Experimental Study on Methane Diffusion Characteristics of Different Metamorphic Deformed Coals Based on the Counter Diffusion Method

Abstract

:1. Introduction

2. Experimental Design

2.1. Experimental Platform Construction

2.2. Experimental Samples

2.3. Experimental Conditions and Steps

- (1)

- Prediction of coal seam temperature and pressure

- (2)

- Experimental procedure

2.4. Calculation Models

3. Results and Discussion

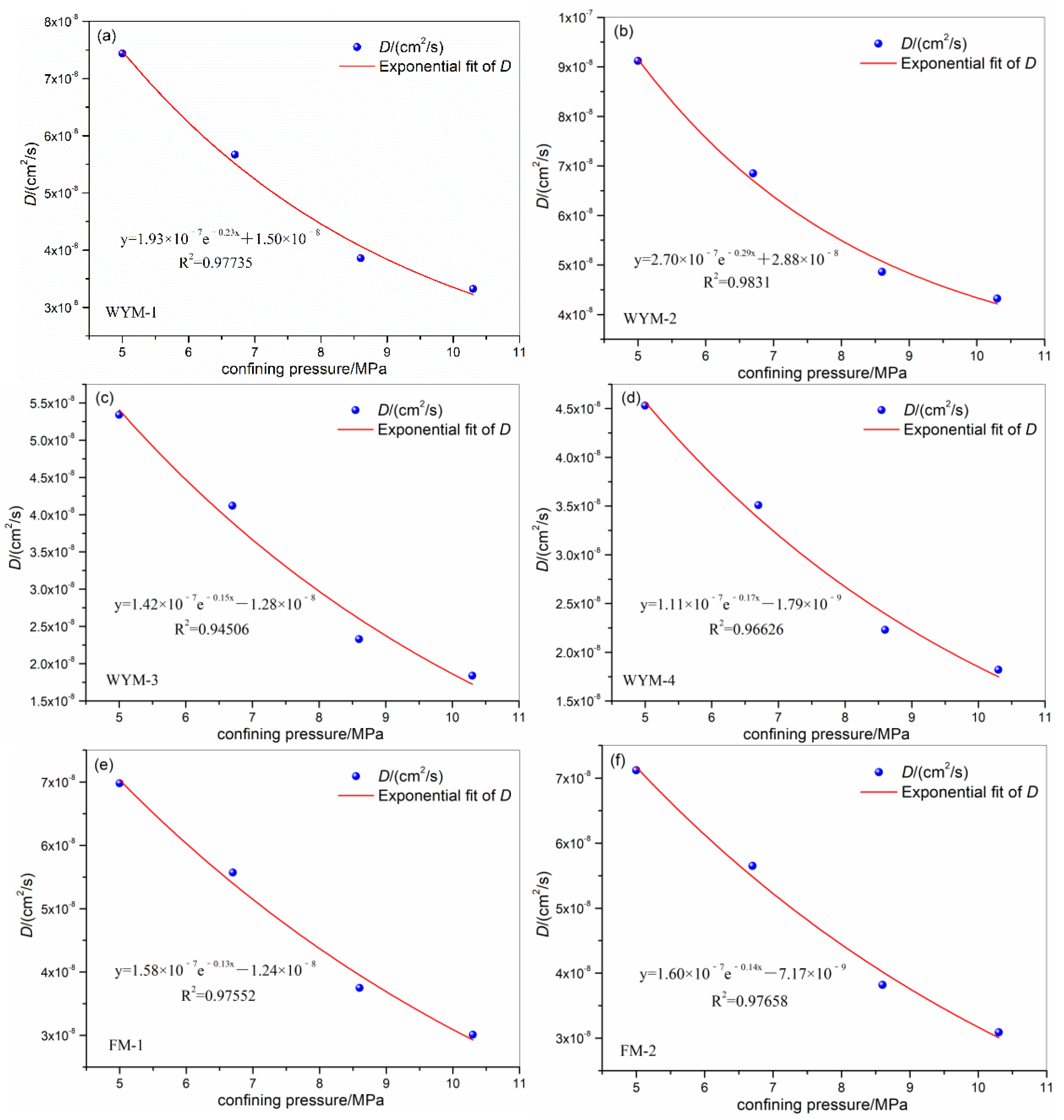

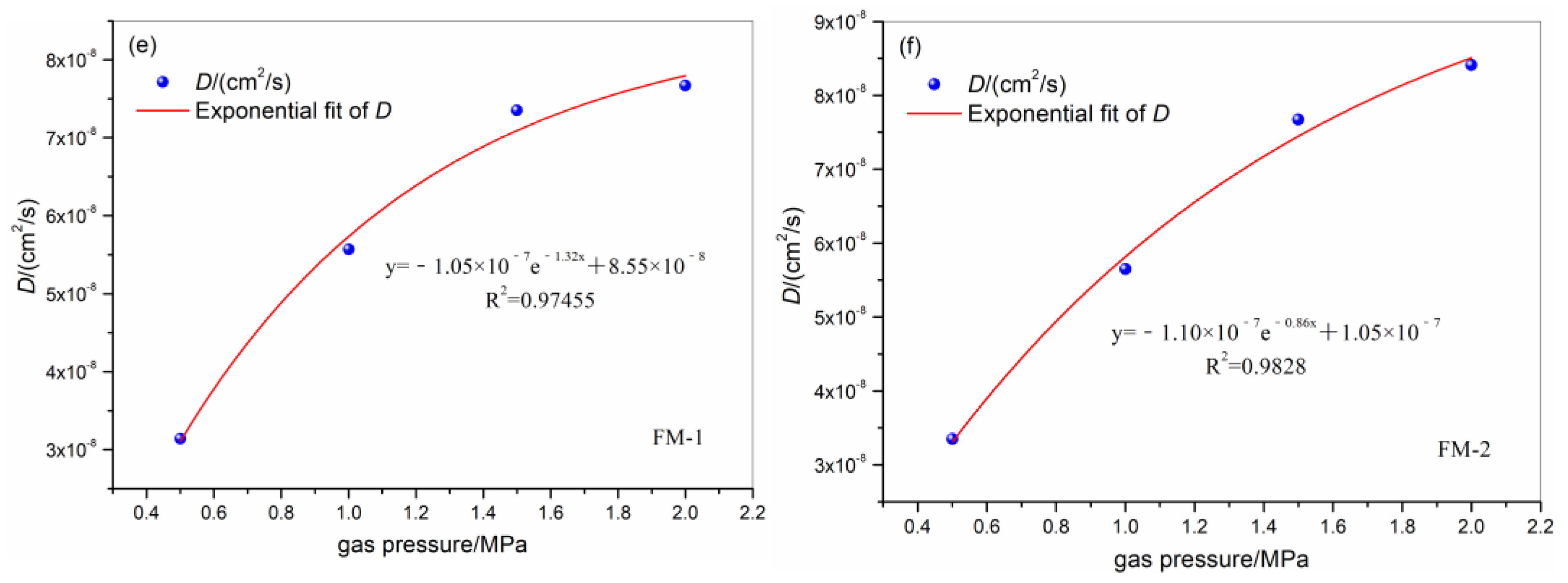

3.1. Influence of Confining Pressure on Diffusion Coefficient

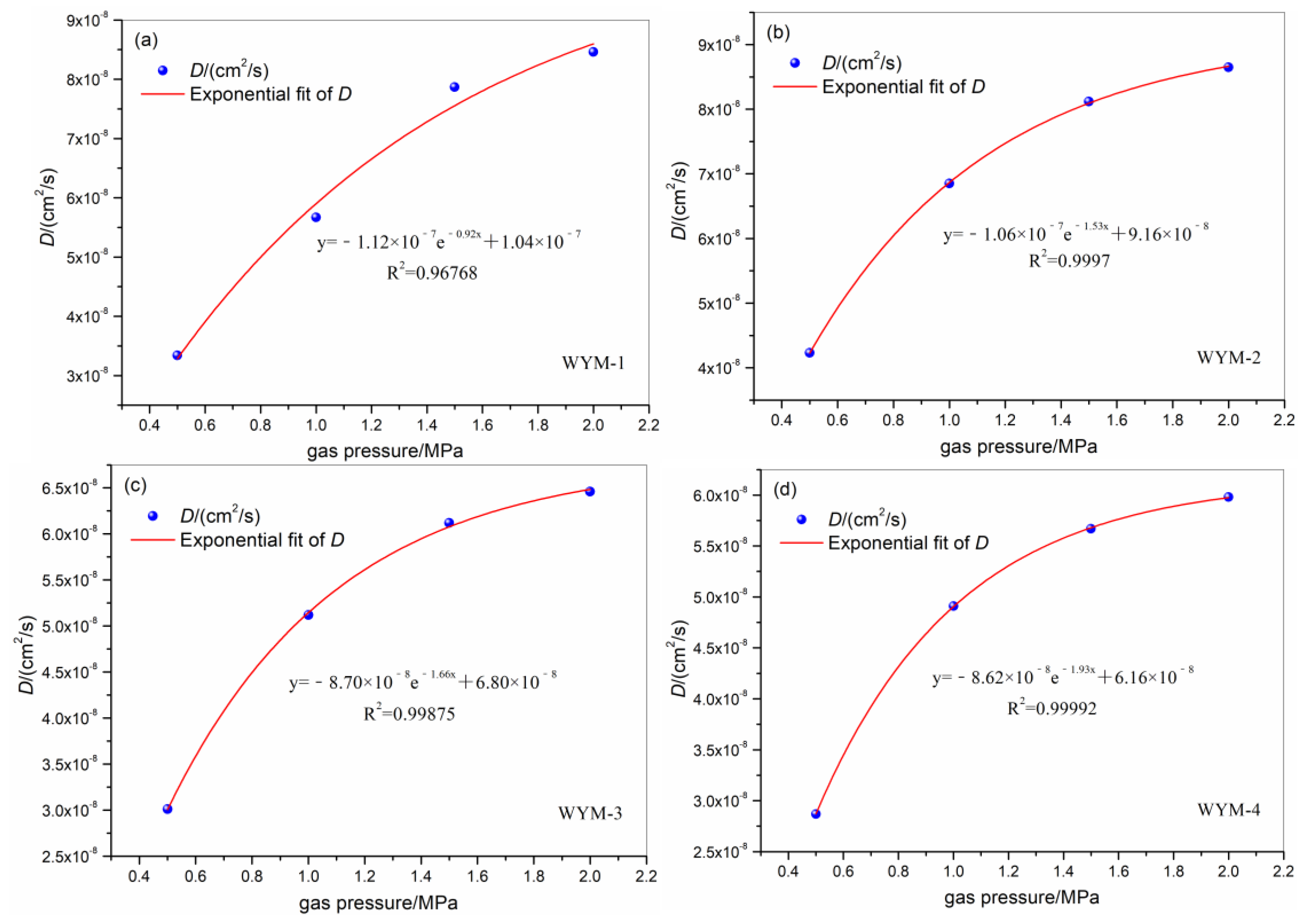

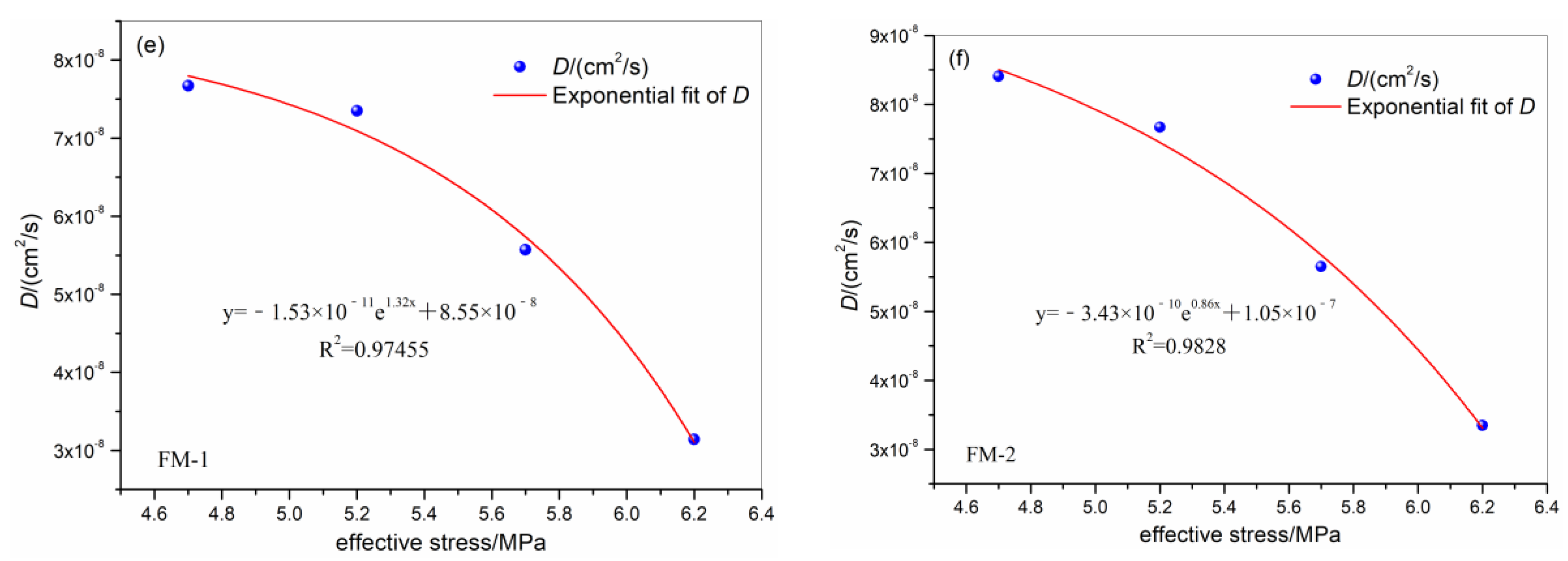

3.2. Influence of Gas Pressure on Diffusion Coefficient

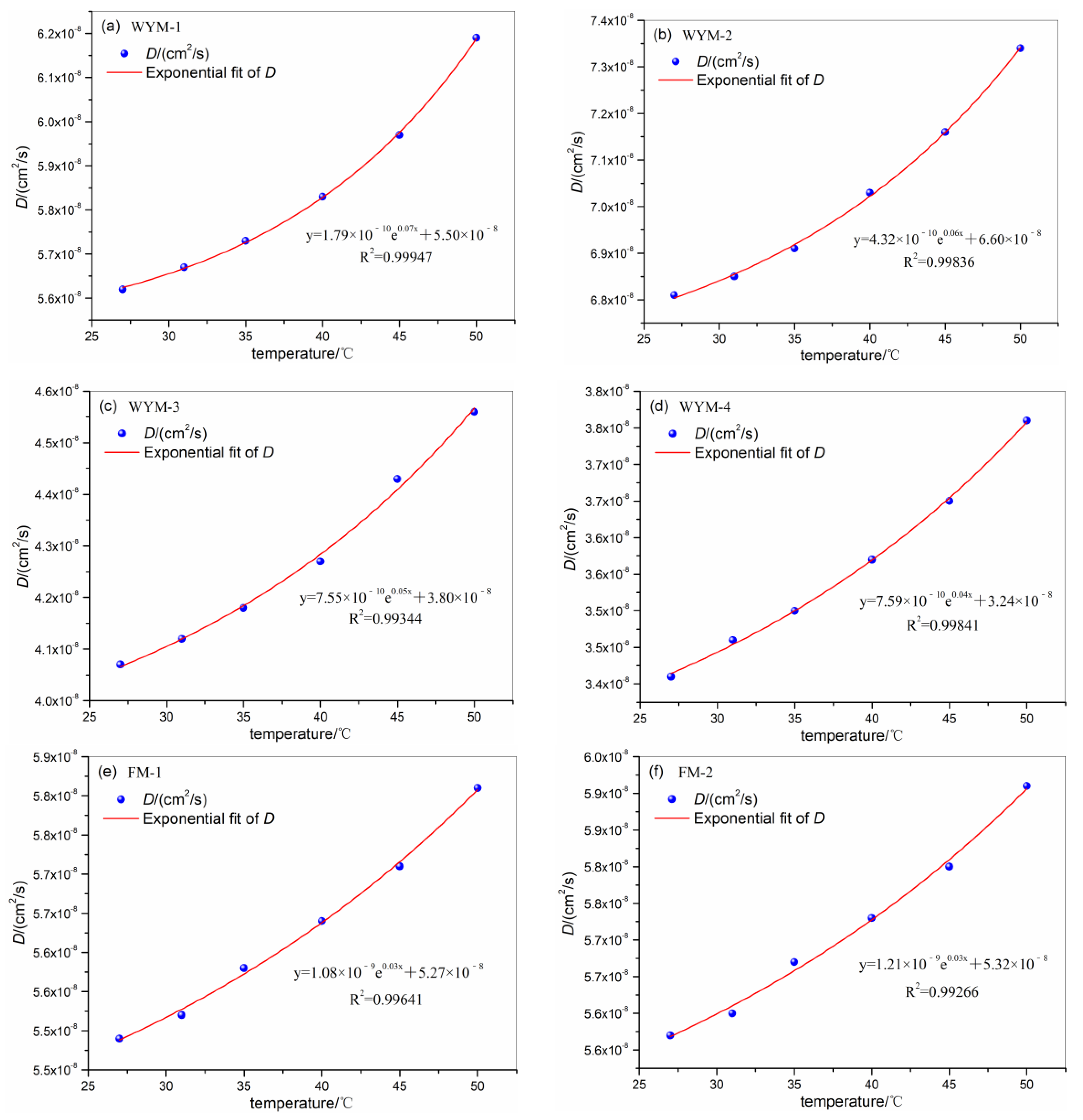

3.3. Influence of Temperature on the Diffusion Coefficient

| Samples | Experimental Conditions | CH4 D/(cm2/s) | Samples | Experimental Conditions | CH4 D/(cm2/s) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Temperature/°C | Confining Pressure/MPa | Gas Pressure/MPa | Temperature/°C | Confining Pressure/MPa | Gas Pressure/MPa | ||||

| WYM-1 | 27 | 6.7 | 1.0 | 5.62 × 10−8 | WYM-3 | 27 | 6.7 | 1.0 | 4.07 × 10−8 |

| 31 | 5.67 × 10−8 | 31 | 4.12 × 10−8 | ||||||

| 35 | 5.73 × 10−8 | 35 | 4.18 × 10−8 | ||||||

| 40 | 5.83 × 10−8 | 40 | 4.27 × 10−8 | ||||||

| 45 | 5.97 × 10−8 | 45 | 4.43 × 10−8 | ||||||

| 50 | 6.19 × 10−8 | 50 | 4.56 × 10−8 | ||||||

| WYM-2 | 27 | 6.7 | 1.0 | 6.81 × 10−8 | WYM-4 | 27 | 6.7 | 1.0 | 3.46 × 10−8 |

| 31 | 6.85 × 10−8 | 31 | 3.51 × 10−8 | ||||||

| 35 | 6.91 × 10−8 | 35 | 3.55 × 10−8 | ||||||

| 40 | 7.03 × 10−8 | 40 | 3.62 × 10−8 | ||||||

| 45 | 7.16 × 10−8 | 45 | 3.70 × 10−8 | ||||||

| 50 | 7.34 × 10−8 | 50 | 3.81 × 10−8 | ||||||

| FM-1 | 27 | 6.7 | 1.0 | 5.54 × 10−8 | FM-2 | 27 | 6.7 | 1.0 | 5.62 × 10−8 |

| 31 | 5.57 × 10−8 | 31 | 5.65 × 10−8 | ||||||

| 35 | 5.63 × 10−8 | 35 | 5.72 × 10−8 | ||||||

| 40 | 5.69 × 10−8 | 40 | 5.78 × 10−8 | ||||||

| 45 | 5.76 × 10−8 | 45 | 5.85 × 10−8 | ||||||

| 50 | 5.86 × 10−8 | 50 | 5.96 × 10−8 | ||||||

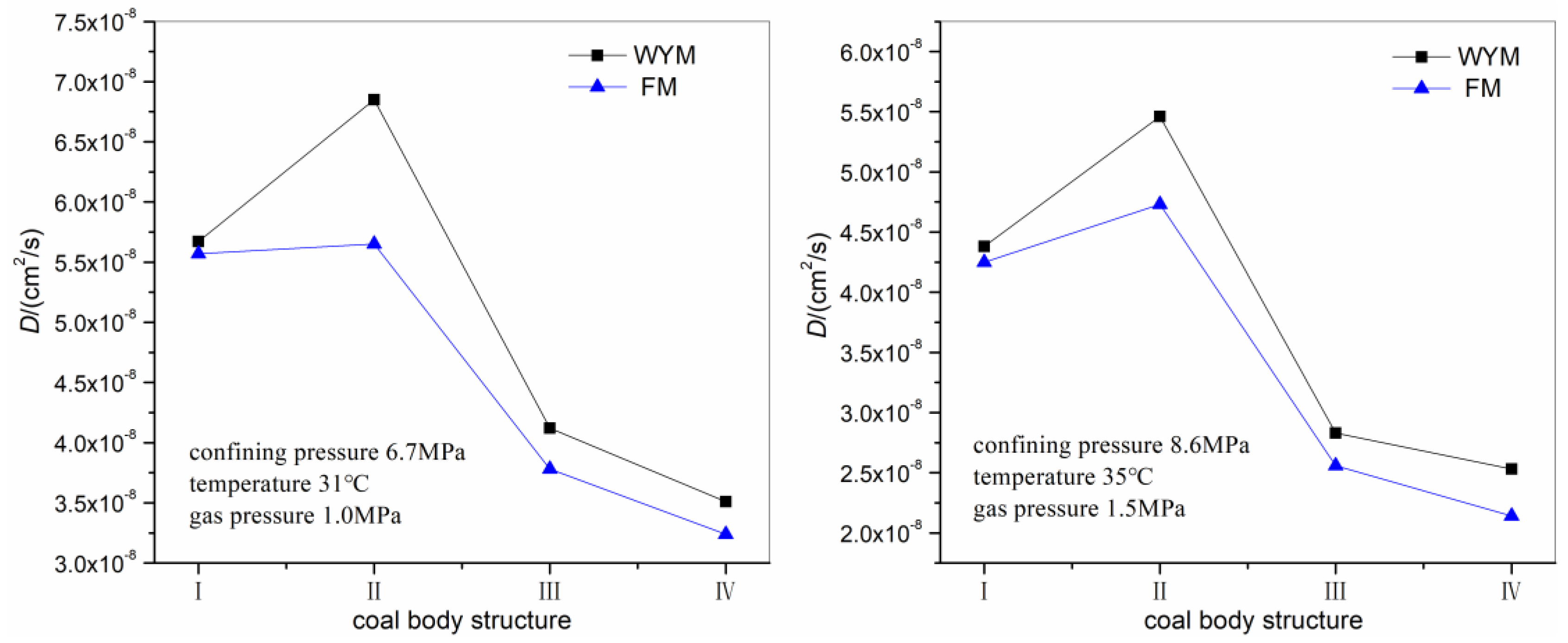

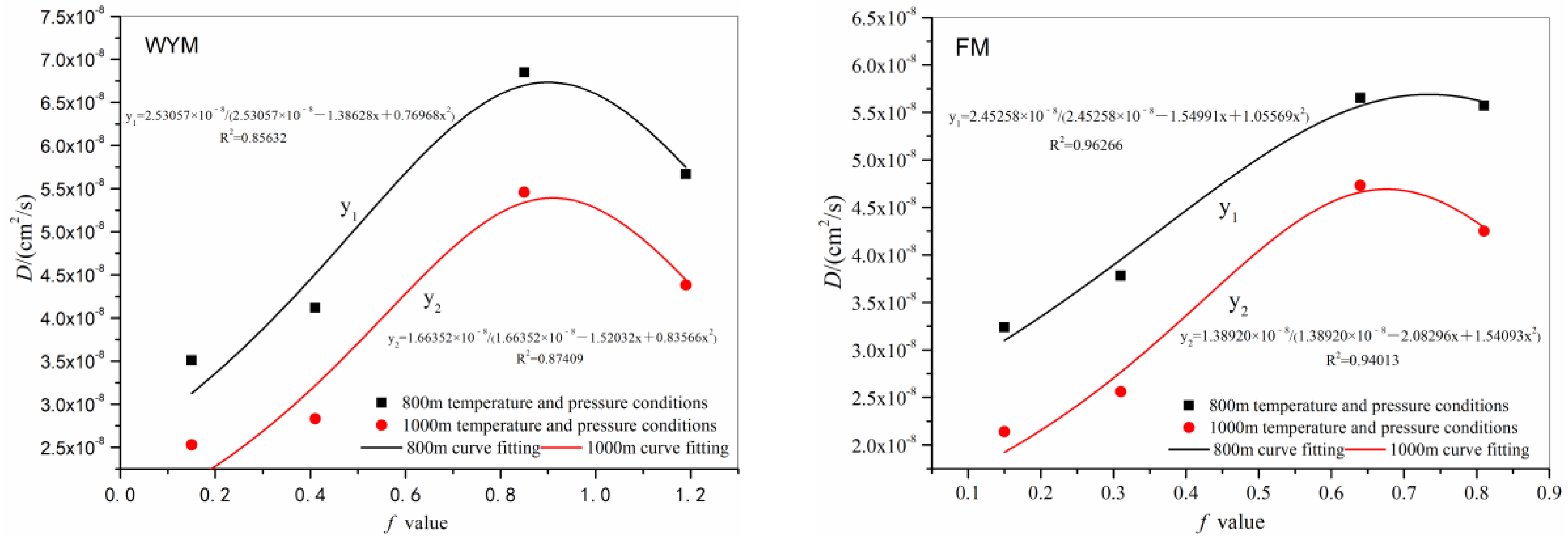

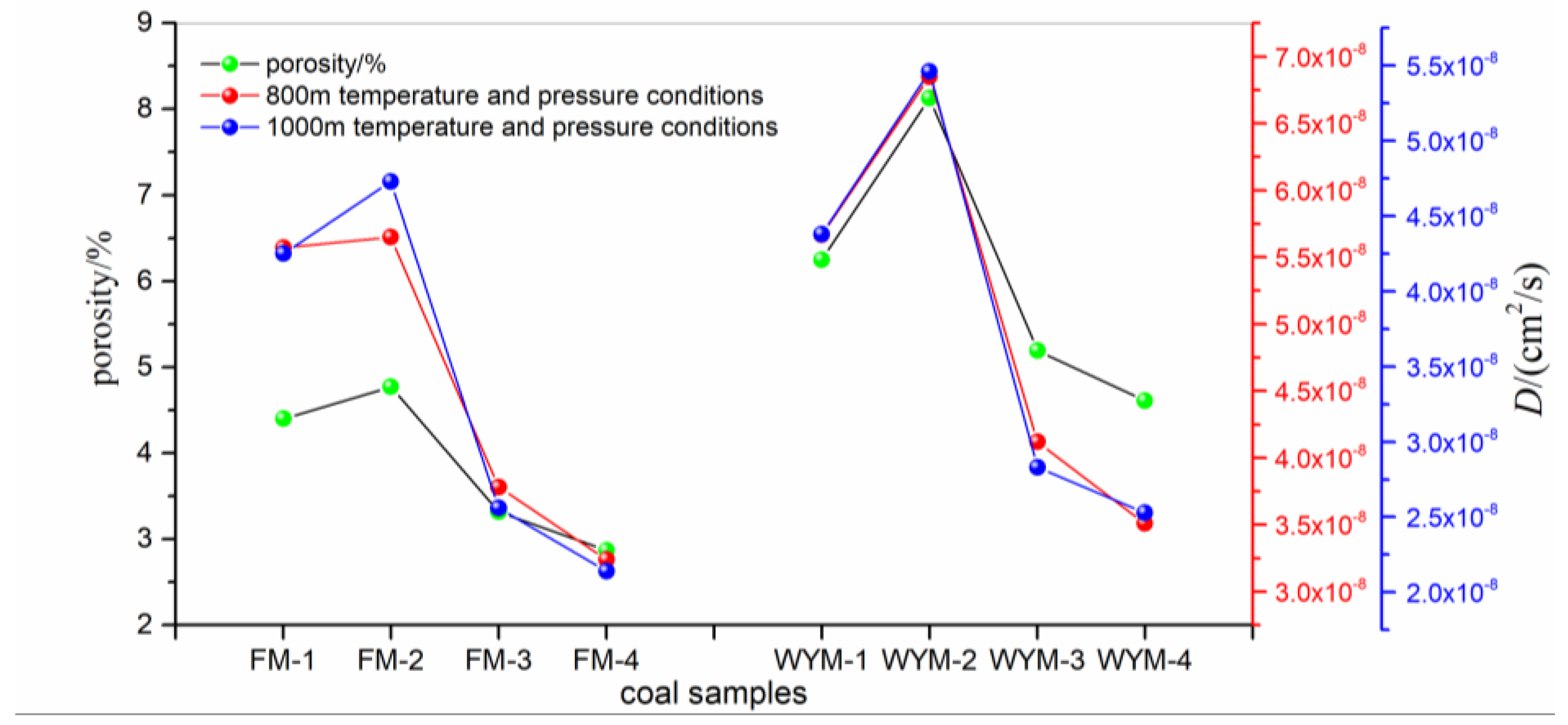

3.4. Influence of Metamorphism and Deformation Degree on the Diffusion Coefficient

4. Conclusions

- (1)

- The methane D of the raw coal cylindrical samples exponentially decreased with increasing confining pressure, and the decrease slightly slowed as the confining pressure further increased in this study. The decrease in D with increasing confining pressure, essentially determined by changes in the effective stress, was exponential. The methane diffusion coefficient of the cylindrical coal samples was similar to that of the permeability, and both decreased with increasing effective stress.

- (2)

- The change in the methane diffusion coefficient with changing gas pressure in the cylindrical raw coal samples was opposite to that with changes in the confining pressure, increasing an exponential relationship. The rate of increase slowed with increasing gas pressure. D exponentially increased with a reduction in the effective stress caused by changes in the gas pressure; the rate of increase slightly slowed with a reduction in the effective stress. A limit exists on D under in situ geological conditions. The impact of gas pressure on D slightly differs from that of confining pressure, involving two mechanisms, mechanical action and adsorption, which are jointly constrained by the effective stress and changes in coal particle shrinkage/expansion. The two mechanisms lead to opposite results but are ultimately restricted by the main controlling factor: the mechanical effect of effective stress.

- (3)

- The methane D of the raw coal cylindrical samples exponentially increased as the temperature increased, and the rate of increase only slightly increased with increasing temperature. The influence of temperature on diffusion is mainly achieved by changes in the root-mean-square speed and mean free path of the methane gas molecules.

- (4)

- Under the same confining pressure, temperature, and gas pressure conditions for coal samples with the same degree of metamorphism, the methane D first increased and then decreased with an increase in the deformation degree, with the maximum D found in fractured coal. D and f of coal exhibited a nonlinear Holliday function variation, and D first increased and then decreased as the coal structure changed from simple to complex. Under similar deformation conditions, D of anthracite was larger than that of fat coal. Porosity is the key factor affecting changes in the methane diffusion coefficient of different metamorphic deformed coals.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, X.L.; Pan, J.N.; Wang, K.; Mou, P.W.; Li, J.X. Fracture variation in high-rank coal induced by hydraulic fracturing using X-ray computer tomography and digital volume correlation. Int. J. Coal Geol. 2022, 252, 103942. [Google Scholar]

- Wang, Q.W.; Guo, B.; Song, M.; Yan, Q. Construction and application of “coal-water-environment” coordinated development evaluation index system: A case study of Sihe Minefield. Coal Geol. Explor. 2022, 50, 98–105. [Google Scholar]

- Ren, J.G.; Song, Z.M.; Li, B.; Liu, J.B.; Lv, R.S.; Liu, G.F. Structure feature and evolution mechanism of pores in different metamorphism and deformation coals. Fuel 2021, 283, 119292. [Google Scholar] [CrossRef]

- Zhao, W.; Cheng, Y.P.; Pan, Z.J.; Wang, K.; Liu, S.M. Gas diffusion in coal particles: A review of mathematical models and their applications. Fuel 2019, 252, 77–100. [Google Scholar]

- Zhang, Q.G.; Li, Q.S.; Fan, X.Y.; Liu, C.; Ge, Z.L.; Jiang, Z.G.; Peng, X.L.; Li, X.C.; Zhu, S.Y.; Zhao, S.L.; et al. Current situation and development trend of theories and technologies for coal and CBM co-mining in China. Nat. Gas Ind. 2022, 42, 130–145. [Google Scholar]

- Wang, Z.Z.; Fu, X.H.; Hao, M.; Li, G.F.; Pan, J.N.; Niu, Q.H.; Zhou, H. Experimental insights into the adsorption-desorption of CH4/N2 and induced strain for medium-rank coals. J. Pet. Sci. Eng. 2021, 204, 108705. [Google Scholar]

- Tao, S.; Pan, Z.J.; Tang, S.L.; Chen, S.D. Current status and geological conditions for the applicability of CBM drilling technologies in China: A review. Int. J. Coal Geol. 2019, 202, 95–108. [Google Scholar] [CrossRef]

- Hu, B.; Cheng, Y.P.; Pan, Z.J. Classification methods of pore structures in coal: A review and new insight. Gas Sci. Eng. 2023, 110, 204876. [Google Scholar]

- Zhou, H.; Wu, C.F.; Pan, J.N.; Wang, Z.Z.; Niu, Q.H.; Du, M.Y. Research on molecular structure characteristics of vitrinite and inertinite from bituminous coal with FTIR, Micro-Raman, and XRD spectroscopy. Energy Fuel 2021, 35, 1322–1335. [Google Scholar] [CrossRef]

- Mou, P.W.; Pan, J.N.; Niu, Q.H.; Wang, Z.Z.; Li, Y.B.; Song, D.Y. Coal pores: Methods, types, and characteristics. Energy Fuel 2021, 35, 7467–7484. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Y.; Ni, X.; Tao, C.; Fan, J.; Wu, X.; Zhao, S. Classification of coal structure combinations and their influence on hydraulic fracturing: A case study from the Qinshui Basin, China. Energies 2020, 13, 4559. [Google Scholar] [CrossRef]

- Li, Z.Q.; Li, P.F.; Wang, L.; Liu, Y.W.; Li, L. Experiment, model, and mechanism of multiscale dynamic diffusion–permeability in coal under different fluids. ACS Omega 2023, 8, 1606–1617. [Google Scholar] [CrossRef] [PubMed]

- Ren, J.G.; Wang, Z.Z.; Li, B.; Chen, F.; Liu, J.B.; Liu, G.F.; Song, Z.M. Fractal-time-dependent Fick diffusion model of coal particles based on desorption–diffusion experiments. Energy Fuel 2022, 36, 6198–6215. [Google Scholar] [CrossRef]

- Li, Z.Q.; Peng, J.S.; Li, L.; Qi, L.L.; Li, W. Novel dynamic multiscale model of apparent diffusion permeability of methane through low-permeability coal seams. Energy Fuel 2021, 35, 7844–7857. [Google Scholar] [CrossRef]

- Pan, Z.J.; Connell, L.D.; Camilleri, M.; Connelly, L. Effects of matrix moisture on gas diffusion and flow in coal. Fuel 2010, 89, 3207–3217. [Google Scholar] [CrossRef]

- Wen, Z.H.; Wang, Q.; Ren, J.G.; Zhang, L.L.; Yuan, Y.W. Dynamic gas diffusion model of capillary pores in a coal particle based on pore fractal characteristics. Transp. Porous Media 2021, 140, 581–601. [Google Scholar]

- Wang, Y.; Liu, S.M. Estimation of pressure-dependent diffusive permeability of coal using methane diffusion coefficient: Laboratory measurements and modeling. Energy Fuel 2016, 30, 8968–8976. [Google Scholar] [CrossRef]

- Xu, H.; Tang, D.Z.; Zhao, J.L.; Li, S.; Tao, S. A new laboratory method for accurate measurement of the methane diffusion coefficient and its influencing factors in the coal matrix. Fuel 2015, 158, 239–247. [Google Scholar]

- Liu, J.J.; Cheng, D.Q.; Li, Y.L.; Zhao, K.; Kou, Q.Q. Quantitative evaluation of the influence of coal particle size distribution on gas diffusion coefficient by image processing method. Fuel 2022, 314, 122946. [Google Scholar] [CrossRef]

- Liu, Z.D.; Lin, X.S.; Cheng, Y.P.; Chen, R.; Zhao, L.Y.; Wang, L.; Li, W.; Wang, Z.Y. Experimental investigation on the diffusion property of different form coal: Implication for the selection of CO2 storage reservoir. Fuel 2022, 318, 123691. [Google Scholar]

- Sander, R.; Connell, L.D.; Camilleri, M.C.; Pan, Z.J. CH4, CO2, N2 diffusion in Bowen Basin (Australia) coal: Relationship between sorption kinetics of coal core and crushed coal particles. J. Nat. Gas Sci. Eng. 2020, 81, 103468. [Google Scholar] [CrossRef]

- Bai, Y.; Lin, H.F.; Li, S.G.; Long, H.; Yan, M.; Li, Y.; Qin, L.; Zhou, B. Experimental study on kinetic characteristics of gas diffusion in coal under nitrogen injection. Energy 2022, 254, 124251. [Google Scholar] [CrossRef]

- Tan, Y.L.; Pan, Z.J.; Liu, J.S.; Kang, J.H.; Zhou, F.B.; Connell, L.D.; Yang, Y.X. Experimental study of impact of anisotropy and heterogeneity on gas flow in coal. Part I: Diffusion and adsorption. Fuel 2018, 232, 444–453. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Wang, J.; Liu, J.J.; Yang, Q.Q.; Huang, W.Y.; Liu, Y.Y.; Wang, L. Determining diffusion coefficients of coal particles by solving the inverse problem based on the data of methane desorption measurements. Fuel 2022, 308, 122045. [Google Scholar] [CrossRef]

- Lu, S.Q.; Li, M.J.; Sa, Z.Y.; Liu, J.; Wang, S.C.; Qu, M. Discrimination of gas diffusion state in intact coal and tectonic coal: Model and experiment. Fuel 2022, 325, 124916. [Google Scholar] [CrossRef]

- An, F.H.; Jia, H.F.; Feng, Y. Effect of stress, concentration and temperature on gas diffusion coefficient of coal measured through a direct method and its model application. Fuel 2022, 312, 122991. [Google Scholar] [CrossRef]

- Li, Y.D.; Pan, J.N.; Cheng, N.N.; Wang, Z.Z.; Zhang, L.; Liu, W.Q. Relationship between micropore structure of different coal ranks and methane diffusion. Nat. Resour. Res. 2022, 31, 2901–2917. [Google Scholar] [CrossRef]

- Lu, X.; Armstrong, R.T.; Mostaghimi, P. Analysis of gas diffusivity in coal using micro-computed tomography. Fuel 2020, 261, 116384. [Google Scholar] [CrossRef]

- Thimons, E.D.; Kissell, F.N. Diffusion of methane through coal. Fuel 1973, 52, 274–280. [Google Scholar] [CrossRef]

- Sevenster, P.G. Diffusion of gases through coal. Fuel 1959, 38, 403–418. [Google Scholar]

- Smith, D.M.; Williams, F.L. Diffusional effects in the recovery of methane from coalbeds. Soc. Pet. Eng. J. 1984, 24, 529–535. [Google Scholar] [CrossRef]

- Meng, Y.; Li, Z.P. Experimental study on diffusion property of methane gas in coal and its influencing factors. Fuel 2016, 185, 219–228. [Google Scholar] [CrossRef]

- Dong, J.; Cheng, Y.P.; Pan, Z.J. Comparison of transient and pseudo-steady diffusion of methane in coal and implications for coalbed methane control. J. Pet. Sci. Eng. 2020, 184, 106543. [Google Scholar] [CrossRef]

- Baatar, L.; Mostaghimi, P.; Yuan, M.; Armstrong, R.T.; Adler, L.; Canbulat, I.; Si, G.Y.; Gaidarov, B.; Jing, Y. Multiscale measurements of gas diffusion coefficient of coal using counter-diffusion and image-based methods. Int. J. Coal Geol. 2023, 265, 104155. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.Q.; Fu, X.H.; Gao, Y.B.; Kong, J.; Zhao, Y.; Song, H.R. Experimental study on gas diffusion dynamics in fractured coal: A better understanding of gas migration in in-situ coal seam. Energy 2020, 195, 117005. [Google Scholar] [CrossRef]

- Qin, Y.J.; An, F.H.; Su, W.W.; Jia, H.F.; Chen, X.J. Direct determination of the diffusion coefficient variation of cylindrical coal based on Fick’s law and model construction. Coal Sci. Technol. 2023, 51, 1–10. [Google Scholar]

- Yi, M.H.; Wang, L.; Cheng, Y.P.; Wang, C.H.; Hu, B. Calculation of gas concentration-dependent diffusion coefficient in coal particles: Influencing mechanism of gas pressure and desorption time on diffusion behavior. Fuel 2022, 320, 123973. [Google Scholar] [CrossRef]

- Fang, X.L.; Liu, D.L.; Zhou, Y.F.; Liu, X.B.; Cai, Y.D. Factors influencing methane diffusion behaviors in micro-nano coal pores: A comprehensive study. Front. Earth Sci. 2023, 17, 71–86. [Google Scholar] [CrossRef]

- Song, H.R.; Lin, B.Q.; Zhong, Z.; Liu, T. Experimental study on methane diffusion kinetics in three typical metamorphic coals. Fuel 2022, 311, 122601. [Google Scholar] [CrossRef]

- Cheng, Y.P.; Pan, Z.J. Reservoir properties of Chinese tectonic coal: A review. Fuel 2020, 260, 116350. [Google Scholar]

- Yang, X.; Wang, G.D.; Zhang, J.Y.; Ren, T. The influence of sorption pressure on gas diffusion in coal particles: An experimental study. Processes 2019, 7, 219. [Google Scholar] [CrossRef]

- Zang, J.; Wang, K.; Liu, A. Phenomenological over-parameterization of the triple-fitting-parameter diffusion models in evaluation of gas diffusion in coal. Processes 2019, 7, 241. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Huang, W.Y.; Lv, B.; Ma, X.H.; Lu, X.D.; Wang, J.; Wang, L. Decoupling experiments for CH4 “diffusion-seepage” in coal columns to effectively measure sorption time. Int. J. Coal Geol. 2022, 261, 104074. [Google Scholar] [CrossRef]

- Cai, Y.Y.; Cheng, J.S.; Cheng, B. Study on the gas emission law of circular column cinder based on time–varying diffusion coefficient. Min. Saf. Environ. Prot. 2020, 47, 32–36. [Google Scholar]

- Song, Y.; Jiang, B.; Li, M.; Hou, C.L.; Xu, S.C. A review on pore-fractures in tectonically deformed coals. Fuel 2020, 278, 118248. [Google Scholar]

- GB/T 6948-2008; Chinese National Standard. Method of Determining Microscopically the REFLECTANCE of vitrinite on Coal. Standardization Administration of China: Beijing, China, 2008. (In Chinese)

- GB/T 212-2008; Chinese National Standard. Proximate Analysis of Coal. Standardization Administration of China: Beijing, China, 2008. (In Chinese)

- GB/T 23561.4-2009; Chinese National Standard. Methods for Determining the Physical and Mechanical Properties of Coal and Rock. Part 4: Methods for Calculating the Porosity of Coal and Rock. Standardization Administration of China: Beijing, China, 2009. (In Chinese)

- GB/T 23561.12-2010; Chinese National Standard. Methods for Determining the Physical and Mechanical Properties of Coal and Rock. Part 12: Methods for Determining Coal Hardiness Coefficient. Standardization Administration of China: Beijing, China, 2010. (In Chinese)

- Ren, J.G.; Weng, H.B.; Song, Z.M.; Li, B.; Lv, R.S. Method of making raw coal isostatic pressing columnar coal samples for heavily tectonically deformed coal. Saf. Coal Mines 2018, 49, 66–69. [Google Scholar]

- Liu, G.F. Mechanism and Model of Coal Adsorption Gas in High Temperature and Pressure and Three-Phase Medium. Ph.D. Thesis, Henan Polytechnic University, Jiaozuo, China, 2011. [Google Scholar]

- Zhu, W.C.; Liu, S.Y.; Zhang, X.F.; Wei, C.H. Coupled coal–gas interaction during CBM and CO2-ECBM recovery in coal seams: A critical review. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 195. [Google Scholar]

- Liu, Z.D.; Lin, X.S.; Wang, Z.Y.; Zhang, Z.; Chen, R.; Wang, L.; Li, W. Modeling and experimental study on methane diffusivity in coal mass under in-situ high stress conditions: A better understanding of gas extraction. Fuel 2022, 321, 124078. [Google Scholar] [CrossRef]

- Niu, Q.H.; Cao, L.W.; Sang, S.X.; Zhou, X.Z.; Wang, W.; Yuan, W.; Ji, Z.M.; Wang, H.C.; Nie, Y. Study on the anisotropic permeability in different rank coals under influences of supercritical CO2 adsorption and effective stress and its enlightenment for CO2 enhance coalbed methane recovery. Fuel 2020, 262, 116515. [Google Scholar] [CrossRef]

- Ji, X.F.; Song, D.Y.; Shi, W.F.; Li, Y.F. Influence of nanopore structure deformation on gas migration in coal. ACS Omega 2021, 29, 19115–19126. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Fu, X.H.; Pan, J.N.; Deng, Z. Effect of N2/CO2 injection and alternate injection on volume swelling/shrinkage strain of coal. Energy 2023, 275, 127377. [Google Scholar] [CrossRef]

- Zhao, D.; Li, X.W.; Feng, Z.C.; Pu, Y.X.; Chang, H.M.; Jia, Y.C. Study on the behavior and mechanism of methane desorption-diffusion for multi-scale coal samples under multi-temperature conditions. Fuel 2022, 328, 125332. [Google Scholar] [CrossRef]

- Qin, Y.P.; Xu, H.; Yang, D.Y.; Sun, Y.; Guo, M.Y.; Zhang, F.J.; Wu, F.; Li, Y.W.; Fan, J.F. Modeling of gas desorption and diffusion kinetics in a coal seam combined with a free gas density gradient concept. Energy Fuel 2022, 36, 10052–10063. [Google Scholar]

- Liu, S.; Wei, C.; Zhu, W.; Zhang, M. Temperature- and pressure-dependent gas diffusion in coal particles: Numerical model and experiments. Fuel 2020, 266, 117054. [Google Scholar] [CrossRef]

- Liu, Y.W.; Du, Y.; Li, Z.Q.; Zhao, F.J.; Zuo, W.Q.; Wei, J.P.; Mitri, H. A rapid and accurate direct measurement method of underground coal seam gas content based on dynamic diffusion theory. Int. J. Min. Sci. Technol. 2020, 30, 799–810. [Google Scholar]

- Lu, S.Q.; Wang, C.F.; Li, M.J.; Sa, Z.Y.; Zhang, Y.L.; Liu, J.; Wang, H.; Wang, S.C. Gas time-dependent diffusion in pores of deformed coal particles: Model development and analysis. Fuel 2021, 295, 120566. [Google Scholar] [CrossRef]

- Qin, Y.; Xu, H.; Liu, W.; Liu, J.; Duan, W. Time- and pressure-independent gas transport behavior in a coal matrix: Model development and improvement. Energy Fuel 2020, 34, 9355–9370. [Google Scholar] [CrossRef]

| Samples | Coal Structure | Ro,max (%) | Mad (%) | Ad (%) | Vdaf (%) | FCd (%) | Porosity/% | f Value |

|---|---|---|---|---|---|---|---|---|

| WYM-1 | original-structure coal | 3.38 | 2.94 | 8.41 | 5.50 | 83.15 | 6.25 | 1.19 |

| WYM-2 | fragmented coal | 3.41 | 2.93 | 8.41 | 5.49 | 83.17 | 8.13 | 0.85 |

| WYM-3 | granulated coal | 3.39 | 2.67 | 8.36 | 5.63 | 83.22 | 5.19 | 0.41 |

| WYM-4 | mylonitic coal | 3.44 | 2.53 | 8.57 | 5.71 | 83.19 | 4.61 | 0.15 |

| FM-1 | original-structure coal | 1.14 | 1.42 | 10.10 | 11.03 | 70.65 | 4.40 | 0.81 |

| FM-2 | fragmented coal | 1.16 | 1.44 | 8.70 | 10.52 | 69.99 | 4.77 | 0.64 |

| FM-3 | granulated coal | 1.14 | 1.21 | 8.65 | 10.79 | 70.52 | 3.32 | 0.31 |

| FM-4 | mylonitic coal | 1.15 | 1.06 | 8.77 | 10.21 | 70.32 | 2.87 | 0.15 |

| Coal Seam Burial Depth/m | Predicted Coal Seam Temperature/°C | Average Value/°C | Predicted Reservoir Pressure/MPa | Average Value/MPa |

|---|---|---|---|---|

| Minimum/Maximum | Minimum/Maximum | |||

| 600 | 22/32 | 27 | 2.4/7.7 | 5.0 |

| 700 | 24/34 | 29 | 2.8/9.0 | 5.9 |

| 800 | 26/36 | 31 | 3.2/10.3 | 6.7 |

| 900 | 28/38 | 33 | 3.6/11.6 | 7.6 |

| 1000 | 30/40 | 35 | 4.0/12.9 | 8.6 |

| 1100 | 32/43 | 37.5 | 4.4/14.2 | 9.5 |

| 1200 | 34/46 | 40 | 4.8/15.5 | 10.3 |

| 1300 | 36/49 | 42.5 | 5.2/16.8 | 11.0 |

| Simulated Burial Depth/m | Confining Pressure/MPa | Gas Pressure/MPa | Temperature/°C | Remarks |

|---|---|---|---|---|

| 600 | 5.0 | 0.5 | 27 | Orthogonal experiment designed accordingly |

| 800 | 6.7 | 1.0 | 31 | |

| 1000 | 8.6 | 1.5 | 35 | |

| 1200 | 10.3 | 2.0 | 40 |

| Samples | Experimental Conditions | Effective Stress/MPa | CH4 D/(cm2/s) | Samples | Experimental Conditions | Effective Stress/MPa | CH4 D/(cm2/s) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Confining Pressure/MPa | Temperature/°C | Gas Pressure/MPa | Confining Pressure/MPa | Temperature/°C | Gas Pressure/MPa | ||||||

| WYM-1 | 5.0 | 31 | 1.0 | 4.0 | 7.44 × 10−8 | WYM-3 | 5.0 | 31 | 1.0 | 4.0 | 5.34 × 10−8 |

| 6.7 | 5.7 | 5.67 × 10−8 | 6.7 | 5.7 | 4.12 × 10−8 | ||||||

| 8.6 | 7.6 | 3.86 × 10−8 | 8.6 | 7.6 | 2.33 × 10−8 | ||||||

| 10.3 | 9.3 | 3.32 × 10−8 | 10.3 | 9.3 | 1.84 × 10−8 | ||||||

| WYM-2 | 5.0 | 31 | 1.0 | 4.0 | 9.12 × 10−8 | WYM-4 | 5.0 | 31 | 1.0 | 4.0 | 4.53 × 10−8 |

| 6.7 | 5.7 | 6.85 × 10−8 | 6.7 | 5.7 | 3.51 × 10−8 | ||||||

| 8.6 | 7.6 | 4.86 × 10−8 | 8.6 | 7.6 | 2.23 × 10−8 | ||||||

| 10.3 | 9.3 | 4.32 × 10−8 | 10.3 | 9.3 | 1.82 × 10−8 | ||||||

| FM-1 | 5.0 | 31 | 1.0 | 4.0 | 6.98 × 10−8 | FM-2 | 5.0 | 31 | 1.0 | 4.0 | 7.12 × 10−8 |

| 6.7 | 5.7 | 5.57 × 10−8 | 6.7 | 5.7 | 5.65 × 10−8 | ||||||

| 8.6 | 7.6 | 3.75 × 10−8 | 8.6 | 7.6 | 3.82 × 10−8 | ||||||

| 10.3 | 9.3 | 3.01 × 10−8 | 10.3 | 9.3 | 3.09 × 10−8 | ||||||

| Samples | Experimental Conditions | Effective Stress/MPa | CH4 D/(cm2/s) | Samples | Experimental Conditions | Effective Stress/MPa | CH4 D/(cm2/s) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gas Pressure/MPa | Temperature/°C | Confining Pressure/MPa | Gas Pressure/MPa | Temperature/°C | Confining Pressure/MPa | ||||||

| WYM-1 | 0.5 | 31 | 6.7 | 6.2 | 3.34 × 10−8 | WYM-3 | 0.5 | 31 | 6.7 | 6.2 | 3.01 × 10−8 |

| 1.0 | 5.7 | 5.67 × 10−8 | 1.0 | 5.7 | 4.12 × 10−8 | ||||||

| 1.5 | 5.2 | 7.87 × 10−8 | 1.5 | 5.2 | 6.12 × 10−8 | ||||||

| 2.0 | 4.7 | 8.46 × 10−8 | 2.0 | 4.7 | 6.46 × 10−8 | ||||||

| WYM-2 | 0.5 | 31 | 6.7 | 6.2 | 4.23 × 10−8 | WYM-4 | 0.5 | 31 | 6.7 | 6.2 | 2.87 × 10−8 |

| 1.0 | 5.7 | 6.85 × 10−8 | 1.0 | 5.7 | 3.51 × 10−8 | ||||||

| 1.5 | 5.2 | 8.12 × 10−8 | 1.5 | 5.2 | 5.67 × 10−8 | ||||||

| 2.0 | 4.7 | 8.65 × 10−8 | 2.0 | 4.7 | 5.98 × 10−8 | ||||||

| FM-1 | 0.5 | 31 | 6.7 | 6.2 | 3.14 × 10−8 | FM-2 | 0.5 | 31 | 6.7 | 6.2 | 3.35 × 10−8 |

| 1.0 | 5.7 | 5.57 × 10−8 | 1.0 | 5.7 | 5.65 × 10−8 | ||||||

| 1.5 | 5.2 | 7.35 × 10−8 | 1.5 | 5.2 | 7.67 × 10−8 | ||||||

| 2.0 | 4.7 | 7.67 × 10−8 | 2.0 | 4.7 | 8.41 × 10−8 | ||||||

| Samples | f Value | Experimental Conditions | CH4 D/(cm2/s) | Simulated Coal Seam Burial Depth/m | ||

|---|---|---|---|---|---|---|

| Confining Pressure/MPa | Temperature/°C | Gas Pressure/MPa | ||||

| WYM-1 | 1.19 | 6.7 | 31 | 1.0 | 5.67 × 10−8 | 800 m |

| WYM-2 | 0.85 | 6.7 | 31 | 1.0 | 6.85 × 10−8 | |

| WYM-3 | 0.41 | 6.7 | 31 | 1.0 | 4.12 × 10−8 | |

| WYM-4 | 0.15 | 6.7 | 31 | 1.0 | 3.51 × 10−8 | |

| FM-1 | 0.81 | 6.7 | 31 | 1.0 | 5.57 × 10−8 | |

| FM-2 | 0.64 | 6.7 | 31 | 1.0 | 5.65 × 10−8 | |

| FM-3 | 0.31 | 6.7 | 31 | 1.0 | 3.78 × 10−8 | |

| FM-4 | 0.15 | 6.7 | 31 | 1.0 | 3.24 × 10−8 | |

| WYM-1 | 1.19 | 8.6 | 35 | 1.5 | 4.38 × 10−8 | 1000 m |

| WYM-2 | 0.85 | 8.6 | 35 | 1.5 | 5.46 × 10−8 | |

| WYM-3 | 0.41 | 8.6 | 35 | 1.5 | 2.83 × 10−8 | |

| WYM-4 | 0.15 | 8.6 | 35 | 1.5 | 2.53 × 10−8 | |

| FM-1 | 0.81 | 8.6 | 35 | 1.5 | 4.25 × 10−8 | |

| FM-2 | 0.64 | 8.6 | 35 | 1.5 | 4.73 × 10−8 | |

| FM-3 | 0.31 | 8.6 | 35 | 1.5 | 2.56 × 10−8 | |

| FM-4 | 0.15 | 8.6 | 35 | 1.5 | 2.14 × 10−8 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, J.; Gao, L.; Wen, Z.; Weng, H.; Liu, J.; Lv, R.; Qu, Y.; Song, Z.; Zhang, Y.; Li, B. Experimental Study on Methane Diffusion Characteristics of Different Metamorphic Deformed Coals Based on the Counter Diffusion Method. Processes 2023, 11, 2808. https://doi.org/10.3390/pr11092808

Ren J, Gao L, Wen Z, Weng H, Liu J, Lv R, Qu Y, Song Z, Zhang Y, Li B. Experimental Study on Methane Diffusion Characteristics of Different Metamorphic Deformed Coals Based on the Counter Diffusion Method. Processes. 2023; 11(9):2808. https://doi.org/10.3390/pr11092808

Chicago/Turabian StyleRen, Jiangang, Liang Gao, Zhihui Wen, Hongbo Weng, Jianbao Liu, Runsheng Lv, Yanwei Qu, Zhimin Song, Yongwang Zhang, and Bing Li. 2023. "Experimental Study on Methane Diffusion Characteristics of Different Metamorphic Deformed Coals Based on the Counter Diffusion Method" Processes 11, no. 9: 2808. https://doi.org/10.3390/pr11092808

APA StyleRen, J., Gao, L., Wen, Z., Weng, H., Liu, J., Lv, R., Qu, Y., Song, Z., Zhang, Y., & Li, B. (2023). Experimental Study on Methane Diffusion Characteristics of Different Metamorphic Deformed Coals Based on the Counter Diffusion Method. Processes, 11(9), 2808. https://doi.org/10.3390/pr11092808