Modeling and Analysis of Internal Leakage Characteristics of the Internal Curve Motor by a CFD-Based Method

Abstract

1. Introduction

2. Experiments

2.1. Experimental Principle

2.2. Experimental Method

3. Numerical Methods

3.1. ICM Structural Characteristics

3.2. Computational Domain and Mesh Grid

3.3. Numerical Simulation

3.3.1. CFD Solver

3.3.2. Model Simulation

3.4. Model Validation

3.4.1. Grid Independence Validation

3.4.2. Calculation Time Step Independence Verification

3.5. Leakage Modeling of the ICM

3.5.1. Leakage Modeling of the Valve Pair

3.5.2. Plunger Pairs Leakage Modeling

3.5.3. Internal Leakage of the ICM

4. Results and Discussions

4.1. Analysis of One-Factor Working Conditions Simulation Test

4.1.1. The Effect of Inlet Pressure on the Internal Leakage of the ICM

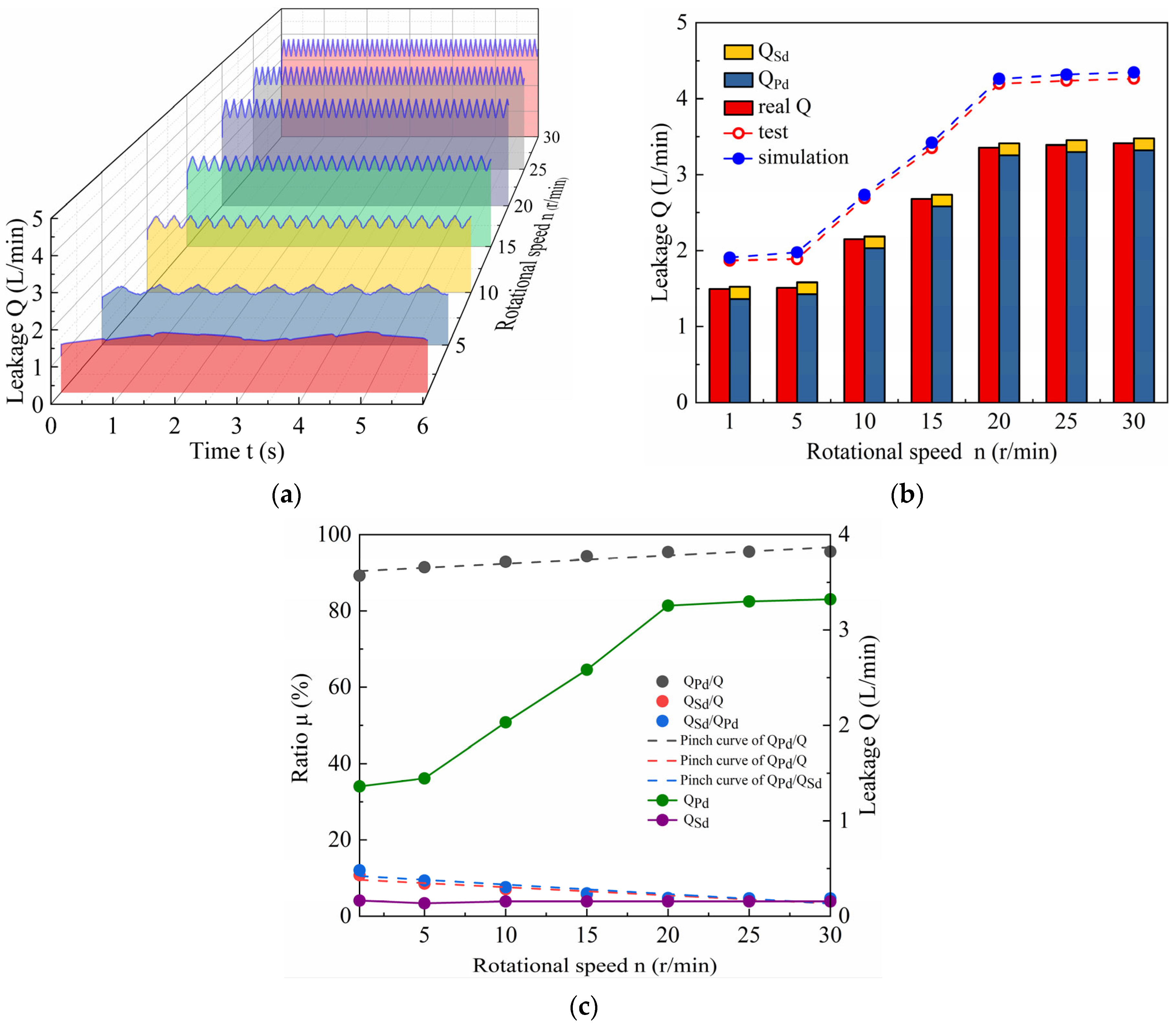

4.1.2. The Effect of Rotational Speed on the Internal Leakage of the ICM

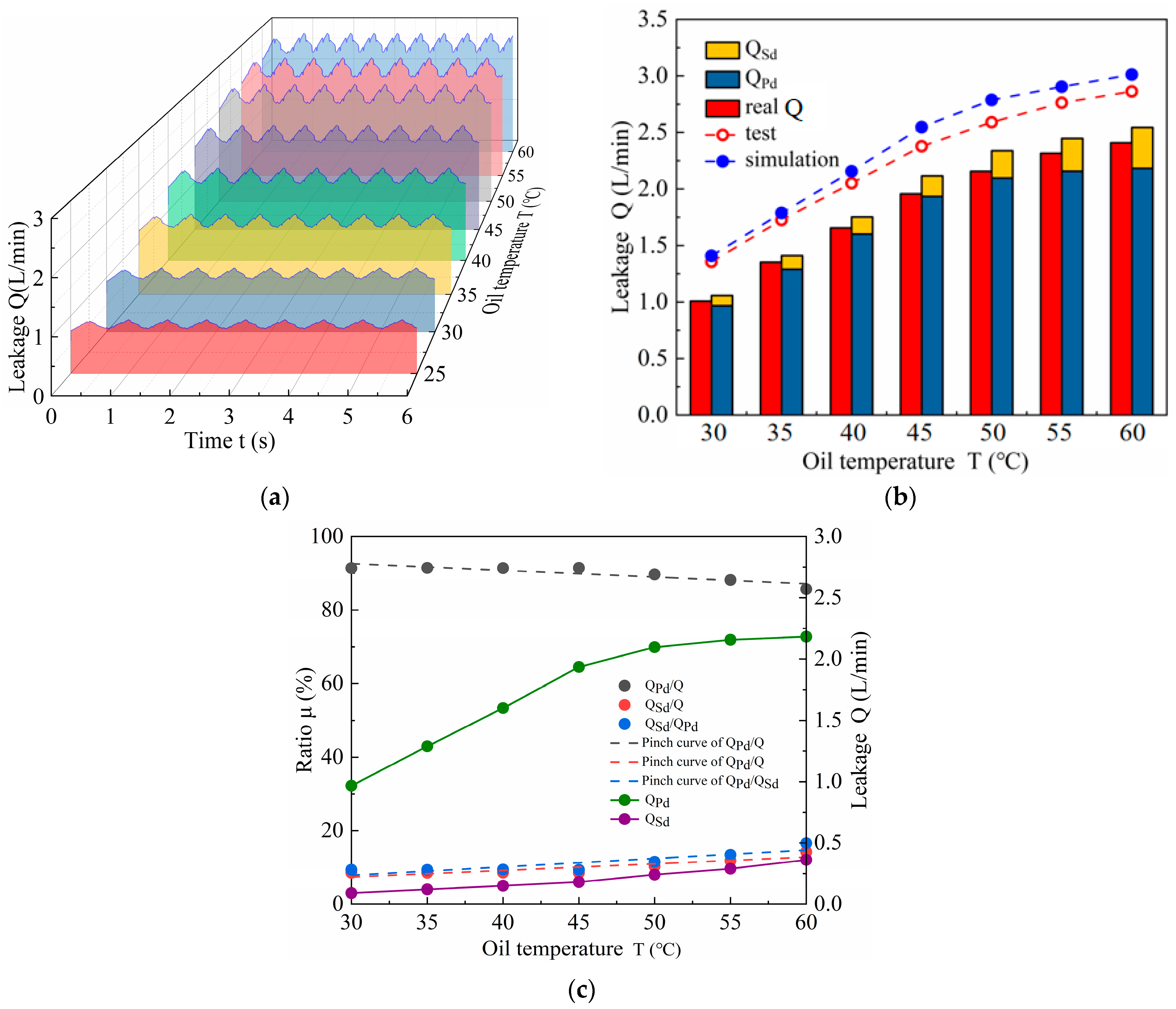

4.1.3. Influence of Oil Temperature on the Internal Leakage of the ICM

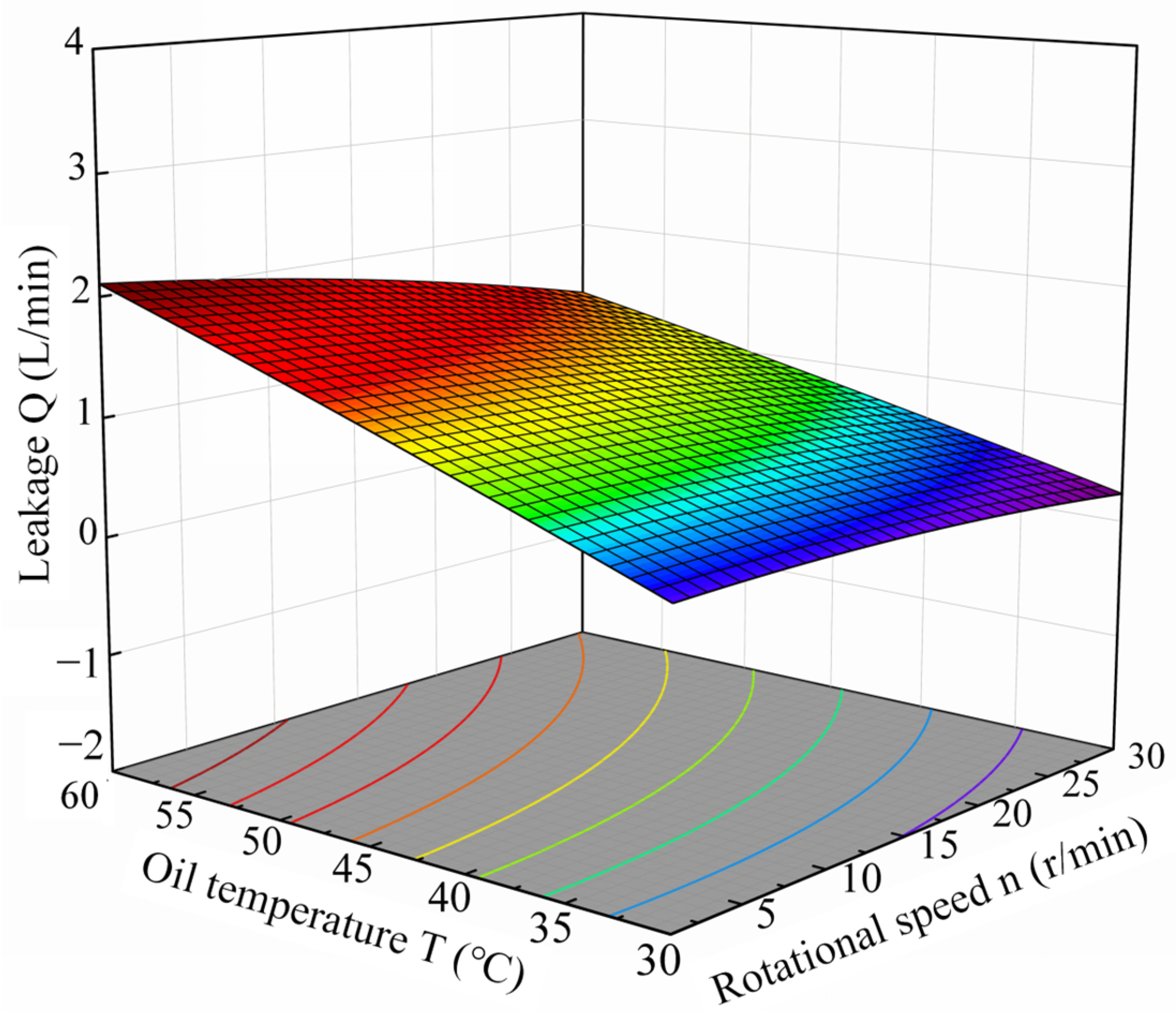

4.2. Simulation and Study of Multi-Factor Working Conditions

5. Conclusions

- Based on the working principle of the ICM, the motion state of the plungers is controlled by the UDF, which solves the problem of the 16 plungers performing both radial reciprocating and rotating motions. The full fluid domain of the ICM was constructed in Fluent, and a transient simulation of the ICM was realized. Its feasibility and reliability were verified by grid and time independence, and the transient pressure of the plunger chamber was obtained.

- As the inlet pressure increased, the pulsation frequency and amplitude of the internal leakage of the ICM did not change significantly, the leakage of the valve pair and the plunger pair increased, the proportion of the valve pair leakage in the ICM leakage decreased, and the proportion of the plunger pair leakage in the ICM leakage increased.

- As the rotational speed increased, the pulsation frequency of the internal leakage of the ICM increased, and the leakage of the valve pair tended to be almost flat when the rotational speed was increased to 20 r/min. The leakage of the plunger pair increased slightly, the proportion of the leakage of the valve pair in the internal leakage of the ICM increased, and the proportion of the leakage of the plunger pair in the internal leakage of the ICM decreased. The leakage of the plunger pair remains unchanged under different rotational speed conditions, and the effect of the rotational speed on the leakage of the plunger pair is not significant.

- As the oil temperature increases, the pulsation amplitude of the ICM leakage decreases, the leakage of the valve pair and plunger pair increases, the proportion of the valve pair leakage in the ICM leakage decreases, and the proportion of the plunger pair leakage in the ICM leakage increases.

- ANOVA analysis of the model revealed that the inlet pressure, oil temperature, and rotational speed influenced motor leakage, in descending order of impact. However, the rotational speed had no significant effect on the internal leakage. The response surface confirmed this, indicating a significant interaction between inlet pressure and oil temperature, but a negligible interaction between rotational speed and either inlet pressure or oil temperature. This is consistent with the ANOVA results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ye, S.; Zhang, J.; Xu, B.; Zhu, S.; Xiang, J.; Tang, H. Theoretical Investigation of the Contributions of the Excitation Forces to the Vibration of an APP. Mech. Syst. Signal Process. 2019, 129, 201–217. [Google Scholar] [CrossRef]

- Lyu, F.; Zhang, J.; Sun, G.; Xu, B.; Pan, M.; Huang, X.; Xu, H. Research on Wear Prediction of plunger/Cylinder Pair in APP. Wear 2020, 456–457, 203338. [Google Scholar] [CrossRef]

- Banaszek, A. Identification of Optimal Efficiency Exploitation Conditions of Axial-plunger Hydraulic Motor A2FM Type Using Artificial Neural Network Algorithms. Procedia Comput. Sci. 2021, 192, 1532–1540. [Google Scholar] [CrossRef]

- An, G.; Wang, W.; Dong, H.; Liu, B.; Song, W.; Hu, Z. Parameter Optimization of Vibration Reduction Structure for Low-Speed, Multi-Acting Cam Ring Motor. Actuators 2023, 12, 388. [Google Scholar] [CrossRef]

- Ceschini, L.; Marconi, A.; Martini, C.; Morris, A. Tribological Behavior of Components for Radial plunger Hydraulic Motors: Bench Tests, Failure Analysis and Laboratory Dry Sliding Tests. Wear 2013, 305, 238–247. [Google Scholar] [CrossRef]

- Wang, H. Structure Optimization Design Approach of Friction Pairs for Low-Temperature Rise Wet Brake in Hydraulic Motor. Case Stud. Therm. Eng. 2024, 61, 104841. [Google Scholar] [CrossRef]

- Tang, S. A Light Deep Adaptive Framework toward Fault Diagnosis of a Hydraulic plunger Pump. Appl. Acoust. 2024, 217, 109807. [Google Scholar] [CrossRef]

- Qing, L.; Gu, L.; Wang, Y.; Lei, Z. Analysis of Leakage Characteristics for Bent-Axis plunger Pump Based on Elasto-Hydrodynamic Deformation. ILT 2022, 74, 18–25. [Google Scholar] [CrossRef]

- Bao, Q.; Zhou, J.; Jing, C.; Zhao, H.; Wu, Y.; Zhang, Z. Nonlinear Dynamic Model for the Free Rotor of the Swash Plate-Rotating Hydraulic Transformer. Energy 2022, 261, 125355. [Google Scholar] [CrossRef]

- Ma, H. Modeling and Analysis of the Leakage Performance of the Spherical Valve Plate Pair in axial piston pump. Eng. Sci. Technol. Int. J. 2023, 45, 101498. [Google Scholar] [CrossRef]

- Yin, F.; Nie, S.; Ji, H.; Huang, Y. Non-Probabilistic Reliability Analysis and Design Optimization for Valve-Port Plate Pair of Seawater Hydraulic Pump for Underwater Apparatus. Ocean Eng. 2018, 163, 337–347. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, C.; He, T.; Luo, G.; Qin, Y.; Fang, S. Theoretical and Experimental Study on Lubrication and Friction of Slipper Pair of Valve Distribution plunger Pump Based on FVM-TRD Coupling Method. Tribol. Int. 2024, 194, 109456. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, X.; Dong, P.; Zhang, H.; Zheng, Z.; Zhang, J.; Xu, B. Composite Thermal Oil Film Lubrication Model for Hybrid Journal Bearings. Tribol. Int. 2024, 194, 109556. [Google Scholar] [CrossRef]

- Zhang, X. Supervised Adaptive Method for Robust and Fast Solving of Lubrication Problems. Tribol. Int. 2025, 201, 110191. [Google Scholar] [CrossRef]

- Isaksson, P.; Nilsson, D.; Larsson, R. Elasto-Hydrodynamic Simulation of Complex Geometries in Hydraulic Motors. Tribol. Int. 2009, 42, 1418–1423. [Google Scholar] [CrossRef]

- Li, Y.; Cui, X.; Zhang, J. A Study on Improving Friction and Wear Performance of Bearing Bush in Radial plunger Hydraulic Motor. Wear 2024, 546–547, 205317. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, J.; Li, R.; Yuan, W.; Sun, Q.; Chen, S.; Li, D.; Sun, Y. Analysis and Optimization of Flow Field Characteristics of Axial plunger Motor Based on CFD. Flow Meas. Instrum. 2024, 99, 102669. [Google Scholar] [CrossRef]

- Li, C.; Jiang, T.; Liu, C.; Xu, H.; Shi, G. Investigation of the Leakage in the Flow Distribution Pair of Radial plunger Hydraulic Motors through CFD Analysis and Experiments. Flow Meas. Instrum. 2024, 96, 102555. [Google Scholar] [CrossRef]

- Xiao, C.; Tang, H.; Ren, Y.; Xiang, J.; Kumar, A. Adaptive MOMEDA Based on Improved Advance-Retreat Algorithm for Fault Features Extraction of APP. ISA Trans. 2022, 128, 503–520. [Google Scholar] [CrossRef]

- Ma, H.; Liu, W.; Wu, D.; Yang, B.; Xia, Y.; Xia, S. An In-Situ Measurement Approach for the Oil Film Characteristics of the Spherical Valve Plate Pair in APP. Measurement 2024, 226, 114113. [Google Scholar] [CrossRef]

- Sun, Y.-N.; Gao, D.-R.; Zhang, Z.-Y.; Zhao, J.-H.; Chen, B. Leakage and Permeability Characteristics of Seawater with Different Concentrations at the Distribution Windows of Variable Motor Pumps for Seawater Desalination. Desalination Water Treat. 2021, 230, 116–128. [Google Scholar] [CrossRef]

- Wang, L.; Deng, H.-s.; Guo, Y.-c.; Wang, C.-l.; Hu, C. Lubrication Characteristics of External Return Spherical Hinge Pair of axial piton pump or Motor under Combined Action of Inclination and Offset Distance. J. Cent. South Univ. 2021, 28, 2375–2393. [Google Scholar]

- Haidak, G.; Wei, X.; Li, F.; Larbi, A.; Wang, D. Heat Effects Modeling on the Efficiency Loss of the Lubricating Interface between plunger and Cylinder in APP. Tribol. Int. 2022, 175, 107846. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, H.; Chen, C.; Wang, D.; Li, S. Oil Film Lubrication State Analysis of plunger Pair in plunger Pump Based on Coupling Characteristics of the Fluid Thermal Structure. Eng. Fail. Anal. 2022, 140, 106521. [Google Scholar] [CrossRef]

- Bergada, J.M.; Kumar, S.; Davies, D.L.; Watton, J. A Complete Analysis of APP Leakage and Output Flow Ripples. Appl. Math. Model. 2012, 36, 1731–1751. [Google Scholar] [CrossRef]

- Zhang, B.; Hong, H.; Ma, J.; Yang, H.; Fang, Y. Analysis of the Flow Dynamics Characteristics of an APP Based on the Computational Fluid Dynamics Method. Eng. Appl. Comput. Fluid Mech. 2017, 11, 86–95. [Google Scholar]

- Kumar, N.; Kumar, R.; Sarkar, B.K.; Maity, S. Condition Monitoring of Hydraulic Transmission System with Variable Displacement APP and Fixed Displacement Motor. Mater. Today Proc. 2021, 46, 9758–9765. [Google Scholar] [CrossRef]

- Sun, Z.; Zeng, Q.; Wan, L. An Indirect Flow Measurement Method for Bi-Tandem APP Based on Leakage Flow Estimation. Measurement 2024, 229, 114473. [Google Scholar] [CrossRef]

- Phan, V.D.; Vo, C.P.; Dao, H.V.; Ahn, K.K. Actuator Fault-Tolerant Control for an Electro-Hydraulic Actuator Using Time Delay Estimation and Feedback Linearization. IEEE Access 2021, 9, 107111–107123. [Google Scholar] [CrossRef]

- Ma, K. Experimental Investigation and Theoretical Evaluation on the Leakage Mechanisms of Seawater Hydraulic APP under Sea Depth Circumstance. Eng. Fail. Anal. 2022, 142, 106848. [Google Scholar] [CrossRef]

- AbdulGafoor, C.P.; Rajananda, A.; Shankar, A.; Vadlamani, N.R. Entropy Damping and Bulk Viscosity Based Artificial Compressibility Methods on Dynamically Distorting Grids. Comput. Fluids 2024, 279, 106328. [Google Scholar] [CrossRef]

- Li, Y.; Ji, Z.; Yang, L.; Zhang, P.; Xu, B.; Zhang, J. Thermal-Fluid-Structure Coupling Analysis for Valve Plate Friction Pair of APP in Electro-hydrostatic Actuator (EHA) of Aircraft. Appl. Math. Model. 2017, 47, 839–858. [Google Scholar] [CrossRef]

- Zhao, J. Review of Cylinder Block/Valve Plate Interface in APP: Theoretical Models, Experimental Investigations, and Optimal Design. Chin. J. Aeronaut. 2021, 34, 111–134. [Google Scholar] [CrossRef]

- Hong, R.; Ji, H.; Nie, S.; He, H.; Guo, M.; Yin, F.; Yan, X. A Hybrid of CFD and PSO Optimization Design Method of the Integrated Slipper/Swashplate Structure in seawater hydraulic axial piston pump. Eng. Appl. Comput. Fluid Mech. 2022, 16, 2123–2142. [Google Scholar] [CrossRef]

- Guan, C.; Jiao, Z.; He, S. Theoretical Study of Flow Ripple for an Aviation Axial-plunger Pump with Damping Holes in the Valve Plate. Chin. J. Aeronaut. 2014, 27, 169–181. [Google Scholar] [CrossRef]

- Li, Y.; Yu, L.; Jiang, H.; Zhao, E. Transient Sealing Characteristics of Glyd-Ring in the High Water-Based plunger Pair under Reciprocating Pump Conditions. Tribol. Int. 2024, 192, 109293. [Google Scholar] [CrossRef]

- Wang, H.; Lin, N.; Yuan, S.; Liu, Z.; Yu, Y.; Zeng, Q.; Fan, J.; Li, D.; Wu, Y. Structural Improvement, Material Selection and Surface Treatment for Improved Tribological Performance of Friction Pairs in APP: A Review. Tribol. Int. 2024, 198, 109838. [Google Scholar] [CrossRef]

- Nie, S. Research on Fluid-Structure Interaction for plunger/Cylinder Tribo-pair of Seawater Hydraulic axial piton pump in Deep-Sea Environment. Ocean Eng. 2021, 219, 108222. [Google Scholar] [CrossRef]

- Liu, Z.; Li, B.; Yao, T.; Sun, M.; Wang, Y.; Niu, L.; Du, Y. Optimization of Slow-Release Salt Storage Snowmelt Aggregate Preparation Process and Its Slow-Release Performance Based on Response Surface Methodology-Orthogonal Test. Constr. Build. Mater. 2024, 449, 138356. [Google Scholar] [CrossRef]

- Duan, X.; Yu, H.; Wu, X.; Hu, L.; Chen, H.; Sun, Y.; Wu, B. Numerical Simulation Analysis and Orthogonal Experiment Optimization of the Factors Affecting Plasma Gasification of Oil-Based Drilling Cuttings. Int. J. Hydrogen Energy 2023, 48, 38617–38633. [Google Scholar] [CrossRef]

| Symbol | Value | Symbol | Value |

|---|---|---|---|

| 127.4 mm | 238.6 mm | ||

| 125.5 mm | 48 mm | ||

| 113.3 mm | 0.043 Pa·S | ||

| 111.2 mm | 2.2 | ||

| 0.015 mm | 15 mm |

| Test Group | Inlet Pressure P (MPa) | Rotational Speed n (rpm) | Oil Temperature T (°C) | Leakage Q (L/min) |

|---|---|---|---|---|

| 1 | 22 | 15.5 | 30 | 1.255 |

| 2 | 13 | 30 | 30 | 0.617 |

| 3 | 4 | 15.5 | 30 | 0.177 |

| 4 | 13 | 15.5 | 45 | 1.108 |

| 5 | 4 | 15.5 | 60 | 0.598 |

| 6 | 13 | 15.5 | 45 | 1.001 |

| 7 | 22 | 15.5 | 60 | 4.360 |

| 8 | 22 | 1 | 45 | 3.492 |

| 9 | 13 | 1 | 60 | 1.439 |

| 10 | 4 | 30 | 45 | 0.392 |

| 11 | 13 | 30 | 60 | 1.056 |

| 12 | 22 | 30 | 45 | 2.026 |

| 13 | 13 | 15.5 | 45 | 1.549 |

| 14 | 13 | 1 | 30 | 0.444 |

| 15 | 4 | 1 | 45 | 0.285 |

| 16 | 13 | 15.5 | 45 | 1.407 |

| 17 | 13 | 15.5 | 45 | 1.111 |

| Source | Sum of Squares | DF | Mean Squares | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 18.89 | 9 | 2.10 | 15.86 | 0.0007 * |

| A-Inlet pressure | 11.72 | 1 | 11.72 | 88.55 | <0.0001 * |

| B-Rotational speed | 0.31 | 1 | 0.31 | 2.33 | 0.1710 |

| C-Oil temperature | 3.07 | 1 | 3.07 | 23.23 | 0.0019 * |

| AB | 0.62 | 1 | 0.62 | 4.68 | 0.0673 |

| AC | 1.80 | 1 | 1.80 | 13.61 | 0.0078 * |

| BC | 0.08 | 1 | 0.08 | 0.58 | 0.4699 |

| A2 | 1.10 | 1 | 1.10 | 8.30 | 0.0236 |

| B2 | 0.16 | 1 | 0.16 | 1.24 | 0.3017 |

| C2 | 0.09 | 1 | 0.09 | 0.71 | 0.4289 |

| Residual | 0.93 | 7 | 0.13 | ||

| Lock of Fit | 0.71 | 3 | 0.24 | 4.44 | 0.0920 |

| Pure Error | 0.21 | 4 | 0.05 | ||

| Total | 19.82 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, W.; Yang, G.; Cao, W.; Bai, G.; Cao, C.; Song, S. Modeling and Analysis of Internal Leakage Characteristics of the Internal Curve Motor by a CFD-Based Method. Processes 2024, 12, 2835. https://doi.org/10.3390/pr12122835

Ma W, Yang G, Cao W, Bai G, Cao C, Song S. Modeling and Analysis of Internal Leakage Characteristics of the Internal Curve Motor by a CFD-Based Method. Processes. 2024; 12(12):2835. https://doi.org/10.3390/pr12122835

Chicago/Turabian StyleMa, Wei, Guolai Yang, Wenbin Cao, Guixiang Bai, Chuanchuan Cao, and Shoupeng Song. 2024. "Modeling and Analysis of Internal Leakage Characteristics of the Internal Curve Motor by a CFD-Based Method" Processes 12, no. 12: 2835. https://doi.org/10.3390/pr12122835

APA StyleMa, W., Yang, G., Cao, W., Bai, G., Cao, C., & Song, S. (2024). Modeling and Analysis of Internal Leakage Characteristics of the Internal Curve Motor by a CFD-Based Method. Processes, 12(12), 2835. https://doi.org/10.3390/pr12122835