Parameter Calibration for Discrete Element Simulation of the Interaction between Loose Soil and Thrown Components after Ginseng Land Tillage

Abstract

1. Introduction

2. Materials and Methods

2.1. Selection of the Contact Model

2.2. Selection of Calibration Parameters

2.3. Test Methods

- (1)

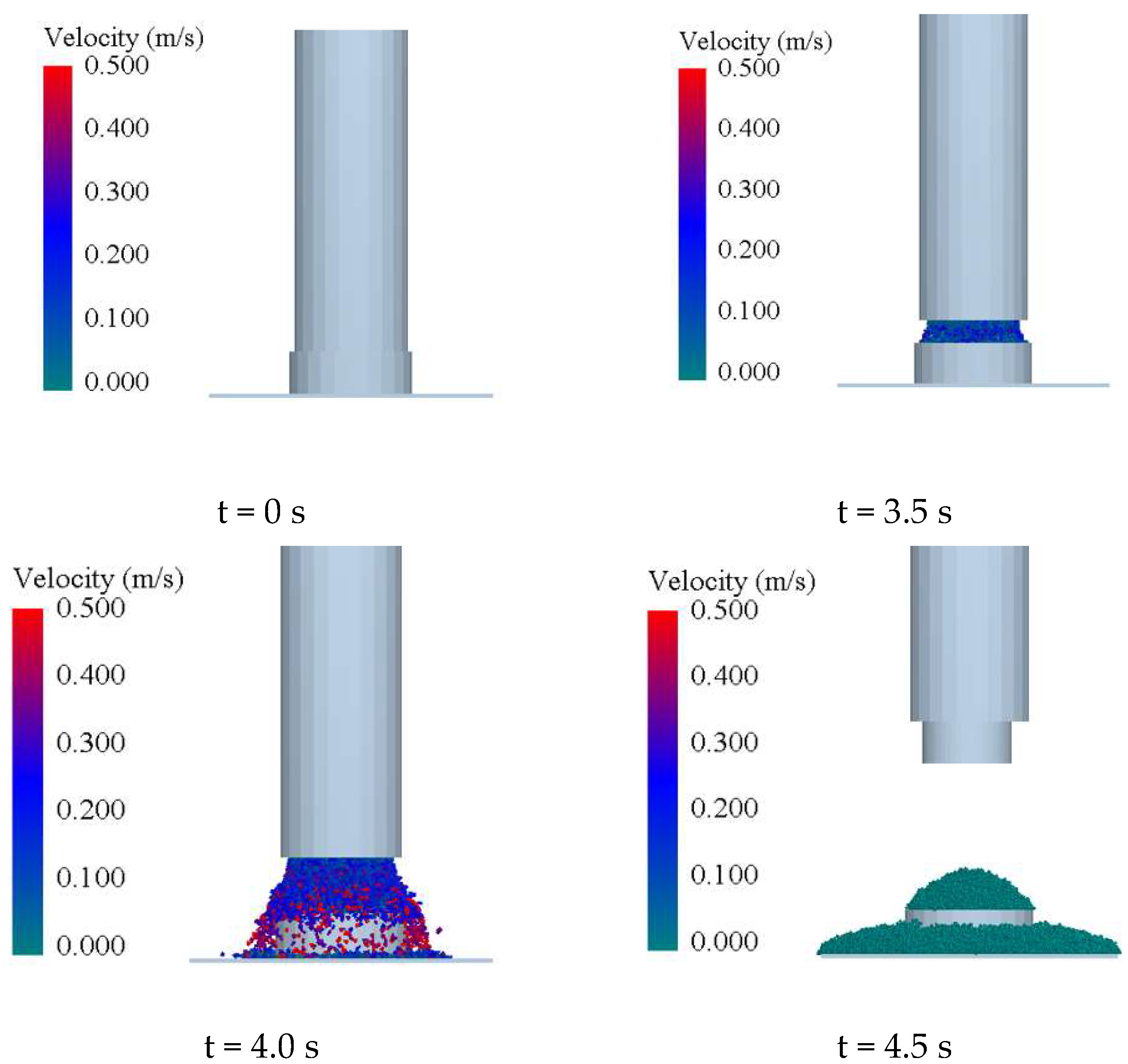

- Soil accumulation test

- (2)

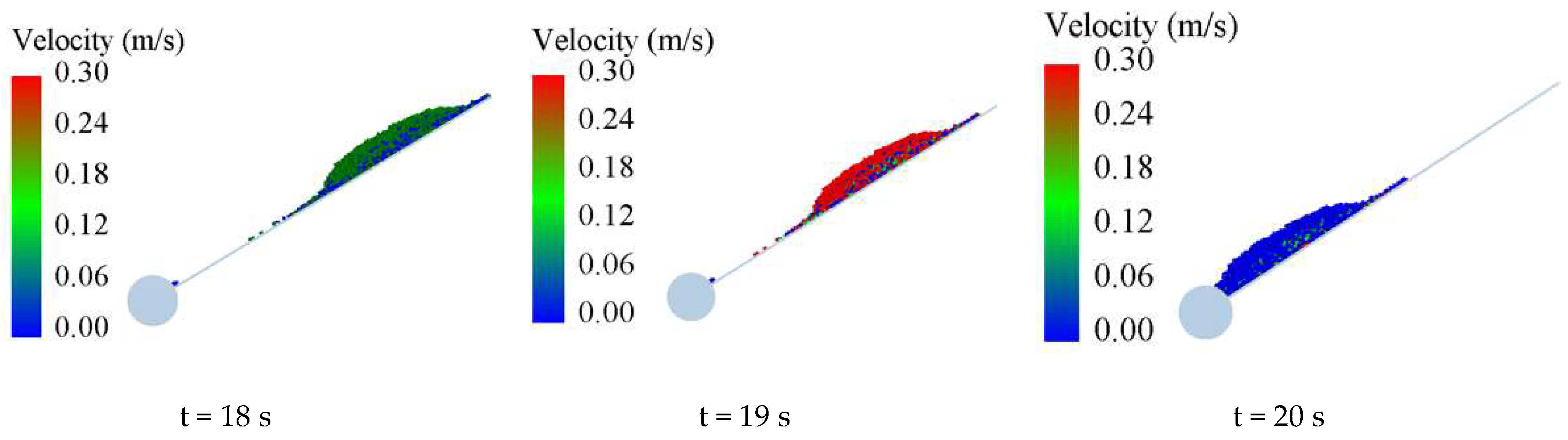

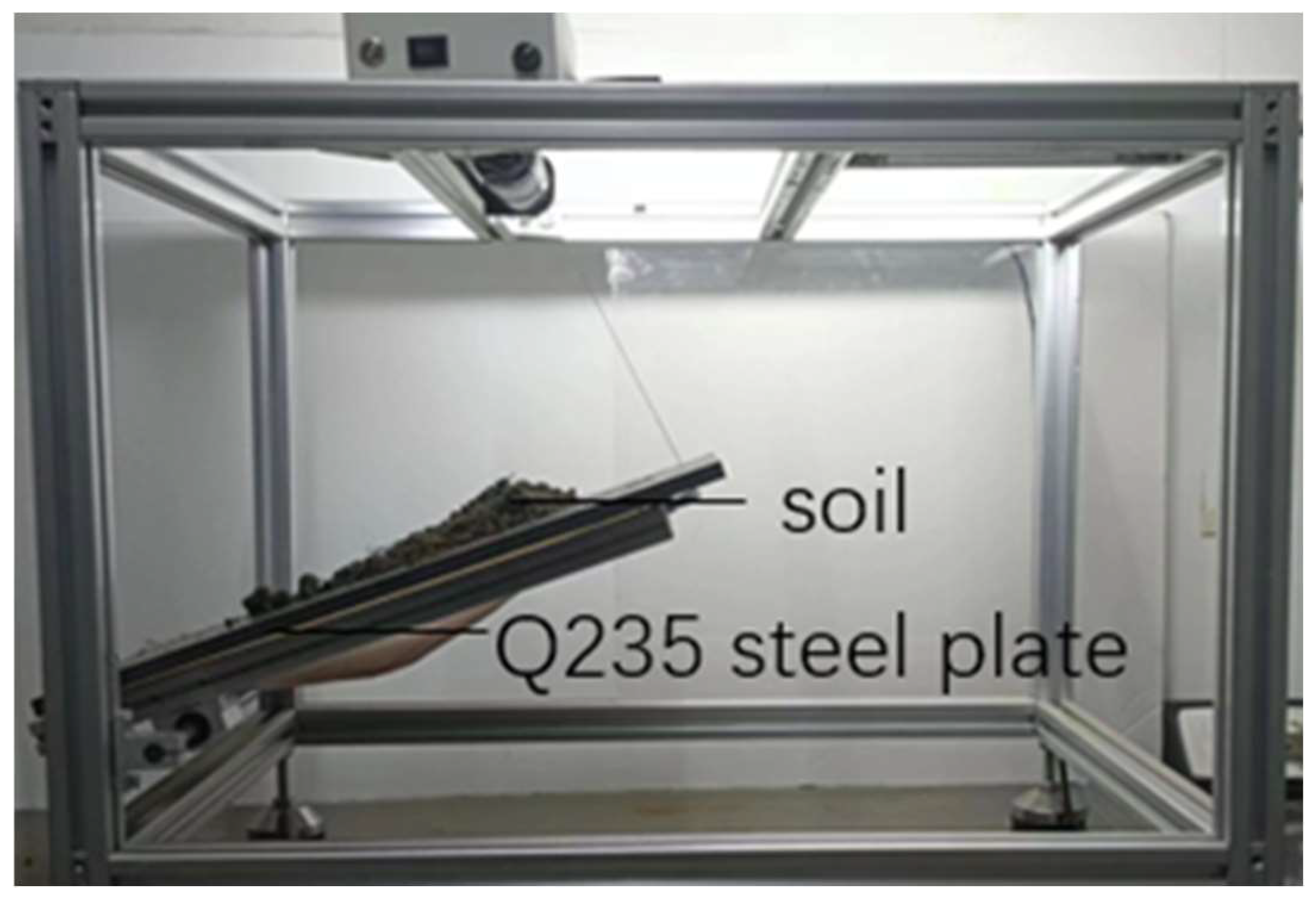

- Soil slip test

2.4. Experimental Design

3. Simulation Results and Analysis

3.1. Soil Accumulation and Sliding Simulation Test Results

3.2. Analysis of Simulation Results

4. Calibration Parameter Determination and Experimental Verification

4.1. Optimal Calibration Parameter Determination

- (1)

- Determination of the stacking angle

- (2)

- Determination of the soil sliding friction angle

4.2. Physical Test Verification

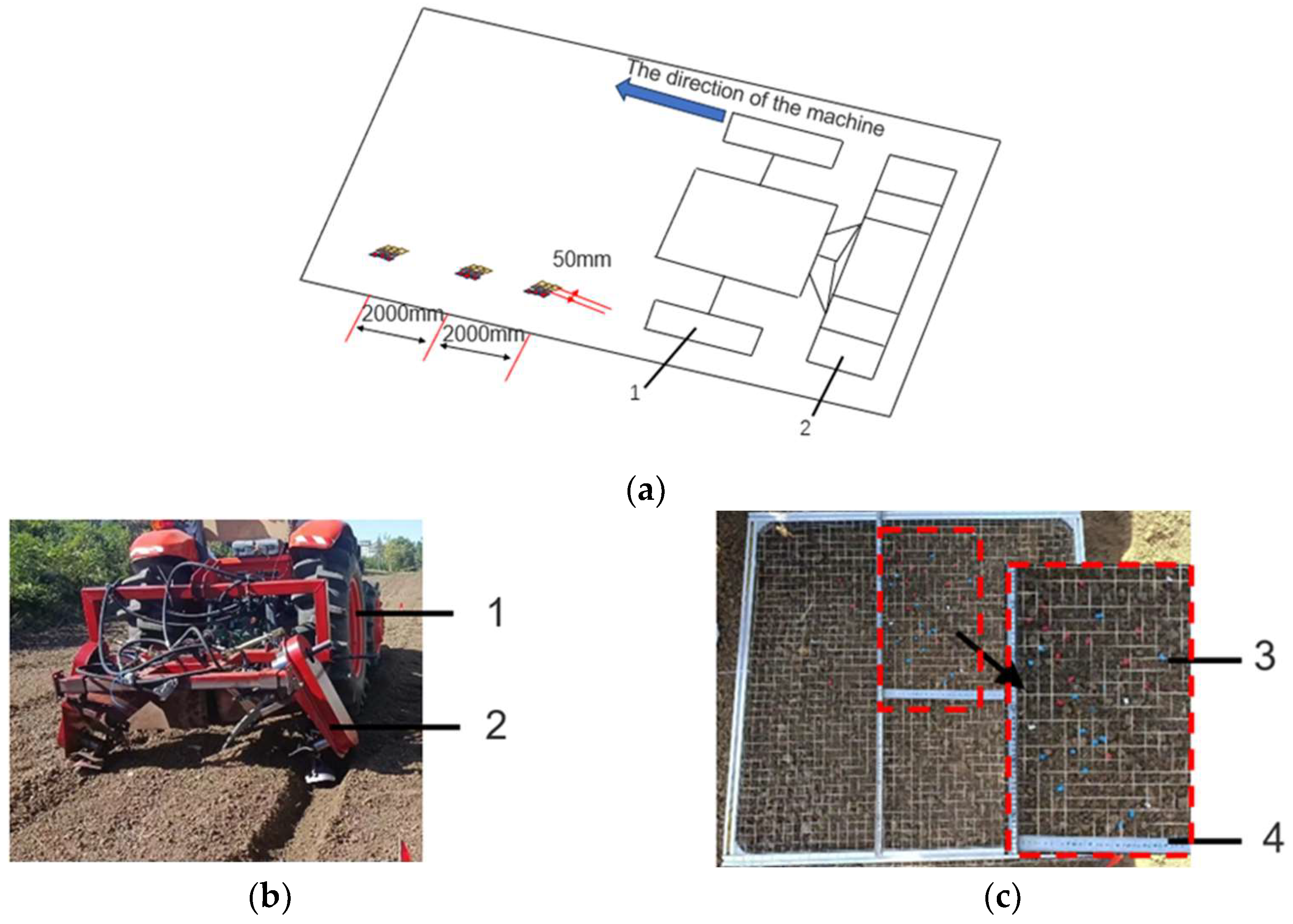

5. Field Trials

5.1. Preparation of Test Conditions

5.2. Field Trials

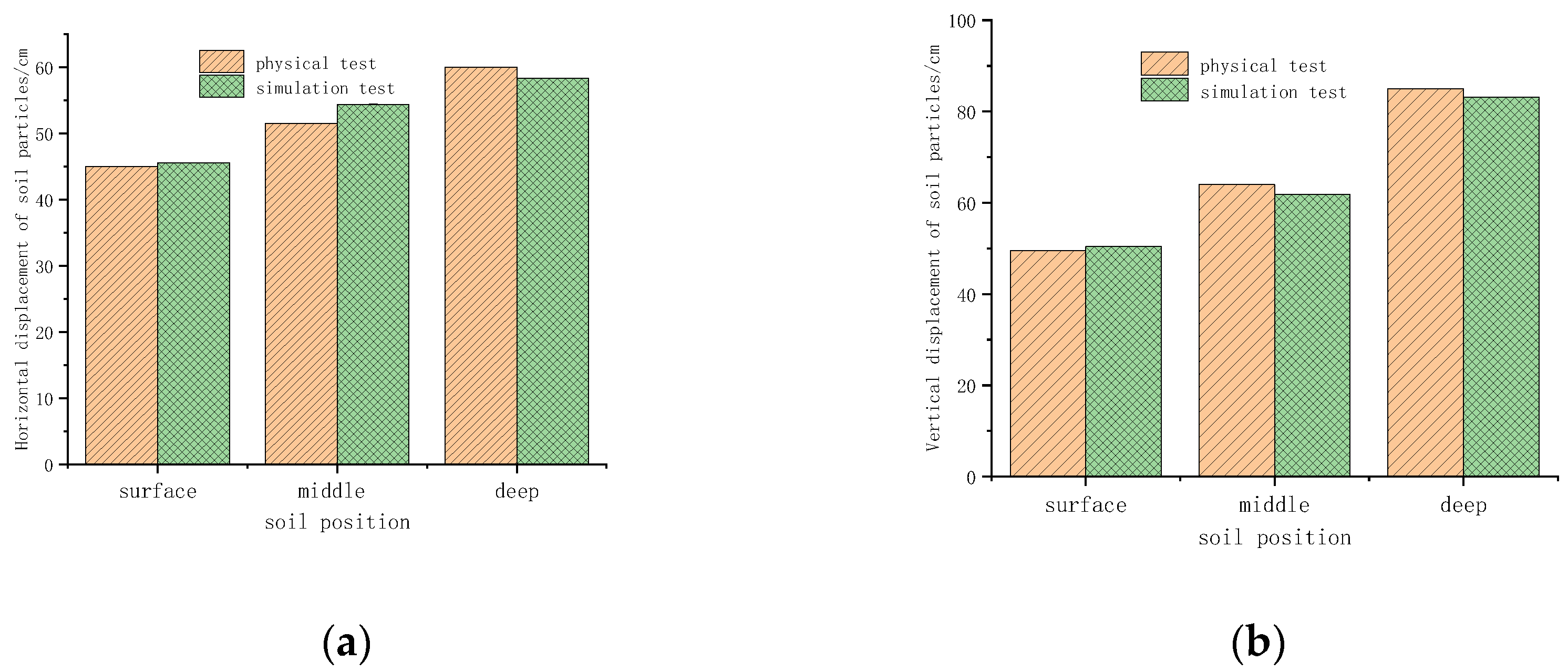

5.3. Simulation Test Verification

5.4. Test Results and Analysis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, X. Jilin Ginseng Industry Optimization and Upgrading Development Space Is Huge. Economic Reference News, 7 June 2023. [Google Scholar] [CrossRef]

- Zhang, J. Analyzing the strategy to achieve leapfrog development of ginseng industry in Jilin Province. South. Agric. 2019, 13, 123+127. [Google Scholar] [CrossRef]

- Milkevych, V.; Munkholm, L.J.; Chen, Y.; Nyord, T. Modeling approach for soil displacement in tillage using discrete element method. Soil Tillage Res. 2018, 183, 60–71. [Google Scholar] [CrossRef]

- Jia, H.L.; Wang, W.P.; Chen, Z.; Zheng, T.Z.; Zhang, P.; Zhuang, J. Current status and prospect of research on optimization of soil-touching components of agricultural machinery. J. Agric. Mach. 2017, 48, 1–13. [Google Scholar]

- Sun, J.; Liu, Q.; Yang, F.; Liu, Z.; Wang, Z. Calibration of discrete element simulation parameters for soil and rotary ploughing component interactions on slopes of the Loess Plateau. J. Agric. Mach. 2022, 53, 63–73. [Google Scholar]

- Coetzee, C.J. Calibration of the discrete element method. Powder Technol. 2017, 310, 104–142. [Google Scholar] [CrossRef]

- Li, J.W.; Tong, J.; Hu, B.; Wang, H.; Mao, C.; Ma, Y. Calibration of discrete element simulation parameters for the interaction between clay-heavy black soil and touchdown components with different water content. J. Agric. Eng. 2019, 35, 130–140. [Google Scholar]

- Ma, S.; Xu, L.; Yuan, Q.; Niu Cong Zeng, J.; Chen, C.; Wang, S.; Yuan, X. Calibration of parameters for discrete element simulation of grapevine cold-proof soil interacting with soil-clearing components. J. Agric. Eng. 2020, 36, 40–49. [Google Scholar]

- Song, S.; Tang, Z.; Zheng, X.; Liu, J.; Meng, X.; Liang, Y. Calibration of discrete elemental parameters of a post-tillage soil model for cotton fields in Xinjiang. J. Agric. Eng. 2021, 37, 63–70. [Google Scholar]

- Xie, F.; Wu, Z.; Wang, X.; Liu, D.; Wu, B.; Zhang, Z. Calibration of soil discrete element parameters based on unconfined compressive strength test. J. Agric. Eng. 2020, 36, 39–47. [Google Scholar]

- Yuan, J. Simulation Analysis and Experimental Research on the Operation Process of Self-Excited Vibration Deep Pine Machine Based on DEM-MBD Coupling; Jilin University: Changchun, China, 2022. [Google Scholar] [CrossRef]

- Yan, D. Soybean Seed Particle Modelling and Simulation Analysis and Experimental Research on Seed Casting and Mulching Compaction Process; Jilin University: Changchun, China, 2021. [Google Scholar] [CrossRef]

- Johnson, K.L.; Kendall, K.; Roberts, A.D. Surface energy and contact in elastic solids. Proc. R. Soc. Lond. A Math. Phys. Sci. 1971, 324, 301–313. [Google Scholar]

- Hu, G.-M. Analytical Simulation of Granular Systems by Discrete Element Method—An Introduction to Industrial Applications of Discrete Element Method and Edem Software; Wuhan University of Technology Press: Wuhan, China, 2010. [Google Scholar]

- Guan, C. Basic Research on the Technology of Double-Axis Layered Rotary Ploughing and Soil Breaking and Ridging; Jiangsu University: Zhenjiang, China, 2021. [Google Scholar] [CrossRef]

- Tian, X. Research on the Technology of Corn Stalk Mixed Burying and Returning to the Field in Black Soil Area and Its Supporting Key Components; Jilin University: Changchun, China, 2022. [Google Scholar] [CrossRef]

- Yang, T. Analysis of Interaction between Elastic Wheels and Soft Ground Based on Discrete Element Method; Jilin University: Changchun, China, 2021. [Google Scholar]

- Xia, R.; Li, B.; Wang, X.; Li, T.; Yang, Z. Measurement and calibration of discrete elemental parameters of wet bulk coal. Measurement 2019, 142, 84–95. [Google Scholar] [CrossRef]

- Franco, Y.; Rubinstein, D.; Shmulevich, I. Determination of discrete element model parameters for soil-bulldozer blade interaction. In Proceedings of the 15th International Conference of the ISTVS, Hayama, Japan, 25–29 September 2005; pp. 25–29. [Google Scholar]

- Asaf, Z.; Shmulevich, I.; Rubinstein, D. Predicting soil-rigid wheel performance using distinct element methods. Trans. ASABE 2006, 49, 607–616. [Google Scholar] [CrossRef]

- Tamas, K.; Bernon, L. Role of particle shape and plant root system in discrete element modelling of soil-sweep interaction. Biosyst. Eng. 2021, 211, 77–96. [Google Scholar] [CrossRef]

- Xu, T.; Zhang, R.; Wang, Y.; Jiang, X.; Feng, W.; Wang, J. Simulation analysis of the mulching and compaction operation process of precision seeding unit based on the coupled model of DEM and MBD. Processes 2022, 10, 1103. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, P.; Zhang, H.; Tan, C.; Wan, W.; Wang, Y. Study on the Parameter Calibration of Discrete Element Simulation of Cotton Straw in Xinjiang. J. Agric. Mach. pp. 1–10. Available online: http://kns.cnki.net/kcms/detail/11.1964.s.20231115.1136.012.html (accessed on 25 December 2023).

- Zhou, H.; Che, H.; Geng, D.; Zhou, H.; Che, H.; Geng, D.; Chen, M.; Zhang, Y. Establishment of discrete element model and parameter calibration of typical soil in cornfield. J. Agric. Mach. 2023, 54, 49−60+113. [Google Scholar]

- Zhang, X.; Yang, Y.; Liu, H.; Liu, J.; Zhang, Z.; Cao, S. Design and test of double-fixed knife sliding-cutting anti-winding banana stalk crushing and returning machine. J. Agric. Mach. pp. 1–17. Available online: http://kns.cnki.net/kcms/detail/11.1964.S.20231213.1343.008.html (accessed on 25 December 2023).

- Li, X.; Liao, Q.; Wang, L.; Li, M.; Du, W. Design and test of the perforated wheel of the high-speed pneumatic collector for rice, wheat and oil. J. Agric. Eng. 2023, 39, 35–48. [Google Scholar]

- Fang, H.; Ji, C.; Chandio, F.A.; Guo, J.; Zhang, Q.; Arslan, C. Analysis of soil kinematic behaviour during rotary ploughing based on discrete element method. J. Agric. Mach. 2016, 47, 22–28. [Google Scholar]

- Zeng, Z.; Ma, X.; Chen, Y.; Qi, L. Modelling residue incorporation of selected chisel ploughing tools using the discrete element method (DEM). Soil Tillage Res. 2020, 197, 104505. [Google Scholar] [CrossRef]

- Ding, Q.; Ren, J.; Adam, B.E.; Zhao, J.; Ge, S.; Li, Y. Discrete meta-analysis of deep loosening process in wet clay rice soil. J. Agric. Mach. 2017, 48, 38–48. [Google Scholar]

| Factor | ||||

|---|---|---|---|---|

| Code | JKR Surface Energy | Soil–Soil Static Friction Coefficient | Soil–Soil Rolling Friction Coefficient | Soil–Soil Restitution Coefficient |

| X1/(J·m−2) | X2 | X3 | X4 | |

| −1 | 0.1 | 0.32 | 0.01 | 0.1 |

| 0 | 0.2 | 0.66 | 0.155 | 0.3 |

| 1 | 0.3 | 1 | 0.3 | 0.5 |

| Factor | |||

|---|---|---|---|

| Code | Soil–Q235 Steel | Soil–Q235 Steel | Soil–Q235 Steel |

| Static Friction Coefficient r1 | Rolling Friction Coefficient r2 | Restitution Coefficient r3 | |

| −1 | 0.1 | 0.02 | 0.1 |

| 0 | 0.35 | 0.21 | 0.3 |

| 1 | 0.6 | 0.4 | 0.5 |

| Factor | |||||

|---|---|---|---|---|---|

| NO. | JKR Surface Energy | Soil–Soil Static Friction Coefficient | Soil–Soil Rolling Friction Coefficient | Soil–Soil Restitution Coefficient | Repose AngleY1/ |

| X1/(J·m−2) | X2 | X3 | X4 | (°) | |

| 1 | 0.3 | 1 | 0.155 | 0.3 | 54.6 |

| 2 | 0.1 | 0.66 | 0.3 | 0.3 | 46.5 |

| 3 | 0.1 | 1 | 0.155 | 0.3 | 49.8 |

| 4 | 0.2 | 0.32 | 0.01 | 0.3 | 40 |

| 5 | 0.2 | 0.66 | 0.3 | 0.1 | 52.3 |

| 6 | 0.3 | 0.66 | 0.155 | 0.5 | 53.65 |

| 7 | 0.3 | 0.32 | 0.155 | 0.3 | 53.2 |

| 8 | 0.2 | 0.66 | 0.155 | 0.3 | 44.73 |

| 9 | 0.2 | 0.32 | 0.3 | 0.3 | 49.7 |

| 10 | 0.1 | 0.66 | 0.155 | 0.5 | 50.34 |

| 11 | 0.1 | 0.32 | 0.155 | 0.3 | 55 |

| 12 | 0.3 | 0.66 | 0.3 | 0.3 | 50.65 |

| 13 | 0.2 | 0.66 | 0.01 | 0.1 | 39.7 |

| 14 | 0.2 | 1 | 0.3 | 0.3 | 49.4 |

| 15 | 0.1 | 0.66 | 0.155 | 0.1 | 55 |

| 16 | 0.2 | 0.66 | 0.155 | 0.3 | 45 |

| 17 | 0.2 | 0.66 | 0.3 | 0.5 | 36.3 |

| 18 | 0.1 | 0.66 | 0.01 | 0.3 | 37.25 |

| 19 | 0.3 | 0.66 | 0.01 | 0.3 | 41.64 |

| 20 | 0.2 | 0.66 | 0.155 | 0.3 | 45 |

| 21 | 0.3 | 0.66 | 0.155 | 0.1 | 49.16 |

| 22 | 0.2 | 0.66 | 0.155 | 0.3 | 46.45 |

| 23 | 0.2 | 0.32 | 0.155 | 0.5 | 46.64 |

| 24 | 0.2 | 1 | 0.155 | 0.5 | 47.8 |

| 25 | 0.2 | 0.32 | 0.155 | 0.1 | 45 |

| 26 | 0.2 | 1 | 0.155 | 0.1 | 43.07 |

| 27 | 0.2 | 0.66 | 0.01 | 0.5 | 34.46 |

| 28 | 0.2 | 1 | 0.01 | 0.3 | 35.18 |

| 29 | 0.2 | 0.66 | 0.155 | 0.3 | 46.22 |

| Factor | ||||

|---|---|---|---|---|

| NO. | Soil–Q235 Steel | Soil–Q235 Steel | Soil–Q235 Steel | Sliding Friction |

| Static Friction Coefficient r1 | Rolling Friction Coefficient r2 | Restitution Coefficient r3 | Angle Y2/(°) | |

| 1 | 0.1 | 0.21 | 0.1 | 8.4 |

| 2 | 0.6 | 0.21 | 0.5 | 32.3 |

| 3 | 0.1 | 0.02 | 0.3 | 7.9 |

| 4 | 0.35 | 0.4 | 0.5 | 20.7 |

| 5 | 0.6 | 0.4 | 0.3 | 32 |

| 6 | 0.35 | 0.21 | 0.3 | 21 |

| 7 | 0.35 | 0.4 | 0.1 | 21 |

| 8 | 0.1 | 0.21 | 0.5 | 7.9 |

| 9 | 0.35 | 0.02 | 0.5 | 21.1 |

| 10 | 0.35 | 0.21 | 0.3 | 20.6 |

| 11 | 0.35 | 0.21 | 0.3 | 20.8 |

| 12 | 0.35 | 0.21 | 0.3 | 20.4 |

| 13 | 0.35 | 0.02 | 0.1 | 21.3 |

| 14 | 0.1 | 0.4 | 0.3 | 7.4 |

| 15 | 0.35 | 0.21 | 0.3 | 21 |

| 16 | 0.6 | 0.21 | 0.1 | 31.7 |

| 17 | 0.6 | 0.02 | 0.3 | 31.9 |

| Variance | Sum of | Degree of | Mean | F | P |

|---|---|---|---|---|---|

| Source | Squares | Freedom | Square | ||

| Model | 832.42 | 14 | 59.46 | 4.80 | 0.0029 |

| X1 | 6.77 | 1 | 6.77 | 0.5462 | 0.4721 |

| X2 | 7.82 | 1 | 7.82 | 0.6318 | 0.4400 |

| X3 | 267.15 | 1 | 267.15 | 21.57 | 0.0004 |

| X4 | 18.85 | 1 | 18.85 | 1.52 | 0.2376 |

| X1X2 | 10.89 | 1 | 10.89 | 0.8793 | 0.3643 |

| X1X3 | 0.0144 | 1 | 0.0144 | 0.0012 | 0.9733 |

| X1X4 | 20.93 | 1 | 20.93 | 1.69 | 0.2146 |

| X2X3 | 5.11 | 1 | 5.11 | 0.4124 | 0.5311 |

| X2X4 | 2.39 | 1 | 2.39 | 0.1927 | 0.6674 |

| X3X4 | 28.94 | 1 | 28.94 | 2.34 | 0.1486 |

| X12 | 185.28 | 1 | 185.28 | 14.96 | 0.0017 |

| X22 | 23.90 | 1 | 23.90 | 1.93 | 0.1865 |

| X32 | 169.98 | 1 | 169.98 | 13.72 | 0.0024 |

| X42 | 0.0381 | 1 | 0.0381 | 0.0031 | 0.9565 |

| Pure Error | 2.51 | 4 | 0.6280 | ||

| Cor Total | 1005.82 | 28 | |||

| Model | 1163.83 | 9 | 129.31 | 2107.57 | <0.0001 |

| r1 | 1159.21 | 1 | 1159.21 | 18,892.85 | <0.0001 |

| r2 | 0.1513 | 1 | 0.1513 | 2.47 | 0.1604 |

| r3 | 0.0200 | 1 | 0.0200 | 0.3260 | 0.5859 |

| r1r2 | 0.0900 | 1 | 0.0900 | 1.47 | 0.2651 |

| r1r3 | 0.3025 | 1 | 0.3025 | 4.93 | 0.0618 |

| r2r3 | 0.0025 | 1 | 0.0025 | 0.0407 | 0.8458 |

| r12 | 3.84 | 1 | 3.84 | 62.59 | <0.0001 |

| r22 | 0.0001 | 1 | 0.0001 | 0.0017 | 0.9681 |

| r32 | 0.3069 | 1 | 0.3069 | 5.00 | 0.0604 |

| Pure Error | 0.2720 | 4 | 0.0680 | ||

| Cor Total | 1164.26 | 16 |

| Simulation Test Parameters | Value |

|---|---|

| JKR surface energy | 0.2 |

| Soil–soil static friction coefficient | 0.596 |

| Soil–soil rolling friction coefficient | 0.01 |

| Soil–soil restitution coefficient | 0.207 |

| Soil–Q235 steel static friction coefficient | 0.589 |

| Soil–Q235 steel rolling friction coefficient | 0.146 |

| Soil–Q235 steel restitution coefficient | 0.369 |

| Parameter | Simulation Test | Physical Test | Relative Error/% |

|---|---|---|---|

| Soil angle of repose/(°) | 37 | 35.5 | 4 |

| soil sliding friction angle/(°) | 32.2 | 31.5 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, K.; Wang, J.; Liu, M.; Wang, P.; Fu, D.; Feng, W.; Chu, L.; Ning, Y.; Wang, Y.; Guo, Y. Parameter Calibration for Discrete Element Simulation of the Interaction between Loose Soil and Thrown Components after Ginseng Land Tillage. Processes 2024, 12, 246. https://doi.org/10.3390/pr12020246

Du K, Wang J, Liu M, Wang P, Fu D, Feng W, Chu L, Ning Y, Wang Y, Guo Y. Parameter Calibration for Discrete Element Simulation of the Interaction between Loose Soil and Thrown Components after Ginseng Land Tillage. Processes. 2024; 12(2):246. https://doi.org/10.3390/pr12020246

Chicago/Turabian StyleDu, Ke, Jingli Wang, Min Liu, Pengyu Wang, Daping Fu, Weizhi Feng, Lidong Chu, Yichao Ning, Yang Wang, and Yingjie Guo. 2024. "Parameter Calibration for Discrete Element Simulation of the Interaction between Loose Soil and Thrown Components after Ginseng Land Tillage" Processes 12, no. 2: 246. https://doi.org/10.3390/pr12020246

APA StyleDu, K., Wang, J., Liu, M., Wang, P., Fu, D., Feng, W., Chu, L., Ning, Y., Wang, Y., & Guo, Y. (2024). Parameter Calibration for Discrete Element Simulation of the Interaction between Loose Soil and Thrown Components after Ginseng Land Tillage. Processes, 12(2), 246. https://doi.org/10.3390/pr12020246