Experimental and Numerical Simulation of Flow Modes in Flow Focusing/Blurring Nozzle

Abstract

:1. Introduction

2. Experimental Facility

2.1. Experimental Nozzle

2.2. Experimental Equipment

3. Numerical Simulation Model

4. Results and Discussions

4.1. Experimental Study on Flow Modes Inside the Nozzle

4.2. Numerical Simulation of Flow Modes and Their Transformation

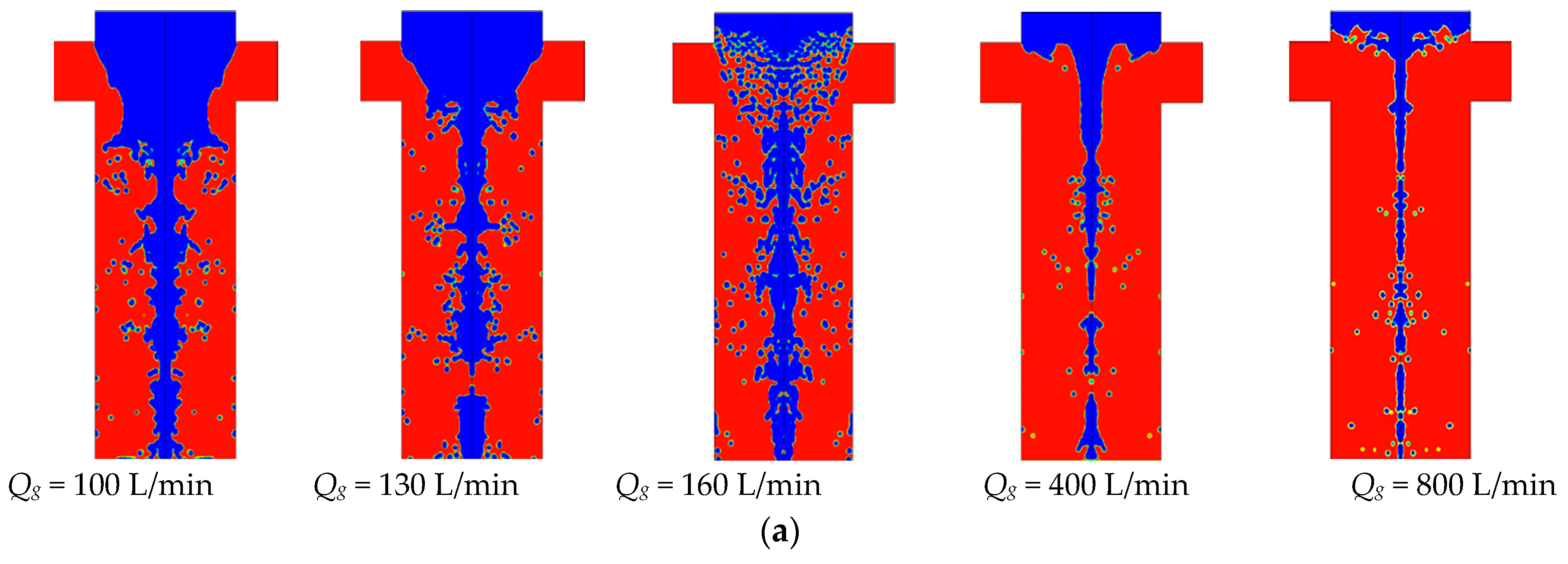

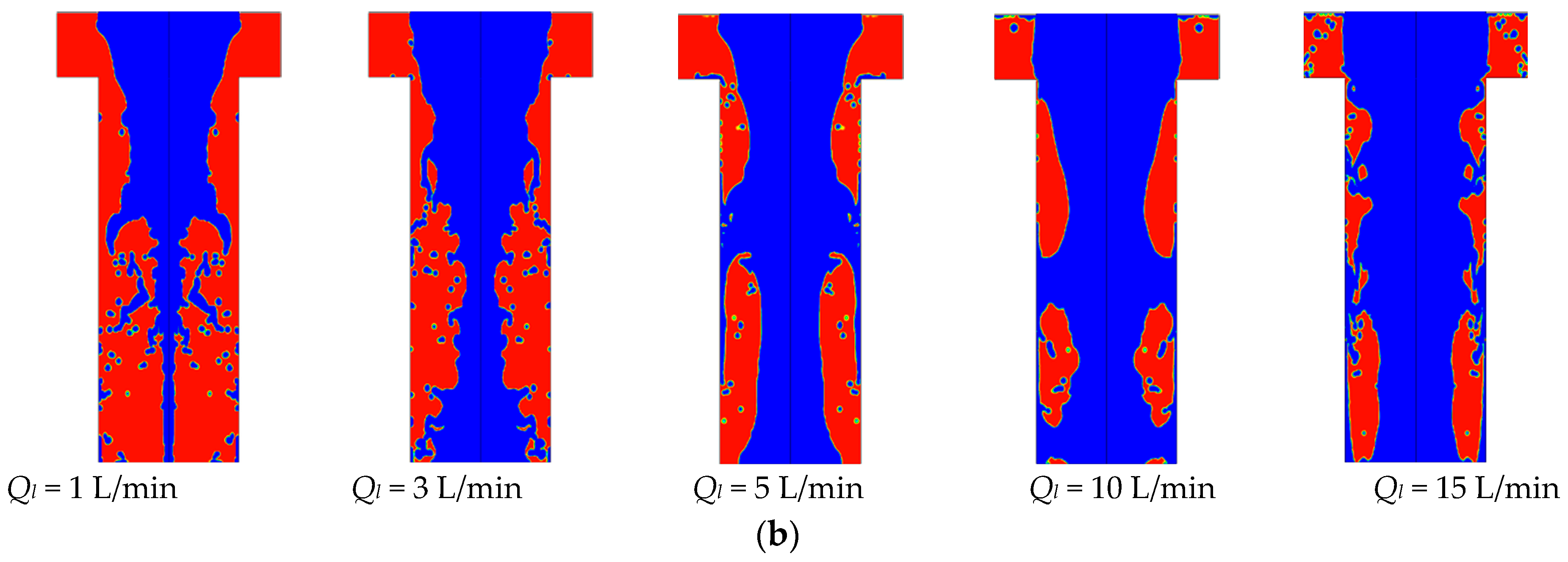

4.3. Numerical Simulation of Flow Morphology Inside the Nozzle Under Special Conditions

5. Conclusions

- (1)

- According to the experimental results, the flow modes of the flow focusing/blurring nozzle are classified into three types from the perspective of liquid jet breakup: flow focusing, transition, and flow blurring. This classification takes into account both the flow inside and outside the nozzle, which is more reasonable.

- (2)

- The flow mode and its transformation are mainly related to viscous shear force, gas pressure on jet surface, and liquid inertia force. The enhancement of viscous shear force caused by the increase in the gas flow rate is an effective method to achieve the transition from flow focusing to flow blurring.

- (3)

- Excessive gas or liquid flow rates can cause the liquid jet inside the nozzle to be difficult to break up or cause them to even be unable to flow; that is, the flow focusing/blurring nozzle cannot function properly when the gas or liquid flow rate is too high.

- (4)

- Based on this study, the design principles for the practical application of the flow focusing/blurring nozzle have been determined. Firstly, for a specific application scenario, selecting the appropriate gas flow rate is the most effective method for designing a suitable nozzle. When the gas flow rate cannot meet the requirements, consider changing the structure (tube hole distance, orifice scheme, etc.) to control the internal gas–liquid interaction and design a nozzle that meets the requirements.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ganan-Calvo, A.M. Generation of Steady Liquid Microthreads and Micron-Sized Monodisperse Sprays in Gas Streams. Phys. Rev. Lett. 1998, 80, 285–288. [Google Scholar] [CrossRef]

- Ganan-Calvo, A.M. Enhanced liquid atomization: From flow-focusing to flow-blurring. Appl. Phys. Lett. 2005, 86, 4601. [Google Scholar] [CrossRef]

- Song, Y.; Zhou, Y.; Zhao, S.; Du, F.-R.; Li, X.-Y.; Zhu, K.; Yan, H.-S.; Xu, Z.; Ding, S.-T. Cyclic coupling and working characteristics analysis of a novel combined cycle engine concept for aviation applications. Energy 2024, 301, 131747. [Google Scholar] [CrossRef]

- Mei, Q.; Liu, L.; Yang, W.; Tang, Y. Combustion model development of future DI engines for carbon emission reduction. Energy Convers. Manag. 2024, 311, 118528. [Google Scholar] [CrossRef]

- Tianyi, H.; Shouwen, Z.; Chenhui, Z. Unlocking the secrets behind liquid superlubricity: A state-of-the-art review on phenomena and mechanisms. Friction 2022, 10, 1137–1165. [Google Scholar]

- Raven, J.P.; Marmottant, P.; Graner, F. Dry microfoams: Formation and flow in a confined channel. Eur. Phys. J. B Condens. Matter Complex Syst. 2006, 51, 137–143. [Google Scholar] [CrossRef]

- Seo, M.; Paquet, C.; Nie, Z.; Xu, S.; Kumacheva, E. Microfluidic consecutive flow-focusing droplet generators. Soft Matter 2007, 3, 986–992. [Google Scholar] [CrossRef]

- Jensen, M.J.; Stone, H.A.; Bruus, H. A numerical study of two-phase stokes flow in an axisymmetric flow-focusing device. Phys. Fluids 2006, 18, 164501. [Google Scholar] [CrossRef]

- Jensen, M.J. Numerical Simulations of Interface Dynamics in Microfluidics. Ph.D. Thesis, Technical University of Denmark, Copenhagen, Denmark, 2005. [Google Scholar]

- Mu, K.; Si, T.; Li, E.; Xu, R.X.; Ding, H. Numerical study on droplet generation in axisymmetric flow focusing upon actuation. Phys. Fluids 2018, 30, 012111. [Google Scholar] [CrossRef]

- Mu, K.; Ding, H.; Si, T. Instability analysis of the cone–jet flow in liquid-driven flow focusing. Microfluid. Nanofluid. 2018, 22, 138. [Google Scholar] [CrossRef]

- Simmons, B.M.; Agrawal, A.K. Flow blurring atomization for low-emission combustion of liquid biofuels. Combust. Sci. Technol. 2012, 184, 660–675. [Google Scholar] [CrossRef]

- Simmons, B.M.; Panchasara, H.V.; Agrawal, A.K. A comparison of air-blast and flow-blurring injectors using phase doppler particle analyzer technique. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009; pp. 981–992. [Google Scholar]

- Simmons, B.M.; Agrawal, A.K. Spray characteristics of a flow-blurring atomizer. At. Sprays 2010, 20, 821–835. [Google Scholar] [CrossRef]

- Simmons, B.M.; Kolhe, P.S.; Taylor, R.P.; Agrawal, A.K. Glycerol combustion using flow-blurring atomization. In Proceedings of the 2010 Technical Meeting of the Central States Section of the Combustion Institute, Champaign, IL, USA, 21–23 March 2010. [Google Scholar]

- Modestolópez, L.B.; Gañáncalvo, A.M. Visualization and size-measurement of droplets generated by Flow Blurring in a high-pressure environment. Aerosol Sci. Technol. 2017, 52, 198. [Google Scholar] [CrossRef]

- Qavi, I.; Jiang, L.; Akinyemi, O.S. Near-field spray characterization of a high-viscosity alternative jet fuel blend C-3 using a flow blurring injector. Fuel 2021, 293, 120350. [Google Scholar] [CrossRef]

- De Azevedo, C.G.; De Andrade, J.C.; Costa, F.D.S. Effects of injector tip design on the spray characteristics of soy methyl ester biodiesel in a blurry injector. Renew. Energy 2016, 85, 287–294. [Google Scholar] [CrossRef]

- Sadasivuni, V.; Agrawal, A.K. A novel meso-scale combustion system for operation with liquid fuels. Proc. Combust. Inst. 2009, 32, 3155–3162. [Google Scholar] [CrossRef]

- Band, C.; Merin, A.P.; Srinivasan, V. Spray characteristics of shear-thinning viscoelastic liquids downstream of a counterflow atomizer. Int. J. Heat Fluid Flow 2024, 109, 109496. [Google Scholar] [CrossRef]

- Nayer Nasim, M.; Qavi, I.; Lulin, J. Effect of varying internal geometry on the near-field spray characteristics of a swirl burst injector. Flow Turbul. Combust. 2023, 111, 641–674. [Google Scholar] [CrossRef]

- Rosell-Llompart, J.; Gañán-Calvo, A.M. Turbulence in pneumatic flow focusing and flow blurring regimes. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2008, 77, 036321. [Google Scholar] [CrossRef]

- Almagro, B.; Gañán-Calvo, A.M.; Hidalgo, M.; Canals, A. Behaviour of a flow focusing pneumatic nebulizer with high total dissolved solids solution on radially- and axially-viewed inductively coupled plasma atomic emission spectrometry. J. Anal. At. Spectrom. 2006, 21, 1072–1075. [Google Scholar] [CrossRef]

- Herrada, M.A.; Gañán-Calvo, A.M.; Ojeda-Monge, A.; Bluth, B.; Riesco-Chueca, P. Liquid flow focused by a gas: Jetting, dripping, and recirculation. Phys. Rev. E 2008, 78, 036323. [Google Scholar] [CrossRef]

- Montanero, J.M.; Rebollo-Muñoz, N.; Herrada, M.A.; Gañán-Calvo, A.M. Global stability of the focusing effect of fluid jet flows. Phys. Rev. E 2011, 83, 036309. [Google Scholar] [CrossRef] [PubMed]

- Murugan, R.; Kolhe, P.S.; Sahu, K.C. A combined experimental and computational study of flow-blurring atomization in a twin-fluid atomizer. Eur. J. Mech.—B/Fluids 2020, 84, 528–541. [Google Scholar] [CrossRef]

- Murugan, R.; Balusamy, S.; Kolhe, P. Experimental study of liquid spray mode of twin fluid atomizer using optical diagnostic tool. Flow Turbul. Combust. 2021, 106, 261–289. [Google Scholar] [CrossRef]

- Murugan, R.; Kolhe, P.S. Experimental investigation into flow blurring atomization. Exp. Therm. Fluid Sci. 2020, 120, 110240. [Google Scholar] [CrossRef]

| Researcher | Methods | Software | Conclusion |

|---|---|---|---|

| Jensen [8] | Second-order Runge–Kutta time integration algorithm; free-surface scheme | MATLAB v.7.0 R14 coupled FEMLAB | The relationship between the flow parameters, structural parameters, and the droplets size |

| Nayer Nasim [21] | Standard k-epsilon viscous model; Eulerian method; second-order upwind scheme; SIMPLE method | Fluent v.6.3 | The decrease in tube hole distance leads to an increase in internal pressure of the nozzle, and the increase in air momentum causes a change in flow mode |

| Herrada [24] | Laminar model; VOF method; third-order modified MUSCL scheme; PISO method | Fluent v.6.3 | The flow blurring mode is related to the stability of the liquid recirculation cell inside the nozzle |

| Montanero [25] | Laminar model; VOF method; third-order modified MUSCL scheme; PISO method | Fluent v.6.3 | The viscosity of a liquid has a significant impact on the transition of flow modes |

| Murugan [26] | LES; VOF method; second order central differencing implicit scheme; PISO method | Fluent v.6.3 | The radial flow of gas in the mixing zone results in a reverse flow towards the inner tube when it meets the liquid jet, enhancing gas–liquid interaction and leading to flow blurring |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, J.; Ye, Z.; Zhao, J. Experimental and Numerical Simulation of Flow Modes in Flow Focusing/Blurring Nozzle. Processes 2024, 12, 2751. https://doi.org/10.3390/pr12122751

Fu J, Ye Z, Zhao J. Experimental and Numerical Simulation of Flow Modes in Flow Focusing/Blurring Nozzle. Processes. 2024; 12(12):2751. https://doi.org/10.3390/pr12122751

Chicago/Turabian StyleFu, Juan, Zhenhuan Ye, and Jin Zhao. 2024. "Experimental and Numerical Simulation of Flow Modes in Flow Focusing/Blurring Nozzle" Processes 12, no. 12: 2751. https://doi.org/10.3390/pr12122751

APA StyleFu, J., Ye, Z., & Zhao, J. (2024). Experimental and Numerical Simulation of Flow Modes in Flow Focusing/Blurring Nozzle. Processes, 12(12), 2751. https://doi.org/10.3390/pr12122751