Abstract

Hydrothermal carbonization (HTC) is a technology designed to improve the efficiency of bioenergy recovery by subjecting biomass to high-temperature and high-pressure conditions. By integrating this technical feature with anaerobic digestion (AD), enhanced energy recovery efficiency is achieved in treating anaerobic digestate (AD-T). The study investigates enhancing bioenergy recovery efficiency through an integrated process, combining AD of livestock manure and HTC. The primary objective is to improve the energy conversion efficiency of biomass characterized by varying solid contents and chemical compositions. Shortening the hydraulic retention time (HRT) in AD of livestock manure resulted in decreased degradation rate efficiency within the AD-T. This led to increased solid material accumulation, which was crucial for the subsequent HTC reaction. The HTC reaction exhibited its maximum bioenergy recovery at 160 °C. The input energy of the livestock manure, obtained by mixing pig slurry and feedlot cattle manure in a 1:1 (w/w) ratio, was 171,167 MJ/day. Under different HRT conditions (40, 30, and 20 days), recoverable energy from AD of livestock manure ranged from 60,336 to 68,517 MJ/ton. Integration of HTC increased net bioenergy recovery to 106,493 to 130,491 MJ/day under corresponding HRT conditions, highlighting the potential of integrating HTC with AD from livestock manure for enhanced bioenergy recovery efficiency.

1. Introduction

In 2020, the theoretical energy potential of livestock manure generated in the Republic of Korea was reported to be 1,705,306 TOE (tons of oil equivalent) per year [1]. The theoretical energy potential of livestock manure generated from cattle (beef and dairy cattle) has the largest share at 912,244 TOE per year (53.5%). The theoretical energy potentials of pig and chicken manure accounted for 426,565 TOE per year (25.0%) and 366,191 TOE per year (21.5%), respectively. Livestock manure, containing various nutrients such as nitrogen and phosphorus, is utilized as liquid fertilizer for soil through biological processes, where organic matter is decomposed into humus [2]. Additionally, technologies for recovering and reusing phosphorus, which is a limited resource present in livestock manure, have been reported [3]. However, if not properly treated before application to the soil, there is a risk of contaminating crops with heavy metals and antibiotics. This uncontrolled application can lead to soil and water pollution, posing negative consequences on both agricultural and aquatic ecosystems [4]. Therefore, there is a demand for energy conversion, such as biogas production, using anaerobic digestion (AD), in the field of livestock manure treatment, which has been predominantly occupied by the conventional livestock manure fertilizer method [5,6]. AD is a biological conversion technology where organic biomass, such as livestock manure, undergoes hydrolysis, acidogenesis, acetogenesis, and finally, methanogenesis stages, resulting in the ultimate conversion into biogas, including CH4 and CO2 [7,8]. However, as of 2021, there were only 110 AD facilities that produced biogas domestically, and among them, the number of facilities specifically for pig slurry (PS) anaerobic digestion was only approximately 8. Particularly, there is a complete absence of AD facilities for cattle (beef and dairy cattle) manure [9].

Livestock manure exhibits different characteristics in terms of composition depending on the type of livestock and the characteristics of the rearing facility. Generally, a slurry storage pit structure is used in pig farming. Pig manure is generated in a slurry state comprising a mixture of feces, urine, and wash water, with a total solid (TS) content of less than 5%. PS with a low organic matter content is advantageous for the wet AD technology commonly used in the Republic of Korea. However, the low methane productivity (approximately 10–15 Nm3-CH4/m3) resulting from low organic matter content poses a challenge to the economic viability of AD facilities [10,11]. Moreover, in the case of cattle (beef and dairy cattle), a barn structure utilizing sawdust as bedding material is commonly adopted. Manure from cattle (beef and dairy cattle), known as feedlot cattle manure (FCM), contains a significant amount of lignocellulosic material that is challenging to digest anaerobically. During the rearing period, FCM is generated in a solid form with a TS content of approximately 70%, owing to moisture evaporation. FCM exhibits high methane productivity, approximately 37–65 Nm3-CH4/m3) owing to its high solids content. However, there are challenges in directly applying FCM to the wet AD technology widely used in the Republic of Korea [12]. In particular, the sawdust included in FCM contains a significant number of lignocellulosic materials that pose challenges for AD. AD of FCM requires a prolonged hydraulic retention time (HRT), which leads to the generation of a substantial amount of anaerobic digestion sludge. This necessitates the establishment of a separate sludge treatment system [13,14]. Therefore, in the Republic of Korea, the diversification of livestock manure characteristics and the predominant adoption of wet AD technologies have posed challenges to the expansion of livestock manure energy facilities. Efforts are being made to address these technical issues by planning anaerobic co-digestion facilities for PS with food waste with high methane potential. However, challenges arise in the widespread implementation of anaerobic co-digestion facilities owing to regional differences in the generation of food waste and PS. Additionally, although efforts are underway to develop technologies for converting FCM into solid fuel through drying and carbonization processes, the high energy consumption during the drying phase has led to low energy conversion efficiency and limited commercialization owing to associated economic challenges [15,16].

Hydrothermal carbonization (HTC) technology is a thermochemical process that converts biomass into a coal-like material with a higher carbon content [17,18]. Furthermore, HTC is characterized by the ability to apply the process without separate drying of the feedstock and lower reaction temperatures when compared to carbonization and torrefaction [19,20]. The HTC process primarily involves a relatively simple closed-vessel reactor containing wet biomass. The HTC reactor was heated to 170–250 °C and maintained at a saturated vapor pressure that was formed in accordance with the given reaction temperature. During the HTC reaction of wet biomass, the hydrogen and oxygen contents of the feed material are reduced, and a solid phase (HTC-S), liquid phase (HTC-L), and a small amount of gas (mainly CO2) are produced [21,22]. These products are obtained via hydrolysis, dehydration, decarboxylation, polymerization, and aromatization [18,23]. HTC-S, referred to as biochar, can be easily separated owing to its dewatering properties and is utilized as a solid fuel with a high calorific value. The HTC hydrolysate (HTC-H) generated after HTC processing requires further treatment because it contains large amounts of soluble organic materials and ammonium nitrogen. Recently, AD has been preferred for HTC-L in terms of energy recovery efficiency from biomass. In particular, in the HTC reaction, organic matter is solubilized by the hydrolysis reaction, and the efficiency of AD can be improved [24,25]. Recently, research has been conducted on the energy conversion efficiency and feasibility of various low-grade biomasses, such as sewage sludge cake and spent grains, through the coupling of AD and HTC [26]. Therefore, in this study, a process system integrating the anaerobic co-digestion of PS and FCM, as well as the HTC of anaerobic digestate (AD-T), is proposed to enhance the energy conversion efficiency of biomass with varying solid contents and chemical composition characteristics. The material and energy balances for each unit process in the integrated system were analyzed to evaluate the energy conversion efficiency of the overall process.

2. Materials and Methods

2.1. Process Scheme

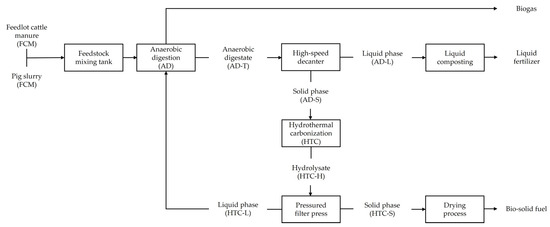

This study presents an integrated AD and HTC process system to produce biogas and solid fuel from PS and FCM, as shown in Figure 1. In the proposed process, PS with high moisture content and FCM with low moisture content were mixed to prepare mixed raw materials with a TS level of approximately 13%, and the mixed raw materials were introduced into an anaerobic digester. After AD, AD-T was separated into a liquid phase (AD-L) and a solid phase (AD-S) using a high-speed decanter. AD-L was used in the liquid composting process to produce liquid fertilizer, whereas AD-S was used in the HTC process. In the HTC process, organic matter is solubilized through a hydrolysis reaction of the residue that has not been decomposed in the anaerobic digester. Simultaneously, a material with high carbon density is produced through a carbonization reaction. In addition, the HTC-H flowing out from the HTC process is separated into the HTC-L and HTC-S using a pressure filter. Finally, HTC-L is used to produce biogas by reinputting it from entering the anaerobic digester, and HTC-S is produced as a bio-solid fuel through a drying process. In this integrated process, the drying process mechanically separates the HTC-S, yielding a solid material with a moisture content of approximately 35%. Subsequently, the drying process is employed to reduce the moisture content to around 10%, facilitating the utilization of the solid material as a solid fuel.

Figure 1.

Integrated process scheme of anaerobic digestion and hydrothermal carbonization.

2.2. Determination of Process Parameters

2.2.1. Anaerobic Digestion

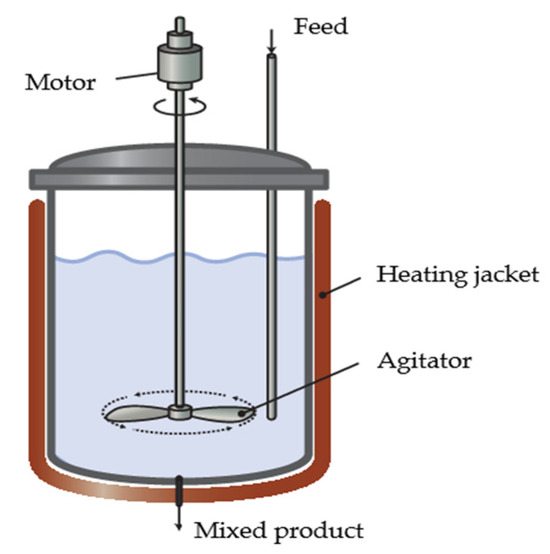

In this study, three continuous stirred tank reactor (CSTR)-type anaerobic reactors with HRTs of 40 (R1), 30 (R2), and 20 days (R3) were operated to derive factors for estimating the material and energy balances of the AD process in the integrated anaerobic co-digestion and HTC system proposed in this study. The form of the CSTR is configured, as shown in Figure 2, with components such as the motor, inlet, outlet ports, agitator, and heating jacket [27]. Each CSTR-type anaerobic reactor has a total volume of 7 L and an effective volume of 5 L. R1 (HRT of 40 days) was operated on for 72 days, R2 (HRT of 30 days) for 56 days, and R3 (HRT of 20 days) for 56 days. Inoculum was obtained from a farm-scale anaerobic digester with a daily capacity of 20 m3 located in Icheon City, Republic of Korea. The inoculum was subjected to mesophilic digestion conditions (38 °C) for 14 days, during which residual gases and organic matter were removed. The chemical properties of the inoculum are listed in Table 1. The anaerobic reactor with the introduced inoculum was fully sealed to maintain anaerobic conditions, and continuous stirring was conducted at a speed of 100 rpm. Subsequently, the temperature of the anaerobic reactor was increased under mesophilic digestion conditions. The feedstock for the anaerobic reactors was prepared by mixing PS and FCM in a 1:1 ratio (w/w), and the physical properties of the mixed feedstock are presented in Table 2. The prepared mixed feedstock was stored in refrigeration at 4 °C during the operation period of the anaerobic reactors. Prior to being introduced into the anaerobic reactors, the feedstock was stored at room temperature (20–25 °C) for 24 h. The input amounts of the mixed feedstock for the anaerobic reactors R1, R2, and R3 were 0.13, 0.17, and 0.25 L/day, respectively, with corresponding organic loading rates (OLRs) of 2.7, 3.7, and 5.5 kg-VS/m3/day. To ensure stable reactor operation during the operating period of the CSTR, the AD-T was sampled at regular intervals of 24 h, followed by the addition of the substrate. The biogas produced in the anaerobic reactor was collected by connecting a 10 L polyethylene gas bag (polyethylene).

Figure 2.

Schematic diagram of the continuous stirred tank reactor (CSTR).

Table 1.

Chemical properties of inoculum used in CSTR start-up.

Table 2.

Chemical properties of substrate used in the operation of CSTR.

2.2.2. Hydrothermal Carbonization

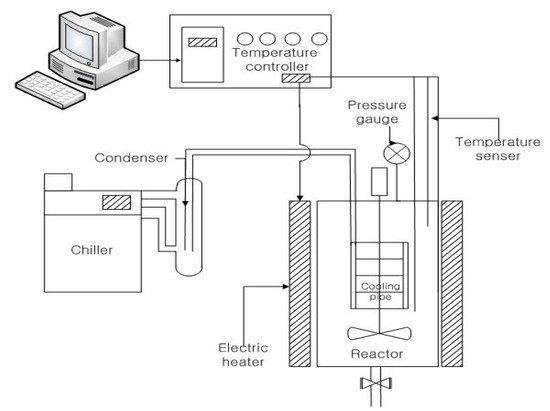

In this study, the feedstock for the HTC reactor operation was obtained from a continuous horizontal anaerobic reactor with a capacity of 100 L and operated with a 1:1 (w/w) mixture of PS and FCM. The anaerobic reactor operated under mesophilic conditions (38 °C) with an HRT of 30 days. The AD-T collected from this system was subjected to solid–liquid separation by centrifugation at 4000 rpm for 20 min to obtain a solid material (AD-S). AD-S was then used as the feedstock for the HTC reactor. To assess the energy yield from the AD-S at several HTC reaction temperatures, a batch-type HTC reactor was designed for the thermochemical treatment of the anaerobic sludge cake (Figure 3). The HTC reactor functions as a closed system, effectively minimizing the risk of heat loss through vaporization or condensation, ensuring precise control and accuracy in the experimental setup. The HTC reactor, with a designed operational capacity of 1.5 kg, featured essential components such as an electric heater, temperature sensor, and pressure gauge. Additionally, the reactor was outfitted with a heating coil. A pressure gauge and temperature sensor were inserted into the reactor to monitor the inner temperature and saturated vapor pressure during the HTC reaction [28]. For the HTC reaction, 1.5 kg of AD-S was placed directly without additional processing water and covered with an airtight sealant. The set temperatures were 160, 180, 200, and 220 °C. Once each temperature reached its set point, each HTC reactor was maintained at an iso-thermic condition for 60 min. The internal vapor pressures were then maintained at 1.0 MPa at 160 °C, 1.2 MPa at 180 °C, 1.8 MPa at 200 °C, and 2.5 MPa at 220 °C. After the HTC reaction, the reactor was cooled to room temperature (20–25 °C) using a chiller. The HTC-H was separated into HTC-S and HTC-L using a filter press. A weight reduction of 5–10% was observed due to moisture absorption by the filtering cloth. However, for theoretical assessment, the HTC-H calculations incorporated the accounted moisture loss.

Figure 3.

Schematic diagram of the HTC batch reactor.

2.3. Methane Production Potential of HTC-L

2.3.1. Theoretical Methane Potential

The theoretical methane potential (Bth) was calculated stoichiometrically using Boyle’s equation based on the elemental analysis results of the samples (Equations (1) and (2)) [29].

2.3.2. Methane Potential Assay of HTC-L

To assess the methane potential of the HTC-L, a batch-type anaerobic reactor was operated under mesophilic conditions (38 °C). Inoculum was collected from a farm-scale anaerobic digester located in Icheon, Republic of Korea. The inoculum was subjected to mesophilic digestion conditions (38 °C) for 14 days, during which residual gases and organic matter were removed. The chemical properties of the inoculum are listed in Table 3.

Table 3.

Chemical properties of inoculum used in the methane potential assay of HTC-L.

The substrate to inoculum ratio in all batch reactors was maintained at 0.5 (g-VSsubstrate/g-VSinoculum). Each anaerobic batch fermentation had a working volume of 80 mL within a 160 mL serum bottle. The headspace of each serum bottle was purged with nitrogen gas and sealed using a butyl rubber stopper. Batch reactors, comprising both samples and blanks, were incubated for a period of 90 days in a convection incubator, with daily manual agitation during the fermentation period. Methane potential was determined by calculating based on the volatile solid (VS) content.

The wet biogas produced was quantified using a water column gas volume meter. The generated biogas underwent conversion to dry gas under standard conditions (1 atm, 0 °C) by adjusting for moisture and temperature levels, as illustrated in Equation (3). This process was undertaken to derive a cumulative methane production curve. In Equation (3), Vdry gas is the volume of dry gas under standard state. T is the operating temperature of the reactor, Vwet gas at T °C is the volume of wet gas at the operating temperature of the reactor (T, 38 °C); P is the atmospheric pressure at the time the volume of the gas was measured; and PT is the saturated water vapor pressure (mmHg) at T °C. In this study, P is 760 mmHg, and PT was calculated as the pressure of the saturated water vapor at 38 °C [30].

To interpret the progress of cumulative methane production, the parallel first-order kinetics model Equation (4) was employed to fit the cumulative methane production data, as shown in the following equation [31,32].

where Bt (mL) is the amount of methane produced at time t, Bmax (mL) is the ultimate amount of methane produced, fe (g/g) is the organic distribution constant for the two first-order kinetics models, and k1 and k2 are kinetic constants in parallel first-order kinetics. The cumulative methane production curves of HTC-L were optimized using SigmaPlot (Version 12.5, Systat Software Inc., Cary, NC, USA) and parallel first-order kinetics models.

2.4. Analysis

pH, TS, VS, chemical oxygen demand (COD), soluble chemical oxygen demand (SCOD), total Kjeldahl nitrogen (TKN), ammonium nitrogen (NH4+-N), and alkalinity were determined according to standard methods [33]. Total volatile fatty acids (TVFAs) were measured using a gas chromatograph (GC2010; Shimadzu Scientific Instruments, Inc., Columbia, MD, USA) equipped with a flame ionization detector (FID) and automatic sampler. This chemical analysis was performed in triplicate. The elemental compositions (C, H, N, O, and S) were determined using an elemental analyzer (EA1108, Thermo Finnigan LLC, San Jose, CA, USA). The higher heating value (HHV) of HTC-S was analyzed using a bomb calorimeter. The biogas (CH4 and CO2) concentrations in the gas samples were determined using a gas chromatograph (Clarus 680, PerkinElmer, Inc., Waltham, MA, USA) equipped with a thermal conductivity detector (TCD) and HayeSepQ packed column (CRS, Inc., Louisville, KY, USA). The column was operated with an argon (Ar) carrier gas at a flow rate of 5 mL/min. The temperatures of the injector, oven, and detector were set to 150, 90, and 150 °C, respectively [34].

2.5. Efficiency Parameters

In this study, the bioenergy recovery efficiency of the integrated anaerobic co-digestion and HTC integrated process for livestock manure was assessed on a daily scale of 100 tons of mixed livestock manure. The material and energy balances were evaluated using the results obtained for each process. Material balance analysis was based on the composition of a mixture of PS and FCM in the integrated anaerobic co-digestion. The HTC process was performed using a feedstock containing approximately 80% moisture. Therefore, AD-S, with a TS concentration of 20%, separated from the anaerobic digestate using a high-speed decanter, was utilized in the HTC reaction [35]. The production quantity of HTC-H was the same as the input quantity of AD-S, but the concentration of solids decreased because of the hydrothermal decomposition reactions during HTC [36]. HTC-H separates from the solid form, HTC-S, using a pressured filter for utilization as a solid fuel. During this process, the TS content of HTC-S was set to 55% and thermal air-drying was conducted until the moisture content reached 20% [37]. The liquid form, HTC-L, was reinputted into an integrated AD reactor for livestock manure to recover biogas.

Energy balance analysis was categorized into input, output, and energy consumption categories. The input energy (Equation (5)) was calculated as the sum of the higher heating values for the PS and FCM, which were 18,895 and 15,339 MJ/ton, respectively [15]. The output energy (Equation (6)) was calculated based on the methane generated from the integrated anaerobic co-digestion (PS, FCM, and HTC-L) and HTC-S heating values. The energy loss (Equation (7)) was calculated as the difference between the input and output energies. The consumed energy (Equation (8)) is the sum of the energy used in the HTC reaction and the drying of HTC-S into solid fuel. The energy consumed in the HTC reaction is 879 MJ/ton when processing feedstock with 80% moisture content [37]. The criteria for calculating the drying energy required to adjust the moisture content of HTC-S to 20% for utilization as a solid fuel were based on the sum of the sensible and latent heat of moisture [10]. The total bioenergy recovery efficiency (Equation (9)) was calculated as (output energy)/(input energy) × 100, and the net bioenergy recovery efficiency (Equation (10)) was calculated as (output energy − consumption energy)/(input energy) × 100.

Input energy = HHV-FCMsolid + HHV-PSsolid

HHV-FCMsolid refers to the higher heating value of FCM, and HHV-PSsolid refers to the higher heating value of PS.

Output energy = HHV-Solid fuel + HHV-Biogas

HHV-Solid fuel refers to the higher heating value of HTC-S, and HHV-Biogas refers to the higher heating value of the biogas produced from PS and FCM, as well as the biogas produced from HTC-L.

Loss energy = Input energy − Output energy

Loss energy refers to the value obtained by subtracting the sum of the output energy, including solid fuel and biogas, from the input energy, which is primarily influenced by the input of livestock manure.

Consumption energy = HTCreaction + HTC-Sdrying

The HTC reaction refers to the energy consumed during the HTC of AD-S, whereas HTC-S drying refers to the energy consumed to dry the HTC-S for utilization as a solid fuel.

Gross bioenergy recovery was obtained by dividing the output energy (HHV-Solid fuel + HHV-Biogas) by the input energy (HHV-FCMsolid + HHV-PSsolid).

The net bioenergy recovery is the value obtained by subtracting the consumption energy (HTCreaction + HTC-Sdrying) from the output energy (HHV-Solid fuel + HHV-Biogas) and then dividing the result by the input energy (HHV-FCMsolid + HHV-PSsolid).

3. Results and Discussion

3.1. Livestock Manure Anaerobic Co-Digestion

The results of the analysis of the anaerobic co-digestion slurry characteristics using a continuous reactor with a 1:1 (w/w) mixture of PS and FCM are listed in Table 4. To evaluate the stability of the continuous reactor, key indicators such as pH, NH4+-N, TVFAs, and alkalinity were analyzed. Under HRT conditions of 40, 30, and 20 days, the pH values were 8.0, 7.9, and 7.9, respectively, and they remained within the suitable pH range for AD, which is known to be between 7.0 and 8.0. NH4+-N levels were 4146, 3450, and 3734 mg/L, respectively. Considering the NH4+-N in the influent material was 3313 mg/L, a slight increase was observed during the AD period. Research suggests that methanogenic bacteria are not significantly inhibited, even at concentrations as high as 5000 mg/L, provided that they have adequate adaptation time to ammonia toxicity [38]. The TVFA concentrations were 2728, 2302, and 2106 mg/L, respectively. TVFAs can accumulate if issues arise during the AD process. Excessive accumulation can adversely affect pH, thereby impacting the bioenergy conversion efficiency of organic matter into biogas [30]. The alkalinity levels were 21,054, 19,843, and 22,730 mg/L, respectively. According to Lili et al., a TVFAs/Alkalinity ratio between 0.10 and 0.25 indicates no risk of acidification in the reactor [39]. Under HRT conditions of 40, 30, and 20 days, the TVFAs/alkalinity ratios were 0.13, 0.12, and 0.09, respectively. This suggests that pH, NH4+-N, TVFAs, and alkalinity were stably maintained during CSTR operation, indicating no factors impeding AD. However, as the HRT was shortened during continuous reactor operation, the increased OLR led to a significant accumulation of TS and VS in the AD-T under HRT conditions of 40, 30, and 20 days. Similarly, COD and SCOD, which represent the amounts of oxygen required for organic matter decomposition, also increased. Demirer and Chen reported that, in continuous reactor operation using dairy manure, increasing the initial OLR resulted in increased biogas production. However, when the maximum OLR was set to 6.3 kg-VS/m3/day, methane yield decreased, and solid accumulation occurred [40]. Li et al. conducted separate AD of CM and anaerobic co-digestion of kitchen waste in a 1:1 (w/w) ratio. When considering Bu-exp, they observed increases of 0.04 and 0.30 Nm3/kg-VSadded, respectively. They reported that the high alkalinity of CM provided a buffering capacity against acidic substances in wastewater [41]. Wei et al. conducted separate AD of CM and anaerobic co-digestion with corn stover at a 1:1 (w/w) ratio. In this study, Bu-exp was 0.44 and 0.61 Nm3/kg-VSadded, respectively. They reported that methane production increased by 1.4 times compared to the AD of CM alone [42]. However, the increase in methane production during the anaerobic co-digestion of CM with other substrates was not attributed to an increased degradation rate of recalcitrant organic compounds in CM, such as lignin and cellulose. Instead, it was primarily due to the characteristics of other substrates that exhibited high degradation rates [43]. Therefore, pretreatment processes for enhancing AD efficiency using FCM are being researched with the aim of solubilizing recalcitrant organic compounds such as lignin and cellulose. The goal was to convert them into a more easily digestible form for anaerobic microorganisms. [44].

Table 4.

Efficiency and operation factors of CSTR in the anaerobic digestion of livestock manure.

3.2. Hydrothermal Carbonization Reaction Using Anaerobic Co-Digestion Sludge from Livestock Manure

The phase analysis results for AD-T, AD-S, and HTC-H are listed in Table 5. HTC-H was separated into HTC-S and HTC-L using a high-speed decanter. The results of the HTC-S composition analysis are listed in Table 6.

Table 5.

Physicochemical properties of AD, AD-S, and HTC-H.

Table 6.

Physicochemical properties of HTC-S.

The higher heating values of HTC-S at 160, 180, 200, and 220 °C were 16,050, 15,661, 15,945, and 15,313 kJ/kg, respectively. Maring-Batista et al. reported that the heating value of a solid fuel increases with an increase in carbon content through the HTC reaction, indicating its enhanced value as a solid fuel. However, they observed an increase in ash content from 19.7% to 24.1% when the reaction temperature increased from 170 °C to 230 °C, resulting in a loss in energy recovery efficiency through solid fuel, as reported [25]. The heating value of HTC-S used in this study was highest at 160 °C, showing a difference from the results of Maring-Batista et al. However, the ash content at 160, 180, 200, and 220 °C was 29.1, 32.3, 33.1, and 32.6%, respectively. The increase in the ash content with increasing reaction temperature suggests that as the reaction temperature increases, the amount of ash produced in the HTC process increases. When the reaction temperature does not reach the melting point of the inorganic compounds, ash accumulates in the HTC-S, leading to an increase in the ash content [45].

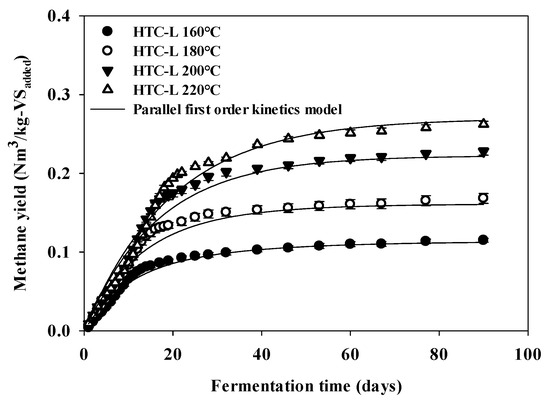

The results of the HTC-L composition analysis are listed in Table 7. HTC is an efficient method for hydrolyzing non-biodegradable organic matter into soluble organic matter. During CSTR operation, the SCOD/COD ratios at HRT of 40, 30, and 20 days were 25.1, 26.6, and 25.5%, respectively. In contrast, the SCOD/COD for HTC-L at 160, 180, 200, and 220 °C was 76.4, 94.5, 97.2, and 96.5%, respectively. This indicated that some non-biodegradable organic matter was converted into soluble organic matter during the HTC process, and the increase in soluble organic matter enhanced methane production and methane production rates [46,47]. The results of the biochemical methane potential analysis of HTC-L, analyzed using a parallel first-order kinetics model, are presented in Table 8 and Figure 4. The biochemical methane potential by parallel first-order kinetics model (Bu-p) at 160, 180, 200, and 220 °C was calculated as 0.11, 0.16, 0.22, and 0.27 Nm3/kg-VSadded, with the highest value observed at 220 °C. However, when considering the vs. that could be converted into methane, the efficiencies were 3.8, 5.6, 7.2, and 6.9 Nm3/ton, showing the highest efficiency at 200 °C.

Table 7.

Physicochemical properties of HTC-L.

Table 8.

Methane yield characteristics analysis by the parallel first-order kinetics model in the HTC-L.

Figure 4.

Methane yield curves optimized by the parallel first-order kinetics model of HTC-L.

Generally, HTC exhibits varying degrees of solubilization depending on the composition of the feedstock, reaction temperature, and time. Kim and Jeon conducted HTC on PS at temperatures of 200, 220, 250, and 270 °C, reporting specific biochemical methane potential by experimental (Bu-exp) values of 0.20, 0.23, 0.22, and 0.20 Nm3/kg-VSadded, respectively [22]. Additionally, Oh and Yoon conducted HTC on chicken slaughterhouse wastewater sludge at temperatures of 170, 180, 190, 200, and 220 °C, reporting Bu-exp values of 0.22, 0.24, 0.24, 0.23, and 0.20 Nm3/kg-COD, respectively [48]. Furthermore, Maring-Batista et al. conducted HTC on urine at temperatures of 170, 200, and 230 °C, reporting specific Bu-exp values of 0.29, 0.24, and 0.08 Nm3/kg-VSadded, respectively [25]. In various HTC studies, it has been reported that an increase in the reaction temperature leads to a decrease in Bu-exp. Although HTC reactions can increase the solubility of cellulose and lignin in raw materials, it has also been reported that the phenolic substances generated during the process may hinder methane production [49]. Moreover, an increase in the reaction temperature has been reported to increase the proportion of soluble organic matter. However, this also increases the concentration of refractory compounds in soluble organic matter [21,50]. If the HTC reaction temperature exceeds 200 °C, the lower methane yield may be attributed to the Maillard reaction, in which carbohydrates react with amino acids to form poorly biodegradable melanoidins at higher temperatures [51,52]. The HTC-S and HTC-L used in this study have limitations, as they were obtained from the anaerobic co-digestion of a mixture of livestock manure (PS and FCM in a 1:1 w/w ratio) under HRT 40 days, where AD-S was separated after centrifugation and used in the HTC reaction. Consequently, AD-S generated under HRT of 30 and 20 days, containing undigested organic matter, may lead to differences in the heating value of HTC-S and the biochemical methane potential of HTC-L when subjected to HTC. Therefore, additional research using HTC reaction materials obtained under HRT of 40, 30, and 20 days is required for an accurate energy efficiency analysis of the HTC reaction.

3.3. Evaluation of Bioenergy Recovery Efficiency in Anaerobic Co-Digestion and Hydrothermal Carbonization Integrated Process for Livestock Manure

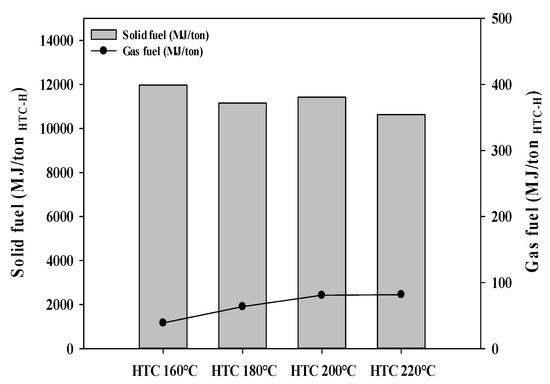

Based on the results of Experiments 1 and 2, the criteria for material and energy balance analysis in the anaerobic co-digestion HTC process integrated with a 1:1 (w/w) mixture of PS and FCM are presented in Table 9. The HTC reaction temperature was set at 160 °C, considering factors such as the ratio of solid–liquid separation using a pressured filter press, calorific value, and methane production (Figure 5). Under HRT 40 days, when 1 kg of mixed livestock manure, comprising PS and FCM at a 1:1 (w/w) ratio, underwent anaerobic co-digestion, 0.133 kg of solid material was partially decomposed, leaving 0.052 kg of solid material in the AD-T. When AD-T was separated into AD-S for the HTC reaction, 0.039 kg of the solid material was isolated. During the HTC reaction of AD-S at 160 °C, some solid material is decomposed, resulting in 0.038 kg of solid material present in HTC-H. After the pressure filter press treatment of HTC-H, the solid material was separated into HTC-S and HTC-L at 0.036 kg and 0.002 kg, respectively. Under HRT of 30 and 20 days, the amount of solid material in AD-S used for the HTC reaction increased because of the undecomposed livestock manure in the AD process. Consequently, the production of HTC-H increased, leading to an increase in the quantities of HTC-S utilized as solid fuel and HTC-L introduced into the anaerobic co-digestion reactor.

Table 9.

Results of total solid analysis by process.

Figure 5.

Calculation results of bioenergy of HTC-S and HTC-L according to hydrothermal carbonization reaction temperature.

The analysis of the bioenergy recovery rates in the integrated process for treating 100 tons/day of mixed livestock manure under HRT of 40, 30, and 20 days, based on the material balance results, is presented in Table 10. With an input energy of 171,167 MJ/day due to the introduction of livestock manure, the output energy under HRT 40 conditions was calculated to be 58,082 MJ/day for solid fuel and 68,517 MJ/day for gas fuel. The gross bioenergy recovery at this point was 74.0%, whereas the net bioenergy recovery, excluding the HTC reaction energy and HTC-S drying energy, was 62.2%. As the HRT decreased, the decomposition rate of the mixed livestock manure decreased, resulting in a lower gas fuel energy. However, an increase in HTC-S generation led to a higher solid fuel energy. Under 30 and 20 HRTs, the gross bioenergy recovery rates were 82.0 and 98.0%, respectively, whereas the net bioenergy recovery rates were 66.8 and 76.2%, respectively. Energy recovery from the conventional AD of livestock manure showed rates of 40.0, 38.0, and 35.3% at HRT of 40, 30, and 20 days, respectively. However, with the integration of the HTC process, the rates increased to 62.2, 66.8, and 76.2%. This indicates that by reducing the residence time and utilizing additional energy recovery through solid fuel, net bioenergy recovery can be increased.

Table 10.

Bioenergy recovery efficiency according to operating conditions.

FCM has a high organic content, which contributes to its high energy potential. However, its efficiency in AD is low due to the presence of lignin, cellulose, and other cell wall materials. Therefore, studies have reported integrating FCM with other substrates in AD or enhancing energy recovery through HTC. Imeniet et al. reported the results of the AD of FCM alone and the co-digestion of FCM and cheese whey (7:3, w/w ratio), with biogas production rates (Bu-exp) of 0.01 and 0.18 Nm3/kg-COD, respectively [53]. Martin-Batista et al. reported that the energy recovery efficiency from AD of FCM alone was 25.6%. When subjected to HTC at temperatures of 170, 200, and 230 °C, the energy recovery efficiencies were reported as 85.0, 85.6, and 73.8%, respectively [25]. Oh and Yoon, in their research on the AD and HTC integrated process using sludge cake from poultry slaughterhouse wastewater, reported gross bioenergy recovery percentages of 93.2, 95.1, 93.4, 92.7, and 88.5% when subjected to HTC at temperatures of 170, 180, 190, 200, and 220 °C, respectively [48]. Studies have been reported indicating that applying the integrated AD and HTC process to sewage sludge, known for its low anaerobic digestion efficiency, enhances energy recovery. Kim et al. evaluated the energy recovery efficiency by conducting HTC at temperatures of 180, 200, 220, 250, and 280 °C using the AD-T generated from sewage sludge digestion. The HHV of the raw sludge was 16.5 MJ/kg. The HHV of HTC-S increased at temperatures of 180, 200, 220, 250, and 280 °C, reaching 17.3, 17.5, 18.3, 20.2, and 22.4 MJ/kg, respectively. However, the product yield decreased to 93.9, 92.6, 88.7, 83.4, and 80.4%. In terms of energy recovery efficiency, values were reported as 92.2, 91.6, 93.1, 90.3, and 89.6%, with the highest efficiency observed at the 180 °C reaction temperature [54]. Aragón-Briceño et al. conducted HTC at temperatures of 160, 220, and 250 °C using the AD-T derived from solid sewage sludge mesophilic digestion. They calculated the energy production based on the HHV of HTC-S and the Bu-exp of HTC-L. The energy production for the control group was 7.1 MJ/kg. In the treatment groups subjected to HTC at 160, 220, and 250 °C, the energy production was reported as 19.8, 18.9, and 18.0 MJ/kg, respectively. It was reported that the highest efficiency was observed at the 160 °C reaction temperature [55]. Various studies evaluating the energy recovery efficiency of AD and HTC integrated processes using different feedstocks have shown variations depending on factors such as the reaction temperature, energy consumption, and assessment criteria for energy loss. Therefore, additional research should be conducted on various energy balances beyond the energy consumption calculated in this study for the HTC reaction energy and solid fuel drying energy when integrating the HTC process with the AD process.

4. Conclusions

FCM is a biomass that has a high energy potential but is difficult for anaerobic digestion because it is discharged in a state containing sawdust substances. Therefore, in this study, to enhance the energy conversion efficiency of biomass with varying solid content and chemical composition, HTC-S generated from the integrated AD and HTC processes of livestock manure was utilized as a solid fuel, and HTC-L was reinputted into the integrated AD system. The aim of this study is to evaluate the efficiency of bioenergy recovery. Anaerobic co-digestion of livestock manure maintained the TVFAs, alkalinity, and TKN within a stable range of AD. However, as the retention time decreased, the digestion rate of AD-T also decreased, leading to a reduction in methane production. Consequently, the accumulation of solid matter increased, leading to an increase in the production of AD-S, which served as feedstock for the HTC reaction. Considering the solid–liquid separation ratio, heat generation, and methane production, the HTC reaction showed the highest efficiency at a reaction temperature of 160 °C. Based on these two analyses, a comprehensive AD and HTC integrated process for a mixture of PS and FCM (1:1, w/w) with a daily processing capacity of 100 tons was analyzed for material and energy balances under HRT conditions of 40, 30, and 20 days. The energy recovery from the biogas generated in the integrated anaerobic co-digestion of livestock manure was 32.1%, 30.5%, and 28.2%, respectively, with decreasing HRTs. As the residence time decreased, the degradation rate also decreased, leading to a decrease in the energy recovery efficiency. However, when the HTC process using AD-S was integrated, the gross bioenergy recoveries, including biogas and solid fuel, were 59.3, 65.7, and 78.5%, whereas the net bioenergy recoveries were 49.9, 53.5, and 61.1%, respectively. These results indicated that as the HRT decreased, energy recovery through biogas decreased. However, energy recovery through solid fuel using HTC-S increases. These results suggest that integrating the AD of livestock manure with the HTC process, where HTC-S is utilized as a solid fuel and HTC-L is reinputted into the anaerobic digestion process, can enhance bioenergy recovery efficiency compared with simply generating biogas through AD alone.

Author Contributions

Conceptualization, Y.-M.Y.; methodology, J.-H.L. and Y.-M.Y.; software, J.-H.L. validation J.-H.L. and Y.-M.Y.; formal analysis, J.-H.L.; investigation, J.-H.L.; resources, Y.-M.Y.; data curation, Y.-M.Y.; writing—original draft preparation, J.-H.L.; writing—review and editing, Y.-M.Y.; visualization, J.-H.L.; supervision, Y.-M.Y.; project administration, Y.-M.Y.; funding acquisition, Y.-M.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and the Ministry of Trade, Industry and Energy (MOTIE) of the Republic of Korea (NO. 20183010092750).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- MOTIE [Ministry of Trade Industry and Energy]. New & Renewable Energy White Paper; Ministry of Trade Industry and Energy: Sejong City, Republic of Korea, 2020. [Google Scholar]

- Zubair, M.; Wang, S.; Zhang, P.; Ye, J.; Liang, J.; Nabi, M.; Zhou, Z.; Tao, X.; Chen, N.; Sun, K. Biological nutrient removal and recovery from solid and liquid livestock manure: Recent advance and perspective. Bioresour. Technol. 2020, 301, 122823. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Li, P.; Fang, C.; Jiang, R. Phosphate recovery from animal manure wastewater by struvite crystallization and CO degasification reactor. Ecol. Chem. Eng. S 2014, 21, 89–99. [Google Scholar] [CrossRef]

- Larson, C. China’s lakes of pig manure spawn antibiotic resistance. Science 2015, 347, 704. [Google Scholar] [CrossRef] [PubMed]

- MAFRA [Ministry of Agriculture Food and Rural Affairs]. 2050 Agricultural and Food Carbon Neutrality Promotion Strategy; Ministry of Agriculture Food and Rural Affairs: Sejong-si, Republic of Korea, 2021. [Google Scholar]

- Nicholson, F.A.; Groves, S.J.; Chambers, B.J. Pathogen survival during livestock manure storage and following land application. Bioresour. Technol. 2005, 96, 135–143. [Google Scholar] [CrossRef] [PubMed]

- Meegoda, J.N.; Li, B.; Patel, K.; Wang, L.B. A review of the processes, parameters, and optimization of anaerobic digestion. Int. J. Environ. Res. Public Health 2018, 15, 2224. [Google Scholar] [CrossRef] [PubMed]

- Laiq Ur Rehman, M.; Iqbal, A.; Chang, C.C.; Li, W.; Ju, M. Anaerobic digestion. Water Environ. Res. 2019, 91, 1253–1271. [Google Scholar] [CrossRef]

- ME [Ministry of Environment]. Status of Installation and Operation of Food Waste Treatment Facilities in 2020; Ministry of Environment: Sejong-si, Republic of Korea, 2021. [Google Scholar]

- Kim, J.; Yoon, Y.-M.; Jeong, K.-H.; Kim, C.-H. Effects of supplementation of mixed methanogens and rumen cellulolytic bacteria on biochemical methane potential with pig slurry. Korean J. Soil Sci. Fertil. 2012, 45, 1049–1057. [Google Scholar] [CrossRef]

- Yoon, Y.; Kim, C.; Kim, Y.; Park, H. The economical evaluation of biogas production facility of pig waste. Korean J. Agric. Manag. Policy 2009, 36, 137–157. [Google Scholar]

- Lehtomäki, A.; Huttunen, S.; Rintala, J. Laboratory investigations on co-digestion of energy crops and crop residues with cow manure for methane production: Effect of crop to manure ratio. Resour. Conserv. Recycl. 2007, 51, 591–609. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kim, C.-H.; Yoon, Y.-M. Effects of hydrothermal pretreatment on methane potential of anaerobic digestion sludge cake of cattle manure containing sawdust as bedding materials. Anim. Biosci. 2023, 36, 818. [Google Scholar] [CrossRef]

- Park, S.Y.; Jang, J.A.; Zhao, X.; Hong, J.K.; Jho, E.H. Effect of Rice Straw on Methane Production Potential of Cow Manure. Korean J. Environ. Agric. 2022, 41, 71–81. [Google Scholar] [CrossRef]

- ME [Ministry of Environment]. The Study for the Establishment of Quality and Classification Criteria of Solid Fuel Using Livestock Manure; Ministry of Environment: Sejong-si, Republic of Korea, 2013. [Google Scholar]

- Oh, S.-Y.; Kim, C.-H.; Yoon, Y.-M. The bioenergy conversion characteristics of feedlot manure discharging from beef cattle barn. Korean J. Soil Sci. Fertil. 2015, 48, 697–704. [Google Scholar] [CrossRef]

- MarañóN, E.; Castrillón, L.; Vázquez, I.; Sastre, H. The influence of hydraulic residence time on the treatment of cattle manure in UASB reactors. Waste Manag. Res. 2001, 19, 436–441. [Google Scholar] [CrossRef] [PubMed]

- Omar, R.; Harun, R.M.; Mohd Ghazi, T.; Wan Azlina, W.; Idris, A.; Yunus, R. Anaerobic treatment of cattle manure for biogas production. In Proceedings of the Annual Meeting of American Institute of Chemical Engineers, Philadelphia, PA, USA, 16–21 November 2008; pp. 1–10. [Google Scholar]

- Acharya, B.; Dutta, A.; Minaret, J. Review on comparative study of dry and wet torrefaction. Sustain. Energy Technol. Assess. 2015, 12, 26–37. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lin, B.-J.; Lin, Y.-Y.; Chu, Y.-S.; Ubando, A.T.; Show, P.L.; Ong, H.C.; Chang, J.-S.; Ho, S.-H.; Culaba, A.B. Progress in biomass torrefaction: Principles, applications and challenges. Prog. Energy Combust. Sci. 2021, 82, 100887. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Y.; Zhu, G.; Xu, J.; Yuan, Q.; Zhu, Y.; Sarma, J.; Wang, Y.; Wang, J.; Ji, L. Microwave-assisted hydrothermal carbonization of dairy manure: Chemical and structural properties of the products. Energy 2018, 165, 662–672. [Google Scholar] [CrossRef]

- Kim, H.; Jeon, Y.-W. Effects of hydro-thermal reaction temperature on anaerobic biodegradability of piggery manure hydrolysate. Korean J. Soil Sci. Fertil. 2015, 48, 602–609. [Google Scholar] [CrossRef]

- Ahring, B.K.; Ibrahim, A.A.; Mladenovska, Z. Effect of temperature increase from 55 to 65 degrees C on performance and microbial population dynamics of an anaerobic reactor treating cattle manure. Water Res. 2001, 35, 2446–2452. [Google Scholar] [CrossRef]

- Kim, D.J. Pre-treatment Technology of Wastewater Sludge for Enhanced Biogas Production in Anaerobic Digestion. Clean Technol. 2013, 19, 355–369. [Google Scholar] [CrossRef][Green Version]

- Marin-Batista, J.; Villamil, J.; Qaramaleki, S.; Coronella, C.; Mohedano, A.; de La Rubia, M. Energy valorization of cow manure by hydrothermal carbonization and anaerobic digestion. Renew. Energy 2020, 160, 623–632. [Google Scholar] [CrossRef]

- González, R.; Ellacuriaga, M.; Aguilar-Pesantes, A.; Carrillo-Peña, D.; García-Cascallana, J.; Smith, R.; Gómez, X. Feasibility of coupling anaerobic digestion and hydrothermal carbonization: Analyzing thermal demand. Appl. Sci. 2021, 11, 11660. [Google Scholar] [CrossRef]

- Lu, Y.; Fang, Z.; Gao, C. Stabilization of (state, input)-disturbed CSTRs through the port-Hamiltonian systems approach. arXiv 2017, arXiv:1707.01560. [Google Scholar] [CrossRef]

- Han, S.K.; Kim, M.I. Solid Fuel Carbonization Characteristics through Hydrothermal Carbonization of Sewage Sludge. J. Korea Org. Resour. Recycl. Assoc. 2023, 31, 53–61. [Google Scholar] [CrossRef]

- Boyle, W. Energy recovery from sanitary landfills—A review. Microb. Energy Convers. 1977, 119–138. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, J.-H.; Kim, S.-Y.; Yoon, Y.-M. Effect of Addition of Zero-Valent Iron (Fe) and Magnetite (Fe3O4) on Methane Yield and Microbial Consortium in Anaerobic Digestion of Food Wastewater. Processes 2023, 11, 759. [Google Scholar] [CrossRef]

- Luna-deRisco, M.; Normak, A.; Orupõld, K. Biochemical methane potential of different organic wastes and energy crops from Estonia. Agron. Res. 2011, 9, 331–342. [Google Scholar]

- Rao, M.; Singh, S.; Singh, A.; Sodha, M. Bioenergy conversion studies of the organic fraction of MSW: Assessment of ultimate bioenergy production potential of municipal garbage. Appl. Energy 2000, 66, 75–87. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater; APHA: Washington, DC, USA, 1998; p. 324. [Google Scholar]

- Lay, J.-J.; Li, Y.-Y.; Noike, T. Mathematical model for methane production from landfill bioreactor. J. Environ. Eng. 1998, 124, 730–736. [Google Scholar] [CrossRef]

- ME [Ministry of Environment]. Practical Guidelines for Maintenance of Public Sewerage Facilities; Ministry of Environment: Sejong-si, Republic of Korea, 2005. [Google Scholar]

- Song, E.; Kim, H.; Kim, K.W.; Yoon, Y.-M. Characteristic Evaluation of Different Carbonization Processes for Hydrochar, Torrefied Char, and Biochar Produced from Cattle Manure. Energies 2023, 16, 3265. [Google Scholar] [CrossRef]

- ME [Ministry of Environment]. Energy-Saving (Less than 210 Mcal/Ton Raw Material) Solid Fuel Production Technology Using a Hydrothermal Carbonization Reactor Using a Sewage/Wastewater Sludge (Water Content of around 80%); Ministry of Environment: Sejong-si, Republic of Korea, 2020. [Google Scholar]

- Van Velsen, A. Adaptation of methanogenic sludge to high ammonia-nitrogen concentrations. Water Res. 1979, 13, 995–999. [Google Scholar] [CrossRef]

- Lili, M.; Biró, G.; Sulyok, E.; Petis, M.; Borbély, J.; Tamás, J. Novel approach on the basis of FOS/TAC method. Analele Univ. Din Oradea Fasc. Protecţia Mediu. 2011, 17, 713–718. [Google Scholar]

- Demirer, G.; Chen, S. Two-phase anaerobic digestion of unscreened dairy manure. Process Biochem. 2005, 40, 3542–3549. [Google Scholar] [CrossRef]

- Li, R.; Chen, S.; Li, X.; Saifullah Lar, J.; He, Y.; Zhu, B. Anaerobic codigestion of kitchen waste with cattle manure for biogas production. Energy Fuels 2009, 23, 2225–2228. [Google Scholar] [CrossRef]

- Wei, L.; Qin, K.; Ding, J.; Xue, M.; Yang, C.; Jiang, J.; Zhao, Q. Optimization of the co-digestion of sewage sludge, maize straw and cow manure: Microbial responses and effect of fractional organic characteristics. Sci. Rep. 2019, 9, 2374. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhao, J.; Krooneman, J.; Euverink, G.J.W. Strategies to boost anaerobic digestion performance of cow manure: Laboratory achievements and their full-scale application potential. Sci. Total Environ. 2021, 755, 142940. [Google Scholar] [CrossRef]

- Gao, J.; Chen, L.; Yuan, K.; Huang, H.; Yan, Z. Ionic liquid pretreatment to enhance the anaerobic digestion of lignocellulosic biomass. Bioresour. Technol. 2013, 150, 352–358. [Google Scholar] [CrossRef] [PubMed]

- Gao, P.; Zhou, Y.; Meng, F.; Zhang, Y.; Liu, Z.; Zhang, W.; Xue, G. Preparation and characterization of hydrochar from waste eucalyptus bark by hydrothermal carbonization. Energy 2016, 97, 238–245. [Google Scholar] [CrossRef]

- Ferrer, I.; Ponsá, S.; Vázquez, F.; Font, X. Increasing biogas production by thermal (70 C) sludge pre-treatment prior to thermophilic anaerobic digestion. Biochem. Eng. J. 2008, 42, 186–192. [Google Scholar] [CrossRef]

- Kim, S.-H.; Kim, H.; Kim, C.-H.; Yoon, Y.-M. Effect of the pretreatment by thermal hydrolysis on biochemical methane potential of piggery sludge. Korean J. Soil Sci. Fertil. 2012, 45, 524–531. [Google Scholar] [CrossRef][Green Version]

- Oh, S.-Y.; Yoon, Y.-M. Energy recovery efficiency of poultry slaughterhouse sludge cake by hydrothermal carbonization. Energies 2017, 10, 1876. [Google Scholar] [CrossRef]

- Gossett, R.W.; Brown, D.A.; Young, D.R. Predicting the bioaccumulation and toxicity of organic compounds. Coast. Water Res. Proj. Bienn. Rep. 1981, 1982, 149–156. [Google Scholar]

- Jain, S.; Sharma, M. Power generation from MSW of Haridwar city: A feasibility study. Renew. Sustain. Energy Rev. 2011, 15, 69–90. [Google Scholar] [CrossRef]

- Bougrier, C.; Delgenès, J.P.; Carrère, H. Effects of thermal treatments on five different waste activated sludge samples solubilisation, physical properties and anaerobic digestion. Chem. Eng. J. 2008, 139, 236–244. [Google Scholar] [CrossRef]

- Martins, S.I.; Jongen, W.M.; Van Boekel, M.A. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2000, 11, 364–373. [Google Scholar] [CrossRef]

- Imeni, S.M.; Pelaz, L.; Corchado-Lopo, C.; Busquets, A.M.; Ponsá, S.; Colón, J. Techno-economic assessment of anaerobic co-digestion of livestock manure and cheese whey (Cow, Goat & Sheep) at small to medium dairy farms. Bioresour. Technol. 2019, 291, 121872. [Google Scholar] [CrossRef]

- Kim, D.; Lee, K.; Park, K.Y. Hydrothermal carbonization of anaerobically digested sludge for solid fuel production and energy recovery. Fuel 2014, 130, 120–125. [Google Scholar] [CrossRef]

- Aragón-Briceño, C.; Ross, A.; Camargo-Valero, M. Evaluation and comparison of product yields and bio-methane potential in sewage digestate following hydrothermal treatment. Appl. Energy 2017, 208, 1357–1369. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).