Pre-Commercial Demonstration of a Photosynthetic Upgrading Plant: Investment and Operating Cost Analysis

Abstract

1. Introduction

2. Materials and Methods

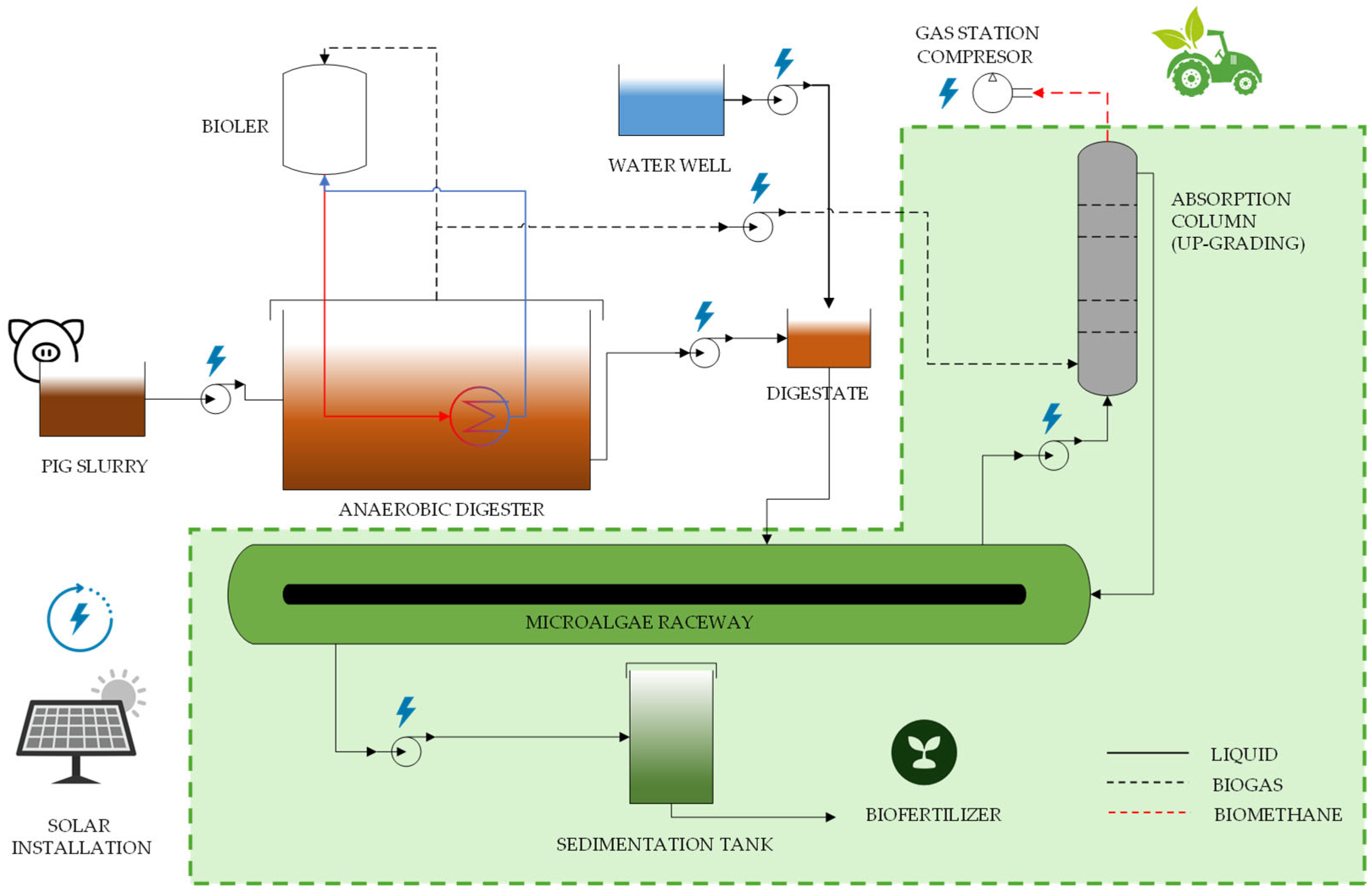

2.1. Biomethane Plant Description

Upgrading Facilities

2.2. Equipment Costs

2.2.1. The Absorption Column

2.2.2. Microalgae Culture, High-Rate Algae Pond

2.2.3. The Settler

2.2.4. The Mixing Tank

2.2.5. Pumping and Piping

2.3. Operating Costs

3. Results

3.1. Biogas and Biomethane Production

3.2. Microalgae Biomass Production

3.3. Investment Cost Study

3.4. Operating Cost Study

4. Discussion

5. Conclusions

- The microalgae-based system demonstrated superior cost-effectiveness compared to other biogas upgrading technologies for the biogas production capacity typical of pig farms.

- Biomethane quality was maintained throughout the year achieving the legal standard despite variable variations in meteorological conditions.

- Operating costs proved to be competitive when compared to alternative upgrading technologies.

- The production of vehicular biomethane using a photosynthetic upgrading system was successfully demonstrated for the first time at a pre-commercial scale.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Deng, L.; Ngo, H.H.; Guo, W.; Chang, S.W.; Nguyen, D.D.; Pandey, A.; Varjani, S.; Hoang, N.B. Recent Advances in Circular Bioeconomy Based Clean Technologies for Sustainable Environment. J. Water Process Eng. 2022, 46, 102534. [Google Scholar] [CrossRef]

- Meier, L.; Barros, P.; Torres, A.; Vilchez, C.; Jeison, D. Photosynthetic Biogas Upgrading Using Microalgae: Effect of Light/Dark Photoperiod. Renew. Energy 2017, 106, 17–23. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and Potential of the Anaerobic Digestion of Waste-Activated Sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Ferrari, G.; Holl, E.; Steinbrenner, J.; Pezzuolo, A.; Lemmer, A. Environmental Assessment of a Two-Stage High Pressure Anaerobic Digestion Process and Biological Upgrading as Alternative Processes for Biomethane Production. Bioresour. Technol. 2022, 360, 127612. [Google Scholar] [CrossRef]

- Massaccesi, L.; Sordi, A.; Micale, C.; Cucina, M.; Zadra, C.; Di Maria, F.; Gigliotti, G. Chemical Characterisation of Percolate and Digestate during the Hybrid Solid Anaerobic Digestion Batch Process. Process Biochem. 2013, 48, 1361–1367. [Google Scholar] [CrossRef]

- EN 16723-1:2016; Natural Gas and Biomethane for Use in Transport and Biomethane for Injection in the Natural Gas Network. Specifications for Biomethane for Injection in the Natural Gas Network. European Committee for Standardization: Brussels, Belgium, 2016.

- Toledo-Cervantes, A.; Estrada, J.M.; Lebrero, R.; Muñoz, R. A Comparative Analysis of Biogas Upgrading Technologies: Photosynthetic vs Physical/Chemical Processes. Algal Res. 2017, 25, 237–243. [Google Scholar] [CrossRef]

- Sahota, S.; Shah, G.; Ghosh, P.; Kapoor, R.; Sengupta, S.; Singh, P.; Vijay, V.; Sahay, A.; Vijay, V.K.; Thakur, I.S. Review of Trends in Biogas Upgradation Technologies and Future Perspectives. Bioresour. Technol. Rep. 2018, 1, 79–88. [Google Scholar] [CrossRef]

- Marín, D.; Carmona-Martínez, A.A.; Blanco, S.; Lebrero, R.; Muñoz, R. Innovative Operational Strategies in Photosynthetic Biogas Upgrading in an Outdoors Pilot Scale Algal-Bacterial Photobioreactor. Chemosphere 2021, 264, 128470. [Google Scholar] [CrossRef]

- Toledo-Cervantes, A.; Lebrero, R.; Cavinato, C.; Muñoz, R. Biogas Upgrading Using Algal-Bacterial Processes. In Microalgae-Based Biofuels and Bioproducts: From Feedstock Cultivation to End-Products; Woodhead Publish: Sawston, UK, 2017; pp. 283–304. [Google Scholar] [CrossRef]

- Kapoor, R.; Ghosh, P.; Kumar, M.; Vijay, V.K. Evaluation of Biogas Upgrading Technologies and Future Perspectives: A Review. Environ. Sci. Pollut. Res. 2019, 26, 11631–11661. [Google Scholar] [CrossRef]

- Gkotsis, P.; Kougias, P.; Mitrakas, M.; Zouboulis, A. Biogas Upgrading Technologies—Recent Advances in Membrane-Based Processes. Int. J. Hydrog. Energy 2023, 48, 3965–3993. [Google Scholar] [CrossRef]

- Ferreira, A.F.; Toledo-Cervantes, A.; de Godos, I.; Gouveia, L.; Munõz, R. Life Cycle Assessment of Pilot and Real Scale Photosynthetic Biogas Upgrading. Algal Res. 2019, 44, 101668. [Google Scholar] [CrossRef]

- Ángeles, R.; Arnaiz, E.; Gutiérrez, J.; Sepúlveda-Muñoz, C.A.; Fernández-Ramos, O.; Muñoz, R.; Lebrero, R. Optimization of Photosynthetic Biogas Upgrading in Closed Photobioreactors Combined with Algal Biomass Production. J. Water Process Eng. 2020, 38, 101554. [Google Scholar] [CrossRef]

- Marín, D.; Carmona-Martínez, A.A.; Lebrero, R.; Muñoz, R. Influence of the Diffuser Type and Liquid-to-Biogas Ratio on Biogas Upgrading Performance in an Outdoor Pilot Scale High Rate Algal Pond. Fuel 2020, 275, 117999. [Google Scholar] [CrossRef]

- Severi, C.A.; Lebrero, R.; Muñoz, R. Chapter 8—Biogas Upgrading Using Microalgae. In Sustainable Industrial Processes Based on Microalgae; Elsevier Science: Amsterdam, The Netherlands, 2024; pp. 157–184. [Google Scholar] [CrossRef]

- Nagarajan, D.; Lee, D.J.; Chang, J.S. Integration of Anaerobic Digestion and Microalgal Cultivation for Digestate Bioremediation and Biogas Upgrading. Bioresour. Technol. 2019, 290, 121804. [Google Scholar] [CrossRef]

- del Rosario Rodero, M.; Lebrero, R.; Serrano, E.; Lara, E.; Arbib, Z.; García-Encina, P.A.; Muñoz, R. Technology Validation of Photosynthetic Biogas Upgrading in a Semi-Industrial Scale Algal-Bacterial Photobioreactor. Bioresour. Technol. 2019, 279, 43–49. [Google Scholar] [CrossRef]

- Yan, C.; Zhu, L.; Wang, Y. Photosynthetic CO2 Uptake by Microalgae for Biogas Upgrading and Simultaneously Biogas Slurry Decontamination by Using of Microalgae Photobioreactor under Various Light Wavelengths, Light Intensities, and Photoperiods. Appl. Energy 2016, 178, 9–18. [Google Scholar] [CrossRef]

- Toledo-Cervantes, A.; Madrid-Chirinos, C.; Cantera, S.; Lebrero, R.; Muñoz, R. Influence of the Gas-Liquid Flow Configuration in the Absorption Column on Photosynthetic Biogas Upgrading in Algal-Bacterial Photobioreactors. Bioresour. Technol. 2017, 225, 336–342. [Google Scholar] [CrossRef]

- Burg, V.; Rolli, C.; Schnorf, V.; Scharfy, D.; Anspach, V.; Bowman, G. Agricultural Biogas Plants as a Hub to Foster Circular Economy and Bioenergy: An Assessment Using Substance and Energy Flow Analysis. Resour. Conserv. Recycl. 2023, 190, 106770. [Google Scholar] [CrossRef]

- Ó Céileachair, D.; O’Shea, R.; Murphy, J.D.; Wall, D.M. Alternative Energy Management Strategies for Large Industry in Non-Gas-Grid Regions Using on-Farm Biomethane. Appl. Energy 2021, 303, 117627. [Google Scholar] [CrossRef]

- García Álvaro, A.; Mediavilla, I.; Ruiz Palomar, C.; Esteban, L.S.; de Godos Crespo, I. Energy Valorization of Solid Residue from Steam Distillation of Aromatic Shrubs. Ind. Crops Prod. 2024, 222, 119485. [Google Scholar] [CrossRef]

- LIFE Smart Agromobility. 2024. Available online: https://lifesmartagromobility.eu/en/index (accessed on 27 November 2024).

- Mendieta, O.; Castro, L.; Escalante, H.; Garfí, M. Low-Cost Anaerobic Digester to Promote the Circular Bioeconomy in the Non-Centrifugal Cane Sugar Sector: A Life Cycle Assessment. Bioresour. Technol. 2021, 326, 124783. [Google Scholar] [CrossRef] [PubMed]

- García Álvaro, A.; Ruiz Palomar, C.; Valenzuela, E.I.; Hermosilla Redondo, D.; Muñoz Torre, R.; de Godos Crespo, I. Microbial Analysis of Anaerobic Digester Reveals Prevalence of Manure Microbiota. J. Water Process Eng. 2024, 60, 105162. [Google Scholar] [CrossRef]

- Rubio, J.A.; Fdez-Güelfo, L.A.; Romero-García, L.I.; Wilkie, A.C.; García-Morales, J.L. Start-up of the Mesophilic Anaerobic Co-Digestion of Two-Phase Olive-Mill Waste and Cattle Manure Using Volatile Fatty Acids as Process Control Parameter. Fuel 2022, 325, 124901. [Google Scholar] [CrossRef]

- Álvaro, A.G.; Palomar, C.R.; Torre, R.M.; Redondo, D.H.; de Godos Crespo, I. Hybridization of Anaerobic Digestion with Solar Energy: A Solution for Isolated Livestock Farms. Energy Convers. Manag. X 2023, 20, 100488. [Google Scholar] [CrossRef]

- IRTA (Ministerio de Agricultura). Datos y Censos—Bdporc. 2024. Available online: https://bdporc.irta.es/datos-y-censos/ (accessed on 27 November 2024).

- Chandra Mal, B. Raceways and Tanks. In Aquacultural Facilities and Equipment; Elsevier: Amsterdam, The Netherlands, 2021; pp. 239–268. [Google Scholar]

- Borowitzka, M.A. Algal biotechnology products and processes—matching science and economics. In Algal Biotechnology Products and Processes-Matching Science and Economics; Springer: Berlin/Heidelberg, Germany, 1992; Volume 4, pp. 267–279. [Google Scholar]

- Borowitzka, M.A. Commercial Production of Microalgae: Ponds, Tanks, and Fermenters. Prog. Ind. Microbiol. 1999, 35, 313–321. [Google Scholar] [CrossRef]

- Trading Economics, Polyethylene Price. 2024. Available online: https://tradingeconomics.com/commodity/polyethylene (accessed on 20 November 2024).

- Mehrabadi, A.; Craggs, R.; Farid, M.M. Wastewater Treatment High Rate Algal Ponds (WWT HRAP) for Low-Cost Biofuel Production. Bioresour. Technol. 2015, 184, 202–214. [Google Scholar] [CrossRef]

- Trading Economics, Steel Price. 2024. Available online: https://tradingeconomics.com/commodity/steel (accessed on 20 November 2024).

- NOV Mono’s PC Pumps for Waterworks. World Pumps 2014, 2014, 10. [CrossRef]

- Trading Economics, Cooper Price. 2024. Available online: https://tradingeconomics.com/commodity/copper (accessed on 20 November 2024).

- Statista Research Department. Monthly Prices for Polyvinyl Chloride (PVC) Worldwide. 2024. Available online: https://www.statista.com/statistics/1350554/monthly-polypropylene-price-worldwide/ (accessed on 20 November 2024).

- Marín, D.; Posadas, E.; Cano, P.; Pérez, V.; Blanco, S.; Lebrero, R.; Muñoz, R. Seasonal Variation of Biogas Upgrading Coupled with Digestate Treatment in an Outdoors Pilot Scale Algal-Bacterial Photobioreactor. Bioresour. Technol. 2018, 263, 58–66. [Google Scholar] [CrossRef]

- Serejo, M.L.; Posadas, E.; Boncz, M.A.; Blanco, S.; García-Encina, P.; Muñoz, R. Influence of Biogas Flow Rate on Biomass Composition During the Optimization of Biogas Upgrading in Microalgal-Bacterial Processes. Environ. Sci. Technol. 2015, 49, 3228–3236. [Google Scholar] [CrossRef]

- Posadas, E.; Marín, D.; Blanco, S.; Lebrero, R.; Muñoz, R. Simultaneous Biogas Upgrading and Centrate Treatment in an Outdoors Pilot Scale High Rate Algal Pond. Bioresour. Technol. 2017, 232, 133–141. [Google Scholar] [CrossRef]

- Posadas, E.; Serejo, M.L.; Blanco, S.; Pérez, R.; García-Encina, P.A.; Muñoz, R. Minimization of Biomethane Oxygen Concentration during Biogas Upgrading in Algal–Bacterial Photobioreactors. Algal Res. 2015, 12, 221–229. [Google Scholar] [CrossRef]

- Hirayama, A.; Sueyoshi, M.N.; Nakano, T.; Ota, Y.; Kurita, H.; Tasaki, M.; Kuroiwa, Y.; Kato, T.; Serizawa, S.; Kojima, K.; et al. Development of Large-Scale Microalgae Production in the Middle East. Bioresour. Technol. 2022, 343, 126036. [Google Scholar] [CrossRef] [PubMed]

- Dodd, J.C. Algae Production and Harvesting from Animal Wastewaters. Agric. Wastes 1979, 1, 23–37. [Google Scholar] [CrossRef]

- Ortiz, A.; García-Galán, M.J.; García, J.; Díez-Montero, R. Optimization and Operation of a Demonstrative Full Scale Microalgae Harvesting Unit Based on Coagulation, Flocculation and Sedimentation. Sep. Purif. Technol. 2021, 259, 118171. [Google Scholar] [CrossRef]

- Nurdogan, Y.; Oswald, W.J. Tube Settling of High-Rate Pond Algae. Water Sci. Technol. 1996, 33, 229–241. [Google Scholar] [CrossRef]

- Ryckebosch, E.; Drouillon, M.; Vervaeren, H. Techniques for Transformation of Biogas to Biomethane. Biomass Bioenergy 2011, 35, 1633–1645. [Google Scholar] [CrossRef]

- Zhu, G.; Zhang, Y.; Ren, J.; Qiu, T.; Wang, T. Flow Simulation and Analysis in a Vertical-Flow Sedimentation Tank. Energy Procedia 2012, 16, 197–202. [Google Scholar] [CrossRef]

- Omoregie, A.I.; Palombo, E.A.; Ong, D.E.L.; Nissom, P.M. A Feasible Scale-up Production of Sporosarcina Pasteurii Using Custom-Built Stirred Tank Reactor for in-Situ Soil Biocementation. Biocatal. Agric. Biotechnol. 2020, 24, 101544. [Google Scholar] [CrossRef]

- Racharaks, R.; Ge, X.; Li, Y. Cultivation of Marine Microalgae Using Shale Gas Flowback Water and Anaerobic Digestion Effluent as the Cultivation Medium. Bioresour. Technol. 2015, 191, 146–156. [Google Scholar] [CrossRef]

- Al-Mallahi, J.; Ishii, K.; Sato, M.; Ochiai, S. Static Supply of Different Simulated Flue Gases for Native Microalgae Cultivation in Diluted Cow Manure Digestate. J. Environ. Manag. 2023, 335, 117557. [Google Scholar] [CrossRef]

- Saranya, D.; Shanthakumar, S. Effect of Culture Conditions on Biomass Yield of Acclimatized Microalgae in Ozone Pre-Treated Tannery Effluent: A Simultaneous Exploration of Bioremediation and Lipid Accumulation Potential. J. Environ. Manag. 2020, 273, 111129. [Google Scholar] [CrossRef] [PubMed]

- Daneshvar, E.; Santhosh, C.; Antikainen, E.; Bhatnagar, A. Microalgal Growth and Nitrate Removal Efficiency in Different Cultivation Conditions: Effect of Macro and Micronutrients and Salinity. J. Environ. Chem. Eng. 2018, 6, 1848–1854. [Google Scholar] [CrossRef]

- EN 16723-2:2017; Natural Gas and Biomethane for Use in Transport and Biomethane for Injection in the Natural Gas Network—Part 2: Automotive Fuels Specification. European Committee for Standardization: Brussels, Belgium, 2017.

- Ferreira, A.; Melkonyan, L.; Carapinha, S.; Ribeiro, B.; Figueiredo, D.; Avetisova, G.; Gouveia, L. Biostimulant and Biopesticide Potential of Microalgae Growing in Piggery Wastewater. Environ. Adv. 2021, 4, 100062. [Google Scholar] [CrossRef]

- IDEA. Ahorro, Eficiencia Energética y Fertilización Nitrogenada. 2007. Available online: https://www.idae.es (accessed on 27 November 2024).

- UNE-EN 16723-2:2017; Normativa Española de Biometano para Uso Vehicular. Asociación Española de Normalización: Madrid, Spain, 2018.

- UNE-EN 16723-1:2017; Gas Natural y Biometano para Uso en Transporte y Biometano para Inyección en la Red de Gas Natural. Asociación Española de Normalización: Madrid, Spain, 2017.

- Angelidaki, I.; Treu, L.; Tsapekos, P.; Luo, G.; Campanaro, S.; Wenzel, H.; Kougias, P.G. Biogas Upgrading and Utilization: Current Status and Perspectives. Biotechnol. Adv. 2018, 36, 452–466. [Google Scholar] [CrossRef] [PubMed]

- Comesaña-Gándara, B.; García-Depraect, O.; Santos-Beneit, F.; Bordel, S.; Lebrero, R.; Muñoz, R. Recent Trends and Advances in Biogas Upgrading and Methanotrophs-Based Valorization. Chem. Eng. J. Adv. 2022, 11, 100325. [Google Scholar] [CrossRef]

- Sander, R. Compilation of Henry’s Law Constants (Version 5.0.0) for Water as Solvent. Atmos. Chem. Phys. 2023, 23, 10901–12440. [Google Scholar] [CrossRef]

- Franco-Morgado, M.; Toledo-Cervantes, A.; González-Sánchez, A.; Lebrero, R.; Muñoz, R. Integral (VOCs, CO2, Mercaptans and H2S) Photosynthetic Biogas Upgrading Using Innovative Biogas and Digestate Supply Strategies. Chem. Eng. J. 2018, 354, 363–369. [Google Scholar] [CrossRef]

- Winkler, M.K.; Straka, L. New Directions in Biological Nitrogen Removal and Recovery from Wastewater. Curr. Opin. Biotechnol. 2019, 57, 50–55. [Google Scholar] [CrossRef]

- García, A.; Valenzuela, E.I.; Vargas, A.; de Godos, I.; Muñoz, R.; Wang, M.; Vital-Jácome, M.; Quijano, G. Wastewater Treatment Potential, Light Penetration Profile and Biomass Settling Performance of a Photo-Sequencing Batch Reactor. J. Chem. Technol. Biotechnol. 2023, 98, 346–356. [Google Scholar] [CrossRef]

- Angelidaki, I.; Xie, L.; Luo, G.; Zhang, Y.; Oechsner, H.; Lemmer, A.; Munoz, R.; Kougias, P.G. Biogas Upgrading: Current and Emerging Technologies. In Biomass, Biofuels, Biochemicals: Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels; Elsevier: Amsterdam, The Netherlands, 2019; pp. 817–843. ISBN 9780128168561. [Google Scholar]

- Chisti, Y. Biodiesel from Microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef]

- de Godos, I.; Blanco, S.; García-Encina, P.A.; Becares, E.; Muñoz, R. Long-Term Operation of High Rate Algal Ponds for the Bioremediation of Piggery Wastewaters at High Loading Rates. Bioresour. Technol. 2009, 100, 4332–4339. [Google Scholar] [CrossRef] [PubMed]

- Craggs, R.; Sutherland, D.; Campbell, H. Hectare-Scale Demonstration of High Rate Algal Ponds for Enhanced Wastewater Treatment and Biofuel Production. J. Appl. Phycol. 2012, 24, 329–337. [Google Scholar] [CrossRef]

- Operador de Mercado Eléctrico Designado (OMIE). Precios Horarios del Mercado Diario en España. Available online: https://www.omie.es/ (accessed on 3 October 2024).

- Azadi Tabar, M.; Maghsoudi, H.; Karimi, K.; Hosseini, S.S.; Gholami, M.; Denayer, J.F.M. Techno-Economic Analysis of Vacuum Pressure Swing Adsorption Process for a Sustainable Upgrading of Biogas. J. Clean. Prod. 2024, 450, 141853. [Google Scholar] [CrossRef]

- Iglesias, R.; Muñoz, R.; Polanco, M.; Díaz, I.; Susmozas, A.; Moreno, A.D.; Guirado, M.; Carreras, N.; Ballesteros, M. Biogas from Anaerobic Digestion as an Energy Vector: Current Upgrading Development. Energies 2021, 14, 2742. [Google Scholar] [CrossRef]

| References | Equipment | Factor Scale | ||||||

|---|---|---|---|---|---|---|---|---|

| 0.5 | 1 | 2 | 3 | 4 | 10 | |||

| [30] | Absorption column | Coefficient applied | 0.7 | 1 | 1.2 | 2 | 3 | 5 |

| Costs (€) | 34,020 | 48,600 | 58,320 | 97,200 | 145,800 | 243,000 | ||

| [31,32,33] | Waterproofing | Coefficient applied | 0.5 | 1 | 2 | 3 | 4 | 10 |

| Costs (€) | 7250 | 14,500 | 29,000 | 43,500 | 58,000 | 145,000 | ||

| [30,31,32,34] | Biological upgrading raft | Coefficient applied | 0.5 | 1 | 2 | 2.8 | 3.5 | 7 |

| Costs (€) | 8932 | 17,864 | 35,729 | 50,020 | 62,526 | 125,051 | ||

| [31,32,35] | Baffles | Coefficient applied | 0.6 | 1 | 1.2 | 2 | 2.9 | 6 |

| Costs (€) | 4715 | 7858 | 9430 | 15,716 | 22,788 | 47,148 | ||

| [31,32,33,35] | Paddle wheel | Coefficient applied | 0.7 | 1 | 1.5 | 1.8 | 2 | 2 |

| Costs (€) | 6951 | 9930 | 14,895 | 17,874 | 19,860 | 19,860 | ||

| [30] | Mixing tank | Coefficient applied | 0.6 | 1 | 1.5 | 2.2 | 2.5 | 4 |

| Costs (€) | 1822 | 3036 | 4554 | 6679 | 7590 | 12,144 | ||

| [30] | Settler | Coefficient applied | 0.6 | 1 | 1.5 | 2.2 | 2.5 | 4 |

| Costs (€) | 2201 | 3669 | 5504 | 8072 | 9173 | 14,676 | ||

| [36] | Pumps | Coefficient applied | 0.6 | 1 | 1.2 | 2.5 | 3 | 4 |

| Costs (€) | 2482 | 4137 | 4964 | 10,342 | 12,410 | 16,547 | ||

| [37] | Electrification | Coefficient applied | 0.7 | 1 | 1.1 | 1.2 | 1.3 | 1.5 |

| Costs (€) | 15,317 | 21,882 | 24,070 | 26,258 | 28,447 | 32,823 | ||

| [38] | Pipelines | Coefficient applied | 0.6 | 1 | 1.2 | 2.5 | 3 | 5 |

| Costs (€) | 2988 | 4979 | 5975 | 12,448 | 14,938 | 24,896 | ||

| Total costs (€) | 86,678 | 136,455 | 192,440 | 288,110 | 381,531 | 681,145 | ||

| Equipment | Power (kW) | Time (h/d) | Energy Consumption (kWh/d) | Consumable Materials | Quantity |

|---|---|---|---|---|---|

| Liquid pump | 0.4 | 24.0 | 9.60 | Oil pumps | 0.1 L/d |

| Biogas pump | 0.2 | 24.0 | 3.60 | Activated carbon | 0.25 kg/d |

| Paddle wheel | 0.2 | 10.0 | 2.00 | Silica gel | 0.5 kg/d |

| Digestate pump | 0.5 | 0.9 | 0.42 | ||

| Setler pump | 0.6 | 6.0 | 3.66 | ||

| SCADA | 0.2 | 24.0 | 3.60 | ||

| T | 22.88 |

| Factor Scale | Capacity Raw Biogas (Nm3/h) | Costs (€) | Capital Costs (€/Nm3 h) |

|---|---|---|---|

| 0.5 | 12.14 | 86,678 | 7138.19 |

| 1 | 24.29 | 136,455 | 5618.75 |

| 2 | 48.57 | 192,440 | 3962.01 |

| 3 | 72.86 | 288,110 | 3954.45 |

| 4 | 97.14 | 381,531 | 3927.52 |

| 10 | 242.86 | 681,145 | 2804.72 |

| Energy consumption (kWh h−1) | 0.950 |

| Upgrading biogas capacity (m3 h−1) | 5.00 |

| Energy consumption (kWh m−3 biogas) | 0.191 |

| Cost per Day (€/d) | Energy Balance (kWh/d) | Cost Balance (€/Year) | |||

|---|---|---|---|---|---|

| Oil pumps | 6.23 | Energy production | 710.0 | Income | 37,620 |

| Activated carbon | 1.25 | Energy consumption | 22.9 | Expenditure | 7272 |

| Silica gel | 9.70 | Net energy | 687.1 | Benefits | 30,348 |

| Electricity | 2.75 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz Palomar, C.; García Álvaro, A.; Muñoz, R.; Repáraz, C.; Ortega, M.F.; de Godos, I. Pre-Commercial Demonstration of a Photosynthetic Upgrading Plant: Investment and Operating Cost Analysis. Processes 2024, 12, 2794. https://doi.org/10.3390/pr12122794

Ruiz Palomar C, García Álvaro A, Muñoz R, Repáraz C, Ortega MF, de Godos I. Pre-Commercial Demonstration of a Photosynthetic Upgrading Plant: Investment and Operating Cost Analysis. Processes. 2024; 12(12):2794. https://doi.org/10.3390/pr12122794

Chicago/Turabian StyleRuiz Palomar, César, Alfonso García Álvaro, Raúl Muñoz, Carlos Repáraz, Marcelo F. Ortega, and Ignacio de Godos. 2024. "Pre-Commercial Demonstration of a Photosynthetic Upgrading Plant: Investment and Operating Cost Analysis" Processes 12, no. 12: 2794. https://doi.org/10.3390/pr12122794

APA StyleRuiz Palomar, C., García Álvaro, A., Muñoz, R., Repáraz, C., Ortega, M. F., & de Godos, I. (2024). Pre-Commercial Demonstration of a Photosynthetic Upgrading Plant: Investment and Operating Cost Analysis. Processes, 12(12), 2794. https://doi.org/10.3390/pr12122794