A Study of the Top-Coal-Drawing Law of Steeply Inclined and Extremely Thick Coal Seams in the Wudong Coal Mine

Abstract

1. Introduction

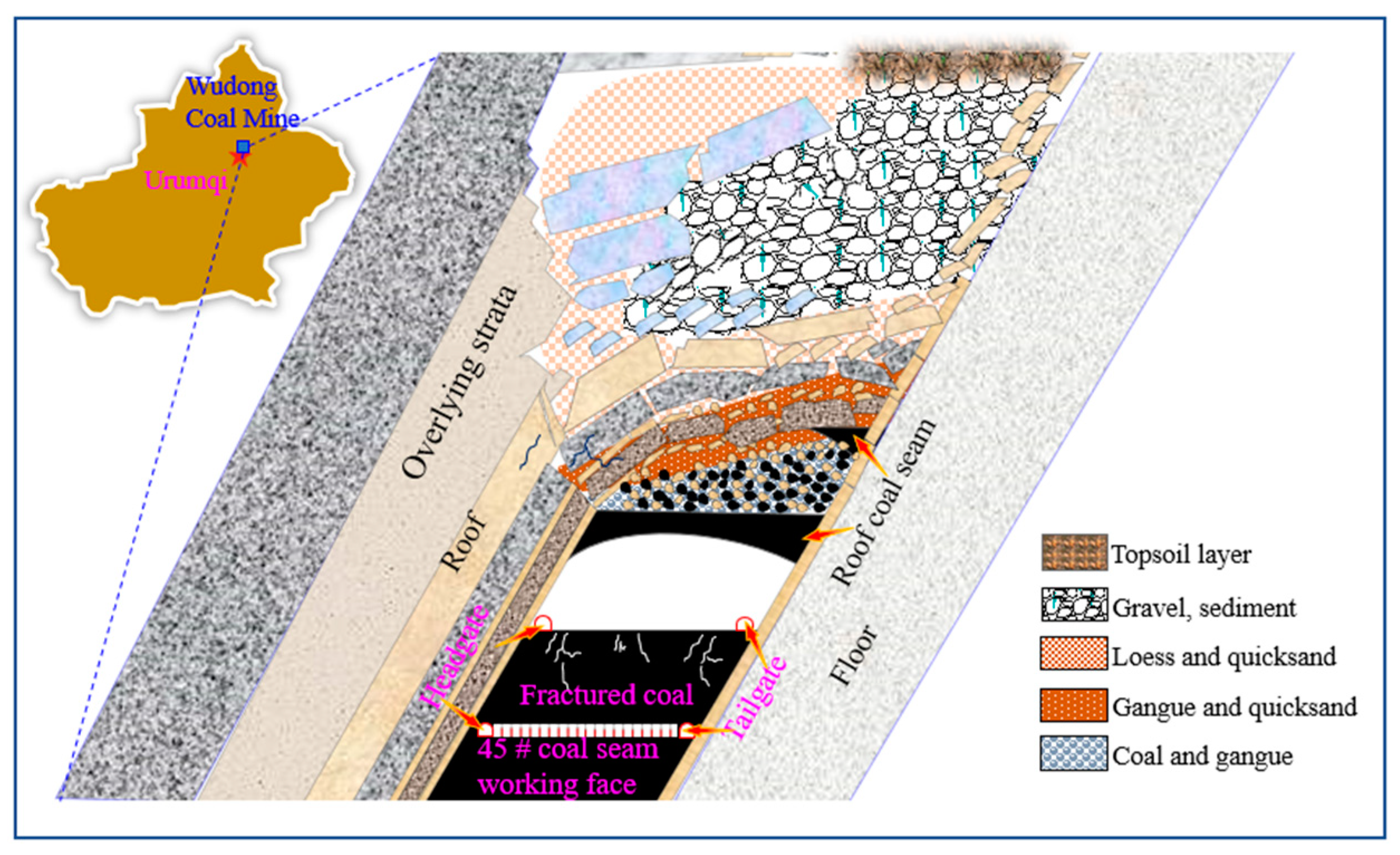

2. Engineering Background

3. Physical Similarity Simulation of the Top-Coal-Drawing Law

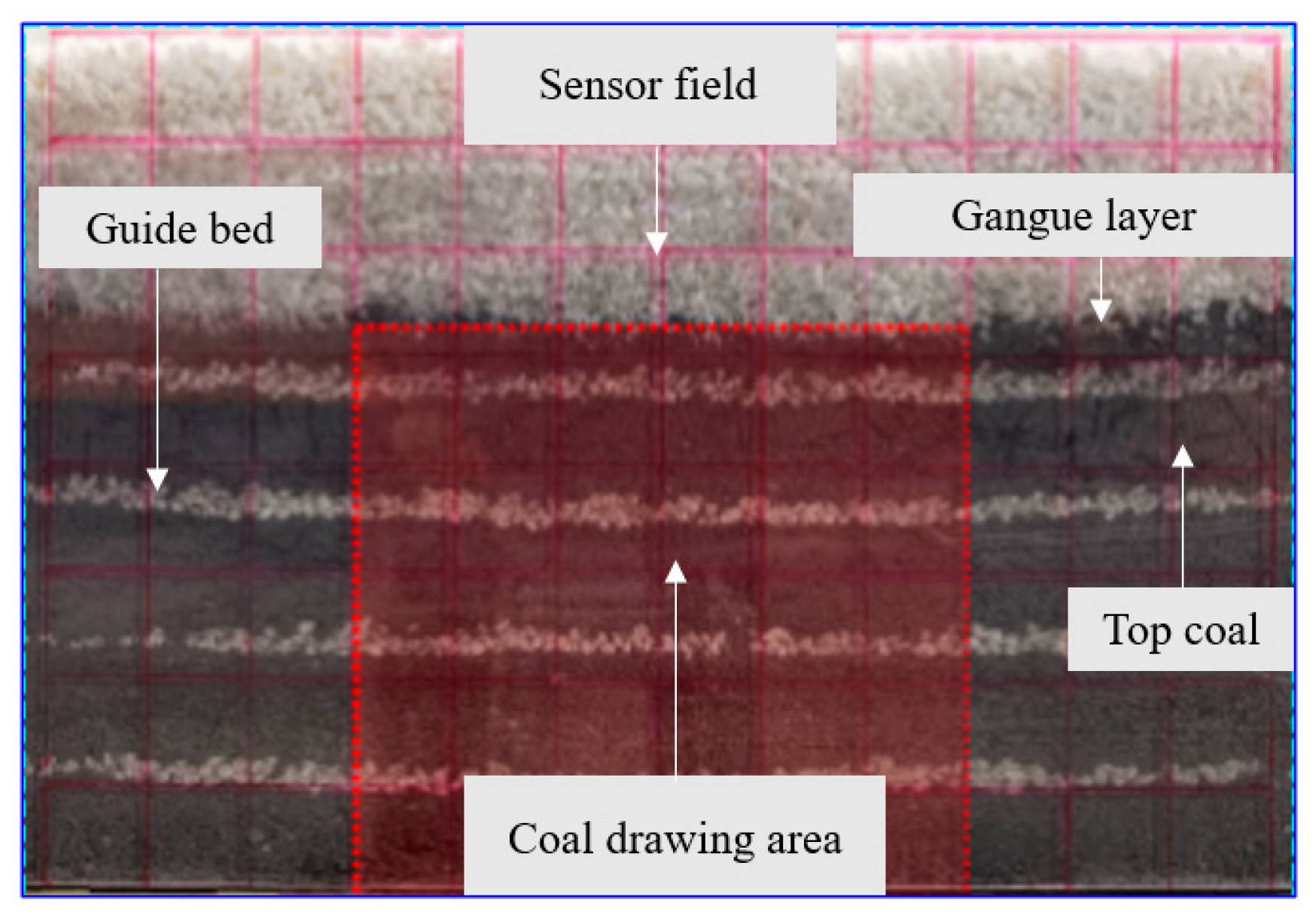

3.1. Similarity Simulation Device and Experimental Steps

3.2. Experimental Result Analysis of the Physical Similarity Simulation

3.2.1. Results of the Initial Drawing Experiment

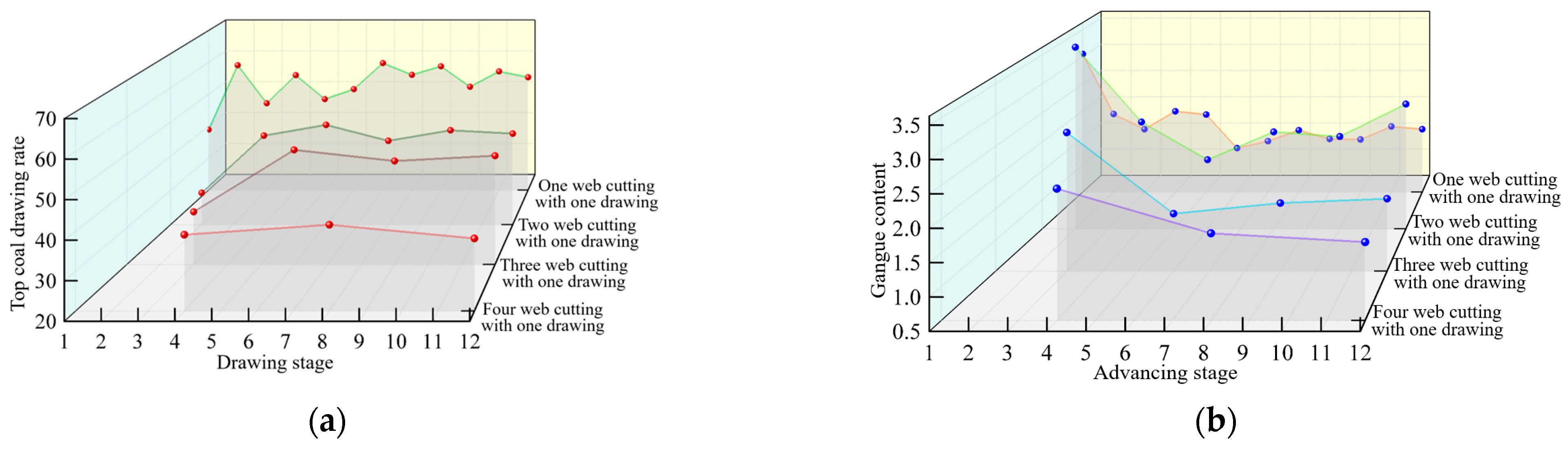

3.2.2. Results of the Periodic-Coal-Drawing Experiment

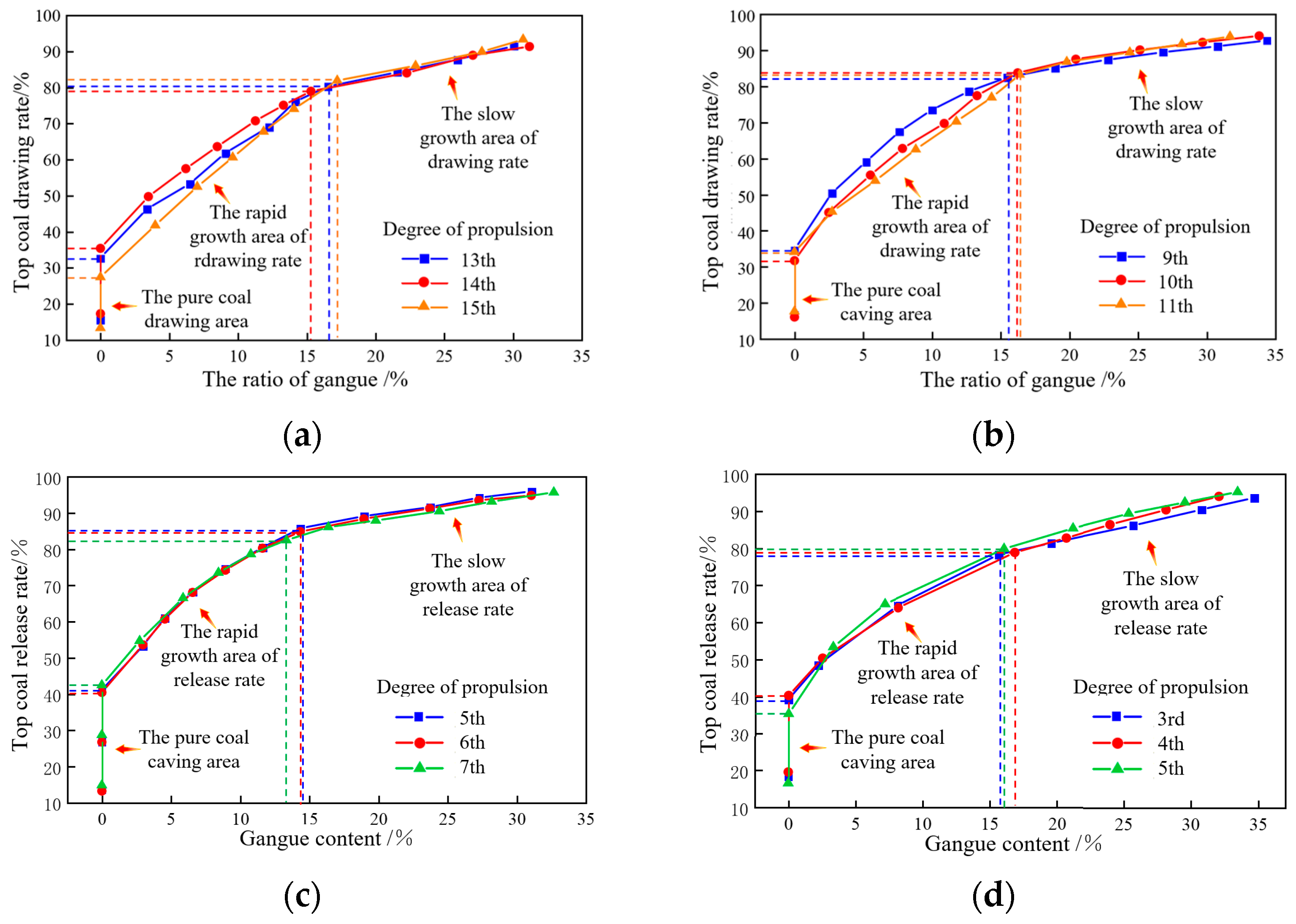

3.2.3. Results of the Excessive-Coal-Drawing Experiment

4. Numerical Simulation of the Top-Coal-Drawing Law

4.1. Numerical Simulation Design

4.2. Numerical Simulation Result Analysis

4.2.1. The Three Drawing-Interval Groups of Supports

4.2.2. Drawing Once Every Two Supports

5. On-Site Verification

6. Conclusions

7. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xie, H.; Ren, S.; Xie, Y.; Jiao, X. Development opportunities of the coal industry towards the goal of carbon neutrality. J. China Coal Soc. 2021, 46, 2197–2211. [Google Scholar]

- Liu, F.; Cuo, L.; Zhao, L. Research on coal safety range and green low-carbon technology patlunder the dual-carbon background. J. China Coal Soc. 2022, 47, 11–22. [Google Scholar]

- Yan, B.; Jia, H.; Yang, Z.; Yilmaz, E.; Liu, H. Goaf instability in an open pit iron mine triggered by dynamics disturbance: A large-scale similar simulation. Int. J. Min. Reclam. Environ. 2023, 37, 606–629. [Google Scholar] [CrossRef]

- Huo, Y.; Zhu, D.; Wang, Z.; Song, X. Numerical Investigation of Top Coal Drawing Evolution in Longwall Top Coal Drawing by the Coupled Finite Difference Method-Discrete Element Method. Energies 2021, 14, 219. [Google Scholar] [CrossRef]

- Fu, Q.; Yang, K.; He, X.; Liu, Q.; Wei, Z.; Wang, Y. Destabilization Mechanism and Stability Control of the Surrounding Rock in Stope Mining Roadways below Remaining Coal Pillars: A Case Study in Buertai Coal Mine. Processes 2022, 10, 2192. [Google Scholar] [CrossRef]

- Wang, J.C.; Zhang, J.W. Longwall top-coal drawing mining in extremely inclined thick coal seam. In Proceedings of the 24th World Mining Congress Proceedings:Underground Mining, Rio de Janeiro, Brazil, 18–21 October 2016; pp. 277–286. [Google Scholar]

- Song, Z.Y.; Konietzky, H.; Herbst, M. Drawing mechanism of fractured top coal in longwall top coal drawing. Int. J. Rock Mech. Min. Sci. 2020, 130, 104329. [Google Scholar] [CrossRef]

- Zeng, Y.; Liu, X.; Wu, Q.; Liang, J. Theory and technical conception of coal-water-thermal positive synergistic co-extraction under the dual carbon background. J. China Coal Soc. 2023, 48, 538–550. [Google Scholar]

- Wang, S.; Liu, L.; Zhao, Y.; Zhang, B.; Wang, J.; Zhu, M.; Wang, M.; Zhang, X. New energy exploitation in coal-endowed areas under the target of “double carbon”: A new path for transformation and upgrading of coal mines in the future. Coal Sci. Technol. 2023, 51, 59–79. [Google Scholar]

- Sun, X.; Liu, Y.; Wang, J.; Li, J.; Sun, S.; Cui, X. Study on three-dimensional stress field of gob-side entry retaining by roof cutting without pillar under near-group coal seam mining. Processes 2019, 7, 552. [Google Scholar] [CrossRef]

- Wang, J. Thick Coal Seam Mining Theory and Technology; Metallurgical Industry Press: Beijing, China, 2009; pp. 2–6. [Google Scholar]

- Wang, Z.; Yang, X.; Wang, G.; Gong, H. Study on Instability Characteristics of the Directional Borehole on the Coal-Seam Roof: A Case Study of the Tingnan Coal Mine. Processes 2023, 11, 1675. [Google Scholar] [CrossRef]

- Wang, G.; Pang, Y.; Xu, Y.; Meng, L.; Han, H. Development of intelligent green and efficient miningtechnology and equipment for thick coal seam. J. Min. Saf. Eng. 2023, 40, 882–893. [Google Scholar]

- Wang, J.H. Development and prospect on fully mechanized mining in Chinese coal mines. Int. J. Coal Sci. Technol. 2014, 1, 253–260. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, B.; Zhao, P.; Yang, S.; An, J.; Jiang, Z. Research on the longwall top-coal drawing mining technique in extremely inclined and soft thick coal seam. J. China Coal Soc. 2017, 42, 286–292. [Google Scholar]

- Zhang, F.; Yang, W. Stress distribution law of steeply inclined horizontal sectional drawing coal mining and prevention and control of rock burst. Saf. Coal Mines 2023, 54, 101–108. [Google Scholar]

- Zhang, J.; Wang, J.; Wei, W. Effect of face dip angle on the drawing mechanism in longwall top-coal drawing mining. J. China Univ. Min. Technol. 2018, 47, 805–814. [Google Scholar]

- Wang, J.; Wei, L.; Zhang, J.; Li, Z. 3-D numerical simulation on the top-coal movement law under drawing mining technique. Coal J. 2013, 38, 1905–1911. [Google Scholar]

- Wang, S.; Huang, Z.; Li, D.; Zhang, W.; Wang, Z.; Li, H. Study of top—Coal flow mechanism under stage and multi—Grouping top—Coal drawing technology in extra thick coal seam. Coal Sci. Technol. 2021, 49, 17–24. [Google Scholar]

- Wei, W.; Wang, J.; Zhang, J.; Wu, S.; Li, Z.; Zhang, X. Drawing mechanisms of granular top coal considering the structure of hydraulic support in longwall top coal caving. Bull. Eng. Geol. Environ. 2023, 82, 138. [Google Scholar] [CrossRef]

- Yang, L.; Wang, J.; Yang, S.; Li, Z.; Wu, S. Improving the top coal recovery ratio in longwall top coal caving mining using drawing balance analysis. Int. J. Min. Reclam. Environ. 2023, 37, 319–337. [Google Scholar] [CrossRef]

- Huo, Y.; Song, X.; Zhu, D. Numerical investigation of top-coal migration in the first coal-drawing process by an FDM–DEM coupling method. Energies 2020, 13, 5493. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, B.; Li, L.; Zhang, S.; Liu, J.; Zhao, J. Study on the effect of roof fracture development on gas drainage in steep full-mechanized drawing mining. J. Min. Saf. Eng. 2014, 31, 809–813. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions, and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim(s) responsibility for any injury to people or property resulting from any ideas, methods, instructions, or products referred to in the content. |

| Research Procedures | Research Methods | Top-Coal-Drawing Methods | Research Content |

|---|---|---|---|

| 1 | Physical similarity simulation | One web cutting with one drawing Two web cuttings with one drawing Three web cuttings with one drawing Four web cuttings with one drawing | Initial coal drawing |

| Periodic coal drawing | |||

| Excessive coal drawing | |||

| 2 | Numerical simulation | Drawing interval of every three groups of supports Drawing-once-every-two-support method | Top-coal-drawing rate |

| Distribution of residual coal in the goaf | |||

| 3 | On-site verification | One web cutting with one drawing and three interval groups of supports | Top-coal-drawing rate of the working face at an elevation level of +721–+575 |

| Altitude Elevation | Strike Length/m | Width of Working Face/m | Height of Horizontal Section/m | Top Coal Height/m | Drawing Ratio | Geological Reserves/Mt | Drawing Rate/% |

|---|---|---|---|---|---|---|---|

| +721 | 810 | 42 | 13.5 | 11 | 1:4.4 | 0.6716 | 86.34 |

| +688 | 900 | 42 | 18.75 | 16.25 | 1:6.5 | 0.9834 | 72.01 |

| +645 | 1628 | 41 | 25 | 22.5 | 1:9 | 1.67.824 | 61.05 |

| +620 | 1135 | 27 | 25 | 22 | 1:7.3 | 0.93486 | 32.86 |

| +575 | 1234 | 33 | 25 | 22.0 | 1:7.3 | 1.171 | 39.12 |

| Drawing Interval | Quality of Coal/g | Quality of Gangue/g | Rate of Drawing/% | Rate of Gangue/% |

|---|---|---|---|---|

| One web cutting with one drawing | 1372.5 | 7.5 | 465.41 | 0.54 |

| Two web cuttings with one drawing | 1436.0 | 8.2 | 243.47 | 0.57 |

| Three web cuttings with one drawing | 1417.7 | 7.8 | 160.25 | 0.55 |

| Four web cuttings with one drawing | 1396.5 | 9.5 | 118.39 | 0.68 |

| Material | Density ρ/(kg/m3) | Radius R/(m) | Normal Stiffness kn/(N/m) | Tangential Stiffness ks/(N/m) | Coefficient of Friction |

|---|---|---|---|---|---|

| Coal | 1312 | 0.05–0.15 | 2 × 108 | 2 × 108 | 0.4 |

| Gangue | 2500 | 0.15–0.25 | 4 × 108 | 4 × 108 | 0.4 |

| Height/(m) | Central Distance/(m) | Dip Angle /(°) | Normal Stiffness /(N/m) | Tangential Stiffness /(N/m) | Coefficient of Friction |

|---|---|---|---|---|---|

| 3.0 | 1.5 | 45 | 2 × 109 | 2 × 109 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, J.; Wu, L.; Lai, X.; Yan, B.; Zhu, H.; Qiao, H. A Study of the Top-Coal-Drawing Law of Steeply Inclined and Extremely Thick Coal Seams in the Wudong Coal Mine. Processes 2024, 12, 481. https://doi.org/10.3390/pr12030481

Cao J, Wu L, Lai X, Yan B, Zhu H, Qiao H. A Study of the Top-Coal-Drawing Law of Steeply Inclined and Extremely Thick Coal Seams in the Wudong Coal Mine. Processes. 2024; 12(3):481. https://doi.org/10.3390/pr12030481

Chicago/Turabian StyleCao, Jiantao, Longquan Wu, Xingping Lai, Baoxu Yan, Haoyu Zhu, and Hao Qiao. 2024. "A Study of the Top-Coal-Drawing Law of Steeply Inclined and Extremely Thick Coal Seams in the Wudong Coal Mine" Processes 12, no. 3: 481. https://doi.org/10.3390/pr12030481

APA StyleCao, J., Wu, L., Lai, X., Yan, B., Zhu, H., & Qiao, H. (2024). A Study of the Top-Coal-Drawing Law of Steeply Inclined and Extremely Thick Coal Seams in the Wudong Coal Mine. Processes, 12(3), 481. https://doi.org/10.3390/pr12030481