Study on Fracture Propagation Rules of Shale Refracturing Based on CT Technology

Abstract

1. Introduction

2. Experiments

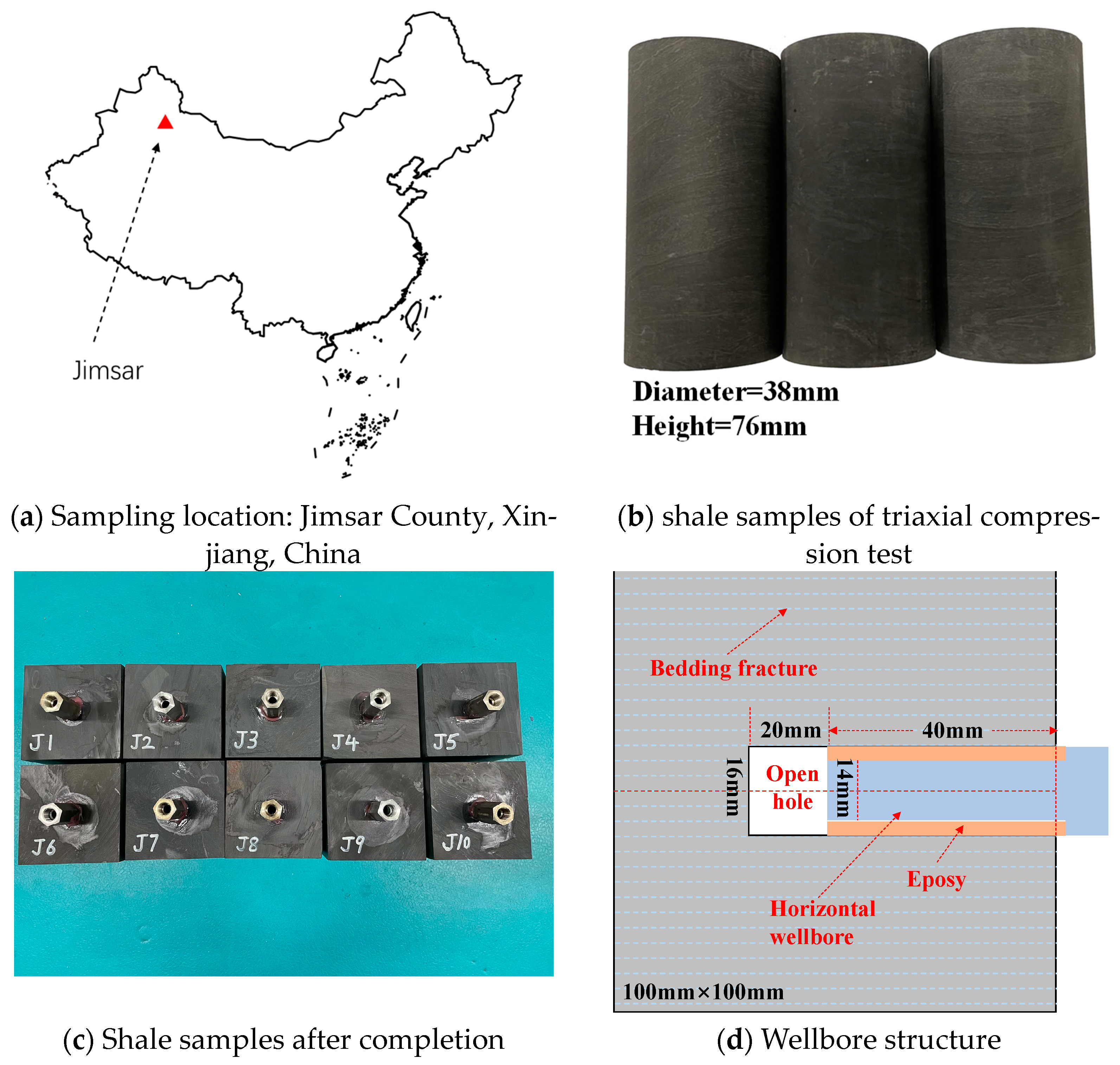

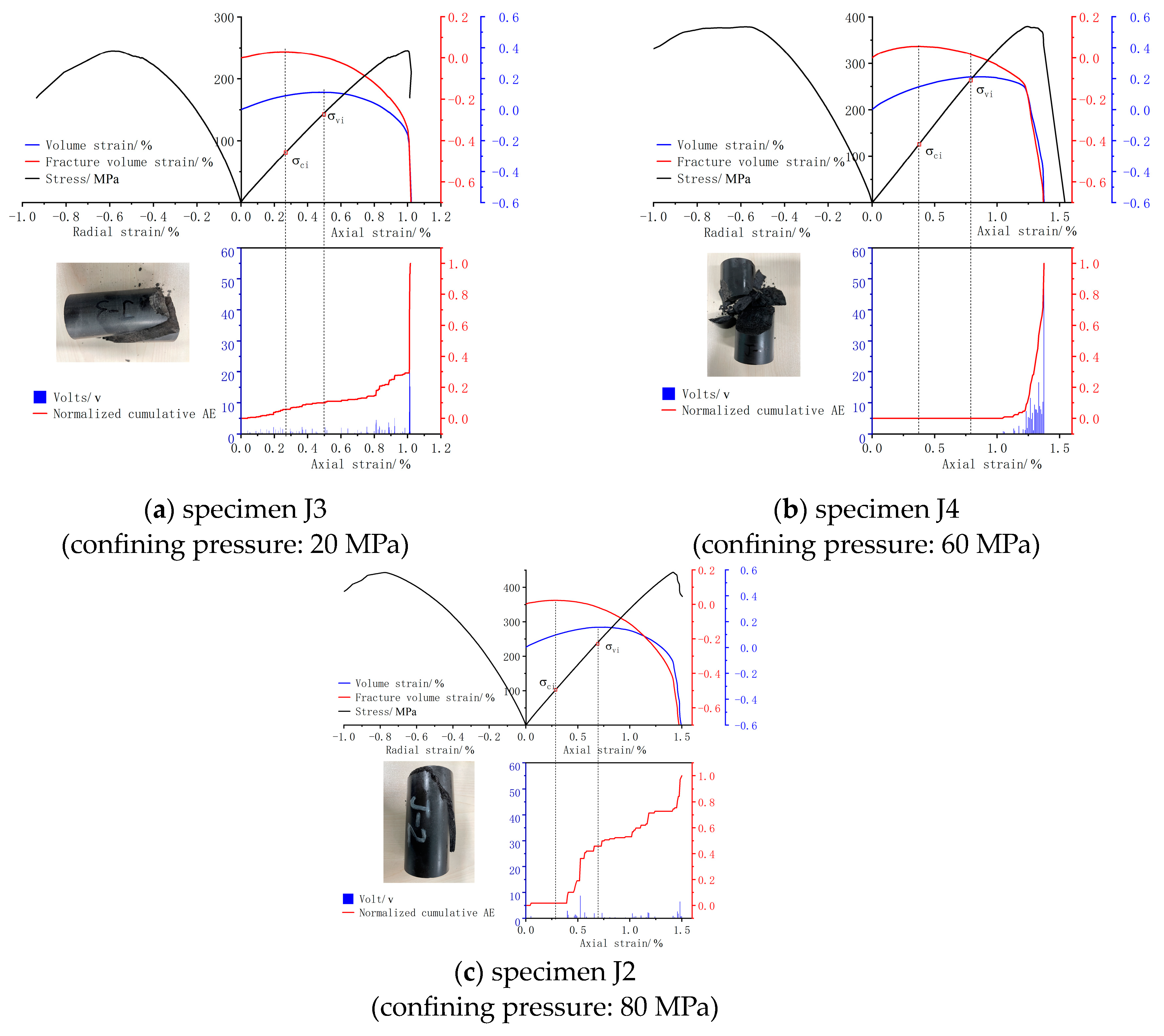

2.1. Preparation of Experimental Samples

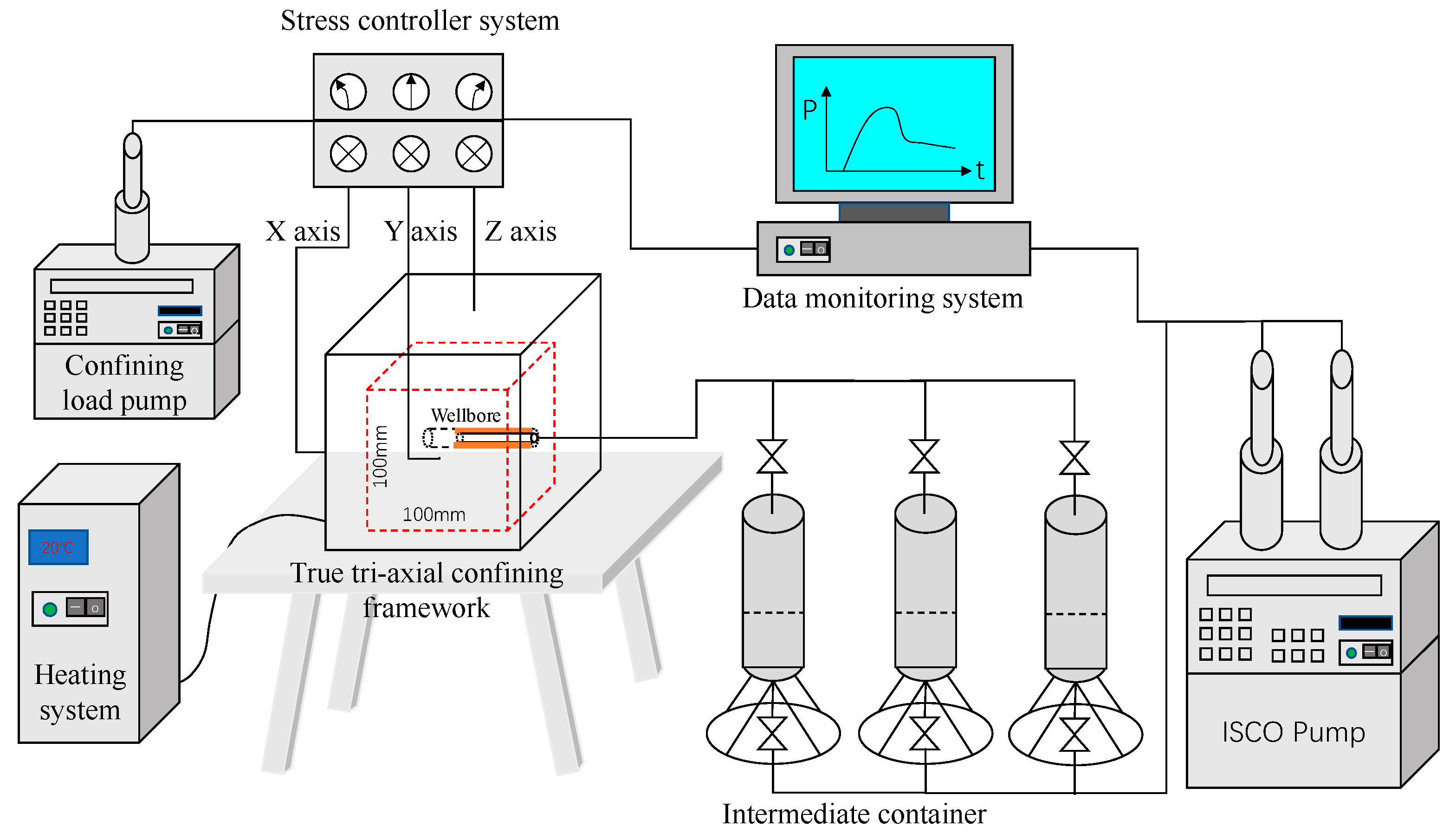

2.2. Experimental System

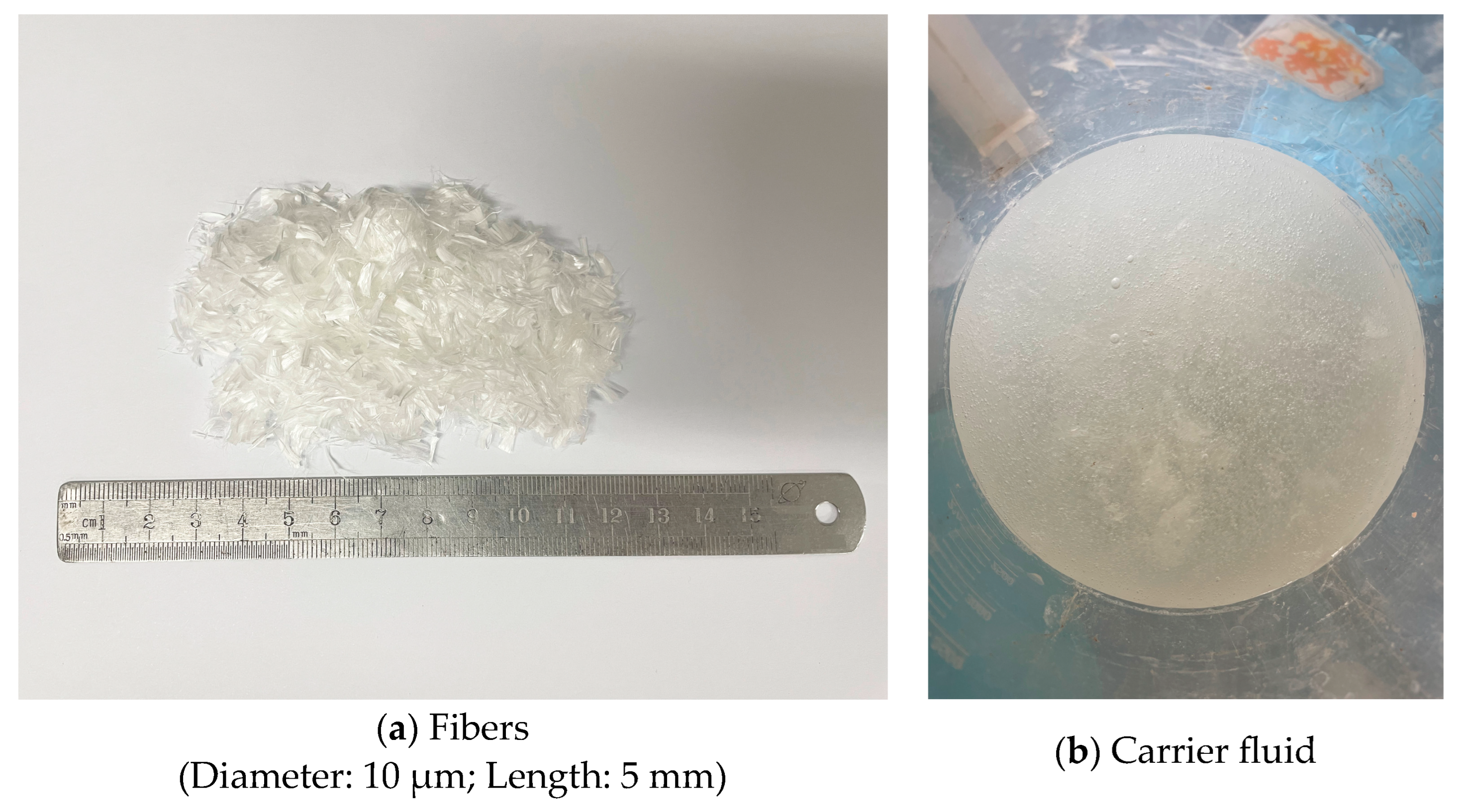

2.3. Fracturing Fluid and Diverters

2.4. Experimental Design and Procedure

- (1)

- Prepare the cores according to the design dimensions and configure the fracturing fluids: slickwater fracturing fluid, variable viscosity slickwater fracturing fluid, and crosslinked guar gum fracturing fluid (HPG) with added fiber diverter.

- (2)

- Infuse the prepared fracturing fluids into different intermediate containers.

- (3)

- Place the cores that have undergone CT scanning into the true triaxial core loading frame, tighten the baffle screws, and connect the pipelines.

- (4)

- Apply confining pressure to the true triaxial core loading frame in three directions through the confining pressure control system and maintain it at a constant level.

- (5)

- According to the experimental plan, pump the fracturing fluid using the ISCO pump, initiate the fracturing experiment, and record the pressure values of the first fracturing until the pressure curve sharply drops to nearly zero, then stop the experiment and record the data.

- (6)

- Unload the confining pressure, dismantle the pipelines, loosen the screws of the core loading frame, and extract the core after the first fracturing. Mark the fractures on the core surface, take photographs, and conduct CT scanning.

- (7)

- Repeat steps 3–6 to complete the refracturing experiments.

- (8)

- Repeat steps 3–7 for all cores to complete the first and refracturing.

- (9)

- Import the CT scanning data into Avizo2019 software for describing the fractures.

3. Results and Discussion

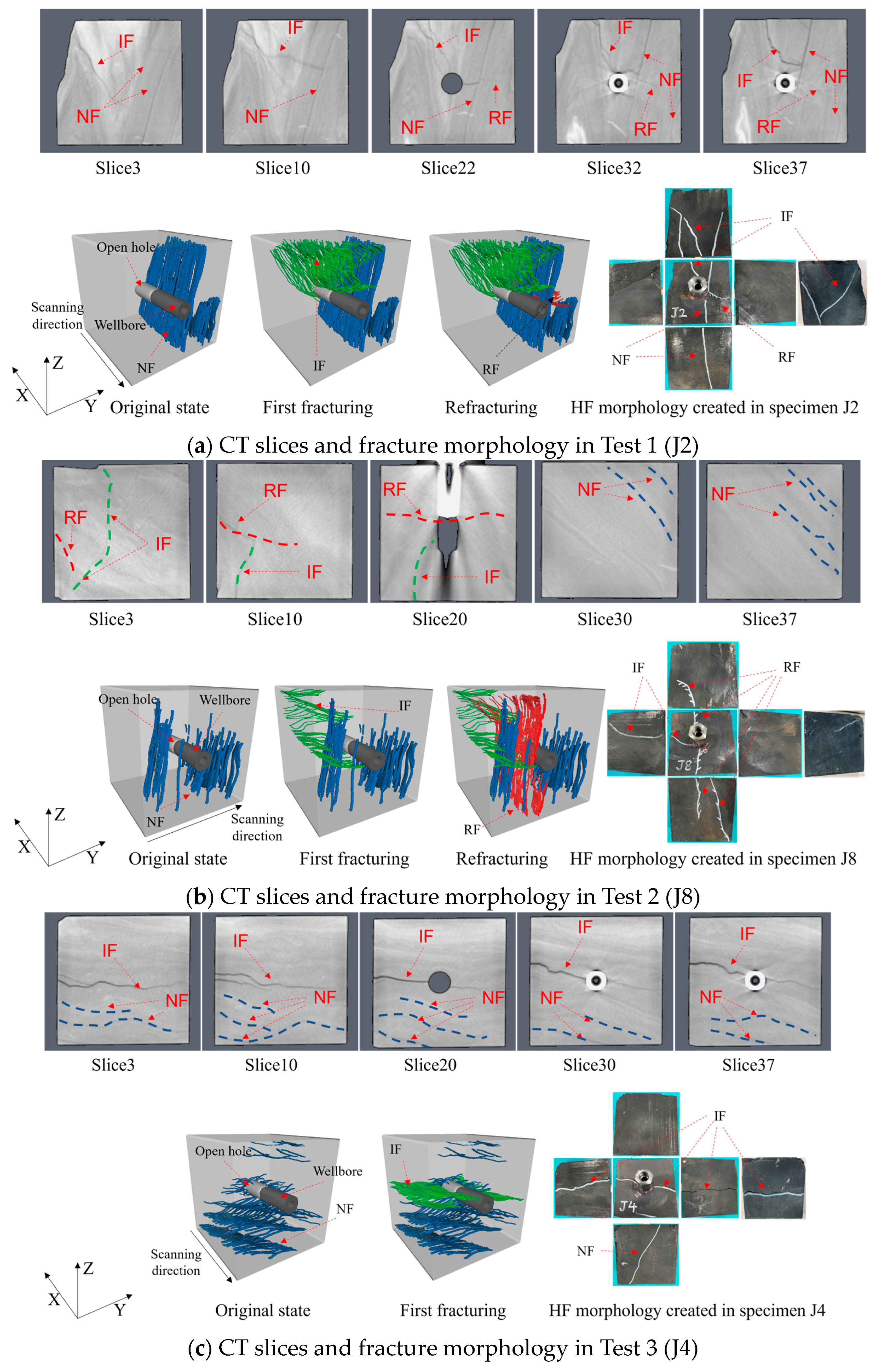

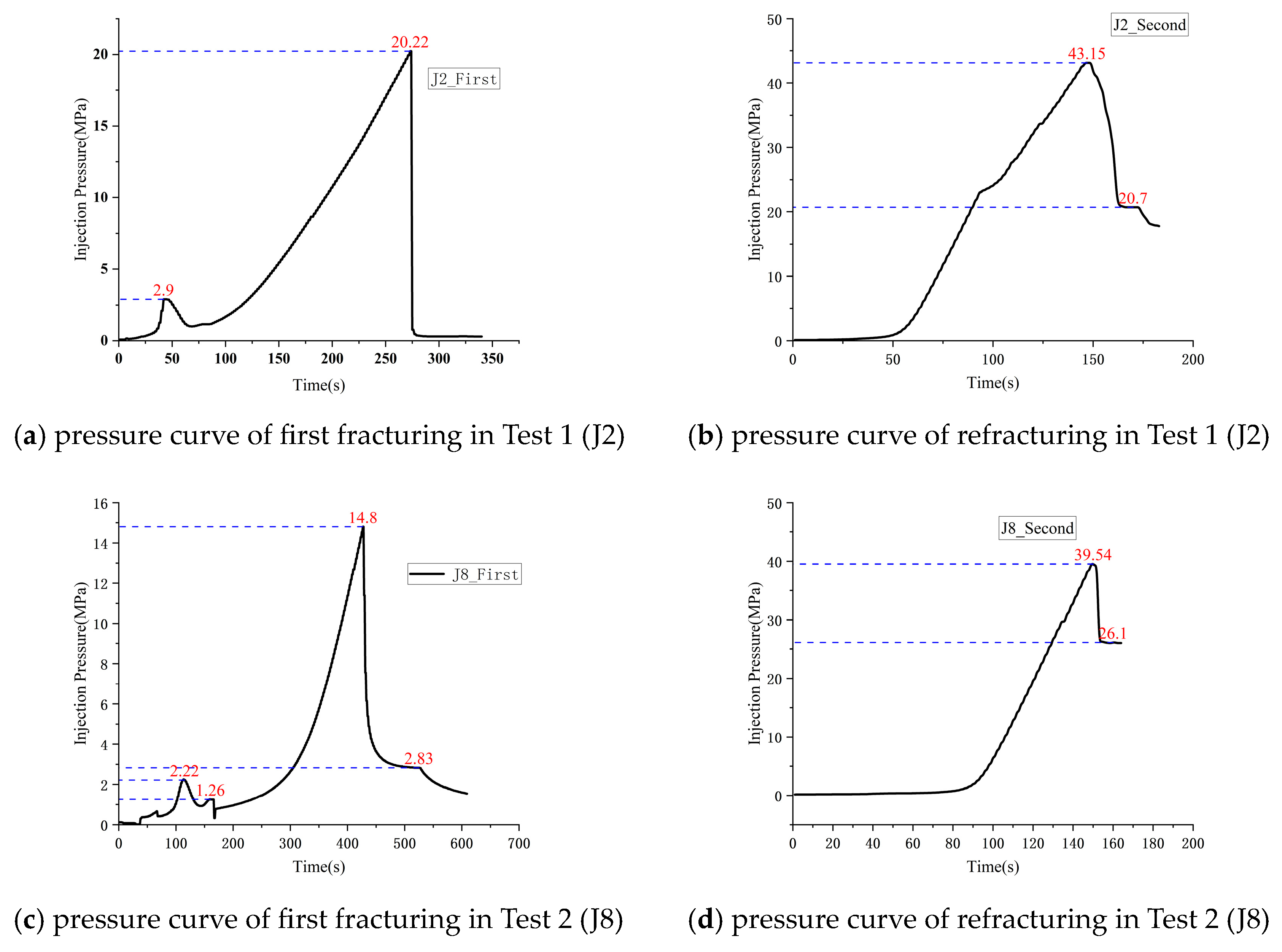

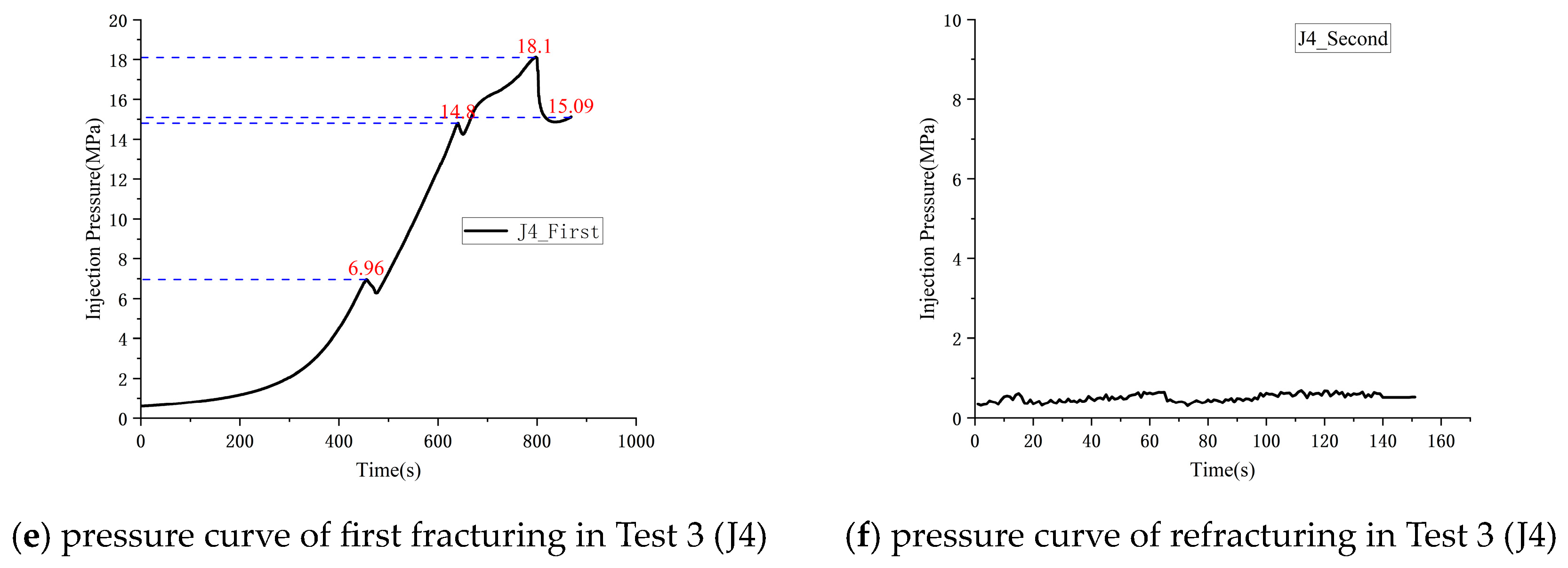

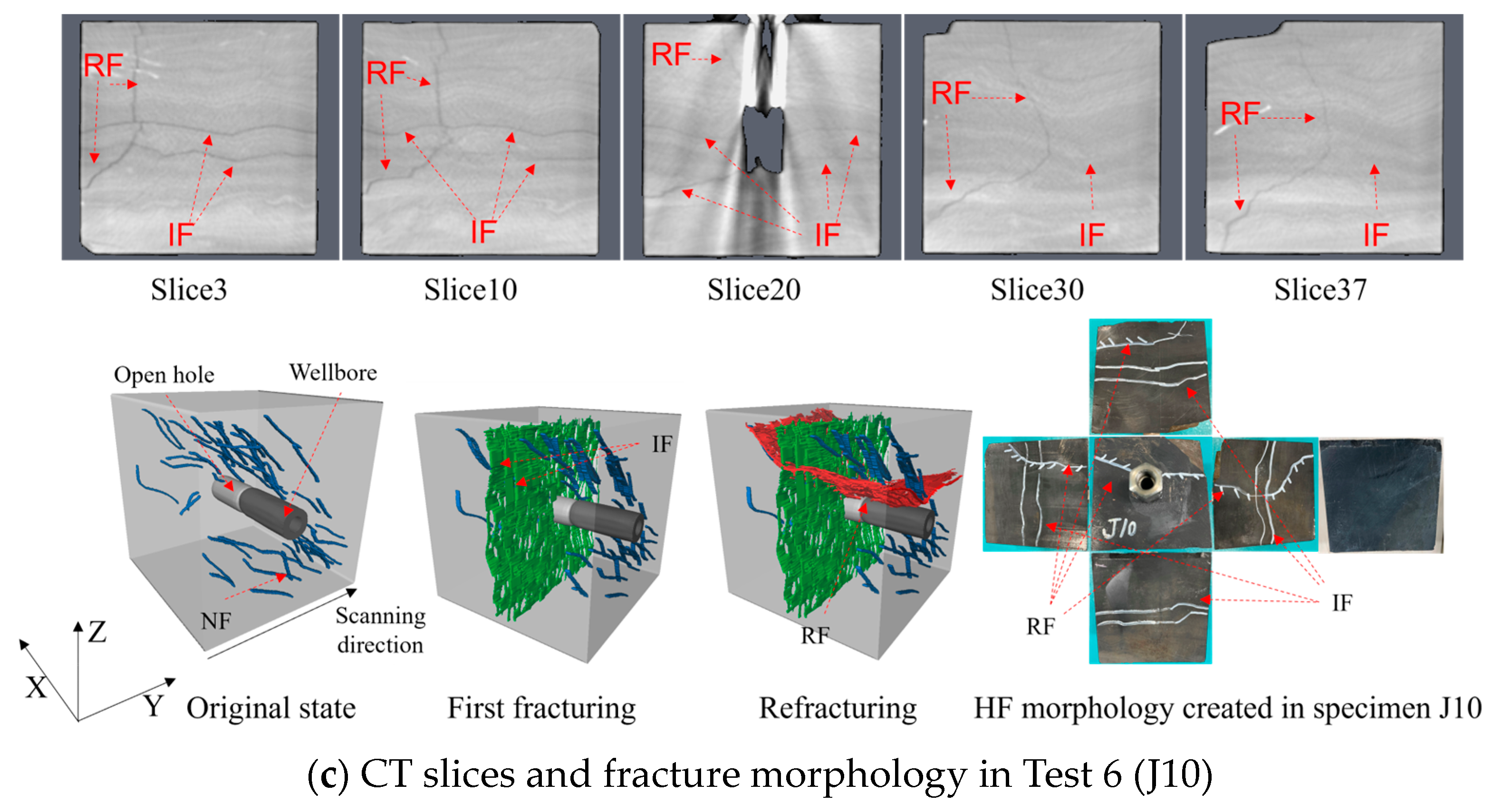

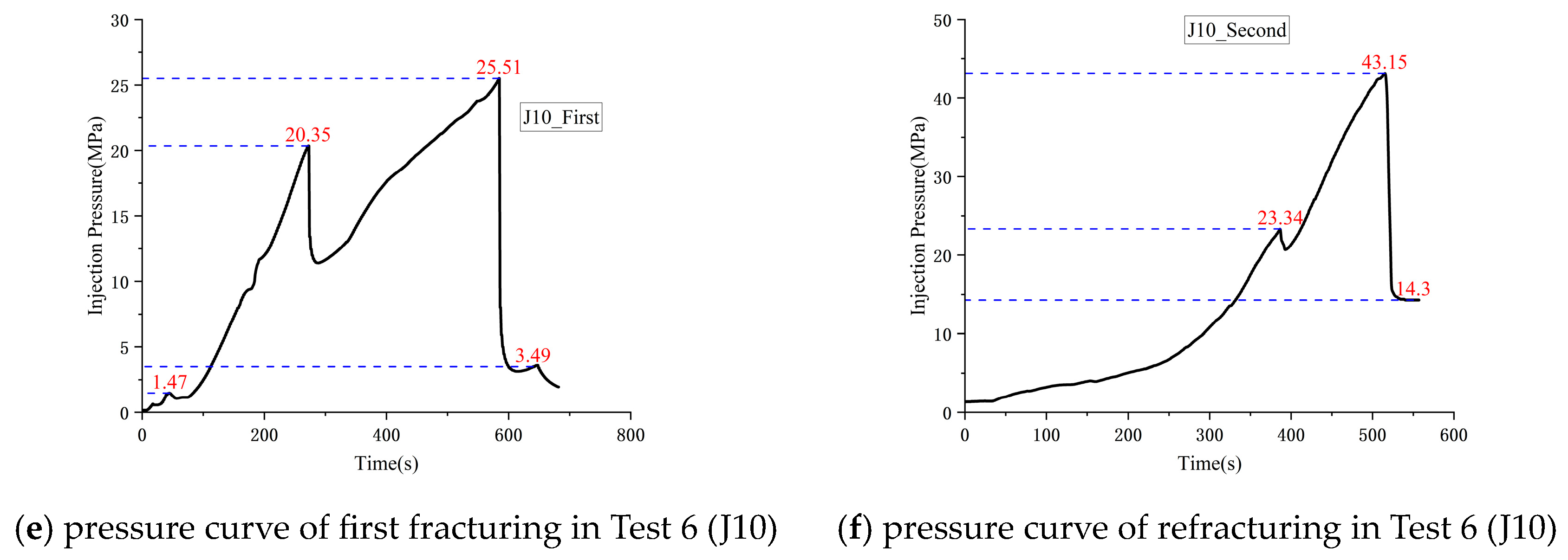

3.1. Impact of Stress State on Refracturing

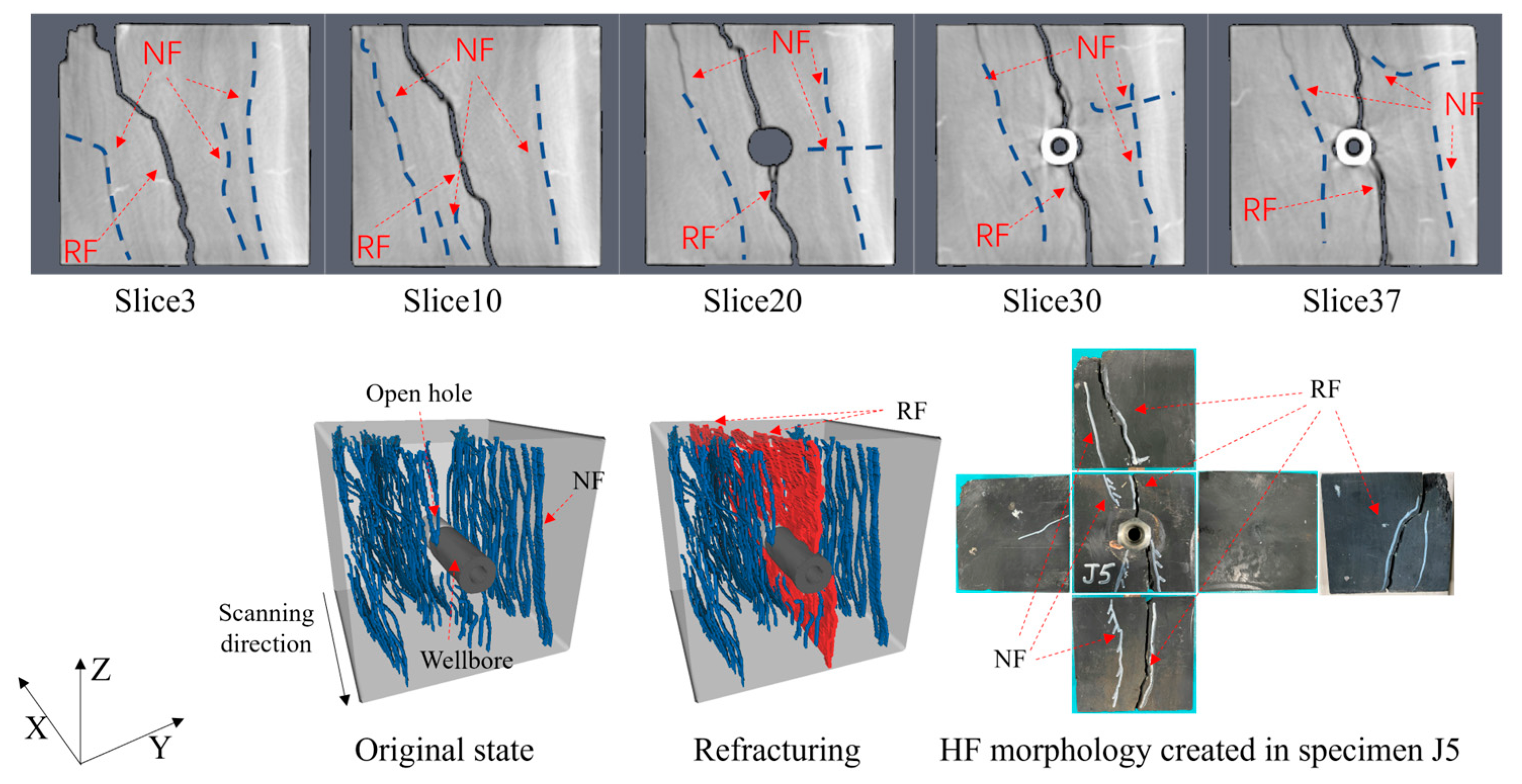

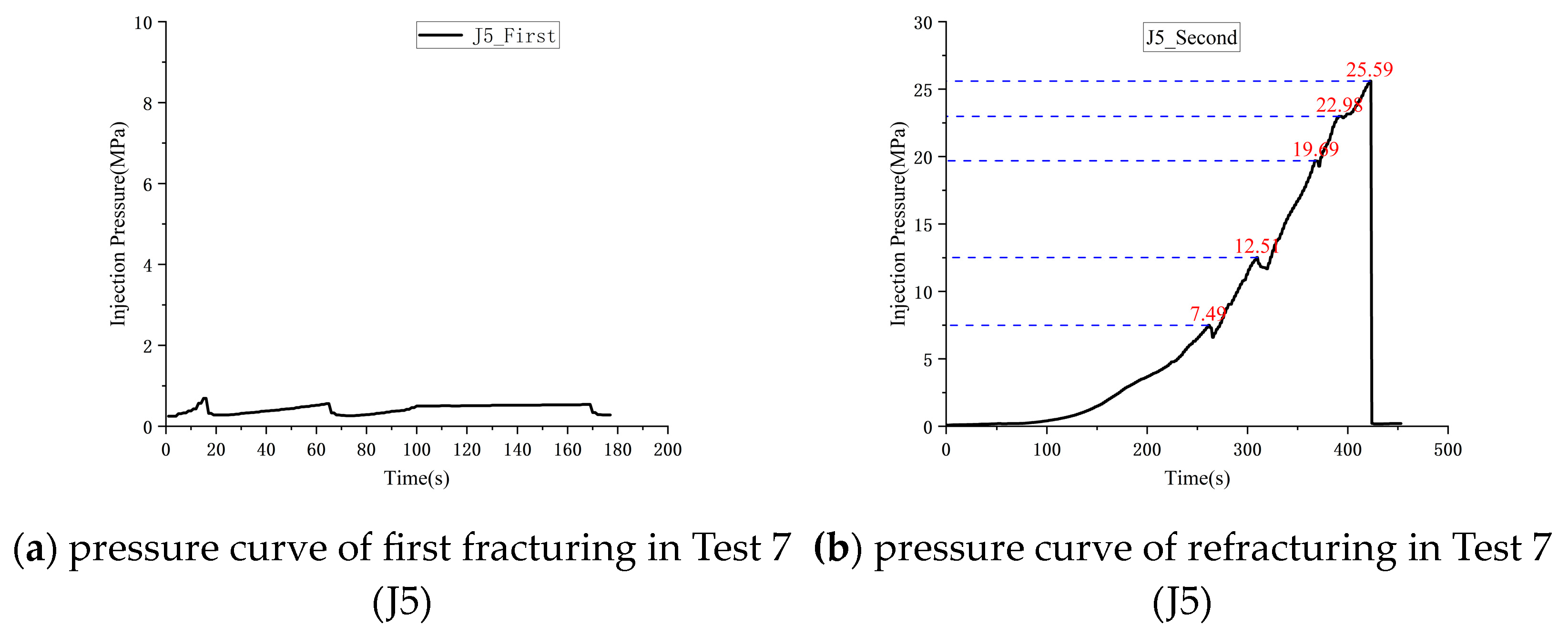

3.2. Impact of Pumping Rate on Refracturing

3.3. Influence of Shale Bedding on Refracturing

3.4. Impact of Fracturing Fluid Viscosity on Refracturing

4. Conclusions

- (1)

- Refracturing is an important way to effectively develop shale oil and gas. The propagation law of re-fracturing fractures is complex, and the fracture morphology and fracture network are affected by stress state, natural fractures and first fracturing fractures.

- (2)

- Temporary plugging is an important method for refracturing to create new fractures. The ‘point’ temporary plugging body cannot effectively inhibit the expansion of fractures along the old fractures, while the ‘sheet-like’ temporary plugging body can effectively block the old fractures.

- (3)

- With the decrease of stress (stress difference), the complexity of re-fracturing fractures increases gradually. With the progress of production, pore pressure and horizontal principal stress decrease. In the process of horizontal stress difference decreasing to equal and then to steering, the complexity of refracturing fractures increases first and then decreases. Only in terms of increasing the complexity of fracture network, the smaller the horizontal stress difference is, the more favorable it is.

- (4)

- During refracturing, the pumping rate of fracturing fluid has an important influence on the effective pumping of old fractures and the formation of temporary plugging. When the pumping rate is low, the temporary plugging agent is easy to form ‘point’ temporary plugging body at the root end of the old fracture, but can not effectively block the old fracture. When the pumping rate is increased (twice as much as that of the initial fracturing in this experiment), the fiber temporary plugging agent is effectively pumped into the old fracture to form a ‘sheet-like’ temporary plugging body.

- (5)

- Shale bedding has a weak plane effect. When natural fractures are blocked, the shale bedding plane is easy to be opened, and a broken fracture zone is easily formed between the bedding planes.

- (6)

- Pumping the temporary plugging agent into the deep formation to form a ‘sheet-like’ temporary plugging body requires a certain degree of fracturing strength. Appropriately increasing the displacement and viscosity is conducive to the formation of a ‘sheet-like’ temporary plugging body.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, A.; Mathukutty, S.; Siegel, S. Refrac Implementation in Legacy Shale Play Re-Development: A Multivariable Approach. In Proceedings of the SPE Eastern Regional Meeting, Charleston, WV, USA, 15–17 October 2019; pp. D31S–D36S. [Google Scholar]

- Charry, L.; Malpani, R.; Clark, B. A Step Change in the Learning Curve for Refracturing in the Eagle Ford. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, San Antonio, TX, USA, 1–3 August 2016; p. 2461344. [Google Scholar]

- Vincent, M.C. Restimulation of Unconventional Reservoirs: When Are Refracs Beneficial? J. Can. Pet. Technol. 2011, 50, 36–52. [Google Scholar] [CrossRef]

- Kong, X.; Shi, X.; Gao, Q.; Xu, H.; Ge, X.; Cui, H. Experimental study on hydraulic fracture propagation behavior of horizontal well on multilayered rock. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 73. [Google Scholar] [CrossRef]

- Jia, Y.; Tsang, C.; Hammar, A.; Niemi, A. Hydraulic stimulation strategies in enhanced geothermal systems (EGS): A review. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 211. [Google Scholar] [CrossRef]

- Chen, B.; Barboza, B.R.; Sun, Y.; Bai, J.; Thomas, H.R.; Dutko, M.; Cottrell, M.; Li, C. A Review of Hydraulic Fracturing Simulation. Arch. Comput. Methods Eng. 2022, 29, 2113–2170. [Google Scholar] [CrossRef]

- Olasolo, P.; Juarez, M.C.; Morales, M.P.; D’Amico, S.; Liarte, I.A. Enhanced geothermal systems (EGS): A review. Renew. Sust. Energ. Rev. 2016, 56, 133–144. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, J.; Wu, H. Experimental and numerical study on hydraulic fracture propagation in coalbed methane reservoir. J. Nat. Gas Sci. Eng. 2016, 35, 455–467. [Google Scholar] [CrossRef]

- Li, D.Q.; Zhang, S.C.; Zhang, S.A. Experimental and numerical simulation study on fracturing through interlayer to coal seam. J. Nat. Gas Sci. Eng. 2014, 21, 386–396. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, S.; Qu, Z.; Zhou, T.; Xiao, Y.; Gao, J. Experimental study of hydraulic fracturing for shale by stimulated reservoir volume. Fuel 2014, 128, 373–380. [Google Scholar] [CrossRef]

- Yang, L.; Sheng, X.; Zhang, B.; Yu, H.; Wang, X.; Wang, P.; Mei, J. Propagation behavior of hydraulic fractures in shale under triaxial compression considering the influence of sandstone layers. Gas Sci. Eng. 2023, 110, 204895. [Google Scholar] [CrossRef]

- Xia, Y.; Tan, P.; Wang, X.; Ren, L. Differences of fracture propagation behavior for two typical fractured formations. Nat. Gas Ind. B 2022, 9, 264–270. [Google Scholar] [CrossRef]

- Lu, Y.; He, M.; Wu, B.; Meng, X. Experimental and theoretical analysis of hydraulic fracturing and gas fracturing of rock under true triaxial compressions. Eng. Fract. Mech. 2020, 234, 107100. [Google Scholar] [CrossRef]

- Jiang, C.; Niu, B.; Yin, G.; Zhang, D.; Yu, T.; Wang, P. CT-based 3D reconstruction of the geometry and propagation of hydraulic fracturing in shale. J. Petrol. Sci. Eng. 2019, 179, 899–911. [Google Scholar] [CrossRef]

- Heng, S.; Liu, X.; Li, X.; Zhang, X.; Yang, C. Experimental and numerical study on the non-planar propagation of hydraulic fractures in shale. J. Petrol. Sci. Eng. 2019, 179, 410–426. [Google Scholar] [CrossRef]

- Guo, P.; Li, X.; Yang, W.; Mao, T. Experimental study on hydrofracture propagation through perforated wellbore in naturally fractured Guanyinqiao calcareous mudstone under true triaxial stress. J. Nat. Gas Sci. Eng. 2022, 99, 104415. [Google Scholar] [CrossRef]

- Liu, Y.L.; Zheng, X.B.; Peng, X.F.; Zhang, Y.Y.; Chen, H.D.; He, J.H. Influence of natural fractures on propagation of hydraulic fractures in tight reservoirs during hydraulic fracturing. Mar. Petrol. Geol. 2022, 138, 105505. [Google Scholar] [CrossRef]

- Zhou, Z.; Jin, Y.; Zeng, Y.; Zhang, X.; Zhou, J.; Zhuang, L.; Xin, S. Investigation on fracture creation in hot dry rock geothermal formations of China during hydraulic fracturing. Renew. Energ. 2020, 153, 301–313. [Google Scholar] [CrossRef]

- Zou, Y.; Shi, S.; Zhang, S.; Li, J.; Wang, F.; Wang, J.; Zhang, X. Hydraulic fracture geometry and proppant distribution in thin interbedded shale oil reservoirs. Pet. Explor. Dev. 2022, 49, 1185–1194. [Google Scholar] [CrossRef]

- Liu, P.; Ju, Y.; Feng, Z.; Mao, L.T. Characterization of hydraulic crack initiation of coal seams under the coupling effects of geostress difference and complexity of pre-existing natural fractures. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 91. [Google Scholar] [CrossRef]

- Li, Y.W.; Yang, S.; Zhao, W.C.; Li, W.; Zhang, J. Experimental of hydraulic fracture propagation using fixed-point multistage fracturing in a vertical well in tight sandstone reservoir. J. Petrol. Sci. Eng. 2018, 171, 704–713. [Google Scholar] [CrossRef]

- Konstantinou, C.; Kandasami, R.K.; Biscontin, G.; Papanastasiou, P. Fluid injection through artificially reconstituted bio-cemented sands. Geomech. Energy Environ. 2023, 34, 100466. [Google Scholar] [CrossRef]

- Liu, B.; Jin, Y.; Chen, M. Influence of vugs in fractured-vuggy carbonate reservoirs on hydraulic fracture propagation based on laboratory experiments. J. Struct. Geol. 2019, 124, 143–150. [Google Scholar] [CrossRef]

- Wang, L.; Chen, W.; Zhang, Y.; Zhang, X.; Vuik, C. Investigating Effects of Heterogeneity and Fracture Distribution on Two-Phase Flow in Fractured Reservoir with adaptive time strategy. Transp. Porous Media 2023, 149, 175–203. [Google Scholar] [CrossRef]

- Wang, L.; Golfier, F.; Tinet, A.; Chen, W.; Vuik, C. An efficient adaptive implicit scheme with equivalent continuum approach for two-phase flow in fractured vuggy porous media. Adv. Water Resour. 2022, 163, 104186. [Google Scholar] [CrossRef]

- Cheng, Y.; Xu, T.; Zhang, Y.; Shangguan, S.; Feng, B. An laboratorial investigation of induced seismicity characteristics in EGS hydraulic fracturing. Geothermics 2022, 105, 102482. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, Y.; Yu, Z.; Hu, Z.; Yang, Y. An investigation on hydraulic fracturing characteristics in granite geothermal reservoir. Eng. Fract. Mech. 2020, 237, 107252. [Google Scholar] [CrossRef]

- Zhang, Y.; Zou, Y.; Zhang, Y.; Wang, L.; Liu, D.; Sun, J.; Ge, H.; Zhou, D. Experimental study on characteristics and mechanisms of matrix pressure transmission near the fracture surface during post-fracturing shut-in in tight oil reservoirs. J. Petrol. Sci. Eng. 2022, 219, 111133. [Google Scholar] [CrossRef]

- Hong, C.; Yang, R.; Huang, Z.; Zhuang, X.; Wen, H.; Hu, X. Enhance liquid nitrogen fracturing performance on hot dry rock by cyclic injection. Petrol. Sci. 2023, 20, 951–972. [Google Scholar] [CrossRef]

- Yang, R.; Hong, C.; Liu, W.; Wu, X.; Wang, T.; Huang, Z. Non-contaminating cryogenic fluid access to high-temperature resources: Liquid nitrogen fracturing in a lab-scale Enhanced Geothermal System. Renew. Energy 2021, 165, 125–138. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, Q.G.; Li, Y.W.; Pan, Z.J.; Liu, B. Hydraulic Fracture Vertical Propagation Mechanism in Interlayered Brittle Shale Formations: An Experimental Investigation. Rock Mech. Rock Eng. 2023, 56, 199–220. [Google Scholar] [CrossRef]

- Shi, X.; Song, W.; Xu, H.; Guo, T.; Feng, Q.; Wang, S.; Jiang, S. The impact of variable density in-plane perforations on fracture propagation and complexity control in the horizontal well. J. Petrol. Sci. Eng. 2022, 212, 110211. [Google Scholar] [CrossRef]

- Zeng, F.; Guo, J.; Ma, S.; Chen, Z. 3D observations of the hydraulic fracturing process for a model non-cemented horizontal well under true triaxial conditions using an X-ray CT imaging technique. J. Nat. Gas Sci. Eng. 2018, 52, 128–140. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, S.; Ma, X.; Zhang, X.; Zhang, S. Hydraulic fracture morphology and conductivity of continental shale under the true-triaxial stress conditions. Fuel 2023, 352, 129056. [Google Scholar] [CrossRef]

- Zou, Y.; Gao, B.; Zhang, S.; Ma, X.; Sun, Z.; Wang, F.; Liu, C. Multi-fracture nonuniform initiation and vertical propagation behavior in thin interbedded tight sandstone: An experimental study. J. Petrol. Sci. Eng. 2022, 213, 110417. [Google Scholar] [CrossRef]

- Li, H.; Huang, B.; Zhao, X.; Wu, Z.; Jiao, X.; Han, X.; Sun, Z. Effects of fluid and proppant properties on proppant transport and distribution in horizontal hydraulic fractures of coal under true-triaxial stresses. J. Nat. Gas Sci. Eng. 2022, 108, 104795. [Google Scholar] [CrossRef]

- Li, J.M.; Zou, Y.S.; Shi, S.Z.; Zhang, S.C.; Wang, J.C.; Ma, X.F.; Zhang, X.H. Experimental Study on Fracture Propagation Mechanism of Shale Oil Reservoir of Lucaogou Formation in Jimusar. Geofluids 2022, 2022, 6598575. [Google Scholar] [CrossRef]

- Zhai, L.; Xun, Y.; Liu, H.; Qi, B.; Wu, J.; Wang, Y.; Chen, C. Experimental study of hydraulic fracturing initiation and propagation from perforated wellbore in oil shale formation. Fuel 2023, 352, 129155. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, S.; Cao, H.; Zheng, M.; Qu, F.; Peng, C. Experimental investigation of crack dynamic evolution induced by pulsating hydraulic fracturing in coalbed methane reservoir1. J. Nat. Gas Sci. Eng. 2020, 75, 103159. [Google Scholar] [CrossRef]

- Wang, T.; Chen, M.; Wu, J.; Lu, J.K.; Luo, C.; Chang, Z. Making complex fractures by re-fracturing with different plugging types in large stress difference reservoirs. J. Petrol. Sci. Eng. 2021, 201, 108413. [Google Scholar] [CrossRef]

- Li, M.H.; Zhou, F.J.; Liu, J.J.; Yuan, L.S.; Huang, G.P.; Wang, B. Quantitative investigation of multi-fracture morphology during TPDF through true tri-axial fracturing experiments and CT scanning. Petrol. Sci. 2022, 19, 1700–1717. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, F.; Ge, H.; Shi, Y.; Yi, X.; Xiong, C.; Liu, X.; Wu, Y.; Li, Y. An experimental study on the mechanism of degradable fiber-assisted diverting fracturing and its influencing factors. J. Nat. Gas Sci. Eng. 2015, 27, 260–273. [Google Scholar] [CrossRef]

- Guo, Y.T.; Wang, L.; Chang, X.; Zhou, J.; Zhang, X.Y. Study on Fracture Morphological Characteristics of Refracturing for Longmaxi Shale Formation. Geofluids 2020, 2020, 1628431. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, S.C.; Ma, X.F.; Zou, Y.S.; Lin, G.Y. Experimental Investigation on Propagation Behavior of Hydraulic Fractures in Coal Seam during Refracturing. Geofluids 2019, 2019, 4278543. [Google Scholar] [CrossRef]

- Shang, D.; Yin, G.; Zhao, Y.; Deng, B.; Liu, C.; Kang, X.; Lu, J.; Li, M. Local asymmetric fracturing to construct complex fracture network in tight porous reservoirs during subsurface coal mining: An experimental study. J. Nat. Gas Sci. Eng. 2018, 59, 343–353. [Google Scholar] [CrossRef]

- She, C.; Peng, H.; Yang, J.; Peng, J.; Han, H.; Yang, X.; Peng, Y. Experimental study on the true triaxial fracturing of tight sandstone with supercritical CO2 and slickwater. Geoenergy Sci. Eng. 2023, 228, 211977. [Google Scholar] [CrossRef]

- Chen, D.; Li, N.; Sun, W. Rupture properties and safety assessment of raw coal specimen rupture process under true triaxial hydraulic fracturing based on the source parameters and magnitude. Process Saf. Environ. Prot. 2022, 158, 661–673. [Google Scholar] [CrossRef]

- Alkan, H.; Cinar, Y.; Pusch, G. Rock salt dilatancy boundary from combined acoustic emission and triaxial compression tests. Int. J. Rock Mech. Min. Sci. 2007, 44, 108–119. [Google Scholar] [CrossRef]

- Brace, W.F.; Paulding, B.W.; Scholz, C. Dilatancy in the fracture of crystalline rocks. J. Geophys. Res. 1966, 71, 3939–3953. [Google Scholar] [CrossRef]

- Mou, J.; Hui, X.; Wang, L.; Zhang, S.; Ma, X. Experimental Investigation on Tool-Free Multi-Stage Acid Fracturing of Open-Hole Horizontal Wells by Using Diversion Agents. In Proceedings of the SPE International Hydraulic Fracturing Technology Conference and Exhibition, Muscat, Oman, 16–18 October 2018; pp. D13S–D15S. [Google Scholar]

- Roussel, N.P.; Sharma, M.M. Quantifying Transient Effects in Altered-Stress Refracturing of Vertical Wells. SPE J. 2010, 15, 770–782. [Google Scholar] [CrossRef]

| Sample Number | Confining Pressure | Elastic Modulus | Poisson’s Ratio | Compressive Strength | Cci | Cvi |

|---|---|---|---|---|---|---|

| MPa | GPa | - | MPa | |||

| J3 | 20 | 28.1 | 0.395 | 245.104 | 0.322 | 0.589 |

| J4 | 60 | 34 | 0.376 | 378.881 | 0.307 | 0.696 |

| J2 | 80 | 34 | 0.377 | 443.03 | 0.227 | 0.538 |

| Average | - | 32.03 | 0.383 | - | 0.285 | 0.608 |

| Test | Specimen | First Fracturing | Refracturing | Research Content | ||||

|---|---|---|---|---|---|---|---|---|

| Stress (X/Y/Z) | Flow Rate | Fracturing Fluid | Stress (X/Y/Z) | Flow Rate | Fracturing Fluid | |||

| MPa | mL/min | MPa | mL/min | |||||

| 1 | J2 | 25/21/18 | 20 | Slickwater | 25/21/18 | 20 | Slickwater | The stress difference of twice fracturings |

| 2 | J8 | 25/21/16 | 20 | Slickwater | 25/21/16 | 20 | Slickwater | |

| 3 | J4 | 25/21/14 | 20 | Slickwater | 25/21/14 | 20 | Slickwater | |

| 4 | J6 | 25/21/18 | 20 | Slickwater | 25/17/15 | 20 | Slickwater | The stress decreases before refracturing |

| 5 | J3 | 25/21/18 | 20 | Slickwater | 25/14/14 | 20 | Slickwater | |

| 6 | J10 | 25/21/18 | 20 | Slickwater | 25/11/13 | 20 | Slickwater | |

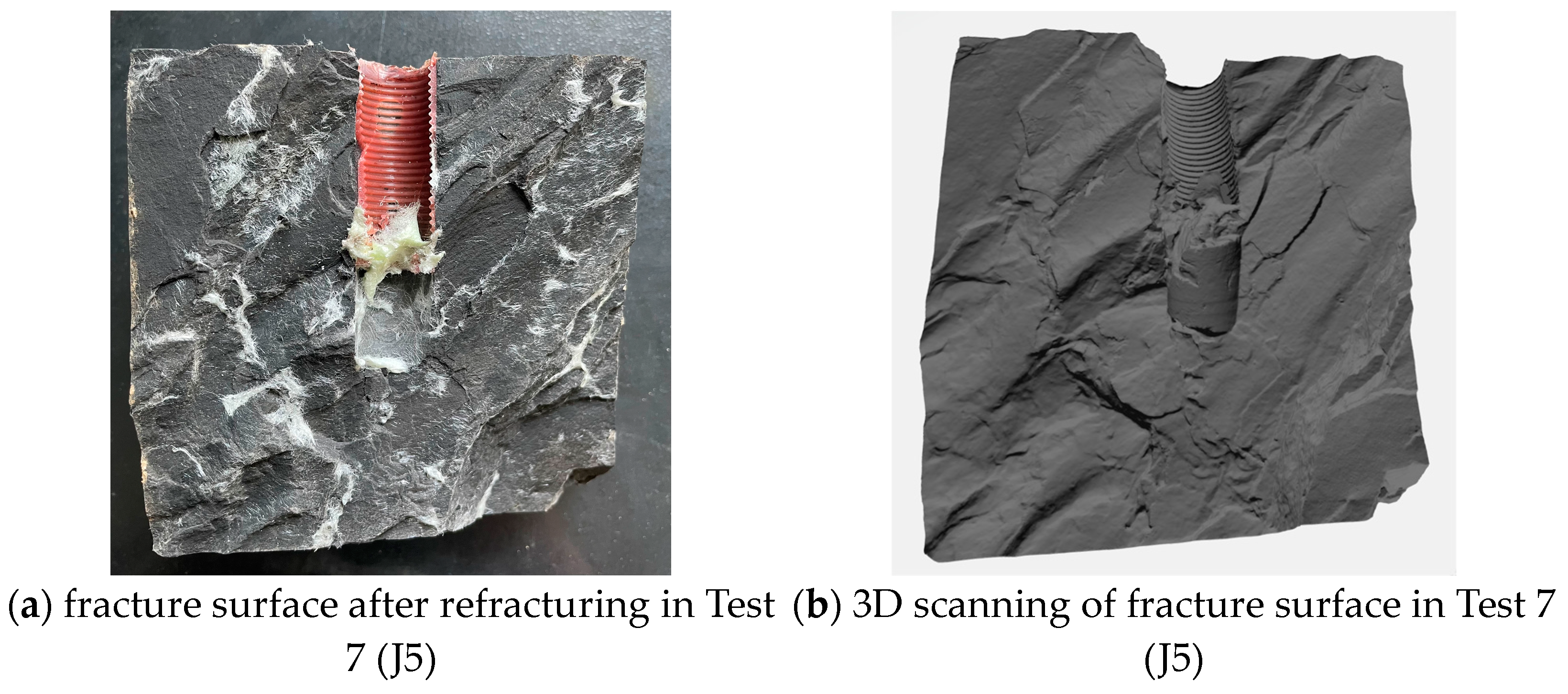

| 7 | J5 | 25/21/18 | 40 | Slickwater | 25/21/18 | 40 | Slickwater | pumping rate |

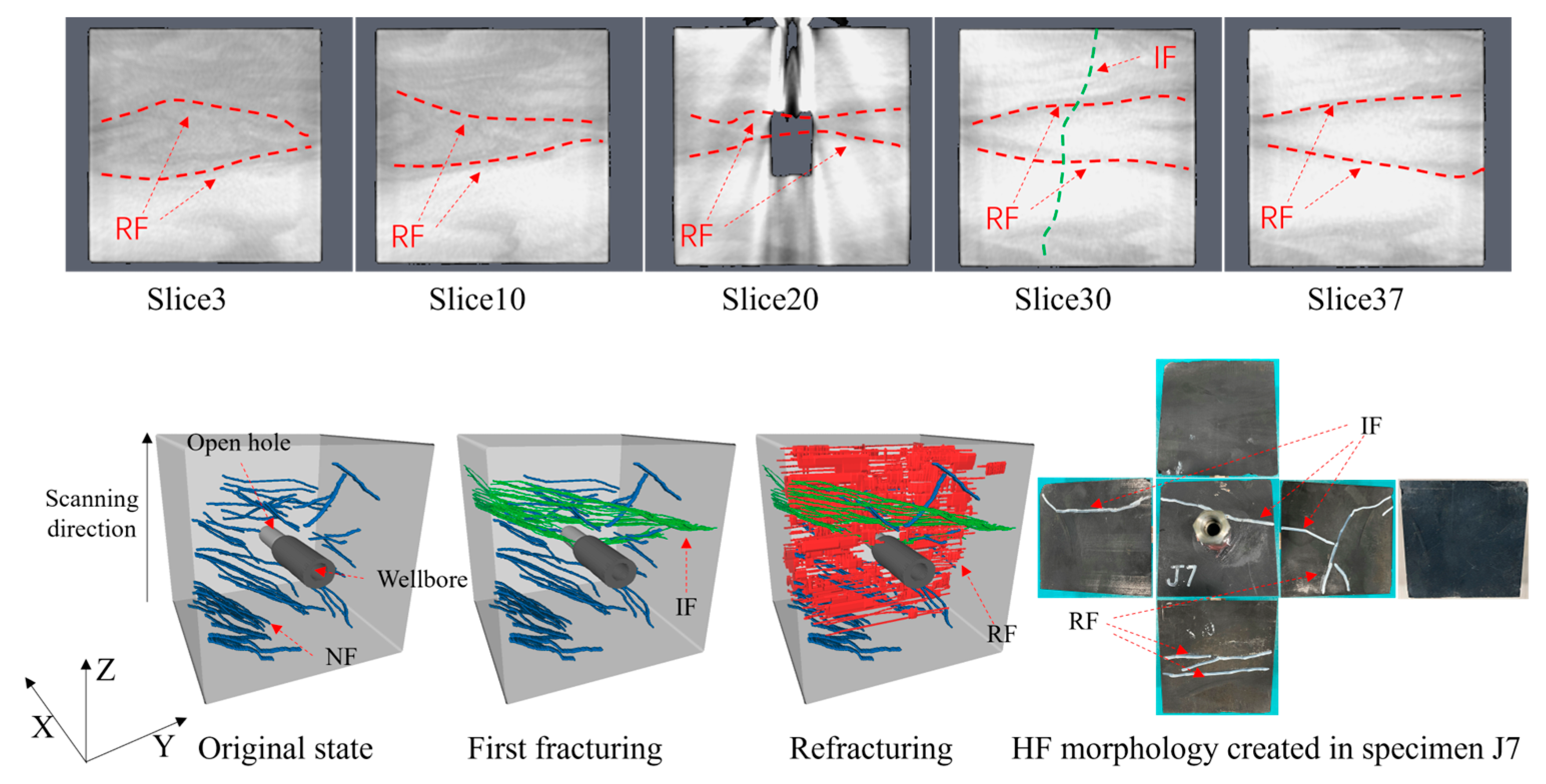

| 8 | J7 | 25/18/18 | 20 | Slickwater | 25/18/18 | 20 | Slickwater | bedding orientation |

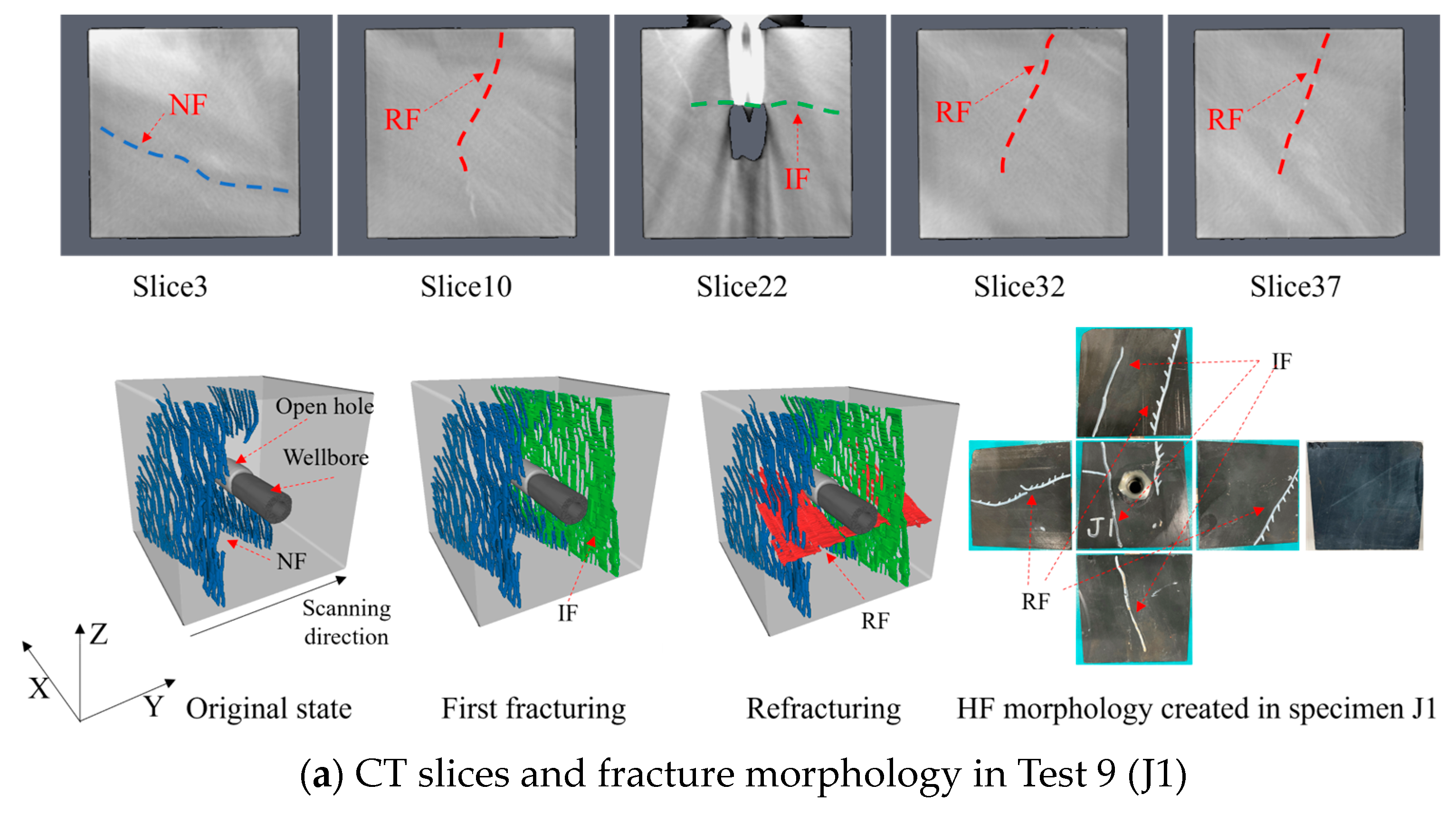

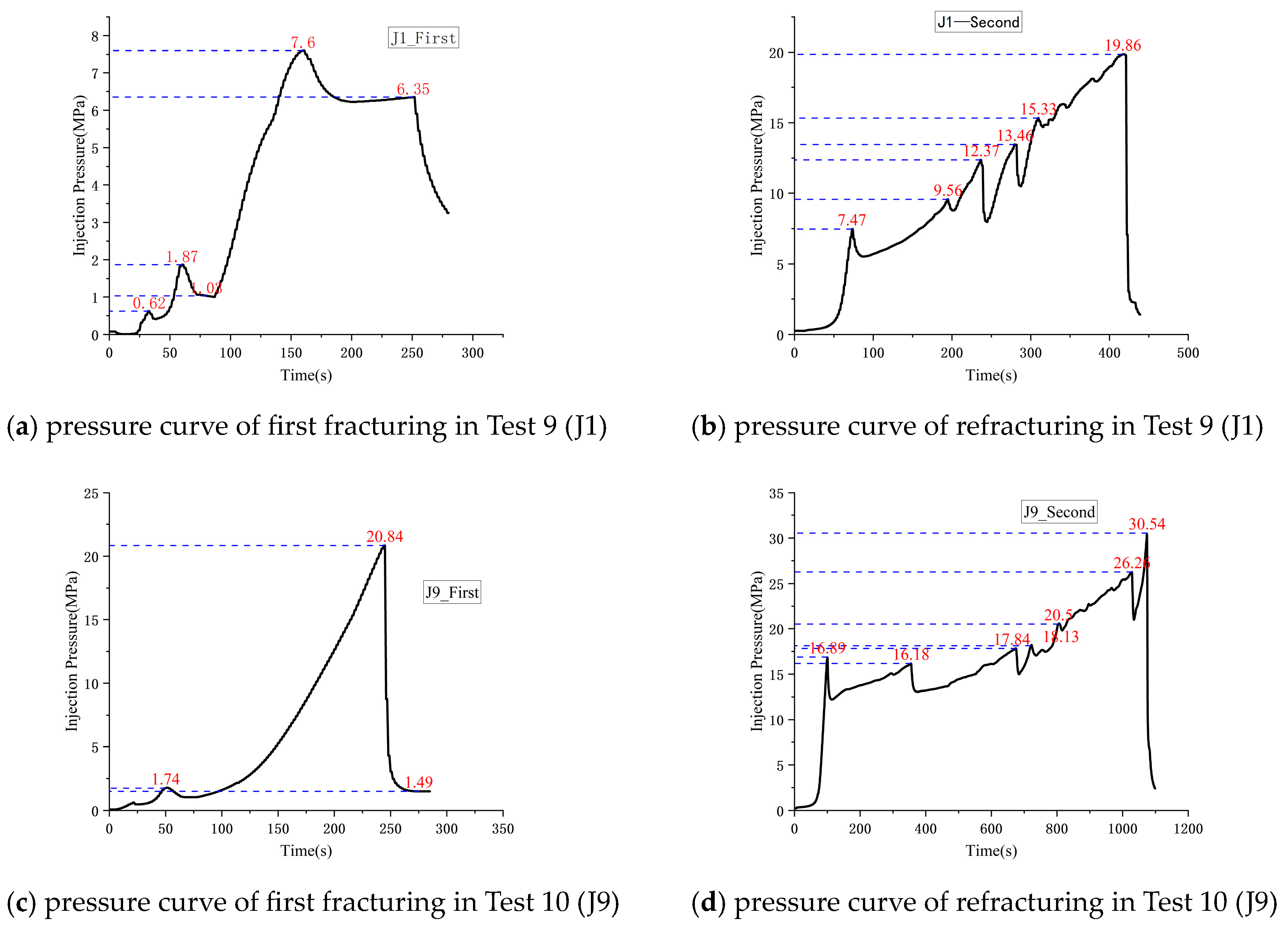

| 9 | J1 | 25/21/18 | 20 | Vicious Slickwater | 25/21/18 | 20 | Vicious Slickwater | fracturing fluids |

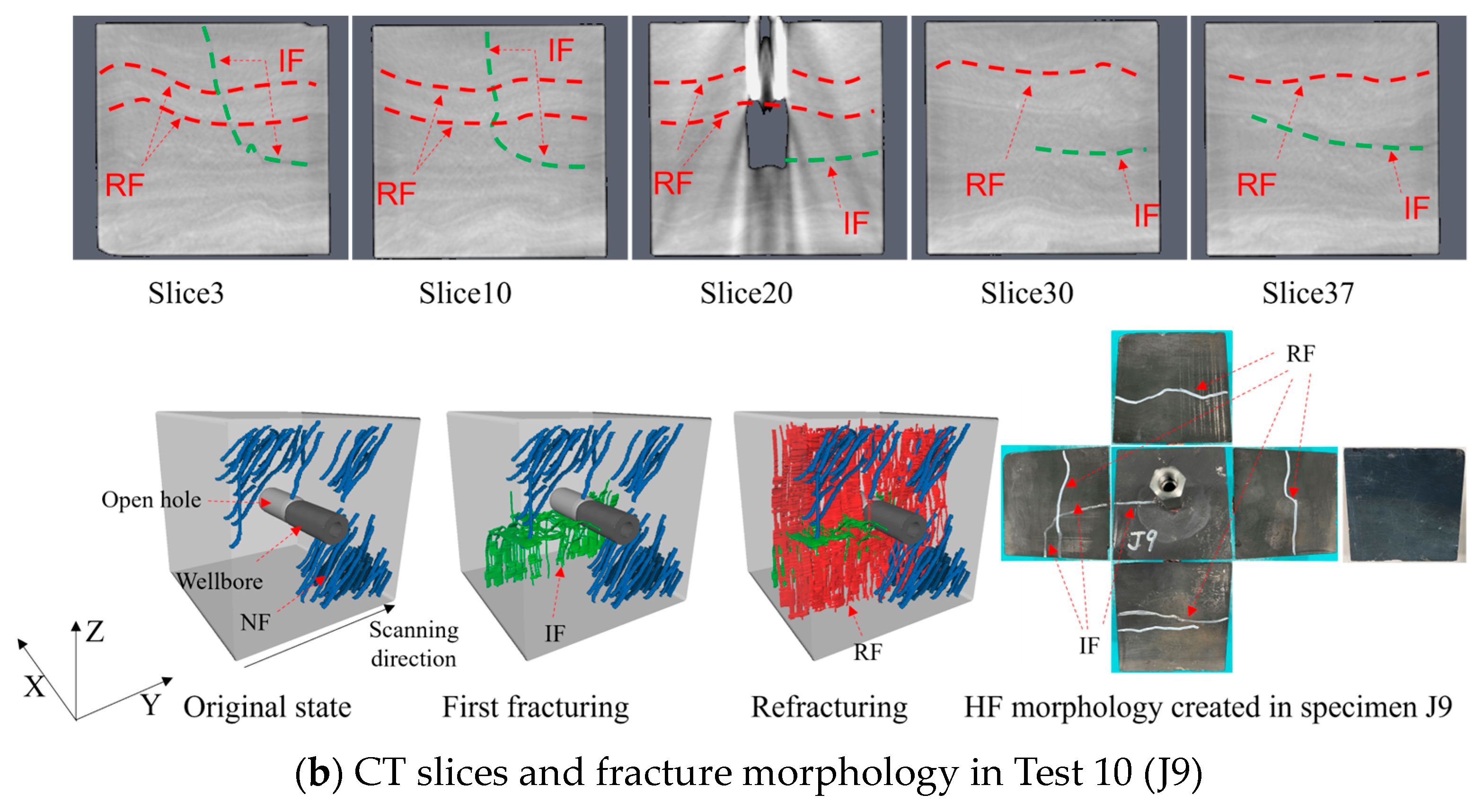

| 10 | J9 | 25/21/18 | 20 | HPG fracturing fluid | 25/21/18 | 20 | HPG fracturing fluid | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wang, X.; Xiao, H.; Ge, H.; He, J. Study on Fracture Propagation Rules of Shale Refracturing Based on CT Technology. Processes 2024, 12, 131. https://doi.org/10.3390/pr12010131

Zhang J, Wang X, Xiao H, Ge H, He J. Study on Fracture Propagation Rules of Shale Refracturing Based on CT Technology. Processes. 2024; 12(1):131. https://doi.org/10.3390/pr12010131

Chicago/Turabian StyleZhang, Jialiang, Xiaoqiong Wang, Huajian Xiao, Hongkui Ge, and Jixiang He. 2024. "Study on Fracture Propagation Rules of Shale Refracturing Based on CT Technology" Processes 12, no. 1: 131. https://doi.org/10.3390/pr12010131

APA StyleZhang, J., Wang, X., Xiao, H., Ge, H., & He, J. (2024). Study on Fracture Propagation Rules of Shale Refracturing Based on CT Technology. Processes, 12(1), 131. https://doi.org/10.3390/pr12010131