Abstract

The separation of high-purity hydrogen from mixed gasses using dense metallic alloy membranes is essential for advancing a hydrogen-based economy. Palladium-based membranes exhibit outstanding catalytic activity and theoretically infinite hydrogen selectivity, but their high cost and limited performance in contaminant-rich environments restrict their widespread use. This study addresses these limitations by exploring strategies to develop cost-effective, high-performance alternatives. Key challenges include the vast compositional design space, lack of systematic design principles, and the slow pace of traditional material development. This review emphasizes the potential of high-throughput and combinatorial techniques, such as composition-spread alloy films and the statistical design of experiments (DoE), combined with machine learning and materials informatics, to accelerate the discovery, optimization, and characterization of palladium-based membranes. These approaches reduce development time and costs while improving efficiency. Focusing on critical properties such as surface catalytic activity, resistance to chemical and physical stresses, and the incorporation of low-cost base metals, this study introduces domain-specific descriptors to address data scarcity and improve material screening. By integrating computational and experimental methods, future research can identify hidden material correlations and expedite the rational design of next-generation hydrogen separation membranes.

1. Introduction

Transitioning to clean energy is one of the most effective solutions to mitigate carbon-induced climate change and remains central to global sustainable development efforts []. At the heart of this transition are low-carbon energy vectors, designed to store and transport energy with minimal environmental impact throughout their lifecycle [,]. Among these, green hydrogen has emerged as a key player in facilitating the shift toward a carbon-neutral energy infrastructure. Hydrogen’s appeal is driven by several factors: it is the most abundant element in the universe, constituting 75% of its mass, and its unique properties make it ideal for energy applications. As the lightest chemical element, with a gaseous H₂ density of 0.00082 g/cm3 at the standard atmospheric pressure and 20 °C, hydrogen offers significant advantages for energy storage and transportation []. Additionally, the conversion of hydrogen’s chemical energy to electricity or heat is entirely carbon-free at the point of use. With an energy-to-weight ratio of 143 MJ/kg based on the higher heating value (HHV) and 120 MJ/kg on the lower heating value (LHV), hydrogen outperforms other non-nuclear energy sources [,,].

However, hydrogen usage depends on its purity, which varies depending on the production method and downstream purification processes. A life cycle assessment shows that hydrogen can achieve near carbon neutrality when supported by power-to-hydrogen systems or carbon capture, utilization, and storage (CCUS) technologies []. Given its status as a priority energy carrier in distributed energy systems, hydrogen is considered a critical element of a decarbonized, sustainable energy future [,].

Although hydrogen gas does occur naturally—such as in Bourakebougou, Mali []—most hydrogen in use today is produced synthetically. Synthetic hydrogen, therefore, will continue to predominate until strategies to harness natural hydrogen sources become techno-economically viable. This predominance arises from various challenges associated with geological hydrogen, including infrastructure, exploration, extraction, environmental and safety considerations, as well as storage and transportation.

Current production methods are often classified using a color-coded system based on their carbon footprint. For example, black hydrogen is produced from coal without carbon capture, while gray hydrogen comes from natural gas without CCUS. Low-carbon hydrogen includes green hydrogen, produced from renewable energy, blue hydrogen from fossil fuels with CCUS, and aqua hydrogen, similar to blue hydrogen but without carbon emissions [,]. Despite a future shift toward green hydrogen, in 2023, two-thirds of the 97 Mt of global hydrogen production came from unabated natural gas, and one-fifth from unabated coal, contributing to 75–95% of the 920 Mt CO₂ emissions associated with global hydrogen production [].

Hydrogen’s demand spans industries such as agriculture and food, chemicals (e.g., methanol production), healthcare, transportation, energy, manufacturing, and nuclear fusion [,,]. However, hydrogen purity requirements vary significantly by application. For instance, ultra-pure hydrogen is critical in contaminant-sensitive industries like polymer electrolyte membrane fuel cell vehicles (PEMFCVs) and microelectronics, where purity levels of ≥99.7% (ISO 14687:2019 standard []) and 99.9999%, respectively, are required [,,]. Meeting these purity standards is challenging due to the impurities typically found in crude hydrogen produced from fossil fuels. These mixtures contain carbon oxides (CO, CO2), O2, H2O, N2, NOx, NH3, SOx, volatile organic compounds (VOCs), sulfur compounds, and metals, among others. Thus, high-purity hydrogen production requires two critical downstream processes: separation, followed by further purification or upgrading to meet industrial standards.

Hydrogen separation and recovery is a well-established industry that uses adsorption, cryogenic, and membrane separation techniques. Pressure swing adsorption (PSA) accounted for over 85% of global hydrogen production in 2009 due to its techno-economic feasibility, with applications ranging from small to large-scale plants, achieving purity levels as high as 99.9999 vol.% [,]. However, PSA is less suited to small-scale production due to high initial investment and operational costs []. Cryogenic separation, while offering superior recovery rates, is the most capital- and cost-intensive method []. Given the rising importance of distributed energy systems—where energy conversion units are located near consumers—membrane technology provides a modular solution with lower investment and maintenance costs []. While polymer membranes dominate due to lower costs and mild operation conditions, metallic membranes offer superior hydrogen permselectivity at high temperatures [,], making them valuable in contaminant-sensitive applications like fuel cells [,].

Despite over 60 years of development, metallic membranes have seen limited application outside niche sectors like microelectronics and nuclear fusion []. The slow adoption is due to the high cost of palladium and other precious metals, combined with insufficient mechanical strength and resistance to chemical poisoning. Efforts have been made to explore multicomponent Pd-based alloys, body-centered cubic (BCC) refractory metal alloys, and amorphous alloys [,,]. However, Pd-based membranes have demonstrated limited long-term resistance to hydrogen sulfide poisoning. BCC refractory metal alloys, while promising, lack the native catalytic surface properties required for effective hydrogen dissociation unless coated with noble metals. Furthermore, amorphous alloys, being metastable, face the risk of crystallizing at high temperatures, restricting their use to lower temperature applications where hydrogen permeation rates are slower and hydrogen embrittlement-induced membrane destruction is a potential threat [,,,]. While computational chemistry based on density functional theory has been employed to screen new alloys, much of the work relies on trial and error, informed guesswork, and past literature. Density functional theory (DFT) approaches become prohibitive in substitutionally disordered systems with more than three components [,], and experimental trials are resource-intensive and prone to failure []. The challenge remains to develop fast, robust methods for rational metallic membrane design.

Recent advances in heterogeneous catalysis and materials science have increasingly used combinatorial and high-throughput techniques, along with data-driven methods, to reveal hidden insights and establish structure–property–performance relationships [,]. A key driver of this shift is Material Informatics (MI)—a term coined by J. R. Rodgers in 2003 []—which has revolutionized materials research by enabling rapid screening and optimization through artificial intelligence, data analytics, and computational methods. Despite its success in catalysis and material design, material informatics remains underutilized in metallic membrane development.

Building on these insights, this review presents selected case studies where combinatorial and high-throughput techniques have significantly advanced research on Pd-based membranes for hydrogen separation. Additionally, it offers a forward-looking perspective on leveraging material informatics to accelerate metallic membrane development. Although the literature on applying material informatics to metallic membrane design is currently scarce, we project how this approach could expedite the design of Pd-based membranes. This includes guidelines for applying machine learning to high-throughput screening and a proposed set of feature descriptors to guide future research in this rapidly evolving field. To ensure completeness, an overview of the three main industrial hydrogen separation methods is given.

2. General Overview of Main Hydrogen Separation Technologies

Industrially applied methods in hydrogen gas separation can be broadly categorized into adsorption-based techniques, cryogenic separation, and membrane diffusion-driven processes [,,,,,,,].

Pressure Swing Adsorption (PSA) is the leading industrial hydrogen separation method, operating through a cyclic process that selectively adsorbs impurities from hydrogen-rich feed gas onto porous materials like zeolites, activated carbons, silica, and alumina gel at high pressure (10–40 bar) and ambient temperature (290–310 K) [,,,,,,]. Impurities are released during regeneration by reducing the pressure (1–3 bar), allowing the adsorbent to be reused []. PSA is effective for feed gasses containing 60–90 mol% hydrogen, producing ultra-pure hydrogen—99.9% purity for ammonia synthesis and >99.9999% purity with <1 ppm CO, CO₂, and CH₄ for semiconductor applications [,]. Recovery rates typically reach 80%, with advanced systems like Honeywell UOP’s Polybed™ PSA achieving over 90% recovery and handling high throughputs of up to 265,000 Nm3/h []. PSA is resilient to impurities such as COx, hydrocarbons, H₂S, and water, unlike dense metallic membranes, and recent advancements have improved its compactness and cost-efficiency. However, it faces challenges, including high energy demands, inefficiency with feed gasses containing less than 90% hydrogen, and impracticality for small-scale applications [,]. Low-hydrogen feeds require larger units to manage impurity loads, further increasing system size and complexity [,].

Cryogenic separation is the second most common method for gas separation, utilizing partial condensation in distillation column cascades to exploit vapor pressure differences at cryogenic temperatures and high pressures [,]. This process separates lighter components with higher vapor pressures and lower boiling points from heavier components and is also used in hydrogen isotope separation for nuclear fusion systems []. While cryogenic separation achieves lower hydrogen purities (95–98%) than PSA, it offers higher productivity and facilitates hydrogen liquefaction, making it well-suited for large industrial applications but impractical for smaller scales, such as hydrogen fuel station purification [,]. Its major drawbacks include high energy consumption, significant costs due to extreme operating conditions, and safety risks associated with the flammability and toxicity of cryogenic fluids [,,,].

Membrane separation is widely studied for hydrogen purification due to its modularity, low cost, and suitability for small to medium-scale operations compared to PSA and cryogenic methods [,,,,]. The most commonly used membranes are polymers, ceramics porous carbons, and dense metallic membranes. The latter group offers an advantage in high-temperature environments and can achieve infinite permselectivity, unlike dense organic polymers [,,]. A comparative study showed that Pd-based membrane-assisted hydrogen separation (0.50 kWh/kg energy, 28.4% exergy efficiency) is more energy-efficient than cryogenic-assisted methods (2.01 kWh/kg energy, 14.7% exergy efficiency), though the latter has achieved higher purity and recovery rates, highlighting a trade-off between efficiency and output quality [].

Table 1 compares the three main hydrogen separation technologies—PSA, cryogenic distillation, and membrane separation—based on feed gas requirements, product purity, yield, operating conditions, recovery capacity, product pressure, and costs. While compression or liquefaction costs may apply for storage or transport, membranes generally provide a favorable trade-off in purity and cost.

Table 1.

Comparison of Hydrogen Purification Techniques [].

3. Market Outlook and Future Potential of Membrane Technologies

As of 2023, the global membrane gas separation market was valued at $1.4 billion, with polymer membranes dominating at 73.3% across sectors []. Gas separation-specific membranes made up 10.53% of the overall market, with polyimide and polyaramids leading due to their chemical resistance, high thermal stability, and superior gas separation capabilities. Other materials such as polysulfone and cellulose acetate are also widely used []. The global hydrogen separation membrane market was valued at USD 194.6 million in 2023, is projected to reach USD 298 million by 2030, and is growing at a CAGR of 6.3% []. Inorganic membranes (ceramics and metal oxides) accounted for 20.3% of the market, while metallic membranes made up 6.68%. This segment is expected to grow at a CAGR of 6.7% from 2024 to 2030 []. Market growth in hydrogen separation is driven by decarbonization efforts, increased demand for clean energy, energy efficiency, and cost-effectiveness, as well as the modularity of membranes, which suit medium- and small-scale applications. Although metallic membranes, such as those used in hydrogen diffusers, can achieve ultra-pure hydrogen (up to 8N purity), they require a pure feed (≥a volume fraction of 99.5%) to avoid corrosion, poisoning, and mechanical issues under high temperature and pressure conditions [,]. Additionally, the high cost and limited availability of certain metals, influenced by geopolitical factors, pose challenges. The characteristics of the most reported hydrogen permselective membranes are summarized in Table 2.

Table 2.

Hydrogen selective membrane main types [,,].

4. Dense Metallic Membranes

Hydrogen purification technologies are crucial for the hydrogen economy, with a focus on medium-scale production units rather than large-scale facilities. Membranes, especially dense metallic ones, offer a promising, cost-effective solution. When defect-free, dense metallic membranes can achieve infinite hydrogen permselectivity, producing impurity-free gas and outperforming conventional methods in recovery rates [,]. Metallic membranes have been extensively researched, with around 10,000 related articles indexed by 2013 []. This research builds on early discoveries, including Deville and Troost’s work on hydrogen permeability through platinum (1863) and Graham’s 1866 study on palladium’s hydrogen absorption [,,]. The first commercial Pd-based membranes (Pd–25%Ag) were introduced in the 1960s, leading to ongoing research on palladium alloys and silver-, gold-free palladium-lean membranes using Group IVB, VB, and VIB alloys as alternatives [,,].

4.1. Applications of Dense Metallic Membranes

Dense metallic membranes (Pd, Pt, Ni, and elements from groups IIIB to VB) are key for providing ultrapure hydrogen (9N, 99.9999999%) with minimal energy consumption in various applications [,,,]. These include:

Commercial-Scale Production of Ultrapure Hydrogen: Used as key components in hydrogen diffusers, with or without heated getters, for ultra-pure hydrogen supply in microelectronics.

Hydrogen Isotope Separation: Palladium alloys are employed in catalyzed isotopic exchange for tritium and deuterium recovery in fusion fuel cycles (tokamak systems) [,,,,].

Gas Sensing: Utilized In Sensitive Detection Systems [].

Permeable Catalyst Applications: Palladium-based membranes can catalyze hydrogenation reactions by allowing hydrogen dosing through the membrane’s high-pressure side and catalyzed hydrogenation reaction on the low-pressure surface enabling reactions such as dienes conversion to olefins, which aids sustainable polymer upgrading [,,].

Process Intensification: Integrated into catalytic membrane reactors to improve energy efficiency in hydrogenation, dehydrogenation, and related reactions [,,,,,,,]. These membranes optimize hydrogen production in systems like steam methane reforming and coal gasification.

Ammonia Synthesis: Group V hydrogen permselective membranes (e.g., niobium-based) have enabled ammonia synthesis under milder conditions (0.8 atm, 500 °C), achieving a synthesis rate of 6 × 10⁻⁹ mol·cm⁻2·s⁻1 [], compared to the energy-intensive Haber-Bosch process (200 atm, 400–450 °C).

Electrochemical Palladium Membrane Reactors (ePMRs): In ePMRs, Pd-based membranes separate the electrochemical chamber from the hydrogenation chamber, utilizing water as the hydrogen source, eliminating the need for pure H₂ gas, and mitigating the competitive hydrogen evolution reaction (HER) [,,].

Hydrogen Storage and Catalysis: Palladium-based hydrides are explored for hydrogen storage and catalytic applications, including hydrogen evolution reactions and superconductivity [,,].

Despite their potential, metallic alloy membranes face limitations that hinder broader industrial adoption, resulting in a smaller market share compared to polymeric and other inorganic membranes.

4.2. Problems with Pure Palladium Membranes

Pure palladium membranes face several challenges that limit their widespread application. These include:

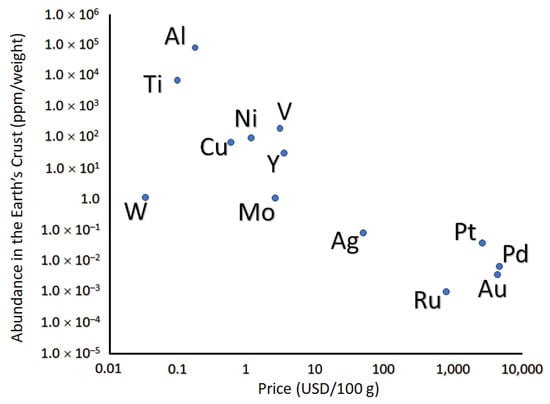

High Cost and Supply Uncertainty: Palladium, along with platinum and rhodium, is costly and scarce due to its low price-to-crustal abundance ratio, as shown in Figure 1.

Figure 1.

Abundance and cost of the most used metals for the fabrication of Pd-based membranes (Each price is referred to 2019. Price of titanium is based on TiO2 with a minimum purity of 95%; price of yttrium is based on yttrium metal with minimum purity 99.9%; price of vanadium is based on the vanadium pentoxide). Reproduced with permission from [], Progress in Energy and Combustion Science; published by Elsevier, 2020.

Hydrogen Embrittlement in Palladium: Hydrogen absorption in palladium (Pd) below critical conditions (Tc = 298 °C, Pc = 2 MPa) causes the formation of two hydride phases: the hydrogen-lean α-PdH and the hydrogen-rich β-PdH, both in a face-centered cubic FCC structure but with different lattice parameters [,]. As hydrogen is absorbed, the Pd lattice parameter expands from 3.889 Å to 3.894 Å at H/Pd ≈ 0.015, reaching the maximum solubility in the α-PdH phase. At higher hydrogen uptakes, the β-PdH phase nucleates and grows, with the lattice parameter increasing to 4.025 Å at H/Pd ≈ 0.6, and up to 4.04 Å at H/Pd = 0.70 as a result of ~70% of the octahedral sites occupied []. The coexistence of α- and β-PdH results in a ΔVβ-α/Vα = 10% irreversible volume expansion, leading to mechanical degradation, including a loss of ductility and increased brittleness, known as hydrogen embrittlement. This issue arises even under controlled temperature cycling in inert gas environments. The critical temperature for the α → β phase transition is reduced by alloying Pd with transition metals [].

Poisoning in Sulfur Environments: In environments with H2S concentrations >100 ppm, a dense tetrapalladium sulfide Pd4S layer forms on palladium membranes, reducing hydrogen permeance to 1/20th of pure Pd [,,]. Pd4S can eventually cover the entire membrane, causing “corrosive decay” []. Despite its presence, pure Pd retains hydrogen dissociation activity, indicating that Pd4S impedes H2 diffusion []. Pd4S formation follows the reaction:

8Pd(s) + S2(g) ⇌ 2Pd4S(s) ΔGf° (J) = −368,790 + 168.2 T (K)

At lower temperatures (623–908 K), Pd4S is favored due to its lowest Gibbs free energy. Additionally, Pd4S can form via:

4Pd + H2S ⇄ Pd4S + H2, ΔG = −71.613 kJ/mol.

Pd4S crystallizes in a tetragonal structure with larger lattice parameters () than pure Pd (~3.89Å), causing stress cracking and sulfur propagation [,]. Below 100 ppm H2S, poisoning may occur through chemisorptive dissociation of H2S, forming Pd-S covalent bonds, and leading to the decomposition of sulfur adatoms that physically block hydrogen dissociation sites or possibly weaken Pd catalytic properties by withdrawing electron density from Pd in the surface vicinity [,], as shown in the reactions (3)–(5) []:

where X* denotes an adsorbed species, and * an unoccupied surface site.

H2S + * ⇌ H2S*

H2S* + * ⇌ HS* + H*

HS* + * ⇌ S* + H*

Poisoning in CO environments: CO inhibits H2 permeation through Pd membranes at temperatures <250 °C (for 50% CO in H2) or <400 °C [,], mainly through reversible blocking of Pd surface sites. CO’s effect is negligible at higher temperatures (>250 °C or 400 °C), where CO adsorption and Pd site blocking becomes reversible [,]. At higher temperatures, CO can react with Pd to form a metastable Pd-C phase leading to a more deleterious effect than the reversible Pd site-blocking mechanism, although Pd-C has been shown to suppress β-PdH formation []. The Pd-C forming reaction involves carbon deposition and diffusion through the Pd lattice, expanding the lattice parameter. The formation of Pd-C phases is promoted by reactions like Boudouard’s (2CO ⇌ C + CO2 (6)) and methanation (CO + 3H2 ⇌ CH4 + H2O (7)) []. In summary, CO poisoning mechanisms include adsorptive site-blocking, carbon deposition, the formation of bulk Pd1−xCx phases [], and the formation of surface-adsorbed methylene species (CH2*) possibly accompanied by gas-phase CH4 molecules exacerbating with lower temperatures and leading to cumulative site-blocking effects [,]. Further readings on the mechanism of poisoning of Pd-based membranes can be found at [].

4.3. Challenges Associated with Pd–Alloy Membranes

Pd-based alloy membranes face challenges such as corrosion under harsh conditions, poisoning, hydrogen embrittlement during thermal cycling, mechanical integrity loss over time, and the high cost and uncertainty supply of platinum group metals [,,,,]. Early membranes in the 1960s used Pd–Ag alloys to address β-hydride nucleation and prevent dimensional expansion in pure Pd membranes. Despite recent advances like applying electric fields to reduce sulfur poisoning, alloying remains the preferred approach for improving membrane performance [,].

Five Key Considerations for Hydrogen Separation Membranes [].

Hydrogen Permeability and Phase Stability: Membranes must resist α→β phase transformation during operation (400–600 °C). Alloys should be designed to avoid hydride formation by closing α-β miscibility gaps at room temperature [].

Thickness–Durability Tradeoff: Thinner membranes improve hydrogen flux and possibly reduce material costs but compromise strength under high-pressure gradients.

Membrane Holder Design: Composite membranes must balance mechanical strength, thermal and chemical stability, and cost-effectiveness.

Membrane Assembly Architecture: Use-case-oriented membrane configurations—tube, folded-foil, or plane-foil—should maximize separation efficiency, productivity, and recovery rate.

Start-up/Shutdown Optimization: Proper operating protocols can enhance performance and extend membrane lifespan.

Considering Intrinsic Properties Specifically of The Dense Metallic Membrane: Membranes should exhibit high hydrogen permeability, corrosion resistance, and mechanical stability at operating conditions (preferably high tensile strength and low Young’s modulus or high elasticity). They must feature low dilatation during hydrogen saturation, small coefficients of thermal expansion, and be easily fabricated into thin foils or tubing [,]. Economically, widespread adoption depends on cost competitiveness and durability compared to alternative technologies.

4.4. Intricacies in Dense Membrane Alloys Development

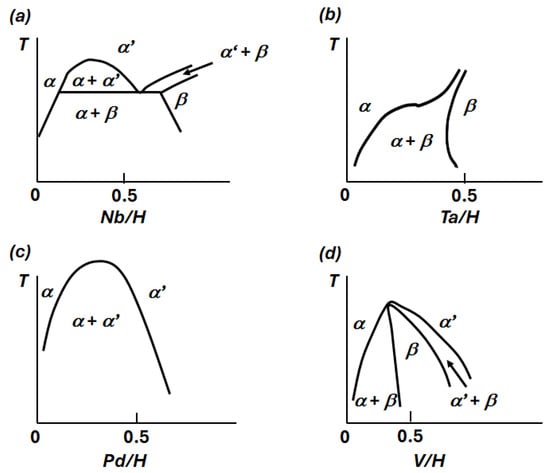

Single-element transition metal membranes (IIIB–VB, Pd) lack long-term stability in hydrogen environments due to hydride phase formation, causing miscibility gaps, volume expansion (ΔV/V0 >> 0), and structural changes, as seen in their PCT diagrams (Figure 2) []. These issues necessitate material modifications for hydrogen transport applications. Table 3 summarizes the hydrogen dissolution properties of commonly used metals.

Figure 2.

Schematic representations of phase diagrams for Group VB and Pd metal–hydrogen systems showing miscibility gaps at low to moderate hydrogen concentrations: (a) Nb–H, (b) Ta–H, (c) Pd–H, (d) V–H. Reproduced with permission from [], Electronic structure and properties of hydrogen in metals; published by Springer Nature, 1983.

Table 3.

Fundamental properties of pure metals for hydrogen separation. Taken from [].

4.4.1. Pd–Cu Series

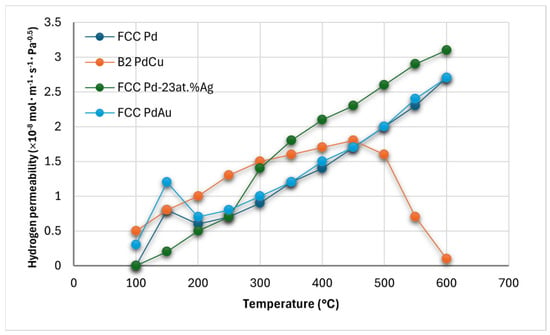

The Pd–Cu binary series offers alloys with distinct hydrogen transport properties, notably Pd60-40 wt.% Cu (Pd47.3–52.7 at.% Cu), an ordered BCC (CsCl-type) structure referred to as B2 structure, exhibiting high hydrogen permeability (comparable to pure Pd at 450–475 °C), superior tensile strength, lower thermal expansivity, and resistance to hydrogen embrittlement due to reduced hydrogen solubility. However, its permeability drops sharply above 500 °C due to a hydrogen-accelerated B2 → FCC + BCC phase transition (Figure 3) [,]. B2 Pd–Cu resists β-hydride nucleation but is less resistant to sulfur poisoning than disordered FCC Pd–Cu, which has lower hydrogen permeability [,]. Density functional theory attributes the lower hydrogen permeability in FCC Pd–Cu compared to BCC Pd–Cu to hydrogen’s diffusion barrier: lower for BCC Pd–Cu (0.016 eV with the interstitial diffusion following a Tet-to-Tet path) than FCC Pd–Cu (0.346 eV with the interstitial diffusion following an Oct-to-Tet path), where interstitial hydrogen clustering impedes diffusion in FCC alloys []. FCC Pd–Cu permeance (908–1173 K) is about 1/10th of pure Pd and depends on synthesis methods for H2S resistance [,]. Figure 3 depicts the hydrogen permeability of Pd60-40 wt.% Cu as a function of the temperature.

Figure 3.

Pure hydrogen permeability in pure FCC Pd (dark blue), FCC Pd–Ag (green), FCC Pd–Au (light-blue), B2 Pd–Cu (orange). Up to ~450° Pd–40wt.%Cu exists in B2 structure, between 450 °C and 550 °C the mixed B2 + FCC exits, and at T > 550 °C a continuous FCC region occurs [].

4.4.2. Pd–Ag Series

The Pd–Ag system, with an optimal composition of Pd-23–25 at.% Ag, has the highest hydrogen permeability in the FCC Pd–Ag series, surpassing pure Pd by 1.7 times at 350 °C [], and offers good hydrogen embrittlement resistance (Figure 3). However, Pd-23 at.% Ag is more susceptible to poisoning by sulfur and carbon compounds than Pd–Cu alloys, making it more suitable for purifiers than separators [,]. Exposure of Pd-25 at.% Ag to a 10 ppm H2S in a 80%H2-concentrated feed causes a rapid flux decline, with Ag5Pd10S5 formation after ~3 days []. Even with sulfur cleanup systems, Pd–Ag membranes risk irreparable poisoning []. Segregation phenomena have also been observed in Pd-25% Ag foils during hydrogen absorption [,,,].

4.4.3. Pd–Au Series

The Pd–Au series, with optimal composition Pd-8–10 at.% Au offers higher chemical stability and superior hydrogen permeability in CO and H2S-rich environments compared to Pd, Pd–Ag, and Pd–Cu alloys [,,]. McKinley found Pd-40 wt.% Au to have higher permeability than Pd–Cu or Pd–Ag when exposed to 4 ppm H2S, though it only achieves less than 50% of pure Pd’s permeability in pure H2 conditions (Figure 3) [,,]. Gold’s high cost is a drawback in Pd–Au alloys.

4.4.4. Pd–Rare-Earth Series

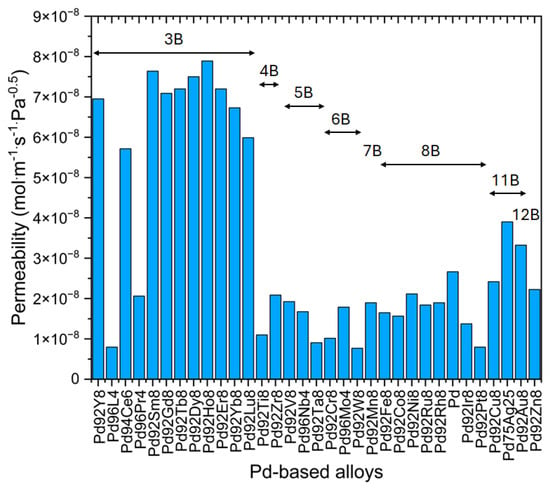

In the Pd–Rare-Earth series, adding to Pd elements like Y, Ce, Gd, Tm, Lu, and Sm in 8.8, 5.75, 8.0, 4.5, 7.70, and 2.6–11.0 at.%, respectively, increases hydrogen permeability compared to pure Pd and Pd-25 at.% Ag due to enhanced high-temperature hydrogen solubility gradients [,,,,]. These alloys also exhibit improved mechanical strength, though solid solution hardening and large lattice expansion compared to pure Pd can impede their mechanical stability. Pd-8.8 wt.% Y, for example, has higher permeability than Pd-25 wt.% Ag but is harder to be worked into thin foils by cold rolling due to several intermediate strain relief annealing requirements []. As a consequence, they are required to be hydrogenated before rolling []. Hydrogen permeability of many binary Pd alloys with solute concentrations equal to 4 at.%, 8 at.%, or 25 at.t% has been studied by Shirasaki and coworkers, and their result is shown in Figure 4 [].

Figure 4.

Hydrogen permeability of various Pd–metal binary alloy membranes PdxM(100−x) ((100–x) represents the atomic concentration of the solute metal) at 873 K, where the metal M’s Group in the Periodic Table of Elements is depicted. The letter B in the figure represents a Group in the Periodic Table of Elements and the preceding roman numeral assigned before B is based on the American Group labelling scheme. Readapted from [].

4.4.5. Refractory Metals Alloys

Refractory metals of Groups VB-VIB transition metals, e.g., tantalum, vanadium, and niobium exhibit hydrogen permeability an order of magnitude higher than pure palladium but are poor catalysts for molecular hydrogen dissociation. To prevent passivation by surface oxidation and enhance dissociative adsorption and recombinative desorption, these metals require surface coating at their entry-terminal layer with more active metals, e.g., palladium [,,].

When designing Pd-based membrane materials, key factors include the maximum solubility of alloying elements in palladium, eliminating the α/β miscibility gap, and optimizing hydrogen permeability, chemical stability, and mechanical resistance. Recent studies suggest that introducing short-range ordered phases improves hydrogen permeability [], and using less expensive dopants as alternatives to silver enhances economic viability []. However, the search for optimal binary or ternary alloys remains complex and resource-intensive due to the large number of potential alloy combinations that need to be synthesized and evaluated.

5. Methods in Palladium Membranes Research

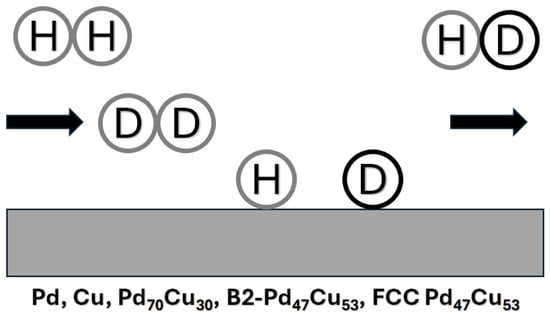

5.1. Mechanism of Mass Transfer in Metallic Membranes

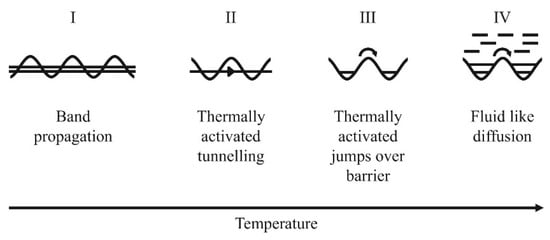

In this review, palladium is deliberately selected as the prototype for metallic membranes, with mechanistic insights applicable to palladium inferred to similar materials. Amongst the variability of theories used to describe light interstitials diffusion, e.g., hydrogen in a host metal crystal lattice, Kehr [] suggested four temperature-dependent possible diffusion mechanisms depicted in Figure 5 below. A summary of each mechanism can be consulted in reference [].

Figure 5.

Kehr’s suggested temperature-dependent diffusion models of light interstitials such as hydrogen in host metal lattice. Reproduced with permission from [], Renewable and Sustainable Energy Reviews; published by Elsevier, 2015.

Specifically, the thermally activated jumps over barrier mechanism commonly applies to hydrogen diffusion in defect-free dense metallic membranes in a gaseous environment and is considered in this review. In such a case, a higher activation energy is required to surmount the barrier, making this process dominant at elevated temperatures.

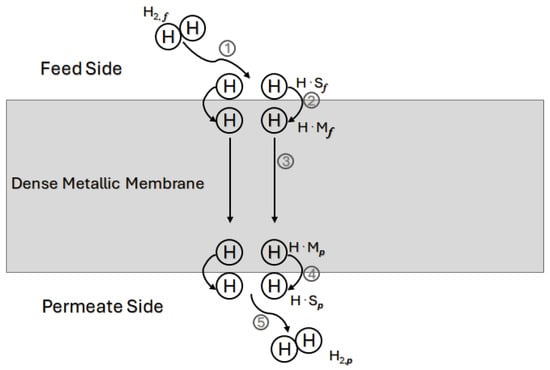

The accepted model of this mechanism (given below) can be attributed to []. Consecutively, when a mixture of gas is to be separated using a Pd-based membrane, from the higher partial pressure side to the lower partial pressure side the solution–diffusion mechanism can be summarized as follows [,,]:

S1: transport of molecular H2(g),f from the bulk gas—the feed gas f—onto the gas layer surrounding the surface Sf, where Sf refers to the membrane’s surface incident to the high-pressure gas flow.

S2 (dissociative adsorption): H2(g),f diatomic molecules are adsorbed at favorable surface sites disseminated on Sf and are catalytically dissociated into H adatoms denoted as H.Sf.

S3 (surface-to-subsurface): hydrogen adatoms H.Sf are absorbed from the adsorbed state into the metal subsurface, occupying thermodynamically favorable interstitial sites M located in the subsurface crystal lattice as H·Mf,

S4 (bulk diffusion): the interstitial H solutes then diffuse across the membrane’s bulk crystal lattice via activated hops with subsequent transition states,

S5 (bulk-to-surface): upon reaching close to the low-pressure side of the membrane referred to as permeate surface Sp, the interstitial H atoms H.Mp egress from the bulk metal onto Sp forming adsorbed HSp species,

S6 (recombinative desorption): pairs of hydrogen atoms species adsorbed on the permeate surface H.Sp associatively desorb as H2(g) molecules,

S7: newly recombined diatomic H2(g),p gas transport away from the low-pressure surface.

Microkinetic modeling is one of the three main approaches for studying reaction kinetics, alongside the Anderson–Schulz–Flory (ASF) distribution and the lumped kinetic model []. Unlike the lumped kinetic model, which primarily focuses on overall reactant conversion—often using empirical power-law expressions that can oversimplify or overcomplicate the reaction details—microkinetic modeling integrates the fundamental surface chemistry of catalytic reactions []. This method is particularly well-suited for investigating reactions involving surface phenomena, as it allows for the identification of key reaction intermediates and the determination of rate-limiting elementary steps. Such insights are crucial for optimizing the performance of membranes and catalysts []. From this perspective, the stepwise diffusion of hydrogen through metals can be described using a detailed sequence of elementary reactions (6)–(11) [].

S2: H2(g),f + 2Sf ⇌ 2H.Sf

S3: H.Sf + Mf ⇌ H.Mf + Sf

S4: H.Mf + Mp ⇌ H.Mp + Mf

S5: H.Mp + Sp ⇌ H.Sp + Mp

S6: 2H.Sp ⇌ H2(g),p + 2Sp

H2(g),f ⇌ H2(g),p

In the previous description, S represents a surface, and M is a metal active site. Note that the S1 is not represented because no reaction happens in that step.

In the case of composite alloy membranes, i.e., supported dense metal membranes, mass transfer through the support layers involving Knudsen, Poiseuille, and ordinary diffusion have to be accounted, when applicable [].

A graphical illustration of the general mechanisms described above is given in Figure 6.

Figure 6.

Schematic of hydrogen-selective diffusion through dense metallic alloy membrane. (1) and (2) external diffusion from the feed gas and dissociative adsorption at the surface metal site followed by transport from the surface to the subsurface, (3) diffusion in the bulk lattice from the subsurface close to the high-pressure side to the subsurface close to the low-pressure side. (4) and (5) the H atoms egress and reassociate followed by desorption in the purified bulk gas. Reproduced with permission from [], Journal of Membrane Science; published by Elsevier, 2013.

Although the dissolution and diffusion mechanisms involved in hydrogen permeation are activated processes, it has been argued that hydrogen surface adsorption is not activation-dependent, provided the Pd surface is perfectly clean [].

To develop robust, domain-specific machine learning feature descriptors—one of the primary goals of this paper—it is essential to gain an in-depth understanding of the hydrogen mass transfer mechanism across membranes. Predicting target properties, such as hydrogen permeability, requires more than simply using the physicochemical properties explicitly present in the mathematical flux expression; indirect and less apparent properties can often serve as even more powerful descriptors. Guided by this rationale, the following sections focus on the experimental determination of the direct properties that describe hydrogen diffusion across dense metallic membranes.

Equation of Diffusion, Richardson Formula, and Siverts’ Law

In the solution–diffusion mechanism, hydrogen diffuses in atomic form through the membrane []. The key physical quantity used to describe hydrogen mass transfer through a dense metallic membrane is the permeation flux J. The latter can be defined as the quantity of hydrogen diffusing through a perpendicular unit cross-sectional area per unit of time []. Fick’s laws of diffusion can model hydrogen mass flow across a dense metal matrix. When one-dimensional and steady-state diffusion are assumed, as is common in practical membrane studies, the mathematical expression is referred to as Fick’s first law, which expression is shown in Equation (12):

where JH represents atomic hydrogen permeation flux, D the coordinate and concentration-independent diffusivity or diffusion coefficient of hydrogen across the medium, the concentration gradient or driving force along the diffusion direction, x. The concentration gradient is assigned a negative sign to indicate that mass flow occurs down the concentration gradient. Strictly speaking, the driving force dC/dx represents the gradient of the chemical potential dμ/dx. As the equilibrium described in Equation (13):

establishes between gaseous molecular hydrogen with pressure and dissolved hydrogen atoms, the chemical potential is expressed as in Equation (14):

where the standard designation (°) indicates 1 bar pressure of , μH refers to H dissolved in the solid phase, is the equilibrium .

By considering the equilibrium in Equation (13) above, one can relate the flux of H to the flux of H2 and integrate Fick’s first law (12) over x = 0 and x = l and keep the concentration difference as ΔCH for the moment being. This gives Equation (15):

where is the thickness of the membrane.

The rate-limiting step for the permeation process can be either surface phenomena or bulk diffusion or a combination of these phenomena thereof [,,], depending on various factors, e.g., the membrane thickness, the presence of defects, membrane surface cleanliness, etc. When the rate-determining step is the transport of hydrogen in the metal matrix (bulk diffusion), surface reactions are considered to be very fast, and the equilibrium reaction above (13) holds. In that case, the equilibrium constant K is:

where is the activity of dissolved hydrogen. For small concentrations (ideal solution), i.e., dilute phase, can be substituted for its concentration, which is conveniently expressed as the dissolved hydrogen-to-metal ratio (H/M), atom ratio r:

Expression (17) is Henry’s law of ideal solubility for a dissociating gas and, for the solution of diatomic gasses that dissolve dissociatively in metals, it is referred to as Sieverts’ law and Ks is Sieverts’ constant. It is remarkable that CH = r, hence combining these equations yields Richardson’s equation defined in Equation (18) as:

where and represent diatomic hydrogen gas partial pressure at the feed and permeate side, respectively. In Equation (18), the quantity:

corresponds to the hydrogen permeability of the membrane.

ϕ has been found to experimentally vary exponentially with the temperature in an Arrhenius-type relationship, thus can be expressed as (19):

where ϕ0 is the pre-exponential factor and Eϕ is the activation energy. It has been suggested that Eϕ < 30 kJ/mol indicates that surface phenomena—such as dissociative adsorption and recombinative desorption of H2—do not significantly contribute to the permeation process, as these surface reactions typically require higher activation energies, ranging from 54 to 146 kJ/mol []. Consequently, designing membranes with lower activation energies for hydrogen permeation, within the operating range, is of critical importance for enhancing performance.

Regularly, there are deviations from ideality (Sievert’s law), and the extended Richardson’s equation is used (20):

where holds for the pressure exponent, a dimensionless number such that 0.5 ≤ n ≤ 1.

Since dissolution and diffusion are activated processes, the solubility constant and diffusivity coefficient have been described by Arrhenius-type relationships (21) and (22), such that:

and

where D0 and K0 are the preexponential factors in the diffusivity and solubility, respectively, and ED and Es their activation energy, respectively. One can easily infer that (23):

Eϕ = ED + ES

A useful alternative to the permeability, where the thickness fluctuates is the permeance defined in Equation (24) as the permeability divided by the thickness:

The steps for the establishment of the previous equations have been discussed in the previous literature [,].

5.2. Experimental Determination of Flux and Permeability

The performance of dense metal membranes is primarily evaluated by their pure hydrogen permeability, selectivity toward hydrogen over other gasses, and long-term durability, specifically, the ability to maintain optimal permeability, selectivity, and mechanical integrity over time. Additionally, the U.S. Department of Energy (DOE) technical targets serve as a benchmark for assessing the viability of metal membranes in hydrogen separation applications (Table 4). The first step in evaluating a dense metallic membrane is to measure its pure hydrogen permeation flux. When only hydrogen permeation is measured during testing, it is referred to as a single-gas permeation test, which assesses the membrane’s performance under pure hydrogen conditions.

Table 4.

U.S. DOE Hydrogen Separation Performance Targets.

5.2.1. Single Gas Permeation Test

Various methods exist to measure the hydrogen permeation flux in single gas permeation testing. The main components of a typical single gas permeation setup are the pure hydrogen and inert gas, e.g., nitrogen gas tanks, mass flow controllers, and if applicable, a soap film flowmeter for permeate gas flow measurements at small flow rates. Digital and manual bubble meters or soap film flow meters are relatively cheap for usage compared to mass flow controllers in pure hydrogen gas testing. The soap film meter directly measures the time taken for the moving front of a soap film to pass through a defined volume at atmospheric pressure, thereby providing the corresponding rate. It is particularly well-suited for measuring small flow rates; however, when a flow tube with a fixed small diameter and length is used, the main design constraint of the flow meter lies in its ability to generate a single coherent soap bubble.

If a flat membrane is taken as an example, the flux is defined as the quantity of hydrogen gas permeating the membrane’s active surface unit area per unit of time. By translating this definition into a Formula (25):

In most recent membrane literature, Quantity can be an extensive parameter such as the volume [L−3] or number of moles. A is the membrane’s active area or the area exposed to incident gas flow.

Since Fick’s First Law and extended Richardson’s equation (given above (20)) are applied, it is recommended that flux values be reported once steady-state conditions are achieved. Establishing this regime can take up to approximately 24 h in some cases []. Monitoring gas permeation over time or observing pressure increases in a calibrated volume on the permeate side of a pre-vacuumed system are commonly used techniques for identifying the steady-state regime. This approach forms the basis of the time-lag method, which is useful for directly determining the diffusion coefficient and indirectly obtaining the solubility constant [,].

From the previous Equation (20), the permeability can be derived as follows:

The permeability is a measure of the gas flux permeated through the membrane at a given partial-pressure difference []. The permeability derived from the above equality is given in Quantity∙[L−1∙T−1∙P−n]. For single gas permeation tests, authors sometimes apply either vacuum on the permeate side in which case can be taken as null, or if the permeate side is left at atmospheric pressure the ≈ 100kPa (depending on geographical localization) has to be taken.

The product of hydrogen flux and membrane thickness is often referred to as specific permeability []. While flux is dependent on membrane thickness, specific permeability is not, as it normalizes the thickness effect. This makes specific permeability a useful parameter for comparing hydrogen permeation fluxes across membranes of varying thicknesses within the same alloy system. Russian researchers have measured the specific hydrogen permeability of metallic membranes by calculating the permeability based on the time required to fill a calibrated volume with permeated hydrogen [,,,].

The determination of the pressure exponent n may give hints on the rate-limiting steps in the permeation process. Oftentimes, the trustworthy value of the pressure exponent n is found by regressing using the least mean-square method the relation from Equation (20) in the straight-line part of the root square function, where the n ∈ [0.5, 1]. The actual value of n is obtained from the regression line with the highest correlation coefficient R2. This value is then compared to 0.5 to predict the rate-limiting step. If n is close to 0.5, the rate-limiting step is bulk diffusion (agreement with Sieverts’ law), and if n considerably deviates from 0.5, other phenomena can be assumed to gain in importance. Regularly, thick Pd-based membranes are found to have n = 0.5 and ultrathin-film membranes can deviate. In their modeling study, ref. [] concluded that bulk diffusion is expected to be the rate-limiting step for pure Pd membrane with thickness down to ~1 μm at temperatures above ∼300 °C, provided that external mass transfer resistance is absent. Care should be taken not to assume n = 0.5 or 1 based on the thickness (inconsistent nature of the rate-limiting step) because several factors other than the thickness (e.g., surface segregation) can cause the mass transfer to deviate from Sieverts’ law. For example, a value of n higher than 1 has been reported in the case of Pd/Ag alloy membranes of thickness 0.5–1.2 μm []. This conclusion is well-known in the literature. Lundin et al. described a method of determining n using a non-linear regression technique consisting of minimizing the sum of the residuals given by the linear regression []. This leads to a curve with a local minimum at one specific pressure dependence indicating the probable value of n, instead of a straight line like in the LMSE method, which will be biased at low n values. Determining whether bulk diffusion or surface phenomena is the rate-limiting step using the parameter n remains a topic of debate in the literature [].

5.2.2. Mixture Gas Tests

Important quality features of palladium membranes or membranes, in general, are the selectivity α, the separation factor SF, and the hydrogen recovery factor HRF [,,]. A common quality parameter characterization technique utilizes an H2/N2 gas mixture to determine hydrogen-to-nitrogen selectivity and separation factor of the membrane. In that case, the H2/N2 separation factor defines how well are H2 components separated compared to N2 components. The as-defined selectivity and separation factor can be inferred for any hydrogen-impurity pair present in the system. The hydrogen recovery factor HRF also represents a critical parameter both in terms of operation and in terms of cost []. The above-mentioned parameters are summarized in Table 5.

Table 5.

Quality parameters for dense metallic membrane separation efficiency.

6. Combinatorial and High-Throughput Experimental Methods in Metallic Membrane Development

Despite the considerable number of investigations geared toward the design and improvement of dense metallic membranes, very few novel alloy compositions have been developed to a wide commercial scale since the first commercialization of palladium–silver membranes in the 1960s. The high cost of precious metals required aligns with their application in advanced fields, such as the fusion fuel cycle []. Outside fusion technology, Pd-based membranes have found only niche applications in fields where high purity of hydrogen is in demand. Tokyo Gas has employed palladium-rare-earth metal-based alloys with much higher permeability and mechanical strength than Pd–Ag in their membrane reformer with world-class performance [].

Although the 17 elements (scandium, yttrium, and the lanthanides) forming the rare-earth (RE) family are relatively abundant, obtaining high-purity RE metals at the desired quantity for making profitable commercial-scale membranes will render the final price onerous. Instead, membranes incorporating base metals might offer a cost-effective advantage. Since, the higher permeability of Pd–RE alloy membranes, e.g., Pd–Y, Pd–Gd, is attributed to some extent (but not only) to the increase in H solubility due to an expansion in lattice parameter compared to pure palladium (), alloying with base metals will contract the lattice parameter () compared to pure Pd, thus H solubility will be lowered and will cause little to negative benefit in gain in permeability compared to pure palladium. Expanding the compositional complexity from binary to higher-order systems (ternary, quaternary, and beyond) through the strategic incorporation of base metals offers a promising avenue to simultaneously enhance membrane robustness and hydrogen permeability. Consequently, developing efficient high-throughput screening methodologies becomes crucial for navigating the vast compositional landscape of these complex alloy systems.

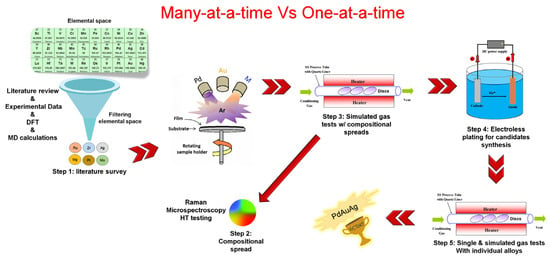

High-throughput techniques operate on two distinct levels: primary screening for the systematic discovery of promising material candidates, and secondary screening for the precise optimization of their compositions []. While the field of dense metallic membranes has seen limited application of combinatorial and high-throughput methodologies, several pioneering efforts warrant careful consideration. This section examines selected case studies of high-throughput experimental approaches in dense metallic membrane development.

6.1. Definition

The terms combinatorial and high-throughput require clarification in the context of materials science. Maier et al. defined combinatorial as “experiments in which groups or elements of different materials or components of a recipe, such as solvents, additives, or other components, are combined” []. In dense metal membrane discovery, this approach involves systematically varying both the types and concentrations of metal components in the membrane’s effective layer. High-throughput methods, on the other hand, focus on the rapid, parallel synthesis, processing, and characterization of large numbers of samples. This includes systematic variation in composition, the number of elements in the alloy, and other parameters, coupled with integrated data recording and analysis systems. While distinct, combinatorial, and high-throughput approaches are often used synergistically in advanced materials research []. In the upcoming discussion, various use cases in the acceleration of dense membrane discovery and optimization are summarized.

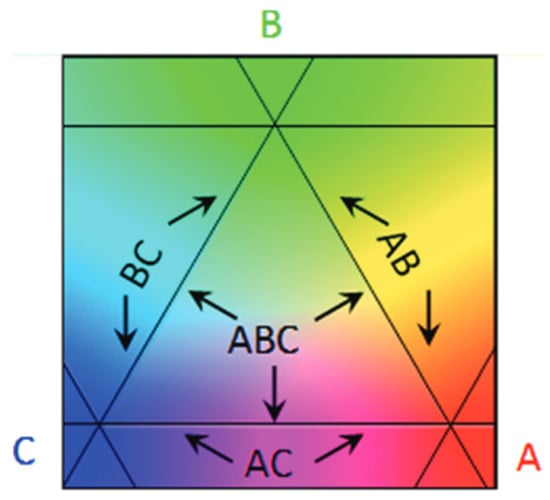

6.2. Compositional Spread Methods

Combinatorial and high-throughput material screening is often based on the preparation of composition spread alloy thin films (CSAF) libraries. These libraries consist of multicomponent materials such as alloys, AxByC1−x−y deposited in such a way that there is a lateral gradient in their local composition []. CSAFs contain continuous composition distributions of binary or higher-order alloys on a single compact substrate. These can span entire composition spaces or focus on composition subspaces of interest. CSAF were originally developed in the 1950s for the determination of alloy phase diagrams []. An example of CSAF prepared using a physical vapor deposition apparatus combining a rotatable shadow mask technique is shown in Figure 7.

Figure 7.

Schematic representation of a CSAF generated by the rotatable shadow mask RSM-CSAF deposition tool with regions containing the entire ternary alloy composition space, AxByC1−x−y (x = 0 → 1, y = 0 → 1 − x), all three binary alloys AxB1−x, AxC1−x, and BxC1−x (x = 0 → 1) and all three pure compositions. A, B, and C are the pure metal components of the ternary system. Reproduced with permission from [], Journal of Vacuum Science & Technology A; published by American Vacuum Society, 2012.

Various methods can be used to create these libraries. One method uses co-deposition from several sources operating simultaneously to produce a mixed film, where no mask is required and the concentration of the component depends on its distance from the source []. A second group uses binary masks or moving edge masks to first deposit components layer-by-layer, with tunable thickness followed by treatment to induce solid-state diffusion of the deposited components []. When spatially resolved methods are used to characterize their composition and functional properties, CSAF libraries allow rapid determination of composition–property relationships across broad, continuous regions of alloy composition space.

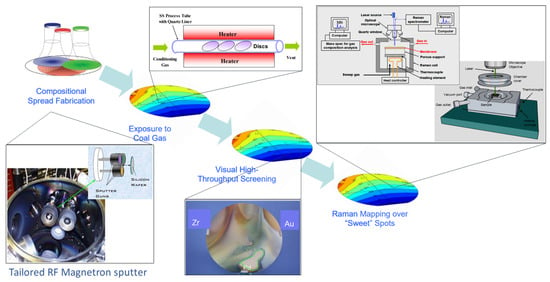

In a study, Lewis et al. reported a combinatorial and high-throughput screening workflow for discovering and optimizing sulfur and carbon-resistant ternary Pd-based ternary alloy membranes []. Before that report, no other has been found in the open English-based literature with such in-depth endeavors for metal membrane development. Given, Pd–Cu, Pd–Ag, and Pd–Au, the goal was to screen a third element capable of reinforcing the final alloy resistance against S/C poisoning, while possessing a high pure H2 permeability and being easily processable in thin film. The sequential procedure adopted is as follows: (1) creation of compositional spread alloys thin films (CSAF) using a four-gun magnetron co-sputtering deposition on silicon wafer substrates; (2) simulated synthetic coal gas exposure of the CSAFs to grossly evaluate resistance to poisoning; (3) visual characterization of the wafers by phasing out all tarnished zone upon S/C interaction and retaining still shining spot as sweet spots; (4) rigorous characterization of the sweet spots using Raman spectroscopy based on the intensity band of potential S–S and M–S bonds; (5) Syntheses of the hits (six composition) using electroless plating technique and/or magnetron sputtering thereof; (6) Measurement of the hydrogen-transport properties of the prepared membranes (the hits) in pure H2 and simulated syngas environment. A description of the custom sputtering apparatus can be found in the reference [], and our adaptation of the general methodology is depicted in Figure 8 and Figure 9, based on the author’s descriptions. The authors also evaluated the reproducibility of the synthesis methods. Despite the characterization of the sweet spots deposited on the silicon wafer by Raman spectroscopy has been reported to be rather fastidious, the rapidity of identification of hits after primary screening is impressive. The study could be improved using: a) a high-throughput permeation testing system. Aware of that limitation, the authors suggested hydrogenography as a high-throughput testing technique. Finally, out of many elements screened Pd–Ag–Au and Pd–Zr–Au (the leads) were the top-performing compositions. In this one-of-a-kind research in dense membrane development, co-sputtering was adopted as the technique for preparing continuous composition spreads. Many examples of the application of this technique in combinatorial material development have been given on the fly by []. Based on the authors’ description, the following graphics were created to summarize the workflow.

Figure 8.

Combinatorial palladium-based ternary alloys development for membrane application. The green circle shows a Pd-based sweet spot of the CSAF which is not tarnished upon sulfur exposure i.e., a promising sulfur-resistant alloy candidate. Readapted from [].

Figure 9.

General approach to screen ternary Pd-based thin film for hydrogen separation application. Proposed based on description from [].

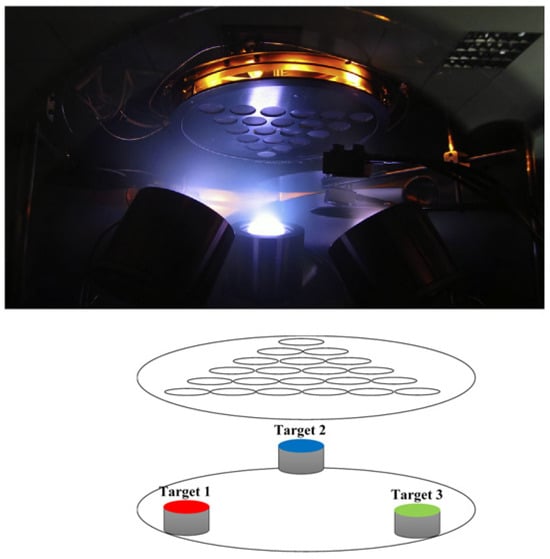

6.3. Thin Film Libraries with Discrete Concentration

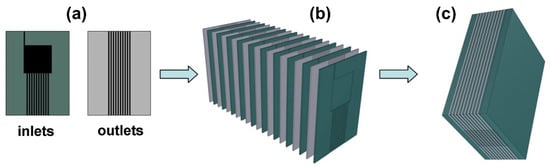

In an attempt to contribute to the shift from the one-at-a-time experimentation paradigm, which still dominates the metal membrane development field, refs. [,,,] engineered a combinatorial and high-throughput technique to screen BCC Nb–Pd–Ti, FCC Pd–Ag–Ti, and FCC Pd–Ag–Ni system of ternary alloys over a broad compositional domain. Unlike the previous description, where the deposition was a composition spread [], herein 21 glass discs arranged to form a triangular shape were used to prepare ternary thin film alloy libraries with discrete concentrations utilizing a magnetron sputtering apparatus tunable in co-deposition or sequential deposition modes (Figure 10).

Figure 10.

Schematic illustration of the combinatorial sputter deposition setup for thin-film membrane synthesis. The triangular configuration of magnetron sputter sources and corresponding substrate array enables the simultaneous fabrication of 21 compositionally distinct membrane specimens. Each position in the substrate array yields a unique compositional point within the ternary phase space. Taken from [,].

The electrical resistivity of alloys upon hydrogen permeation is known to increase. Therefore, the physical parameter used for the high-throughput screening procedure was the reactivity index, which the authors defined as “the ratio of resistivity under hydrogen to that under argon in the same conditions” []. Based on those criteria, the higher the resistivity the higher the reactivity index (>>1), thus the higher the potential of the alloy to be nominated a hit. Three alloys Pd–Ag–Ni were identified as hits and were all synthesized by arc-melting with subsequent roll milling, following which they were tested in single gas H2 tests, and an alloy with 55%Pd content was identified as the most promising. Later on, the same group [] conducted a study to screen other alloys incorporating base metals, such as, viz. Pd–Mn–Ag and Pd–Co–Ni using a similar approach. Quickly, it was concluded that Pd–Co–Ni was ineffective and only Pd–Mn–Ag was promising.

Although the protocol described here may necessitate high initial investing costs, the methodology adopted appears highly reproducible. In that work, the pace at which new promising metal membrane materials were screened was impressive. The validation of electrical resistance measurements as a reliable high-throughput screening technique remains incomplete, as membrane performance was evaluated only in pure hydrogen streams rather than industrially relevant gas mixtures.

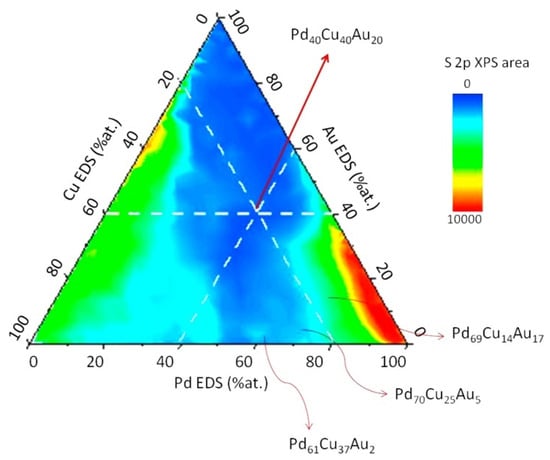

6.4. Composition Spread Using E-Beam

The Gellman Group at Carnegie Mellon University, USA, developed a novel rotating shadow mask composition spread alloy films (CSAFs) library preparation apparatus that allows the co-deposition of up to four metal elements using an electron beam physical vapor deposition system []. The apparatus was used to perform the high-throughput screening studies of sulfur uptake in the Pd–Cu–Au series in an annealed PdxCuyAu100−x−y CSAF in order to discover corrosion-resistant alloys satisfying the formula PdxCuyAu100−x−y. The screening consists of exposing the CSAF to 100 ppm H2S in H2 at 673 K for 24 h after which surface sulfur is mapped using spatially resolved XPS. This apparatus allows Tarditi et al. [] to establish a structure–property relationship, i.e., sulfur intake as a function of alloy composition. Based on that study, ternary alloys with a low sulfur intake having at least 40 at.%Pd (to allow for high H2 permeability) were selected. Figure 11 shows the sulfur content of the CSAF’s surface as a function of alloy composition. Following that primary screening step, nominated candidate alloys have been prepared by sequential electroless plating and individually tested in single gas and mixture gas tests.

Figure 11.

Surface sulfur enrichment across the CSAFs, quantified via S2p XPS peak intensity. Exposure conditions: 100 ppm H2S in H2 at 400 °C for 24 h. Reproduced with permission from [], Journal of Membrane Science; published by Elsevier, 2015.

The insights drawn from that research are that the ternary alloy with the highest gold content possesses the highest hydrogen permeability and that the poisoning effect of sulfur was reversible (~80% of flux recovery to the initial value) upon reintroduction in pure H2, demonstrating that the discovered alloys are effectively more sulfur-resistant and permeable than pure Pd.

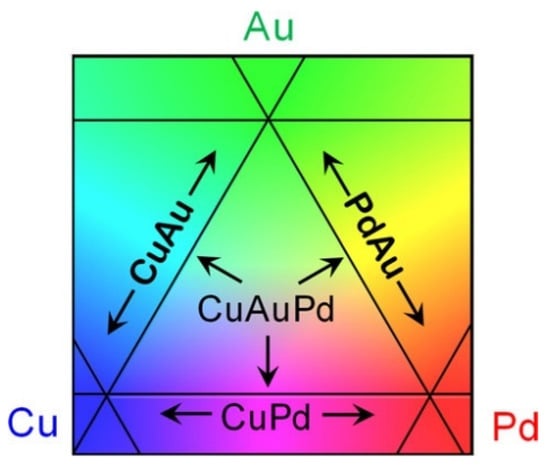

Gellman and coworkers have consistently developed methods for the high throughput study of surface phenomena. Amongst works of interest, one cannot turn a blind eye to the study of surface segregation in alloys of the type CuxPd1−x [], CuxAuyPd1−x−y [], in an attempt to accelerate and parallelize the methods of sample preparation and characterization. In the former, an offset filament tool was developed to co-deposit binary CSAFs of CuxPd1−x (x = 0.05–0.95) via evaporation of metals at high temperatures in ultra-high vacuum (UHV). Spatially resolved XPS and LEISS have enabled the high throughput characterization of surface segregation through composition mapping. The local structure across the CSAFs as given by the Electron Backscatter Diffraction EBSD method was shown to accurately corroborate the phase diagram of Pd–Cu. Bearing in mind that the thermodynamic nature of surface segregation is dependent on the temperature, pressure, and component concentration in the bulk thin films, the authors constructed a Langmuir–McLean thermodynamic model that relates the composition x to the enthalpy and entropy of the segregation of Cu on the outermost layer in a 427 °C–627 °C range. The authors distinguished that Cu preferentially segregates to the topmost layer at each bulk concentration. This constitutes another use case of CSAFs and high-throughput techniques to fuel the structure–property relationship mapping. The authors emphasized that this was the first report of an experimental high-throughput technique for the study of surface segregation in the Pd–Cu system, although the study was restricted to ideal conditions, i.e., vacuum.

Similarly, a recent paper [] used apparatus developed in [] to implement a high-throughput workflow for the study of surface segregation in the entire composition space of CuxAuyPd1−x−y in UHV at 227 °C and 327 °C over 164 different bulk compositions forming the CSAF. The investigators noticed the segregation tendency of Au in the topmost layer, with increasing temperatures in every case, and the depletion of Pd on the surface. Those observations are very important in membrane development. The concentration profile of the rotatable shadow mask-physical vapor deposition generated CSAF is depicted in Figure 12.

Figure 12.

Schematic representation of a CSAF. Subregions of the Cu–Au–Pd ternary alloy, Cu–Pd, Au–Pd, Cu–Au binary alloys, and pure Pd, Cu, and Au can be found on a single CSAF. The CSAF is deposited as ∼100 nm thick films on a 14 × 14 × 3 mm3 Mo substrate. Reproduced with permission from [], The Journal of Physical Chemistry C; published by American Chemical Society, 2020.

High-throughput methods based on CSAFs and spatially resolved XPS core level shift can also help to demonstrate uncommon properties []. Using a variant of CSAF having both compositions spread in one direction and thickness gradient in another direction, it was demonstrated that for thin film thickness < 6 nm binary alloys of composition CuzPd1−z with 0.35 < z < 0.55 was still in a face-centered cubic phase in conditions where they should have a CsCl B2 type structure in the bulk phase diagram. This phenomenon was referred to as a dimensionally stabilized phase, where at the nanoscale the morphology is determined by both the composition and the thickness of the thin film. The implications of this research are probably of interest in membrane and membrane catalysts. This constitutes an example of composition and phase-thickness relationship definition.

In the previous cases, the resistivity upon hydrogen uptake, intensity band in Raman spectroscopy, spatially resolved XPS, LEIS, and EBSD have been mentioned as high-throughput characterization techniques to analyze various compositions contained in the combinatorial library, either gradient or discrete. In addition, the reversible optical transformations exhibited by rare-earth metals upon hydrogen incorporation provide another powerful platform for high-throughput membrane characterization.

6.5. Hydrogenography

In this part, many use cases of a new kind of high-throughput technique that allows the indirect determination of the hydrogen permeability, viz. hydrogenography will be described.

6.5.1. Principle of Hydrogenography

Yttrium, lanthanum, and other trivalent rare-earth metals, when capped with a catalytic palladium overlayer, undergo a hydrogen-induced metal-to-insulator transition characterized by dramatic optical transformations—a phenomenon known as the switchable mirror effect [,]. In their as-deposited state, hydrogen switchable mirrors are shiny metals, but they become optically transparent when exposed to a hydrogen-rich environment []. This switchable mirror behavior is particularly promising for energy-saving applications, such as enhancing heat insulation in buildings. In particular, metallic YH2 and LaH2 transform into their respective semiconducting trihydride phases, YH3 and LaH3, accompanied by distinct electronic structure changes. As a consequence, the thin film of YHx or LaHx can be transformed rapidly from metal to insulator, from shiny mirror to transparent window (the switchable mirror behavior), simply by changing the surrounding hydrogen gas pressure or an electrolytic cell potential at room temperature []. A detailed review of the switchable mirror effect was provided by Griessen et al. (2004) [].

As a high-throughput combinatorial technique, hydrogenography exploits the characteristic optical response of rare-earth metals to hydrogen absorption, facilitating parallel evaluation of intrinsic permeability across vast compositional libraries under uniform experimental conditions []. The measured permeability is referred to as intrinsic because it only accounts for bulk phenomena. This versatile technique has found widespread applications across hydrogen-related materials research, including: high-throughput screening of hydrogen storage materials []; visualization of hydrogen isotope diffusion dynamics []; determination of important thermodynamic parameters, e.g., enthalpy, and entropy of hydrogen storage in metal hydrides; optimization of hydrogen sensing materials, development of catalytic cap layers hydrogen uptake promoters, development of smart coatings for adaptive solar collectors []; screening of hydrogen sorption catalysts [], combinatorial and high-throughput screening of palladium-based membranes [,,].

6.5.2. Use Case #1: Combinatorial Screening of PdyCu1−y Alloys Membranes

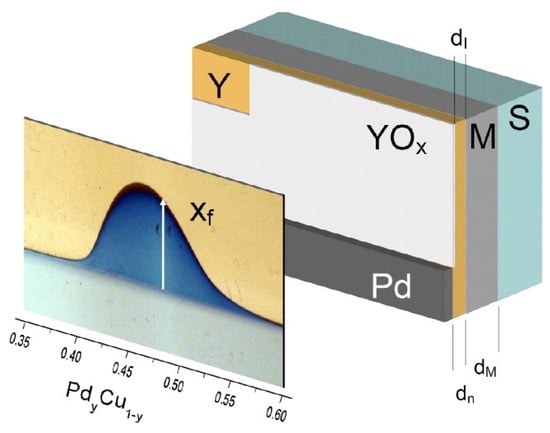

De Man et al. [] reported synthesizing a composition gradient thin film sample of PdyCu1−y alloys using an ultra-high vacuum magnetron sputtering co-deposition system. The composition of the films as determined by Rutherford Backscattering Spectrometry was mapped to contain both the BCC (0.35< y < 0.47), the FCC + BCC 0.47 < y < 0.61 and FCC (y > 0.61) phases, as characterized using XRD. The application of the hydrogenography technique for intrinsic hydrogen permeability measurement consists of using an indicator, viz. a yttrium layer to entirely cover the gradient sample top surface, while the yttrium layer itself is partially coated using a hydrogen dissociating catalyst, viz. palladium allowing the uncoated yttrium surface to be oxidized by air and form an inactivate hydrogen dissociating skin, viz. yttrium oxide Y2O3. If the conditioned sample is sealed in a chamber with an optical window, the color of the non-oxidized yttrium layer directly located under the palladium cap layer will instantaneously start to change and form a moving front bell-curve-type shape upon 105 Pa hydrogen uptake at room temperature due to the penetration of hydrogen into the indicator layer. Even if the membrane material is located under the yttrium layer, one can understand how the phenomena on the yttrium indicator relate to hydrogen diffusion in the membrane. The lateral hydrogen diffusion mainly takes place in the membrane alloy, because the hydrogen diffusion coefficient in the membrane is 105-fold (or more) higher than that in yttrium. Due to the low plateau pressure of YH2 and YH3, the hydrogen lateral diffusion through the Pd–Cu layer will leak back into the yttrium layer to form the yttrium hydride phase [].

By taking photographs at regular intervals of the moving-front using a charge-coupled device (CCD) camera, one can determine the position of the front position xf at the time t and fit a time series xf = (t∙K)0.5 where the K0.5, the slope of the straight line obtained represents the mobility front and is directly related to the intrinsic permeability. This previous procedure represents an embodiment of the application of hydrogenography. A photograph of the optical response of the membrane–yttrium indicator assembly is depicted in Figure 13.

Figure 13.

Spatially resolved hydrogen permeation visualization in a compositional gradient PdyCu1−y membrane. Surface-view photograph after hydrogen exposure (105 Pa, room temperature, 48 h) showing lateral diffusion with maximum front displacement xf = 7.2 mm. The membrane architecture consists of a PdyCu1−y gradient film (M) fabricated via an ultra-high vacuum magnetron co-sputtering on a Ti-modified Si substrate (S), overlaid with a 60 nm yttrium indicator layer (Y), and partially capped with a Pd catalyst. The hydrogen transport pathway involves dissociation at the Pd surface, through-thickness diffusion across the membrane, and subsequent chromatic transformation of the yttrium layer from reflective to blue. A protective yttrium oxide layer (YOx) prevents direct hydrogen uptake by the indicator. Reproduced with permission from [], Journal of Membrane Science; published by Elsevier, 2013.

By applying hydrogenography, the permeability values of hundreds of PdyCu1−y alloys were determined. It was shown that permeability is a function of the composition. Most importantly, the technique clearly distinguished Pd0.47Cu0.53 (at.%), the popular BCC Pd-40 wt.%Cu attributed with the largest hydrogen permeability at 623 K in the Pd–Cu series, even though the authors experimented with room temperature, which they attributed to the fact that permeability of hydrogen in the Pd–Cu family is weakly dependent on temperature compared to diffusivity. Because, the permeability values considered were intrinsic, i.e., entirely neglecting surface phenomena, the value determined at room temperature for Pd0.47Cu0.53 was k = 1.2 × 10−8 mol/m/s/Pa0.5 and was a little higher than the extrapolated value determined by density functional theory [].

In an attempt to generalize, the authors extended the technique to Pd–Cu–Mo, Pd–Cu–Ti, and Pd–Cu–Ta composition gradient samples and demonstrated that it is easier to apply for ternary systems. This work constitutes a powerful demonstration of the hydrogenography technique coupled with compositional gradient samples that can advance membrane research within hours instead of relying on serendipity for a long period.

6.5.3. Use Case #2: High-Throughput Determination of Hydrogen Permeability in Pd–Cu Alloy Membranes

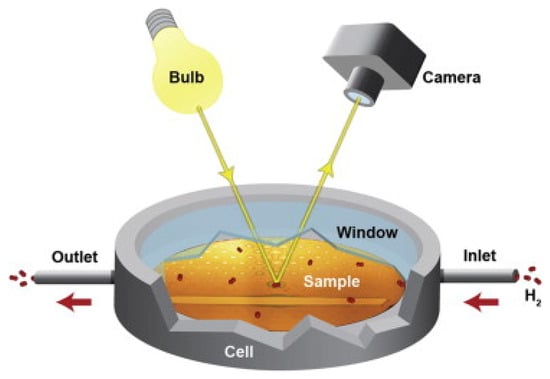

A more recent application of the hydrogenography technique has been documented by Westerwaal et al. []. The goal was to build a structure–property relationship, viz. Pd–Cu series microstructure-intrinsic permeability relationship. A composition gradient sample deposition technique and analysis similar to that described by de Man et al. (2013) in use case #1 [], for determining lateral intrinsic permeation was employed, but with varying substrate temperatures. Using this approach, Westerwaal et al. measured hydrogen permeability as a function of alloy composition and correlated the results with the low-temperature phase diagram of Pd–Cu []. The schematic representation of the experimental setup is depicted in Figure 14. The palladium hydrogen dissociating catalyst cap layers had either dots or quadrilateral shapes. Quickly, the technique identified FCC + BCC Pd48Cu58 as the alloy with the highest hydrogen intrinsic permeability within the composition gradient. Alloys of FCC and BCC structure were found to possess much lower permeability than mixed FCC + BCC. This is unusual in bulk Pd–Cu as a comparison with experimental knowledge. Therefore, by comparing to data from the literature, the authors remarked that other phenomena might occur, and they concluded that diffusion occurs mainly via heterogeneous grain boundaries []. Although a difference is found between the result and those from the literature, this constitutes a formidable opportunity to study phenomena that would have been fastidious in normal routine.

Figure 14.

Schematic of the optical hydrogen migration measurement setup. The configuration comprises: (i) a light source, (ii) a CCD camera, and (iii) a hydrogenation cell housing the assembled gradient diffusion sample. The sample is a composition gradient sample prepared by magnetron co-sputtering. The sample was assembled with the yttrium cover and dot-shaped palladium cap layer. The cell, connected to a gas handling system for controlled hydrogen supply and venting, is positioned 40 cm below both the illumination source and the camera. Reproduced with permission from [], International Journal of Hydrogen Energy; published by Elsevier, 2015.

In an earlier attempt, the same authors combined the hydrogenography technique and the cluster expansion method—a statistical thermodynamic method—to implement a high-throughput screening routine of Pd–alloys membranes (in the Pd–Cu series) with critical temperature below room temperature, and it was demonstrated that such a method can reveal fundamental insights where thermodynamic data are inexistent [].

While hydrogenography efficiently maps composition–property relationships through parallel screening of compositional gradients, it cannot identify optimal operating conditions for promising membrane candidates. The traditional one-factor-at-a-time optimization approach commonly used in membrane development is time-consuming and may overlook complex parameter interactions. Statistical Design of Experiments (DoE) methodologies offer a more systematic route to membrane optimization, enabling efficient parameter space exploration with minimal experimental iterations.

6.6. Design of Experiments

Rational statistical methods, particularly Design of Experiments (DoE), have a long-standing history in the design and optimization of chemicals, materials, and processes. Statistical experimental design approaches offer fundamental advantages over trial-and-error and one-factor-at-a-time (OFAT) methodologies, as they: (i) maximize the knowledge-to-experiment ratio, (ii) provide precise factor effect estimations, (iii) enable systematic quantification of parameter interactions, and (iv) explore broader parameter spaces []. The statistical design of experiments constitutes a mandatory part of the modern combinatorial material cycle [], and can also intervene in process optimization. This section summarizes a few recent use cases of design of experiments in dense metallic membrane development relevant to the scope of this paper.

6.6.1. Use Case #1: Hybrid Statistical-Observational Screening of Appropriate Support Surface Parameters for Reproducible Electroless-Plating Deposition of Pd–Base Alloys Membranes

A critical challenge in scaling electroless-plated composite metallic membranes to industrial applications lies in the selection of support materials compatible with standard stainless steel reactors []. While ceramic supports offer ideal characteristics for electroless palladium deposition—notably controlled surface roughness and optimized pore architecture—their industrial implementation is hindered by challenges in sealing, module integration, and chemical resistance. Metallic supports, while offering an alternative substrate platform, present inherent surface challenges that necessitate pre-treatment protocols before successful electroless plating deposition. The challenge was to study which suitable target surface parameters can be reproducibly and repeatably achieved by surface pre-treatment to permit electroless plating to be successfully realized for metallic supports.

Gallucci’s group [], proposed a solving scheme for this problem for highly rough Hastelloy X (nickel–chromium–iron–molybdenum alloy) supports with large pore diameter, using a hybrid observational (solid state support surface characterization)-statistical approach, i.e., a sequential approach composed of: surface pretreatment–surface parameters characterization–design of experiments–analysis of variance (ANOVA). Analysis of variance (ANOVA) is a statistical technique used to analyze the differences between two or more means []. As a result, threshold values of average surface roughness < 0.8 μm, average profile height < 7 μm, and in-pore leveling < 6 μm were identified as the target surface parameters for pretreatment reproducibility.

In the previous application, a statistical experimental design approach was used to optimize the surface properties of membrane support materials. Similarly, DoE can be applied to study the effect of process conditions on membrane efficiency. This approach is demonstrated in the second use case.

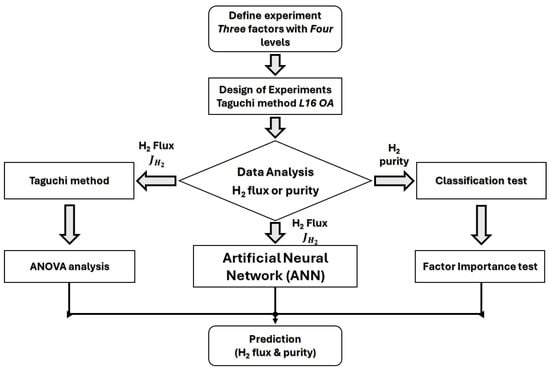

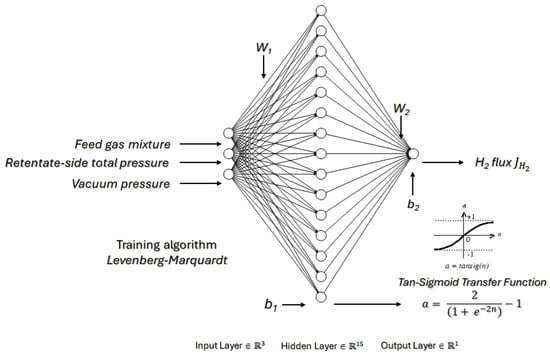

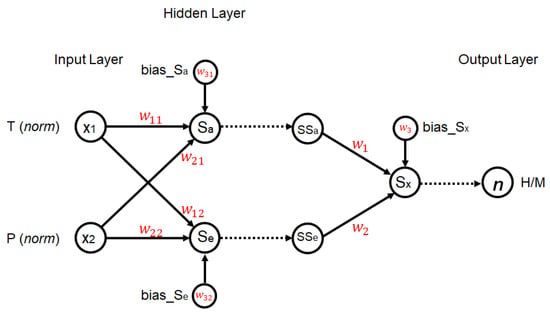

6.6.2. Use Case #2: Mixed Taguchi Design-Machine Learning Analyses of Hydrogen Permeation in Pd Membranes