1. Introduction

Recently, internal radiation therapy, in which radioisotopes are administered to treat cancer, has attracted considerable interest [

1,

2,

3]. Targeted alpha therapy (TAT) is a form of radiation therapy in which specific cells, such as tumor cells, are destroyed using radiation emitted from radiopharmaceuticals collected in those cells. It has been employed in the treatment of prostate cancer and disseminated cancer, among others [

1,

2,

3]. In particular, the treatment of castration-resistant prostate cancer with Ac-225 offers 14-times more effectiveness than Ra-223 [

1]. The development of alpha-emitting radiopharmaceuticals for TAT is an active academic and commercial research area worldwide. However, the supply of alpha-emitting radionuclides has not even kept pace with the demand for research purposes. Currently, Ac-225 is mainly produced by Oak Ridge National Laboratory (ORNL), Institute for Transuranium Elements (ITU), and Institute for Physics and Power Engineering (IPPE) using Th-229 as the parent nuclide, and the annual production is limited to approximately 63 GBq [

4,

5,

6]. The annual supply capacity of Ac-225 obtained from milking Th-229 was estimated to be approximately 37 GBq in 2018 [

4]. Similarly, JSC SSC RF-IPPE extracts Ac-225 from Th-229 by milking, and has an annual supply capacity of approximately 15 GBq [

6]. Because of the limited supply of Ac-225, several methods have been proposed to produce Ac-225 using diverse types of accelerators.

Various Ac-225 production methods have been developed. In the (γ,n) reaction method, Ra-226 is irradiated with an electron beam using an electron linear accelerator [

4,

7,

8]. Moreover, in the spallation method, Th-232 is irradiated with protons using a proton accelerator [

3,

8,

9]. In the (p, 2n) reaction method, 20-MeV protons are irradiated using a low-energy cyclotron [

4,

10,

11]. In addition, other accelerator-based Ac-225 production methods are being actively researched and developed worldwide. Using a nuclear reactor, a neutron irradiation experiment was conducted to measure the cross-sections of Ra-226, Ra-228, and Ac-227 using a high-neutron-flux reactor owned by ORNL, and 74 MBq/g of Th-229, the parent nuclide of Ac-225, was produced in approximately one month [

12].

Among the various Ac-225 production methods, the accelerator-based method offers Ac-225 production from a small amount of target nuclides with high efficiency, whereas the use of a nuclear reactor offers large amounts of stable neutron irradiation over a long time, large irradiation area, high heat removal capability, and high energy efficiency without the need for external energy supply. We previously reported the use of a fast reactor for Ac-225 production [

13]. Using this method, a large amount of Ac-225 can be produced in a short time by generating Ra-225 and its β-decay in a single (n,2n) reaction by fast neutron irradiation of an irradiated target. On the other hand, using light water reactors, the parent nuclide of Ac-225, Th-229 is produced via three rounds of neutron-capture (3n,x) reactions by irradiating the irradiation target for a long time, and Ac-225 is generated semi-permanently via milking. The (3n,x) reaction includes three rounds of neutron capture reaction and two rounds of β-decay (3n,2β) reaction or one-time α-decay and two rounds of β-decay (3n,α2β) reaction.

This study examines the feasibility of the mass production of high-purity Ac-225 via (3n,x) reactions using Pressurized Water Reactor (PWR)s: commercial reactors with multiple units. Ra-226, which is commonly used to produce Ac-225, and Th-230, which is 50-times more abundant than Ra-226, were considered as target nuclides. The Ac-225 production method currently being studied in Japan uses an accelerator to irradiate Ra-226 with electron beams [

14,

15], so ensuring a sufficient supply of Ra-226 is a problem. Higashi et al. state that securing a good supply of Ra-226 is a very important issue for Japan [

15]. Therefore, the use of Th-230 as an irradiation target is important from the viewpoint of material diversification. Furthermore, the use of Th-230 is accompanied by Th-232, which is difficult to separate, so the two were in mixed conditions. The establishment of an Ac-225 production method using light water reactors, commonly used in Japan, is important to realize the self-sufficiency of Ac-225, for which the demand is expected to increase in the future.

Section 2 of this paper describes the process of generating Ac-225.

Section 3 describes the analytical model for neutron irradiation of target nuclides using PWR, and

Section 4 describes the results of those analyses.

Section 5 provides the research conclusions.

2. Ac-225 Generation Process

Multiple neutron transmutation pathways exist to produce Ac-225. Since Ac-225 is in the neptunium series, Ac-225 can be produced from parent nuclides in this series. However, the nuclides in that decay chain do not exist naturally because their parent nuclide, Np-237, has a short half-life compared to the age of the Earth. Therefore, we produce nuclides that decay to Ac-225 using neutron irradiation.

Currently, Ac-225 is produced using Th-229 as the parent nuclide, which is obtained from the decay of legacy U-233 generated as an alternative fuel source for nuclear reactors [

5]. Therefore, we focused on the isotopes of radium, actinium, and thorium, nuclides close to Th-229 on the nuclear chart, as irradiation targets. Among them, those with short half-lives, including parent nuclides, are almost nonexistent in nature; thus, we focused on Ra-226, which has a long half-life of more than 1000 years and exists in nature only as a daughter nuclide of the uranium series, and Th-230, which is 50-times more abundant than Ra-226, as an alternative nuclide. By irradiating these nuclides in a fast reactor, Ra-226 is transmuted to Ra-225 upon the (n,2n) reaction in the high-energy region (threshold: 6.4 MeV); consequently, the β-decays produce Ac-225. Similarly, Th-230 is also transmuted to Th-229 upon the (n,2n) reaction in the high-energy region (threshold: 6.8 MeV).

Fast reactors can produce reactions that knock out neutrons away from nuclides via the (n,2n) reaction. On the contrary, using a light water reactor, neutrons can be added to the nuclide by the (n,γ) reaction. Therefore, we developed a method to produce Th-229 by adding neutrons to the target nuclide.

2.1. Nuclear Transmutation Path of the Ra-226 (3n,2β) Method

The neutron irradiation of a target nuclide using a light water reactor produces the parent nuclide Th-229 via multiple (n,γ) reactions.

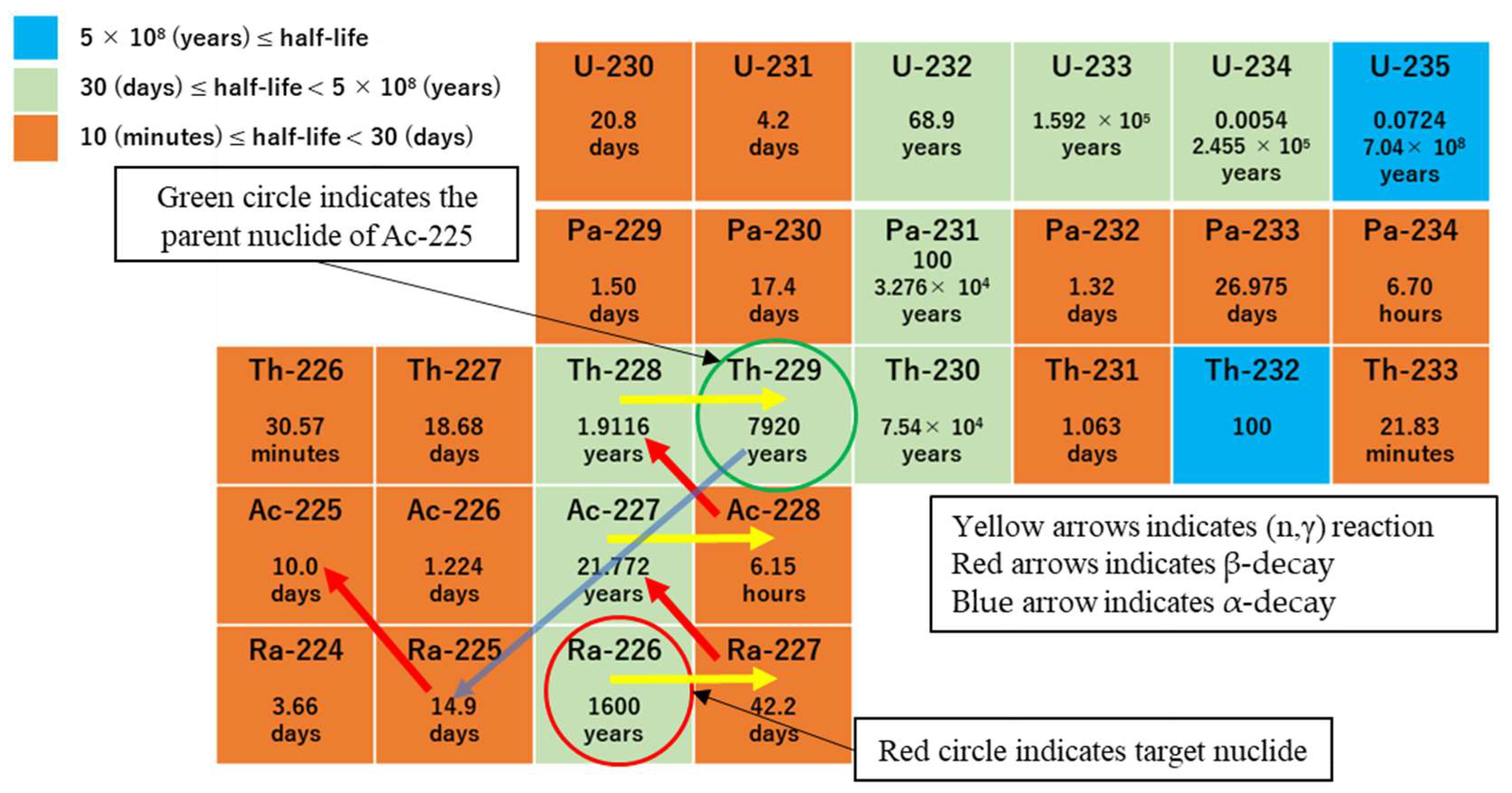

Figure 1 shows the path to produce Ac-225 from Ra-226. Ra-226 (12.79 barn) absorbs neutrons to produce Ra-227 (T1/2 = 42.2 min) via the (n,γ) reaction; then, the β-decays produce Ac-227. Ac-227 (800.3 barn) produces Ac-228 (T1/2 = 6.15 h) via the (n,γ) reaction and Th-228 via the β-decays. Furthermore, Th-228 (122.9 barn) produces Th-229 (T1/2 = 7920 years), which has a long half-life, via the (n,γ) reaction, from which Ra-225 (T1/2 = 14.9 days) and Ac-225 are generated by the α- and β-decays, respectively. This path produces Th-229 with a long half-life as the parent nuclide of Ac-225; thus, Ac-225 can be produced semi-permanently by milking from Ra-225 accumulated by the α-decay.

2.2. Nuclear Transmutation Path of the Th-230 (3n,α2β) Method

The long-term neutron irradiation of Th-230 using a light water reactor produces Th-229 by three rounds of (n,γ) reactions, two β-decays and one α-decay from Th-230.

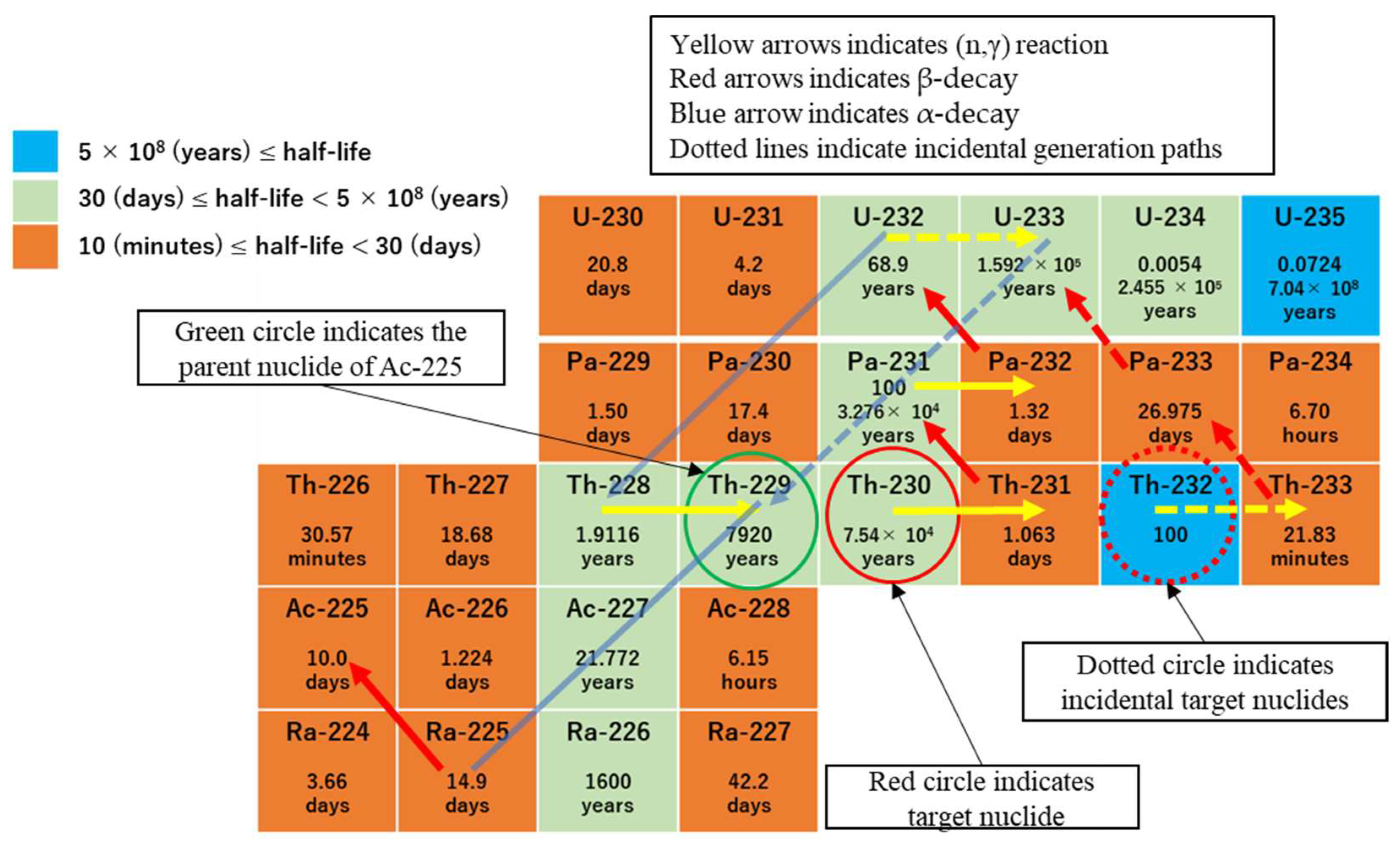

Figure 2 shows the path that produces Ac-225 from Th-230. Th-230 (23.41 barn) produces Th-231 (T1/2 = 1.063 days) by the (n,γ) reaction, and the β-decays produce Pa-231. Pa-231 (201.7 barn) produces Pa-232 (T1/2 = 1.32 days) by the (n,γ) reaction and U-232 by the β-decay. Then, as U-232 (T1/2 = 68.9 years) accumulates, the production of Th-228 (122.9 barn) accelerates by α-decay, and the (n,γ) reaction forms a new cyclic chain [

17] that accelerates the production of Th-229 compared to the initial state with only the (n,2n) reaction. Incidentally, U-232 (75.39 barn) absorbs neutrons to produce U-233 (T1/2 = 159,200 years) via the (n,γ) reaction; however, owing to its long half-life, the amount of Th-229 produced by the α-decay is small. In addition, Th-230 undergoes an (n,2n) reaction with fast neutrons with a threshold of 6.824 MeV to produce Th-229, but the fast neutron flux is very small in light water reactors.

2.3. Natural Thorium (Mixed Th-230 + Th-232) Transmutation Path

In the case of using Th-230 as the target nuclide, the stable nuclide Th-232 is contained in large amounts as an isotope. The ratio of Th-230 to Th-232 varies depending on the mining location, i.e., the use of Florida ores [

18], which are rich in U-238 (uranium ores), the parent nuclide of Th-230 (their uranium-to-thorium ratio is approximately 100:1).

Figure 3 shows the path of Ac-225 transmutation from Th-230 and Th-232. Therefore, two transmutation paths exist to produce Th-229, one from Th-230 and the other from Th-232. The irradiation of Th-232 (7.338 barn) produces Th-233 (T1/2 = 21.83 min) via the (n,γ) reaction and Pa-233 (T1/2 = 21.83 min) via the β-decay. Then, Pa-233 (T1/2 = 26.975 days) undergoes the β-decay to form U-233. Consequently, the α-decay of U-233 (T1/2 = 159,200 years) produces Th-229, but its contribution to Th-229 formation is very small, owing to its long half-life.

The main nuclides produced by the irradiation of target nuclides are radium, actinium, thorium, protoactinium, and uranium. After the irradiated targets are removed from the reactor and cooled for 10 days to allow the byproduct Th-231 (T1/2 = 1.063 days) to fully decay, thorium is recovered by chemical separation using N,N,N′,N′-tetra-n-octyldiglycolamide (DGA resin). Thorium is adsorbed on the DGA resin in a nitric acid solution at a lower concentration than that used for actinium separation. Th-228, Th-229, Th-230, and Th-232 are the main thorium isotopes recovered. In these nuclides, Th-229 is the parent nuclide of Ac-225. Therefore, high-purity Ac-225 can be obtained semi-permanently from Th-229 with a long half-life of 7920 years without reloading into the reactor.

3. Analysis

3.1. Target Nuclide Loading in PWR Fuel Assembly

We evaluated the core characteristics of a PWR loaded with (1) pure Ra-226 and (2) natural thorium, as well as the production characteristics of Ac-225 and its parent nuclide Th-229, using the continuous energy Monte Carlo code MVP-3.0 [

19].

The target core specification was designed to be a typical commercial PWR with a thermal power of 3411 MWt. Since the long irradiation period on the order of years is effective for Ac-225 generation, frequent loading/unloading of targets is not necessary, and the operation can be performed at the normal loading/unloading timing of fuel assemblies. Therefore, (1) pure Ra-226 and (2) natural thorium targets were mounted in the control rod guide tube in the fuel assembly.

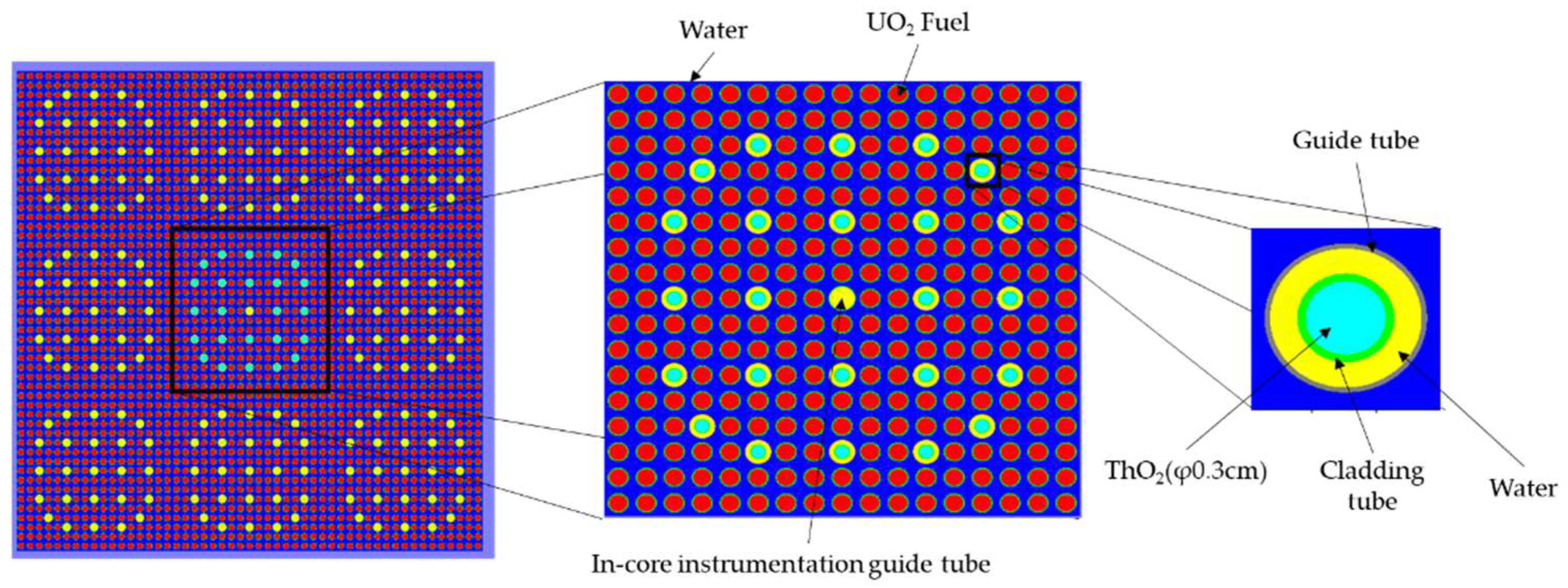

The fuel assembly in which irradiation target loading was performed is shown in

Figure 4, and the plugging device and the target loading method to the PWR are shown in

Figure 5. In PWR cores, most of the control rod guide tubes that are not used during operation are attached with plugging devices and sealed to reduce unnecessary coolant flow. Therefore, this plugging device was replaced with a target pin. Using the unused area inside the plugged guide tube, the target nuclide was loaded with no major modification of the fuel assembly geometry.

An amount of 1 g of Ra-226 was used for target nuclide loading. At least 3 tons of natural uranium is required to obtain 1 g of Ra-226.

Table 1 shows the composition of nuclides in 3 tons of natural uranium. Since 3 tons of natural uranium contains 50 g of Th-230, it was assumed that 50 g of Th-230 would be used as the irradiation target. However, the uranium ore contains the thorium ore when mined. Therefore, the stable isotope Th-232 was extracted along with Th-230 from natural uranium as a byproduct.

In the case of using Th-230 as the target nuclide, it is loaded with Th-232 in a mixed state into the core. The ratio of Th-230 to Th-232 varies depending on the mining area, although we assumed that the ratio of the uranium ore to the thorium ore is 100:1 [

18]. Since 3 tons of natural uranium contains 50 g of Th-230, if the ratio of the thorium ore is 1% of the uranium ore, the ratio would be 50 g of Th-230 to 30 kg of Th-232, which is 1:600.

3.2. Examination of Natural Thorium Target Analysis

In the case of (2) natural thorium used to load 50 g of Th-230, the ratio of Th-230 to Th-232 was 1:600; therefore, a total of 30 kg of the target was loaded. However, if the natural thorium target is loaded in the guide tube for in-core instrumentation on the order of tens of kilograms, it is necessary to consider whether the heat generated by thorium fission adversely affects its integrity. Therefore, to determine whether the central temperature of (2) natural thorium target pin satisfies the limit for general uranium fuel, the temperature distribution of the target was obtained using the finite element method, and coolant pressure loss and coolant outlet temperature in the control rod guide tube were evaluated.

The parameters of the irradiation target and fuel assembly specifications for thermal and hydraulic analysis are shown in

Table 2 and

Table 3. The geometric parameters in

Table 2 and

Table 3 were set assuming a general PWR fuel assembly. In addition,

Figure 6 shows the heat generation rates for the main nuclides. The heat generation density of the target was obtained by ORIGEN2 [

20] analysis using the cross-section created by considering the self-shielding of the (2) natural thorium target and the core average neutron flux of the PWR. Target pin radiuses of 0.2 cm and 0.3 cm, target heights in the range of 0.5–3.5 m, and coolant flow velocities ranging from 0–4.5 m/s in the inner circular part of the guide tube were considered with a core average velocity of 4.5 m/s as the upper limit, assuming that the coolant velocity was adjusted by the size and number of coolant inlet holes at the bottom of the guide tube.

3.3. Thermal and Hydraulic Analysis Results

Replacing the plugging device with an irradiation target pin and loading it inside the guide tube cause coolant to flow into the tube. Consequently, if the local coolant temperature fluctuates, the coolant density changes, negatively affecting the core power distribution and criticality. In addition, if the coolant pressure loss is small, an excessive amount of coolant flows in, and if the pressure loss is large, coolant flow is blocked. Therefore, the height and radius of the irradiation target pin needed to satisfy the uranium fuel limit for the coolant outlet temperature (325.35 °C) and pressure loss (28 kPa) were estimated.

The relationship between irradiation target pin height and coolant flow rate, determined using thermal and hydraulic analyses, is shown in

Figure 7. For the target pin radius of 0.2 cm, no conditions for the coolant outlet temperature and pressure drop satisfied the uranium fuel limits. For the target pin radius of 0.3 cm, the limits were satisfied at a coolant flow velocity of 2.5 m/s and a target height of 2.36 m. Therefore, the target pin size was set to 0.3 cm in radius and 236 cm in height. The maximum temperature at the center of the thorium target pin was evaluated to be approximately 800 °C, which is much lower than the limit temperature of 1800 °C for uranium fuel pins.

3.4. Analytical Model and Calculation Conditions

Based on the irradiation target specifications obtained from the thermal and hydraulic analyses, a Th-230 + Th-232 target with a radius of 0.3 cm and a height of 236 cm was to be loaded into 24 control rod guide tubes of the fuel assembly (16 kg of ThO

2 and 14.1 kg of thorium were to be loaded). Therefore, approximately two fuel assemblies were required to load 30 kg of thorium. The analytical model involved an infinite array of 3 × 3 fuel assemblies with one target-loaded fuel assembly at the center. The specifications of the PWR [

21], assuming target loading and the analytical conditions for the neutron irradiation of the target, are shown in

Table 4 and

Table 5.

Figure 8 show the cross-sections of the thorium target-loaded fuel assembly drawn by the MVP visualization function.

In the case of the Ra-226 target, thermal and hydraulic analyses were not performed because the amount of the loaded target was only 1 g. Transmutation analyses performed under the same conditions were applied to (1) 1 g of pure Ra-226 and (2) 30 kg of natural thorium targets, except for the difference in the loading amount. The Ra-226 target can be loaded in one control rod guide tube because of its small amount, but for symmetry reasons, it was loaded in four tubes. The analytical conditions and the cross-section of the fuel assembly loaded with the thorium target drawn using the visualization function of MVP are shown in

Table 6 and

Figure 9, respectively.

Table 7 shows the amounts of nuclides analyzed in

Section 4 in the case of Ra-226 as the target nuclide, natural thorium, pure Th-232, and enriched Th-230. In addition, the natural uranium ore required to obtain these nuclides and the number of assemblies needed to maximally load the PWR are also described.

4. Analysis Results

4.1. Th-229 Production by Pure Ra-226 Target Irradiation (Case 1)

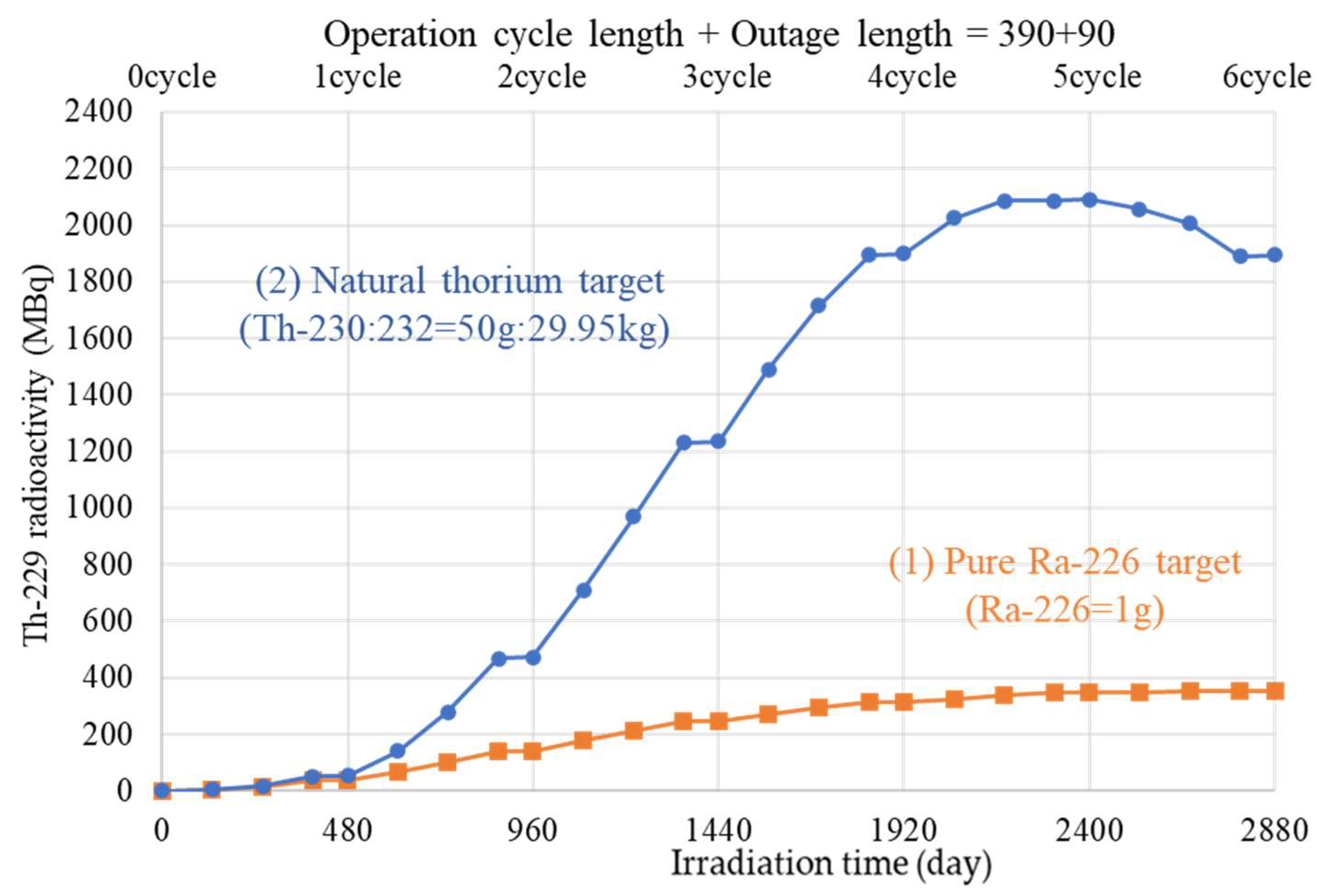

The amount of Th-229 produced by neutron irradiation of pure Ra-226 target for six cycles (approximately 8 years) is shown in

Figure 10. Irradiating 1 g of pure Ra-226 with neutrons for six cycles (approximately 8 years) produces approximately 350 MBq of Th-229 through three rounds of (n,γ) reactions and two rounds of β-decays. In the case of producing Th-229 from Ra-226, the half-lives of decay nuclides in the generation path are as short as 42 min for Ra-227 and 6.15 h for Ac-228. Thus, it is possible to quickly build up to and produce Th-229 efficiently. The Th-230 + Th-232 target has a long half-life owing to U-232 (T1/2 = 68.9 years) in the generation path; thus, Th-228 takes longer to accumulate because it is produced by α-decay. Furthermore, U-232 absorbs neutrons and produces U-233 (T1/2 = 160,000 years), which has a long half-life and is fissile, thereby deteriorating the efficiency of Th-229 production.

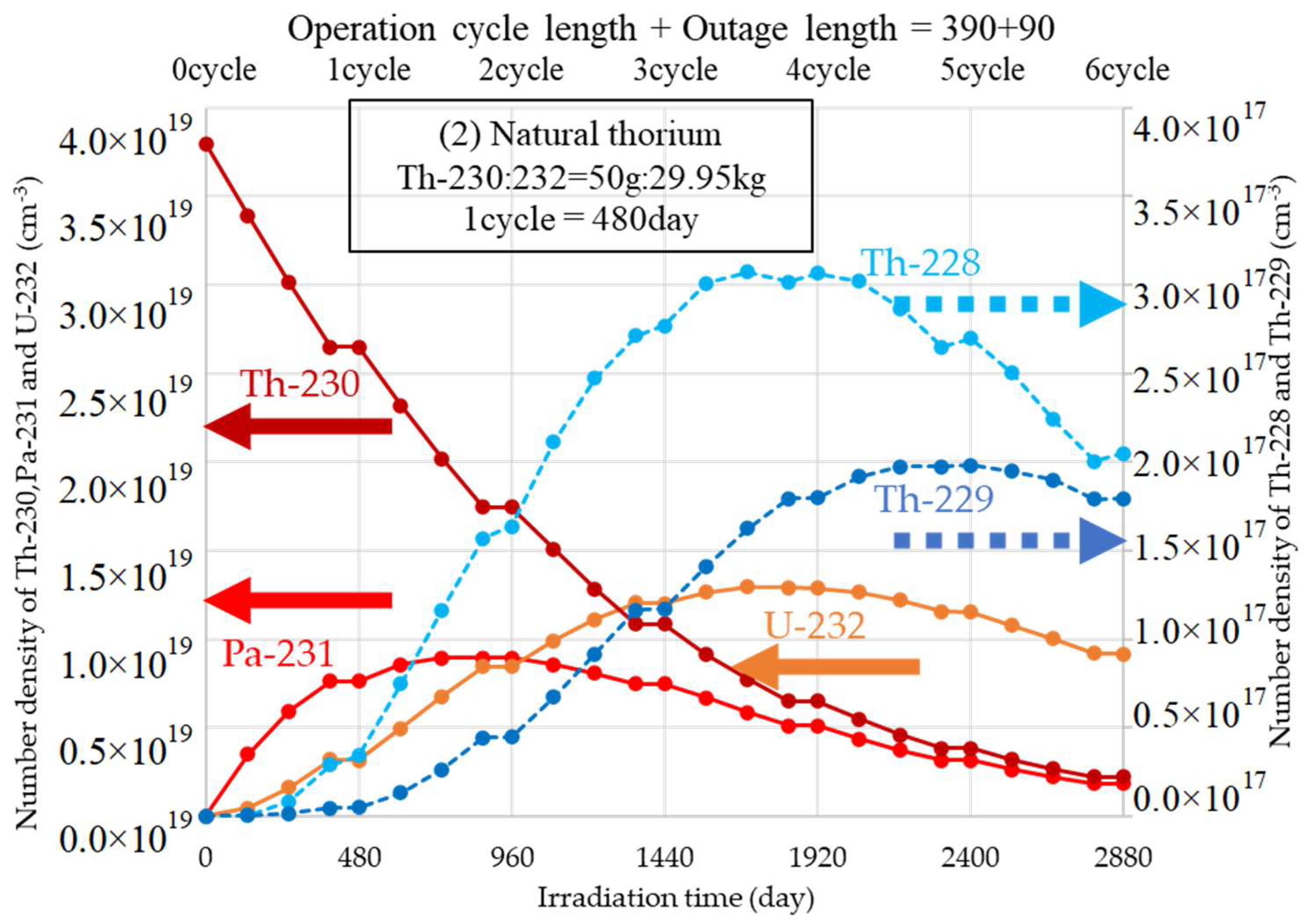

4.2. Th-229 Production by Natural Thorium Target Irradiation (Case 2)

The composition changes in major nuclides and Th-229 activity upon the irradiation of the natural thorium target for six cycles (approximately 8 years) are shown in

Figure 11 and

Figure 12. Irradiation of 30 kg of the Th-230 + Th-232 target containing 50 g of Th-230 loaded for five cycles (approximately 6 years) resulted in the maximum Th-229 production (approximately 2100 MBq). Approximately 41 MBq/g of Th-229 was produced per Th-230 weight of the Th-230 + Th-232 target.

In the Th-229 production path, Th-230 absorbs neutrons to produce Pa-231, which again absorbs neutrons to produce U-232. It α-decays with a half-life of 68.9 years, and the resulting Th-228 continues to accumulate even during reactor shutdown, and further neutron absorption produces Th-229.

Cyclic chain-constituting Pa-231 and U-232 gradually accumulate in the (n,γ) reaction, from which Th-228 produced by α-decay also accumulates, gradually accelerating the rate of Th-229 production. However, the production of Pa-231, U-232, and Th-228 also decreases with the decrease in Th-230, which is the target nuclide for irradiation, and Th-229 also decreases upon its neutron absorption reaction when a sufficient amount is accumulated. In addition, Th-229 is produced by the α-decay of U-233, obtained from the neutron irradiation of Th-232, and the half-life of U-233 is very long (approximately 160,000 years); thus, its effect on the amount of Th-229 produced was small.

Figure 12 shows the irradiation results for the natural thorium target with an accelerated Th-229 production by cyclic chain and pure Ra-226 target with a constant rate of Th-229 accumulation.

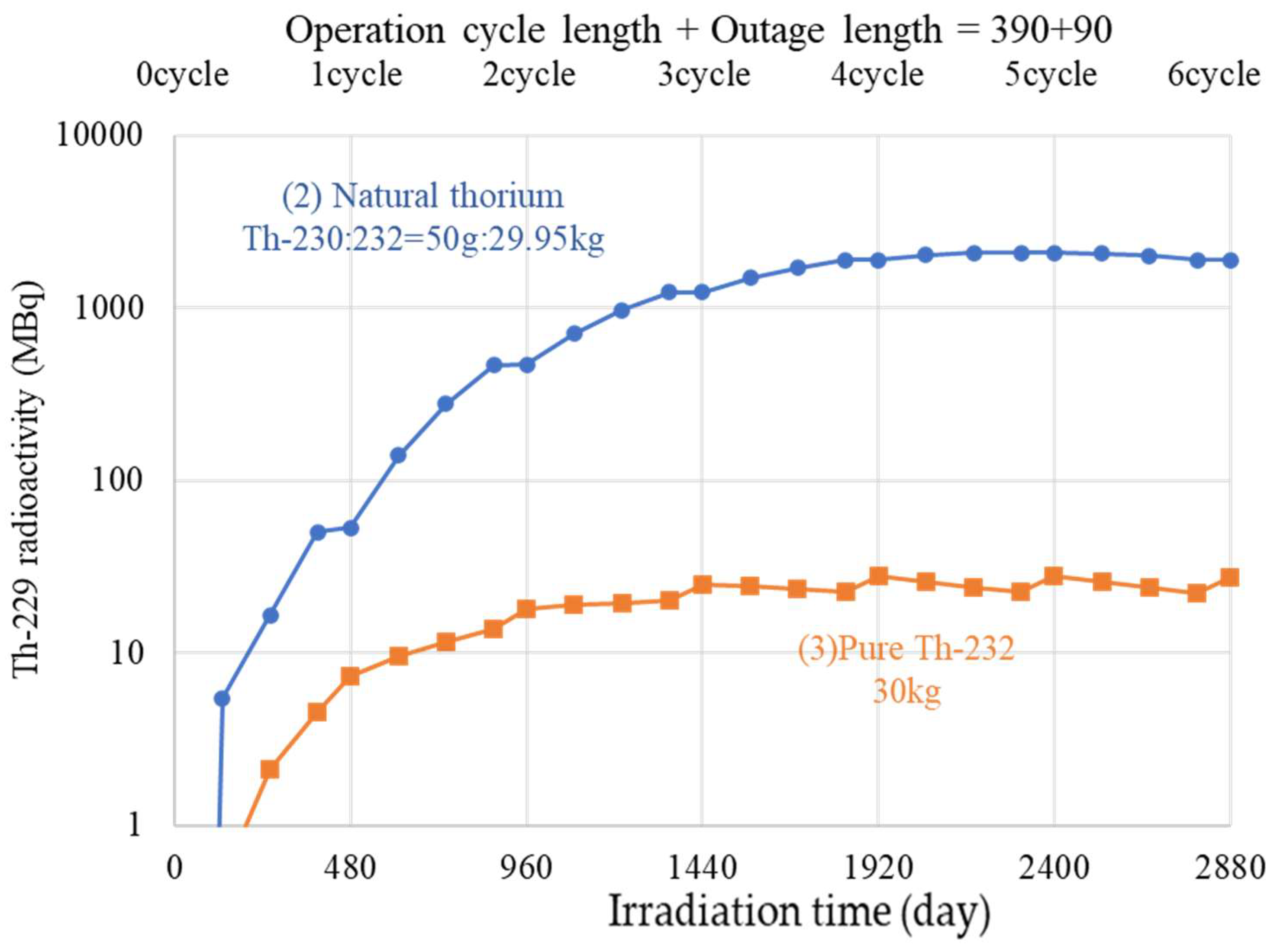

4.3. Contribution of Pure Th-232 (Case 3)

The natural thorium target contained a mixture of Th-230 and Th-232. Therefore, to investigate the contribution of Th-232 to Th-229 production, we analyzed the case of an irradiated target loaded with pure Th-232 (case 3). The results of pure Th-232 irradiation are shown in

Figure 13.

In the case of irradiation of 30 kg of pure Th-232, the maximum production of Th-229 was approximately 28 MBq, which is approximately 1.3% of that obtained from the natural thorium. After 1500 days, Th-229 decreased during irradiation and increased during reactor shutdown. The decrease in Th-229 during irradiation is because the amount of Th-229 that decreases due to neutron absorption was larger than the amount produced by the α-decay of U-233. The only production path for Th-232 as an irradiation target was via U-233, but the amount of Th-229 produced was very small because the half-life of U-233 is very long (approximately 160,000 years); thus, a small Th-232 fraction in the target nuclide is desirable.

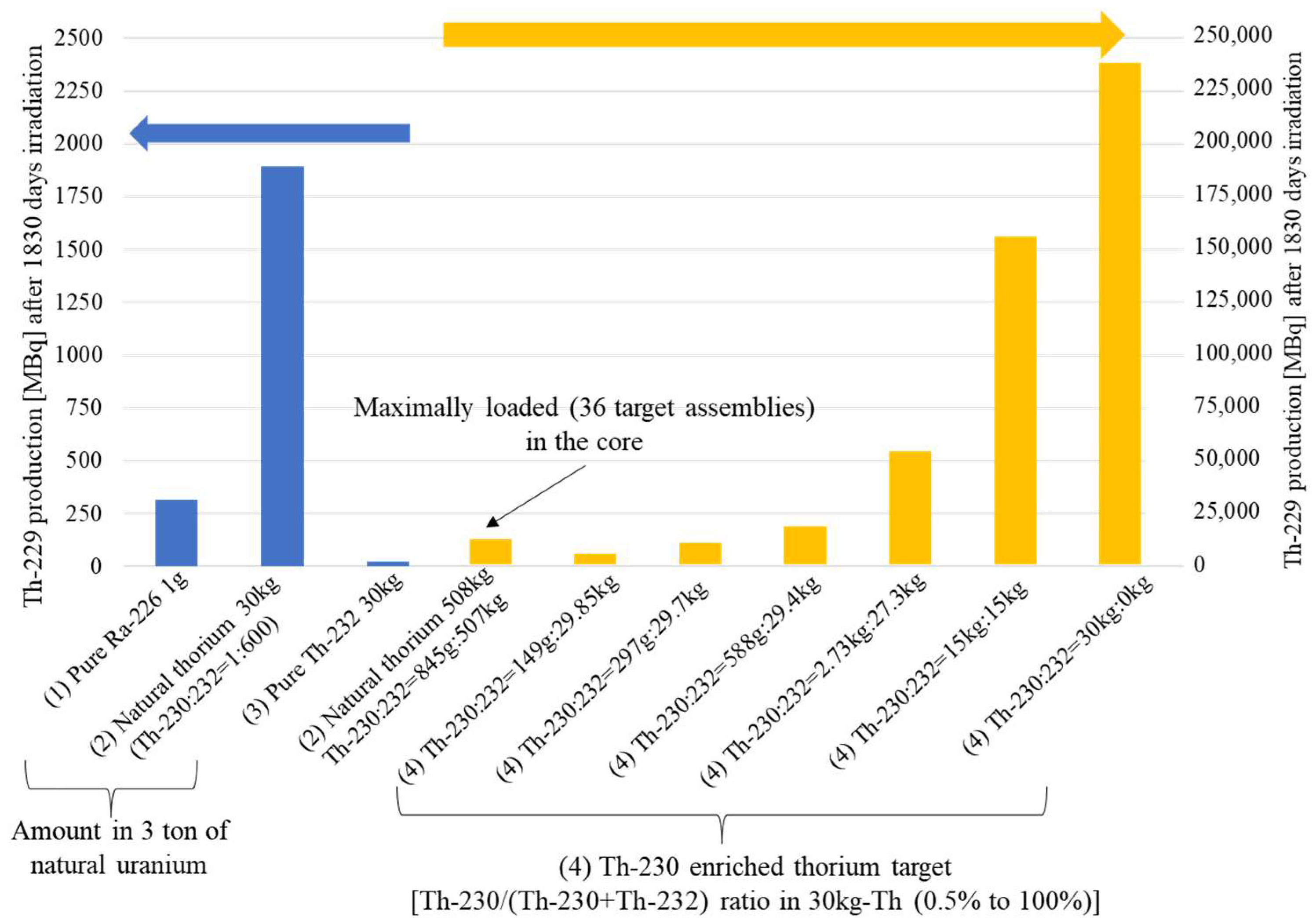

4.4. Th-229 Production with Enriched Thorium (Case 4)

As described in

Section 4.3, a high Th-230 ratio is desirable for Th-229 production. Therefore, we evaluated the amount of Th-229 produced when the Th-230 isotope ratio becomes 100% upon Th-230 isotope enrichment, assuming that the irradiation conditions (thorium loading and geometry) of the target were the same as those of the Th-230 + Th-232 target.

The total Th-229 production and the Th-229 production per gram of Th-230 loading are shown in

Figure 14. The results showed that enriching Th-230 improved the production of Th-229 but decreased the amount of Th-229 produced per gram. This is because the enrichment of Th-230, which has a large absorption cross-section, reduces its absorption efficiency due to the self-shielding effect. The black circled area is the result of the natural thorium target.

The heat generation of pure Th-230 upon neutron irradiation is shown in

Figure 15. In the case of the enrichment to 100% Th-230 composition, after two cycles (870 days) of irradiation, the amount of heat generated exceeded that of the natural thorium target with the Th-230 ratio of 1/600. Therefore, even if pure Th-230 is prepared, the amount of Th-229 that can be produced at the time its heat generation exceeds natural thorium (two-cycle irradiation) is approximately 40 GBq. In the case of pure Th-230 irradiation, the main power source is U-232, which accounts for approximately 70% of the total power.

4.5. Maximization of Ac-225 Production by Optimizing Milking Interval

The target nuclide Ac-225 is produced by the α-decay of Th-229 and the β-decay of Ra-225, so the optimal interval was investigated for milking Ac-225 from these nuclides. The amount of Ac-225 that can be milked from Th-229 specific activity produced by neutron irradiation of the pure Ra-226 and natural thorium targets is shown in

Figure 16.

Th-229 and Ra-225 quickly reach a permanent equilibrium after being removed from the reactor, so it is efficient to milk radium from thorium at an interval of 52.5 days when Ra-225 reaches 90% of the equilibrium amount.

The separated Ra-225 is halved in 15 days by β-decay to produce Ac-225, and Ac-225 is halved in 10 days, so the maximum amount of Ac-225 is reached in approximately 17.5 days owing to the balance between their half-lives. Therefore, it is appropriate to perform Th/Ra separation at 52.5-day intervals and Ra/Ac separation three rounds at 17.5-day intervals to recover Ac-225. In addition, every 52.5 days, it is possible to recover pure Ac-225 produced from Th-229 as well as Ra-225. By optimizing the milking interval in consideration of the half-life of each radionuclide, Ac-225 with approximately 11-times more radioactivity than Th-229 can be retrieved in one year.

Approximately 350 MBq of Th-229 is produced from the pure Ra-226 target, and 2100 MBq of Th-229 is produced from the natural thorium target, so approximately 4 GBq and 23 GBq of Ac-225 can be milked annually, respectively.

4.6. Reactivity Effects by Target Loading

To evaluate the reactivity effects of loading the natural thorium target into the core, effective multiplication factors were calculated for the initial burnup and after one cycle of irradiation. The analysis condition was set to load one natural thorium target in the center of the 3 × 3 assembly. Assume that natural thorium targets are loaded in one of the nine assemblies and have no effect on criticality. In that case, loading natural thorium targets in two of the 193 assemblies in the core does not affect the criticality of the reactor. The effect of irradiated target loading on reactivity is shown in

Table 8.

In the case of 14.1 kg of natural thorium target-loading in the center of the 3 × 3 assembly, the reactivity was affected by approximately −0.6% at the beginning of the burnup cycle and −0.8% at the end of the cycle. The loading of 1 g of the pure Ra-226 target had almost no effect on the reactivity: only approximately −0.02% at the beginning of the burnup cycle and approximately 0% at the end of the burnup cycle.

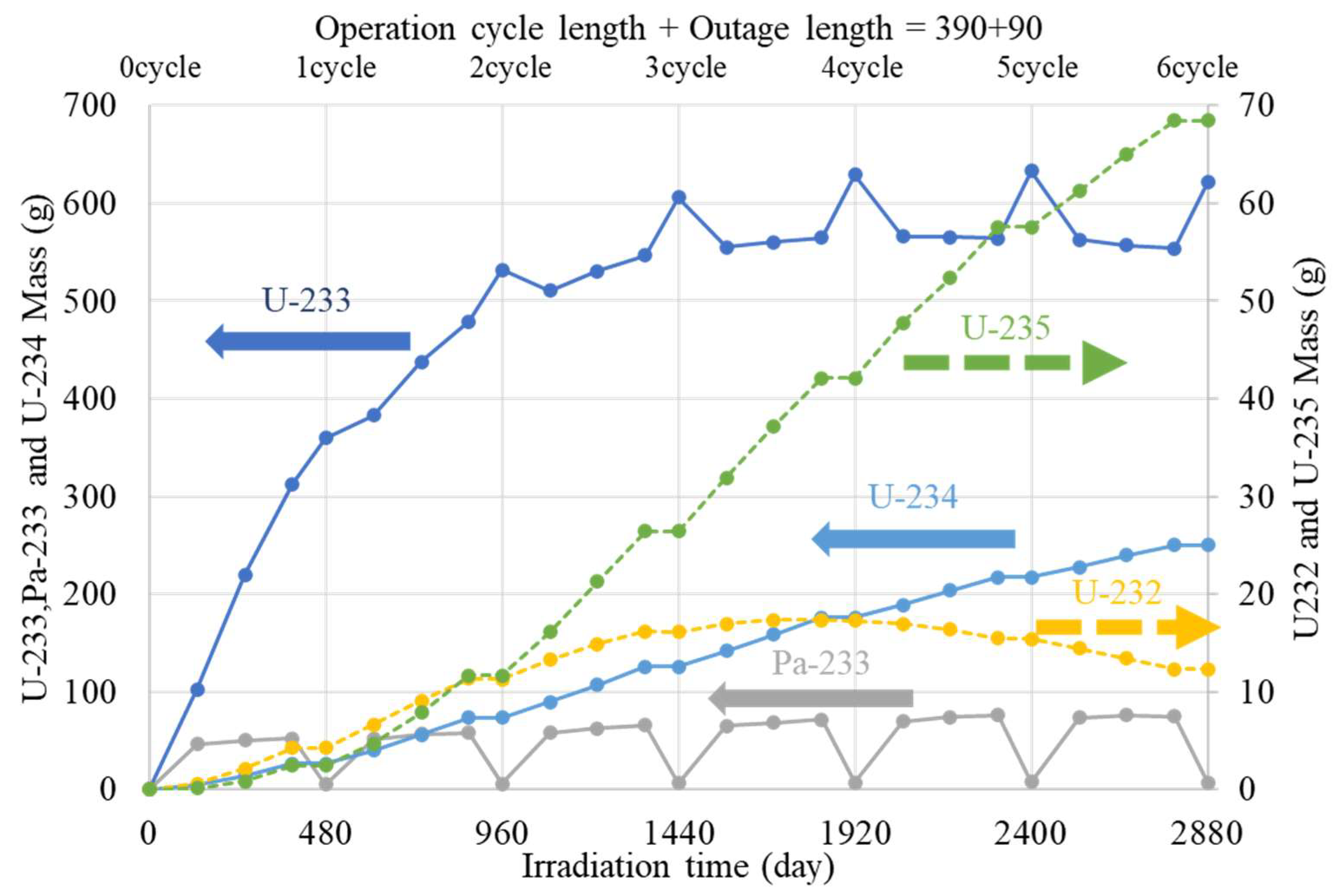

4.7. Evaluation of U-233 Production

U-233 was produced from Th-232 upon one (n,γ) reaction and two β-decays when the Th-230 + Th-232 target was irradiated.

Figure 17 shows the amount of U-233 production.

The maximum amount of U-233 produced per 30 kg of the Th-230 + Th-232 target was approximately 600 g. Since the significant amount (SQ) of U-233 as defined in IAEA safeguards is 8 kg [

22], the amount of U-233 produced per 30 kg of the natural thorium was less than 10% of the SQ values. The absorption cross-section (σa + σf) of U-233 is approximately 577 barn [

23], which is larger than the production cross-section (σa) of Th-232 (approximately 7.338 barn [

23]), so the amount of U-233 production reached its peak after approximately 2000 days of the irradiation period. The increase in U-233 found in the cooling period is due to the β-decay of Pa-233, which has a half-life of approximately 27 days.

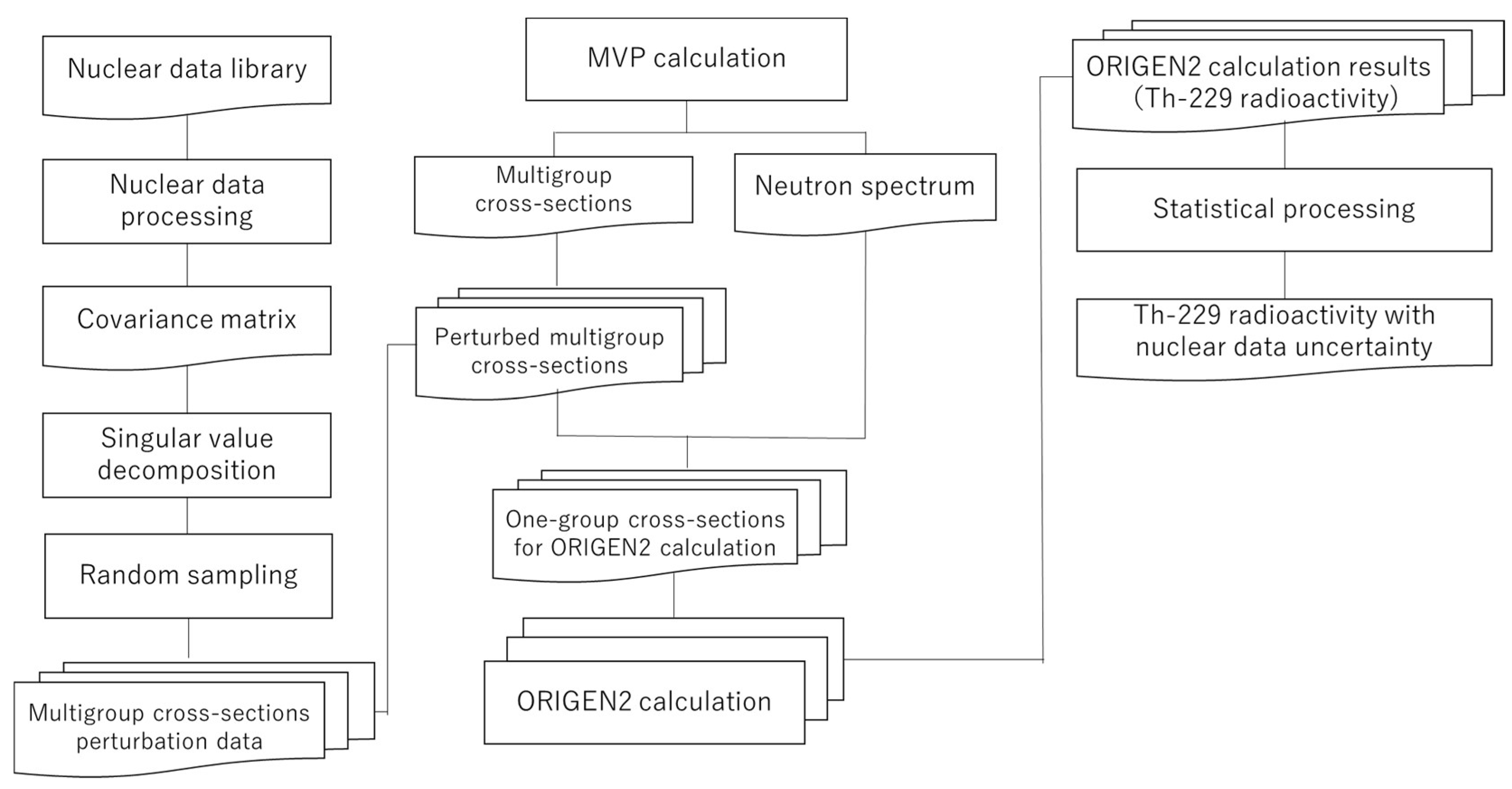

4.8. Th-229 Production Evaluation Considering Nuclear Data Uncertainty

Nuclear data such as capture cross-sections and fission cross-sections are used to calculate nuclear reactions. It contains uncertainty, and covariance data are being developed to represent this uncertainty. Therefore, the effect of nuclear data uncertainty on Th-229 production was evaluated using the random sampling method [

24]. The evaluation flow is shown in

Figure 18.

First, the nuclear data library was processed to obtain the covariance matrix. The covariance matrix was decomposed to obtain singular values and vectors, and using these and normal random numbers, perturbations of the cross-sections of 1000 patterns were obtained. Next, the microscopic cross-sections of the irradiated target were obtained using the MVP. The obtained microscopic cross-sections and perturbations were used to create 1000 patterns of one group cross-sections for ORIGEN2 calculations, and 1000 calculations were performed. The uncertainty was estimated by statistically processed several different Th-229 production quantities.

Since no covariance data for Ra-226 exist in JENDL-4.0 [

23] but for Th-230 and nuclides included in the production path, uncertainty evaluation was performed for the natural thorium target. The nuclear data considered for uncertainty evaluation included the capture cross-sections, fission cross-sections, and (n,2n) reaction cross-sections for Th-228, 229, 230, 232, Pa-231, U-232, and 233 nuclides in the Th-229 production path. Taking these nuclear data uncertainties into account, the calculation for the Th-230 + Th-232 target was evaluated to have an uncertainty of approximately 11% in the Th-229 production after six cycles of irradiation. In addition, Sasaki et al. performed an uncertainty analysis of Ra-225 production when Ra-226 was irradiated with fast neutrons using Joyo [

25], and the uncertainty of Ra-225 production was evaluated to be 40%. In our study, the uncertainty analysis was performed considering only the uncertainty of nuclear data, whereas Sasaki et al. performed the analysis considering the uncertainty of the neutron spectra in addition to the nuclear data, which explains the reason for the large uncertainty. Sasaki et al. also conducted their uncertainty evaluation using the covariance data of Ra-226, which were not published but were obtained originally from the measured data and other sources.

4.9. Analysis for Full Core Configuration

To evaluate Ac-225 production per PWR, Ac-225 production was evaluated under the maximum loading of natural thorium targets in the full core. As for core conditions, an equilibrium core loading pattern of 193 fuel assemblies operated in three batches was assumed with one cycle of 390 days and an outage length of 90 days. Two types of fuel compositions were used: 4.1 wt% enriched UO

2 fuel and 8 wt% enriched Gd-doped fuel. The fuel composition of the assemblies in each batch was obtained from the burnup analysis of one assembly. For chemical shim control, the boric acid concentration was adjusted in the range of 300–1200 ppm depending on the burnup. The number of target assemblies was 36 out of 193 fuel assemblies in the core, satisfying two conditions: (1) target assemblies were equipped with a plugging device without loading control rods, and (2) target assemblies were not adjacent to each other and could be arranged symmetrically. The loading positions of the target assemblies are shown in

Figure 19.

In the case of the maximum loading of natural thorium targets, 24 (pins/assembly) × 36 (assembles/core) = 864 target pins per core were used, so the total weight of thorium oxide was approximately 577 kg according to the 1:600 ratio mentioned above, the weight of Th-230 was approximately 845 g, and the weight of Th-232 was approximately 507 kg. Notably, oxygen constituted the remaining weight. In the case of irradiation with the maximum loading of the natural thorium targets in the full core, approximately 12 GBq of Th-229 was produced after four cycles (approximately 5 years) of irradiation, and approximately 130 GBq of Ac-225 could be milked annually.

Figure 20 shows the Th-229 production when the maximum amount of natural thorium was loaded into the core in addition to each of the previous cases.

The reactivity effects, Doppler coefficients, and void coefficients for the maximum loading of the natural thorium targets in the core are shown in

Table 9,

Table 10 and

Table 11. As for the reactivity effect, it was approximately −0.3%dk/kk′ through one cycle of irradiation. The Doppler coefficient decreased by approximately 9% at the end of the burnup period, and the void coefficient decreased by approximately 2% in the early burnup period, indicating the slight effect of loading. These results indicate a negligible effect of loading approximately 600 kg of thorium oxide in 36 assemblies on the safety factor.

4.10. Methods for Semi-Permanent Mass Production of Ac-225

As a result of the study of target nuclides for Ac-225 production using nuclides contained in 3 tons of natural uranium, it was found that approximately 4 GBq of Ac-225 can be produced annually from (1) pure Ra-226 target (1 g) and approximately 23 GBq from (2) natural thorium target (30 kg). On the other hand, since the current world supply of Ac-225 is 63 GBq per year, 16 g of Ra-226 (equivalent to approximately 48 tons of natural uranium) or 80 kg (equivalent to approximately 8 tons of natural uranium) of natural thorium target (Th-230:232 = 1:600) would be required to produce the same amount of Ac-225.

Ac-225 was shown to be effective in the treatment of castration-resistant prostate cancer [

1,

2,

3], and it is expected that labeling Ac-225 with ligands for various cancer cells can enable its use in the treatment of other cancers. According to the National Cancer Center, approximately 400,000 people die annually from cancer in Japan [

26]. Therefore, the demand for Ac-225 for cancer treatment is expected to grow in the future. Therefore, we will consider a method to produce Ac-225 therapeutics for 100,000 people, which is 1/4 of the annual number of deaths due to cancer.

Cancer treatment requires 40 MBq of Ac-225 per patient (4 TBq of Ac-225 per year). To meet the domestic demand, 8 TBq of Ac-225 per year must be generated, assuming a 50% loss in milking, transportation process, etc. Based on the analysis results in

Section 4.9, approximately 130 GBq of Ac-225 can be produced by loading approximately 507 kg of the natural thorium target in the full core and irradiating it for four cycles (approximately 5 years). To produce 8 TBq of Ac-225, it is necessary to use approximately 31 tons of natural thorium targets, which is approximately 60-times the amount (equivalent to 60 PWRs). If that amount is available, it is possible to milk 8 TBq of Ac-225 per year by irradiating PWRs for 5 years. Since there are 23 PWRs in Japan, if all the power plants can be utilized, it is expected that Ac-225 can be produced to meet the domestic demand in Japan in three 5-year irradiation cycles (approximately 15 years). Incidentally, the PWRs assumed for irradiation target loading in this study are large reactor of 3000 MWth or more, and the same amount of Ac-225 can be generated using a smaller reactor if a small amount is loaded. However, the amount of Ac-225 produced per PWR is assumed to decrease in the case of maximum irradiation target loading. It is because the amount of irradiation target that can be loaded in the core is small and the power density is small, so the neutron fluence is reduced.

In the case of irradiating a 31-ton natural thorium target, approximately 600 kg of U-233, which exceeds the significant quantity values, will be produced as a byproduct, so it is necessary to either reduce the amount produced by enriching Th-230 or mix U-233 into a normal fuel assembly for consumption as fuel once it is extracted.

5. Conclusions

Th-229 was produced upon a single long-term irradiation of Ra-226 or Th-230 + Th-232 using PWR, followed by the semi-permanent mass production of Ac-225. In addition to the well-known and valuable Ra-226 as a target nuclide to produce Ac-225, the more abundant Th-230 was considered as an alternative target nuclide. However, natural uranium also contains thorium ore, so when thorium targets were used, Th-230 and the stable nuclide Th-232 were mixed. Even when the uranium ore with low thorium content was used, the ratio of Th-230 to Th-232 was 1:600. The irradiation of the target nuclide generated Th-229 and then semi-permanently generated Ac-225. Four cycles (approximately 5 years) of irradiation of the pure Ra-226 target (case 1) can be used to produce approximately 3 GBq of Ac-225 per year semi-permanently. In addition, the natural thorium target (case 2) can be used as an alternative target to Ra-226 owing to its abundance, producing approximately 21 GBq of Ac-225 per year after four cycles (approximately 5 years) of irradiation.

The reactivity effects of loading irradiation targets were evaluated, and it was confirmed that loading the pure Ra-226 and natural thorium targets did not significantly affect the criticality.

The neutron irradiation of the natural thorium target also produces the special fissionable material U-233. However, the amount of U-233 produced is very small, approximately 2% of the target loading amount. In addition, enriched thorium (case 3) can be used to improve the Th-229 production rate and reduce the U-233 production rate.

The maximum amount (507 kg) of the natural thorium target can be loaded in PWR and irradiated for approximately 5 years to produce more than twice the current world supply of Ac-225 annually. Therefore, the PWR irradiation method using natural thorium as the target nuclide is considered effective.

In the case of pure Ra-226, only 16 g of Ra-226 was needed to produce Ac-225 semi-permanently, which is equivalent to the current world supply. Thus, its irradiation and milking are easier than those of the natural thorium target.

These results will greatly contribute to the research and development of targeted alpha therapy and its application in medicine, which has been stalled due to limited supply.

To efficiently produce Ac-225, it is necessary to irradiate the irradiation target for a long period of approximately 5 years. However, since the fuel assemblies in commercial PWRs are replaced after approximately 3 years, it is necessary to consider methods such as loading only the fuel assembly loaded with the irradiation target in the reactor for a long period or replacing the irradiation target with a different fuel assembly.

Author Contributions

Conceptualization, D.I., Y.S., T.S. and N.T.; methodology, D.I., Y.S., T.S. and N.T.; formal analysis, D.I. and T.S.; writing—original draft preparation, D.I.; writing—review and editing, N.T.; supervision, N.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Acknowledgments

This research includes some of the results of the Ministry of Education, Culture, Sports, Science, and Technology of Japan National Project for Medical RI production using domestic nuclear infrastructures for self-sufficient supply.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Azorín-Vega, E.; Rojas-Calderón, E.; Ferro-Flores, G.; Aranda-Lara, L.; Jiménez-Mancilla, N.; Nava-Cabrera, M.A. Assessment of the radiation absorbed dose produced by 177Lu-iPSMA, 225Ac-iPSMA and 223RaCl2 to prostate cancer cell nuclei in a bone microenvironment model. Appl. Radiat. Isot. 2019, 146, 66–71. [Google Scholar] [CrossRef] [PubMed]

- Miederer, M.; Scheinberg, D.A.; McDevitt, M.R. Realizing the potential of the actinium-225 radionuclide generator in targeted alpha-particle therapy applications. Adv. Drug Deliv. Rev. 2008, 60, 1371–1382. [Google Scholar] [CrossRef] [PubMed]

- Nelson, B.J.B.; Andersson, J.D.; Wuest, F. Targeted alpha therapy: Progress in radionuclide production, radiochemistry, and applications. Pharmaceutics 2020, 13, 49. [Google Scholar] [CrossRef] [PubMed]

- Robertson, A.K.H.; Ramogida, C.F.; Schaffer, P.; Radchenko, V. Development of 225Ac radiopharmaceuticals: TRIUMF perspectives and experiences. Curr. Radiopharm. 2018, 11, 156–172. [Google Scholar] [CrossRef] [PubMed]

- Garland, M. United States Department of Energy production of actinium-225 from thorium-229. In Proceedings of the Report on Joint IAEA-Jrc Workshop “Supply of Actinium-225”, Vienna, Austria, 9 October 2018. [Google Scholar]

- Nerozin, N.A.; Khamianov, S.V.; Shapovalov, V.V.; Tkachev, S.V. Current status and perspective of actinium-225 production at JSC “SSC RF—IPPE”. In Proceedings of the Report on Joint IAEA-Jrc Workshop “Supply of Actinium-225”, Vienna, Austria, 9 October 2018. [Google Scholar]

- Starovoitova, V.N.; Grimm, T.L.; Grimm, A.K.; Peters, W.C.; Zamiara, M.A. High-Purity Ac-225 production from Ra-226 using a superconducting electron linac. In Proceedings of the Report on Joint IAEA-Jrc Workshop “Supply of Actinium-225”, Vienna, Austria, 9 October 2018. [Google Scholar]

- Chemerisov, S.; Nolen, J.; Song, J.; Rotsch, D.; Brown, A.; Hafidi, K. Photonuclear capabilities at Argonne National Laboratory. In Proceedings of the Report on Joint IAEA-Jrc Workshop “Supply of Actinium-225”, Vienna, Austria, 9 October 2018. [Google Scholar]

- Zhuikov, B.L.; Ermolaev, S.V.; Lapshina, E.V.; Vasiliev, A.N.; Kobtsev, A.A. Production of Ac-225 from Th-232 metallic targets on 160 MeV proton beam at Institute for Nuclear Research (Moscow-Troitsk). In Proceedings of the Report on Joint IAEA-Jrc Workshop “Supply of Actinium-225”, Vienna, Austria, 9 October 2018. [Google Scholar]

- Pozzi, O.R.; Alpha Project. Argentina project for developing production of Ac-225 and Bi-213 and corresponding radiopharmaceuticals for targeted therapy. In Proceedings of the Report on Joint IAEA-Jrc Workshop “Supply of Actinium-225”, Vienna, Austria, 9 October 2018. [Google Scholar]

- Higashi, T.; Nagatsu, K.; Tsuji, A.B.; Zhang, M.-R. Research and Development for cyclotron production of 225Ac from 226Ra—The challenges in a country lacking natural resources for medical applications. Processes 2022, 10, 1215. [Google Scholar] [CrossRef]

- Susan, H.; Rose, A.B.; Karen, M.; David, D.; Allison, O.; Tamara, J.H.; Marc, G.; Saed, M. Reactor production of thorium-229. Applied radiation and isotopes. Appl. Radiat. Isot. 2016, 114, 19–27. [Google Scholar]

- Iwahashi, D.; Kawamoto, K.; Sasaki, Y.; Takaki, N. Neutronic study on ac-225 production for cancer therapy by (n,2n) reaction of ra-226 or th-230 using fast reactor joyo. Processes 2022, 10, 1239. [Google Scholar] [CrossRef]

- Nagatsu, K.; Suzuki, H.; Fukada, M.; Ito, T.; Ichinose, J.; Honda, Y.; Minegishi, K.; Higashi, T.; Zhang, M.R. Cyclotron production of 225Ac from an electroplated 226Ra target. Eur. J. Nucl. Med. Mol. Imaging 2021, 49, 279–289. [Google Scholar] [CrossRef] [PubMed]

- Nihon Medi-Physics. Nihon Medi-Physics Attains World’s First Manufacturing of Actinium-225 with Cyclotron on Production Scale for Investigational Drugs. Available online: https://www.nmp.co.jp/sites/default/files/public/en/press_release/20220405_newsrelease_ac225_e.pdf (accessed on 15 December 2023).

- WWW Chart of the Nuclides. 2014. Available online: https://wwwndc.jaea.go.jp/CN14/index.html (accessed on 19 February 2023).

- Takaki, N.; Takezawa, H.; Iwahashi, D.; Kawamoto, K.; Sasaki, Y. Actinium-225 Production Method. Japan Patent JP2022062962A. Available online: https://patents.google.com/patent/JP2022062962A/ja (accessed on 19 February 2023). (In Japanese).

- Takada, M.; Kobashi, A.; Sato, J.; Saito, N. Uranium and thorium content in phosphate ores and radiation equilibrium of uranium-series nuclides. Radioisotopes 1987, 36, 213–220. (In Japanese) [Google Scholar] [CrossRef] [PubMed][Green Version]

- Nagaya, Y.; Okumura, K.; Sakurai, T.; Mori, T. MVP/GMVP Version 3: General Purpose Monte Carlo Codes for Neutron and Photon Transport Calculations Based on Continuous Energy and Multigroup Methods (No. JAEA-Data/Code 2016-018); Japan Atomic Energy Agency: Tokai, Japan, 2017.[Green Version]

- Croff, A.G. User’s Manual for the ORIGEN2 Computer Code (No. ORNL/TM—7175); Oak Ridge National Lab.: Oak Ridge, TN, USA, 1980.[Green Version]

- Nuclear Safety Research Association. Keisuironenryounohurumai (Behavior of Light Water Reactor Fuel), 4th ed.; Nuclear Safety Research Association: Tokyo, Japan, 1998. [Google Scholar][Green Version]

- International Atomic Energy Agency. IAEA Safeguards Glossary, 2022nd ed.; International Atomic Energy Agency: Vienna, Austria, 2022; Available online: https://www-pub.iaea.org/MTCD/publications/PDF/PUB2003_web.pdf (accessed on 19 February 2023).[Green Version]

- Shibata, K.; Iwamoto, O.; Nakagawa, T.; Iwamoto, N.; Ichihara, A.; Kunieda, S.; Chiba, S.; Furutaka, K.; Otuka, N.; Ohsawa, T.; et al. JENDL-4.0: A new library for nuclear science and engineering. J. Nucl. Sci. Technol. 2011, 48, 1–30. [Google Scholar] [CrossRef]

- Stover, T.E., Jr. Quantification of Back-End Nuclear Fuel Cycle Metrics Uncertainties Due to Cross Sections; Idaho National Lab. (INL): Idaho Falls, ID, USA, 2007. [CrossRef][Green Version]

- Sasaki, Y.; Sano, A.; Sasaki, S.; Iwamoto, N.; Ouchi, K.; Kitatsuji, Y.; Takaki, N.; Maeda, S. Evaluation of the production amount of 225Ac and its uncertainty through the 226Ra(n,2n) reaction in the experimental fast reactor Joyo. J. Nucl. Sci. Technol. 2023, 1–12. [Google Scholar] [CrossRef]

- National Cancer Center Japan. Available online: https://epi.ncc.go.jp/paf/evaluation/7956.html (accessed on 30 July 2023).

Figure 1.

Th-229 production nuclear transmutation path using the Ra-226 (3n,2β) method [

16].

Figure 1.

Th-229 production nuclear transmutation path using the Ra-226 (3n,2β) method [

16].

Figure 2.

Th-229 production nuclear transmutation path using the Th-230 (3n,α2β) method [

16].

Figure 2.

Th-229 production nuclear transmutation path using the Th-230 (3n,α2β) method [

16].

Figure 3.

Th-229 production nuclear transmutation paths using the Th-230 (3n,α2β) and Th-232(n, α2β) methods [

16].

Figure 3.

Th-229 production nuclear transmutation paths using the Th-230 (3n,α2β) and Th-232(n, α2β) methods [

16].

Figure 4.

Schematic view of the fuel assembly of PWR.

Figure 4.

Schematic view of the fuel assembly of PWR.

Figure 5.

Simplified view of the plugging device loaded with target nuclides.

Figure 5.

Simplified view of the plugging device loaded with target nuclides.

Figure 6.

Specific power in the case of (2) natural thorium irradiation.

Figure 6.

Specific power in the case of (2) natural thorium irradiation.

Figure 7.

Coolant velocity and target height that meet coolant outlet temperature and pressure loss limits for guide tubes loaded with target pins. (Left: Target pin radius of 0.2 cm, Right: Target pin radius of 0.3 cm).

Figure 7.

Coolant velocity and target height that meet coolant outlet temperature and pressure loss limits for guide tubes loaded with target pins. (Left: Target pin radius of 0.2 cm, Right: Target pin radius of 0.3 cm).

Figure 8.

Arrangement and cross-sectional view of the fuel assemblies loaded with the thorium target for three-dimensional Monte-Carlo calculations (drawn using MVP input data).

Figure 8.

Arrangement and cross-sectional view of the fuel assemblies loaded with the thorium target for three-dimensional Monte-Carlo calculations (drawn using MVP input data).

Figure 9.

Cross-sectional view of the fuel assemblies loaded with the radium target for three-dimensional Monte Carlo calculations (drawn using MVP input data).

Figure 9.

Cross-sectional view of the fuel assemblies loaded with the radium target for three-dimensional Monte Carlo calculations (drawn using MVP input data).

Figure 10.

Th-229 production in case 1 (Pure Ra-226 target).

Figure 10.

Th-229 production in case 1 (Pure Ra-226 target).

Figure 11.

Th-229 production in case 2 (natural thorium target).

Figure 11.

Th-229 production in case 2 (natural thorium target).

Figure 12.

Comparison of Th-229 production by irradiation in cases 1 and 2 (pure Ra-226 target and natural thorium target, respectively).

Figure 12.

Comparison of Th-229 production by irradiation in cases 1 and 2 (pure Ra-226 target and natural thorium target, respectively).

Figure 13.

Comparison of Th-229 production using natural thorium target (case 2) and pure Th-232 target (case 3).

Figure 13.

Comparison of Th-229 production using natural thorium target (case 2) and pure Th-232 target (case 3).

Figure 14.

Effects of Th-230 enrichment on Th-229 production efficiency (after 1830 days of irradiation).

Figure 14.

Effects of Th-230 enrichment on Th-229 production efficiency (after 1830 days of irradiation).

Figure 15.

Comparison of power density and Th-229 radioactivity of the enriched thorium (case 4) and natural thorium (case 2) targets.

Figure 15.

Comparison of power density and Th-229 radioactivity of the enriched thorium (case 4) and natural thorium (case 2) targets.

Figure 16.

Pure Ac-225 production obtained by the chemical separation of Th/Ra/Ac from 1 GBq of Th-229 with optimized milking interval.

Figure 16.

Pure Ac-225 production obtained by the chemical separation of Th/Ra/Ac from 1 GBq of Th-229 with optimized milking interval.

Figure 17.

Accumulation of U-233 in case 2 (natural thorium target) Th-230/Th-232 = 50 g/29.95 kg.

Figure 17.

Accumulation of U-233 in case 2 (natural thorium target) Th-230/Th-232 = 50 g/29.95 kg.

Figure 18.

Flowchart of Th-229 production error evaluation considering nuclear data uncertainty.

Figure 18.

Flowchart of Th-229 production error evaluation considering nuclear data uncertainty.

Figure 19.

Core configuration with maximum thorium target loading.

Figure 19.

Core configuration with maximum thorium target loading.

Figure 20.

Amount of Th-229 produced in various targets (after 1830 days of irradiation).

Figure 20.

Amount of Th-229 produced in various targets (after 1830 days of irradiation).

Table 1.

Composition of nuclides in the uranium series in 3 tons of natural uranium.

Table 1.

Composition of nuclides in the uranium series in 3 tons of natural uranium.

| Uranium Series |

|---|

| Nuclide | Amount (g) | Half-Life |

|---|

| U-238 | 2.98 × 106 | 4.47 × 109 years |

| U-234 | 1.61 × 102 | 2.46 × 105 years |

| Pa-234 | 6.51 × 10−10 | 6.70 h |

| Pa-234m | 1.44 × 10−9 | 1.16 min |

| Th-234 | 4.32 × 10−5 | 24.1 days |

| Th-230 | 4.86 × 10 | 7.54 × 104 years |

| Ra-226 | 1.01 | 1.60 × 103 years |

| Rn-222 | 6.51 × 10−6 | 3.82 days |

| Po-218 | 3.60 × 10−9 | 3.10 min |

| Po-214 | 3.12 × 10−15 | 1.64 × 10−4 s |

| Po-210 | 2.23 × 10−4 | 138 days |

| Bi-214 | 2.27 × 10−8 | 19.9 min |

| Bi-210 | 8.07 × 10−6 | 3.04 × 106 years |

| Pb-214 | 3.05 × 10−8 | 26.8 min |

| Pb-210 | 1.31 × 10−2 | 22.2 years |

| Pb-206 | 2.60 × 106 | Stable |

Table 2.

Thermal and hydraulic analysis conditions of the irradiation target.

Table 2.

Thermal and hydraulic analysis conditions of the irradiation target.

| Thorium target pin radius | 0.2 cm | 0.3 cm |

| Gap thickness (cm) | 0.01 |

| Cladding thickness (cm) | 0.065 |

| Width of coolant channel (cm) | 0.294 | 0.194 |

| Guide tube thickness (cm) | 0.041 |

| Effective height of reactor (cm) | 366 |

| Outlet coolant temperature (°C) | 325.35 |

| Coolant pressure (MPa) | 15.5 |

| Target power density (W/cm3) | 349.7 | 312.3 |

| Coolant heat transfer coefficient (W/m2K) | 3.824 × 104 | 4.142 × 104 |

Table 3.

Fuel assembly specifications.

Table 3.

Fuel assembly specifications.

| U-235 enrichment (wt%) | 4.1 |

| Fuel assembly type | 17 × 17 |

| Fuel pellet radius (cm) | 0.410 |

| Cladding radius (cm) | 0.475 |

| Instrumentation tube radius (cm) | 0.610 |

| Thickness (cm) | 0.041 |

| Control rod tube radius (cm) | 0.610 |

| Thickness (cm) | 0.041 |

| Fuel pin pitch (cm) | 1.260 |

| Core height (cm) | 366 |

| Assembly gap (cm) | 0.110 |

Table 4.

Main specifications [

21].

Table 4.

Main specifications [

21].

| Reactor Type | PWR |

|---|

| Thermal power (MWt) | 3411 |

| Number of fuel assemblies | 193 |

| U-235 enrichment (wt%) | 4.1 |

| Operation cycle length + Outage length (days) | 390 + 90 |

Table 5.

Analysis conditions for irradiating thorium target.

Table 5.

Analysis conditions for irradiating thorium target.

| Number of fuel assemblies | 8 |

| Number of fuel assemblies loaded with thorium target | 1 |

9 assemblies (above 8 fuel assemblies

+ thorium-loaded assembly) power (MWt) | 159 |

| Number of thorium target pins | 24 |

| Thorium target pin radius (cm) | 0.3 |

| Cladding radius (cm) | 0.365 |

| Thorium target pin height (cm) | 236 |

| Thorium target (ThO2) density (g/cm3) | 10 |

| Mass of thorium oxide target (kg) | 16 |

| Mass of thorium target isotopes (kg) | 14.1 |

| Th-230:Th-232 (mass ratio) | 1:600 |

| Mass of Th-230 (g) | 23 |

| Mass of Th-232 (kg) | 14.1 |

Table 6.

Analysis conditions for radium target irradiation.

Table 6.

Analysis conditions for radium target irradiation.

| Number of fuel assemblies | 8 |

| Number of fuel assembly loaded with the thorium target | 1 |

| Core (193 assemblies) power (MWt) | 3411 |

| 9 assemblies (above 8 fuel assemblies + thorium-loaded assembly) power (MWt) | 159 |

| Number of thorium target pins | 4 |

| Radium target pin radius (cm) | 0.1 |

| Cladding radius (cm) | 0.165 |

| Radium target pin height (cm) | 1.447 |

| Radium target (Ra) density (g/cm3) | 5.5 |

| Mass of radium target isotopes (g) | 1 |

Table 7.

Amount of target nuclides for the examined target cases.

Table 7.

Amount of target nuclides for the examined target cases.

| Cases | Nuclide Amounts | Comments |

|---|

| (1) Ra-226 | 1 g | 1 g of Ra-226 is contained in 3 tons of natural uranium. |

| (2) Natural thorium | Thorium (30 kg)

= Th-230 (50 g) +

Th-232 (29.95 kg)

(Th-230: Th-232 = 1:600) | 50 g of Th-230 is contained in 3 tons of natural uranium.

Uranium ore mined for mineralogical properties always contains thorium ore, so Th-230 and Th-232 are mixed.

It was assumed that an ore with a ratio of uranium ore to

thorium ore of 100:1 [18] would be used.

29.95 kg of Th-232 is contained in

3 tons of uranium and thorium ore.

The chemical form of the loaded thorium is oxide, and its amount is 34 kg. |

Thorium (508 kg)

= Th-230 (845 g) +

Th-232 (507 kg)

(Th-230: Th-232 = 1:600) | Maximum loading of natural thorium target in the PWR core

in the case of symmetrical arrangement

without adjoining control rods.

845 g of Th-230 and 507 kg of Th-232 were in

36 natural thorium target assemblies. |

| (3) Pure Th-232 | 30 kg | Analysis targeted pure Th-232 to assess the amount of Th-229 produced from Th-232. |

(4) Enriched

thorium | Thorium (30 kg)

= Th-230 (50 g–30 kg) + Th-232 (29.95 kg–0 kg) | Sensitivity analysis with Th-230 enrichment as a case for improvement of Th-229 generation efficiency. |

Table 8.

Effects of target loading on criticality.

Table 8.

Effects of target loading on criticality.

| Target | Reference | (1) Pure Ra-226 | (2) Natural Thorium |

|---|

| Mass of target isotopes (g) | - | 1 | 14,100 |

| k-eff (BOC) | 1.38229 | 1.38194 | 1.37176 |

| Target ρ (%dk/kk′)

| - | −0.01827 | −0.55538 |

| k-eff (EOC) | 1.15647 | 1.15646 | 1.14650 |

| Target ρ (%dk/kk′) | - | −0.00030 | −0.75180 |

Table 9.

Effects of the loading of 36 natural thorium target assemblies in the core on criticality.

Table 9.

Effects of the loading of 36 natural thorium target assemblies in the core on criticality.

| | BOC | EOC |

|---|

Without

Thorium | With

Thorium | Without

Thorium | With

Thorium |

|---|

| k-eff | 1.06264 | 1.05906 | 1.00116 | 0.99845 |

ρ(%dk/kk′)

(With thorium

− Without thorium) | −0.31811 | −0.27111 |

Table 10.

Effects of the loading of 36 natural thorium target assemblies in the core on doppler coefficient.

Table 10.

Effects of the loading of 36 natural thorium target assemblies in the core on doppler coefficient.

| | BOC | EOC |

|---|

Without

Thorium | With

Thorium | Without

Thorium | With

Thorium |

|---|

Doppler coefficient

(Δk/kk′/°C) | −2.39 × 10−5 | −2.44 × 10−5 | −1.91 × 10−5 | −2.09 × 10−5 |

Effect of thorium target loading on doppler coefficient (With thorium

− Without thorium) | −4.97 × 10−7 | −1.84 × 10−6 |

Table 11.

Effects of the loading of 36 natural thorium target assemblies in the core on void coefficient.

Table 11.

Effects of the loading of 36 natural thorium target assemblies in the core on void coefficient.

| | BOC | EOC |

|---|

Without

Thorium | With

Thorium | Without

Thorium | With

Thorium |

|---|

| Void coefficient(Δk/kk′/Void%) | −2.60 × 10−3 | −2.66 × 10−3 | −2.91 × 10−3 | −2.94 × 10−3 |

Effect of thorium target loading on void coefficient

(With thorium

− Without thorium) | −6.03 × 10−5 | −3.34 × 10−5 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).