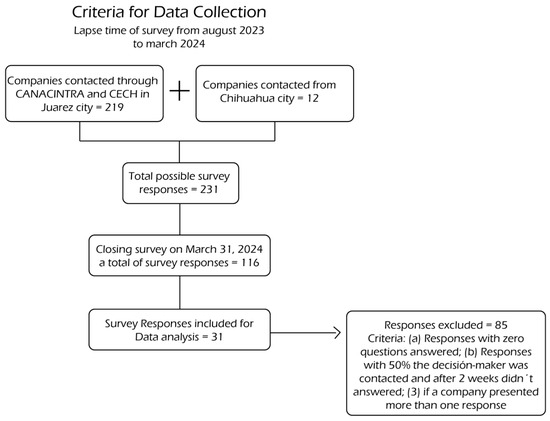

The survey was presented to a Mexican organization and a cluster, Cámara Nacional de la Industria de la Transformación, North Zone (CANACINTRA, for its acronym in Spanish) and Clúster de Energía Chihuahua (CECH, for its acronym in Spanish), to obtain a higher response rate from manufacturing and service companies. Both organizations are in Juarez city, Chihuahua, a city of great importance to the manufacturing sector in the country. Additional responses were received from companies from Chihuahua city because the link was shared to known businessmen. From the elapsed time, from August 2023 to March 2024, a total of 116 survey responses were received. Figure 2 shows the diagram flow for the data collected.

Figure 2.

Data collection diagram flow.

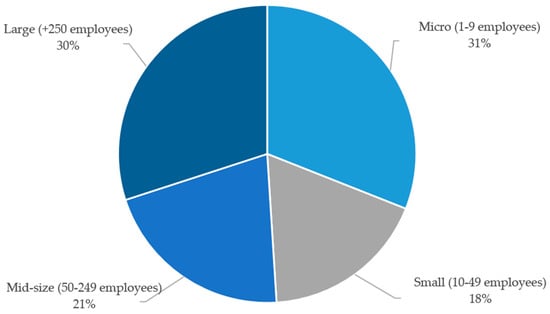

As mentioned before, certain criteria were taken into account for excluding companies’ responses, such as: (1) only one decision maker from the company could respond to the survey—more than one survey response from the same company were not taken into account; (2) for responses received with 50% of survey responded to, the decision maker was contacted asking them to finish the survey—if they did not respond within a period of two weeks, the response was eliminated; (3) responses with zero items answered and no contact data were discarded. From the demographic section, the following information was obtained from the decision makers: 61.29% were companies located in Juarez city, and 38.70% in Chihuahua City. Table 5 presents demographic data regarding the 31 companies that responded to the survey.

Table 5.

Demographic data from companies.

From the decision makers that responded to the survey, their job titles ranged from Assistant Director (1), Quality Coordinator (1), Leader (1), Manager (2), General Manager (6), Director (11), CEO (2), Owner (3), and Teacher (4). Moreover, their level of education was Technician (1), Bachelor’s degree (16), Specialization (2), and Master (12).

The next step was to analyze the rest of the six sections through an integrated MCDM method, named CODAS–Hamming–Mahalanobis, presented by [12].

3.4. Analytic Instruments

The authors of [12] proposed Mahalanobis distance to be used as the second distance measure for the CODAS methodology. The resulting methodology presented better results from the original primary and secondary distance measures (e.g., Euclidean and Taxicab distances), gaining better numbers for Hamming and Mahalanobis distances. From this point on, the present article uses this proposed methodology, named CODAS–Hamming–Mahalanobis to obtain, analyze, and identify green energy items from a sample size defined by the elapsed time. The main distance presented below is the Mahalanobis distance, because Ref. [12] proposed three distance variants, and one of them, the robust variant, showed better results.

Mahalanobis Distance Robust Variant

P.C. Mahalanobis proposed Mahalanobis distance in 1936, where it was defined as a set of parameters of a particular cluster replacing the population via sample statistics [32]. Research presents Mahalanobis distance as a statistical tool that focuses on measurable variables for data-driven decision-making [33,34], as well as a statistical technique measuring a distance point from the center of a multivariate normal distribution [35]. Defined as a distance that measures the distance between variables, different patterns can be analyzed concerning the population parameters [33,36,37], as shown in Equation (1).

Mahalanobis distance:

where:

- Xi represents a row vector of a multivariate measurement being observed;

- S−1 is the covariance matrix of the sample;

- is the mean of the sample.

As globalized manufacturing processes are integrated with cyber-physical features and Industry 4.0, more data are received. Due to this situation, disruptions in statistical themes present an opportunity for researchers to propose Mahalanobis distance measurements with a series of functionalities. The reason for this usage is that Mahalanobis distance can detect normal to abnormal data from a series of multivariate data [37,38,39]. Alternatively, as described by [33], highlights and analysis outliers are observations that are left out of the known sample and are not consistent with the first sample of data clouding the primary analysis. This presents a wide range of applicability such as multivariate analysis techniques, classification techniques, clustering analysis, discriminant analysis, and goodness of fit tests, among others [33,37]. In the health system, it is used to classify Chronic Myeloid Leukemia neutrophils [40], studying circulating biomarkers like lipid metabolism, inflammation, and microbiome [41], or for calculating a symmetry metric from segmented NIR spectra [42]. It is also applied in environmental sciences by measuring data and identifying differences to quantify species–environment relationships [35], detecting damage effects on structural health monitoring [43], and detecting and measuring risk levels in the international energy market system [44].

It is differentiated from Euclidean distance by showing correlations and data distribution [33,37]. One of the functionalities presented in the literature is the Mahalanobis–Taguchi System, which is a forecasting method for detecting outliers from the mechanical state of a logistics system for potential failure prediction [45,46]. This can be used to distinguish between criteria selection for strategies within educational institutions [47], and as a forecasting method for consumer satisfaction for vehicle handling [33]. On the other hand, FAST-MCD has been applied in order to achieve a more accurate result with larger datasets [48], and a minimum covariance determinant is used as an approach for multivariate outliers’ detection [49]. Alternatively, Ref. [50] evaluates the resilience system through a TOPSIS model of weighted Mahalanobis distance or an ensemble method for unsupervised learning by applying three options: (1) univariate Mahalanobis distance, (2) Mahalanobis-square distance, and (3) local Mahalanobis-square distance.

As a multi-criteria decision-making (MCDM) tool, Mahalanobis distance facilitates an analysis of a decision matrix of a MCDM problem, such as green energy indicators and their measurements towards sustainable manufacturing in enterprises, as shown in Table 6.

Table 6.

Multi-criteria decision matrix.

In [12], the authors proposed three variants of the Mahalanobis distance as the secondary measurement distance for hierarchizing horizontal collaboration factors within the CODAS methodology. One of the variants, MDrv (Cov(_rij); ns), presented a higher proportion in concordance compared to the Taxicab distance and the other two MD variants proposed. From this point forward, this paper presents the Mahalanobis distance robust variant, MDrv (Cov(_rij); ns), for green energy indicators to reach sustainable manufacturing. As presented in [12], this paper follows a specific MCDM technique to determine green energy indicators and their measurements through hierarchical analysis within the sample to successfully carry out decision-making activity.

The Mahalanobis distance robust variant (Cov(_rij); ns) presented by [12] follows the Mahalanobis distance original equation (Equation 1), modifying the original terms as shown in Equation (2):

where:

- 4.

- represents the average of the aggregated matrix maximum score of the enterprises’ survey data;

- 5.

- C−1 is the transposed centered matrix;

- 6.

- represents the average of the aggregated matrix maximum score of the enterprises’ survey data.

So, the CODAS–Hamming–Mahalanobis methodology follows 8 steps, presented by [12], where Step 5 includes Hamming distance as the primary distance, as shown in Equation (3), and Mahalanobis distance as the secondary distance, as shown in Equation (2).

From the designed instrument to the data collection presented in Table 4 and Table 5, respectively, the decision makers from the participating companies responded using a Likert scale. To analyze the resulting scales from the 31 enterprises, an aggregated and normalized matrix was obtained from the enterprises’ evaluation, setting the maximum value criteria as shown in Table 7.

Table 7.

Aggregated decision matrix.

For the criterion’s weight calculation, the ambiguity reduction method was utilized to reduce the ambiguity of the values obtained from the enterprises through the AHP methodology, as presented by [12]. Using the formula , where γ represents the impact of the dimensional criterion weighting with respect to the decision makers; is the obtained weighting from the literature review for the critical dimension j; is the obtained weighting from the enterprises’ survey for the critical dimension j; is the AHP weighting for the critical criterion j; and is the ambiguity reduction weighting for the critical criterion . Table 8 displays the weighting values obtained.

Table 8.

Ambiguity reduction criteria assessment.

To obtain the a pair-wise comparison matrix was developed, and then a standardized autovector was generated to obtain wj, the normalized average value. The consistency index was calculated as , and the consistency ratio was given by , which is accepted when it is not greater than 10% of the random index (RI). The resulting CI and RI were obtained as 0.0166 and 5.8%, respectively, demonstrating the consistency index.

The process following each criterion evaluation value was taken from the CODAS–Hamming–Mahalanobis methodology proposed by [12], calculating the normalized decision matrix (Step 2), the weighted normalized decision matrix (Step 3), the negative ideal solution (Step 4), and the main (Hamming distance) and secondary (Mahalanobis distance (Cov(), )) measure (Step 5). This set of distance combinations was used to construct the relative evaluation matrix (Step 6), from which the preference score was obtained for each evaluated alternative (Step 7), and finally, the hierarchy of green energy indicators and their measurements was found (Step 8).

4. Results

Micro-, small, and mid-size enterprises (MSMEs) are well recognized worldwide as each country’s economic contribution [51,52,53], leading local innovation, skill, and distribution of goods and services [54]. Employing around 60% of the labor force and with a 50% average GDP share [55,56], MSMEs tend to become a workforce that complement large enterprises’ supply chains.

Overall, MSMEs represent a social and local synergy that drives job creation [57]. Nevertheless, we are in the middle of a globalized, rapidly changing supply chain in which there is an increase in the number of new enterprises, and customers have high expectations of quality, delivery, service, and the uniqueness of each product [58,59]. In addition, there are exceptions where major disruptions can affect and reduce demand from the market, such as the coronavirus pandemic [60] or climate change and environmental emissions caused by fossil-fuel usage [61]; MSMEs face challenging disruptions in enhancing sustainability in manufacturing processes within a global value chain.

By 2019, MSMEs from the OECD countries accounted for one in three people in a micro firm, and two out of three in an SME enterprise [57]. Figure 3 displays the OECD average of persons employed in MSMEs and large enterprises.

Figure 3.

Average of people employed in a MSMEs and large firms [21].

Through the 2008 economic crisis, MSMEs opened up through innovation and the era of digitalization, transforming their business models and supply chain production, facing challenges with technology adoption but gaining market share by adapting digital platforms as strategic resources and networks [57]. In 2020, facing the coronavirus outbreak, the whole business platform experienced great difficulties. Even though the digital era has aided certain business activities, the majority of economic activities have come to a halt. MSMEs, as the OECD describes, have experienced an impact that has been demonstrated in a few countries, as shown in Table 9, where some of these countries’ actual situations are displayed [60].

Table 9.

MSMEs situation through COVID-19 outbreak, across OECD countries [60].

Now, in 2024, MSMEs have been subject to more disrupting processes along the value chain, driven partly by climate change. As enterprises represent approximately 90% of each country’s economic units, they tend to have a significant footprint.

Overall, in regular times, passing through a pandemic outbreak, or dealing with threats of climate change such as natural disasters and extreme weather, MSMEs are still recognized as a labor force weight for all countries’ economies. As described above, MSMEs face everyday challenges from supply and demand sides to financial markets. The literature review displays strategies for enterprises to follow, such as effective supply chain management, technology information for timely handling of data, logistics systems to achieve product delivery, distribution and warehouse storage, and sustainable manufacturing [62,63,64]. Further strategies include analyzing the working environment, working on alliances, and cooperation among enterprises [10,51,65,66]; additionally, as the Organization of Economic and Cooperation Development describes it, MSMEs should develop and create joint strategies to achieve goals that individually are difficult to reach [67].

Of the 31 enterprises that responded to the survey, 70.96% represent MSMEs and 29.03% large enterprises. Seeing the importance for them to deploy sustainable manufacturing practices, to gain market shares and complement large enterprises’ supply chains, the survey analytic instrument shows the preference scores. From these preference scores, the authors obtained a hierarchy list of green energy indicators and their measurements and items, as shown in Table 10.

Table 10.

Top 10 green energy indicators and their measurements.

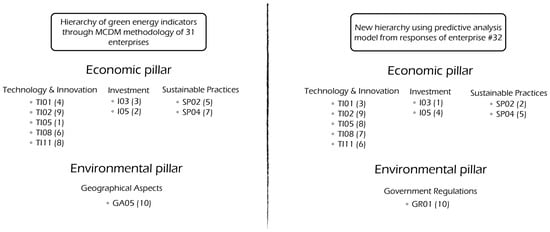

The resulting hierarchy was obtained from an MCDM methodology that took into account 31 decision-making entrepreneurs, within different goods and service sectors, located in the cities Chihuahua and Juarez. It also gives top 10 indicators for enterprises to focus on and start developing ideas and strategies for implementing changes towards sustainable manufacturing. New companies can delve into green energy indicators and their measurements and not know if the hierarchy applies to them; for these new cases, this paper proposes a linearity factor model for predictive analysis. Calculating the sum of the 31 companies from the green energy survey gives a total for each of the 50 items. From this point forward, an index score is obtained, as shown in Equation (4).

where Ps is equal to the preference score obtained from the CODAS–Hamming–Mahalanobis method, and s is equal to the sum of the Likert scale evaluation for each of the 50 items made by the panel. With this linearity factor model, each new company that desires to fill in the green energy survey can obtain their green energy indicators, which are hierarchized by this predictive model. This proposed linearity factor model is restricted by the following aspect: if the new responses obtained from several companies are higher than the 10% of the 31 businesses’ panel used for the primary evaluation, then the CODAS–Hamming–Mahalanobis method will have to be calculated again to obtain the green energy hierarchy. This restriction exists because if it is higher than 90%, the level of confidence will be affected. Table 11 shows the 32nd business that responded to the green energy survey on 24 April 2024, where the linearity factor model was applied, predicting the new green energy indicator hierarchy from the new enterprise’s perspective.

Table 11.

Predicting new indicators hierarchy through linearity factor model.

Comparing both top 10 tables, the sustainable manufacturing pillars remained unchanged, i.e., the economic pillar had nine indicators and the environmental pillar had one indicator. On the other hand, the green energy indicators changed in ranking, as the proposed predictive linearity factor model takes into account the enterprise’s evaluation within the preference score obtained from the CODAS–Hamming–Mahalanobis method.

5. Discussion

In Mexico, green energy resources represent just 9.74% of enterprises’ energy consumption. Policy makers are more focused on raising economic standards and maintaining their global position, so the implications of green energy are given little attention. From a managerial perspective, manufacturing businesses require a lot of change, but it is difficult for decision makers to focus on one or two strategies towards a sustainable manufacturing approach.

The literature presents research from a variety of perspectives regarding green energy definition, usage, implementation, and infrastructure. Riosvelasco et al. [21] propose a literature review using a PRISMA 2020 methodology, focused on identifying green energy indicators and their measurements. From the obtained final list, previously shown in Table 1, the following are identified as the more frequent indicators and their measurements: six green energy indicators were established, with a total of 18 measurements and 50 items.

From a previous research proposal using an MCDM method, the CODA–Hamming–Mahalanobis methodology was applied to hierarchize the 50-item list from an enterprise’s perspective according to the Likert Scale importance they gave to each green energy indicator and their measurements. From the 50-item list, the top 10 green energy indicators are focused on two of the sustainable manufacturing pillars: nine indicators from the economic pillar and one indicator from the environmental pillar, as shown in Table 12.

Table 12.

Green energy hierarchy using the CODAS–Hamming–Mahalanobis method.

It can be observed that 90% of the top 10 items are categorized under the economic pillar for sustainable manufacturing. As described by [68], sustainability takes into account “…the transformation of resources into economically valuable goods…”; that is to say, businesses can gain by rethinking specific actions that will boost economic behavior, such as optimizing material and energy usage and creating production processes that can be maintained by themselves, among other characteristics [69]. The green energy indicators identified are focused on initiatives such as protecting innovation through IP, dynamic collaboration between supply chain members to implement technology, engineering relying on information, and encouraging human and natural resources towards a sustainable manufacturing environment, among others. Nevertheless, it gives a comprehensive approach to decision makers to organize and manage small projects within actual procedures to create a sustainable culture in the supply chain and in their business, allowing decision makers to take a specific course of action.

Furthermore, the authors propose a predictive analysis model whereby the preference score is taken into account to calculate the index score for new enterprises to evaluate important green energy indicators, and to obtain their ranking of items to deploy specific green energy practices toward sustainable manufacturing. The EM-32’s prediction on the green energy hierarchy presented a new ranking in items, such as identifying areas of opportunity to upgrade equipment for efficient use of energy and designing production processes to avoid waste, among other practices. Both hierarchized lists are represented in Figure 4. From the sustainable manufacturing pillars, it can be observed that enterprises are more focused on the economic pillar, which takes into account actions such as product cost, business model, and consumption of resources, among others.

Figure 4.

Resulting top 10 hierarchy list from an MCDM methodology and a predictive analysis model.

6. Conclusions

Sustainable manufacturing is happening globally, and nowadays, it affects enterprises in developing or emerging countries due to the lack of systemic procedures and finite strategies for green energy implementation. As mentioned by [68], enterprises know about sustainable manufacturing but do not necessarily know how to deploy specific practices. Our research has contributed a literature review on green energy, in which a hierarchized top 10 list was not found in research, especially from enterprises’ perspectives by grading green energy indicators. The following research proposes two models to hierarchize and predict a top 10 list of green energy indicators, measurements, and their items to incentivize decision makers to deploy specific actions and initiatives in their supply chain towards a sustainable manufacturing culture. From the results obtained from the green energy indicators, measurements, and items survey, it is concluded that enterprises search for initiatives from the economic pillar of sustainable manufacturing, giving priority to those focused on deploying actions towards equipment, machinery, and production processes for the efficient use of energy. In addition to this, they seek to collaborate with research centers or universities for the development of practices and designs of new production processes to avoid waste. Not least, they choose to use photovoltaic solar energy as a source of their everyday processes. Besides these results, this article proposes a linearity factor model as a predictive analysis to allow new enterprises to respond to the survey and obtain their hierarchy in green energy indicators, measurements, and items.

7. Implications and Future Research

Future research on the effects of green energy indicators, measurements, and items is required. Research could extend to empirical studies or case studies, in addition to introducing the development of standards or metrics of performance for each of the top 10 items. This field presents opportunities for future understanding and deployment of specific initiatives for the industrial field. The survey presented in this paper could be broadened to include Mexico’s north zone, including the United States, by translating the questionnaire. Moreover, it could include a Gaussian process regression model as the predictive analysis model.

Author Contributions

Conceptualization, G.E.R.-M., I.J.C.P.-O. and S.N.-M.; methodology, G.E.R.-M., I.J.C.P.-O. and L.A.P.-D.; software, G.E.R.-M.; validation, I.J.C.P.-O., L.A.P.-D., L.C.M.-G. and L.A.R.-P.; formal analysis, S.N.-M.; investigation, G.E.R.-M.; resources, G.E.R.-M., I.J.C.P.-O., L.A.P.-D., L.C.M.-G. and L.A.R.-P.; data curation, G.E.R.-M.; writing—original draft preparation, G.E.R.-M.; writing—review and editing, G.E.R.-M., I.J.C.P.-O. and S.N.-M.; visualization, S.N.-M., L.A.P.-D., L.C.M.-G. and L.A.R.-P.; supervision, I.J.C.P.-O. and S.N.-M.; project administration, G.E.R.-M. and I.J.C.P.-O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Survey URL https://energiasverdes.limesurvey.net/686967?lang=es (accessed on 8 May 2024).

Acknowledgments

Special thanks for the support from Cluster de Energía Chihuahua (CECH) and Cámara Nacional de la Industria y la Transformación, North Zone (CANACINTRA) for their initiative to share the green energy survey with their members.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sotelo, C.K.C.; Cotón, S.G.H.; Salamanca, P.I.M. La innovación y su interrelación con la competitividad. Sector manufacturero de la zona metropolitana de Guadalajara. Red Int. Investig. Compet. 2018, 8, 1–21. Available online: https://riico.net/index.php/riico/article/view/1164/832 (accessed on 8 May 2024).

- García, M.A.B.; Romero, E.D.; Mena, R.S.A.; López, N.A.S. La innovación y su influencia en el servicio al cliente en la industria del vestido de Puebla, México. Rev. Int. Adm. Finanz. 2018, 11, 21–37. Available online: http://www.theibfr2.com/RePEc/ibf/riafin/riaf-v11n4-2018/RIAF-V11N4-2018-3.pdf (accessed on 8 May 2024).

- Emenike, S.N.; Falcone, G. A review on energy supply chain resilience through optimization. In Renewable and Sustainable Energy Reviews; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; Volume 134. [Google Scholar] [CrossRef]

- Riosvelasco-Monroy, G.E.; Flores-Amador, J.; Pérez-Olguín, I.J.C. Gestión del Conocimiento a través de la Colaboración Horizontal en el Clúster MACH Knowledge transfer through a Horizontal Collaboration in Cluster MACH. Rev. Int. Investig. E Innovación Tecnológica 2019, 7, 1–22. Available online: https://riiit.com.mx/ojs/index.php/riiit/article/view/93 (accessed on 8 May 2024).

- Yu, S.; Liu, J.; Hu, X.; Tian, P. Does development of renewable energy reduce energy intensity? Evidence from 82 countries. Technol. Forecast. Soc. Change 2022, 174, 121254. [Google Scholar] [CrossRef]

- Choy, C.S.; Yew, W.K.; Lin, B. Criteria for measuring KM performance outcomes in organisations. Ind. Manag. Data Syst. 2006, 106, 917–936. [Google Scholar] [CrossRef]

- Maldonado-Guzmán, G.; Garza-Reyes, J.A.; Pinzón-Castro, S.Y.; Kumar, V. Barriers to innovation in service SMEs: Evidence from Mexico. Ind. Manag. Data Syst. 2017, 117, 1669–1686. [Google Scholar] [CrossRef]

- Hernández, A.S. Factores Relevantes De Competitividad En Pymes. Eur. Sci. J. ESJ 2018, 14, 193. [Google Scholar] [CrossRef]

- Merritt, H. Mexican Technology Based Firms and their Capacity for Innovation: A methodological proposal. Trayectorias 2012, 14, 33–34. [Google Scholar]

- Tobiassen, A.E.; Pettersen, I.B. Exploring open innovation collaboration between SMEs and larger customers. Balt. J. Manag. 2018, 13, 65–83. [Google Scholar] [CrossRef]

- Rashid, S.H.A.; Evans, S.; Longhurst, P. A comparison of four sustainable manufacturing strategies. Int. J. Sustain. Eng. 2008, 1, 214–229. [Google Scholar] [CrossRef]

- Riosvelasco-Monroy, G.E.; Perez-Olguín, I.J.C.; Flores-Amador, J.; Pérez-Domínguez, L.A.; Hernández-Gómez, J.A. Horizontal Collaboration Business Model towards a Sustainable I4.0 Value Creation. In Sustainable Manufacturing in Industry 4.0: Pathways and Practices; Gholami, H., Abdul-Nour, G., Sharif, S., Streimikiene, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar] [CrossRef]

- Melo, D.I.C.; Queiroz, G.A.; Junior, P.N.A.; de Sousa, T.B.; Yushimito, W.F.; Pereira, J. Sustainable digital transformation in small and medium enterprises (SMEs): A review on performance. In Heliyon; Elsevier Ltd.: Amsterdam, The Netherlands, 2023; Volume 9. [Google Scholar] [CrossRef]

- Patalas-Maliszewska, J.; Łosyk, H. An approach to assessing sustainability in the development of a manufacturing company. Sustainability 2020, 12, 8787. [Google Scholar] [CrossRef]

- Niewiadomski, P.; Stachowiak, A. Identification of Barriers to Sustainable Manufacturing Implementation—The Perspective of Manufacturers of Parts and Components for Agricultural Transport. Sustainability 2024, 16, 2244. [Google Scholar] [CrossRef]

- Kuś, A.; Grego-Planer, D. A model of innovation activity in small enterprises in the context of selected financial factors: The example of the renewable energy sector. Energies 2021, 14, 2926. [Google Scholar] [CrossRef]

- Shankar, K.M.; Kannan, D.; Kumar, P.U. Analyzing sustainable manufacturing practices—A case study in Indian context. J. Clean Prod. 2017, 164, 1332–1343. [Google Scholar] [CrossRef]

- Polcyn, J.; Us, Y.; Lyulyov, O.; Pimonenko, T.; Kwilinski, A. Factors influencing the renewable energy consumption in selected european countries. Energies 2022, 15, 108. [Google Scholar] [CrossRef]

- Zastempowski, M. Analysis and modeling of innovation factors to replace fossil fuels with renewable energy sources—Evidence from European Union enterprises. Renew. Sustain. Energy Rev. 2023, 178, 113262. [Google Scholar] [CrossRef]

- Neri, A.; Cagno, E.; Lepri, M.; Trianni, A. A triple bottom line balanced set of key performance indicators to measure the sustainability performance of industrial supply chains. Sustain. Prod. Consum. 2021, 26, 648–691. [Google Scholar] [CrossRef]

- Monroy, G.E.R.; Rojas-Ramírez, A.; Noriega-Morales, S. Sustainable practices for the efficient use of green energy in Ciudad Juárez SMEs. Rev. Cienc. Tecnológicas 2023, 6, e265. [Google Scholar] [CrossRef]

- Fatima, Z.; Oksman, V.; Lahdelma, R. Enabling small medium enterprises (Smes) to become leaders in energy efficiency using a continuous maturity matrix. Sustainability 2021, 13, 10108. [Google Scholar] [CrossRef]

- Riosvelasco-Monroy, G.E.; Pérez-Olguín, I.J.C.; Pérez-Domínguez, L.A.; Méndez-González, L.C.; Noriega-Morales, S. Application of the COHRV Conceptual Framework to Enhance Sustainable Manufacturing. Sustainability 2022, 14, 16804. [Google Scholar] [CrossRef]

- Rosen, M.A.; Kishawy, H.A. Sustainable manufacturing and design: Concepts, practices and needs. Sustainability 2012, 4, 154–174. [Google Scholar] [CrossRef]

- Alegre-Vidal, J.; Lapiedra-Alcamí, R.; Chiva-Gómez, R. Linking operations strategy and product innovation: An empirical study of Spanish ceramic tile producers. Res. Policy 2004, 33, 829–839. [Google Scholar] [CrossRef]

- Hariyani, D.; Mishra, S.; Hariyani, P.; Sharma, M.K. Drivers and motives for sustainable manufacturing system. Innov. Green Dev. 2023, 2, 100031. [Google Scholar] [CrossRef]

- Saxena, P.; Stavropoulos, P.; Kechagias, J.; Salonitis, K. Sustainability assessment for manufacturing operations. Energies 2020, 13, 2730. [Google Scholar] [CrossRef]

- Hariyani, D.; Mishra, S. Organizational enablers for sustainable manufacturing and industrial ecology. Clean. Eng. Technol. 2022, 6, 100375. [Google Scholar] [CrossRef]

- Khan, I.S.; Ahmad, M.O.; Majava, J. Industry 4.0 and sustainable development: A systematic mapping of triple bottom line, Circular Economy and Sustainable Business Models perspectives. J. Clean. Prod. 2021, 297, 126655. [Google Scholar] [CrossRef]

- Nezami, F.G.; Yildirim, M.B. A sustainability approach for selecting maintenance strategy. Int. J. Sustain. Eng. 2013, 6, 332–343. [Google Scholar] [CrossRef]

- Mengistu, A.T.; Dieste, M.; Panizzolo, R.; Biazzo, S. Sustainable product design factors: A comprehensive analysis. J. Clean. Prod. 2024, 142260. [Google Scholar] [CrossRef]

- Mahalanobis, P.C. On the Generalized Distance in Statistics. J. Asiat. Soc. Bengal. 1930, XXVI, 49–55. [Google Scholar]

- Cudney, E.A.; Paryani, K.; Ragsdell, M.K. Applying the Mahalanobis-Taguchi system to vehicle handling. Concurr. Eng. Res. Appl. 2006, 14, 343–354. [Google Scholar] [CrossRef]

- Detwal, P.K.; Soni, G.; Jakhar, S.K.; Shrivastava, D.K.; Madaan, J.; Kayikci, Y. Machine learning-based technique for predicting vendor incoterm (contract) in global omnichannel pharmaceutical supply chain. J. Bus. Res. 2023, 158, 113688. [Google Scholar] [CrossRef]

- Etherington, T.R. Mahalanobis distances for ecological niche modelling and outlier detection: Implications of sample size, error, and bias for selecting and parameterising a multivariate location and scatter method. PeerJ 2021, 9, e11436. [Google Scholar] [CrossRef] [PubMed]

- Pronzato, L.; Wynn, H.P.; Zhigljavsky, A.A. Simplicial variances, potentials and Mahalanobis distances. J. Multivar. Anal. 2018, 168, 276–289. [Google Scholar] [CrossRef]

- Ghorbani, H. Mahalanobis distance and its application for detecting multivariate outliers. Facta Univ. Ser. Math. Inform. 2019, 34, 583. [Google Scholar] [CrossRef]

- Sarmadi, H.; Entezami, A.; Razavi, B.S.; Yuen, K.V. Ensemble learning-based structural health monitoring by Mahalanobis distance metrics. Struct. Control. Health Monit. 2021, 28, e2663. [Google Scholar] [CrossRef]

- Yao, L.; Lin, T.B. Evolutionary mahalanobis distance–based oversampling for multi-class imbalanced data classification. Sensors 2021, 21, 6616. [Google Scholar] [CrossRef] [PubMed]

- Panda, A.; Pachori, R.B.; Sinnappah-Kang, N.D. Classification of chronic myeloid leukemia neutrophils by hyperspectral imaging using Euclidean and Mahalanobis distances. Biomed. Signal Process. Control. 2021, 70, 103025. [Google Scholar] [CrossRef]

- Flores-Guerrero, J.L.; Grzegorczyk, M.A.; Connelly, M.A.; Garcia, E.; Navis, G.; Dullaart, R.P.; Bakker, S.J. Mahalanobis distance, a novel statistical proxy of homeostasis loss is longitudinally associated with risk of type 2 diabetes. EBioMedicine 2021, 71, 103550. [Google Scholar] [CrossRef]

- Huo, J.; Ma, Y.; Lu, C.; Chenggang, L.; Kun, D.; Huaiqi, L. Mahalanobis distance based similarity regression learning of NIRS for quality assurance of tobacco product with different variable selection methods. Spectrochim. Acta. A Mol. Biomol. Spectrosc vol. 2021, 251, 119364. [Google Scholar] [CrossRef] [PubMed]

- Mousavi, M.; Gandomi, A.H. Structural health monitoring under environmental and operational variations using MCD prediction error. J. Sound Vib. 2021, 512, 116370. [Google Scholar] [CrossRef]

- Xiong, S.; Chen, W. A robust hybrid method using dynamic network analysis and Weighted Mahalanobis distance for modeling systemic risk in the international energy market. Energy Econ. 2022, 109, 105954. [Google Scholar] [CrossRef]

- Asakura, T.; Yashima, W.; Suzuki, K.; Shimotou, M. Anomaly detection in a logistic operating system using the mahalanobis-taguchi method. Appl. Sci. 2020, 10, 4376. [Google Scholar] [CrossRef]

- Chang, Z.P.; Li, Y.W.; Fatima, N. A theoretical survey on Mahalanobis-Taguchi system. Meas. J. Int. Meas. Confed. 2019, 136, 501–510. [Google Scholar] [CrossRef]

- Hadighi, S.A.; Sahebjamnia, N.; Mahdavi, I.; Asadollahpour, H.; Shafieian, H. Mahalanobis-Taguchi System-based criteria selection for strategy formulation: A case in a training institution. J. Ind. Eng. Int. 2013, 9, 26. [Google Scholar] [CrossRef]

- Qiu, Z.; Zhou, B.; Yuan, J. Protein–protein interaction site predictions with minimum covariance determinant and Mahalanobis distance. J. Theor. Biol. 2017, 433, 57–63. [Google Scholar] [CrossRef] [PubMed]

- Leys, C.; Klein, O.; Dominicy, Y.; Ley, C. Detecting multivariate outliers: Use a robust variant of the Mahalanobis distance. J. Exp. Soc. Psychol. 2018, 74, 150–156. [Google Scholar] [CrossRef]

- Liu, D.; Qi, X.; Fu, Q.; Li, M.; Zhu, W.; Zhang, L.; Faiz, M.A.; Khan, M.I.; Li, T.; Cui, S. A resilience evaluation method for a combined regional agricultural water and soil resource system based on Weighted Mahalanobis distance and a Gray-TOPSIS model. J. Clean Prod. 2019, 229, 667–679. [Google Scholar] [CrossRef]

- Agostini, L.; Nosella, A. Inter-organizational relationships involving SMEs: A bibliographic investigation into the state of the art. Long Range Plan. 2019, 52, 1–31. [Google Scholar] [CrossRef]

- Farzin, F. Localising the impact of techno-entrepreneurship in Eastern Iran: Birjand’s Science and Technology Park as a local innovation community. Local Econ. J. Local Econ. Policy Unit 2017, 32, 692–710. [Google Scholar] [CrossRef]

- Méndez, L.H.; Villalobos, K.J.O.; Méndez, O.J.M. Perfil operativo de las PYME juarenses. novaRua 2014, 4, 14–25. Available online: http://148.210.132.19/ojs/index.php/NovaRua/article/view/304 (accessed on 8 May 2024). [CrossRef]

- María, L.; Torrejón, P.; Sánchez, L.C. Factores que impactan en la competitividad de la micro y pequeña empresa: Municipio de Huejotzingo Puebla. Red Int. De Investig. En Compet. 2016, 1035–1049. Available online: https://riico.net/index.php/riico/article/view/1361/1031 (accessed on 8 May 2024).

- OCDE. Financiamiento de PyMes y Emprendedores 2018: Un Marcador de la OCDE; OCDE: Paris, France, 2018. [Google Scholar]

- Valdés, J.; Sánchez, G. Las Pymes en el contexto mundial: Sus particularidades en méxico. Iberóforum. Revista de Ciencias Sociales de la Universidad Iberoamericana 2012, VII, 126–156. [Google Scholar]

- OECD. OECD SME and Entrepreneurship Outlook 2019; OECD: Paris, France, 2019. [Google Scholar] [CrossRef]

- Jaharuddin, N.S.; Mansor, Z.D.; Yaakob, S. Assessing the Supply Chain Intelligence Practices of Small Medium Enterprises in Malaysia. Procedia Econ. Financ. 2016, 35, 515–521. [Google Scholar] [CrossRef]

- Sablón-Cossío, N.; Medina-León, A.; Acevedo-Suárez, J.A.; Acevedo-Urquiaga, A.J.; López-Joy, T. Consideraciones sobre la planificación de productos alimenticios en una cadena de suministro comercial. Ing. Ind. 2013, 34, 353–362. [Google Scholar]

- OECD. Financing SMEs and Entrepreneurs 2020: An OECD Scoreboard; OCDE: Paris, France, 2020. [Google Scholar]

- Ali, W.; Gohar, R.; Chang, B.H.; Wong, W.-K. Revisiting the impacts of globalization, renewable energy consumption, and economic growth on environmental quality in South Asia. Adv. Decis. Sci. 2022, 26, 1–23. [Google Scholar]

- Colin, M.; Galindo, R.; Hernández, O. Information and Communication Technology as a Key Strategy for Efficient Supply Chain Management in Manufacturing SMEs. Procedia Comput. Sci. 2015, 55, 833–842. [Google Scholar] [CrossRef]

- Kumar, M.; Raman, J.; Priya. A Supply Chain Collaboration Model for Product Development with R&D Subsidies. J. Supply Chain Manag. Syst. 2015, 4. [Google Scholar] [CrossRef]

- Sarkis, J.; Gonzalez, E.D.S.; Koh, S.C.L. Effective multi-tier supply chain management for sustainability. Int. J. Prod. Econ. 2019, 217, 1–10. [Google Scholar] [CrossRef]

- Pfeifer, S.; Peterka, S.O.; Stanić, M. Business models of micro businesses: Empirical evidence from creative industries. J. Contemp. Manag. 2017, 22, 1–19. [Google Scholar]

- Xue, X.; Wang, S.; Lu, B. Manufacturing service composition method based on networked collaboration mode. J. Netw. Comput. Appl. 2016, 59, 28–38. [Google Scholar] [CrossRef]

- OCDE. Economy Raising Productivity in Small Traditional Enterprises. 2017. Available online: https://www.oecd.org/mexico/mexico-raising-productivity-in-small-traditional-enterprises.pdf (accessed on 8 May 2024).

- Sartal, A.; Bellas, R.; Mejías, A.M.; García-Collado, A. The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review. Adv. Mech. Eng. 2020, 12, 1687814020925232. [Google Scholar] [CrossRef]

- Athamneh, M.H.A.; Al-Ajlouni, M.M. Unleashing the Power of Green: Sustainable Success through HRM, Supply Chains, and Innovation—A Comprehensive Review of Literature. Management 2024, 1, 73–105. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).