A Simulation Study of an Electro-Hydraulic Load-Sensitive Variable Pressure Margin Diverter Synchronous Drive System with Time-Varying Load Resistance

Abstract

1. Introduction

- (1)

- The EHLS drive system was constructed, and variable load-sensitive pressure margin control was realized;

- (2)

- The diverter valve diverter synchronous technology was used in the EHLS synchronous drive system to construct the EHLS diverter synchronous drive system. It effectively improved the diverter synchronous accuracy of the system. However, it reduced the synchronous control performance of the system;

- (3)

- The solenoid pressure compensation valve replaced the conventional pressure compensation valve. The variable pressure compensation valve pressure margin control was realized;

- (4)

- The system synchronous control performance was ensured, and the system diverter synchronous accuracy was improved by variable pressure margin control.

2. Analysis of the System’s Working Principle

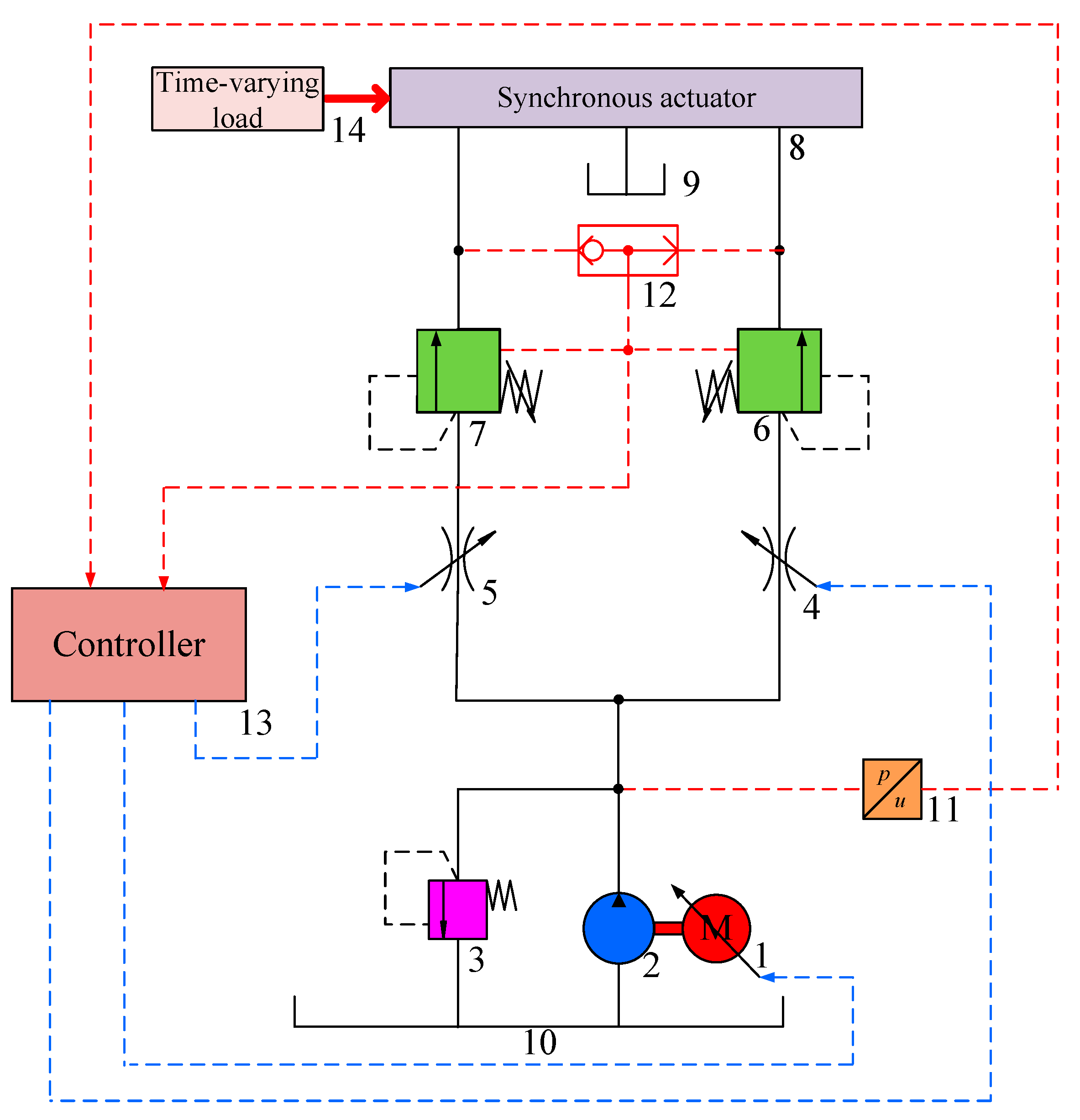

2.1. Analysis of the Working Principle of the Conventional System

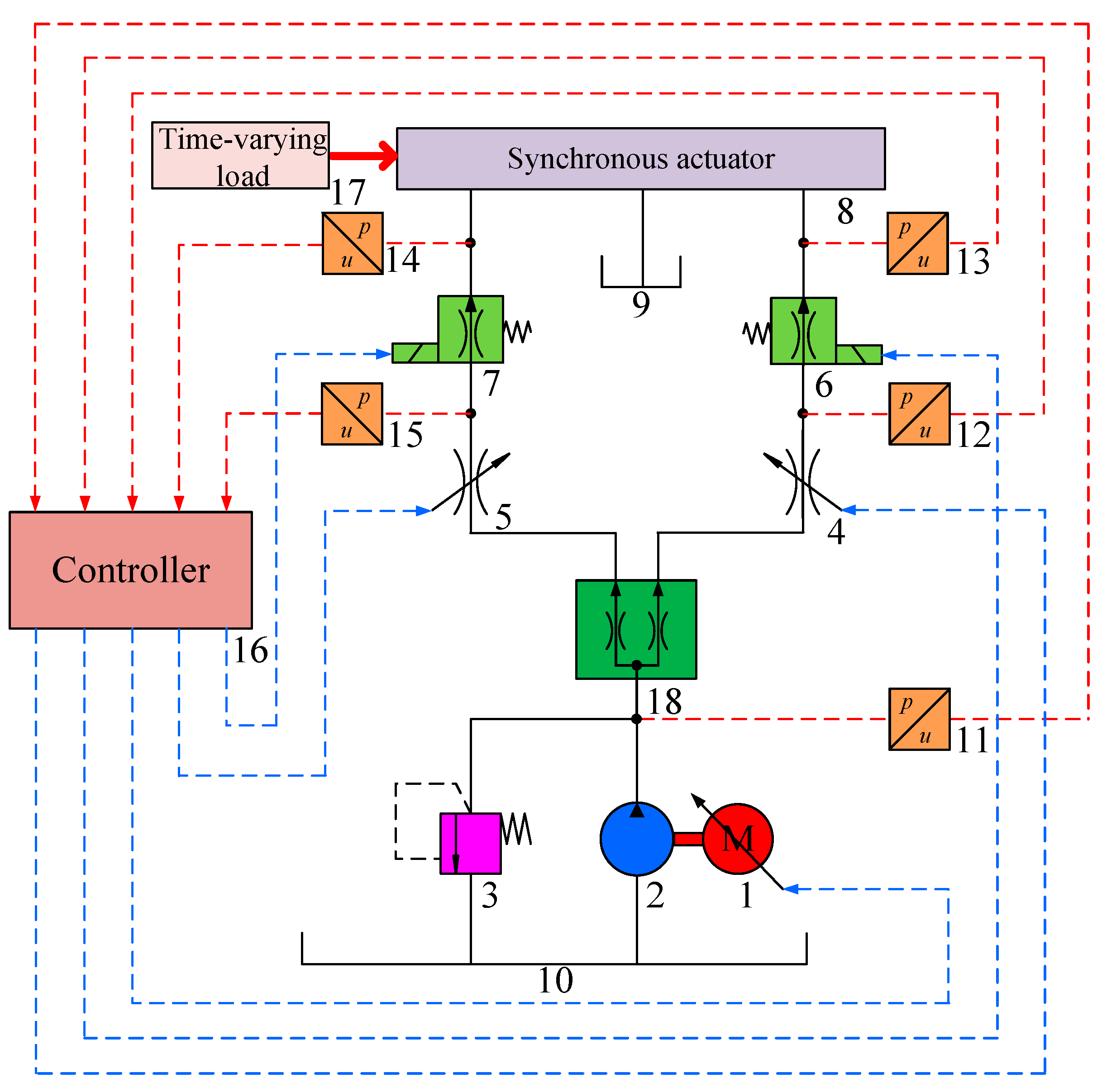

2.2. Analysis of the Working Principle of the New System

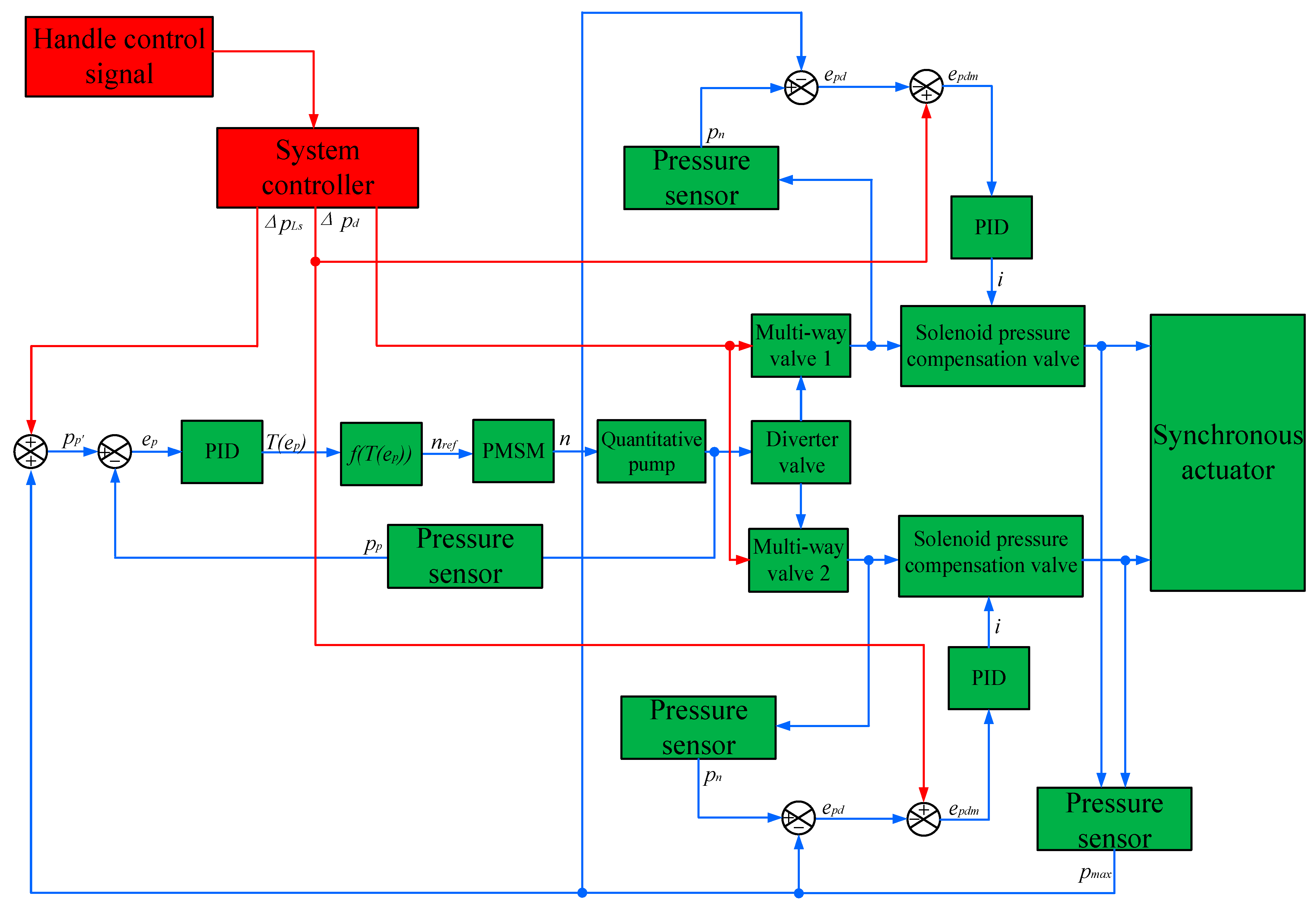

3. Analysis of System Control Strategy

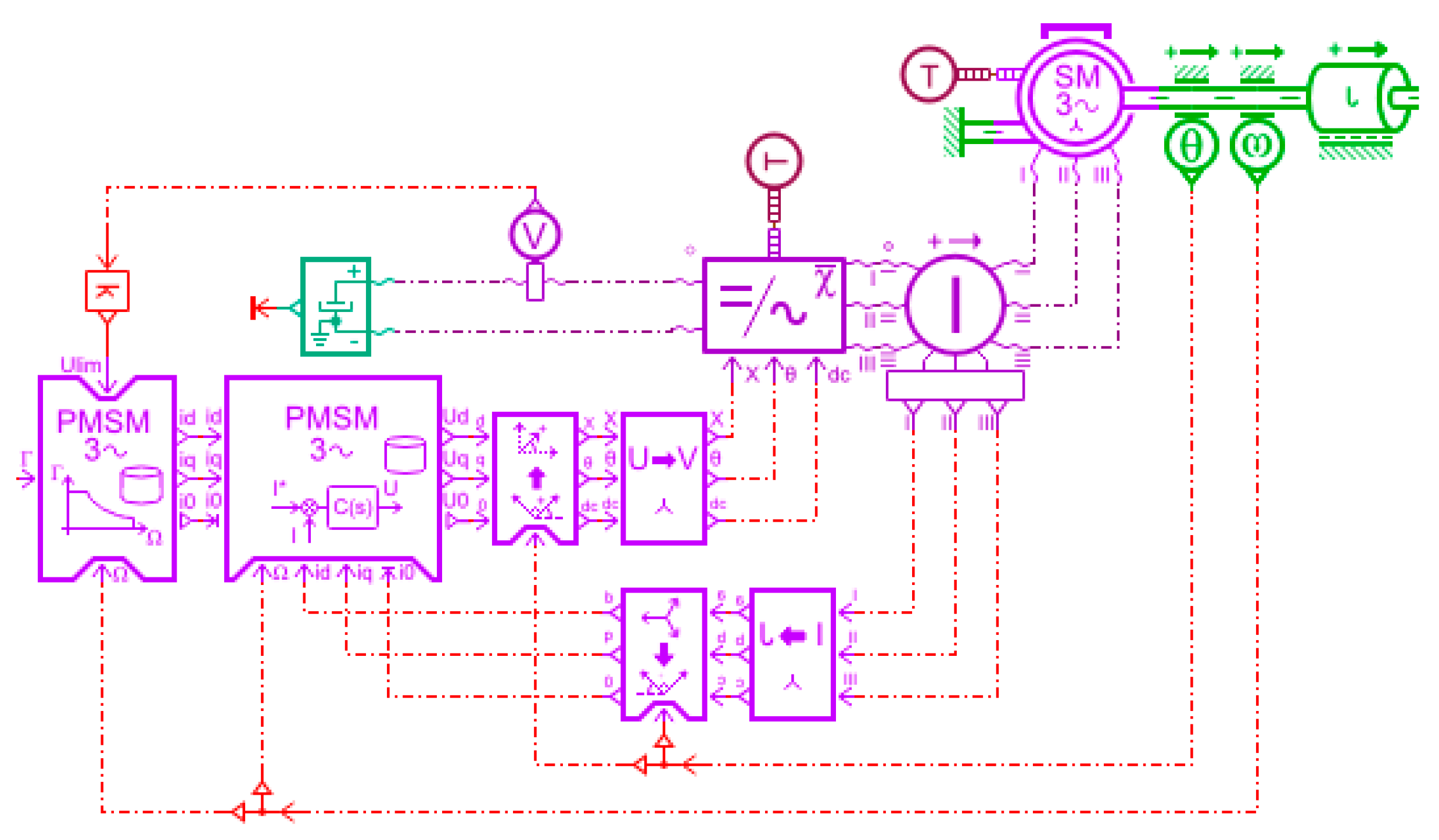

3.1. Variable Speed Control

3.2. Variable Load-Sensitive Pressure Margin Control

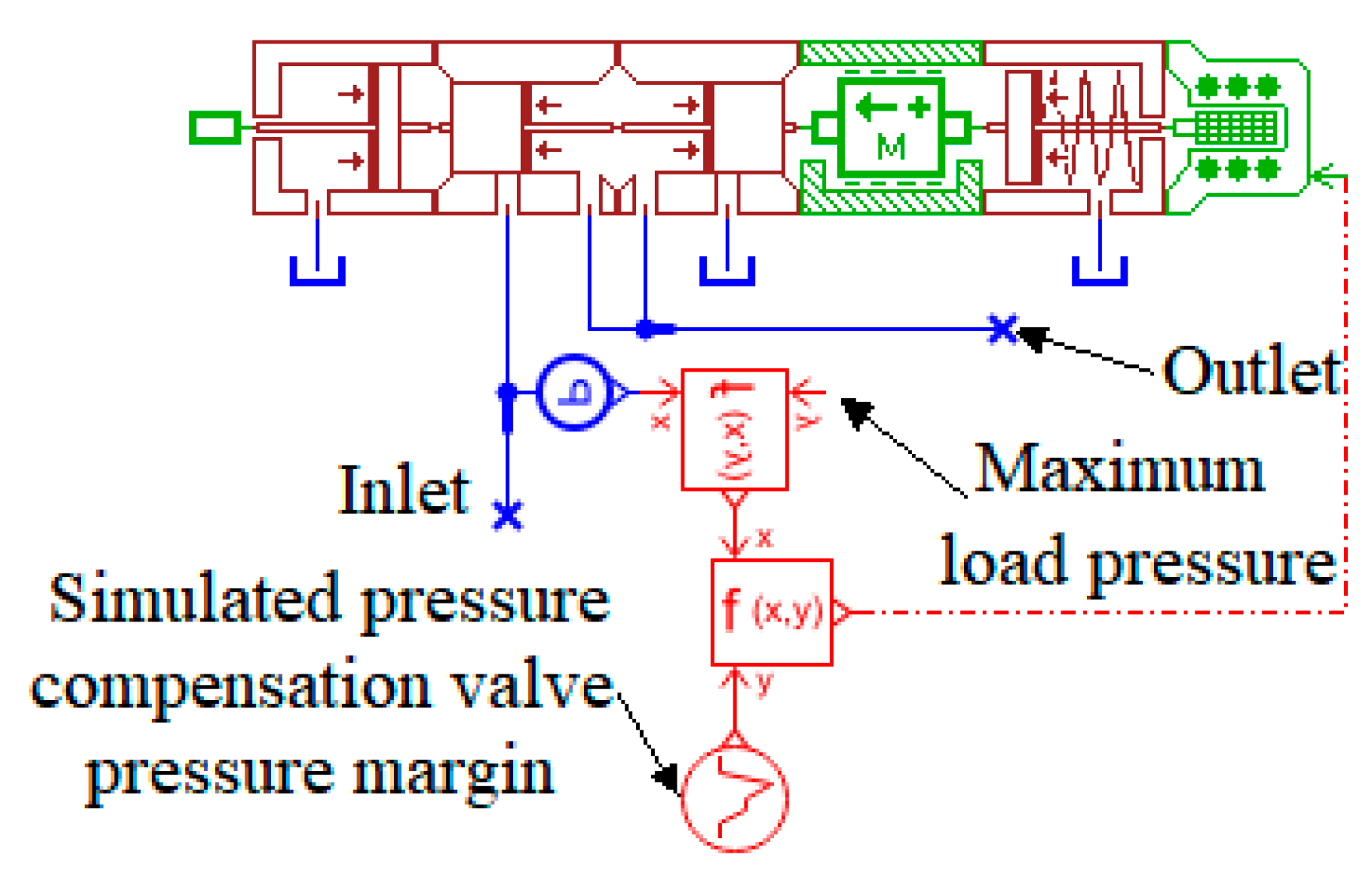

3.3. Variable Pressure Compensation Valve Pressure Margin Control

4. Analysis of Components’ Mathematical Model

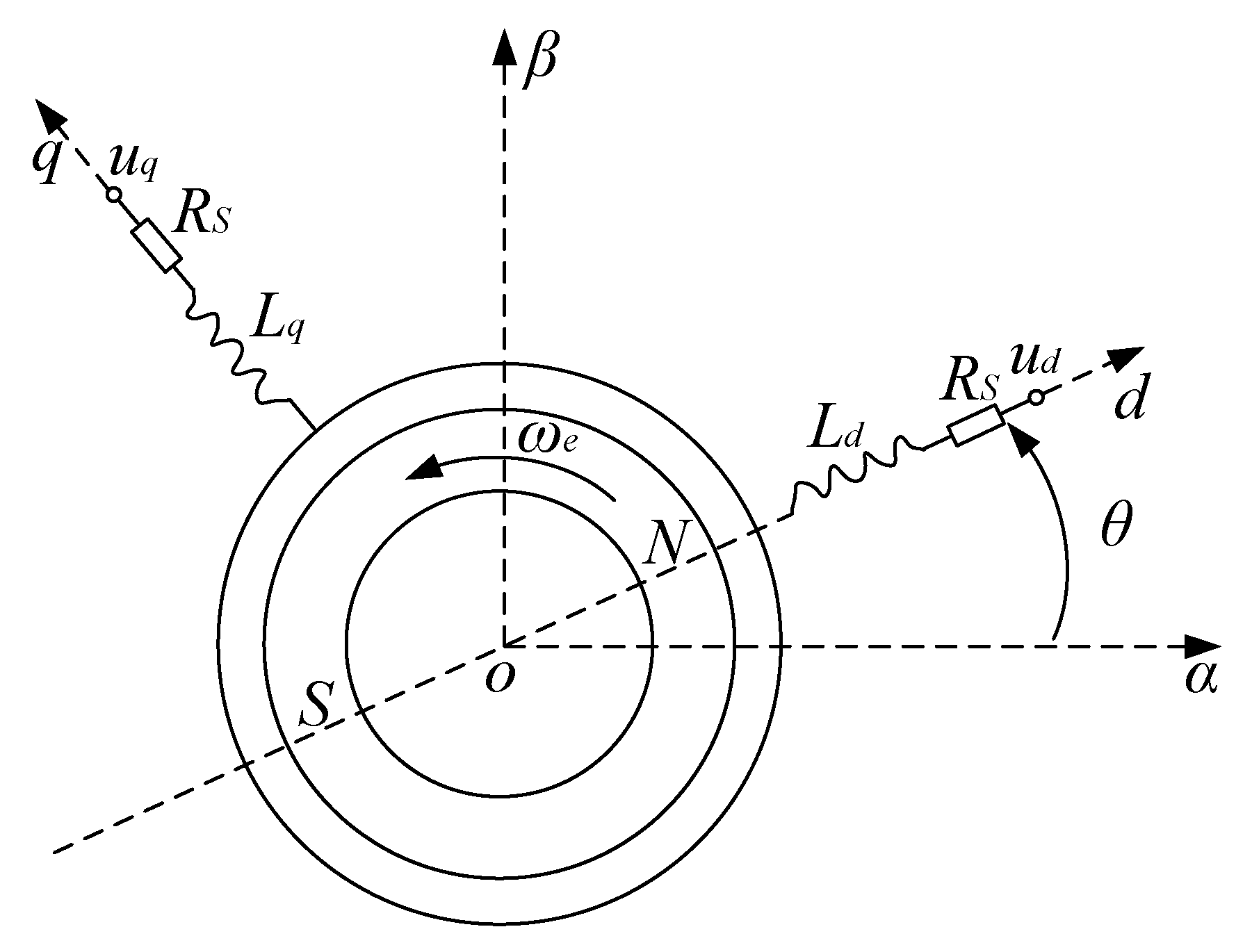

4.1. PMSM Mathematical Model

4.2. Mathematical Modeling of Solenoid Pressure Compensation Valve

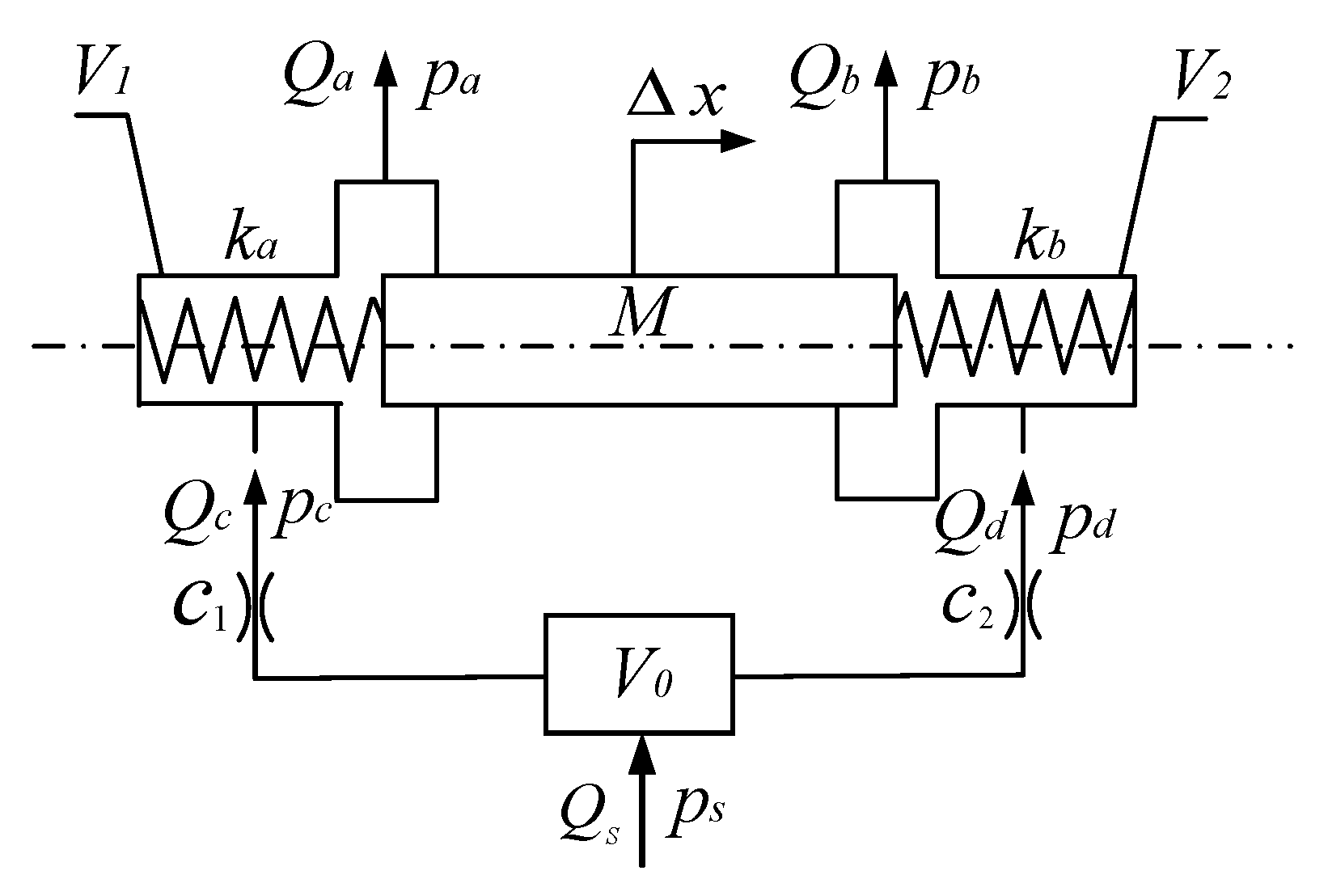

4.3. Mathematical Modeling of the Diverter Valve

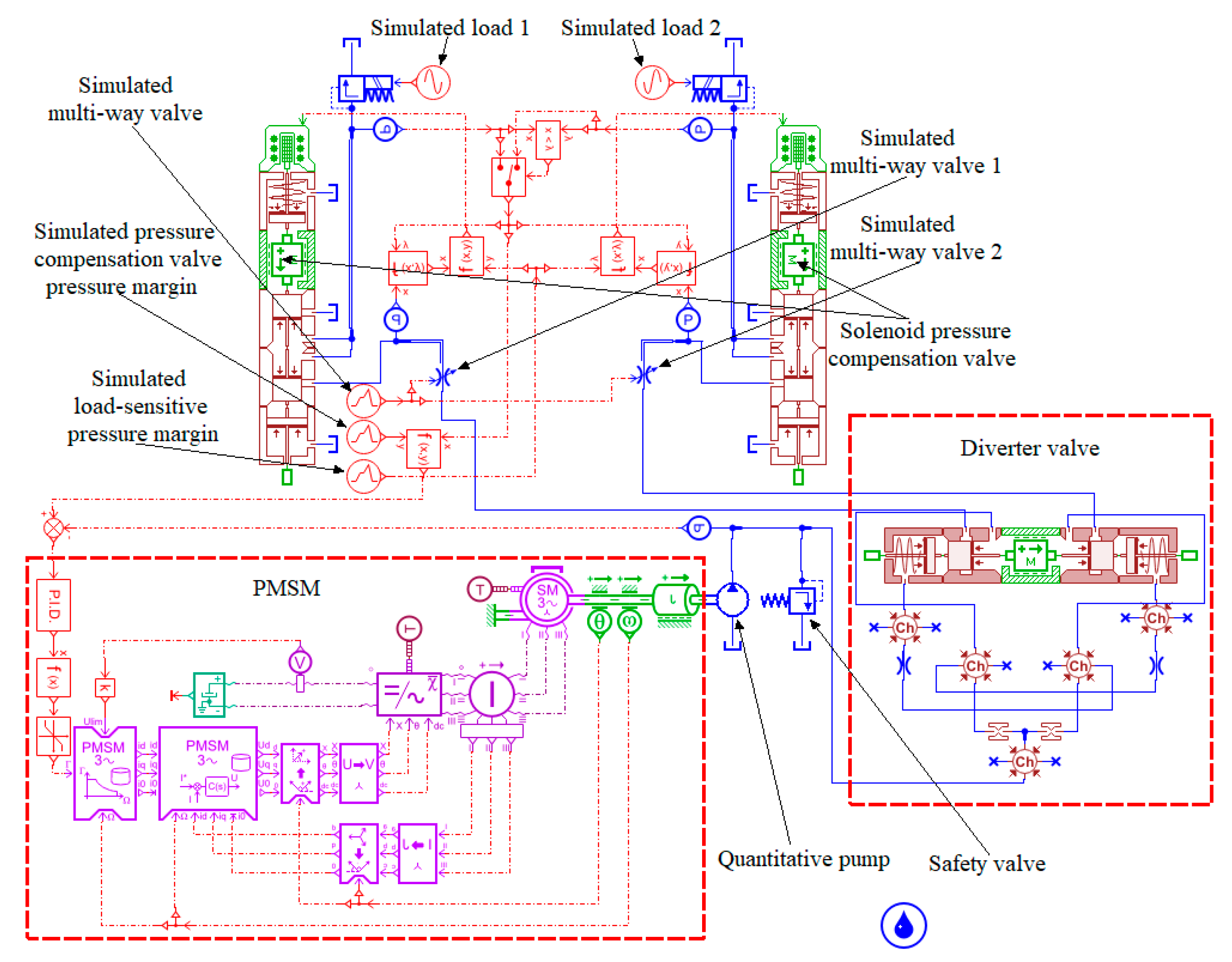

5. System Modeling and Simulation

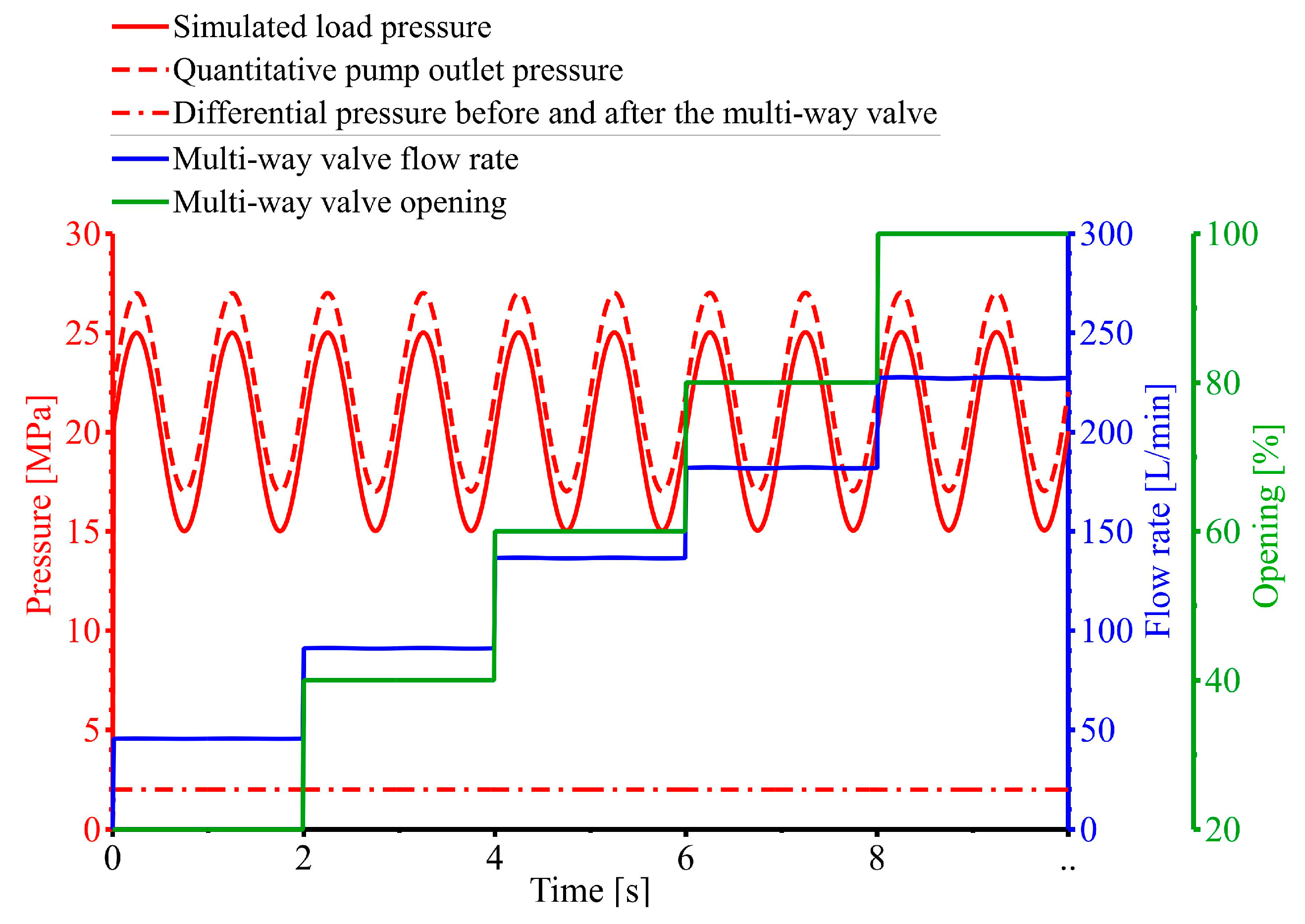

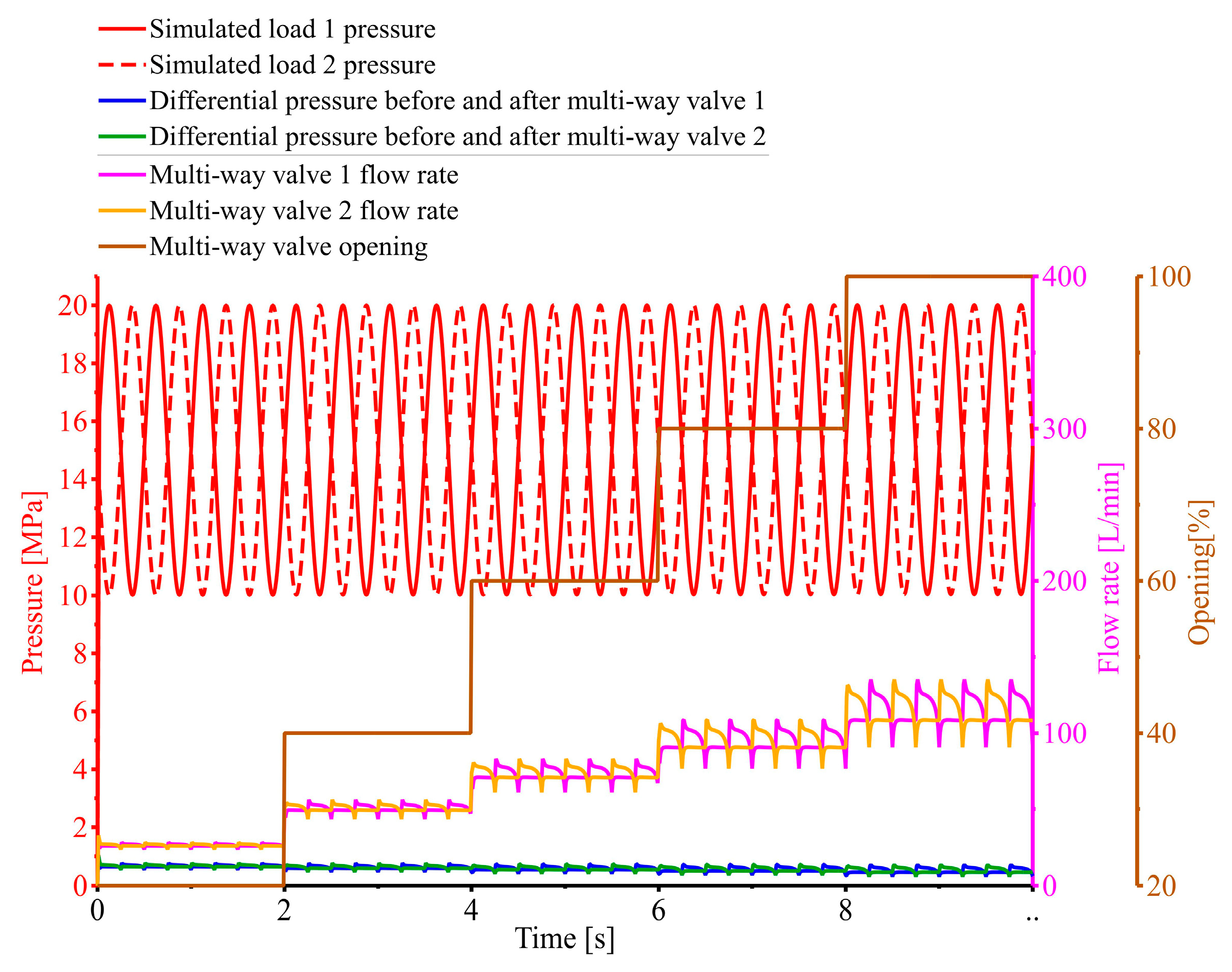

5.1. The EHLS Drive System

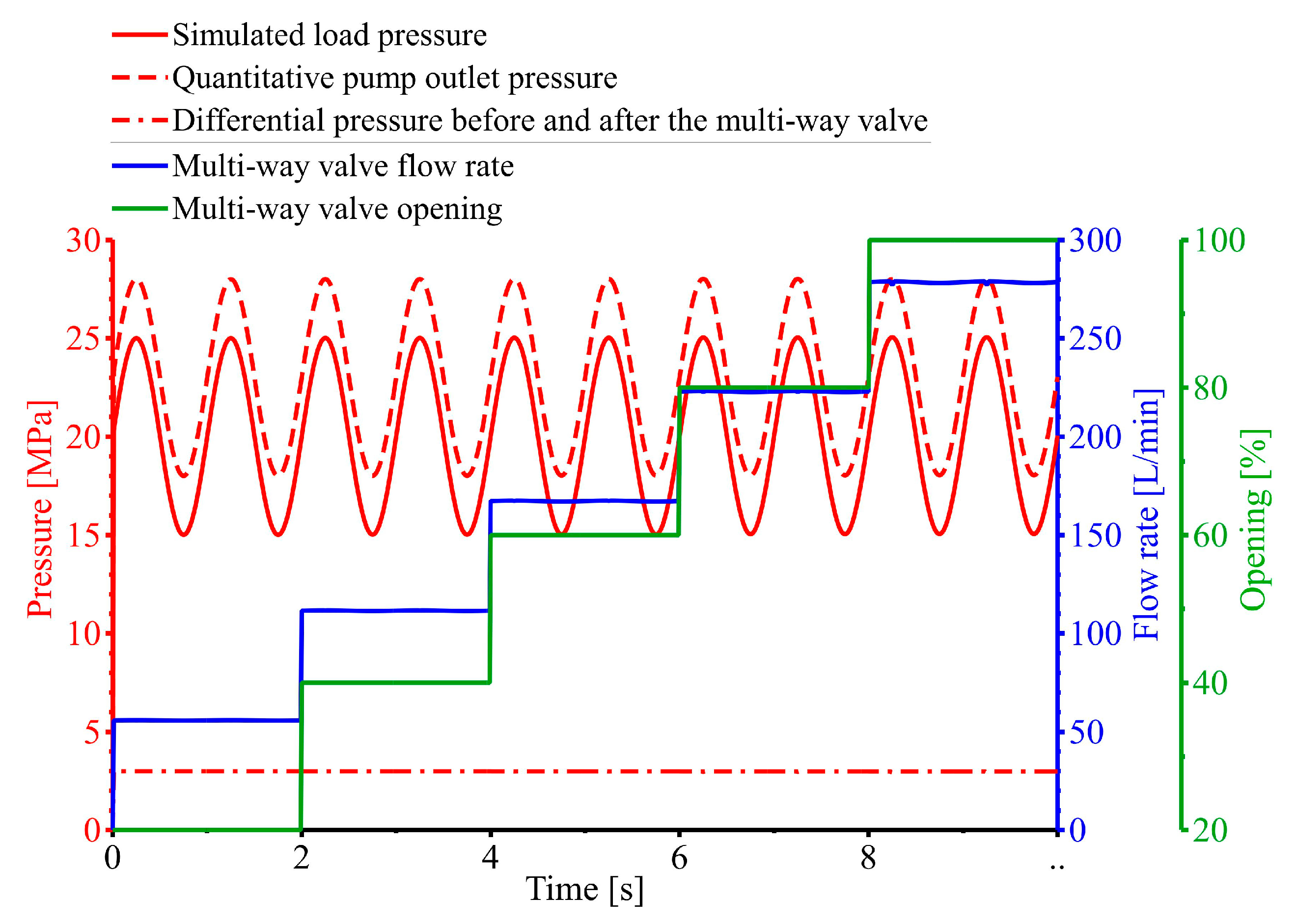

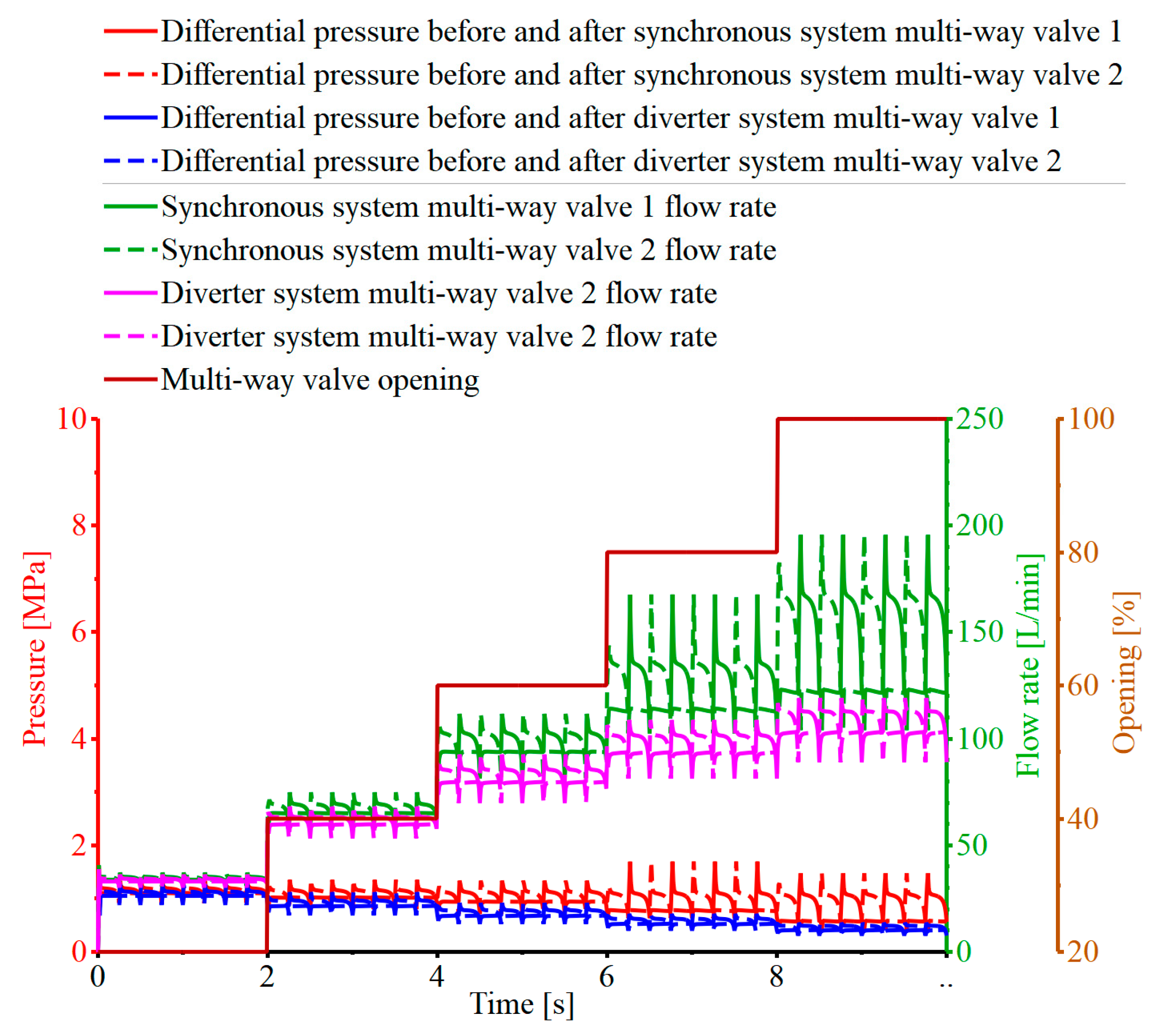

5.2. The EHLS Synchronous Drive System

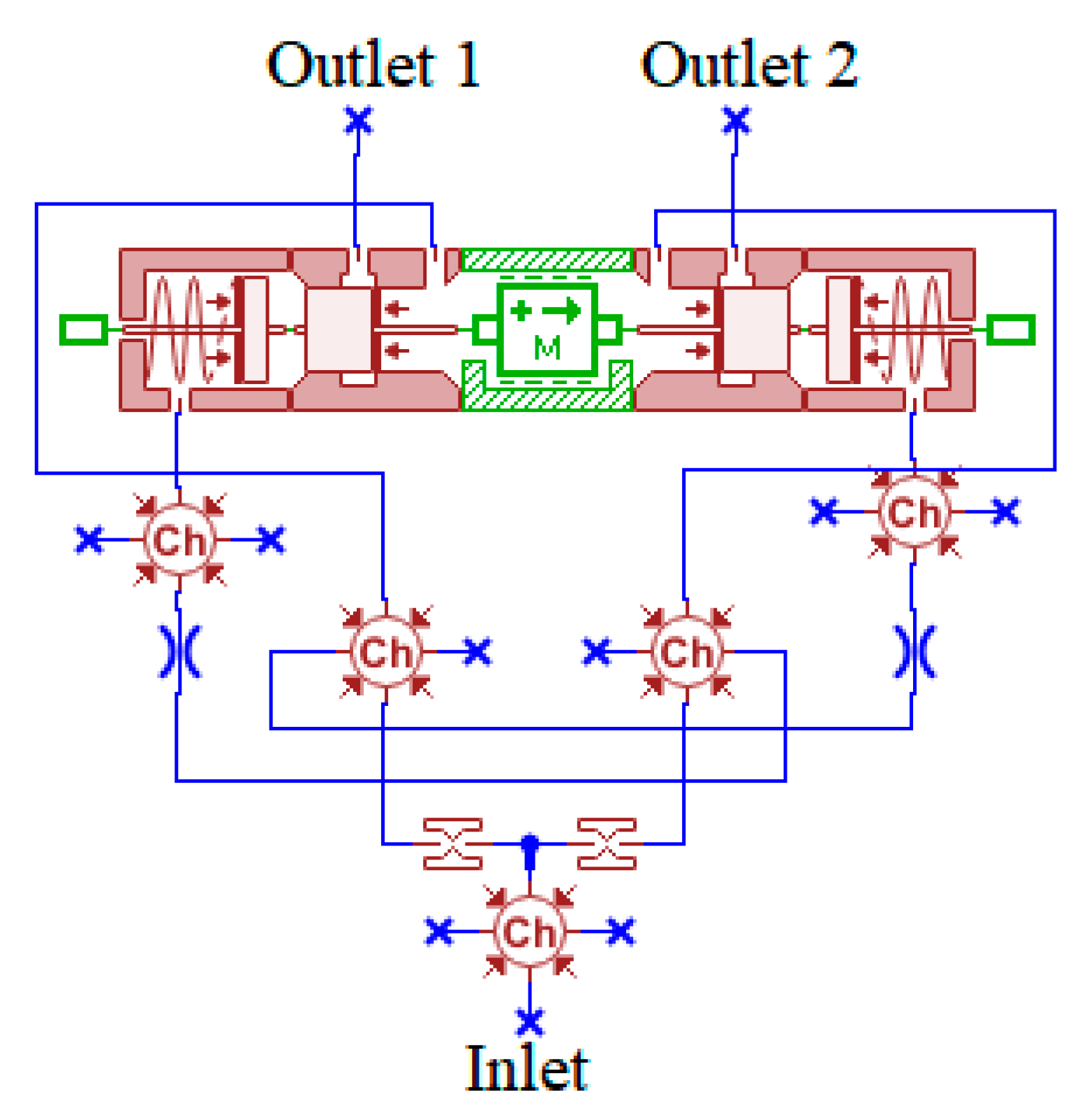

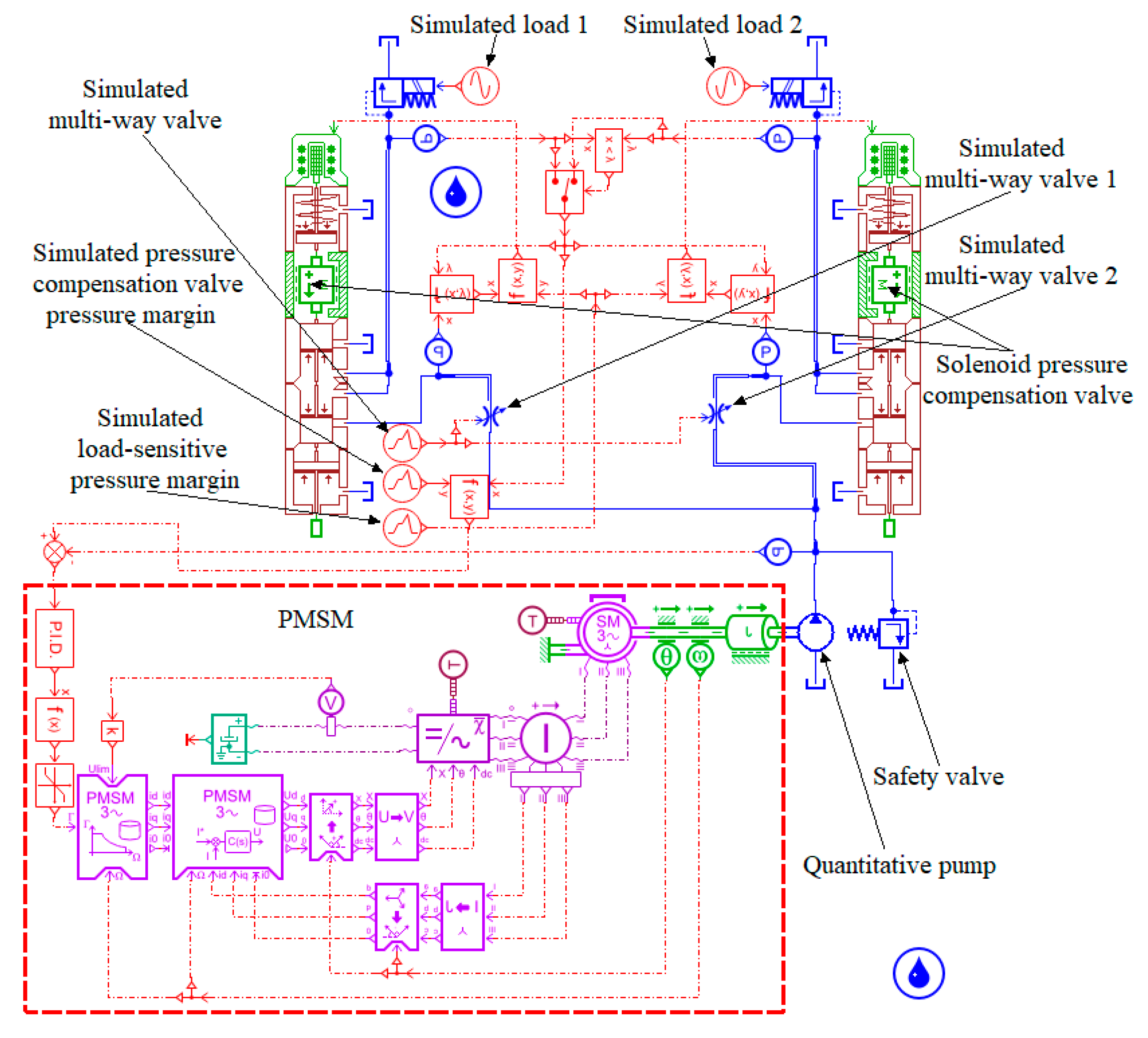

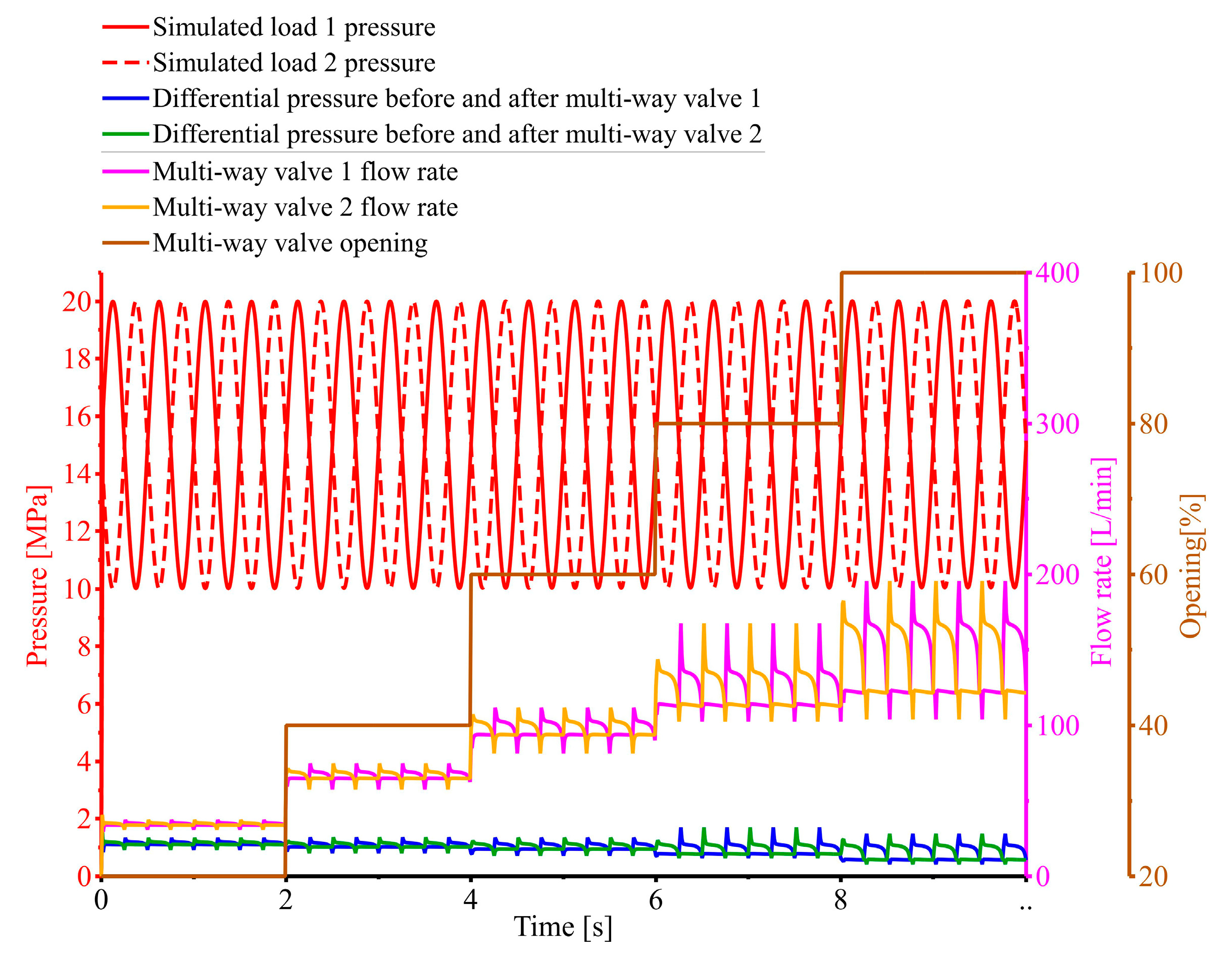

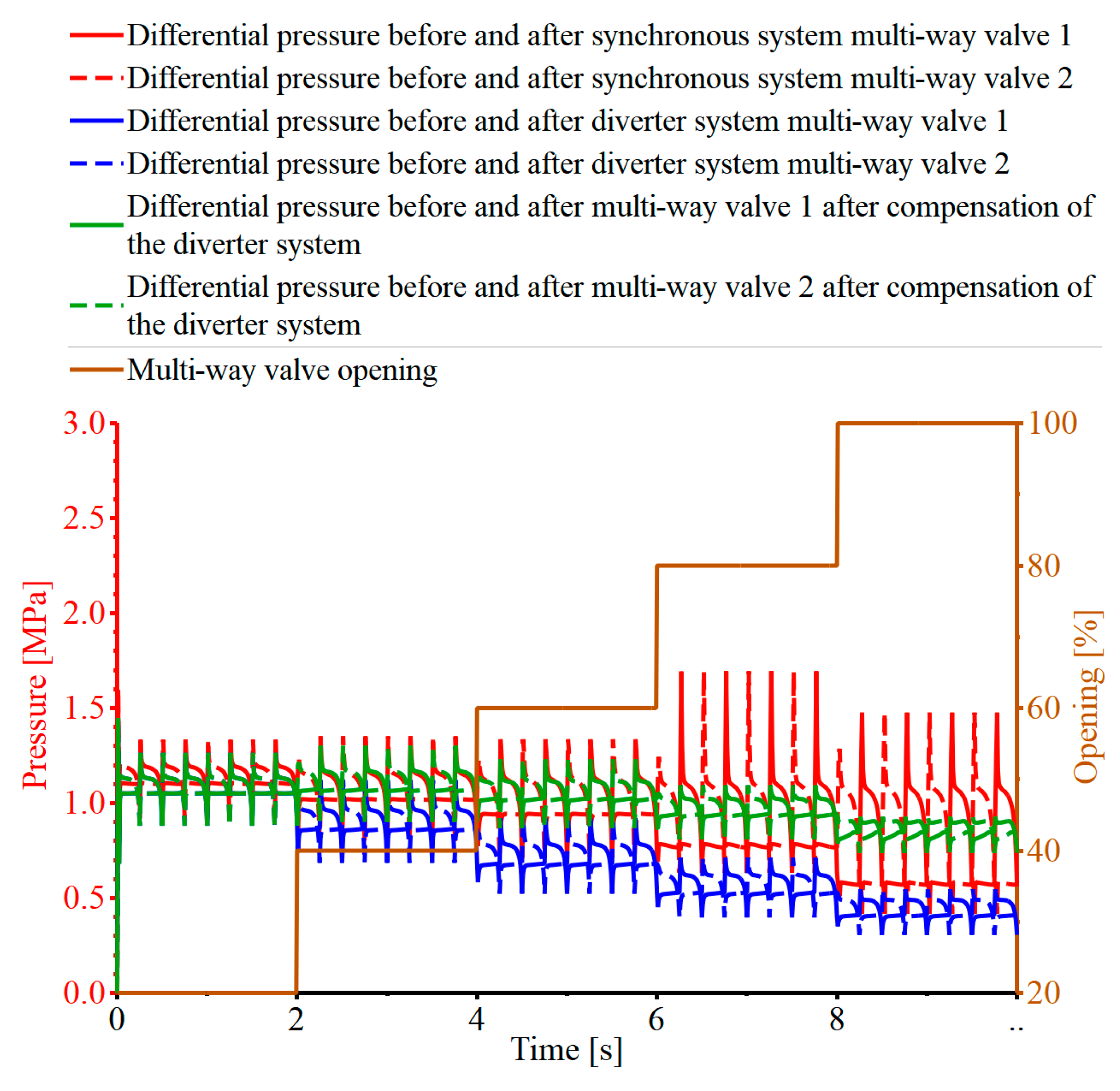

5.3. The EHLS Diverter Synchronous Drive System

6. Discussion

7. Conclusions

- The EHLS drive system realizes the primary function of the load-sensitive system. It can realize the variable load-sensitive pressure margin control to regulate the differential pressure and flow rate before and after the multi-way valve;

- The EHLS synchronous drive system has poor synchronous control accuracy. It can realize variable pressure compensation valve pressure margin control to regulate the differential pressure and flow before and after the multi-way valve;

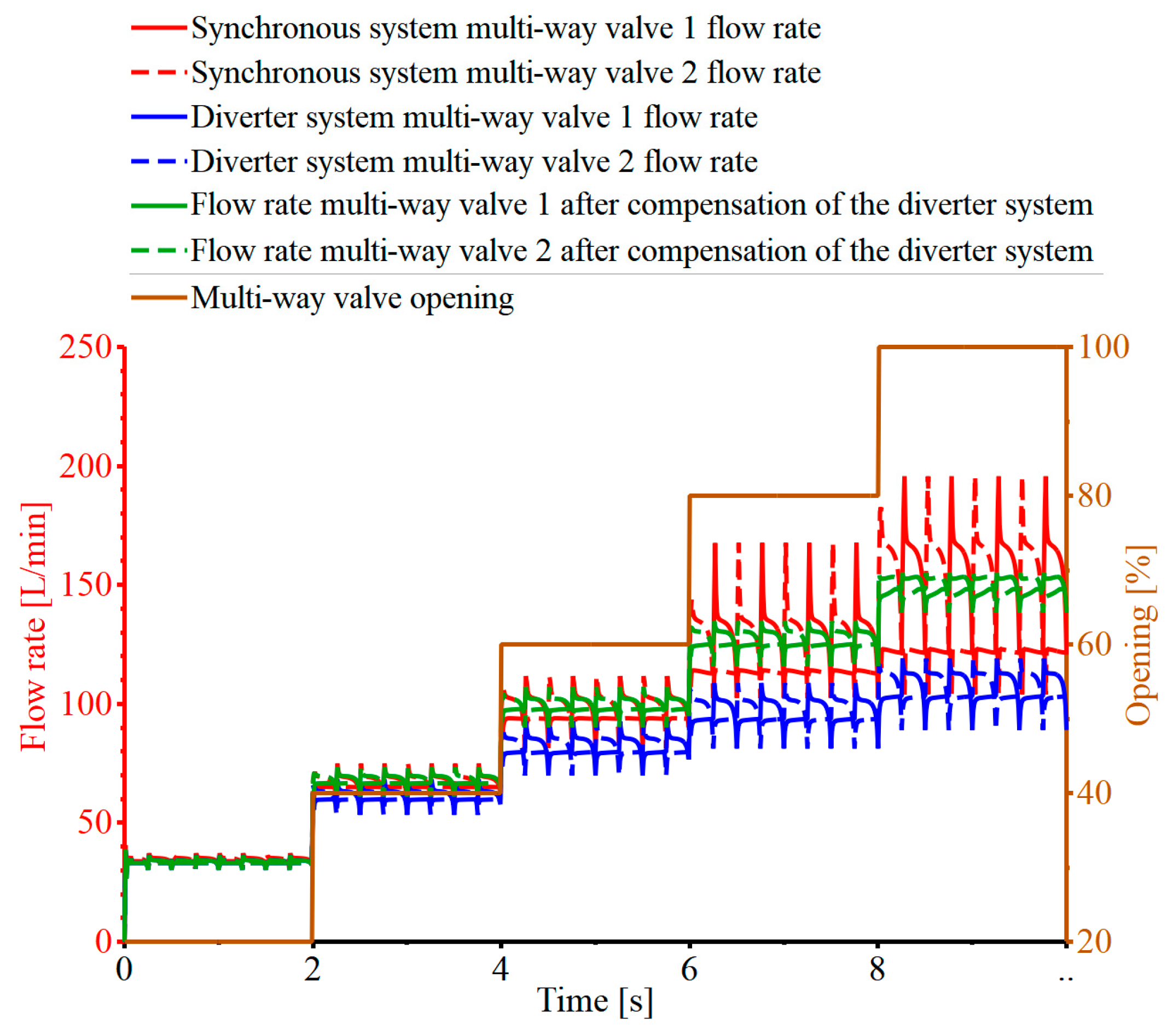

- The EHLS diverter synchronous drive system effectively improves the synchronous control performance of the system through variable pressure margin compensation control. The diverter system diverter error is reduced by 40.8%, and the diverter compensation system diverter error is reduced by 52.6% when the multi-way valve is fully opened. After the variable pressure margin compensation control, the diverter system effectively improves the diverter synchronous accuracy;

- The system provides a high-performance hydraulic synchronous drive solution under severe working conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, H. Analysis of Current Situation and Prospect of Electrification of Construction Machinery. Constr. Mach. Dig. 2022, 3, 23–25. [Google Scholar]

- Nie, H.; Shen, W. Research on Popularization and Application of Electric Construction Machinery. Constr. Mech. 2022, 43, 19–21. [Google Scholar]

- Fu, S.; Lin, T.; Wang, L.; Miao, C. Load Sensitive System Based on Variable Speed Control. China J. Highw. Transp. 2020, 33, 189–196. [Google Scholar]

- Zuo, D.; Qian, L.; Yang, T.; Cui, X.; Luo, Q. Coupling Leveling Control Based on Fuzzy PID for Synchronous Loading System of Load-Bearing Test Bed. Chin. J. Electron. 2017, 26, 1206–1212. [Google Scholar] [CrossRef]

- He, B.; Zhao, C.; Wang, H.; Chang, X.; Wen, B. Dynamics of synchronization for four hydraulic motors in a vibrating pile driver system. Adv. Mech. Eng. 2016, 8, 1–15. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, Q.; Yu, C.; Li, X.Y.; Guan, W.L.; Deng, G.F. Collaborative Synchronization Digital Control for Double Hydraulic Cylinders. Adv. Mech. Eng. 2014, 6 Pt 9, 371403. [Google Scholar] [CrossRef]

- Wang, X.; Liao, R.; Shi, C.; Wang, S. Linear extended state observer-based motion synchronization control for hybrid actuation system of more electric aircraft. Sensors 2017, 17, 2444. [Google Scholar] [CrossRef] [PubMed]

- Rehman, U.; Wang, X.; Hameed, Z.; Gul, M.Y. Motion Synchronization Control for a Large Civil Aircraft’s Hybrid Actuation System Using Fuzzy Logic-Based Control Techniques. Mathematics 2023, 11, 1576. [Google Scholar] [CrossRef]

- Ding, H.; Liu, Y.; Zhao, J.; Chao, C. Research on principle of variable speed flow dividing synchronous drive in load-sensing under time-varying bias loads. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2021, 49, 62–67. [Google Scholar]

- Ding, H.; Liu, Y.; Zhao, Y. A new hydraulic synchronous scheme in open-loop control: Load-sensing synchronous control. Meas. Control 2020, 53, 119–125. [Google Scholar] [CrossRef]

- Li, R.; Yuan, W.; Ding, X.; Xu, J.; Sun, Q.; Zhang, Y. Review of Research and Development of Hydraulic Synchronous Control System. Processes 2023, 11, 981. [Google Scholar] [CrossRef]

- Ma, T.; Guo, X.; Su, G.; Deng, H.; Yang, T. Research on Synchronous Control of Active Disturbance Rejection Position of Multiple Hydraulic Cylinders of Digging-Anchor-Support Robot. Sensors 2023, 23, 4092. [Google Scholar] [CrossRef] [PubMed]

- Ding, H.; Wang, Y.; Zhang, H. Robust Output Feedback Position Control of Hydraulic Support with Neural Network Compensator. Actuators 2023, 12, 263. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, Z.; Liu, Q.; Nie, Z.; Gong, D.W. Decoupling-based adaptive sliding-mode synchro-position control for a dual-cylinder driven hydraulic support with different pipelines. ISA Trans. 2021, 123, 357–371. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Zhang, H.; Wang, W.; Li, K.; Zhou, Z.; He, H. Compound Control on Constant Synchronous Output of Double Pump-Double Valve-Controlled Motor System. Processes 2022, 10, 528. [Google Scholar] [CrossRef]

- Yao, J.; Cao, X.; Zhang, Y.; Li, Y. Cross-coupled fuzzy PID control combined with full decoupling compensation method for double cylinder servo control system. J. Mech. Sci. Technol. 2018, 32, 2261–2271. [Google Scholar] [CrossRef]

- Mu, H.; Luo, Y.; Deng, H.; Du, W.; Liu, Y. Simulation study on load-sensing shunt synchronous drive of agricultural machinery. Mach. Tool Hydraul. 2022, 50, 164–168. [Google Scholar]

- Hu, J.; Wang, X.; Liu, C. Research on design of load sensitive synchronous control hydraulic system of static pile driver. Manuf. Autom. 2021, 43, 94–98. [Google Scholar]

- Yang, L.; Yang, C.; Zhang, Y.; Wang, Q. Design of Load Sensitive Synchronous Drive System and Analysis of Synchronous Characteristics. Constr. Mach. Equip. 2021, 52, 97–102+12. [Google Scholar]

- Wang, F.; Zhao, J.; Liu, J.; Li, H. Simulation Research of Synchronous System with Large Eccentric Loads Based on Load-Sensing Principle. Mach. Tool Hydraul. 2017, 45, 142–144. [Google Scholar]

- Yang, X. Research on the Hydraulic Synchronous Control System in Load-Sensing NC Bending Machine. Master’s Thesis, Anhui University of Technology, Maanshan, China, 2016. [Google Scholar]

- Ding, H.; Liu, Y.; Zhao, J. Load Sensitive Variable Speed Synchronous Drive Principle and Characteristics. Chin. Hydraul. Pneum. 2021, 45, 77–81. [Google Scholar]

- Cheng, M.; Yu, J.; Ding, R. Electrohydraulic Load Sensing System via Compound Control of Flow Feedforward and Pressure Feedback. J. Mech. Eng. 2018, 54, 262–270. [Google Scholar] [CrossRef]

- Du, L. Research on Load-Sensitive System of Hydrostatic Drive Rotary Tiller. Master’s Thesis, Guizhou University, Guiyang, China, 2022. [Google Scholar]

- Yu, X. Research on Dual-Variable Control Algorithm of Electro-Hydrostatic Actuator. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2020. [Google Scholar]

- Qin, D. Research and Implementation of PMSM-DTC System. Master’s Thesis, Anhui University of Science and Technology, Huainan, China, 2018. [Google Scholar]

- Chen, W. Research on Hybrid Pressure Compensation Hydraulic Control System. Master’s Thesis, Guizhou University, Guiyang, China, 2021. [Google Scholar]

- Liu, Y. Study on Load Sensitive Variable Speed Flow Dividing Principle and Synchronous Drive Characteristics. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2021. [Google Scholar]

- Chen, L.; Liu, Z.; Zhu, W. Simulation and Research on Dynamic Performance of Hydraulic Diverter Valve. Constr. Mach. Equip. 2004, 9, 42–45+1. [Google Scholar]

| Components | Parameters | Value |

|---|---|---|

| Solenoid pressure compensation valve | Spool diameter | 0.01 m |

| Zero displacement length | 0.003 m | |

| Rated current | 0.04 A | |

| Damping factor | 50 N/(m/s) | |

| Spool quality | 0.01 kg |

| Components | Parameters | Value |

|---|---|---|

| Diverter valve | Spring stiffness | 1000 N/m |

| Spring pre-compression force | 10 N | |

| Spool diameter | 0.01 m | |

| Zero displacement length | 0.003 m | |

| Maximum opening displacement length | 0.01 m | |

| Spool quality | 0.01 kg |

| Components | Parameters | Value |

|---|---|---|

| PMSM | Rated speed | 1500 rev/min |

| Quantitative pump | Displacement | 0.0002 m3/rev |

| Rated speed | 1500 rev/min | |

| Safety valve | Cracking pressure | 28 MPa |

| Proportional throttle | Maximum opening diameter | 0.01 m |

| Minimum signal | 0 | |

| Maximum signal | 1 | |

| Proportional relief valve | Maximum opening pressure | 25 MPa |

| Valve lagging pressure | 0 | |

| Valve rated current | 0.25 A |

| Components | System Performance | |

|---|---|---|

| The EHLS drive system | The variable load-sensitive pressure margin control is realized | |

| The EHLS synchronous drive system | The variable pressure compensation valve pressure margin control is realized | |

| The EHLS diverter synchronous drive system | Conventional system | The system diverter synchronous accuracy is low, and the maximum diverter error is 61% |

| Diverter system | The synchronous control performance decreases, the maximum diverter error is 20.2%, and the diverter error is reduced by 40.8% | |

| Diverter system after compensation | The synchronous control performance is guaranteed, the maximum diverter error is 8.4%, and the diverter error is reduced by 52.6% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, W.; Luo, Y.; Luo, Y.; Mu, H. A Simulation Study of an Electro-Hydraulic Load-Sensitive Variable Pressure Margin Diverter Synchronous Drive System with Time-Varying Load Resistance. Processes 2024, 12, 170. https://doi.org/10.3390/pr12010170

Du W, Luo Y, Luo Y, Mu H. A Simulation Study of an Electro-Hydraulic Load-Sensitive Variable Pressure Margin Diverter Synchronous Drive System with Time-Varying Load Resistance. Processes. 2024; 12(1):170. https://doi.org/10.3390/pr12010170

Chicago/Turabian StyleDu, Wei, Yu Luo, Yanlei Luo, and Hongyun Mu. 2024. "A Simulation Study of an Electro-Hydraulic Load-Sensitive Variable Pressure Margin Diverter Synchronous Drive System with Time-Varying Load Resistance" Processes 12, no. 1: 170. https://doi.org/10.3390/pr12010170

APA StyleDu, W., Luo, Y., Luo, Y., & Mu, H. (2024). A Simulation Study of an Electro-Hydraulic Load-Sensitive Variable Pressure Margin Diverter Synchronous Drive System with Time-Varying Load Resistance. Processes, 12(1), 170. https://doi.org/10.3390/pr12010170