Digital Twin Implementation in Additive Manufacturing: A Comprehensive Review

Abstract

1. Introduction

2. The State of the Art

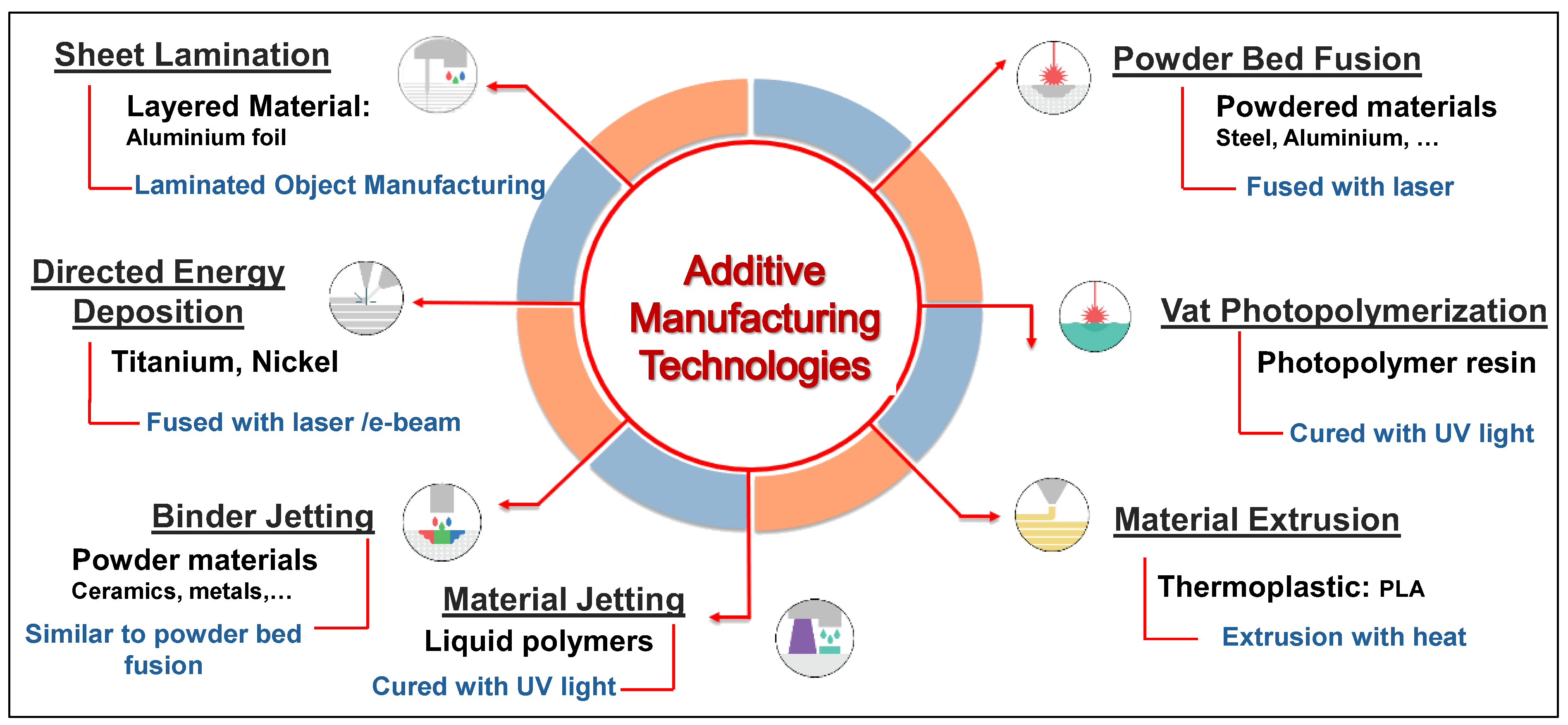

2.1. Additive Manufacturing

2.2. Digital Twin

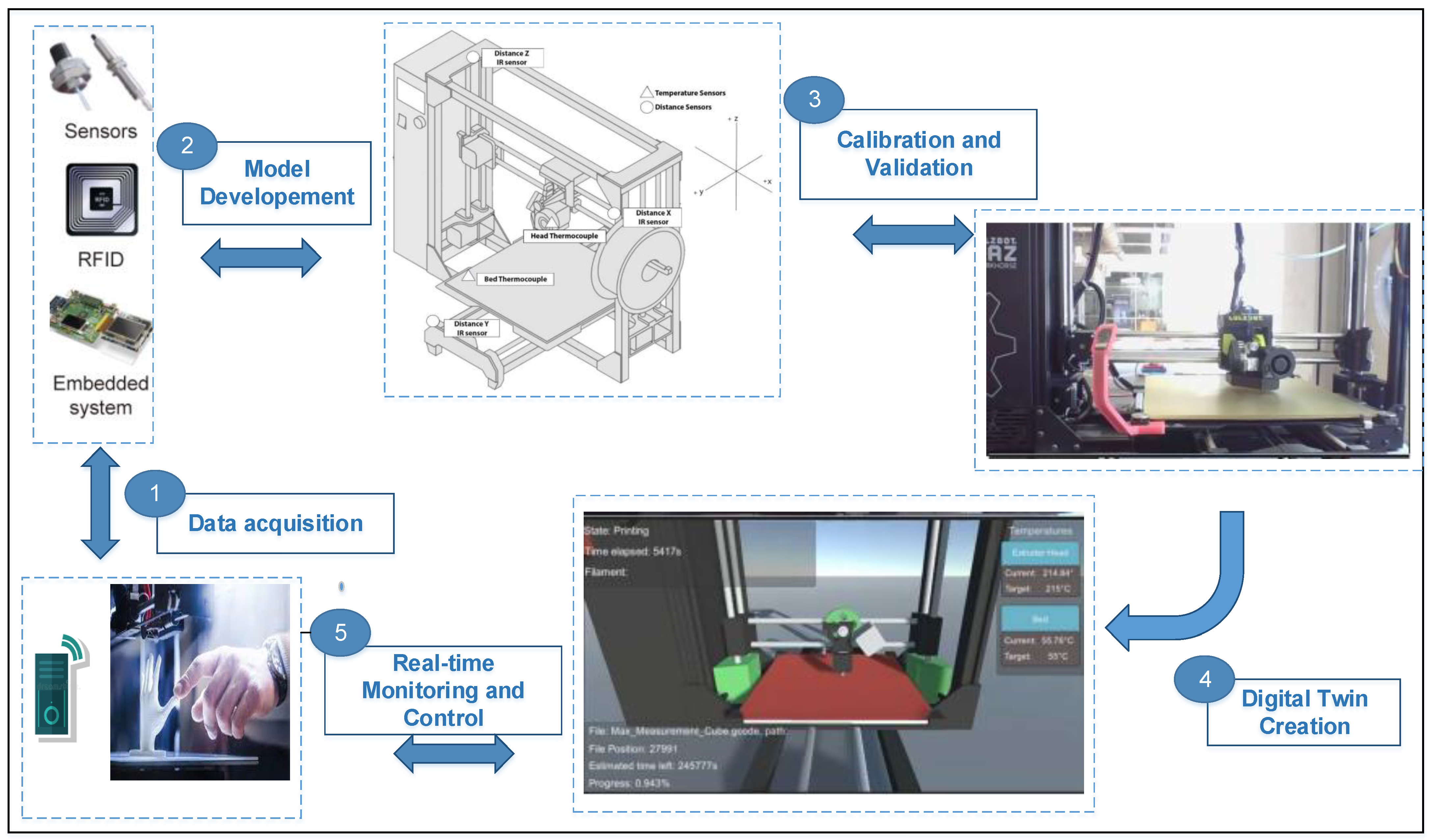

3. The Hierarchy for Building a DT System for the AM Process

3.1. Data Acquisition

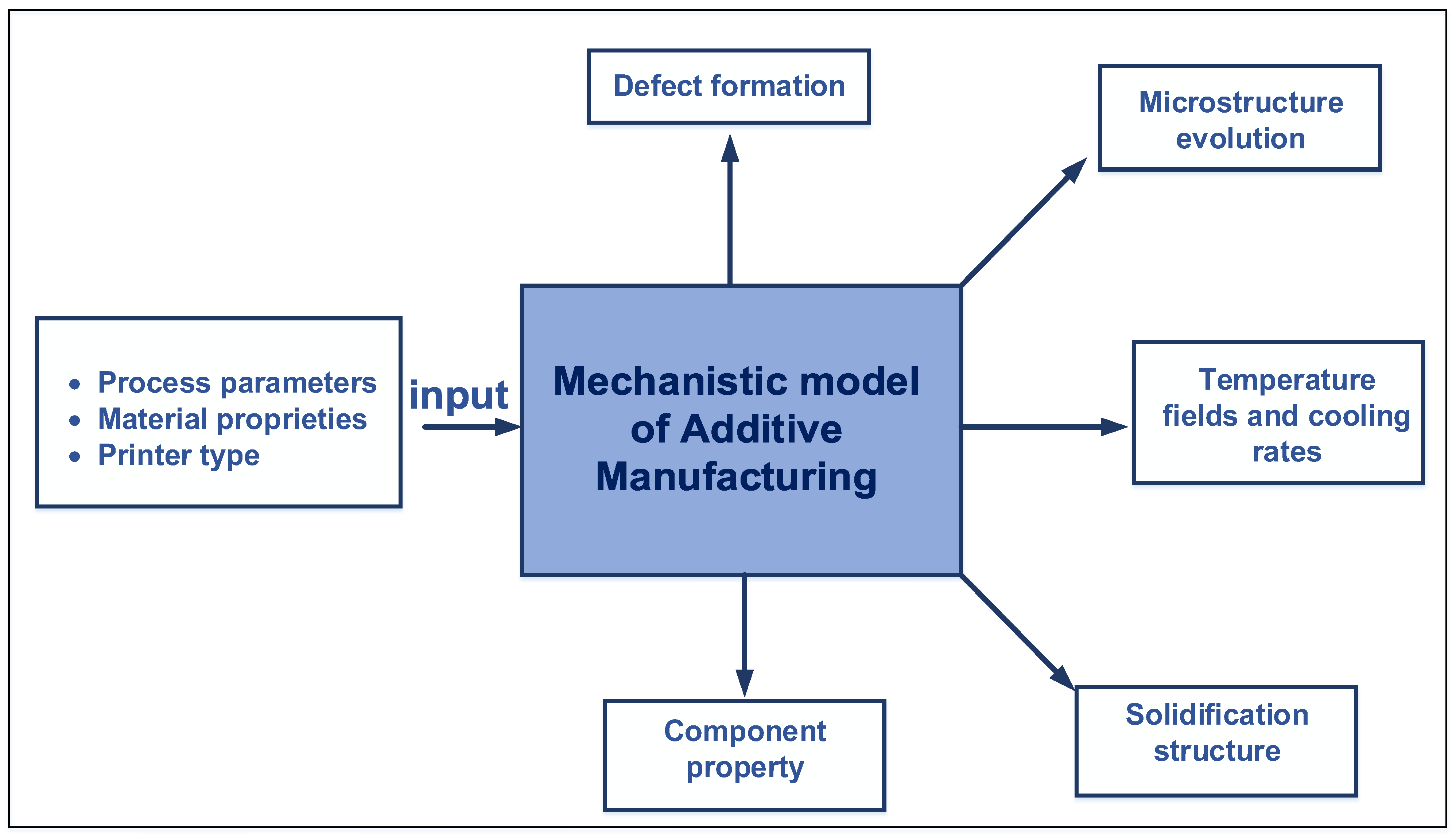

3.2. Model Development

3.3. Calibration and Validation

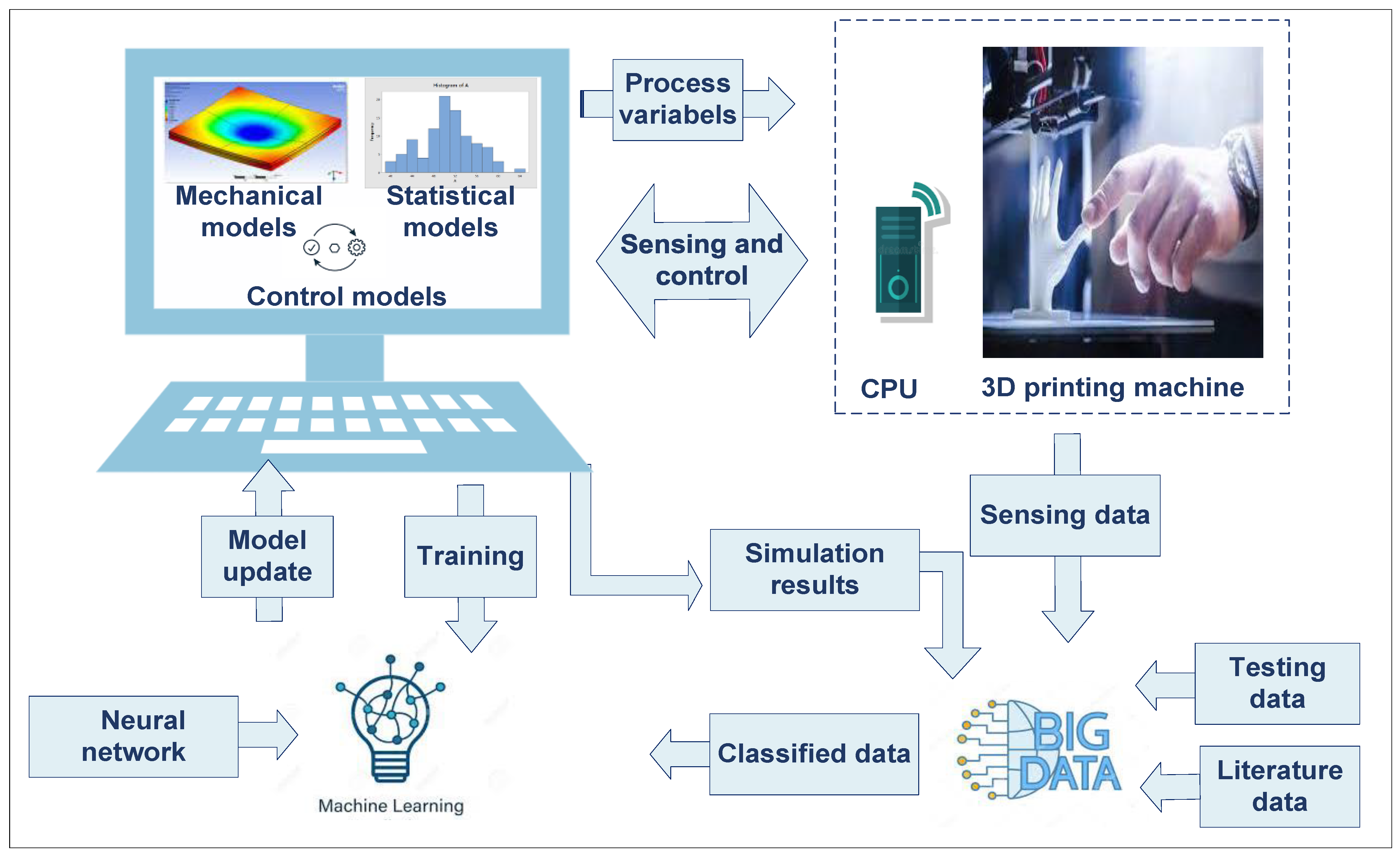

3.4. Digital Twin Creation

3.5. Real-Time Surveillance and Management

4. The Development of Digital Twins for the AM Process

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qin, Y.; Qi, Q.; Shi, P.; Scott, P.J.; Jiang, X. Status, issues, and future of computer-aided part orientation for additive manufacturing. Int. J. Adv. Manuf. Technol. 2021, 115, 1295–1328. [Google Scholar] [CrossRef]

- Ben Amor, S.; Tahan, A.; Louhichi, B. Proposition of a Geometric Complexity Model for Additive Manufacturing Process Based on CAD. In Proceedings of the IEEE 2019 23rd International Conference Information Visualisation (IV), Paris, France, 2–5 July 2019; pp. 442–448. [Google Scholar] [CrossRef]

- Shimamura, T.F.; Timper, D.A. Feasibility Study of Digital Twin for Additive Manufacturing from the Perspective of Resource Efficiency; Degree Project in Technology: Stockholm, Sweden, 2021. [Google Scholar]

- Tambrallimath, V.; Keshavamurthy, R. Glimpses of 3D Printing in the 21st Century; IGI Global: Hershey, PN, USA, 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Ben Amor, S.; Tahan, A.; Louhichi, B. The Impact of Geometric Complexity on Printing Time and Cost for Additive Manufacturing (AM) Process. In Advances in Mechanical Engineering and Mechanics II. CoTuMe 2021; Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2022; pp. 203–210. [Google Scholar] [CrossRef]

- Pant, M.; Pidge, P.; Nagdeve, L.; Kumar, H. A Review of Additive Manufacturing in Aerospace Application. Rev. Des. Compos. Des. Matériaux Avancés 2021, 31, 109–115. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Jacoby, M.; Usländer, T. Digital Twin and Internet of Things—Current Standards Landscape. Appl. Sci. 2020, 10, 6519. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Mourtzis, D. Digital Twins in Industry 4.0. Design and Operation of Production Networks for Mass Personalization in the Era of Cloud Technology; Elsevier: Amsterdam, The Netherlands, 2022; pp. 277–316. [Google Scholar] [CrossRef]

- Ahuett-Garza, H.; Kurfess, T. A brief discussion on the trends of habilitating technologies for Industry 4.0 and Smart manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Pantelidakis, M.; Mykoniatis, K.; Liu, J.; Harris, G. A digital twin ecosystem for additive manufacturing using a real-time development platform. Int. J. Adv. Manuf. Technol. 2022, 120, 6547–6563. [Google Scholar] [CrossRef] [PubMed]

- Duman, B.; Süzen, A.A. Modeling of IOT-based additive manufacturing machine’s digital twin for error detection. Mühendislik Bilimleri ve Tasarım Dergisi 2023, 11, 486–497. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, X.; Zhou, W.; Cheng, T.; Chen, L.; Guo, Z.; Han, B.; Lu, L. Digital Twins for Additive Manufacturing: A State-of-the-Art Review. Appl. Sci. 2020, 10, 8350. [Google Scholar] [CrossRef]

- Song, J.; Chew, Y.; Jiao, L.; Yao, X.; Moon, S.K.; Bi, G. Numerical study of temperature and cooling rate in selective laser melting with functionally graded support structures. Addit. Manuf. 2018, 24, 543–551. [Google Scholar] [CrossRef]

- Loh, L.-E.; Song, J.; Guo, F.; Bi, G. Analytical Solution of Temperature Distribution in a Nonuniform Medium Due to a Moving Laser Beam and a Double Beam Scanning Strategy in the Selective Laser Melting Process. J. Heat Transf. 2018, 140, 082302. [Google Scholar] [CrossRef]

- Song, J.; Chew, Y.; Bi, G.; Yao, X.; Zhang, B.; Bai, J.; Moon, S.K. Numerical and experimental study of laser aided additive manufacturing for melt-pool profile and grain orientation analysis. Mater. Des. 2018, 137, 286–297. [Google Scholar] [CrossRef]

- Ren, K.; Chew, Y.; Zhang, Y.F.; Fuh, J.Y.H.; Bi, G.J. Thermal field prediction for laser scanning paths in laser aided additive manufacturing by physics-based machine learning. Comput. Methods Appl. Mech. Eng. 2020, 362, 112734. [Google Scholar] [CrossRef]

- Ren, K.; Chew, Y.; Zhang, Y.F.; Bi, G.J.; Fuh, J.Y.H. Thermal analyses for optimal scanning pattern evaluation in laser aided additive manufacturing. J. Mater. Process Technol. 2019, 271, 178–188. [Google Scholar] [CrossRef]

- Ren, K.; Chew, Y.; Fuh, J.Y.H.; Zhang, Y.F.; Bi, G.J. Thermo-mechanical analyses for optimized path planning in laser aided additive manufacturing processes. Mater. Des. 2019, 162, 80–93. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Digital twin for smart manufacturing, A review. Sustain. Manuf. Serv. Econ. 2023, 2, 100017. [Google Scholar] [CrossRef]

- Jyeniskhan, N.; Shaimergenova, K.; Ali, M.H.; Shehab, E. Digital Twin for Additive Manufacturing: Challenges and Future Research Direction. In Proceedings of the 2023 IEEE International Conference on Smart Information Systems and Technologies (SIST), Astana, Kazakhstan, 4–6 May 2023; pp. 337–342. [Google Scholar] [CrossRef]

- Gaikwad, A.; Yavari, R.; Montazeri, M.; Cole, K.; Bian, L.; Rao, P. Toward the digital twin of additive manufacturing: Integrating thermal simulations, sensing, and analytics to detect process faults. IISE Trans. 2020, 52, 1204–1217. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Scheffel, R.M.; Fröhlich, A.A.; Silvestri, M. Automated fault detection for additive manufacturing using vibration sensors. Int. J. Comput. Integr. Manuf. 2021, 34, 500–514. [Google Scholar] [CrossRef]

- DebRoy, T.; Zhang, W.; Turner, J.; Babu, S.S. Building digital twins of 3D printing machines. Scr. Mater. 2017, 135, 119–124. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Paraskevoudis, K.; Karayannis, P.; Koumoulos, E.P. Real-Time 3D Printing Remote Defect Detection (Stringing) with Computer Vision and Artificial Intelligence. Processes 2020, 8, 1464. [Google Scholar] [CrossRef]

- Ben Amor, S.; Zongo, F.; Eltaief, A.; Maatki, A.; Louhichi, B.; Tahan, A. A new method to select optimal part building orientation for additive manufacturing processes based on geometric complexity and heat shrinkage. Prog. Addit. Manuf. 2023, 8, 211–222. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- ISO/ASTM. Additive Manufacturing—General Principles Terminology (ASTM52900); Rapid Manufacturing Association: Anaheim, CA, USA, 2013; pp. 10–12. [Google Scholar]

- Lee, B.N.; Pei, E.; Um, J. An overview of information technology standardization activities related to additive manufacturing. Prog. Addit. Manuf. 2019, 4, 345–354. [Google Scholar] [CrossRef]

- Steenhuis, H.-J.; Pretorius, L. The additive manufacturing innovation: A range of implications. J. Manuf. Technol. Manag. 2017, 28, 122–143. [Google Scholar] [CrossRef]

- Tambrallimath, V.; Keshavamurthy, R.; Davim, P.; Kumar, G.P.; Pignatta, G.; Badari, A.; Khan, T.Y.; Badruddin, I.A. Synthesis and characterization of flyash reinforced polymer composites developed by Fused Filament Fabrication. J. Mater. Res. Technol. 2022, 21, 810–826. [Google Scholar] [CrossRef]

- Montez, M.; Willis, K.; Rendler, H.; Marshall, C.; Rubio, E.; Rajak, D.K.; Rahman, M.H.; Menezes, P.L. Fused deposition modeling (FDM): Processes, material properties, and applications. In Tribology of Additively Manufactured Materials; Elsevier: Amsterdam, The Netherlands, 2022; pp. 137–163. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Slemenik Perše, L.; Nanni, F. Advancements in Metal Additive Manufacturing: A Comprehensive Review of Material Extrusion with Highly Filled Polymers. J. Manuf. Mater. Process. 2024, 8, 14. [Google Scholar] [CrossRef]

- Wang, W.; Li, Z.; Gao, X.; Huang, Y.; He, R. Material extrusion 3D printing of large-scale SiC honeycomb metastructure for ultra-broadband and high temperature electromagnetic wave absorption. Addit. Manuf. 2024, 85, 104158. [Google Scholar] [CrossRef]

- Elkaseer, A.; Chen, K.J.; Janhsen, J.C.; Refle, O.; Hagenmeyer, V.; Scholz, S.G. Material jetting for advanced applications: A state-of-the-art review, gaps and future directions. Addit. Manuf. 2022, 60, 103270. [Google Scholar] [CrossRef]

- Sarila, V.; Koneru, H.P.; Pyatla, S.; Cheepu, M.; Kantumunchu, V.C.; Ramachandran, D. An Overview on 3D Printing of Ceramics Using Binder Jetting Process. Eng. Proc. 2024, 61, 44. [Google Scholar] [CrossRef]

- Yap, Y.L.; Wang, C.; Sing, S.L.; Dikshit, V.; Yeong, W.Y.; Wei, J. Material jetting additive manufacturing: An experimental study using designed metrological benchmarks. Precis Eng. 2017, 50, 275–285. [Google Scholar] [CrossRef]

- Shakor, P.; Chu, S.H.; Puzatova, A.; Dini, E. Review of binder jetting 3D printing in the construction industry. Prog. Addit. Manuf. 2022, 7, 643–669. [Google Scholar] [CrossRef]

- Li, M.; Du, W.; Elwany, A.; Pei, Z.; Ma, C. Metal Binder Jetting Additive Manufacturing: A Literature Review. J. Manuf. Sci. Eng. 2020, 142, 090801. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Li, S.-H.; Kumar, P.; Chandra, S.; Ramamurty, U. Directed energy deposition of metals: Processing, microstructures, and mechanical properties. Int. Mater. Rev. 2023, 68, 605–647. [Google Scholar] [CrossRef]

- Pilipović, A. Sheet lamination. In Polymers for 3D Printing; Elsevier: Amsterdam, The Netherlands, 2022; pp. 127–136. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Sheet Lamination. In Additive Manufacturing Technologies; Springer International Publishing: Cham, Switzerland, 2021; pp. 253–283. [Google Scholar] [CrossRef]

- Li, J.; Wei, L.; Shen, J.; Zhang, X.; Li, S.; Wang, Z. Research progress of the metal powder reuse for powder bed fusion additive manufacturing technology. Powder Technol. 2024, 441, 119815. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, L.; Guo, X.; Kane, S.; Deng, Y.; Jung, Y.G.; Lee, J.H.; Zhang, J. Additive Manufacturing of Metallic Materials: A Review. J. Mater. Eng. Perform. 2018, 27, 1–13. [Google Scholar] [CrossRef]

- Abd-Elaziem, W.; Elkatatny, S.; Abd-Elaziem, A.E.; Khedr, M.; Abd El-baky, M.A.; Hassan, M.A.; Abu-Okail, M.; Mohammed, M.; Järvenpää, A.; Allam, T.; et al. On the current research progress of metallic materials fabricated by laser powder bed fusion process: A review. J. Mater. Res. Technol. 2022, 20, 681–707. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D.; Tsaramirsis, G.; Papageorgas, P.; Tamimi, H. 3D Printing and Implementation of Digital Twins: Current Trends and Limitations. Appl. Syst. Innov. 2021, 5, 7. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, M.; Peng, S.; Pan, R.; Liu, Y. Introduction to vat polymerization 3D printing technologies. In Vat Photopolymerization Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2024; pp. 1–28. [Google Scholar] [CrossRef]

- Shaukat, U.; Rossegger, E.; Schlögl, S. A Review of Multi-Material 3D Printing of Functional Materials via Vat Photopolymerization. Polymers 2022, 14, 2449. [Google Scholar] [CrossRef] [PubMed]

- Pazhamannil, R.V.; Govindan, P. Current state and future scope of additive manufacturing technologies via vat photopolymerization. Mater. Today Proc. 2021, 43, 130–136. [Google Scholar] [CrossRef]

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-Material 3D and 4D Printing: A Survey. Adv. Sci. 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-Pap. 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Parvanda, R.; Kala, P. Trends, opportunities, and challenges in the integration of the additive manufacturing with Industry 4.0. Prog. Addit. Manuf. 2023, 8, 587–614. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, D.; Tao, B.; Xiang, F.; Jiang, G.; Sun, Y.; Kong, J.; Li, G. A systematic review of digital twin about physical entities, virtual models, twin data, and applications. Adv. Eng. Inform. 2023, 55, 101876. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, K.I.-K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Stark, R.; Fresemann, C.; Lindow, K. Development and operation of Digital Twins for technical systems and services. CIRP Ann. 2019, 68, 129–132. [Google Scholar] [CrossRef]

- Tuegel, E.J.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering Aircraft Structural Life Prediction Using a Digital Twin. Int. J. Aerosp. Eng. 2011, 2011, 1–14. [Google Scholar] [CrossRef]

- Sahal, R.; Alsamhi, S.H.; Brown, K.N. Digital Twins Collaboration in Industrial Manufacturing. In Digital Twins: Basics and Applications; Springer International Publishing: Cham, Switzerland, 2022; pp. 59–72. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Suman, R. Digital Twin applications toward Industry 4.0: A Review. Cogn. Robot. 2023, 3, 71–92. [Google Scholar] [CrossRef]

- Wagner, R.; Schleich, B.; Haefner, B.; Kuhnle, A.; Wartzack, S.; Lanza, G. Challenges and Potentials of Digital Twins and Industry 4.0 in Product Design and Production for High Performance Products. Procedia CIRP 2019, 84, 88–93. [Google Scholar] [CrossRef]

- Perno, M.; Hvam, L.; Haug, A. Implementation of digital twins in the process industry: A systematic literature review of enablers and barriers. Comput. Ind. 2022, 134, 103558. [Google Scholar] [CrossRef]

- Digital Twin Market by Enterprise, Application (Predictive Maintenance, Business optimization), Industry (Aerospace, Automotive & Transportation, Healthcare, Infrastructure, Energy & Utilities) and Geography—Global Forecast to 2027. Available online: https://www.researchandmarkets.com/reports/5146336/global-digital-twin-market-by-application (accessed on 10 May 2024).

- Pires, F.; Cachada, A.; Barbosa, J.; Moreira, A.P.; Leitao, P. Digital Twin in Industry 4.0: Technologies, Applications and Challenges. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki-Espoo, Finland, 22–25 July 2019; pp. 721–726. [Google Scholar] [CrossRef]

- Böttjer, T.; Tola, D.; Kakavandi, F.; Wewer, C.R.; Ramanujan, D.; Gomes, C.; Larsen, P.G.; Iosifidis, A. A review of unit level digital twin applications in the manufacturing industry. CIRP J. Manuf. Sci. Technol. 2023, 45, 162–189. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Phanden, R.K.; Aditya, S.V.; Sheokand, A.; Goyal, K.K.; Gahlot, P.; Jacso, A. A state-of-the-art review on implementation of digital twin in additive manufacturing to monitor and control parts quality. Mater. Today Proc. 2022, 56, 88–93. [Google Scholar] [CrossRef]

- Mukherjee, T. Recent progress in process, structure, properties, and performance in additive manufacturing. Sci. Technol. Weld. Join. 2023, 28, 1–5. [Google Scholar] [CrossRef]

- Jain, R.; Bharat, N.; Bose, P.S.C. Digital Twins of Hybrid Additive and Subtractive Manufacturing Systems–A Review. In Machining and Additive Manufacturing. CPIE 2023. Lecture Notes in Mechanical Engineering; Springer: Singapore, 2024; pp. 173–183. [Google Scholar] [CrossRef]

- Rachmawati, S.M.; Putra, M.A.P.; Lee, J.M.; Kim, D.S. Digital twin-enabled 3D printer fault detection for smart additive manufacturing. Eng. Appl. Artif. Intell. 2023, 124, 106430. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Murphy, A.B.; Matthews, M.J.; DebRoy, T. The case for digital twins in metal additive manufacturing. J. Physics: Mater. 2021, 4, 040401. [Google Scholar] [CrossRef]

- Uhlemann, T.H.-J.; Schock, C.; Lehmann, C.; Freiberger, S.; Steinhilper, R. The Digital Twin: Demonstrating the Potential of Real Time Data Acquisition in Production Systems. Procedia Manuf. 2017, 9, 113–120. [Google Scholar] [CrossRef]

- Krückemeier, S.; Anderl, R. Concept for Digital Twin Based Virtual Part Inspection for Additive Manufacturing. Procedia CIRP 2022, 107, 458–462. [Google Scholar] [CrossRef]

- Phua, A.; Davies, C.H.J.; Delaney, G.W. A digital twin hierarchy for metal additive manufacturing. Comput. Ind. 2022, 140, 103667. [Google Scholar] [CrossRef]

- Cai, Y.; Starly, B.; Cohen, P.; Lee, Y.-S. Sensor Data and Information Fusion to Construct Digital-twins Virtual Machine Tools for Cyber-Physical Manufacturing. Procedia Manuf. 2017, 10, 1031–1042. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Segovia, M.; Garcia-Alfaro, J. Design, Modeling and Implementation of Digital Twins. Sensors 2022, 22, 5396. [Google Scholar] [CrossRef] [PubMed]

- Francois, M.M.; Sun, A.; King, W.E.; Henson, N.J.; Tourret, D.; Bronkhorst, C.A.; Carlson, N.N.; Newman, C.K.; Haut, T.; Bakosi, J.; et al. Modeling of additive manufacturing processes for metals: Challenges and opportunities. Curr. Opin. Solid State Mater. Sci. 2017, 21, 198–206. [Google Scholar] [CrossRef]

- Mukherjee, T.; DebRoy, T. A digital twin for rapid qualification of 3D printed metallic components. Appl. Mater. Today 2019, 14, 59–65. [Google Scholar] [CrossRef]

- Corradini, F.; Silvestri, M. Design and testing of a digital twin for monitoring and quality assessment of material extrusion process. Addit. Manuf. 2022, 51, 102633. [Google Scholar] [CrossRef]

- Mourtzis, D.; Togias, T.; Angelopoulos, J.; Stavropoulos, P. A Digital Twin architecture for monitoring and optimization of Fused Deposition Modeling processes. Procedia CIRP 2021, 103, 97–102. [Google Scholar] [CrossRef]

- Jyeniskhan, N.; Keutayeva, A.; Kazbek, G.; Ali, M.H.; Shehab, E. Integrating Machine Learning Model and Digital Twin System for Additive Manufacturing. IEEE Access 2023, 11, 71113–71126. [Google Scholar] [CrossRef]

- Toprak, C.B.; Dogruer, C.U. A Critical Review of Machine Learning Methods Used in Metal Powder Bed Fusion Process to Predict Part Properties. Int. J. Precis. Eng. Manuf. 2023, 25, 429–452. [Google Scholar] [CrossRef]

- Xu, H.; Wu, J.; Pan, Q.; Guan, X.; Guizani, M. A Survey on Digital Twin for Industrial Internet of Things: Applications, Technologies and Tools. IEEE Commun. Surv. Tutor. 2023, 25, 2569–2598. [Google Scholar] [CrossRef]

- Kaur, M.J.; Mishra, V.P.; Maheshwari, P. The Convergence of Digital Twin, IoT, and Machine Learning: Transforming Data into Action. In Digital Twin Technologies and Smart Cities. Internet of Things; Springer: Berlin/Heidelberg, Germany, 2020; pp. 3–17. [Google Scholar] [CrossRef]

- Machado, M.; Oliveira, E.; Silva, L.; Silva, J.; Sousa, J. Development of a Digital Twin for Additive Manufacturing. In Volume 2B: Advanced Manufacturing; American Society of Mechanical Engineers: New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- Nagar, S.V.; Chandrashekar, A.C.; Suvarna, M. Optimized Additive Manufacturing Technology Using Digital Twins and Cyber Physical Systems; Springer: Berlin/Heidelberg, Germany, 2020; pp. 65–73. [Google Scholar] [CrossRef]

- Butt, J.; Mohaghegh, V. Combining Digital Twin and Machine Learning for the Fused Filament Fabrication Process. Metals 2022, 13, 24. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Murphy, A.B.; Barnard, A.; DebRoy, T.; Matthews, M.J.; Ladani, L.; Gu, D. Towards developing multiscale-multiphysics models and their surrogates for digital twins of metal additive manufacturing. Addit. Manuf. 2021, 46, 102089. [Google Scholar] [CrossRef]

- Sampedro, G.A.R.; Putra, M.A.P.; Abisado, M. 3D-AmplifAI: An Ensemble Machine Learning Approach to Digital Twin Fault Monitoring for Additive Manufacturing in Smart Factories. IEEE Access 2023, 11, 64128–64140. [Google Scholar] [CrossRef]

- Abhilash, P.M.; Boban, J.; Ahmed, A.; Luo, X. Digital twin-driven additive manufacturing. In Hybrid Metal Additive Manufacturing; CRC Press: Boca Raton, FL, USA, 2023; pp. 196–221. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, W.; Chen, X. Digital Twins and Additive Manufacturing. In Digital Twins: Basics and Applications; Springer International Publishing: Cham, Switzerland, 2022; pp. 27–35. [Google Scholar] [CrossRef]

- Knapp, G.L.; Mukherjee, T.; Zuback, J.S.; Wei, H.L.; Palmer, T.A.; De, A.; DebRoy, T.J.A.M. Building blocks for a digital twin of additive manufacturing. Acta Mater. 2017, 135, 390–399. [Google Scholar] [CrossRef]

- Kabaldin, Y.G.; Kolchin, P.V.; Shatagin, D.A.; Anosov, M.S.; Chursin, A.A. Digital Twin for 3D Printing on CNC Machines. Russ. Eng. Res. 2019, 39, 848–851. [Google Scholar] [CrossRef]

- Haw, J.; Sing, S.L.; Liu, Z.H. Digital twins in design for additive manufacturing. Mater. Today Proc. 2022, 70, 352–357. [Google Scholar] [CrossRef]

- Scime, L.; Singh, A.; Paquit, V. A scalable digital platform for the use of digital twins in additive manufacturing. Manuf. Lett. 2022, 31, 28–32. [Google Scholar] [CrossRef]

- Phua, A.; Cook, P.S.; Davies, C.H.J.; Delaney, G.W. Smart recoating: A digital twin framework for optimisation and control of powder spreading in metal additive manufacturing. J. Manuf. Process 2023, 99, 382–391. [Google Scholar] [CrossRef]

- Castelló-Pedrero, P.; García-Gascón, C.; Bas-Bolufer, J.; García-Manrique, J.A. Integrated computational modeling of large format additive manufacturing: Developing a digital twin for material extrusion with carbon fiber-reinforced acrylonitrile butadiene styrene. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 238, 332–346. [Google Scholar] [CrossRef]

- Reddy, K.S.S.; Rajesh, R.; Raj, P.A.C.; Arya, N.; Bhaskaran, R.; Prasad, J.L. Implementation and Manufacturing of DT Sensor Ecosystem for Real-Time Monitoring of Virtual 3D Printers. SN Comput. Sci. 2023, 4, 556. [Google Scholar] [CrossRef]

- Reisch, R.T.; Hauser, T.; Lutz, B.; Tsakpinis, A.; Winter, D.; Kamps, T.; Knoll, A. Context awareness in process monitoring of additive manufacturing using a digital twin. Int. J. Adv. Manuf. Technol. 2022, 119, 3483–3500. [Google Scholar] [CrossRef]

- Mu, H.; He, F.; Yuan, L.; Commins, P.; Wang, H.; Pan, Z. Toward a smart wire arc additive manufacturing system: A review on current developments and a framework of digital twin. J. Manuf. Syst. 2023, 67, 174–189. [Google Scholar] [CrossRef]

- Noh, I.; Shin, H.; Choi, Y.; Lee, Y.; Jeon, Y.; Lee, S.W. Development of an Interactive Digital Twin for Directed Energy Deposition (DED) Process. In Volume 2: Manufacturing Processes; Manufacturing Systems; American Society of Mechanical Engineers: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Fergani, O.; Eissing, K. A machine learning-based digital twin of the manufacturing process: Metal powder-bed fusion case. Eng. Arch. 2020, 1–8. [Google Scholar] [CrossRef]

- Yeung, H.; Kim, F.; Donmez, A. Application of Digital Twins to Laser Powder Bed Fusion Additive Manufacturing Process Control. In Volume 1: Additive Manufacturing; Advanced Materials Manufacturing; Biomanufacturing; Life Cycle Engineering; American Society of Mechanical Engineers: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

| Authors | Contributions | Limitations |

|---|---|---|

| Pantelidakis et al. [12] | A digital twin ecosystem designed to test, monitor processes, and remotely manage the fused deposition modeling (FDM) printer using a virtual simulation platform. | The experimental conditions relating to the environment were not fully regulated. Specifically, the room lighting and printer surfaces were left unchanged to optimize the accuracy of the sensor readings. |

| Arden et al. [99] | An innovative approach to improving the assessment, configuration, and control of powder spreading throughout the AM process. | Surface texture cannot be measured in real time by current additive manufacturing powder bed monitoring systems. To meet this challenge, sophisticated hardware controllers and sensors are needed to update the parameters and measurements of the printing process in real time. |

| Castelló et al. [100] | A digital twin for material extrusion in large-format additive manufacturing involves the integration of machine learning, real-time data acquisition, and computational modeling to optimize and control the manufacturing process. | Computing requirements and the complexity of modeling processes, prevent real-time implementation and integration in practical contexts. |

| Noh et al. [104] | A digital representation of the DED machine, including a three-dimensional model of the DED machine, was developed. | The lack of real-life implementation studies for the proposed digital twin. |

| Yeung et al. [106] | A digital twin system for monitoring and optimizing the laser powder bed fusion process. | Manufacturing requires enhanced incorporation of machine learning and data management. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben Amor, S.; Elloumi, N.; Eltaief, A.; Louhichi, B.; Alrasheedi, N.H.; Seibi, A. Digital Twin Implementation in Additive Manufacturing: A Comprehensive Review. Processes 2024, 12, 1062. https://doi.org/10.3390/pr12061062

Ben Amor S, Elloumi N, Eltaief A, Louhichi B, Alrasheedi NH, Seibi A. Digital Twin Implementation in Additive Manufacturing: A Comprehensive Review. Processes. 2024; 12(6):1062. https://doi.org/10.3390/pr12061062

Chicago/Turabian StyleBen Amor, Sabrine, Nessrine Elloumi, Ameni Eltaief, Borhen Louhichi, Nashmi H. Alrasheedi, and Abdennour Seibi. 2024. "Digital Twin Implementation in Additive Manufacturing: A Comprehensive Review" Processes 12, no. 6: 1062. https://doi.org/10.3390/pr12061062

APA StyleBen Amor, S., Elloumi, N., Eltaief, A., Louhichi, B., Alrasheedi, N. H., & Seibi, A. (2024). Digital Twin Implementation in Additive Manufacturing: A Comprehensive Review. Processes, 12(6), 1062. https://doi.org/10.3390/pr12061062