Research on Sealing Premium Connections in Corrosive CO2 Environments

Abstract

1. Introduction

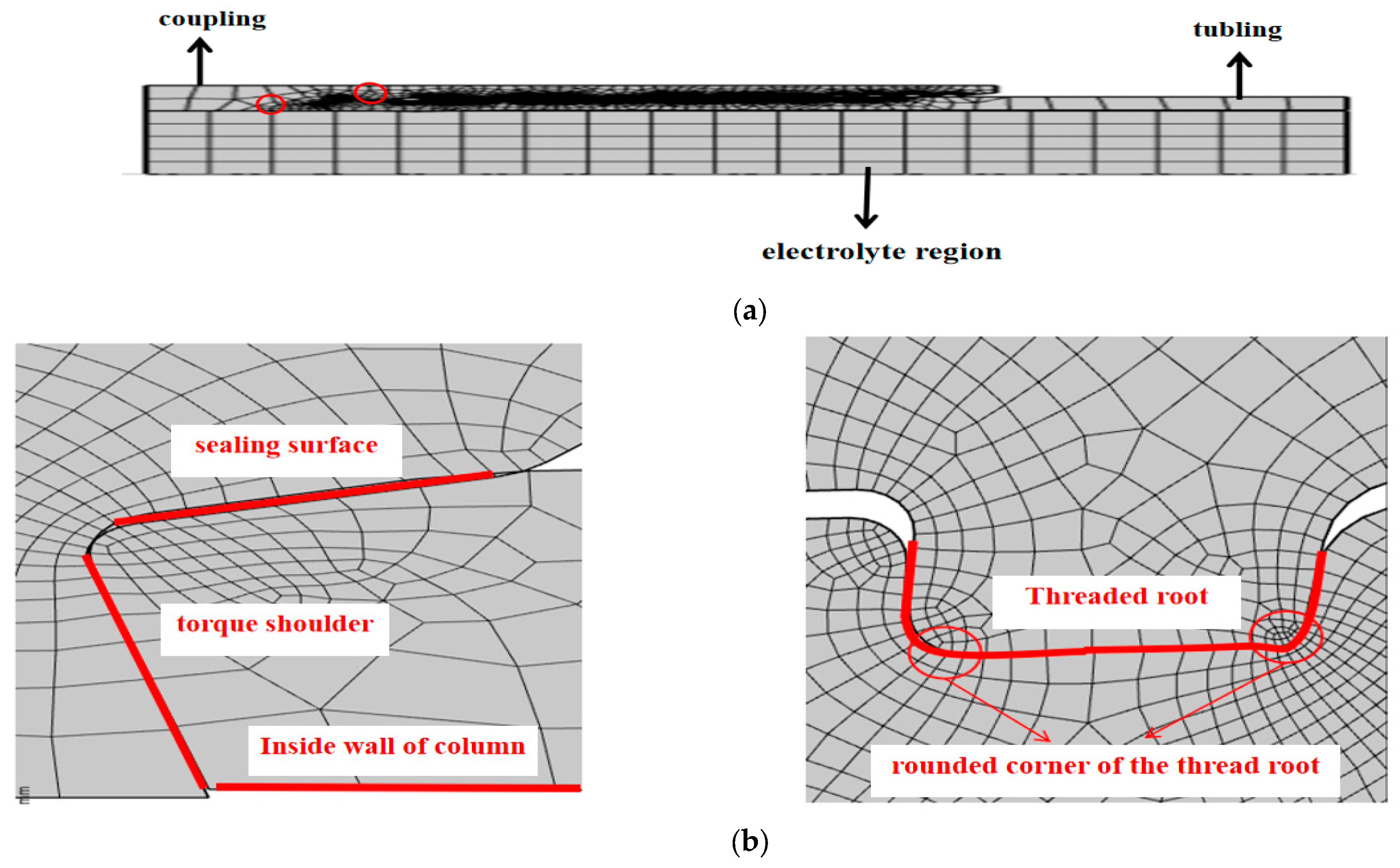

2. Two-Dimensional Axisymmetric Modeling of Premium Connections

3. Analysis of Corrosion Results for Premium Connections

3.1. Influence of Environmental Parameters on Corrosion Laws of P110 Premium Connections

3.1.1. Temperature Effect on Corrosion Laws

3.1.2. Effect of CO2 Partial Pressure on Corrosion Laws

3.1.3. Effect of pH Value on Corrosion Laws

3.2. Corrosion Thickness Analysis of Premium Connections

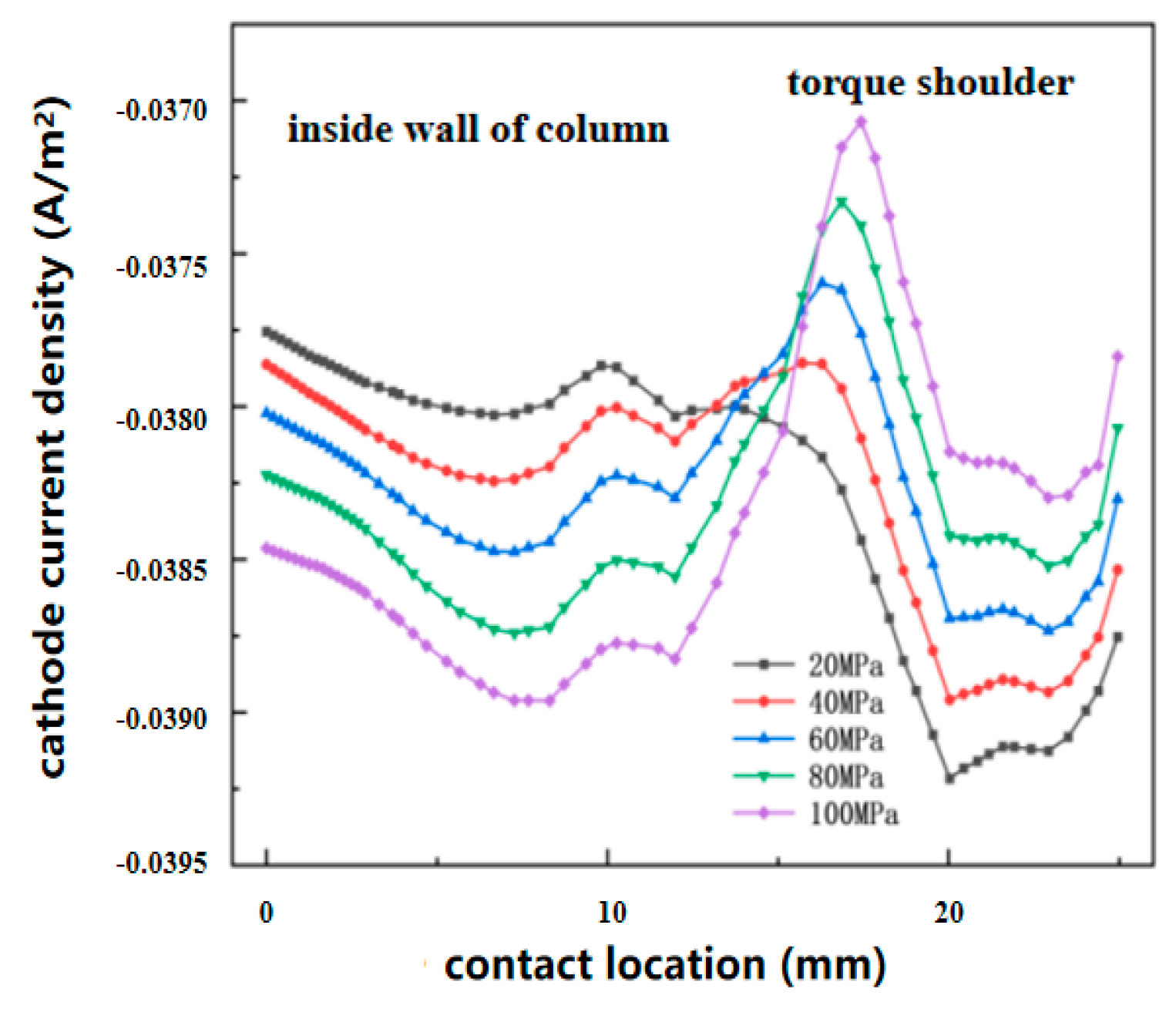

3.3. Anodic/Cathodic Current Density Analysis of Premium Connections

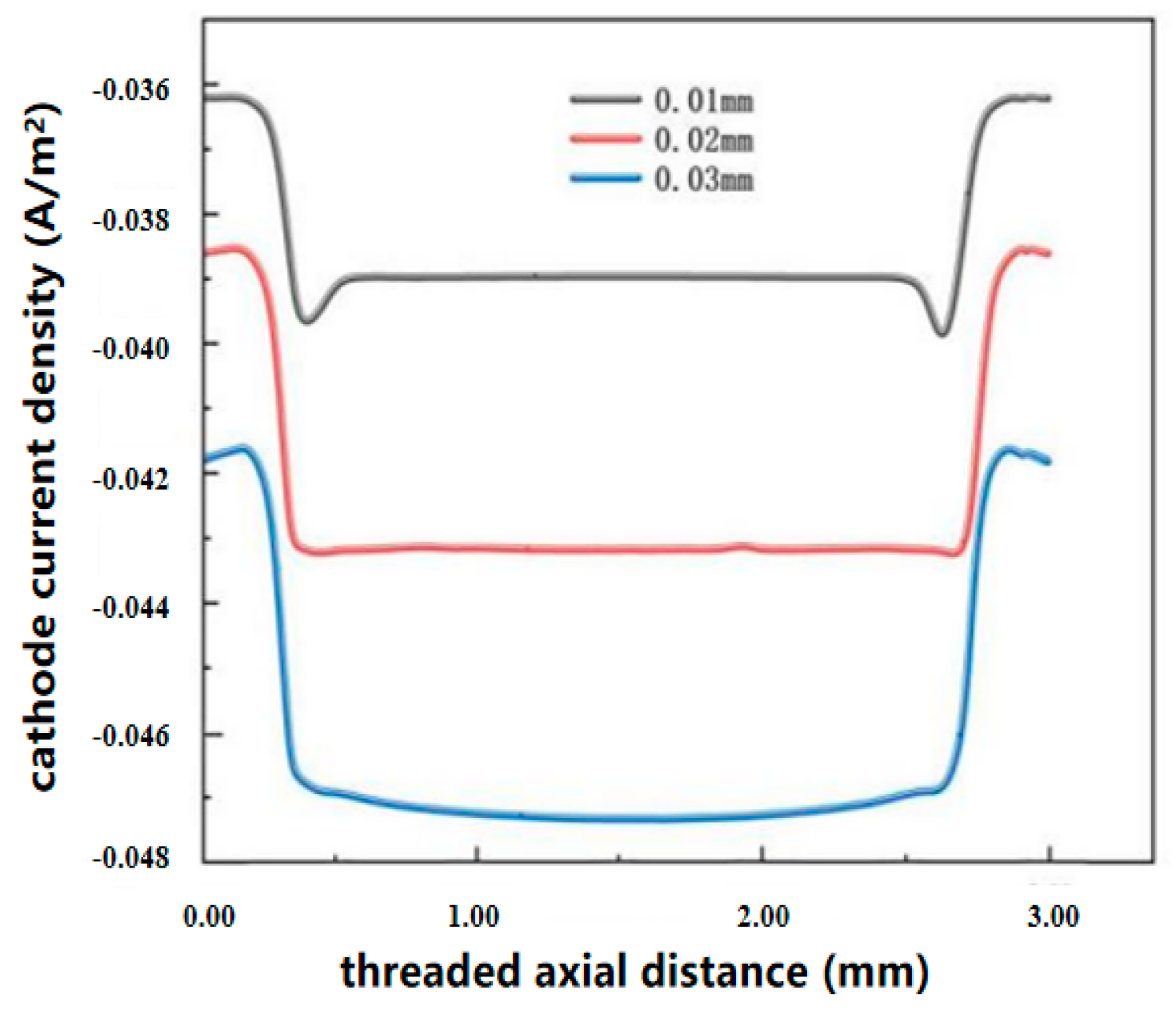

3.4. Premium Connections’ Threaded Anodic/Cathodic Current Density Analysis

3.5. Von Mises Stress and Contact Pressure Cloud Analysis of Premium Connections

4. Sealing Performance Evaluation Criteria

5. Conclusions

- (1)

- We studied the influence of environmental factors such as temperature, pH value, and CO2 partial pressure on the corrosion of P110 premium connections in CO2 production wells. The surface CO2 partial pressure most obviously influenced corrosion, and the corrosion rate and downhole time demonstrated a positive linear relationship; the longer the working time, the greater the corrosion depth. When the corrosion system reaches equilibrium, the premium connections’ shoulder electrolyte potential is high, indicating a greater degree of corrosion.

- (2)

- Under an internal pressure of 20 MPa, the corrosion rate of the torque shoulder was larger than that of the inner wall of the column, indicating that corrosion damage is more likely at the shoulder than at the inner wall of the column. However, with an increase in internal pressure (100 MPa), the corrosion rate of the inner wall of the column was larger than the corrosion rate of the torque shoulder, indicating that corrosion damage is more likely at the inner wall of the column than at the torque shoulder.

- (3)

- With increased tensile strain, the corrosion rate of the threads became larger. The corrosion rate of the thread root fillet was the largest, indicating that the thread root fillet is more susceptible to corrosion damage; the reason for this may be the stress concentration at the thread root fillet.

- (4)

- Under five internal pressure loads, the sealing strength of the premium connections increased with an increase in internal pressure. The sealing strength of the premium connections before and after corrosion was greater than the critical value, indicating that their performance fulfilled the criterion. However, the sealing strengths of the premium connections after corrosion were smaller than those of non-corroded connections, indicating that the sealing performance of premium connections decreases after corrosion.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, L.; Dou, H.; Li, Z.; Hu, Y.; Hao, X. Assessment of CO2 storage potential and carbon capture utilization and storage prospect in China. J. Energy Inst. 2017, 91, 970–977. [Google Scholar] [CrossRef]

- Xiang, Y.; Yuan, Y.; Zhou, P.; Liu, G.; Lyu, W.; Li, M.; Zhang, C.; Zhou, Q.; Zhao, X.; Yan, W. Metal Corrosion in Carbon Capture, Utilization, and Storage: Progress and Challenges. Strateg. Study CAE 2023, 25, 197–208. [Google Scholar] [CrossRef]

- Zhang, K.; Sun, Y.; Wang, C.; Ge, H.; Zhua, Y.; Wang, H. Research on CO2 Corrosion and Protection in Carbon Capture, Utilization and Storage. Surf. Technol. 2022, 51, 43–52. [Google Scholar]

- Xiao, Z.; Shen, B.; Yang, J.; Yang, K.; Zhang, Y.; Yang, S. Deep Learning Framework for Accurate Static and Dy-namic Prediction of CO2 Enhanced Oil Recovery and Storage Capacity. Processes 2024, 12, 1693. [Google Scholar] [CrossRef]

- Nguyen, H.B.T.; Bahzad, M.Y.H.; Leonzio, G. Economic and Environmental Optimization of a CCUS Supply Chain in Germany. Processes 2024, 12, 1575. [Google Scholar] [CrossRef]

- Xing, L.R.; Wu, Z.W.; Zhang, R.Y. Development status and prospect analysis of CCUS industry. Int. Pet. Econ. 2021, 29, 99–105. [Google Scholar]

- de Visser, E.; Hendriks, C.; Barrio, M.; Mølnvik, M.J.; de Koeijer, G.; Liljemark, S.; Le Gallo, Y. Dynamis CO2 quality recommendations. Int. Greenh. Gas Control 2008, 2, 478. [Google Scholar] [CrossRef]

- Halseid, M.; Dugstad, A.; Morland, B. Corrosion and bulk phase reactions in CO2 transport pipelines with impurities: Review of recent published studies. Energy Procedia 2014, 63, 2557. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, P.; Mou, C.; Wang, S.; Shang, L.; Cao, X.; Zhang, G.; Xue, Q. Unraveling the corrosion behavior and mechanism of DL-C film on the inner surface of N80 lengthy pipeline in CO2-H2S-Cl− environment. Surf. Coat. Technol. 2024, 494 Pt 1, 131350. [Google Scholar] [CrossRef]

- Lv, S.L.; Song, W.W.; Yang, X.T.; Peng, J.X.; Han, Y.; Zhao, G.X.; Lv, X.H.; Guo, Z.D.; Wen, Y.X.; Zhu, L.L. Corrosion Causes of Premium Connection S13Cr Tubing in a Well. Corros. Prot. 2015, 36, 76–80+83. [Google Scholar]

- Lv, S.L.; Luo, F.Q.; Xiang, M.; Zhou, J.; Chang, Z.; Qin, H.; Fu, D. Cases Analysis on Corrosion for API Tubing. Corros. Sci. Prot. Technol. 2008, 20, 388–390. [Google Scholar]

- Wang, B.D.; Duan, Q.Q.; Liu, X.B.; Yu, Y.; Wu, K. Stress analysis and failure assessment on threaded connection between N80 tubing and collar. J. Saf. Sci. Technol. 2017, 13, 56–60. [Google Scholar]

- Yu, H.; Cheng, X.T.; Lian, Z.H.; Ding, L.; Wang, H.; Chen, Y. Comprehensive Performance Evaluation of Sealing and Safety of Premium Tubing Connection. Lubr. Eng. 2023, 48, 191–199. [Google Scholar]

- Xu, Z.Q.; Wang, B.B.; Yan, Y.F.; Yan, X.; Gai, Y. Integrity Evaluation Analysis of Casing Premium Connection. Press. Vessel. Technol. 2019, 36, 35–42+13. [Google Scholar]

- Shen, Z.X.; Li, H.J.; Zhao, G.; Wang, H.M.; Liu, J.D.; Yan, Y.; Wang, J.J. Discussion on Evaluation Methods for Sealing Test of Tubing and Casing Premium Connection. Pet. Tubul. Goods Instrum. 2024, 1–5. [Google Scholar] [CrossRef]

- Dong, G.Y.; Sun, J.A.; Gao, Z. Numerical simulation analysis of sealing performance of premium connection. Baosteel Technol. 2023, 61–65. [Google Scholar] [CrossRef]

- Wang, C.; Dan, H.; Dai, H.Y.; Gao, L.X. Comparative analysis of sealing performance between tapered/tapered and spherical/tapered structures of special threaded joint of oil casing. Mech. Sci. Technol. Aerosp. Eng. 2024, 1–8. [Google Scholar] [CrossRef]

- Dou, Y.H.; Qiang, N.; Yu, Y.; Cao, Y.P. Element Analysis of Make-up Torque of Special Threaded Tubing oints. Mech. Electr. Eng. Technol. 2022, 51, 56–59. [Google Scholar]

- Guoxi, H.; Qing, Z.; Kexi, L.; Leng, L.; Zhao, S. Corrosion mechanism of high temperature and O2 c-ontent in steamed CO2/O2/SO2 system and failure behavior of 20G steel on steam-injection pipelines. Process Saf. Environ. Prot. 2022, 163, 528–542. [Google Scholar]

- Yang, B.; Xu, H.; Xiang, S.; Zhang, Z.; Su, K.; Yang, Y. Effects of Make-Up Torque on the Sealability of Sphere-Type Premium Connection for Tubing and Casing Strings. Processes 2023, 11, 256. [Google Scholar] [CrossRef]

- Yu, Y.; Qu, Z.; Dou, Y.; Cao, Y. Analysis of Energy Dissipation on the Sealing Sur-face of Premium Connection Based on a Microslip Shear Layer Model. Energies 2022, 15, 8400. [Google Scholar] [CrossRef]

- Song, W.; Zhou, Y.; Wu, Y.; Yang, Y.; Ye, S. A Study on Sealing Performance of UGS Well Casing Thread Under High-speed Injection-production. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2024, 46, 170–178. [Google Scholar]

- Liang, H.; Fan, H.; Ren, X. Simulation Study on Sealing Performance of Special Threaded oints of Pipe String under Action of Additional Bending Moment. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2024, 1–10. Available online: http://kns.cnki.net/kcms/detail/61.1435.TE.20240515.1012.002.html (accessed on 29 October 2024).

- Yang, D.M.; Li, Y.G.; Zhang, J.J.; Liang, G.S. Tubing Corrosion Analysis and Control Measures in Dalaoba Gas Field. Pet. Drill. Tech. 2011, 39, 82–85. [Google Scholar]

- Li, Z. Research on Corrosion Mechanism and Control Technology of Production and Transportation System in Taha Oil and Gas Field. China Petroleum and Chemical Corporation Northwest Oilfield Branch. Available online: www.cnki.net (accessed on 29 October 2024).

- Lv, S.L.; Zhao, G.X.; Wang, X.H.; Yan, M.L.; Fu, D.M.; Zhang, J.X. Analysis of Downhole Premium Connection Tubing Corrosion. Corros. Prot. 2005, 4, 179–181. [Google Scholar]

- Lv, S.L.; Peng, J.X.; Gao, W.X.; Yang, S.B.; Geng, H.L.; Wang, P.; Liu, W.H.; Zhu, L.J. Causes Analysis on Corrosion Barrier Ring Squeezed out in Premium Connection Tubing during Pressure Test. Drill. Prod. Technol. 2021, 44, 123–126. [Google Scholar]

- Wang, X.H.; Yi, C.X.; Wang, D. Influence of compressive stress on corrosion of premium connection casing material. J. China Univ. Pet. (Ed. Nat. Sci.) 2013, 37, 119–123+129. [Google Scholar]

- Li, Y.H.; Du, N.; Liu, M. Failure Analysis of FE-HP1-13Cr Steel Tubing. Total Corros. Control 2017, 31, 71–75+86. [Google Scholar]

- Du, J.N.; Yang, C.Y.; Jin, W.; Li, Y.H. Failure Analysis of Corrosion Perforation of Manifold Pipeline in an Oilfield. Total Corros. Control 2017, 31, 39–42. [Google Scholar]

- Zhao, J.; Bai, X.; Qu, T.; Li, D.; Liu, W.; Wei, Z.; Xiaolong, L. Corrosion Failure Analysis of a S135 Drill Pipe. J. Fail. Anal. Prev. 2024, 24, 368–379. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, G.; Zhao, J.; Deng, B.; Zhang, L. Failure Analysis of Tripping Tubing in an Oilfield. J. Fail. Anal. Prev. 2022, 22, 1268–1275. [Google Scholar] [CrossRef]

- Malyshev, V.; Gelfgat, M.; Scherbakov, A.; Alkhimenko, A. Protection enhancing of threaded conne-ctions of light-alloy drill pipes against contact corrosion. E3S Web Conf. 2021, 225, 03003. [Google Scholar] [CrossRef]

- Yan, H.; Zheng, C.L.; Li, H.Z.; Li, Y.F.; Zhu, D.J. Analysis of Corrosion Behavior on External Surf-Ace of 110S Tubing. Mater. Sci. Forum 2020, 930, 1242–1250. [Google Scholar]

- SY/T 6262-2008; Recommended Practices for Tubing Selection. Petroleum Industry Press: Beijing, China, 2008.

- Zhang, Z.; Ding, C.; Liu, W.; Zhao, Y. Study on corrosion of Cr-containing steel under diff-erent CO2 partial pressures at high temperatures. Geoenergy Sci. Eng. 2024, 243, 213365. [Google Scholar] [CrossRef]

- Murtagian, G.R.; Fanelli, V.; Villasante, J.A.; Johnson, D.H.; Ernst, H.A. Seal-ability of stationary metal-to-metal seals. J. Tribolo-Gy 2004, 126, 591–596. [Google Scholar] [CrossRef]

- Xie, R.; Rong, F. Desseint Methodology for Reliabilitybased Design and Assessment of Tubular Connection Sealabilityin HPHT Wells. 2014. Available online: https://www.researchgate.net/publication/307957467 (accessed on 29 October 2024).

| Bearing Surface Angle/° | Tracking Surface Angle/° | Shoulder Angle/° | Thread Distance/mm | Thread Taper | Sealing Surface Taper |

|---|---|---|---|---|---|

| −3° | 10° | −10° | 4.234 | 1/16 | 1/2 |

| Steels | Elastic Modulus/GPa | Poisson’s Ratio | Yield Strength/MPa | Friction Coefficient |

|---|---|---|---|---|

| P110 | 210 | 0.3 | 758 | 0.1 |

| Parameters | Numerical |

|---|---|

| Reference exchange current density for H+ reduction | 0.05 A/m2 |

| Reference exchange current density for H2CO3 reduction | 0.06 A/m2 |

| Reference exchange current density for water reduction | 3 × 10−5 A/m2 |

| Reference exchange current density for Fe oxidation | 1 A/m2 |

| Tafel slope for H+ reduction | 0.118 V |

| Tafel slope for H2CO3 reduction | 0.12 V |

| Tafel slope for water reduction | 0.118 V |

| Tafel slope for Fe oxidation | 0.04 V |

| Stress/MPa | Critical Sealing Strength/(m·MPa) |

|---|---|

| 20 | 0.847 |

| 40 | 1.515 |

| 60 | 2.128 |

| 80 | 2.708 |

| 100 | 3.265 |

| Stress/MPa | Average Contact Pressure/MPa | Effective Contact Length/mm | Sealing Strength/(m·MPa) | |||

|---|---|---|---|---|---|---|

| Before Corrosion | After Corrosion | Before Corrosion | After Corrosion | Before Corrosion | After Corrosion | |

| 20 | 716.41 | 572.54 | 0.40 | 0.35 | 3.9 | 2.5 |

| 40 | 872.54 | 690.78 | 0.44 | 0.38 | 5.7 | 3.5 |

| 60 | 939.45 | 710.41 | 0.52 | 0.40 | 7.5 | 3.9 |

| 80 | 1030.78 | 803.78 | 0.56 | 0.41 | 9.2 | 4.7 |

| 100 | 1134.10 | 894.10 | 0.60 | 0.50 | 11.3 | 6.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Gu, P.; Yu, Y.; Dou, Y. Research on Sealing Premium Connections in Corrosive CO2 Environments. Processes 2024, 12, 2680. https://doi.org/10.3390/pr12122680

Cao Y, Gu P, Yu Y, Dou Y. Research on Sealing Premium Connections in Corrosive CO2 Environments. Processes. 2024; 12(12):2680. https://doi.org/10.3390/pr12122680

Chicago/Turabian StyleCao, Yinping, Pengsheng Gu, Yang Yu, and Yihua Dou. 2024. "Research on Sealing Premium Connections in Corrosive CO2 Environments" Processes 12, no. 12: 2680. https://doi.org/10.3390/pr12122680

APA StyleCao, Y., Gu, P., Yu, Y., & Dou, Y. (2024). Research on Sealing Premium Connections in Corrosive CO2 Environments. Processes, 12(12), 2680. https://doi.org/10.3390/pr12122680