The Assessment of Abrasion Resistance of Casted Non-Ferrous Metals and Alloys with the Use of 3D Scanning

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemical Composition

2.2. Properties Characterization

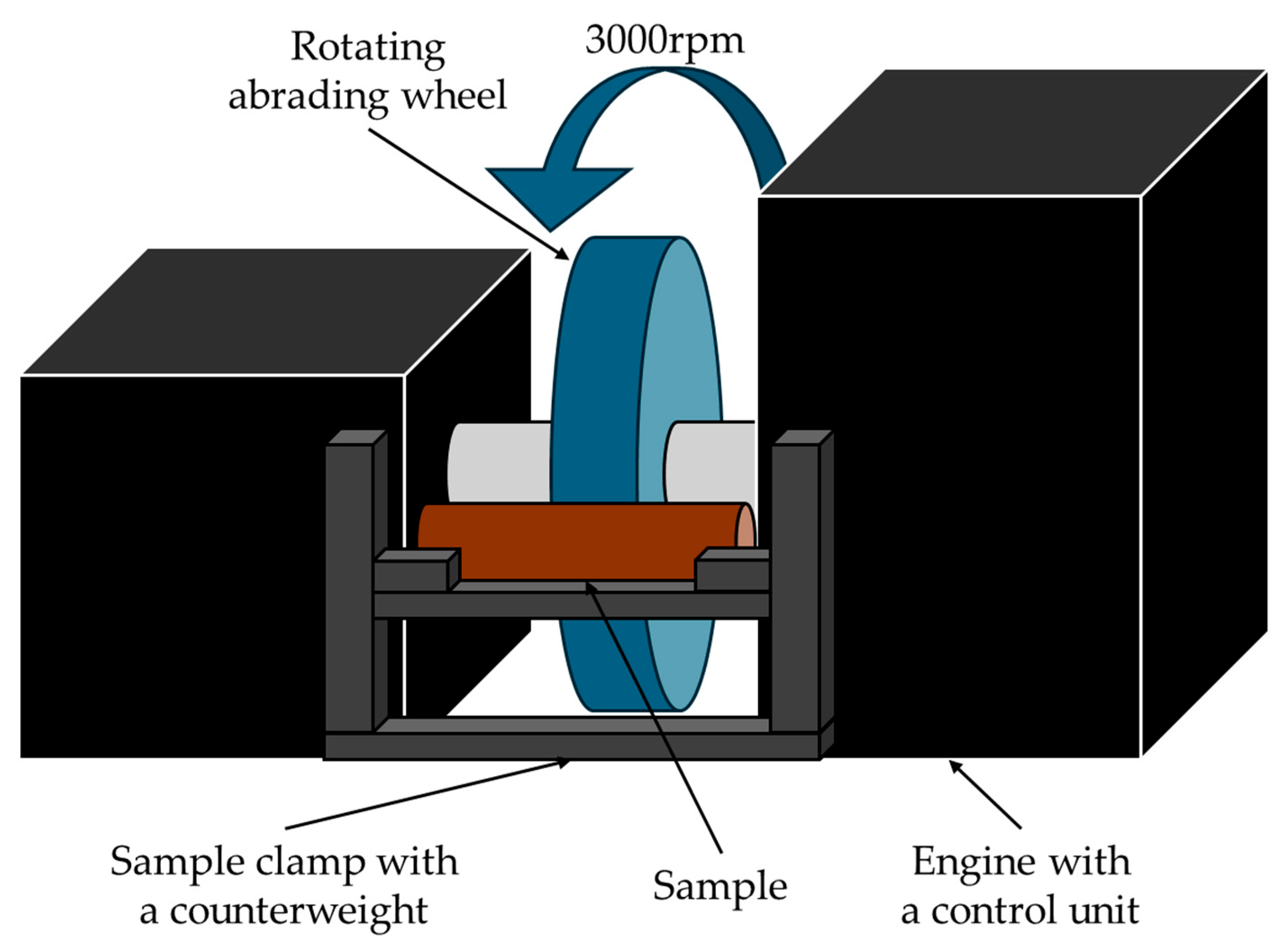

2.3. Abrasion Resistance Test

3. Results and Discussion

3.1. Chemical Composition

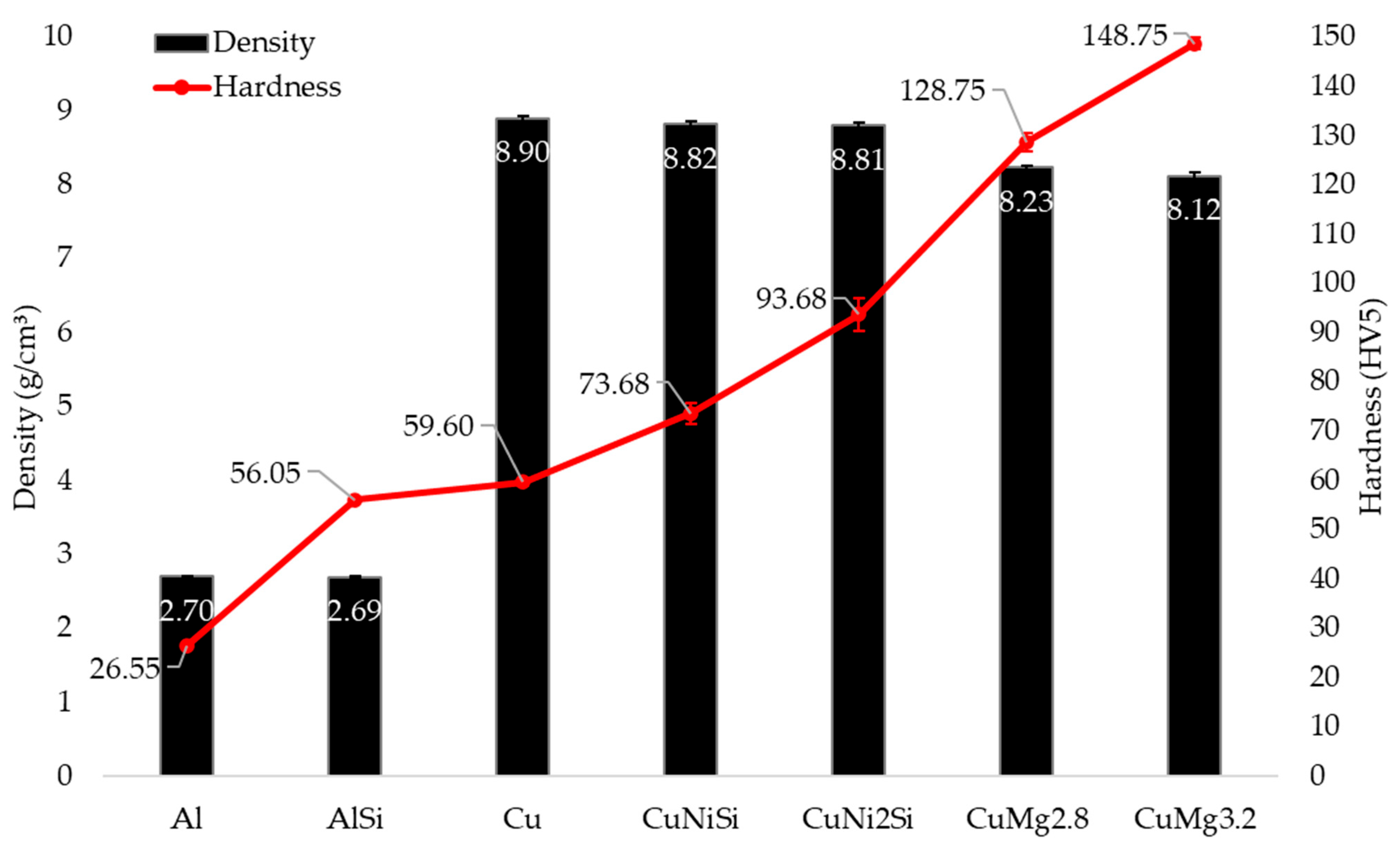

3.2. Properties Characterization

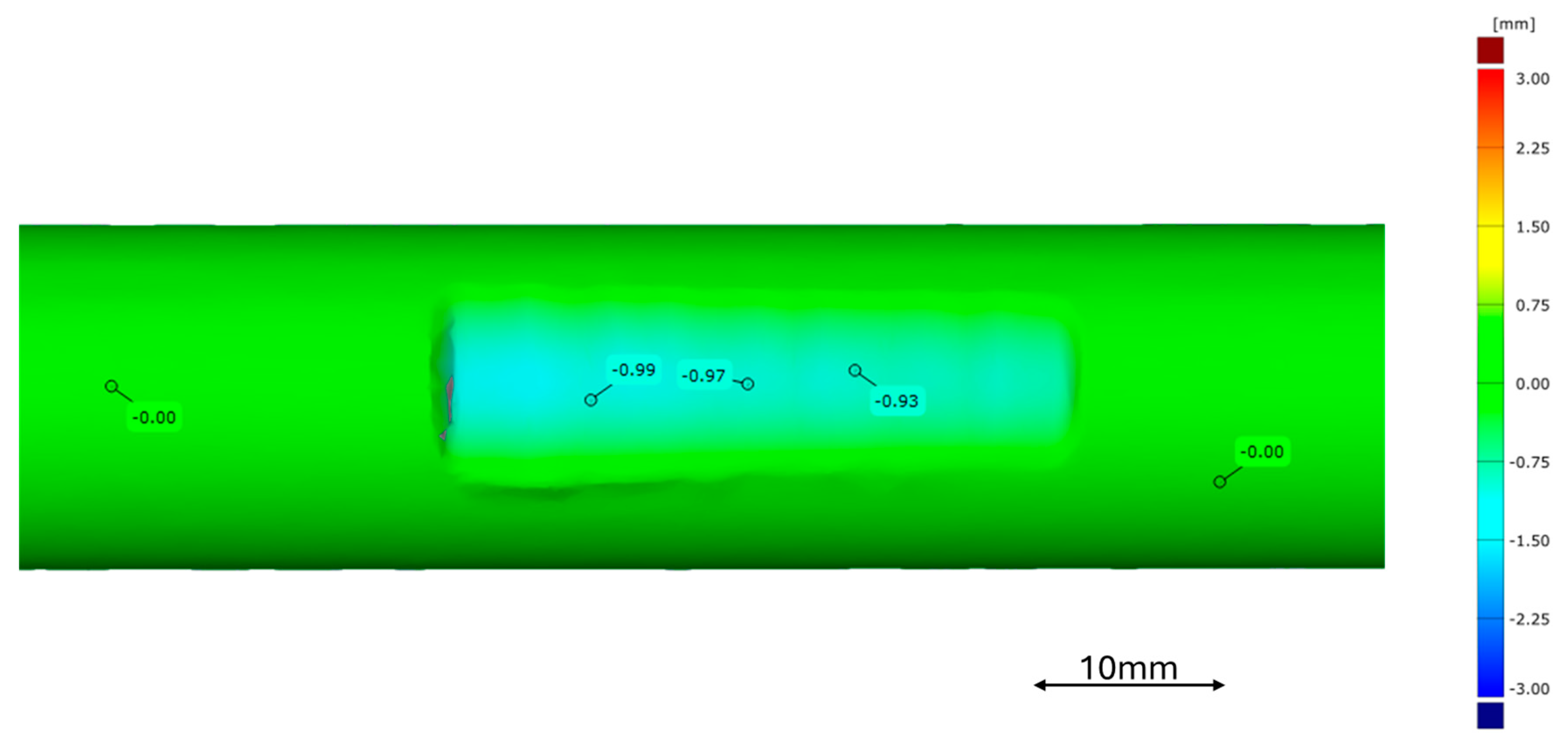

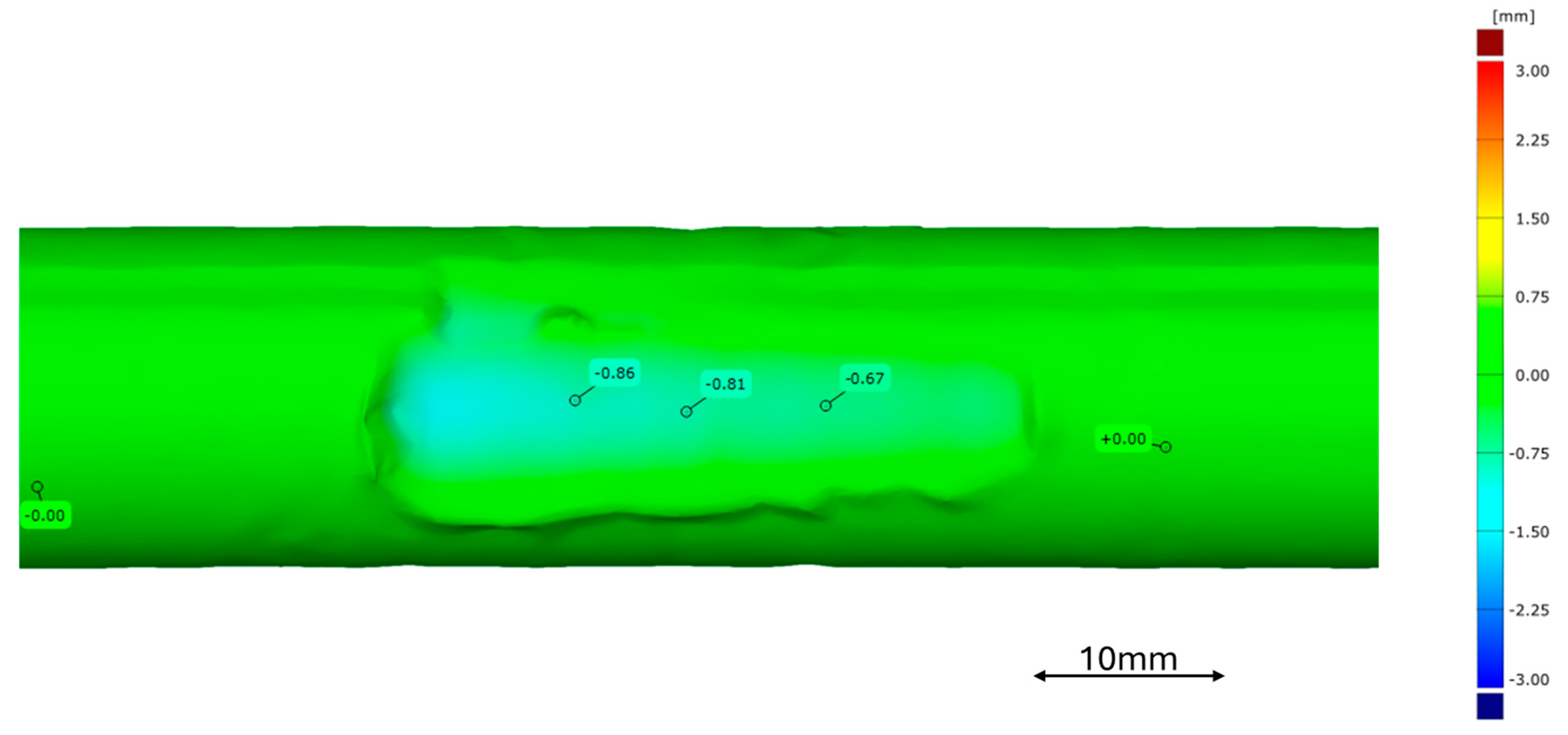

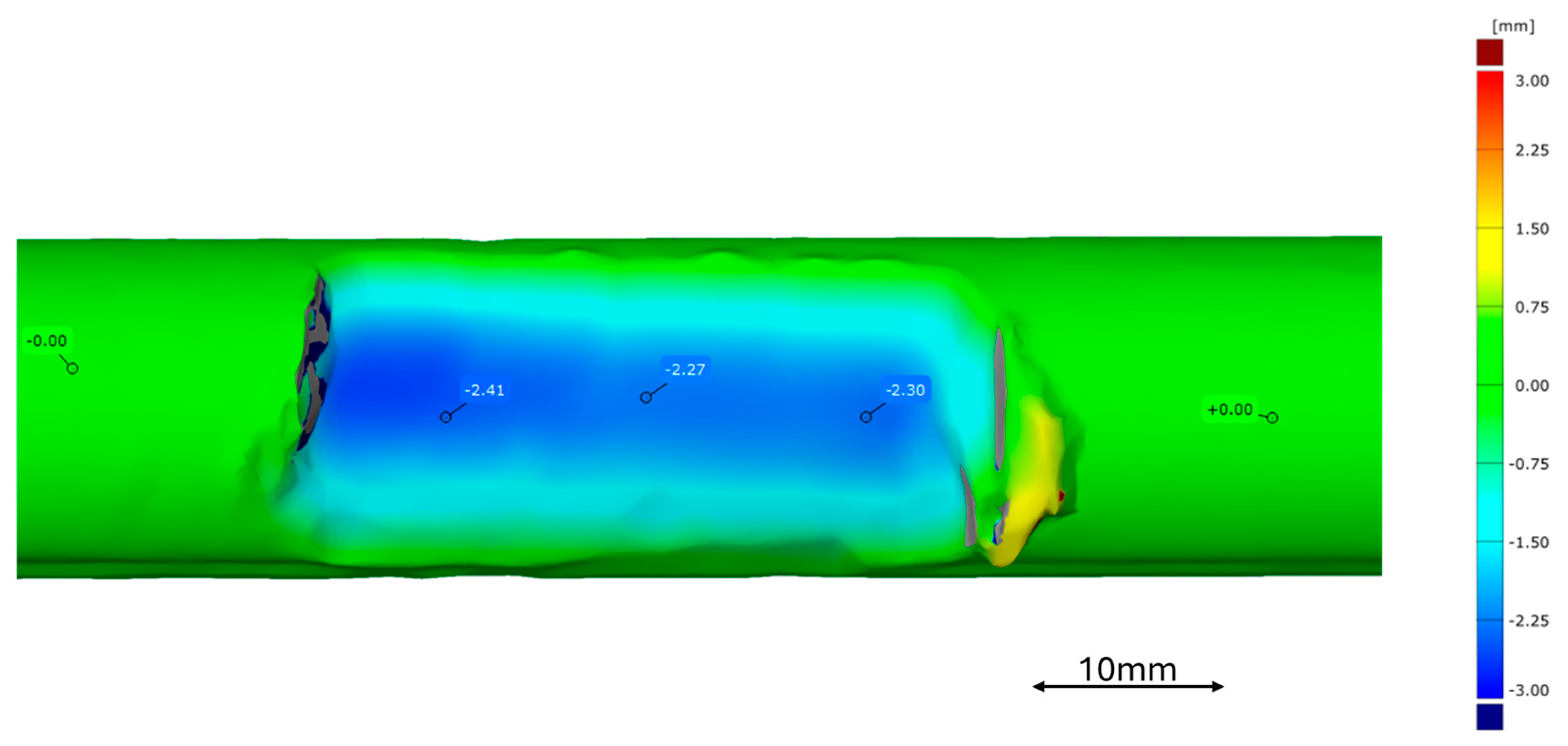

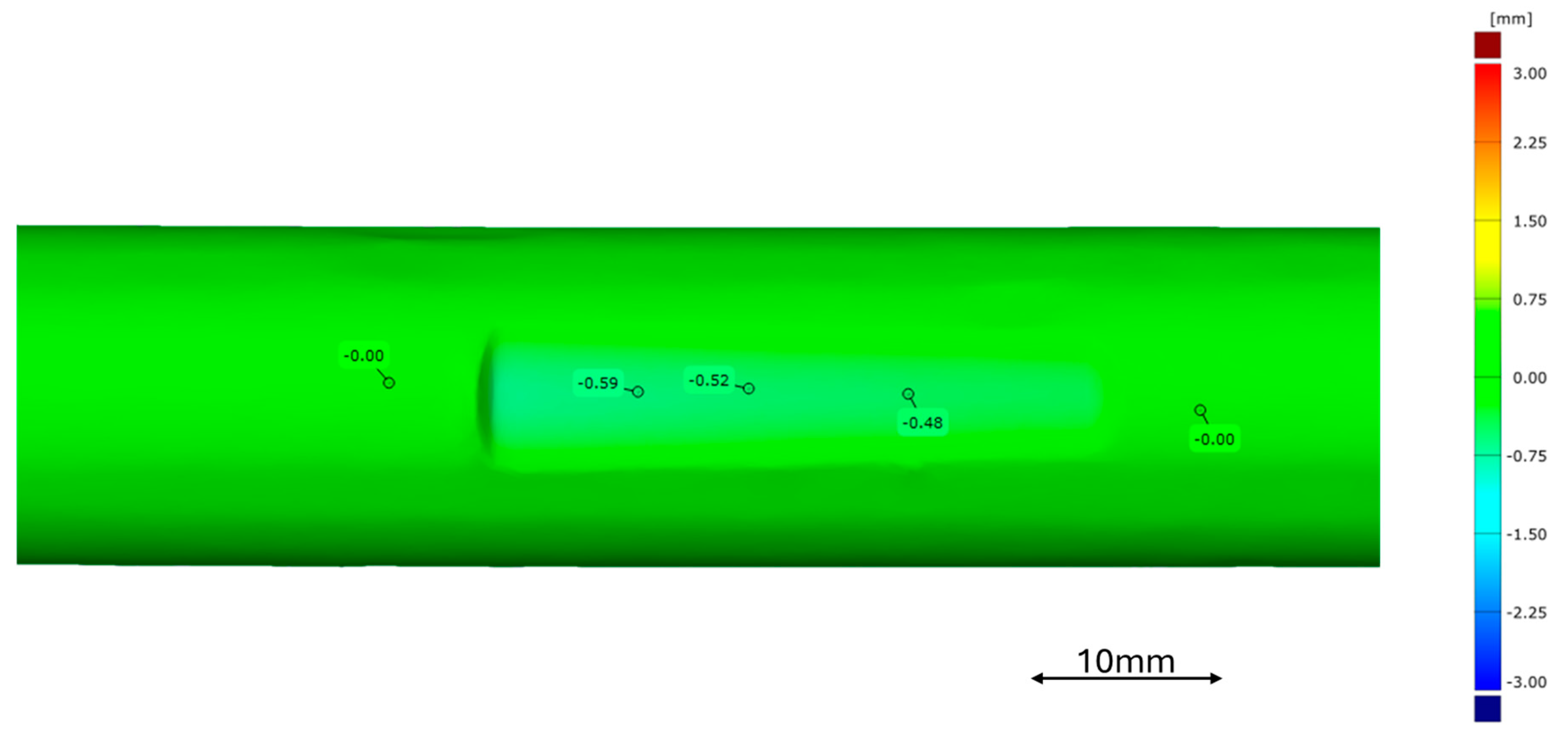

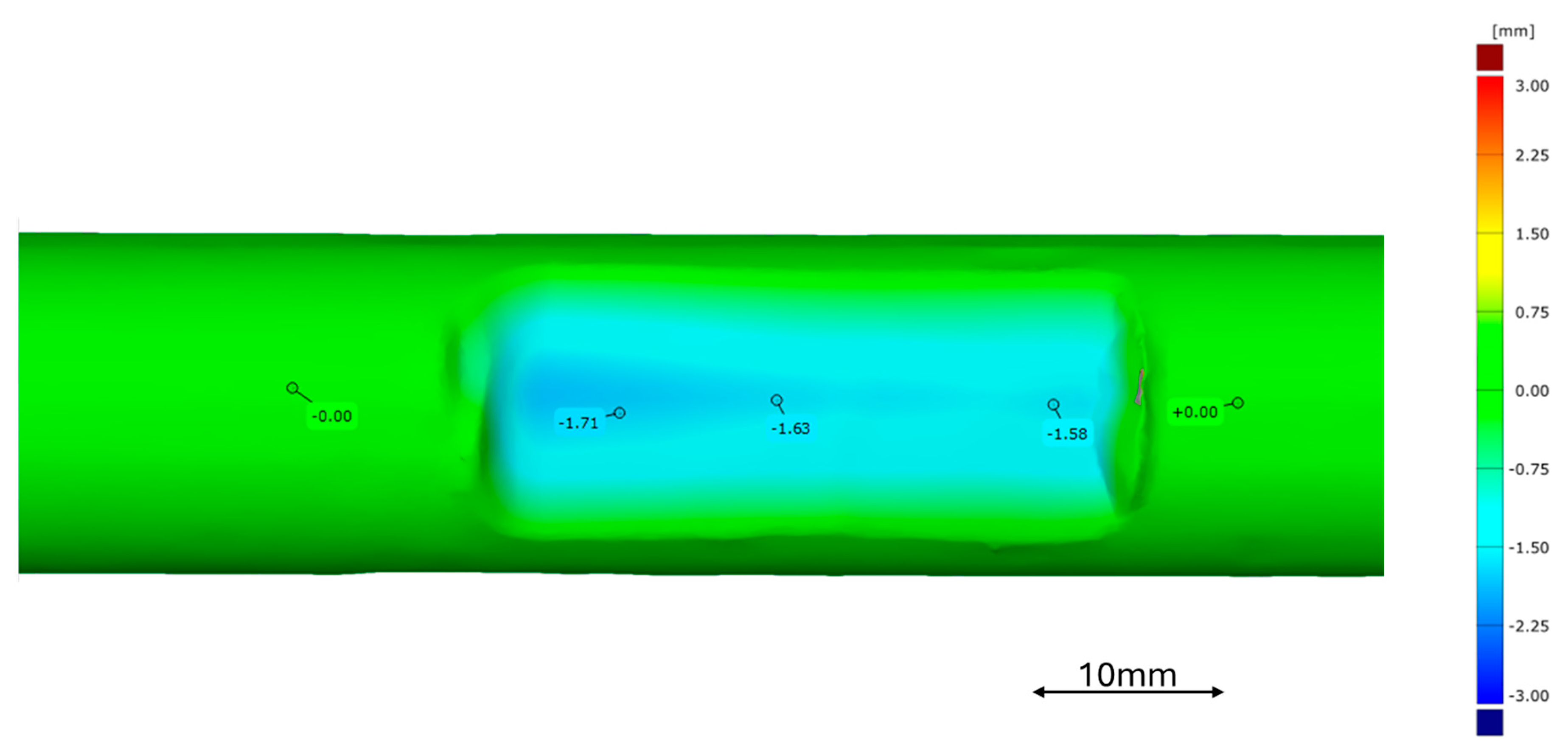

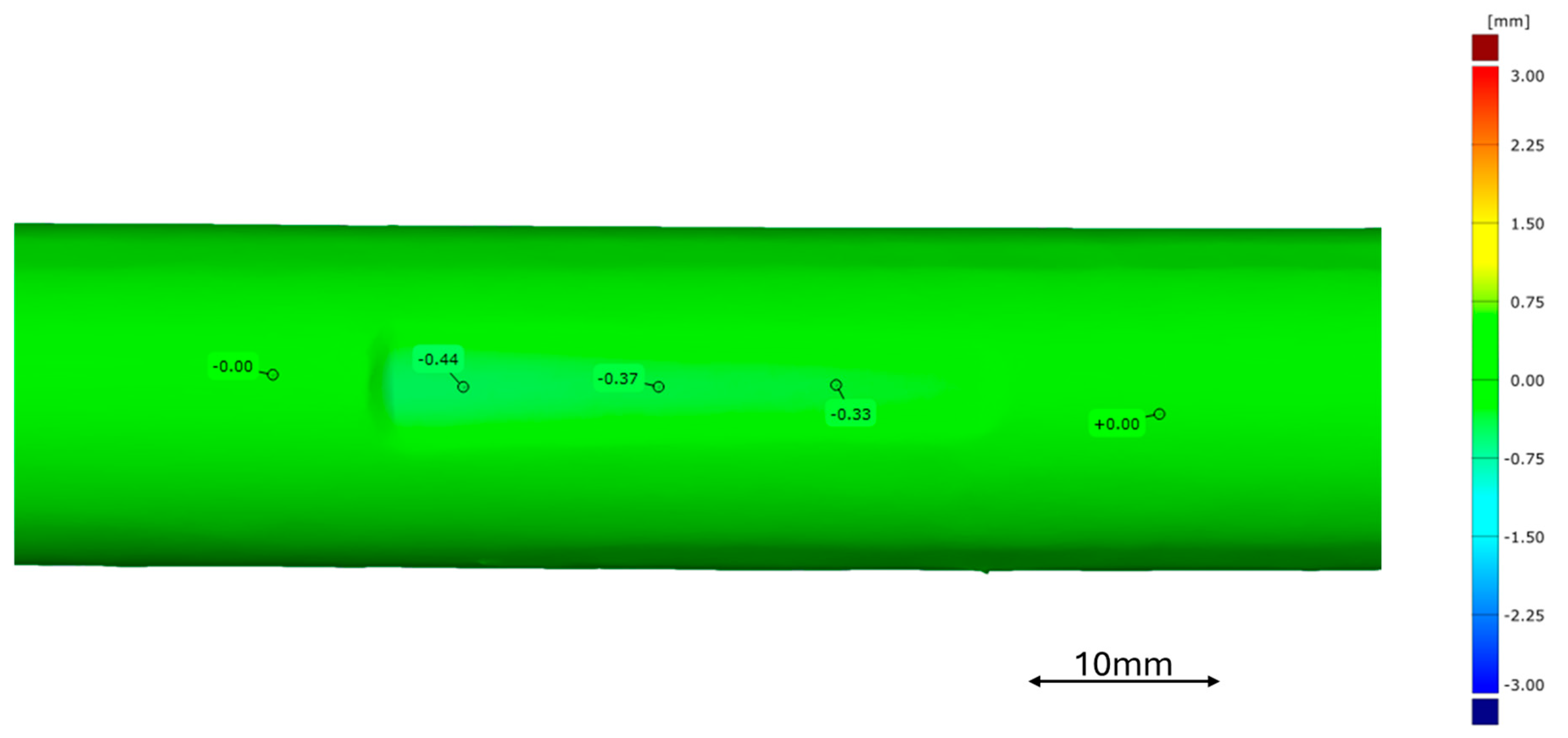

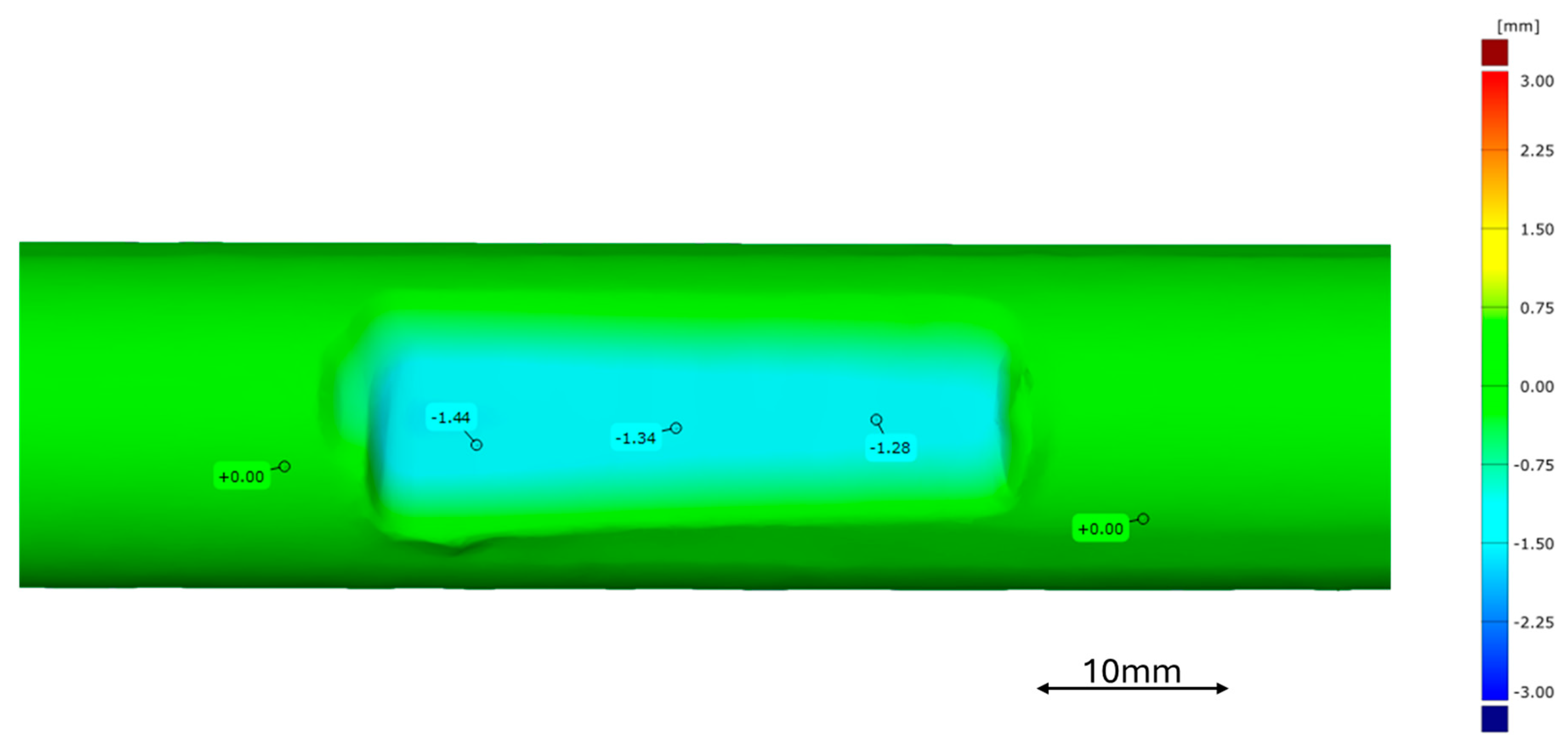

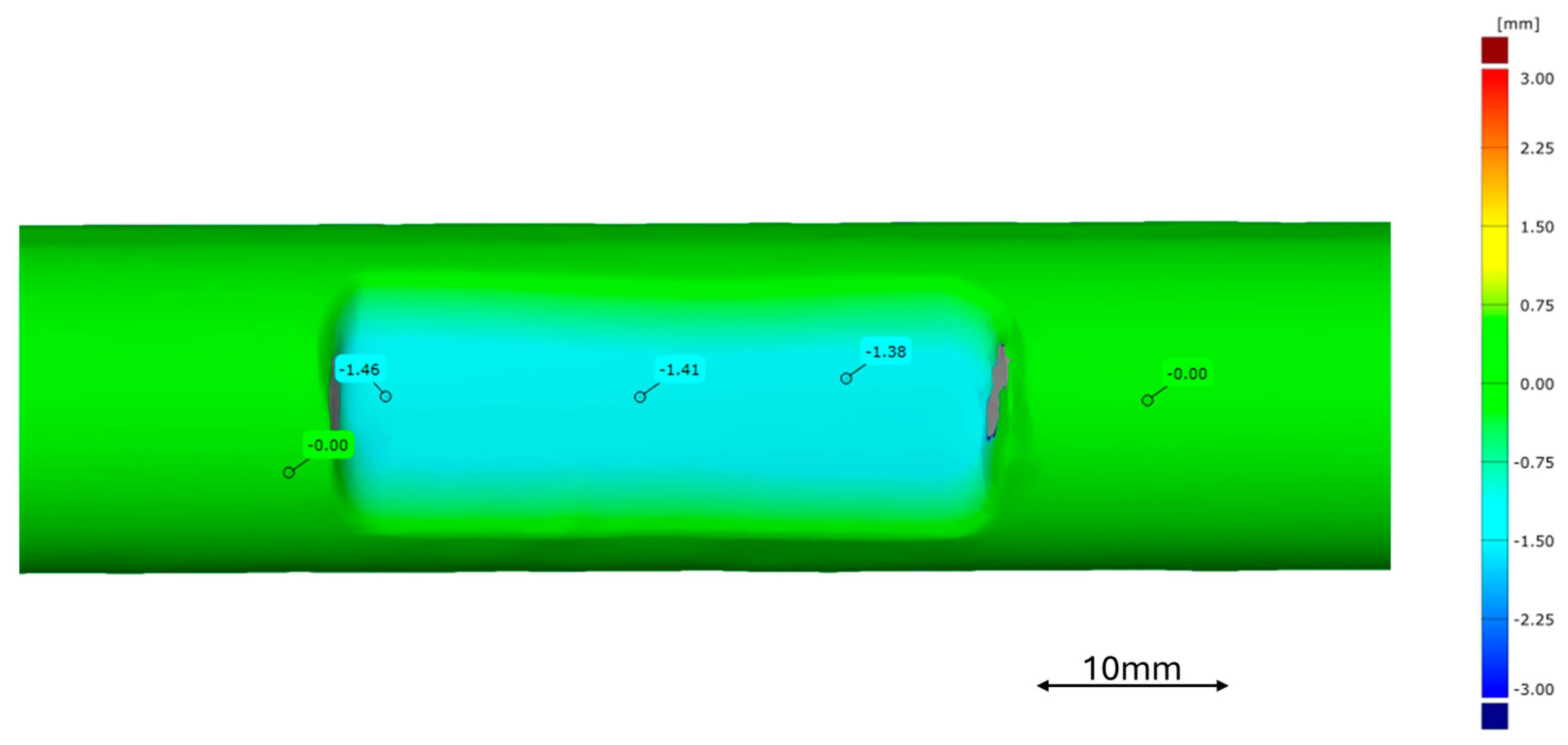

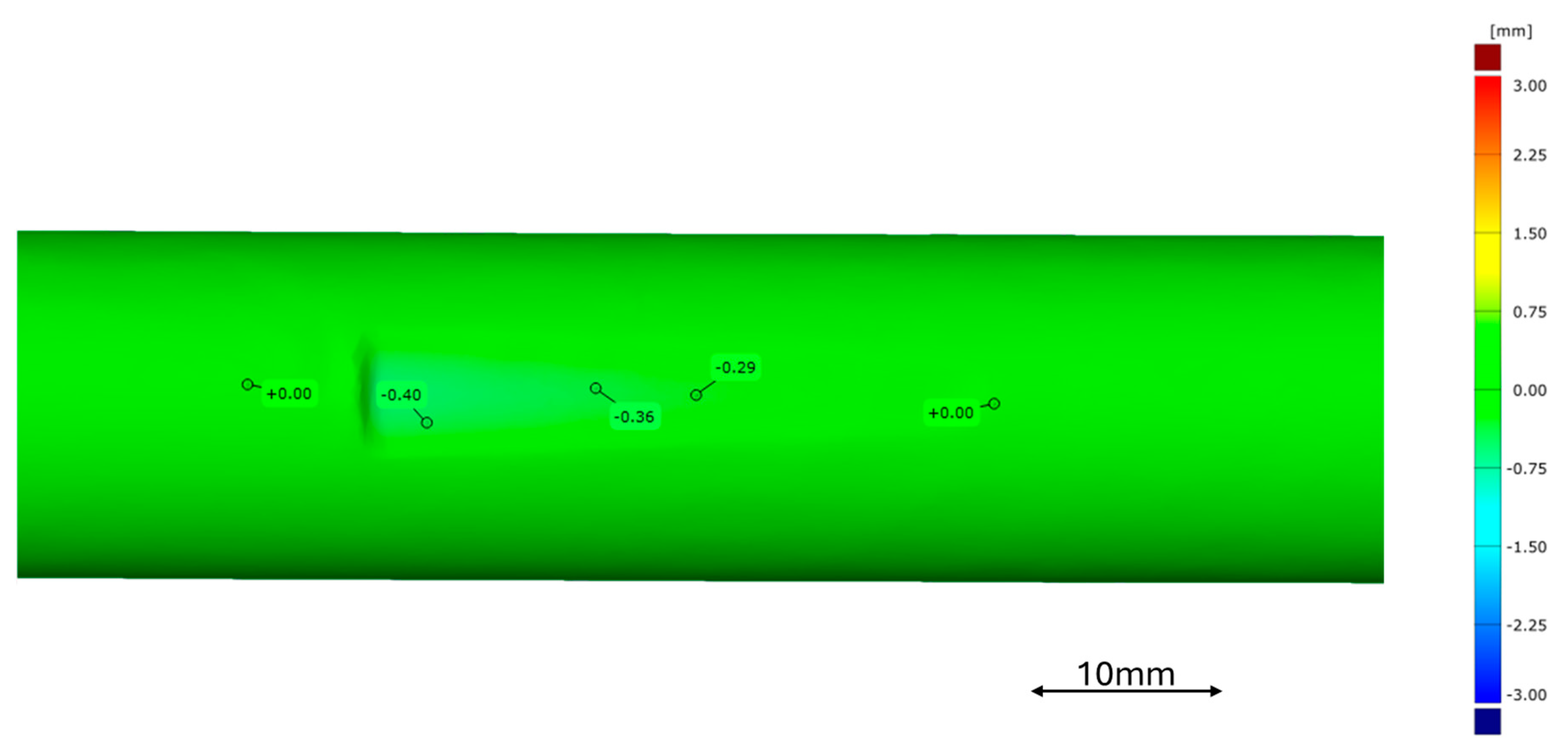

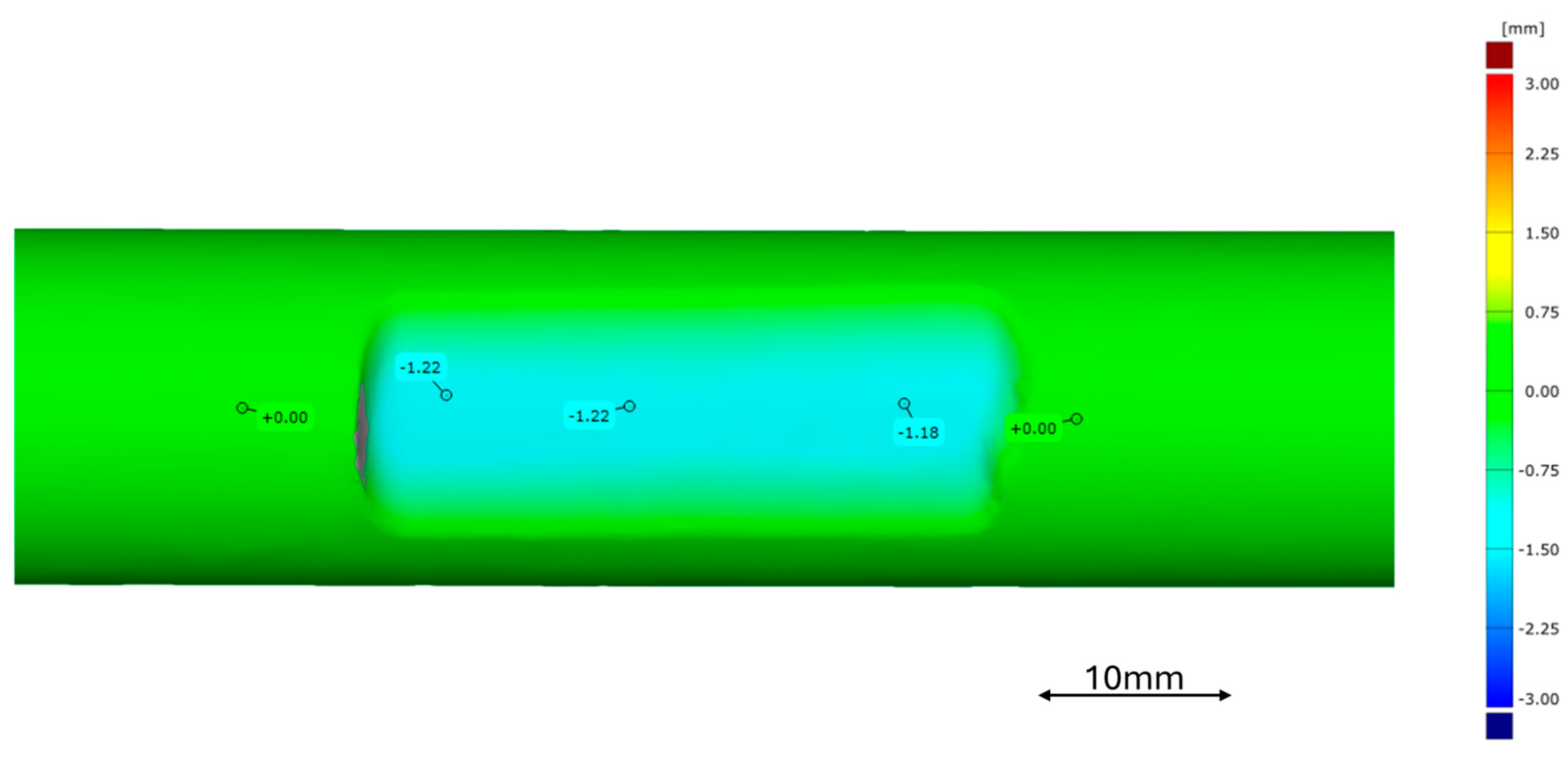

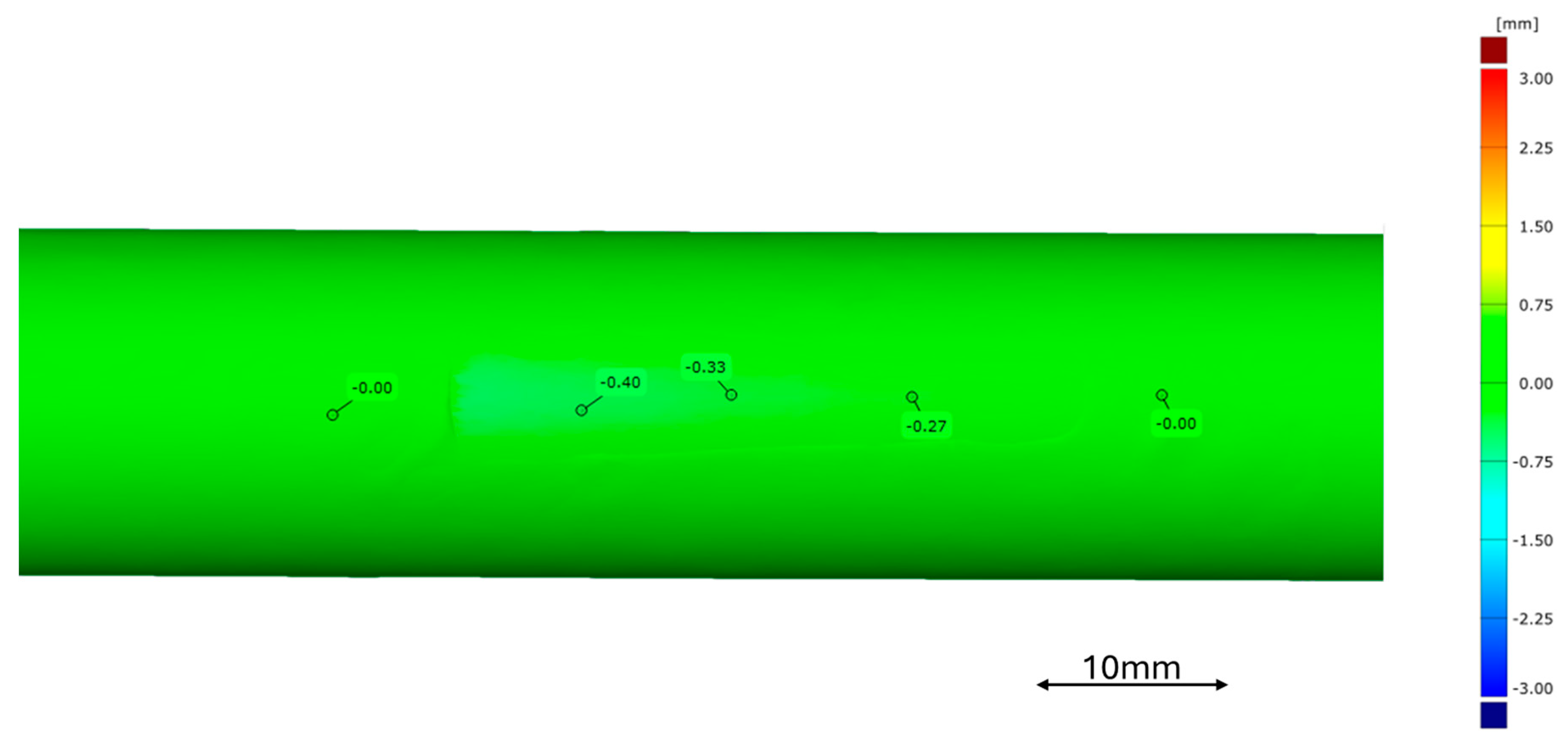

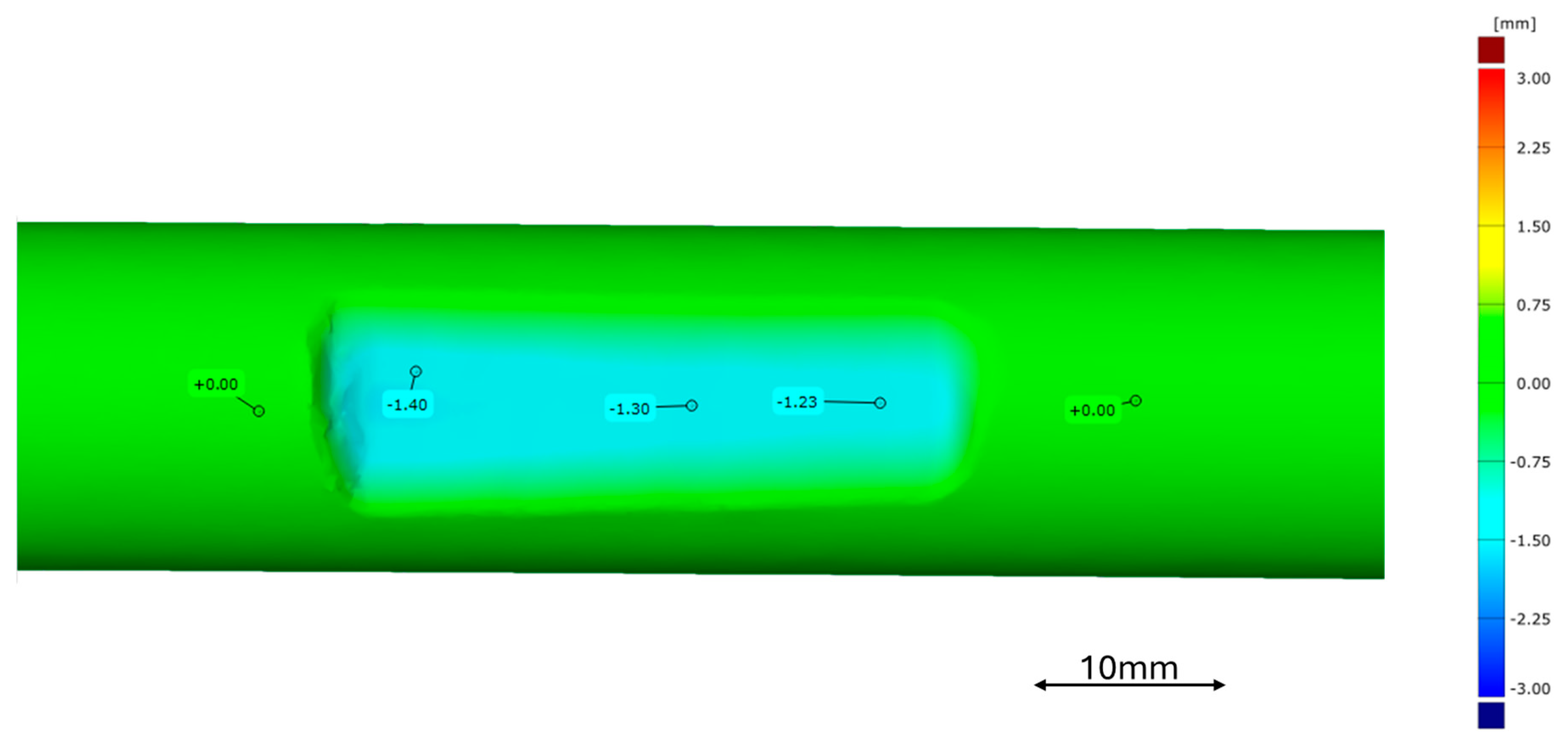

3.3. Abrasion Resistance Test

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fahlman, B.D. Metals. In Materials Chemistry; Springer: Cham, Switzerland, 2023; pp. 191–289. [Google Scholar]

- Ellappan, R.; Arumugam, S.; Sundararajan, R.; Venkatesh, K. Comparative Corrosion Behaviour of Ferrous and Non-ferrous Metals in Bio-lubricant and Bio-diesel Environment. Adv. Mater. Manuf. Eng. Springer Proc. Mater. 2021, 7, 425–432. [Google Scholar] [CrossRef]

- Ziouche, A.; Zergoug, M.; Boucherrou, N.; Boudjelal, H.; Mokhtari, M.; Abaidia, S. Pulsed eddy current signal analysis of ferrous and non-ferrous metals under thermal and corrosion solicitations. Russ. J. Nondestruct. Test 2017, 54, 652–659. [Google Scholar] [CrossRef]

- Avdeeva, L.K.; Godulyan, L.V.; Kovalev, A.I.; Wainstein, D.L.; Vakhrushev, V.O. Corrosion properties, chemical composition, and surface morphology of non-ferrous metals after tests at different temperature and humidity conditions. Metallurgist 2024, 68, 66–82. [Google Scholar] [CrossRef]

- Panda, S. Magnetic separation of ferrous fractions linked to improved bioleaching of metals from waste-to-energy incinerator bottom ash (IBA): A green approach. Environ. Sci. Pollut. Res. 2020, 27, 9475–9489. [Google Scholar] [CrossRef]

- Saini, D.K.; Bafna, N.; Jha, P.K. Effect of sheet thickness on the solidification and quality of Al-Mg2Si composite sheet fabricated by continuous casting. J. Manuf. Process. 2024, 131, 27–37. [Google Scholar] [CrossRef]

- Bagherian, E.-R.; Fan, Y.; Cooper, M.; Frame, B.; Abdolvand, A. Effect of melt temperature, cleanout cycle, continuous casting direction (horizontal / vertical) and super-cooler size on tensile strength, elongation percentage and microstructure of continuous cast copper alloys. Metall. Res. Technol. 2016, 113, 502. [Google Scholar] [CrossRef]

- Strzępek, P.; Zasadzińska, M.; Mamala, A.; Walkowicz, M.; Osuch, P. The Effect of the Percentage of Mg on the Properties of Cu-Mg Alloys Manufactured by Horizontal Continuous Casting Process. JOM 2024, 76, 3153–3160. [Google Scholar] [CrossRef]

- Maleta MGłuchowski, W.; Rdzawski, Z.; Łagoda, M.; Domagała-Dubiel, J. Influence of the speed of downward semi-continuous casting on the crystal size and mechanical properties of recycled copper. Metalugija 2023, 62, 387–390. [Google Scholar]

- Smyrak, B.; Jurkiewicz, B.; Zasadzińska, M.; Gniełczyk, M.; Jałowy, P. The Effect of Al-Mg-Si Wire Rod Heat Treatment on Its Electrical Conductivity and Strength. Metals 2020, 10, 1027. [Google Scholar] [CrossRef]

- Davis, J.R. ASM Specialty Handbook: Copper and Copper Alloys; ASM International: Novelty, OH, USA, 2001; ISBN 978-087170-726-0. [Google Scholar]

- Zasadzińska, M.; Knych, T. The Morphology of Eutectic Copper Oxides I (Cu2O) in The Processing of Wire Rod and Wires made from ETP Grade Copper. Arch. Metall. Mater. 2019, 64, 1611–1616. [Google Scholar] [CrossRef]

- Nordheim, L. Zur Elektronentheorie der Metalle. I. Ann. Phys. 1931, 401, 607–640. [Google Scholar] [CrossRef]

- Yadav, R.; Dwivedi, V.K.; Dwivedi, S.P. Analysis of Mechanical Properties and Manufacturing Process of Aluminum Series. J. Inst. Eng. India Ser. D 2024. [Google Scholar] [CrossRef]

- Kammer, C. Aluminum and Aluminum Alloys. In Springer Handbook of Materials Data; Springer: Cham, Switzerland, 2018; pp. 161–197. [Google Scholar]

- Kaufman, J.G. Introduction to Aluminum Alloys and Tempers; ASM International: Novelty, OH, USA, 2000; ISBN 978-0-87170-689-8. [Google Scholar]

- Shariyari, F.; Shaeri, M.H.; Dashti, A.; Zarei, Z.; Noghani, M.T.; Cho, J.H.; Djavanroodi, F. Evolution of mechanical properties, microstructure and texture and of various brass alloys processed by multi-directional forging. Mater. Sci. Eng. A 2022, 831, 142149. [Google Scholar] [CrossRef]

- Birch, J.; Jenkins, E.; Vrettou, A.; Said, M.; Vashishtha, H.; Connelley, T.; Brooks, J.; Collins, D.M. A micromechanical study of heat treatment induced hardening in α-brass. Acta Mater. 2024, 278, 120277. [Google Scholar] [CrossRef]

- Mao, Z.; Zhang, D.Z.; Jiang, J.; Fu, G.; Zhang, P. Processing optimisation, mechanical properties and microstructural evolution during selective laser melting of Cu-15Sn high-tin bronze. Mater. Sci. Eng. A 2018, 721, 125–134. [Google Scholar] [CrossRef]

- Gupta, R.; Srivastava, S.; Kumar, N.K.; Panthi, S.K. High leaded tin bronze processing during multi-directional forging: Effect on microstructure and mechanical properties. Mater. Sci. Eng. A 2016, 654, 282–291. [Google Scholar] [CrossRef]

- Brudny, A.; Kulasa, J.; Cwolek, B.; Malec, W.; Juszczyk, B. Influence of the continuous casting process of tin-zinc-lead bronze on the wear of the graphite crystallizer. Metalurgija 2022, 61, 785–788. [Google Scholar]

- Ma, S.; Ye, C.; Yang, X.; Fu, L.; Fan, J.; Wang, J.; Shan, A. Microstructure evolution during the heavy warm rolling of a nickel aluminum bronze. Mater. Sci. Eng. A 2023, 883, 145458. [Google Scholar] [CrossRef]

- Cao, Y.; Han, S.Z.; Choi, E.-A.; Ahn, J.H.; Mi, X.; Lee, S.; Shin, H.; Kim, S.; Lee, J. Effect of inclusion on strength and conductivity of Cu-Ni-Si alloys with discontinuous precipitation. J. Alloys Compd. 2020, 843, 156006. [Google Scholar] [CrossRef]

- Zhang, R.; Li, Z.; Sheng, X.; Gao, Y.; Lei, Q. Grain refinement and mechanical properties improvements in a high strength Cu–Ni–Si alloy during multidirectional forging. Fusion Eng. Des. 2020, 159, 111766. [Google Scholar] [CrossRef]

- Pranshanth, M.; Satish, N.; Ajay Kumar, B.S. Effect of Brass and Silver on Mechanical Properties of Copper. Mater. Today Proc. 2018, 5, 25404–25411. [Google Scholar] [CrossRef]

- Tardieu, S.; Mesguich, D.; Lonjon, A.; Lecouturier, F.; Ferreira, N.; Chevallier, G.; Proietti, A.; Estournes, C.; Caurent, C. Nanostructured 1% silver-copper composite wires with a high tensile strength and a high electrical conductivity. Mater. Sci. Eng. A 2019, 761, 138048. [Google Scholar] [CrossRef]

- Dölling, J.; Henle, R.; Prahl, U.; Zilly, A.; Nandi, G. Copper-Based Alloys with Optimized Hardness and High Conductivity: Research on Precipitation Hardening of Low-Alloyed Binary CuSc Alloys. Metals 2022, 12, 902. [Google Scholar] [CrossRef]

- Henle, R.; Kött, S.; Jost, N.; Nandi, G.; Dölling, J.; Zilly, A.; Prahl, U. Investigation of the Solid Solution Hardening Mechanism of Low-Alloyed Copper–Scandium Alloys. Metals 2024, 14, 831. [Google Scholar] [CrossRef]

- Li, R.; Guo, E.; Chen, Z.; Kang, H.; Wang, W.; Zou, C.; Li, T.; Wang, T. Optimization of the balance between high strength and high electrical conductivity in CuCrZr alloys through two-step cryorolling and aging. J. Alloys Compd. 2019, 771, 1044–1051. [Google Scholar] [CrossRef]

- Ma, B.; An, B.; Zhao, X.; Li, Y.; Du, J.; Wang, E. Microstructure and properties of Cu-Cr-Zr alloy by doping Sc. Mater. Lett. 2023, 336, 133917. [Google Scholar] [CrossRef]

- Leśniak, D.; Zasadziński, J.; Libura, W.; Gronostajcki, Z.; Śliwa, R.; Leszczyńska-Madej, B.; Kaszuba, M.; Woźnicki, A.; Płonka, B.; Widomski, P.; et al. Latest advances in extrusion processes of light metals. Arch. Mech. Eng. 2024, 24, 184. [Google Scholar] [CrossRef]

- Feng, Y.; Ding, F.; Wang, S.; Zhu, C. ZrB2–Copper–Graphite Composite for Electric Brushes: Positive Effect of ZrB2 Addition on Composite Properties. Materials 2024, 17, 2980. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Xu, Z.; Xu, B.; Yu, B.; Dong, J.; Li, C. Improving the Mechanical Properties of Al-Si Composites through the Synergistic Strengthening of TiB2 Particles and BN Nanosheets. Metals 2024, 14, 957. [Google Scholar] [CrossRef]

- Korbel, A.; Pieła, K.; Ostachowski, P.; Łagoda, M.; Błaż, L.; Bochniak, W.; Pawlyta, M. Structural phenomena induced in the course of and post low-temperature KOBO extrusion of AA6013 aluminum alloy. Mater. Sci. Eng. A 2018, 710, 349–358. [Google Scholar] [CrossRef]

- Bochniak, W.; Korbel, A.; Ostachowski, P.; Lagoda, M. Plastic flow of metals under cyclic change of deformation path conditions. Arch. Mech. Eng. 2018, 18, 679–686. [Google Scholar] [CrossRef]

- Gronostajski, Z.; Hawryluk, M. The main aspects of precision forging. Arch. Mech. Eng. 2008, 8, 39–55. [Google Scholar] [CrossRef]

- Muszka, K.; Madej, L.; Majta, J. The effects of deformation and microstructure inhomogeneities in the Accumulative Angular Drawing (AAD). Mater. Sci. Eng. A 2013, 574, 68–74. [Google Scholar] [CrossRef]

- Pourbashiri, M.; Sedighi, M.; Poletti, M.C.; Sommitsch, C. Enhancing mechanical properties of wires by a novel continuous severe plastic deformation method. Int. J. Mater. Res. 2017, 108, 741–749. [Google Scholar] [CrossRef]

- Strzępek, P.; Zasadzińska, M. Prospective cold metal working and analysis of deformation susceptibility of CuMg alloys with high magnesium content. Sci. Rep. 2024, 14, 6447. [Google Scholar] [CrossRef] [PubMed]

- Gorsse, S.; Ouvard, B.; Goune, M.; Poulon-Quintin, A. Microstructural design of new high conductivity—high strength Cu-based alloy. J. Alloys Compd. 2015, 633, 42–47. [Google Scholar] [CrossRef]

- Ito, Y.; Matsunaga, H.; Mori, H.; Maki, K. Effect of Plastic Deformation on the Proof Strength and Electrical Conductivity of Copper-Magnesium Supersaturated Solid-Solution Alloys. Mater. Trans. 2014, 55, 1738–1741. [Google Scholar] [CrossRef]

- Rodriguez-Calvillo, P.; Ferrer, N.; Cabrera-Marrero, J.M. Analysis of microstructure and strengthening in CuMg alloys deformed by equal channel angular pressing. J. Alloys Compd. 2015, 626, 340–348. [Google Scholar] [CrossRef]

- Andrews, J. A modelling approach to railway track asset management. Proc. Inst. Mech. Eng. Part F J. Rail. Rapid. Transit 2012, 7, 56–73. [Google Scholar] [CrossRef]

- Kilsby, P.; Remenyte-Prescott, R.; Andrews, J. A modelling approach for railway overhead line equipment asset management. Reliab. Eng. Syst. Saf. 2017, 168, 326–337. [Google Scholar] [CrossRef]

- Leśniak, D.; Zasadziński, J.; Libura, W.; Żaba, K.; Puchlerska, S.; Madura, J.; Balcerzak, M.; Płonka, B.; Jurczak, H. FEM Numerical and Experimental Study on Dimensional Accuracy of Tubes Extruded from 6082 and 7021 Aluminium Alloys. Materials 2023, 16, 556. [Google Scholar] [CrossRef]

- Balcerzak, M.; Żaba, K.; Hojny, M.; Puchlerska, S.; Kuczek, Ł.; Trzepieciński, T.; Novák, V. Experimental Research and Numerical Modelling of the Cold Forming Process of the Inconel 625 Alloy Sheets Using Flexible Punch. Materials 2024, 17, 85. [Google Scholar] [CrossRef] [PubMed]

- Priyadarshi, A.; Bin Shahrani, S.; Choma, T.; Zrodowski, L.; Qin, L.; Leung, C.L.A.; Clark, S.J.; Fezzaa, K.; Mi, J.; Lee, P.D.; et al. New insights into the mechanism of ultrasonic atomization for the production of metal powders in additive manufacturing. Addit. Manuf. 2024, 83, 104033. [Google Scholar] [CrossRef]

- Momber, A.W.; Irmer, M. Taber abrasive wear resistance of organic offshore wind power coatings at varying normal forces. J. Coat. Technol. Res. 2021, 18, 729–740. [Google Scholar] [CrossRef]

- Rossi, S.; Deflorian, F.; Scrinzi, E. Comparison of different abrasion mechanisms on aesthetic properties of organic coatings. Wear 2009, 267, 1574–1580. [Google Scholar] [CrossRef]

- Rossi, S.; Parziani, N.; Zanella, C. Abrasion resistance of vitreous enamel coatings in function of frit composition and particles presence. Wear 2015, 332–333, 702–709. [Google Scholar] [CrossRef]

- ASTM G65; Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM G77; Standard Test Method for Ranking Resistance of Materials to Sliding Wear Using Block-on-Ring Wear Test. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D2714; Standard Test Method for Calibration and Operation of the Falex Block-on-Ring Friction and Wear Testing Machine. ASTM International: West Conshohocken, PA, USA, 2019.

- Taber Industries—Taber Abraser (Abrader). Available online: https://www.taberindustries.com/taber-rotary-abraser (accessed on 16 September 2024).

- MatWeb Material Property Data. Available online: https://www.matweb.com/ (accessed on 18 September 2024).

- Copper Alloys Knowledge Base. Available online: http://www.conductivity-app.org/ (accessed on 18 September 2024).

- Yao, H.; Gong, J.; Cheng, S.; Liu, C.; Huang, H. Effects of Travel Speed on the Microstructure and Abrasion Resistance of Hardfacing Alloys Deposited with Composite Powder Particles and Solid Wire. Metals 2020, 10, 740. [Google Scholar] [CrossRef]

- Chao, L.; Jianxun, G.; Hongjiang, H. Effects of K2co3 Flux on the Microstructure and Abrasion Resistance of High-Chromium Hardfacing Alloys. Trans. Indian Inst. Met. 2022, 75, 3139–3148. [Google Scholar] [CrossRef]

- Bezzon, O.L.; de Barros, C.; de Almeid, J.M.; Di Lorenzo, P.L. Pilot study of the relationship between the hardness and abrasion resistance of two base metal alloys used for metal-ceramic restorations. J. Prosthet. Dent. 2001, 85, 190–194. [Google Scholar] [CrossRef]

- Yang, Q.-S.; Duan, J.-X.; Deng, A.-Y.; Wang, E.-G. Numerical simulation of macrosegregation phenomenon in Cu-6wt%Ag alloy ingots fabricated by electromagnetic stirring. J. Mater. Res. Technol. 2024, 28, 300–315. [Google Scholar] [CrossRef]

- Lesoult, G. Macrosegregation in steel strands and ingots: Characterisation, formation and consequences. Mater. Sci. Eng. A-Struct. 2005, 413, 19–29. [Google Scholar] [CrossRef]

- Prescott, P.; Incropera, F.P. Convection heat and mass transfer in alloy solidification. Adv. Heat Tran. 1996, 28, 231–238. [Google Scholar] [CrossRef]

- Zhao, Q.; Holmedal, B. The effect of silicon on the strengthening and work hardening of aluminum at room temperature. Mater. Sci. Eng. A 2013, 563, 147–151. [Google Scholar] [CrossRef]

- Dash, S.S.; Liu, Z.Y.; Zou, Y.; Li, D.J.; Zeng, X.Q.; Li, D.Y.; Chen, D.L. Strengthening mechanisms and work hardening in a heterostructured cast aluminum alloy under compressive loading: Correlation with nanomechanical properties. J. Alloys Compd. 2023, 968, 171844. [Google Scholar] [CrossRef]

- Lumley, R. (Ed.) Fundamentals of Aluminium Metallurgy: Production, Processing and Applications, 1st ed.; Woodhead Publishing Limited: Sawston, UK, 2011; ISBN 978-1-84569-654-2. [Google Scholar]

- Gholami, M.; Vesely, J.; Altenberger, I.; Kuhn, H.-A.; Wollmann, M.; Janecek, M.; Wagner, L. Influence of grain size and precipitation hardening on high cycle fatigue performance of CuNiSi alloys. Mater. Sci. Eng. A 2017, 684, 524–533. [Google Scholar] [CrossRef]

- Gholami, M.; Vesely, J.; Altenberger, I.; Kuhn, H.-A.; Janecek, M.; Wollmann, M.; Wagner, L. Effects of microstructure on mechanical properties of CuNiSi alloy. J. Alloys Compd. 2017, 696, 201–212. [Google Scholar] [CrossRef]

- Badisch, E.; Mitterer, C. Abrasive wear of high speed steels: Influence of abrasive particles and primary carbides on wear resistance. Tribol. Int. 2003, 36, 765–770. [Google Scholar] [CrossRef]

- Tęcza, G. Changes in the Microstructure and Abrasion Resistance of Tool Cast Steel after the Formation of Titanium Carbides in the Alloy Matrix. Arch. Foundry Eng. 2023, 23, 173–180. [Google Scholar] [CrossRef]

- Zhen, M.; Xiaoxia, L.; Ping, L.; Qichong, L.; Shidan, Y.; Xin, X.; Chao, C.; Minghui, Z. Microstructure and two-body abrasive wear behavior of Fe-B surfacing alloys with different chromium and vanadium contents. Mater. Today Commun. 2023, 34, 105441. [Google Scholar] [CrossRef]

- Formanek, B.; Piątkowski, J.; Szymszal, J. Aluminium composite casting dispersion reinforced with iron-aluminium and silicon carbide phases. Arch. Foundry Eng. 2010, 10, 35–38. [Google Scholar]

- Kucharska, B.; Kowalczyk, J. Resistance Properties of Al–Si Coatings. Acta Phys. Pol. A 2016, 129, 197–199. [Google Scholar] [CrossRef]

- Wróbel, A.; Kucharska, B. Modification of Silicon Crystals in the Al-Si Coating by means of Heat Treatment. Arch. Metall. Mater. 2010, 55, 205–210. [Google Scholar]

- Saheb, N.; Laoui, T.; Daud, A.R.; Harun, M.; Radiman, S.; Yahaya, R. Influence of Ti addition on wear properties of Al–Si eutectic alloys. Wear 2001, 249, 656–662. [Google Scholar] [CrossRef]

- Prasad, B.K.; Venkateswarlu, K.; Modi, O.P.; Jha, A.K.; Dasupta, R.; Yegneswara, A.H. The Effects of Primary Silicon Particles on the Sliding Wear Behavior of Aluminum-silicon Alloys. J. Mater. Sci. Lett. 1998, 17, 1381–1383. [Google Scholar] [CrossRef]

- Prasad, B.K.; Venkateswarlu, K.; Modi, O.P.; Yegneswaran, A.H. Influence of the size and morphology of silicon particles on the physical, mechanical and tribological properties of some aluminium—Silicon alloys. J. Mater. Sci. Lett. 1996, 15, 1773–1776. [Google Scholar] [CrossRef]

- Shaik, M.A.; Golla, B.R. Development of highly wear resistant Cu—Al alloys processed via powder metallurgy. Tribol. Int. 2019, 136, 127–139. [Google Scholar] [CrossRef]

| Aluminum Based | |||||||

|---|---|---|---|---|---|---|---|

| Element | Al | Si | Fe | Cu | Mn | Zn | Other |

| Al (EN AW 1050) | Min. 99.5 | Max. 0.25 | Max. 0.4 | Max. 0.05 | Max. 0.05 | Max 0.07 | Max. 0.03 |

| AlSi (EN AW 4044) | 89.3–92.2 | 7.8–9.2 | Max. 0.8 | Max. 0.25 | Max. 0.1 | Max. 0.2 | Max. 0.15 |

| Copper Based | |||||||

| Element | Cu | Ni | Si | Mg | Other | ||

| Cu | Min. 99.9 | Max. 0.02 | Max. 0.02 | Max. 0.02 | Max. 0.1 | ||

| CuNiSi | 97.1–98.3 | 0.6–1.5 | 0.4–0.7 | Max. 0.02 | Max. 0.3 | ||

| CuNi2Si | 95.9–97.7 | 1.0–2.5 | 0.4–0.8 | Max. 0.02 | Max. 0.3 | ||

| CuMg2.8 | 97–97.3 | Max. 0.02 | Max. 0.02 | 2.7–2.9 | Max. 0.1 | ||

| CuMg3.2 | 96.6–96.9 | Max. 0.02 | Max. 0.02 | 3.1–3.3 | Max. 0.1 | ||

| Aluminum Based | |||||||

|---|---|---|---|---|---|---|---|

| Element | Al | Si | Fe | Cu | Mn | Zn | Other |

| Al (EN AW 1050) | 99.633 ± 0.012 | 0.135 ± 0.002 | 0.175 ± 0.007 | 0.019 ± 0.001 | 0.004 ± 0.00004 | 0.005 ± 0.001 | Bal. |

| AlSi (EN AW 4044) | 91.013 ± 0.176 | 8.564 ± 0.097 | 0.277 ± 0.01 | 0.051 ± 0.004 | 0.007 ± 0.00006 | 0.019 ± 0.001 | Bal. |

| Copper Based | |||||||

| Element | Cu | Ni | Si | Mg | Other | ||

| Cu | 99.92 ± 0.011 | 0.008 ± 0.001 | 0.011 ± 0.001 | 0.001 ± 0.001 | Bal. | ||

| CuNiSi | 98.25 ± 0.115 | 1.05 ± 0.009 | 0.491 ± 0.002 | 0.000 ± 0.000 | Bal. | ||

| CuNi2Si | 97.32 ± 0.074 | 2.08 ± 0.014 | 0.475 ± 0.002 | 0.001 ± 0.001 | Bal. | ||

| CuMg2.8 | 97.15 ± 0.055 | 0.01 ± 0.001 | 0.013 ± 0.001 | 2.787 ± 0.029 | Bal. | ||

| CuMg3.2 | 96.78 ± 0.031 | 0.008 ± 0.001 | 0.014 ± 0.001 | 3.203 ± 0.021 | Bal. | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strzępek, P. The Assessment of Abrasion Resistance of Casted Non-Ferrous Metals and Alloys with the Use of 3D Scanning. Processes 2024, 12, 2200. https://doi.org/10.3390/pr12102200

Strzępek P. The Assessment of Abrasion Resistance of Casted Non-Ferrous Metals and Alloys with the Use of 3D Scanning. Processes. 2024; 12(10):2200. https://doi.org/10.3390/pr12102200

Chicago/Turabian StyleStrzępek, Paweł. 2024. "The Assessment of Abrasion Resistance of Casted Non-Ferrous Metals and Alloys with the Use of 3D Scanning" Processes 12, no. 10: 2200. https://doi.org/10.3390/pr12102200

APA StyleStrzępek, P. (2024). The Assessment of Abrasion Resistance of Casted Non-Ferrous Metals and Alloys with the Use of 3D Scanning. Processes, 12(10), 2200. https://doi.org/10.3390/pr12102200