A Prediction Method for Calculating Fracturing Initiation Pressure Considering the Modification of Rock Mechanical Parameters After CO2 Treatment

Abstract

1. Introduction

1.1. Experimental Study on CO2 Fracturing

1.2. Numerical Study on CO2 Fracturing

2. Evolution of Rock Mechanical Properties Under CO2 Action

2.1. Experimental Sample and Design

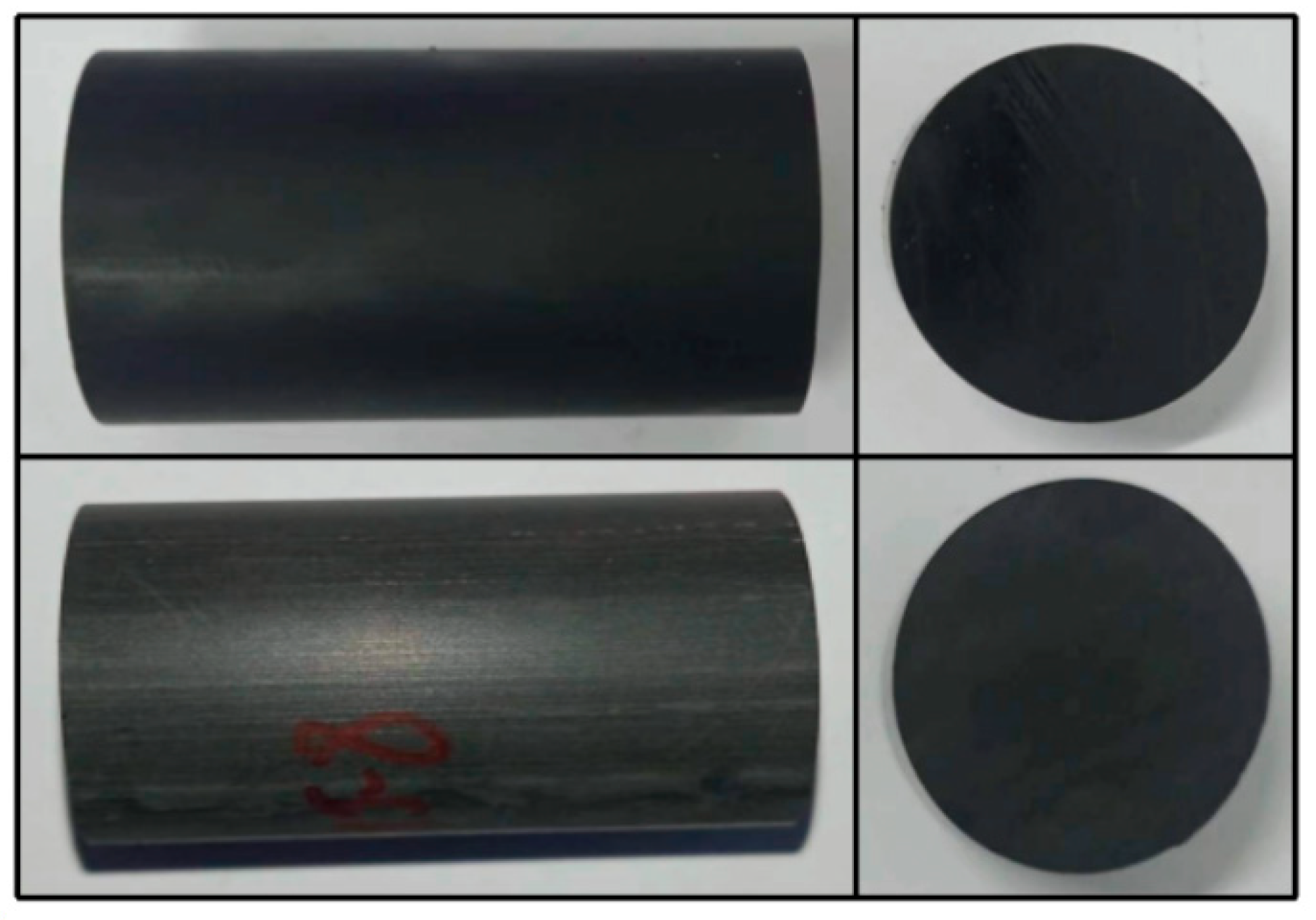

2.1.1. Experimental Sample

2.1.2. Experimental Design

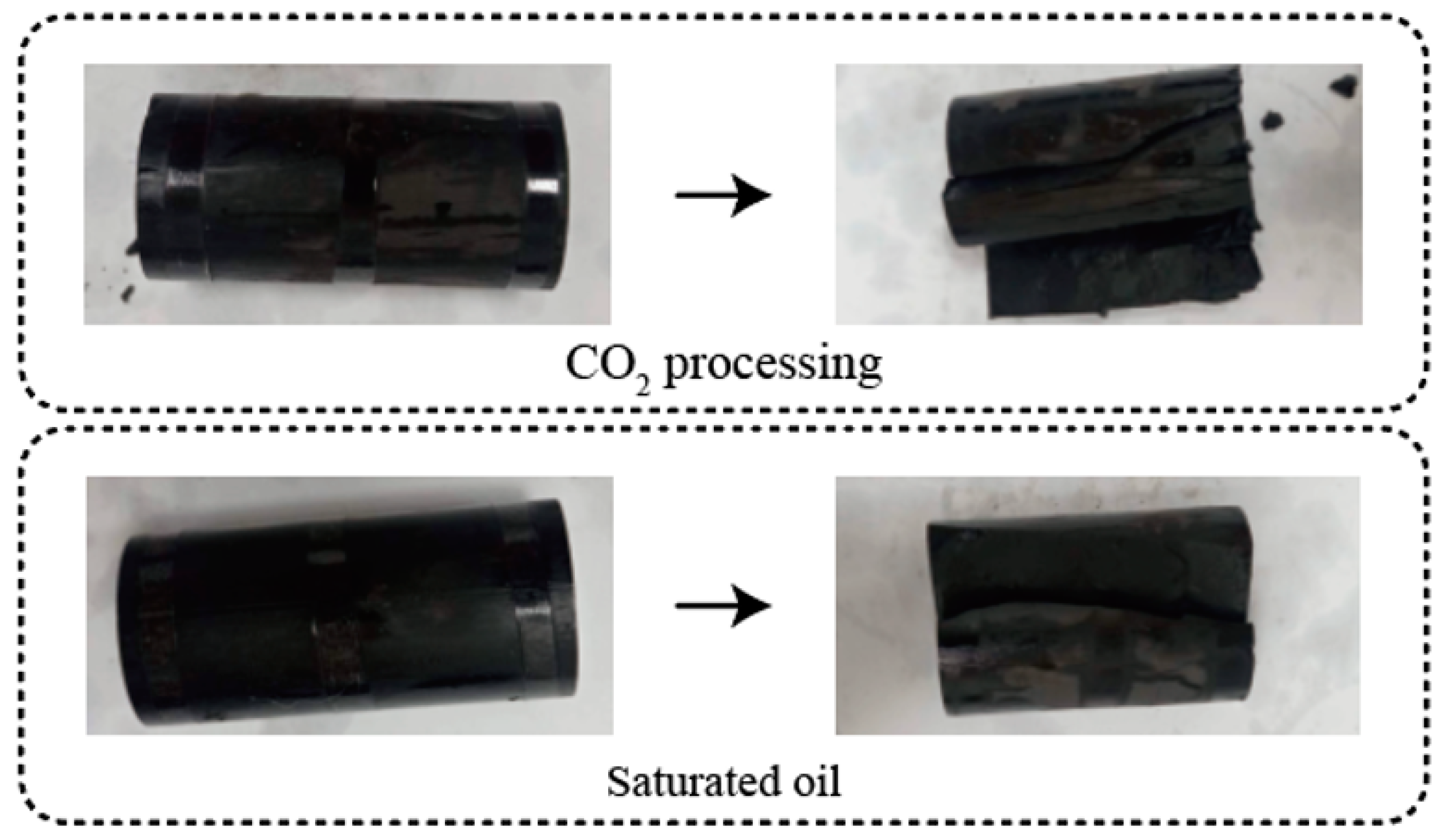

2.2. Analysis of Experimental Results

2.2.1. The Influence of CO2 on the Rocks’ Elastic Modulus

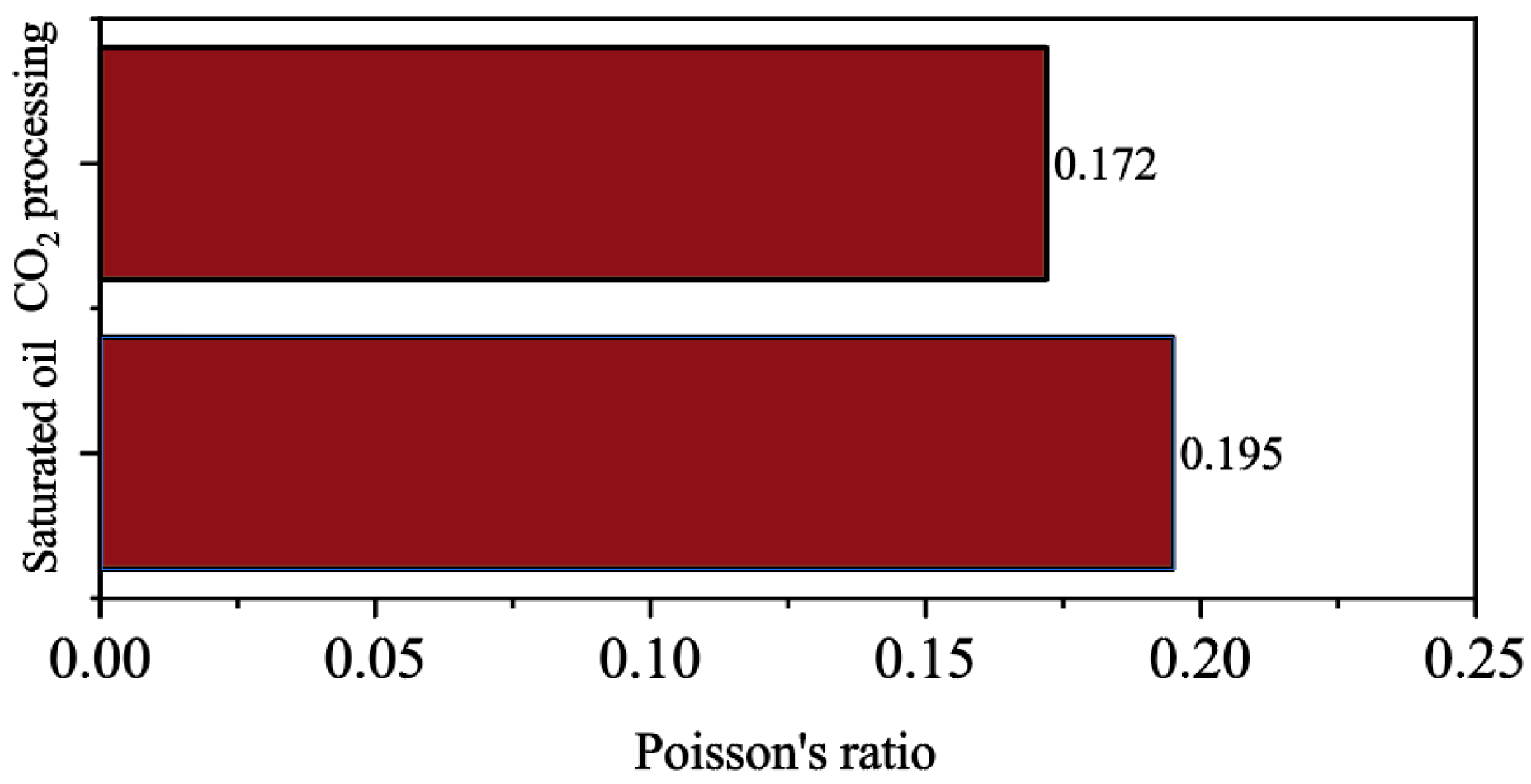

2.2.2. The Influence of CO2 on the Rocks’ Poisson’s Ratio

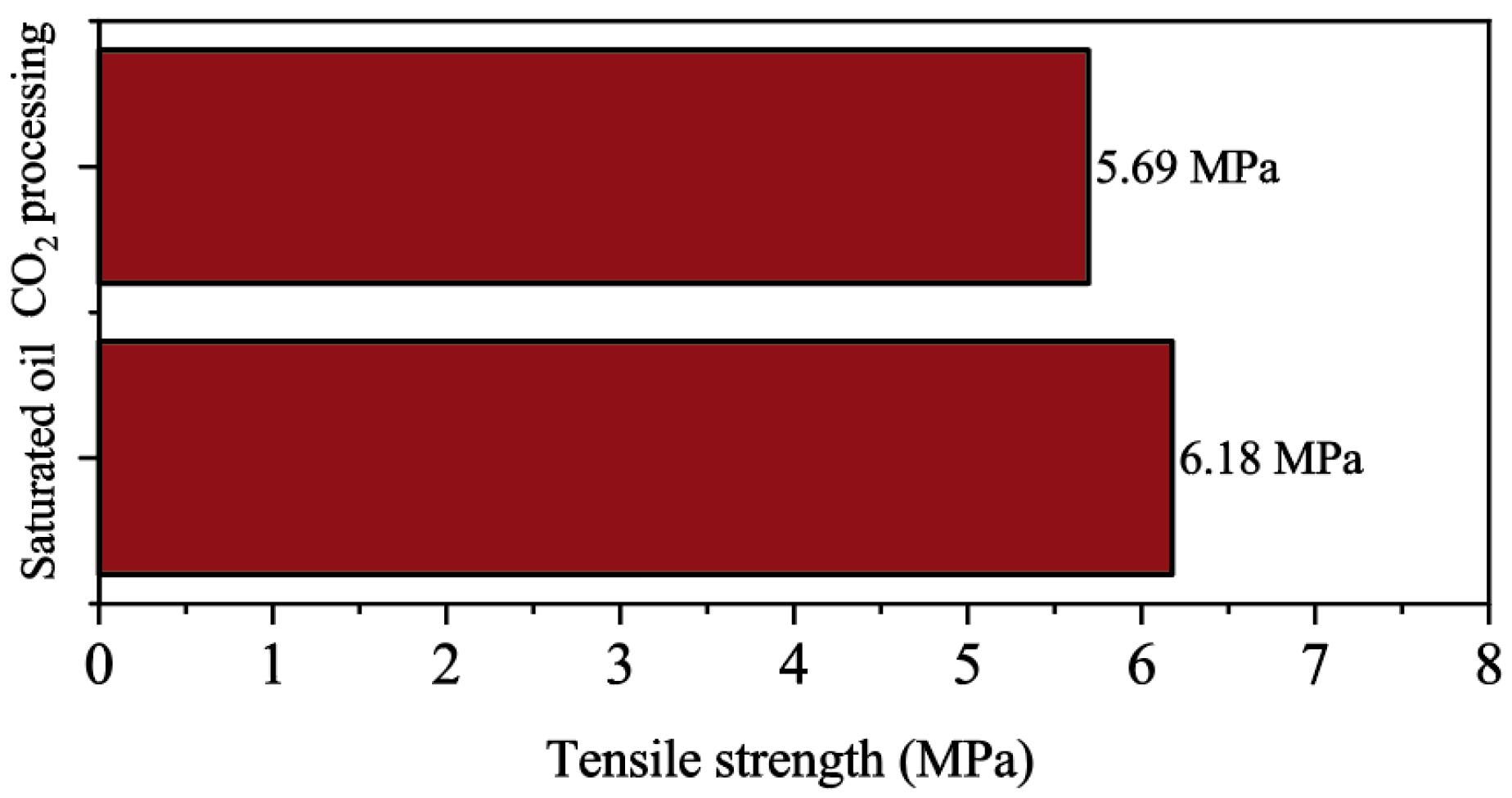

2.2.3. The Influence of CO2 on Rock Tensile Strength

2.2.4. The Influence of CO2 on Rock Permeability

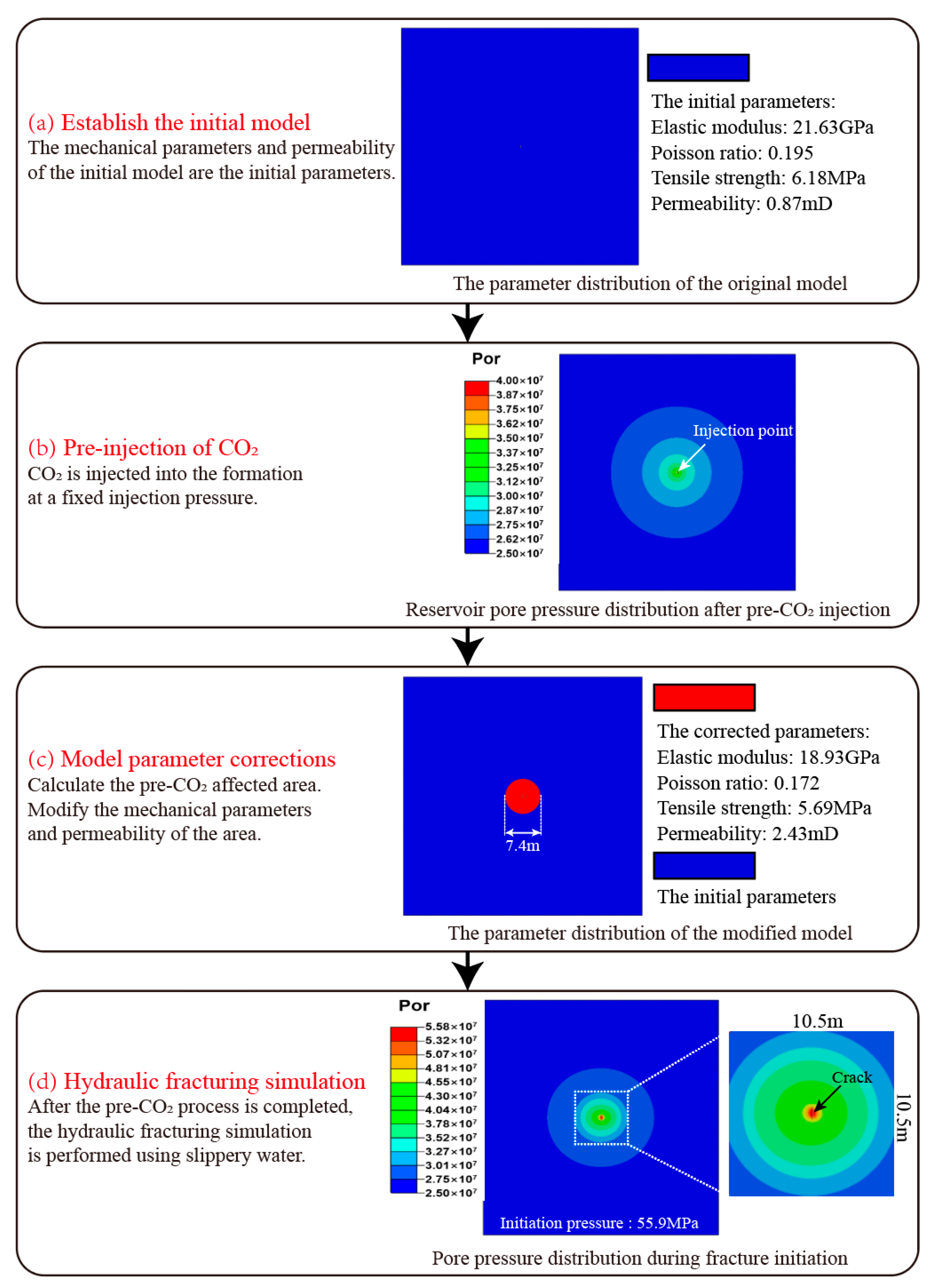

3. Numerical Simulation of Pre-CO2 Fracturing

3.1. Numerical Implementation Methods

3.2. Modeling

3.2.1. Seepage Control Equation

3.2.2. Rock Constitutive Equation

3.2.3. Fracture Propagation Equation

3.2.4. Modified Area Equation

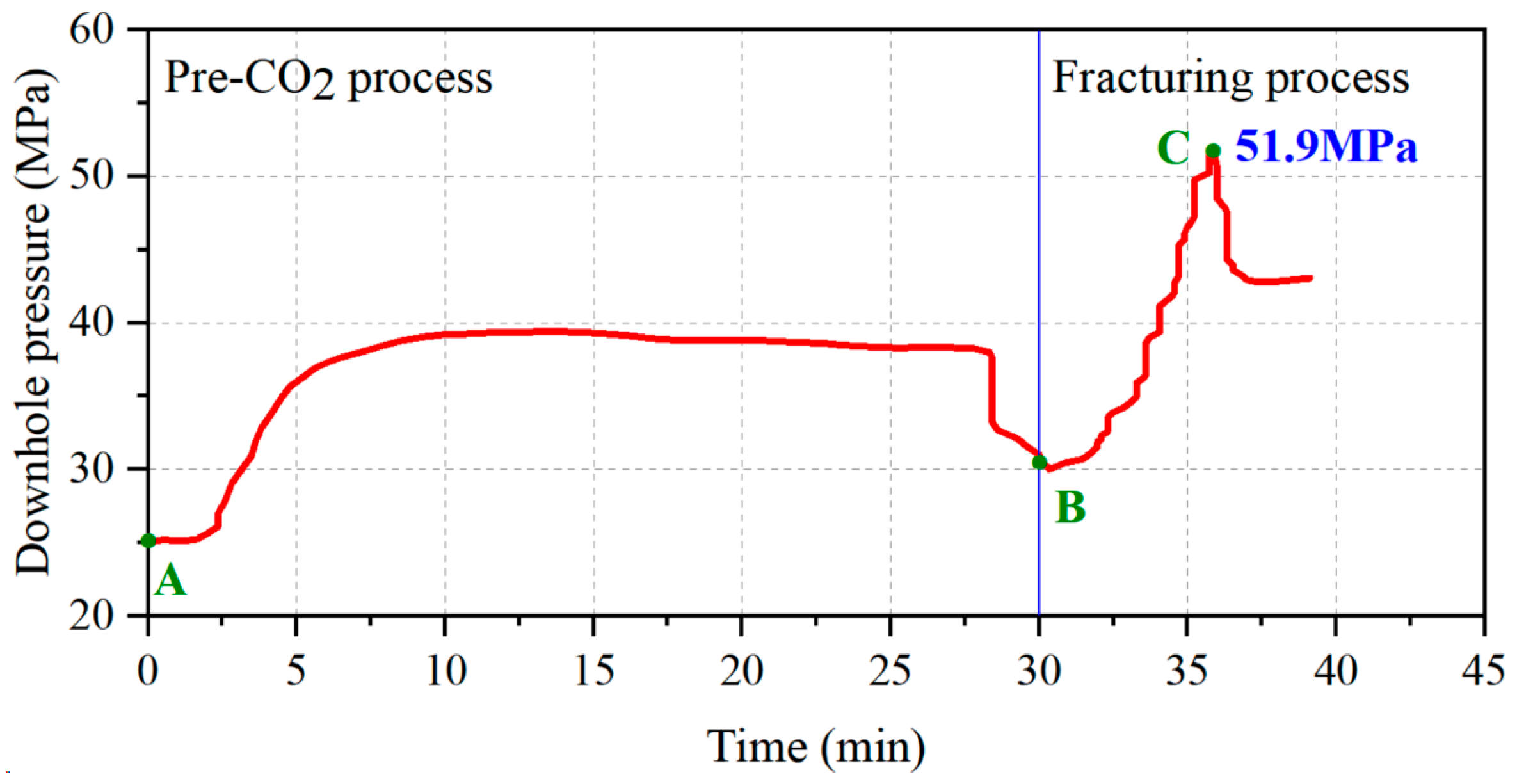

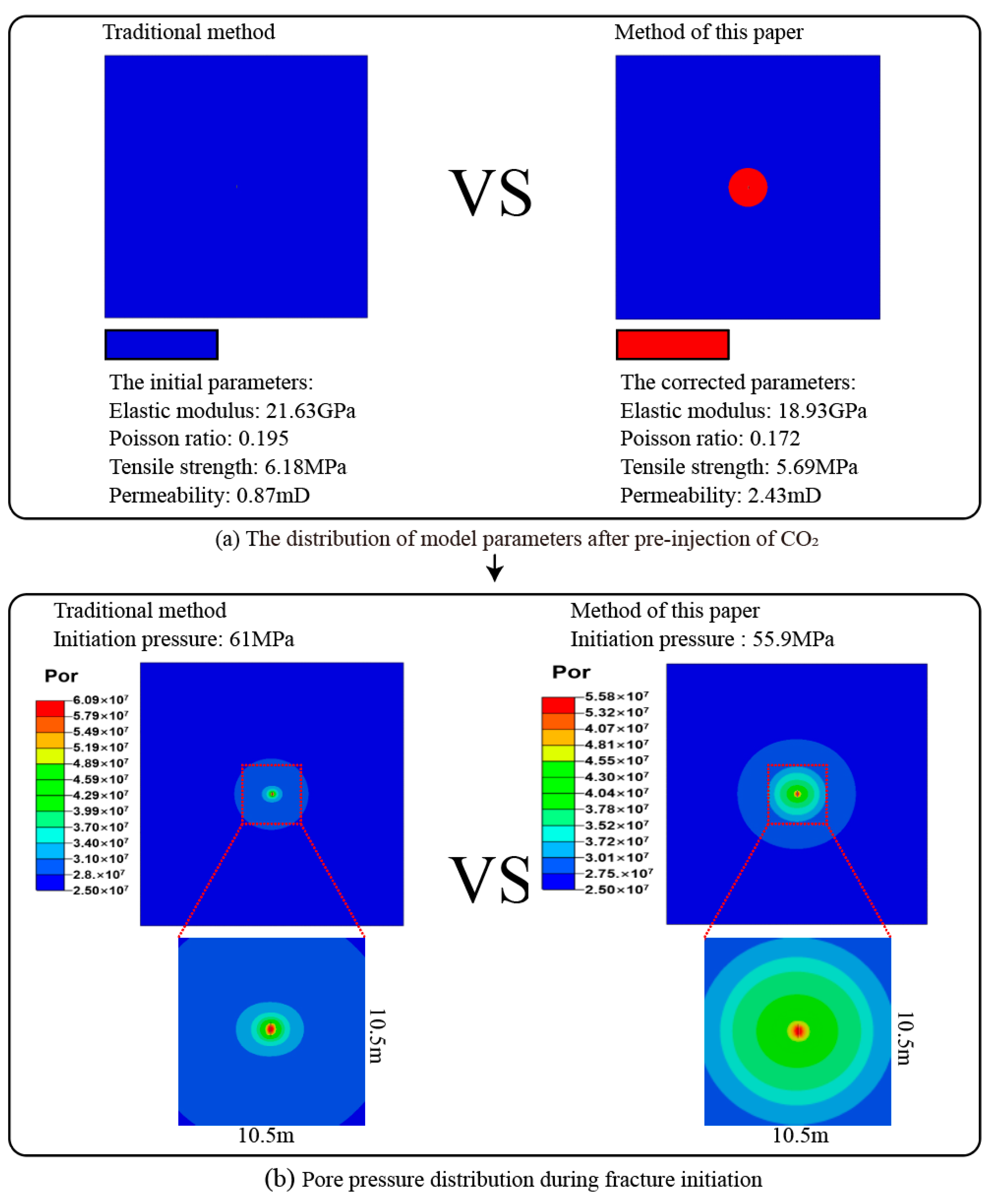

4. Verification

5. Discussion

6. Conclusions

- (1)

- After being treated with carbon dioxide in situ, the elastic modulus of reservoir shale decreased by 12.5%, Poisson’s ratio decreased by 11.8%, the tensile strength decreased by 7.9%, and the permeability increased by 180%.

- (2)

- Upon pre-CO2 injection into the reservoir, there was a noteworthy increase in pore pressure within the near-wellbore region. This augmentation not only supplemented formation capacity but also induced modifications in the reservoir rocks near the wellbore area.

- (3)

- The accurate prediction of pre-CO2 fracturing initiation pressure necessitates the consideration of CO2’s influence on the modification of reservoir rock mechanical properties. In comparison with traditional numerical simulation methods, the approach proposed in this paper achieves a reduction in the predicted initiation pressure error of 9.8%.

- (4)

- This study provides guidance for the design of operational parameters in pre-injected CO2 fracturing.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, X.; Yao, D.; Qu, J.; Sun, S.; Qin, Z.; Tao, L.; Zhao, Y. A novel transient hole cleaning algorithm for horizontal wells based on drift-flux model. Geoenergy Sci. Eng. 2024, 233, 212517. [Google Scholar] [CrossRef]

- Cong, Z.; Li, Y.; Tang, J.; Martyushev, D.A.; Yang, F. Numerical simulation of hydraulic fracture height layer-through propagation based on three-dimensional lattice method. Eng. Fract. Mech. 2022, 264, 108331. [Google Scholar] [CrossRef]

- Li, Y.; Long, M.; Tang, J.; Chen, M.; Fu, X. A hydraulic fracture height mathematical model considering the influence of plastic region at fracture tip. Pet. Explor. Dev. 2020, 47, 175–185. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, W.; Xu, Z.; Liu, S.; Wei, C. A review of experimental apparatus for supercritical CO2 fracturing of shale. J. Pet. Sci. Eng. 2022, 208, 109515. [Google Scholar] [CrossRef]

- Li, Y.; Peng, G.; Tang, J.; Zhang, J.; Zhao, W.; Liu, B.; Pan, Y. Thermo-hydro-mechanical coupling simulation for fracture propagation in CO2 fracturing based on phase-field model. Energy 2023, 284, 128629. [Google Scholar] [CrossRef]

- Cong, Z.; Li, Y.; Pan, Y.; Liu, B.; Shi, Y.; Wei, J.; Li, W. Study on CO2 foam fracturing model and fracture propagation simulation. Energy 2022, 238, 121778. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, K.; Huang, Z.; Xu, Z.; Shi, H.; Wang, H. Numerical model of CO2 fracturing in naturally fractured reservoirs. Eng. Fract. Mech. 2021, 244, 107548. [Google Scholar] [CrossRef]

- Liu, B.; Suzuki, A.; Ito, T. Estimating the seepage effect of SC-CO2 and water fracturing with a steady-state flow model considering capillary and viscous forces at the pore scale. J. Pet. Sci. Eng. 2020, 184, 106483. [Google Scholar] [CrossRef]

- Sun, H.; Chen, J.; Ji, X.; Karunakaran, G.; Chen, B.; Ranjith, P.G.; Song, Y.; Yang, M. Optimizing CO2 hydrate storage: Dynamics and stability of hydrate caps in submarine sediments. Appl. Energy 2024, 376, 124309. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Peng, J.; Ge, D.; Bo, K. Effect of artificially induced microcracks near the rock surface on granite fragmentation performance under heating treatment. Int. J. Rock Mech. Min. Sci. 2024, 182, 105894. [Google Scholar] [CrossRef]

- Yarushina, V.M.; Bercovici, D.; Oristaglio, M.L. Rock deformation models and fluid leak-off in hydraulic fracturing. Geophys. J. Int. 2013, 194, 1514–1526. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Sun, B.; Gao, Y.; Wang, X.; Fu, W. Optimization design of hydraulic parameters for supercritical CO2 fracturing in unconventional gas reservoir. Fuel 2019, 235, 795–809. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, G.; Jiang, Y.; Xian, X.; Liu, Q.; Zhang, D.; Tan, J. Supercritical carbon dioxide fracturing in shale and the coupled effects on the permeability of fractured shale: An experimental study. J. Nat. Gas Sci. Eng. 2016, 36, 369–377. [Google Scholar] [CrossRef]

- Li, Y.; Long, M.; Zuo, L.; Li, W.; Zhao, W. Brittleness evaluation of coal based on statistical damage and energy evolution theory. J. Pet. Sci. Eng. 2019, 172, 753–763. [Google Scholar] [CrossRef]

- Hou, L.; Zhang, S.; Elsworth, D.; Liu, H.; Sun, B.; Geng, X. Review of fundamental studies of CO2 fracturing: Fracture propagation, propping and permeating. J. Pet. Sci. Eng. 2021, 205, 108823. [Google Scholar] [CrossRef]

- Liu, B.; Suzuki, A.; Ito, T. Numerical analysis of different fracturing mechanisms between supercritical CO2 and water-based fracturing fluids. Int. J. Rock Mech. Min. Sci. 2020, 132, 104385. [Google Scholar] [CrossRef]

- Middleton, R.; Viswanathan, H.; Currier, R.; Gupta, R. CO2 as a fracturing fluid: Potential for commercial-scale shale gas production and CO2 sequestration. Energy Procedia 2014, 63, 7780–7784. [Google Scholar] [CrossRef]

- Zou, Y.; Li, S.; Ma, X.; Zhang, S.; Li, N.; Chen, M. Effects of CO2–brine–rock interaction on porosity/permeability and mechanical properties during supercritical-CO2 fracturing in shale reservoirs. J. Nat. Gas Sci. Eng. 2018, 49, 157–168. [Google Scholar] [CrossRef]

- Ishida, T.; Chen, Y.; Bennour, Z.; Yamashita, H.; Inui, S.; Nagaya, Y.; Naoi, M.; Chen, Q.; Nakayama, Y.; Nagano, Y. Features of CO2 fracturing deduced from acoustic emission and microscopy in laboratory experiments. J. Geophys. Res. Solid Earth 2016, 121, 8080–8098. [Google Scholar] [CrossRef]

- Ishida, T.; Aoyagi, K.; Niwa, T.; Chen, Y.; Murata, S.; Chen, Q.; Nakayama, Y. Acoustic emission monitoring of hydraulic fracturing laboratory experiment with supercritical and liquid CO2. Geophys. Res. Lett. 2012, 39, L16309. [Google Scholar] [CrossRef]

- Kizaki, A.; Tanaka, H.; Ohashi, K.; Sakaguchi, K.; Matsuki, K. Hydraulic fracturing in Inada granite and Ogino tuff with super critical carbon dioxide. In Proceedings of the ISRM International Symposium-Asian Rock Mechanics Symposium, ISRM 2012, Seoul, Republic of Korea, 15–19 October 2012; p. ISRM-ARMS7-2012-109. [Google Scholar]

- Zhang, X.; Lu, Y.; Tang, J.; Zhou, Z.; Liao, Y. Experimental study on fracture initiation and propagation in shale using supercritical carbon dioxide fracturing. Fuel 2017, 190, 370–378. [Google Scholar] [CrossRef]

- Bennour, Z.; Ishida, T.; Nagaya, Y.; Chen, Y.; Nara, Y.; Chen, Q.; Sekine, K.; Nagano, Y. Crack extension in hydraulic fracturing of shale cores using viscous oil, water, and liquid carbon dioxide. Rock Mech. Rock Eng. 2015, 48, 1463–1473. [Google Scholar] [CrossRef]

- Zou, Y.; Li, N.; Ma, X.; Zhang, S.; Li, S. Experimental study on the growth behavior of supercritical CO2-induced fractures in a layered tight sandstone formation. J. Nat. Gas Sci. Eng. 2018, 49, 145–156. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, J.; Zhou, N.; Li, M. Staged numerical simulations of supercritical CO2 fracturing of coal seams based on the extended finite element method. J. Nat. Gas Sci. Eng. 2019, 65, 275–283. [Google Scholar] [CrossRef]

- He, Y.; Yang, Z.; Jiang, Y.; Li, X.; Zhang, Y.; Song, R. A full three-dimensional fracture propagation model for supercritical carbon dioxide fracturing. Energy Sci. Eng. 2020, 8, 2894–2906. [Google Scholar] [CrossRef]

- Zhang, C.; Cheng, P.; Ranjith, P.; Lu, Y.; Zhou, J. A comparative study of fracture surface roughness and flow characteristics between CO2 and water fracturing. J. Nat. Gas Sci. Eng. 2020, 76, 103188. [Google Scholar] [CrossRef]

- Middleton, R.S.; Carey, J.W.; Currier, R.P.; Hyman, J.D.; Kang, Q.; Karra, S.; Jiménez-Martínez, J.; Porter, M.L.; Viswanathan, H.S. Shale gas and non-aqueous fracturing fluids: Opportunities and challenges for supercritical CO2. Appl. Energy 2015, 147, 500–509. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Pan, Y.; Wang, X.; Yan, M.; Shi, X.; Zhou, X.; Li, H. Experiments and analysis on the influence of multiple closed cemented natural fractures on hydraulic fracture propagation in a tight sandstone reservoir. Eng. Geol. 2021, 281, 105981. [Google Scholar] [CrossRef]

- Cong, Z.; Li, Y.; Liu, Y.; Xiao, Y. A new method for calculating the direction of fracture propagation by stress numerical search based on the displacement discontinuity method. Comput. Geotech. 2021, 140, 104482. [Google Scholar] [CrossRef]

- Li, Y.; Dai, H.; Zhang, J.; Ma, X.; Yu, Y.; Cong, Z.; Xiao, Y. Numerical simulation of proppant migration in horizontal wells with multi-fracture fracturing. Geoenergy Sci. Eng. 2023, 227, 211964. [Google Scholar] [CrossRef]

- Wang, L.; Yao, B.; Xie, H.; Winterfeld, P.H.; Kneafsey, T.J.; Yin, X.; Wu, Y.-S. CO2 injection-induced fracturing in naturally fractured shale rocks. Energy 2017, 139, 1094–1110. [Google Scholar] [CrossRef]

- He, L.; Feng, W.; Zhang, J.; Siwei, M.; Yongwei, D. Fracturing with carbon dioxide: Application status and development trend. Pet. Explor. Dev. 2014, 41, 513–519. [Google Scholar]

- Deng, B.; Yin, G.; Li, M.; Zhang, D.; Lu, J.; Liu, Y.; Chen, J. Feature of fractures induced by hydrofracturing treatment using water and L-CO2 as fracturing fluids in laboratory experiments. Fuel 2018, 226, 35–46. [Google Scholar] [CrossRef]

- Zhang, J.; Xingyao, Y.; Zhang, G.; Yipeng, G.; Xianggang, F. Prediction method of physical parameters based on linearized rock physics inversion. Pet. Explor. Dev. 2020, 47, 59–67. [Google Scholar] [CrossRef]

- Haque, M.S.; Stewart, C.M. Comparative analysis of the sin-hyperbolic and Kachanov–Rabotnov creep-damage models. Int. J. Press. Vessel. Pip. 2019, 171, 1–9. [Google Scholar] [CrossRef]

- Li, Y.; Peng, J.; Huang, C.; Lian, M.; Xu, T.; Zhang, Y.; Bo, K.; Feng, B.; Zhou, J. Multi-fractured stimulation technique of hydraulic fracturing assisted by the DTH-hammer-induced impact fractures. Geothermics 2019, 82, 63–72. [Google Scholar] [CrossRef]

- Gaus, I. Role and impact of CO2–rock interactions during CO2 storage in sedimentary rocks. Int. J. Greenh. Gas Control 2010, 4, 73–89. [Google Scholar] [CrossRef]

- Whitaker, S. Flow in porous media I: A theoretical derivation of Darcy’s law. Transp. Porous Media 1986, 1, 3–25. [Google Scholar] [CrossRef]

| Saturated Oil Shale | CO2-Modified Shale | |

|---|---|---|

| Elastic modulus (Gpa) | 21.63 | 18.93 |

| Poisson’s ratio | 0.195 | 0.172 |

| Tensile strength (Mpa) | 6.18 | 5.69 |

| Permeability (mD) | 0.87 | 2.43 |

| Parameters | Value | Unit |

|---|---|---|

| Model size | 50∗50 | m |

| Reservoir temperature | 110 | °C |

| Vertical in situ stress | 50 | MPa |

| Minimum horizontal principal stress | 45 | MPa |

| Maximum horizontal principal stress | 55 | MPa |

| Porosity | 4.3% | / |

| Formation pressure | 25 | MPa |

| Fracturing section length | 50 | M |

| Pre-CO2 injection pressure | 40 | MPa |

| Pre-CO2 injection time | 30 | min |

| Pre-CO2 injection volume | 75 | m3 |

| Bound water saturation | 0.18 | / |

| Initial elastic modulus | 21.63 | GPa |

| Elastic modulus after CO2 action | 18.93 | GPa |

| Initial Poisson’s ratio | 0.195 | / |

| Poisson’s ratio after CO2 action | 0.172 | / |

| Initial tensile strength | 6.18 | MPa |

| Tensile strength after CO2 action | 5.69 | MPa |

| Initial permeability | 0.87 | mD |

| Permeability after CO2 action | 2.43 | mD |

| Smooth water fracturing flow rate | 16 | m3/min |

| CO2 viscosity | 0.0001 | Pa·s |

| Slippery water viscosity | 0.001 | Pa·s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, C.; Sun, Y.; Bian, H.; Wei, J.; Li, G.; Yang, Y.; Tang, C.; Wei, X.; Cong, Z.; Shen, A. A Prediction Method for Calculating Fracturing Initiation Pressure Considering the Modification of Rock Mechanical Parameters After CO2 Treatment. Processes 2024, 12, 2525. https://doi.org/10.3390/pr12112525

Kong C, Sun Y, Bian H, Wei J, Li G, Yang Y, Tang C, Wei X, Cong Z, Shen A. A Prediction Method for Calculating Fracturing Initiation Pressure Considering the Modification of Rock Mechanical Parameters After CO2 Treatment. Processes. 2024; 12(11):2525. https://doi.org/10.3390/pr12112525

Chicago/Turabian StyleKong, Cuilong, Yuxue Sun, Hao Bian, Jianguang Wei, Guo Li, Ying Yang, Chao Tang, Xu Wei, Ziyuan Cong, and Anqi Shen. 2024. "A Prediction Method for Calculating Fracturing Initiation Pressure Considering the Modification of Rock Mechanical Parameters After CO2 Treatment" Processes 12, no. 11: 2525. https://doi.org/10.3390/pr12112525

APA StyleKong, C., Sun, Y., Bian, H., Wei, J., Li, G., Yang, Y., Tang, C., Wei, X., Cong, Z., & Shen, A. (2024). A Prediction Method for Calculating Fracturing Initiation Pressure Considering the Modification of Rock Mechanical Parameters After CO2 Treatment. Processes, 12(11), 2525. https://doi.org/10.3390/pr12112525