Microstructure Imaging and Characterization of Rocks Subjected to Liquid Nitrogen Cooling

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

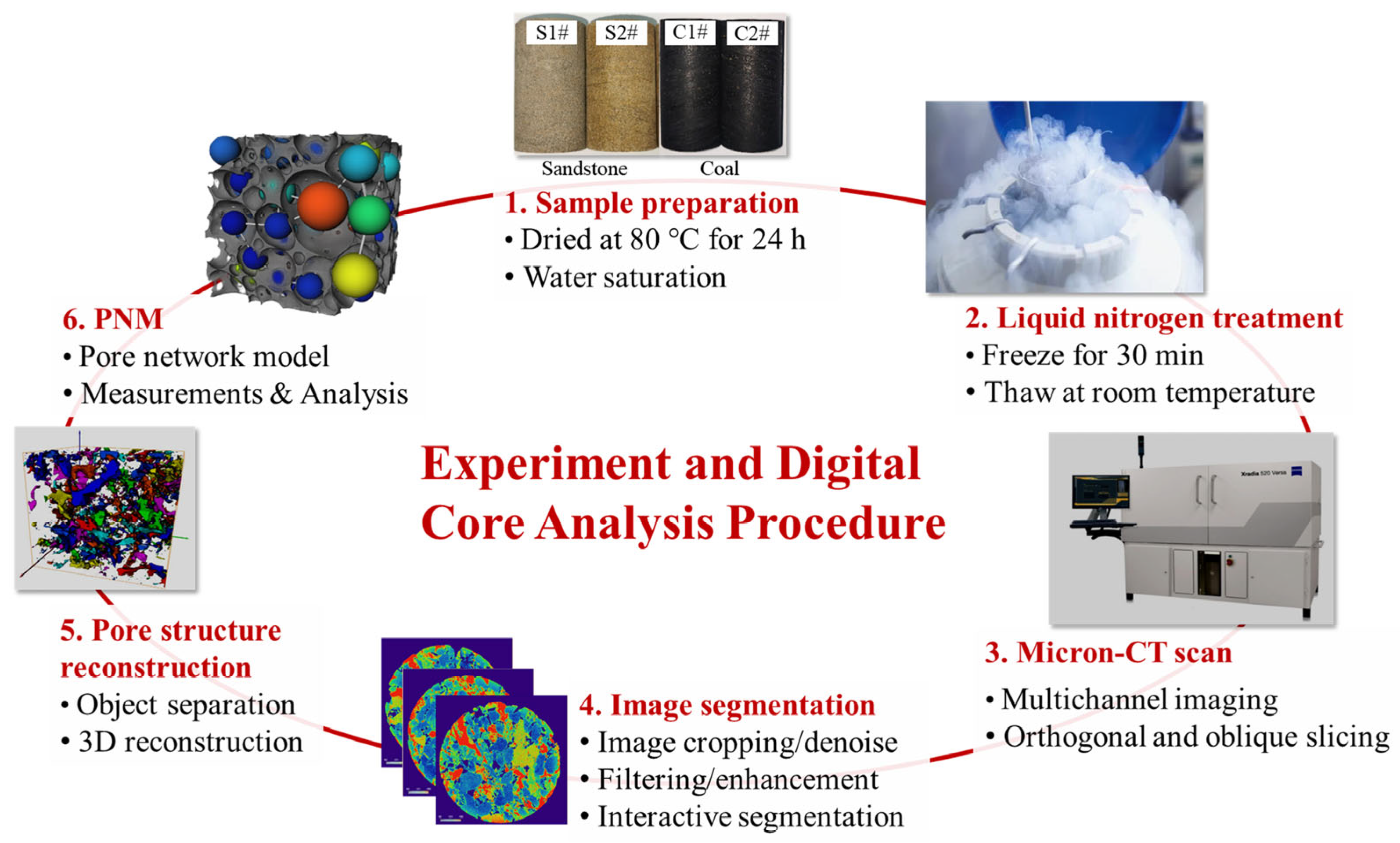

2.2. Experimental Setup and Procedures

2.2.1. Experiment Schedule

- (1)

- Initial micro-CT scanning experiments were conducted on both the dry and saturated group samples to obtain 2D slice images of the initial microscopic pore structure.

- (2)

- Rock samples in both groups were immersed in a LN2 Dewar for 30 min and subsequently thawed at room temperature (about 25 °C) for 4 h.

- (3)

- A second round of CT scanning experiments was performed on these samples to obtain 2D slice images of the post-treated pore structures.

- (4)

- The visualization software AVIZO 9.0.1 was used to analyze the CT slice images before and after LN2 cooling, which could be stacked mathematically to reconstruct the 3D pore-skeleton structures following the procedure illustrated in Figure 2.

2.2.2. CT Scanning Setup

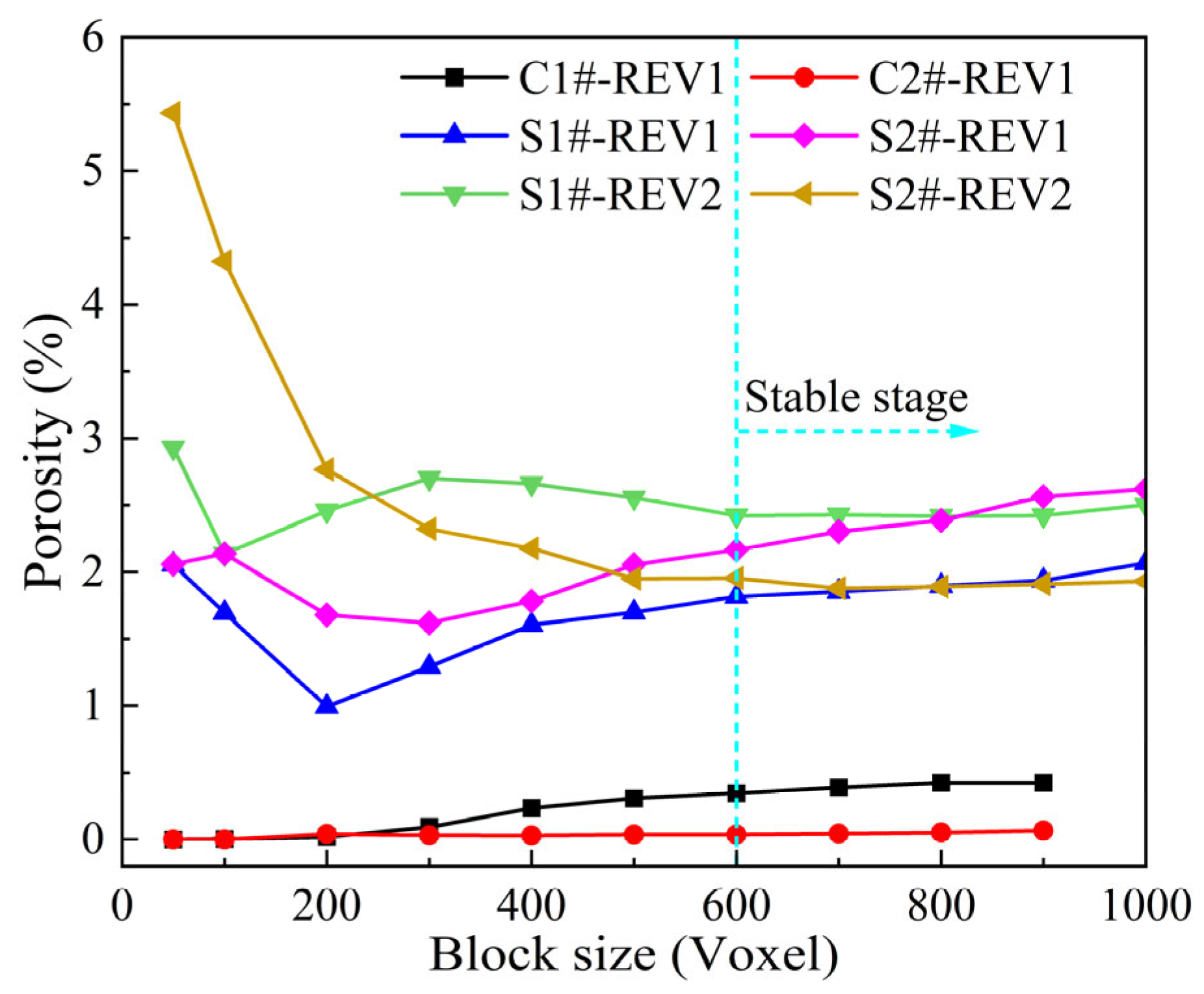

2.3. Digital Core Analysis

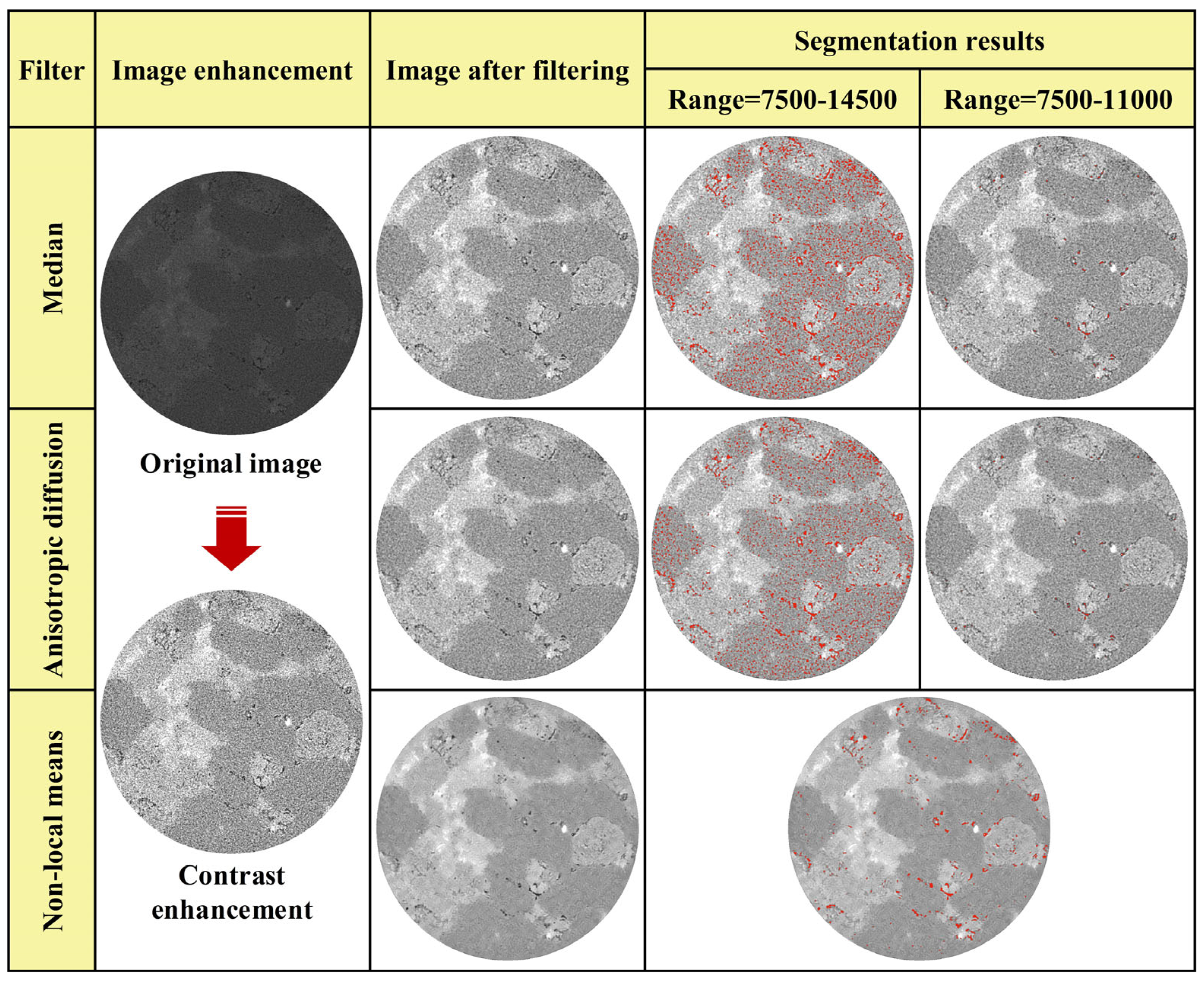

2.3.1. Image Enhancement and Denoising

2.3.2. Image Recognition and Segmentation

3. Results and Analyses

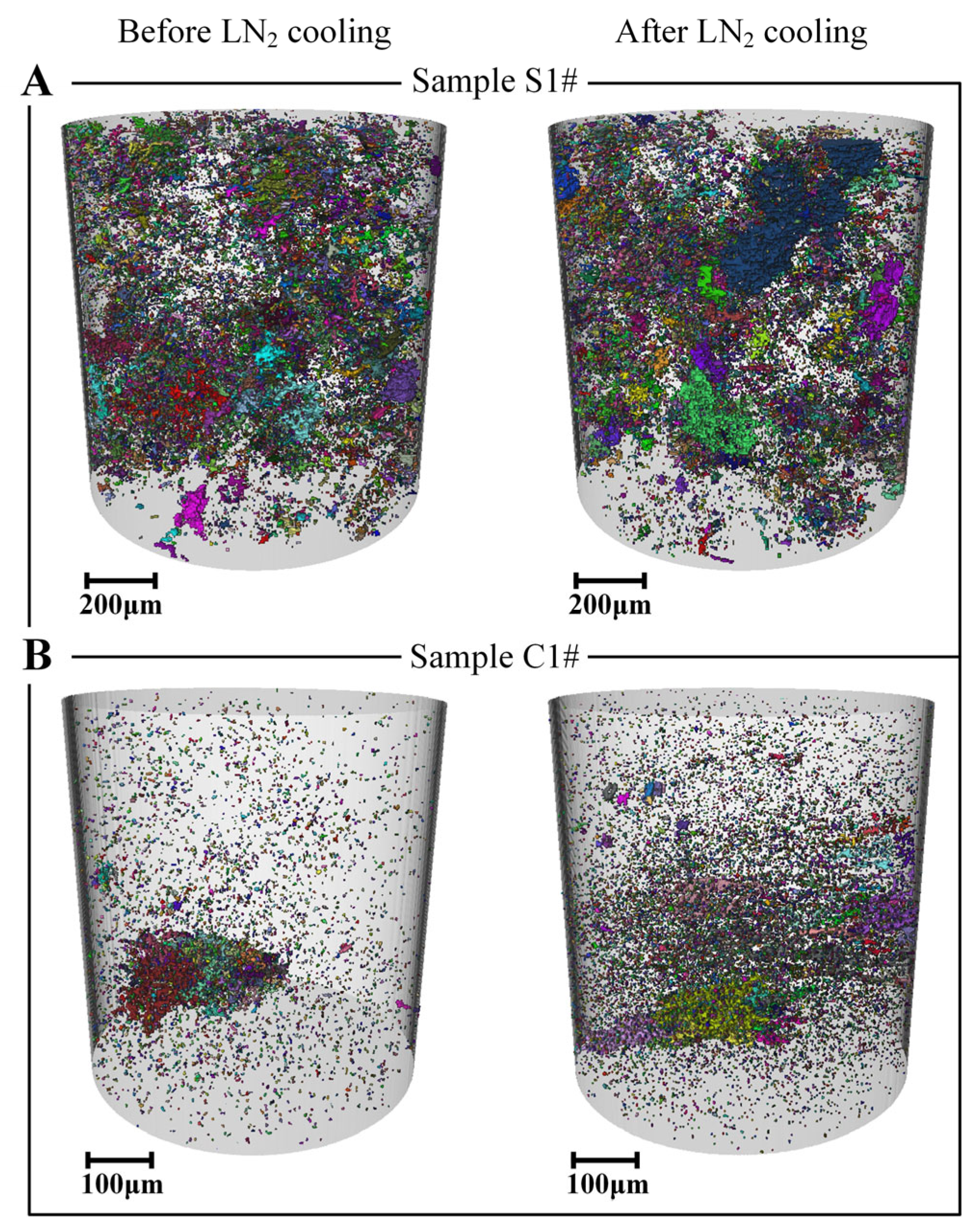

3.1. Micro-Failure Characteristics

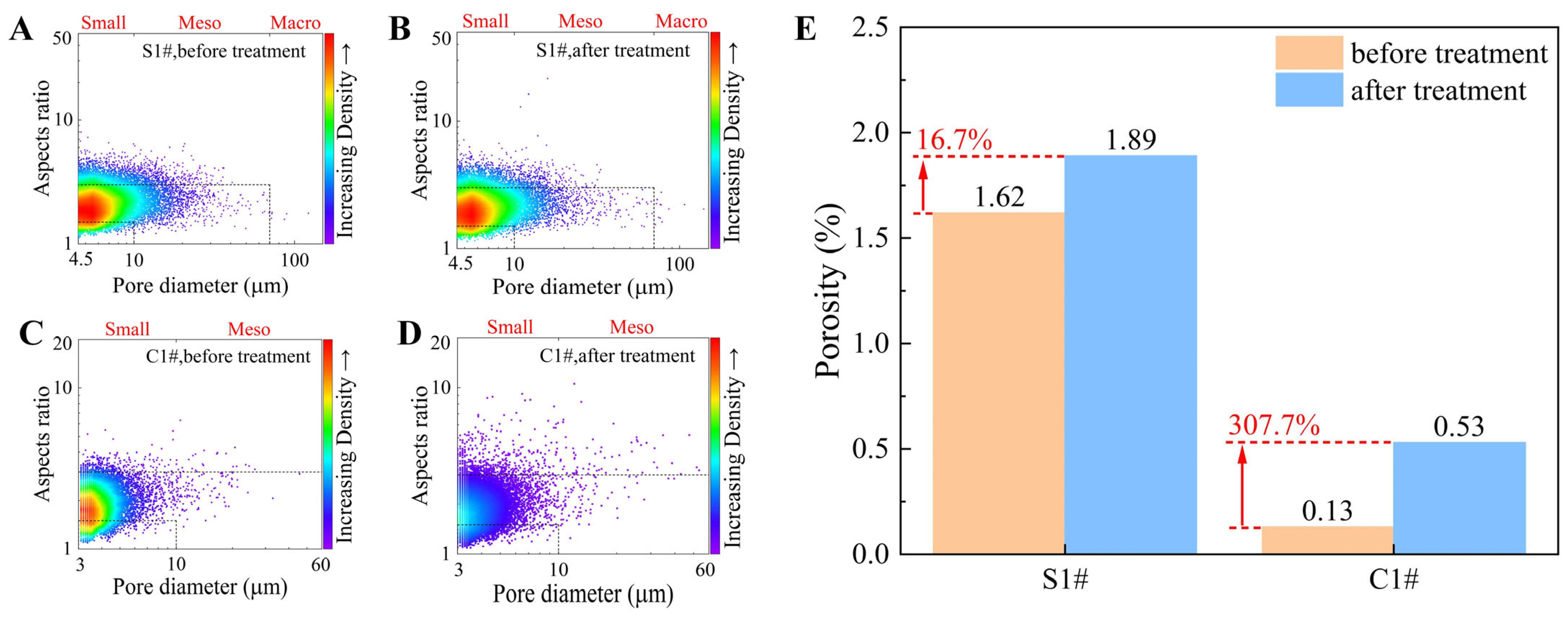

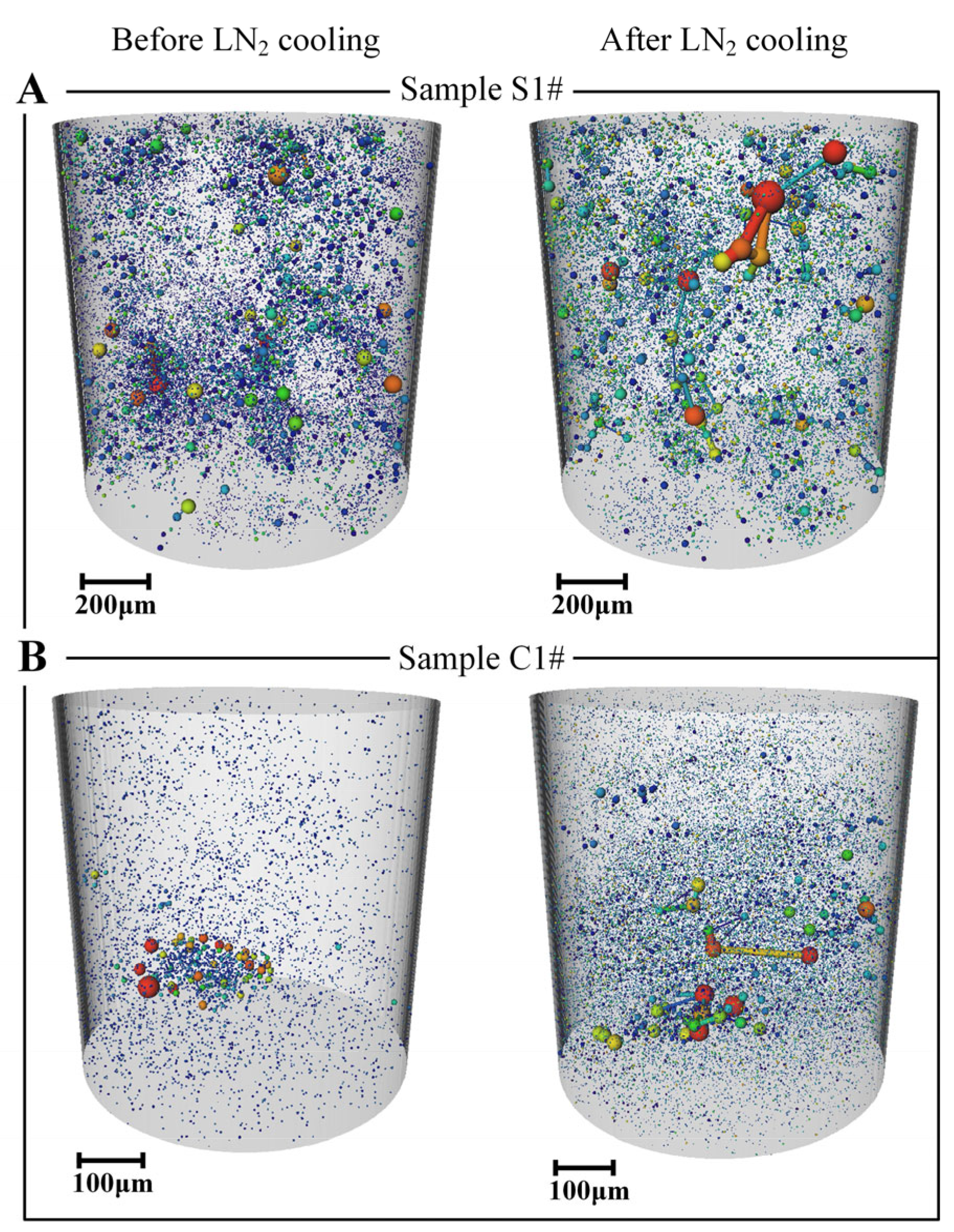

3.2. Pore Morphology and Spatial Distribution

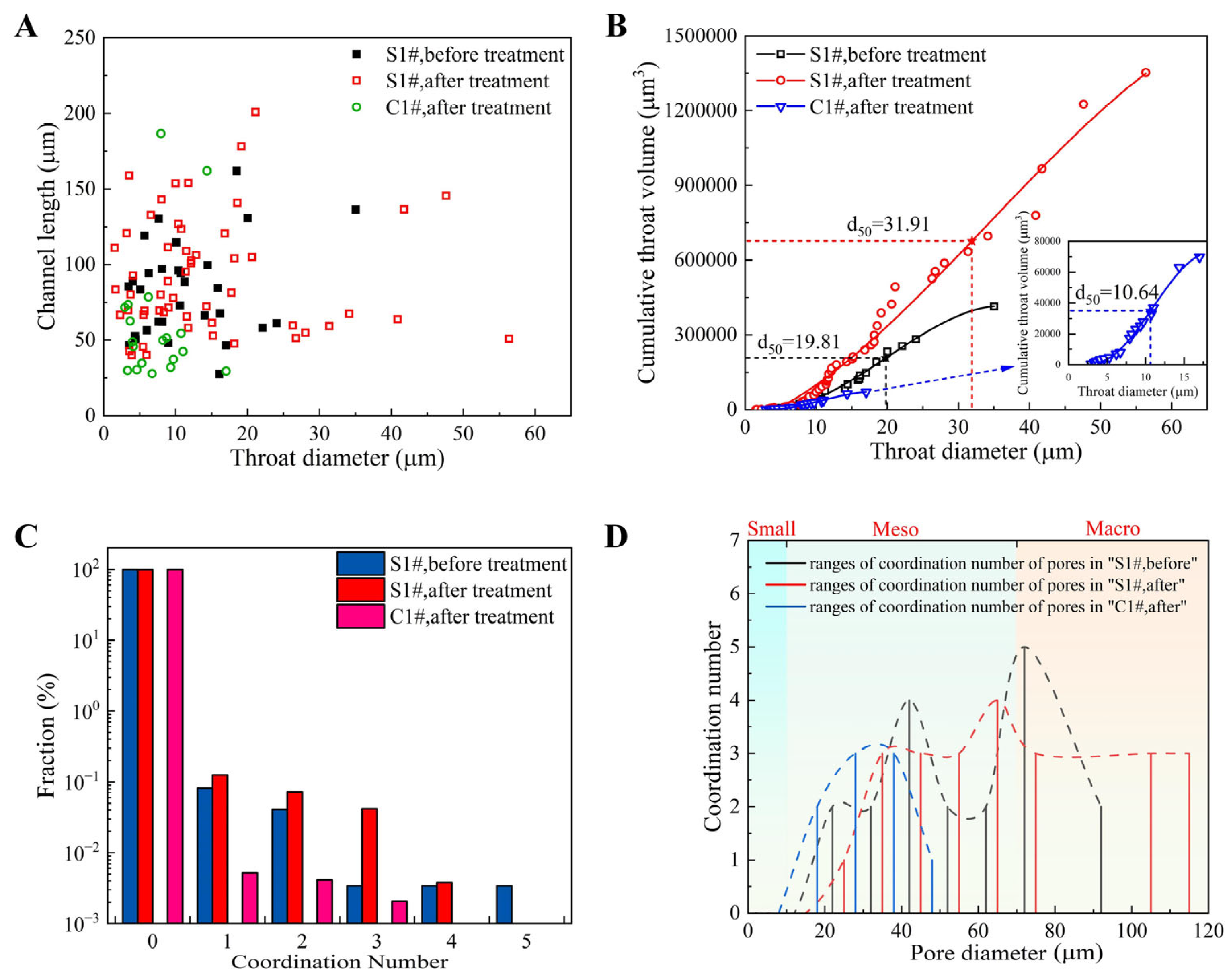

3.3. The Influence of Pore Water

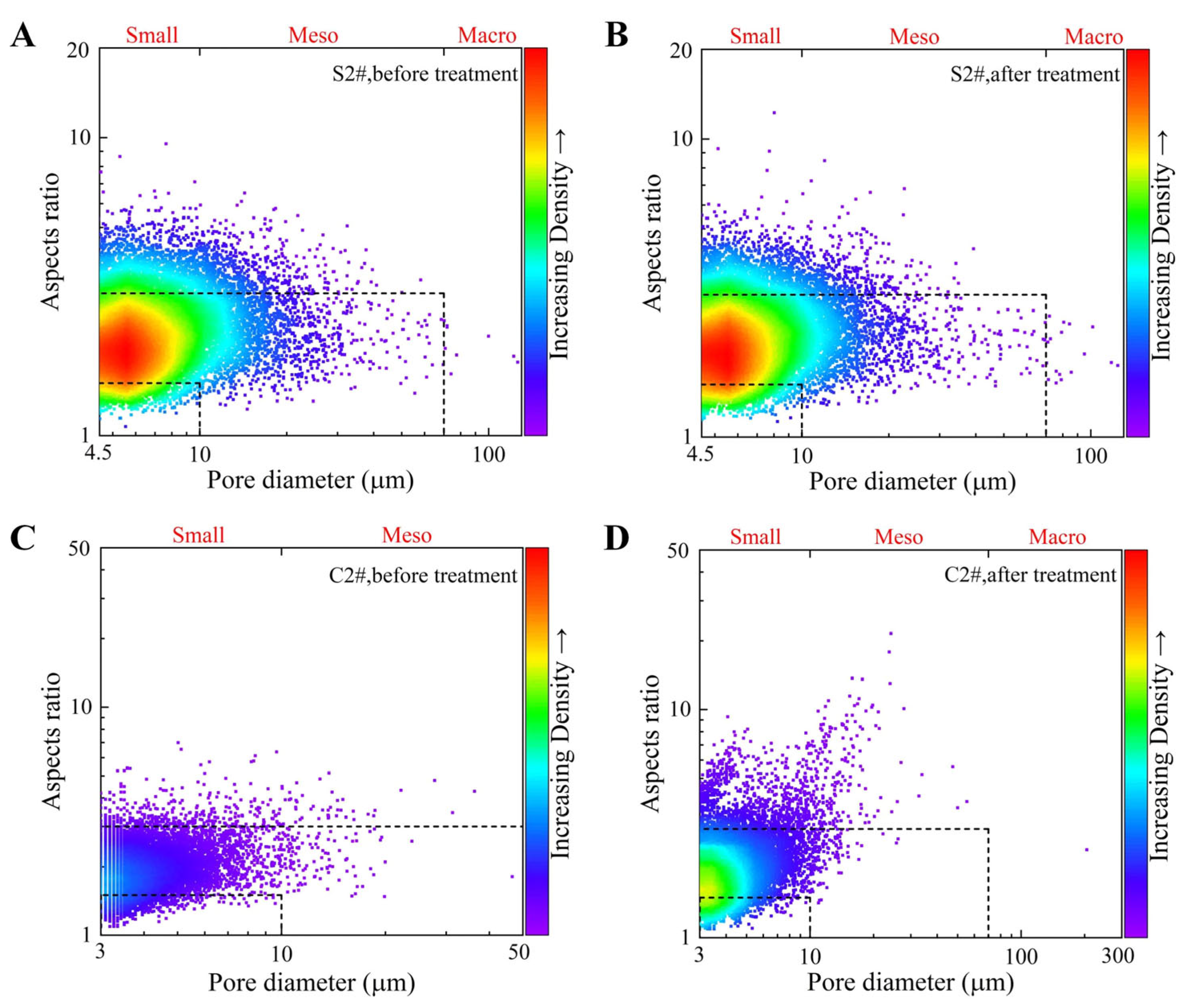

4. Discussion

5. Conclusions

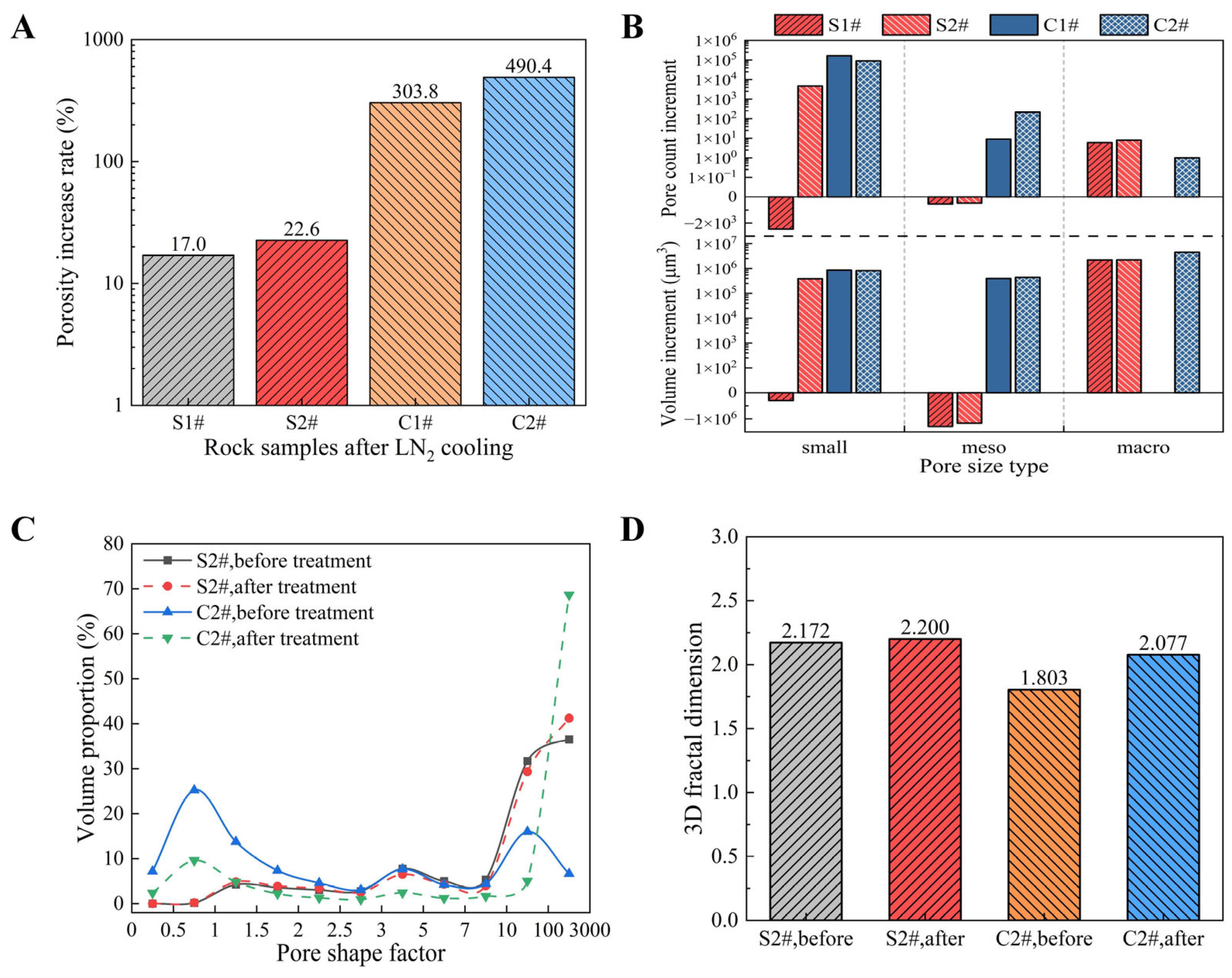

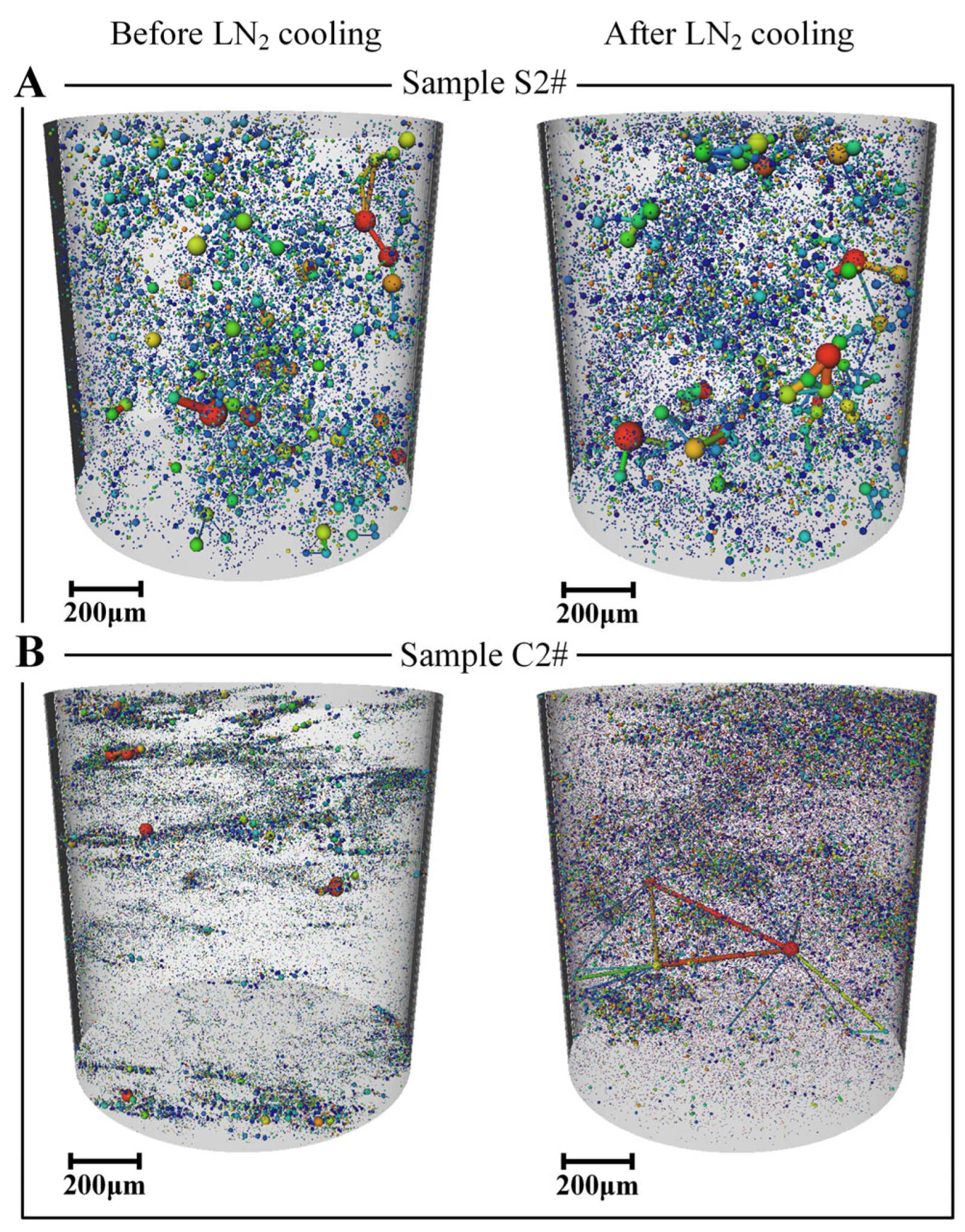

- LN2 cooling causes rock damage and significantly changes the three-dimensional pore structures of rock. After cooling, both intergranular and intragranular cracking appeared in the sandstone, while macroscopic cracks parallel to bedding appeared in the coal rock. The porosity and connectivity in the rock were greatly improved. As compared to the sandstone, coal is more sensitive to LN2 cooling, with more noticeable changes in pore–throat size, aspect ratio and fractal dimensions. After LN2 cooling, the porosity of coal grows by 307.7%, which is 291% higher as compared to that of sandstone.

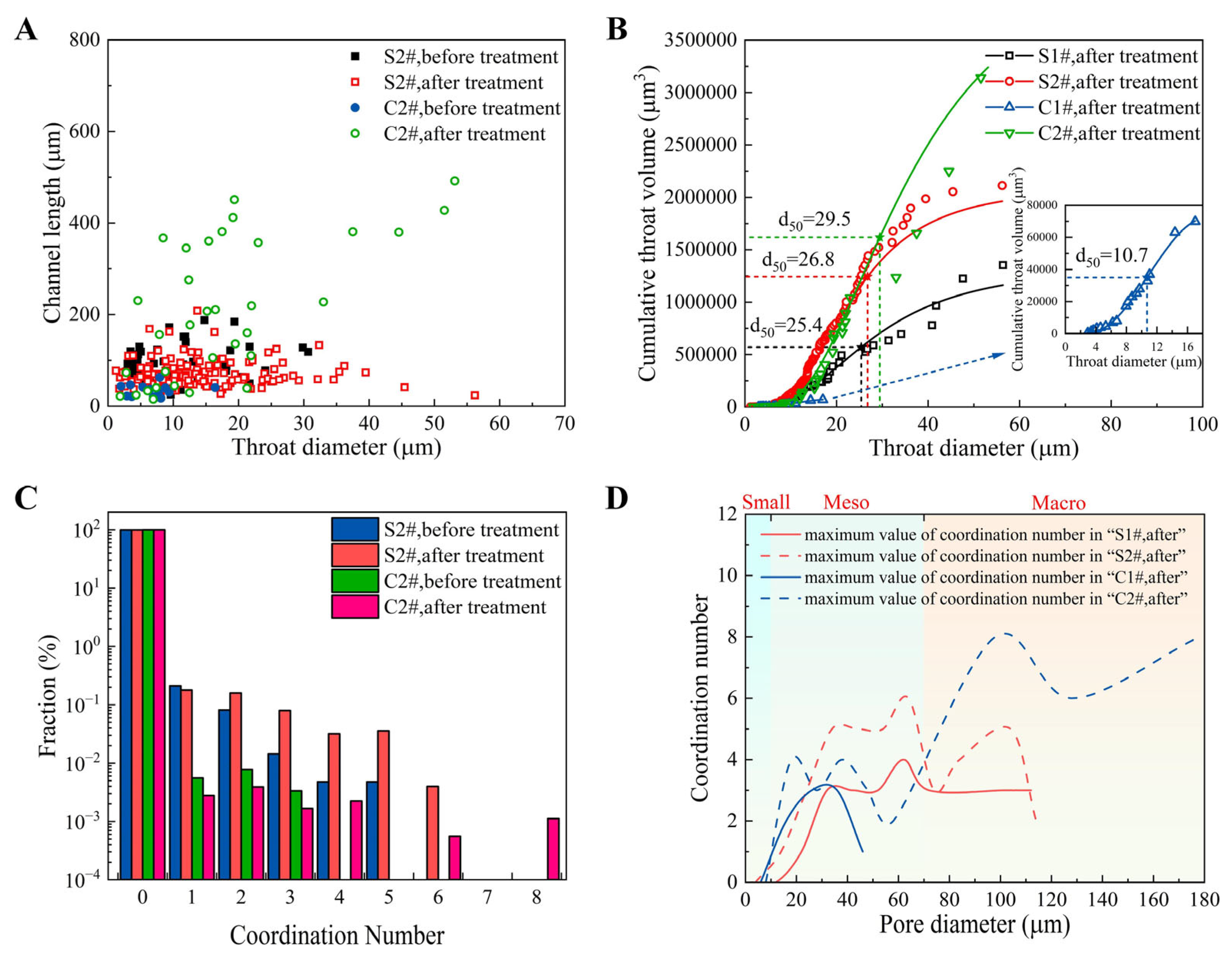

- LN2 cooling has a great effect on the morphology and spatial distribution of pore structures, increasing pore diameter and aspect ratio greatly. There is a growing trend in the irregularity of pore structures after LN2 cooling. The proportion of pores with a shape factor > 100 increases sharply, and more bundle-like and strip-shape pores that are multi-branched are generated, intensifying the complexity and roughness of pores. The fractal dimensions of the pores of sandstone and coal grow by 11.7% and 0.87% after LN2 cooling, respectively.

- LN2 cooling can enhance the pore connectivity significantly. More large-sized pores and throats appeared in the rocks, the proportion of connected pores with the coordination number ≥ 1 increased by 25.3% in the sample S1# and the median throat diameter d50 increased by 29.8%. The maximum value of the coordination number in the sample C1# increased from 0 to 3, although no throat structures were found in the original sample, creating throats with a median diameter of 10.64 μm after LN2 cooling.

- Pore water aggravates the damage to rocks during LN2 cooling, improving pore space and enhancing the connectivity significantly. The porosities of the saturated sandstone S2# and coal sample C2# increases by 22.6% and 490.4%, respectively, which are 5.6% and 186.6% higher as compared to dry samples. The meso- and macropores of water-saturated rocks have a greater coordination number than dry rocks. The generation of macropores is the main contributor to porosity growth during LN2 cooling. Although the macropores account for only a small proportion in the total number, the volume proportion increment of them is significantly higher than that of other pores.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Qiao, J.; Zeng, J.; Jiang, S.; Feng, S.; Feng, X.; Guo, Z.; Teng, J. Heterogeneity of reservoir quality and gas accumulation in tight sandstone reservoirs revealed by pore structure characterization and physical simulation. Fuel 2019, 253, 1300–1316. [Google Scholar] [CrossRef]

- Guo, C.; Xu, J.; Wei, M.; Jiang, R. Experimental study and numerical simulation of hydraulic fracturing tight sandstone reservoirs. Fuel 2015, 159, 334–344. [Google Scholar] [CrossRef]

- He, P.; Lu, Z.; Lu, Y.; Huang, Y.; Pan, L.; Ouyang, L.; Zhou, J. Experimental study on fracture propagation and induced earthquake reduction by pulse hydraulic fracturing in shale reservoirs. Gas Sci. Eng. 2023, 110, 204908. [Google Scholar] [CrossRef]

- Wu, S.; Ge, H.; Wang, X.; Meng, F. Shale failure processes and spatial distribution of fractures obtained by AE monitoring. J. Nat. Gas Sci. Eng. 2017, 41, 82–92. [Google Scholar] [CrossRef]

- Yang, L.; Sheng, X.; Zhang, B.; Yu, H.; Wang, X.; Wang, P.; Mei, J. Propagation behavior of hydraulic fractures in shale under triaxial compression considering the influence of sandstone layers. Gas Sci. Eng. 2023, 110, 204895. [Google Scholar] [CrossRef]

- Wang, H. Hydraulic fracture propagation in naturally fractured reservoirs: Complex fracture or fracture networks. J. Nat. Gas Sci. Eng. 2019, 68, 102911. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, A.; Wu, H. Competition growth of biwing hydraulic fractures in naturally fractured reservoirs. Gas Sci. Eng. 2023, 109, 204873. [Google Scholar] [CrossRef]

- Guo, J.; Liu, Y. Opening of natural fracture and its effect on leakoff behavior in fractured gas reservoirs. J. Nat. Gas Sci. Eng. 2014, 18, 324–328. [Google Scholar] [CrossRef]

- Wang, L.; Yao, B.; Cha, M.; Alqahtani, N.B.; Patterson, T.W.; Kneafsey, T.J.; Miskimins, J.L.; Yin, X.; Wu, Y. Waterless fracturing technologies for unconventional reservoirs-opportunities for liquid nitrogen. J. Nat. Gas Sci. Eng. 2016, 35, 160–174. [Google Scholar] [CrossRef]

- Lai, F.; Li, Z.; Wang, Y. Impact of water blocking in fractures on the performance of hydraulically fractured horizontal wells in tight gas reservoir. J. Pet. Sci. Eng. 2017, 156, 134–141. [Google Scholar] [CrossRef]

- Cheng, Y. Impact of water dynamics in fractures on the performance of hydraulically fractured wells in gas-shale reservoirs. J. Can. Pet. Technol. 2012, 51, 143–151. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, X.; Sun, W. Hydraulic fracturing in transversely isotropic tight sandstone reservoirs: A numerical study based on bonded-particle model approach. J. Struct. Geol. 2020, 136, 104068. [Google Scholar] [CrossRef]

- Duan, W.; Sun, B.; Pan, D.; Wang, T.; Guo, T.; Wang, Z. Experimental study on fracture propagation of hydraulic fracturing for tight sandstone outcrop. Energy Explor. Exploit. 2021, 39, 156–179. [Google Scholar] [CrossRef]

- Kalam, S.; Afagwu, C.; Al Jaberi, J.; Siddig, O.M.; Tariq, Z.; Mahmoud, M.; Abdulraheem, A. A review on non-aqueous fracturing techniques in unconventional reservoirs. J. Nat. Gas Sci. Eng. 2021, 95, 104223. [Google Scholar] [CrossRef]

- Wilson, D.R.; Siebert, R.M.; Lively, P. Cryogenic Coal Bed Gas Well Stimulation Method. U.S. Patent No. 5,464,061, 7 November 1995. [Google Scholar]

- McDaniel, B.W.; Grundmann, S.R.; Kendrick, W.D.; Wilson, D.R.; Jordan, S.W. Field Applications of Cryogenic Nitrogen as a Hydraulic Fracturing Fluid. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 5–8 October 1997; p. SPE-38623-MS. [Google Scholar]

- Grundmann, S.R.; Rodvelt, G.D.; Dials, G.A.; Allen, R.E. Cryogenic Nitrogen as a Hydraulic Fracturing Fluid in the Devonian Shale. In Proceedings of the SPE Eastern Regional Meeting, Pittsburgh, PA, USA, 9–11 November 1998; p. SPE-51067-MS. [Google Scholar]

- Cai, C.; Li, G.; Huang, Z.; Tian, S.; Shen, Z.; Fu, X. Experiment of coal damage due to super-cooling with liquid nitrogen. J. Nat. Gas Sci. Eng. 2015, 22, 42–48. [Google Scholar] [CrossRef]

- Li, Z.; Xu, H.; Zhang, C. Liquid nitrogen gasification fracturing technology for shale gas development. J. Pet. Sci. Eng. 2016, 138, 253–256. [Google Scholar] [CrossRef]

- Wu, X.; Huang, Z.; Li, R.; Zhang, S.; Wen, H.; Huang, P.; Dai, X.; Zhang, C. Investigation on the damage of high-temperature shale subjected to liquid nitrogen cooling. J. Nat. Gas Sci. Eng. 2018, 57, 284–294. [Google Scholar] [CrossRef]

- Qin, L.; Zhai, C.; Liu, S.; Xu, J. Mechanical behavior and fracture spatial propagation of coal injected with liquid nitrogen under triaxial stress applied for coalbed methane recovery. Eng. Geol. 2018, 233, 1–10. [Google Scholar] [CrossRef]

- Jiang, L.; Cheng, Y.; Han, Z.; Gao, Q.; Yan, C.; Wang, G.; Wang, H.; Fu, L. Experimental Investigation on Pore Characteristics and Carrying Capacity of Longmaxi Shale Under Liquid Nitrogen Freezing and Thawing. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition, Bangkok, Thailand, 27–29 August 2018; p. SPE-191111-MS. [Google Scholar]

- Jiang, L.; Cheng, Y.; Han, Z.; Gao, Q.; Yan, C.; Wang, H.; Fu, L. Effect of liquid nitrogen cooling on the permeability and mechanical characteristics of anisotropic shale. J. Pet. Explor. Prod. Technol. 2019, 9, 111–124. [Google Scholar] [CrossRef]

- Wu, X.; Huang, Z.; Cheng, Z.; Zhang, S.; Song, H.; Zhao, X. Effects of cyclic heating and LN2-cooling on the physical and mechanical properties of granite. Appl. Therm. Eng. 2019, 156, 99–110. [Google Scholar] [CrossRef]

- Li, Z.; Wang, F.; Shu, C.; Wen, H.; Wei, G.; Liang, R. Damage effects on coal mechanical properties and micro-scale structures during liquid CO2-ECBM process. J. Nat. Gas Sci. Eng. 2020, 83, 103579. [Google Scholar] [CrossRef]

- Memon, K.R.; Ali, M.; Awan, F.U.R.; Mahesar, A.A.; Abbasi, G.R.; Mohanty, U.S.; Akhondzadeh, H.; Tunio, A.H.; Iglauer, S.; Keshavarz, A. Influence of cryogenic liquid nitrogen cooling and thermal shocks on petro-physical and morphological characteristics of Eagle Ford shale. J. Nat. Gas Sci. Eng. 2021, 96, 104313. [Google Scholar] [CrossRef]

- Yang, Z.Z.; Zhang, Y.P.; Jia, M.; Li, X.G.; Wei, Z.; Zhang, L. Experimental research on influence of low temperature on coal permeability. Rock Soil Mech. 2017, 38, 354–360. [Google Scholar]

- Zhao, Y.; He, X.; Jiang, L.; Wang, Z.; Ning, J.; Sainoki, A. Influence analysis of complex crack geometric parameters on mechanical properties of soft rock. Int. J. Coal Sci. Technol. 2023, 10, 78. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Liu, B.; Wang, S.; Liu, Q.; Luo, Y.; Luo, J. Experimental and numerical investigation on failure characteristics and mechanism of coal with different water contents. Int. J. Coal Sci. Technol. 2023, 10, 49. [Google Scholar] [CrossRef]

- Cai, C.; Li, G.; Huang, Z.; Shen, Z.; Tian, S.; Wei, J. Experimental study of the effect of liquid nitrogen cooling on rock pore structure. J. Nat. Gas Sci. Eng. 2014, 21, 507–517. [Google Scholar] [CrossRef]

- Qin, L.; Zhai, C.; Liu, S.; Xu, J.; Yu, G.; Sun, Y. Changes in the petrophysical properties of coal subjected to liquid nitrogen freeze-thaw—A nuclear magnetic resonance investigation. Fuel 2017, 194, 102–114. [Google Scholar] [CrossRef]

- Qin, L.; Zhai, C.; Liu, S.; Xu, J.; Wu, S.; Dong, R. Fractal dimensions of low rank coal subjected to liquid nitrogen freeze-thaw based on nuclear magnetic resonance applied for coalbed methane recovery. Powder Technol. 2018, 325, 11–20. [Google Scholar] [CrossRef]

- Qin, L.; Li, S.; Zhai, C.; Lin, H.; Zhao, P.; Shi, Y.; Bai, Y. Changes in the pore structure of lignite after repeated cycles of liquid nitrogen freezing as determined by nitrogen adsorption and mercury intrusion. Fuel 2020, 267, 117214. [Google Scholar] [CrossRef]

- Wu, X.; Huang, Z.; Zhang, S.; Cheng, Z.; Li, R.; Song, H.; Wen, H.; Huang, P. Damage analysis of high-temperature rocks subjected to LN 2 thermal shock. Rock Mech. Rock Eng. 2019, 52, 2585–2603. [Google Scholar] [CrossRef]

- Cai, C.; Wang, B.; Zou, Z.; Feng, Y.; Tao, Z. Experimental Study on the Damage and Failure Characteristics of High-Temperature Granite after Liquid-Nitrogen Cooling. Processes 2023, 11, 1818. [Google Scholar] [CrossRef]

- Guo, P.; Zhang, P.; Bu, M.; Xing, H.; He, M. Impact of cooling rate on mechanical properties and failure mechanism of sandstone under thermal-mechanical coupling effect. Int. J. Coal Sci. Technol. 2023, 10, 26. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Xie, Z.; Li, J.; Zhang, X.; Sun, K.; Wang, F. Characterization of microscopic pore types and structures in marine shale: Examples from the Upper Permian Dalong formation, Northern Sichuan Basin, South China. J. Nat. Gas Sci. Eng. 2018, 59, 326–342. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, Q.; Li, D.; Feng, Z. Experimental study on infiltration and freeze—Thaw damage of water-bearing coal samples with cryogenic liquid nitrogen. J. Nat. Gas Sci. Eng. 2018, 60, 24–31. [Google Scholar] [CrossRef]

- Song, S.; Liu, J.; Yang, D.; Ni, H.; Huang, B.; Zhang, K.; Mao, X. Pore structure characterization and permeability prediction of coal samples based on SEM images. J. Nat. Gas Sci. Eng. 2019, 67, 160–171. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, L.; Li, B.; Wen, Z. Non-uniformity of coal damage caused by liquid nitrogen freeze-thaw. J. Nat. Gas Sci. Eng. 2019, 69, 102946. [Google Scholar] [CrossRef]

- Chu, Y.; Sun, H.; Zhang, D.; Yu, G. Nuclear magnetic resonance study of the influence of the liquid nitrogen freeze—Thaw process on the pore structure of anthracite coal. Energy Sci. Eng. 2020, 8, 1681–1692. [Google Scholar] [CrossRef]

- Li, Q.; Yin, T.; Li, X.; Zhang, S. Effects of rapid cooling treatment on heated sandstone: A comparison between water and liquid nitrogen cooling. Bull. Eng. Geol. Environ. 2020, 79, 313–327. [Google Scholar] [CrossRef]

- Lin, H.; Long, H.; Yan, M.; Li, S.; Shu, C.; Bai, Y. Methane adsorption thermodynamics of coal sample subjected to liquid nitrogen freezing-thawing process. J. Nat. Gas Sci. Eng. 2021, 90, 103896. [Google Scholar] [CrossRef]

- Zhang, Y.; Okere, C.J.; Su, G. Effect of loading rates on accurate in-situ stress determination in different lithologies via Kaiser effect. Arab. J. Geosci. 2021, 14, 1304. [Google Scholar] [CrossRef]

- Ahmadi, Y.; Aminshahidy, B. Inhibition of asphaltene precipitation by hydrophobic CaO and SiO2 nanoparticles during natural depletion and CO2 tests. Int. J. Oil Gas Coal Technol. 2020, 24, 394–414. [Google Scholar] [CrossRef]

- Zhao, T.; Zhang, P.; Xiao, Y.; Guo, W.; Zhang, Y.; Zhang, X. Master crack types and typical acoustic emission characteristics during rock failure. Int. J. Coal Sci. Technol. 2023, 10, 2. [Google Scholar] [CrossRef]

- Akhondzadeh, H.; Keshavarz, A.; Al-Yaseri, A.Z.; Ali, M.; Awan, F.U.R.; Wang, X.; Yang, Y.; Iglauer, S.; Lebedev, M. Pore-scale analysis of coal cleat network evolution through liquid nitrogen treatment: A Micro-Computed Tomography investigation. Int. J. Coal Geol. 2020, 219, 103370. [Google Scholar] [CrossRef]

- Akhondzadeh, H.; Keshavarz, A.; Awan, F.U.R.; Ali, M.; Al-Yaseri, A.; Liu, C.; Yang, Y.; Iglauer, S.; Gurevich, B.; Lebedev, M. Liquid nitrogen fracturing efficiency as a function of coal rank: A multi-scale tomographic study. J. Nat. Gas Sci. Eng. 2021, 95, 104177. [Google Scholar] [CrossRef]

- Liu, W.; Wang, G.; Han, D.; Xu, H.; Chu, X. Accurate characterization of coal pore and fissure structure based on CT 3D reconstruction and NMR. J. Nat. Gas Sci. Eng. 2021, 96, 104242. [Google Scholar] [CrossRef]

- Xie, W.; Li, X.; Zhang, M. Reservoir evaluation of Upper Triassic Xujiahe formation in southwest Sichuan basin. Nat. Gas Geosci. 2008, 19, 94–99. [Google Scholar]

- Rukai, Z.; Xia, Z.; Liuhong, L.; Xuesong, W.; Nai, Z.; Hongli, G.; Lihong, S. Depositional system and favorable reservoir distribution of Xujiahe Formation in Sichuan Basin. Pet. Explor. Dev. 2009, 36, 46–55. [Google Scholar] [CrossRef]

- Zhang, B.; Fu, X.; Li, G.; Deng, Z.; Shen, Y.; Hao, M. An experimental study on the effect of nitrogen injection on the deformation of coal during methane desorption. J. Nat. Gas Sci. Eng. 2020, 83, 103529. [Google Scholar] [CrossRef]

- Li, R.; Wang, S.; Li, G.; Wang, J. Influences of coal seam heterogeneity on hydraulic fracture geometry: An in situ observation perspective. Rock Mech. Rock Eng. 2022, 55, 4517–4527. [Google Scholar] [CrossRef]

- Gong, L.; Zeng, L.; Gao, Z.; Zhu, R.; Zhang, B. Reservoir characterization and origin of tight gas sandstones in the Upper Triassic Xujiahe formation, Western Sichuan Basin, China. J. Pet. Explor. Prod. Technol. 2016, 6, 319–329. [Google Scholar] [CrossRef][Green Version]

- ISO 11760: 2005(E); Classification of Coals. International Organization for Standardization (ISO): Geneva, Switzerland, 2005; 9p.

- Wildenschild, D.; Sheppard, A.P. X-ray imaging and analysis techniques for quantifying pore-scale structure and processes in subsurface porous medium systems. Adv. Water Resour. 2013, 51, 217–246. [Google Scholar] [CrossRef]

- Wildenschild, D.; Vaz, C.; Rivers, M.L.; Rikard, D.; Christensen, B. Using X-ray computed tomography in hydrology: Systems, resolutions, and limitations. J. Hydrol. 2002, 267, 285–297. [Google Scholar] [CrossRef]

- Ma, J. Pore-scale characterization of gas flow properties in shale by digital core analysis. In Unconventional Oil and Gas Resources Handbook; Elsevier: Amsterdam, The Netherlands, 2016; pp. 127–150. [Google Scholar]

- Wang, J.; Jiang, F.; Zhang, C.; Song, Z.; Mo, W. Study on the pore structure and fractal dimension of tight sandstone in coal measures. Energy Fuels 2021, 35, 3887–3898. [Google Scholar] [CrossRef]

| Mineral | Q | K | Pl | Ca | D | Py | B | C |

|---|---|---|---|---|---|---|---|---|

| Sandstone | 50.6% | 1.2% | 3.2% | 13.0% | 15.8% | - | - | 16.2% |

| Coal | 18.2% | - | - | - | 31.2% | 1.2% | 3.4% | 46.0% |

| Rmin (%) | Ro (%) | Rmax (%) | Proximate Analysis | Maceral Content | Coal Rank | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fixed Carbon (%) | Moisture (%) | Ash Yield (%) | Volatile (%) | Vitrinite (%) | Inertinite (%) | |||||

| Coal | 0.91 | 1.14 | 1.36 | 57.38 | 2.99 | 12.95 | 26.68 | 78 | 22 | Bituminous B |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Zou, W.; Li, K.; Wang, Z.; Huang, Z.; Huang, P.; Gao, R.; Qin, X. Microstructure Imaging and Characterization of Rocks Subjected to Liquid Nitrogen Cooling. Processes 2024, 12, 127. https://doi.org/10.3390/pr12010127

Wu X, Zou W, Li K, Wang Z, Huang Z, Huang P, Gao R, Qin X. Microstructure Imaging and Characterization of Rocks Subjected to Liquid Nitrogen Cooling. Processes. 2024; 12(1):127. https://doi.org/10.3390/pr12010127

Chicago/Turabian StyleWu, Xiaoguang, Wenchao Zou, Kun Li, Zikang Wang, Zhongwei Huang, Pengpeng Huang, Ruimin Gao, and Xinyu Qin. 2024. "Microstructure Imaging and Characterization of Rocks Subjected to Liquid Nitrogen Cooling" Processes 12, no. 1: 127. https://doi.org/10.3390/pr12010127

APA StyleWu, X., Zou, W., Li, K., Wang, Z., Huang, Z., Huang, P., Gao, R., & Qin, X. (2024). Microstructure Imaging and Characterization of Rocks Subjected to Liquid Nitrogen Cooling. Processes, 12(1), 127. https://doi.org/10.3390/pr12010127