Abstract

Energy conservation has emerged as a strategic target worldwide, which will enable the protection of the environment and the preservation of natural resources. Energy consumption in buildings for heating and cooling is considered one of the main sources of energy consumption in several countries. For this reason, there is an ongoing search for appropriate alternatives to preserve energy and reduce energy losses. To overcome this challenge, thermal insulation is becoming increasingly essential to save energy. Although a large number of insulation materials are used commercially, this sector still faces various challenges such as cost, thermal and mechanical properties, the end-of-life cycle, as well as health issues, etc. Furthermore, the harmful impact of buildings on the environment and health issues should be considered not only in relation to the energy expended whilst using them but also in relation to the energy performance materials they are constructed from. The insulation materials commonly used in the construction industry today are polymer-based materials such as polystyrene and polyurethane foam. These materials have a critical impact on the environment. In light of these results, several researchers have concluded that it is imperative to develop insulating materials with outstanding properties that have a lower impact on the environment and are relatively affordable. Agricultural and/or industrial wastes, and even natural fibers, are increasingly used as green insulation materials, as they are an eco-friendly, cost-effective alternative to conventional oil-based materials, as well as the fact that their end-of-life cycle does not pose a critical problem. This review paper discusses the several renewable resources and industrial wastes developed as thermal insulations. Furthermore, it sheds light on composite materials used as construction materials, as well as their end-of-life cycle.

1. Introduction

Energy consumption in today’s world is responsible for pollution, environmental deterioration and greenhouse gas emissions. One of the most energy-intensive sectors is the construction industry. Worldwide, buildings are involved in roughly 1/3 of greenhouse gas emissions and consume about 40% of resources [1]. Furthermore, in the European Union (EU), the building sector is involved in more than 40% of the overall energy consumption and contributes significantly to CO2 emissions [2]. Existing building cooling, heating and air-conditioning systems significantly counteract the sustainability concept, with the concomitant consumption of fossil fuels resulting in air pollution [3]. The environmental impact associated with buildings is not only due to the energy consumed during their use but also related to the materials used in their construction and their impact on human health.

As energy becomes extremely precious, it is necessary to develop a solution to save energy consumption, especially in the building sector. Indeed, the requirement for green buildings is expanding globally. The use of thermal insulation materials has become more and more widespread in buildings as an innovative solution to save energy in buildings. Thermal insulation is a material or assembly of materials that retards the spread of heat by conduction, convection and radiation when properly applied [4]. These products contribute to reducing the reliance on heating, ventilation and air conditioning. They thereby preserve energy and minimize the use of natural resources; but most importantly, they mitigate the emission of contaminants into a building’s environment [1]. The disposal of buildings could have another adverse impact on the environment. Building materials may turn out to be waste and therefore not readily available for disposal. When building materials are natural or based on organic materials, their disposal is not a crucial contributor to environmental pollution [5].

Regrettably, several inorganic materials are used to produce thermal insulation, most of these materials come from mineral wool (52%) and plastics (41%): these materials are not sustainable and lead to further pollution and health problems [5]. To overcome this problem, the global research community has developed several sustainable building insulation materials that fulfill current comfort standards. Sustainable insulation products with limited intrinsic energy and reduced environmental emissions are also gaining in momentum, and many innovative new insulations are steadily reaching the market [3].

For this purpose, natural raw materials either from plant origin such as hemp, flax, bamboo and/or recycled materials—in the case of countries with climatic conditions that are not conducive to the cultivation of these plants—including cellulose-rich waste such as paper (wood, etc.) or textiles (cotton, wool, silk, etc.) have been thoroughly examined for several years in order to develop eco-friendly thermal insulation materials [6]. Several researchers have demonstrated that due to their properties, such as low thermal conductivity and fibrous characteristics, organic materials significantly improve thermal insulation performance after insertion into the building’s outer shell structure [3,6,7,8,9]. Other benefits include extended periods of indoor thermal comfort, a higher specific heat capacity, decreased acoustic levels, fire protection, etc. These materials will lead to energy-efficient systems compared to conventional materials [9]. Additionally, they are readily recyclable, biodegradable, renewable and indigenously available which is very important when considering their end-of-life cycle.

This review discusses the circularization of textile and agriculture waste into a valuable product which is insulating materials. This review has three steps: First, a literature review was conducted on the challenges related to the construction and solid-waste generation sectors. Second, thermal insulation materials, especially those from renewable resources, as well as the performance of conventional and natural materials were studied. Finally, end-of-life cycle studies of both the non-conventional or conventional materials were discussed.

2. Challenge

The industrial transition and revolution have brought virtues to humanity, switching from a purely agrarian and artisanal society to an industrial society. Since then, we have adopted an irreversible approach: extract, manufacture, consume and throw away; this is the linear economy. But this approach leads us to exhaust a limited supply of natural resources, and often produce toxic waste. It simply cannot work in the long term. Among the most serious drawbacks of this industrial revolution are the scarcity of natural resources, climate change and high energy consumption, which require a more sustainable governance to guarantee the continuity of modern society and ensure the future of the upcoming generations [10].

Taking into consideration the world’s energy expenditure, the case of the construction sector is especially important, as it is considered the heaviest consumer of resources—not only of energy but also raw materials and water. In addition, it is recognized as the main source of greenhouse gases emissions, which contribute to global warming by furthering climate change and endangering the survival of humanity [4]. To overcome this challenge, the sector is switching to thermal insulation to reduce energy consumption and save it, but the existing insulating materials are exerting a tremendous burden on the environment, either while they are being produced or after they are used in the building.

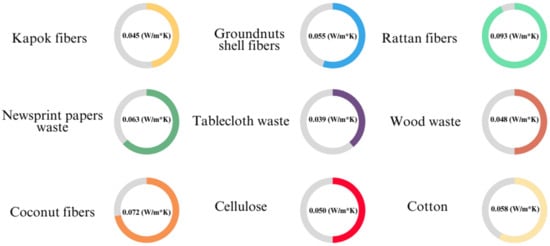

In this regard, the European Commission (EC) Directorate General for Energy estimates that the building sector is involved in 36% of carbon emissions and 40% of energy consumption in the European Union. Furthermore, these industrialism and consumption behaviors lead to resource scarcity [11]. A further concern is the continuing growth in the quantity of solid waste being generated, with the lack of a feasible management method to handle it, which has a harmful effect on the environment and humanity [12]. In light of these findings, it is crucial to adopt more sustainable, innovative and eco-friendly alternative materials and methods for development rather than energy-intensive ones [10,13] (Figure 1).

Figure 1.

Thermal conductivity of some durable materials used in the insulating materials [10,13].

In general, the principles of sustainable development are closely related to current development trends. Concerns about the scarcity of raw materials and energy resources, as well as concerns about undue air pollution, are much stronger today than in previous years. In this regard, to overcome the intensive energy consumption in the construction sector and the tremendous amount of solid waste generated, there has been a significant expansion of attention to the development of alternative sustainable thermal insulation materials from renewable resources and industrial waste [13,14].

3. Insulation Materials

Since antiquity, our forefathers have employed natural materials such as reed, straw, hemp and flax to protect their shelters against hot and/or cold temperatures. Nowadays, modern society has substituted this behavior with thermal insulation, through the use of synthetic materials that are obviously toxic and directly affect the environment and therefore human health. Thermal and acoustic insulation plays an essential role in saving and minimizing the energy and electricity expenditures of buildings by reducing the heat losses in winter time and cooling during the summer and therefore reducing the carbon emission. Consequently, a sustainable approach to building engineering involves ensuring the indoor thermal coziness of the residents throughout the entire year, since the storage and insulation properties of the envelope are crucial [15]. According to Hadded et al. [16], thoroughly insulating buildings would save roughly 65% of household energy consumption.

Almost all available thermal insulation materials can be broadly categorized into four groups, comprising inorganic, organic, combination and advanced materials [4]. In this respect, Zach et al. [17] reported that more than 60% of thermal insulation materials produced from mineral and/or inorganic fibrous materials such as glass, rock and slag wool, as well as ceramic products; roughly 30% are foam materials such as expanded polystyrene, extruded polystyrene and less widespread polyurethane; 10% are other composite materials such as wool–wood insulations, gypsum–foam, etc. These polymers are considered to be efficient insulating materials owing to their stable physical and chemical properties; however, they are further not sustainable, leading to climate change and environmental pollution, as well as the fact that these insulation materials are also a preoccupation for all involved in their production, installation or recovery in the demolition process, as they affect their health [18].

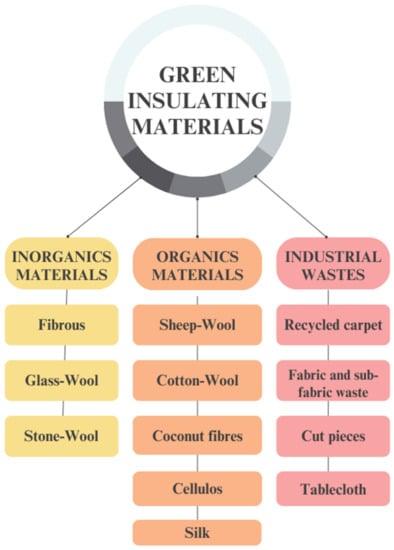

Nevertheless, as the requirements for the development of more sustainable materials, as well as environmental protection, become more stringent, the shift towards the use of easily renewable, recyclable raw resources and/or industrial waste is intensifying [3] (Figure 2). However, consideration must be made regarding the significant amounts of organic waste and residues from industrial and agricultural processes, which are still underused. In this regard, a new insulation material has been developed from plant fibers provided from agriculture such as fiber from cereal crops whose stalks are classified as waste and used mostly as fertilizer or burned as biomass or even waste fibers from the textile or car industries.

Figure 2.

Most common sustainable insulating materials [3].

Thermal insulation produced from these materials could be used to decrease energy loss throughout the year by enhancing the efficiency of both cooling and heating systems.

In this review, several innovative eco-friendly alternative materials promoted for green building will be discussed: organic materials, waste materials, composite materials, etc.

3.1. Organic Thermal Insulators

Organic insulation materials are developed from natural resources and are presently employed in buildings owing to their renewable, recyclable, biodegradable, environmentally friendly nature and cost-effectiveness, as well as the lower energy required to manufacture them compared to conventional petroleum-derived materials [7].

The use of natural resources as insulation materials has significant advantages over petroleum by-products and/or synthetic fibers, as they are friendlier to the environment. Also, carbon and nitrogen are not released into the environment as hazardous gases and ash. This is due to the ability of the fibrous materials to trap air within the fibers, preventing convective heat transfer and limiting gaseous heat conduction by reducing the occurrence of collisions between the gas molecules [3]. Also, natural materials do not threaten either human or environmental health, as well as the embodied energy and life cycle costs of natural materials being substantially cheaper [6]. Generally, natural materials have many advantages related to the environment, so the appropriate employment of natural materials for the insulation of buildings can yield several benefits such as:

- ✓

- Less energy required for the production of building components as well as the control indoor environmental temperature;

- ✓

- Less environmental consequences during the use and disposal phases;

- ✓

- CO2 environmental capture [1].

Several research studies have been conducted on natural fibrous materials to further upgrade the thermal insulation mechanical and physical properties of composite materials, which are therefore the leading prospect for buildings [3,4,6,9]. Cellulose, wood (date palm wood, wood cellulose), silk, kapok fibers, groundnuts shell fibers, rattan fibers and cotton are amongst the most appropriate natural fibrous materials to produce thermal insulation according to several investigations, owing to their excellent performances; thus, they are recommended to be employed as they represent a natural fiber and are non-hazardous [1,3,8,19]. Furthermore, these materials of plant origin are all bonded by the common chemical composition of cellulose, lignin, hemicellulose, pectin and ash (inorganic substances). The chief function of cellulose in nature is mechanical, i.e., it provides strength and stability. The comparative performance (low thermal conductivity, etc.) of using cellulose-based materials as thermal insulation showed that the thermal efficiency is higher than conventional insulation materials, which renders cellulose-based materials worthwhile for thermal insulation [14].

Ultimately, natural fibers boast many favorable properties such as low weight, low cost, low density, strong specific properties and accessibility from renewable resources. Furthermore, these natural materials are readily recycled at the end of the building life cycle and do not involve extensive energy or labor. Equally, the environmental impact of the disposed waste is lower than that of other building materials [1]. But the excessive production of natural fibers could lead to the scarcity of natural resources. This is what prompted us to develop new alternative materials.

3.2. Thermal Insulators from Waste Materials

One of the toughest environmental challenges today is to find novel alternatives for handling waste and residues from industrial or agricultural processes [20]. To overcome the challenges related to waste management, several researchers have geared towards producing insulations from agricultural and industrial waste by re-utilizing it rather than discarding or incinerating it [3,21,22,23,24] which can reduce the economic and environmental impact by using natural and local waste resources and decreasing the consumption of oil and non-renewable sources.

Fabrics from the textile industry have attracted the attention of thermal insulation producers used in the construction sector for decennia, and their use has expanded dramatically. Therefore, these materials, especially recycled textile wastes, have been selected to reinforce buildings owing to their good properties such as toxicity absorption, air purification, thermal conductivity (0.14 W/m·K), high heat capacity (844 J/Kg·K), hygrometric comfort, vibration absorption and radioactive emissions: materials with a great affinity with human beings. The fibrous layer enhances the sound absorption coefficient, as well as respect for the environment and sustainable development [16].

In this regard, several researchers have proven that cotton waste, wool, recycled carpet, fabric waste, fabric sub-waste and other textile waste residues (cut pieces, tablecloth, fibers and particles) can be used to achieve improved thermal and acoustic insulation outcomes (Figure 3) (Table 1) [16,23,25].

Figure 3.

Textile fiber (a), sheep’s wool (b) and cotton (c).

These studies revealed that the application of these wastes produced a comparable result in terms of thermal conductivity and heat capacity to thermal insulation from expanded polystyrene (EPS), extruded polystyrene (XPS), clay pellets, vermiculite or expanded perlite, and mineral wool (MW). Cotton fibers are natural fibers and contribute a large volume of waste to the textile industry, but they also have a low thermal conductivity, low density and are cost-effective [26]. The use of cotton waste mixed with ash and barite as a material has proven to be effective in improving the thermal insulation properties produced [3].

Sheep’s wool is the oldest well-known natural fiber, which has been applied over thousands of years for the production of high-quality garments [27] (Figure 3) (Table 1). Recently, with the revolution in textile production, a huge amount of wool waste is produced, which depicts a threat to both health and the environment. On average, sheep’s wool is composed of 60% animal protein fiber, 15% moisture, 10% fat, 10% sheep sweat and 5% extraneous matter [28]. It is also known to be a sustainable, reusable and eco-friendly material, which is increasingly attracting material developers. In this regard, Broda et al. (2016) [28] had the insight to use these materials as thermal and acoustic insulators in the construction and automotive industry or as geotextiles. This has revealed that thermal insulation from sheep’s wool has outstanding acoustic and thermal insulation characteristics similar to those of mineral/rock wool, and in some cases outperforms it, as well as the fact that sheep wool has less damaging health aspects.

Regarding the agricultural field, both harvesting and post-harvest activities yield large quantities of solid waste annually, predominantly from coconuts, rice straw, rye straw, cork, bagasse, hemp and sheep wool, etc. (Figure 4) (Table 1). These organic materials are usually residues from agricultural activities. Agricultural residues are one of greatest environmental challenges currently for farmers because organic waste is considered hazardous and disposal is very costly; hence, waste reuse is the best way to recycle these materials [2].

Figure 4.

Rye straw (a), sunflower straw (b), rice straw (c) and cork (d).

Commonly, each region is distinguished by a variety of crops that can provide an appropriate raw material. Agricultural waste can be a valuable substitute for conventional insulation materials: it is annually renewable and compostable, and it naturally has a low thermal conductivity [26]. In this regard, the predominant material is straw, which has been used for centuries. It is often sunflower straw or rice straw, materials known for their low thermal conductivity [17].

Hemp shives are commonly thought of as waste, derived from the splitting of fibers from the hemp stalk. The environmental sustainability of certain agro-residue-based thermal insulation panels, such as hemp and rice husk materials, is readily established [13,26]. Furthermore, the work of Vasiliauskienė et al. [29] led to the use of hemp, which is rich in cellulose, hemicellulose, lignin, aromatic compounds such as waxes and other lipids, and inorganic substances (ash) in materials as a bio-composite to produce an ecological insulation material. Other studies have shown that the use of durian peel and coconut bark as a new low-cost panel has properties comparable to those of conventional thermal insulation. Another agricultural fiber waste resource is the corncob. For decades, corncobs have been used as a wall insulator owing to their properties such as a greater thickness which can provide similar characteristics to traditional insulation. This finding was confirmed by Pinto et al. [30], who investigated the potential use of corn stover as a renewable building material for thermal insulation. They discovered that there are notable commonalities between corn stovers and extruded polystyrene in terms of microstructure and chemical composition. They also deduced that corn stovers can have suitable thermal characteristics for construction. Date palm wood is another suitable prospect for thermal insulation. Agoudjil et al. [8] deduced that due to its thermal conductivity (0.08 W/m·K), high heat capacity (826 J/Kg·K), chemical and dielectric properties, date palm wood could be a potential target for the further processing of cost-effective and secure insulation materials [13]. Bakatovich and Gaspar [6] tested the availability of producing environmentally friendly insulation boards from plant-based raw materials: moss, rye straw, and reed. They found that the board produced had excellent properties and could be used as insulation safely. Furthermore, Silvestre et al. [2] conducted a study on the use of cork chipboard, a typical natural material of the Mediterranean region, as an insulation material.

Cellulose is the most widespread macromolecule in nature. As a result of its properties, especially its toughness and stability, cellulose is of interest to producers of insulation materials. Recently, a new low thermal conductivity composite panel made from a mixture of solid waste from tissue paper processing and corn husks was revealed [7]. Cellulose insulation, especially from recycled paper or wood fiber mass, is used as a filling compound to fill diverse spaces, but cellulose insulation panels and batts are also produced [3]. According to Silvestre et al. [18], the production of expanded polystyrene (EPS) or polyurethane elastomer (PUR) can use over 40 times the energy required to produce cellulose insulation. Recently, nanocellulose has gained considerable momentum as an extensive and sustainable nanomaterial that blends ultralow density, high strength and flexibility with chemical inertness and the ability to modify surface chemistry, rendering it appealing for a broad range of applications, notably biomedical scaffolds, thermal insulation, and energy storage and generation devices. Massoudinejad et al. [26] investigated the use of cardboard as an acoustic insulation material, which consisted of two honeycomb boards stuffed with cellulose fibers. Additionally, the cellulose produced from the paper is a noise-absorbing material and can be shaped to achieve an adequate noise reduction coefficient. Lavoinea et al. [31] studied the development and exploitation of “nanocelluloses” derived from wood biomass.

Table 1.

The most common green insulating materials in the production of thermal insulation and their applications.

Table 1.

The most common green insulating materials in the production of thermal insulation and their applications.

| Insulating Materials | Potential Application | References | |

|---|---|---|---|

| Industrial waste | Cardboard-based panels with recycled cardboard from packaging; Composite of onion skin and peanut shell fibers; Rice husk; Composite of cotton waste; Wood processing by-products waste. | Floors and ceilings; Unfinished walls; Construction walls, ceilings, floors, and roofs for new construction; Enclosed existing wall or open new wall cavities; places requiring insulation that can withstand high temperatures | [2,3,6,7,9,26] |

| Recycled waste agriculture straw | Maize husk after separation of the corn; Recycled concrete with cores of textile waste; Recycled cardboard based panels; Textile fiber waste; Cellulose sound absorbers produced by using extracted cellulose from recycled paper; Maize cob; Coconut pith with groundnut shell Sheep’s waste wool; Sunflower stalks; Corn peel; Wheat straw board composed of coconut coir and durian peel; Kenaf binderless board; Bagasse after extracting sugar. | [3,8,9,13,18,26,30,32,33,34,35,36] |

4. End-of-Life Cycle

Thermal insulation systems were applied to the insulation of external walls centuries ago. For this purpose, several inorganic insulation polymers have chiefly been used. Nevertheless, although these materials have several advantages in the use phase, such as a low cost, ease of handling, low density and low thermal conductivity, their end-of-life treatment remains a serious challenge, and even the newly established European laws do not contribute to facilitate its resolution [15]. This is owing to the heterogeneity of the input materials used; as a result, these issues compromise any potential recycling process, which affects their end-of-life evaluation and their most obvious fate is unfortunately landfill or incineration [2]. Equally, health concerns remain a stumbling block to sending mineral and petroleum-derived insulation materials to the best end-of-life options [37].

As an alternative, many developers are leaning towards the use of natural fibers and/or agricultural and industrial waste as input materials for the production of thematic insulation boards. The use of these materials represents an environmentally friendly and substantially improved alternative [20]. These materials are distinguished by their recycling behavior because they are composed of a significant quantity of organic matter, which facilitates their treatment and recovery compared to inorganic materials.

However, further insight into the behavior of these materials during recycling is still lacking and does not recommend this procedure. To overcome this challenge, a high homogeneity rating of the input material is required, by introducing recycled materials into the composition of the products and the use of natural resins to enable material recycling options such as mechanical recycling and biological recycling. Insulation materials developed from industrial and agricultural waste which are 100% recycling such as wool, wood, textile fibers, flax (crop grown), cellulose, etc., contribute to green construction materials, as the layers are recyclable and biodegradable; even after their lifespan, used wool fiber layers can be used in agricultural land to fix plant nitrogen, thus reducing the use of chemical fertilizers to some extent [35]. Additionally, these materials could be used after demolition, stripped of glue or stone waste, and fully recycled by granulation and placed on the market in granular form [37]. Agriculture waste could also be used as a feedstock to produce bioenergy. Recently, the production of hydrogen using renewable resources through the dark-fermentation process has gained the attention of researchers owing to its sustainability. The process consists of transforming organic waste, including biodegradable plastics, agricultural waste and sewage sludge, into green H2 and CO through a thermolytic process, and then a water–gas transfer reaction converts CO and water into hydrogen and CO2 [38]. This technology could enable the recovery of thermal insulation from agricultural waste after its life cycle, transforming it into a high value-added product which is H2, thus also overcoming the challenge of green energy production. In the case of thermal insulation from textile fibers, Biyada et al. [39] conducted the valorization of these materials on biofertilizer using composting treatment; they concluded that the cellulosic character of textile waste enables it to be recycled into a valuable product that can then be used as an organic soil amendment. In a further study, Biyada et al. [40] described the use of selected strains to treat textile waste. Czeka et al. and Ribul et al. [41,42] proved that these materials could also be used as a feedstock to produce energy by anaerobic digestion. Väisänen et al. [20] investigated the production of biochar and biofuels from biomass (nearly all types of biomasses can be transformed into biochar) though pyrolysis as a prospective technology; both technologies are inexpensive and eco-friendly.

Ultimately, it can be concluded that the recycling of thermal insulation at the end of its life enables industries to save the consumption of non-renewable primary energy in production and to reduce the amount of solid waste generated annually, as well as the production and consumption of natural fibers used throughout the production of thermal insulation.

5. Conclusions

This review article has pinpointed a variety of issues in the building sector, as well as in waste management, that require further research and attention. It outlines an in-depth study on the different types of thermal insulation materials’ characteristics, as well as their end-of-life cycle. Eco-design, energy efficiency and safety are pressing concepts that reflect the requirement to replace conventional insulation materials with new materials that are eco-friendly and lead to a reduction in material and energy consumption on one hand. On the other hand, the limited availability of landfill space, greenhouse gas emissions and waste-stream runoff have prompted the search for alternative solutions to conventional waste management. As a result, new composites using organic waste and residues from agricultural and industrial processes have been established.

In this regard, considerable attention has been devoted to research into the development of thermal insulation and building materials using renewable resources and waste materials. Potentially, plant-based by-product and/or industrial waste insulation is an affordable and sustainable alternative to conventional materials, with properties comparable to those of traditional materials. Their installation enables significant energy efficiency savings and, consequently, reduces CO2 emissions into the environment, regulates the indoor climate and ensures the comfort of the occupants.

The use of natural materials, agricultural and/or industrial waste as insulating materials has several advantages, amongst which:

- ○

- They are readily recycled at the end of the building’s life cycle, which does not require much energy or labor, and the recycled material can be used in other applications, such as packaging, mixing it with cement to allow it to become lighter, etc. The most important consideration is that the environmental impact of discarded waste is less than that of other building materials.

- ○

- These materials are biodegradable and can be used to produce bioenergy and as biofertilizer for plants to improve their growth and/or in agriculture; they are a suitable material to improve the performance of cultivated soils, especially by improving air renewal and moisture control.

Ultimately, this review depicts the initial steps for further research. In this regard, as a perspective, we propose a global study on the different combinations that can be formed from textile waste and agricultural waste while studying the different thermal and chemical properties in order to produce high-quality thermal insulation materials.

Author Contributions

Conceptualization, S.B., M.M. and J.U.; methodology, S.B., J.U. and M.M., data curation, S.B. and J.U.; validation, J.U. and M.M.; writing—original draft preparation, S.B.; writing— review and editing, S.B., J.U. and M.M.; supervision, M.M. and J.U. All authors have read and agreed to the published version of the manuscript.

Funding

This article is based upon work from COST Action FULLRECO4US, CA20133, supported by COST (European Cooperation in Science and Technology).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the author Saloua Biyada, upon reasonable request.

Conflicts of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationship that could be construed as a potential conflict of interest.

Nomenclature

| Nomenclature | Property |

| EC | European Commission |

| EPS | Expanded polystyrene |

| EU | European Union |

| MW | Mineral wool |

| PUR | Polyurethane elastomer |

| W/m·K | Watt per meter-Kelvin (thermal conductivity unit) |

| XPS | Extruded polystyrene |

References

- Barreca, F.; Martinez, A.; Flores, J.A.; Pastor, J.J. Innovative use of giant reed and cork residues for panels of buildings in Mediterranean area. Resour. Conserv. Recycl. 2019, 140, 259–266. [Google Scholar] [CrossRef]

- Silvestre, J.D.; Pargana, N.; Brito, J.; De Pinheiro, M.D.; Durão, V. Insulation Cork Boards—Environmental Life Cycle Assessment of an Organic Construction Material. Materials 2016, 9, 394. [Google Scholar] [CrossRef] [PubMed]

- Abu-jdayil, B.; Mourad, A.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2016, 214, 709–735. [Google Scholar] [CrossRef]

- Duong, L.; Anh, H. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Palumbo, M.; Avellaneda, J.; Lacasta, A.M. Availability of crop by-products in Spain: New raw materials for natural thermal insulation. Resour. Conserv. Recycl. 2015, 99, 1–6. [Google Scholar] [CrossRef]

- Bakatovich, A.; Gaspar, F. Composite material for thermal insulation based on moss raw material. Constr. Build. Mater. 2019, 228, 116699. [Google Scholar] [CrossRef]

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Agoudjil, B.; Benchabane, A.; Boudenne, A.; Ibos, L.; Fois, M. Renewable materials to reduce building heat loss: Characterization of date palm wood. Energy Build. 2011, 43, 491–497. [Google Scholar] [CrossRef]

- Dikmen, N.; Ozkan, S.T.E. Unconventional Insulation Materials; IntechOpen: London, UK, 2016. [Google Scholar]

- Briga-sá, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Hill, C.; Norton, A.; Dibdiakova, J. A comparison of the environmental impacts of different categories of insulation materials. Energy Build. 2018, 162, 12–20. [Google Scholar] [CrossRef]

- Biyada, S.; Merzouki, M.; Imtara, H.; Alajmi, M.F.; Elkarrach, K.; Mechchate, H.; Conte, R.; Benlemlih, M. Advanced Characterization of Organic Matter Decaying during Composting of Industrial Waste Using Spectral Methods. Processes 2021, 9, 1364. [Google Scholar] [CrossRef]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable thermal insulation biocomposites from rice husk, wheat husk, wood fibers and textile waste fibers: Elaboration and performances evaluation. Ind. Crops Prod. 2019, 135, 238–245. [Google Scholar] [CrossRef]

- Wazna, M.; El Fatihi, M.; El Bouari, A.; El Cherkaoui, O. Thermo physical characterization of sustainable insulation materials made from textile waste. J. Build. Eng. 2017, 12, 196–201. [Google Scholar] [CrossRef]

- Llantoy, N.; Chàfer, M.; Cabeza, L.F. A comparative life cycle assessment (LCA) of different insulation materials for buildings in the continental Mediterranean climate. Energy Build. 2020, 225, 110323. [Google Scholar] [CrossRef]

- Hadded, A.; Benltoufa, S.; Jemni, A. Thermo physical characterization of recycled textile materials used for building insulating. J. Build. Eng. 2015, 5, 34–40. [Google Scholar] [CrossRef]

- Zach, J.; Hroudová, J.; Korjenic, A. Environmentally efficient thermal and acoustic insulation based on natural and waste fibers †. J. Chem. Technol. Biotechnol. 2016, 91, 2156–2161. [Google Scholar] [CrossRef]

- Silvestre, J.D.; De Brito, J.; Pinheiro, M.D. Life-Cycle Assessment of Thermal Insulation Materials for External Walls of Buildings; InspectApedia: New York, NY, USA, 2011. [Google Scholar]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. J. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Väisänen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef]

- Chopra, S.S.; Dong, L.; Kaur, G.; Len, C.; Sze, C.; Lin, K. Sustainable process design for circular fashion: Advances in sustainable chemistry for textile waste valorisation. Curr. Opin. Green Sustain. Chem. 2023, 39, 100747. [Google Scholar] [CrossRef]

- Khairul, M.; Nasrin, U.; Islam, M. Textile-apparel manufacturing and material waste management in the circular economy: A conceptual model to achieve sustainable development goal (SDG) 12 for Bangladesh. Clean. Environ. Syst. 2022, 4, 100070. [Google Scholar] [CrossRef]

- Piribauer, B.; Bartl, A. Textile recycling processes, state of the art and current developments: A mini review. Waste Manag. Res. 2019, 37, 112–119. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.N.D.; Zhang, Z. The use of hemp fibres as reinforcements in composites. Biofiber Reinf. Compos. Mater. 2015, 86–103. [Google Scholar] [CrossRef]

- Schumacher, K.A.; Forster, A.L. Textiles in a circular economy: An assessment of the current landscape, challenges, and opportunities in the United States. Front. Sustain. 2022, 3, 146. [Google Scholar] [CrossRef]

- Massoudinejad, M.; Amanidaz, N.; Santos, R.M.; Bakhshoodeh, R. Use of municipal, agricultural, industrial, construction and demolition waste in thermal and sound building insulation materials: A review article. J. Environ. Health Sci. Eng. 2019, 17, 1227–1242. [Google Scholar] [CrossRef] [PubMed]

- Broda, J.; Kobiela-mendrek, K.; Binia, D.; Rom, M.; Grzybowska-pietras, J.; Laszczak, R. Biodegradation of sheep wool geotextiles. Int. Biodeterior. Biodegrad. 2016, 115, 31–38. [Google Scholar] [CrossRef]

- Petek, B.; Marinšek, R. Management of waste sheep wool as valuable organic substrate in European Union countries. J. Mater. Cycles Waste Manag. 2020, 23, 44–54. [Google Scholar] [CrossRef]

- Vasiliauskiene, D.; Balciunas, G.; Boris, R.; Kairyte, A.; Urbonavicius, J. The Effect of Different Plant Oil Impregnation and Hardening Temperatures on Physical-Mechanical Properties of Modified Biocomposite Boards Made of Hemp Shives and Corn Starch. Materials 2020, 13, 5275. [Google Scholar] [CrossRef]

- Pinto, J.; Paiva, A.; Varum, H.; Costa, A.; Cruz, D.; Pereira, S.; Fernandes, L.; Tavares, P.; Agarwal, J. Corn’s cob as a potential ecological thermal insulation material. Energy Build. 2011, 43, 1985–1990. [Google Scholar] [CrossRef]

- Lavoinea, N.; Bergströma, L. Nanocellulose-based foams and aerogels: Processing, properties, and applications. J. Mater. Chem. A 2017, 5, 16105–16117. [Google Scholar] [CrossRef]

- Binici, H.; Eken, M.; Kara, M. An environment-friendly thermal insulation material from sunflower stalk, textile waste and stubble fibers. Constr. Build. Mater. 2013, 51, 20–23. [Google Scholar] [CrossRef]

- Fakhfakh, N.; Ktari, N.; Siala, R.; Nasri, M. Wool-waste valorization: Production of protein hydrolysate with high antioxidative potential by fermentation with a new keratinolytic bacterium, Bacillus pumilus A1. J. Appl. Microbiol. 2013, 115, 424–433. [Google Scholar] [CrossRef] [PubMed]

- Johnson, B.S.; Echeverria, D.; Venditti, R.; Jameel, H.; Yao, Y.; Carolina, N. Supply Chain of Waste Cotton Recycling and Reuse: A Review. AATCC J. Res. 2020, 7, 19–31. [Google Scholar] [CrossRef]

- Patnaik, A.; Mvubu, M.; Muniyasamy, S.; Botha, A.; Anandjiwala, R.D. Thermal and sound insulation materials from waste wool and recycled polyester fibers and their biodegradation studies. Energy Build. 2015, 92, 161–169. [Google Scholar] [CrossRef]

- Norhisham, D.A.; Saad, N.M.; Ahmad Usuldin, S.R.; Vayabari, D.A.G.; Ilham, Z.; Ibrahim, M.F.; Wan-Mohtar, W.A.A.Q.I. Bioactivities of Kenaf Biomass Extracts: A Review. Processes 2023, 11, 1178. [Google Scholar] [CrossRef]

- Pargana, N.; Duarte, M.; Dinis, J.; De Brito, J. Comparative environmental life cycle assessment of thermal insulation materials of buildings. Energy Build. 2014, 82, 466–481. [Google Scholar] [CrossRef]

- Santhosh, J.; Sarkar, O.; Mohan, S.V. Green Hydrogen-Compressed natural gas (bio-H-CNG) production from food waste: Organic load influence on hydrogen and methane fusion. Bioresour. Technol. 2021, 340, 125643. [Google Scholar] [CrossRef] [PubMed]

- Biyada, S.; Merzouki, M.; Demcenko, T.; Vasiliauskiene, D.; Marciulaitiene, E.; Vasarevicius, S.; Urbonavicius, J. The Effect of Feedstock Concentration on the Microbial Community Dynamics during Textile Waste Composting. Front. Ecol. Evol. 2022, 10, 813488. [Google Scholar] [CrossRef]

- Biyada, S.; Imtara, H.; Elkarrach, K.; Laidi, O.; Saleh, A. Bio-Augmentation as an Emerging Strategy to Improve the Textile Compost Quality Using Identified Autochthonous Strains. Appl. Sci. 2022, 12, 3160. [Google Scholar] [CrossRef]

- Czeka, W.; Nowak, M.; Piechota, G. Sustainable management and recycling of anaerobic digestate solid fraction by composting: A review. Bioresour. Technol. 2023, 375, 128813. [Google Scholar] [CrossRef]

- Ribul, M.; Lanot, A.; Tommencioni, C.; Purnell, P.; Mcqueen-mason, S.J.; Baurley, S. Mechanical, chemical, biological: Moving towards closed-loop bio-based recycling in a circular economy of sustainable textiles. J. Clean. Prod. 2021, 326, 129325. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).