Energy-Saving Testing System for a Coal Mine Emulsion Pump Using the Pressure Differential Flow Characteristics of Digital Relief Valves

Abstract

:1. Introduction

2. Analysis of Key Issues and Proposal of New Solutions

2.1. Analysis of Key Issues

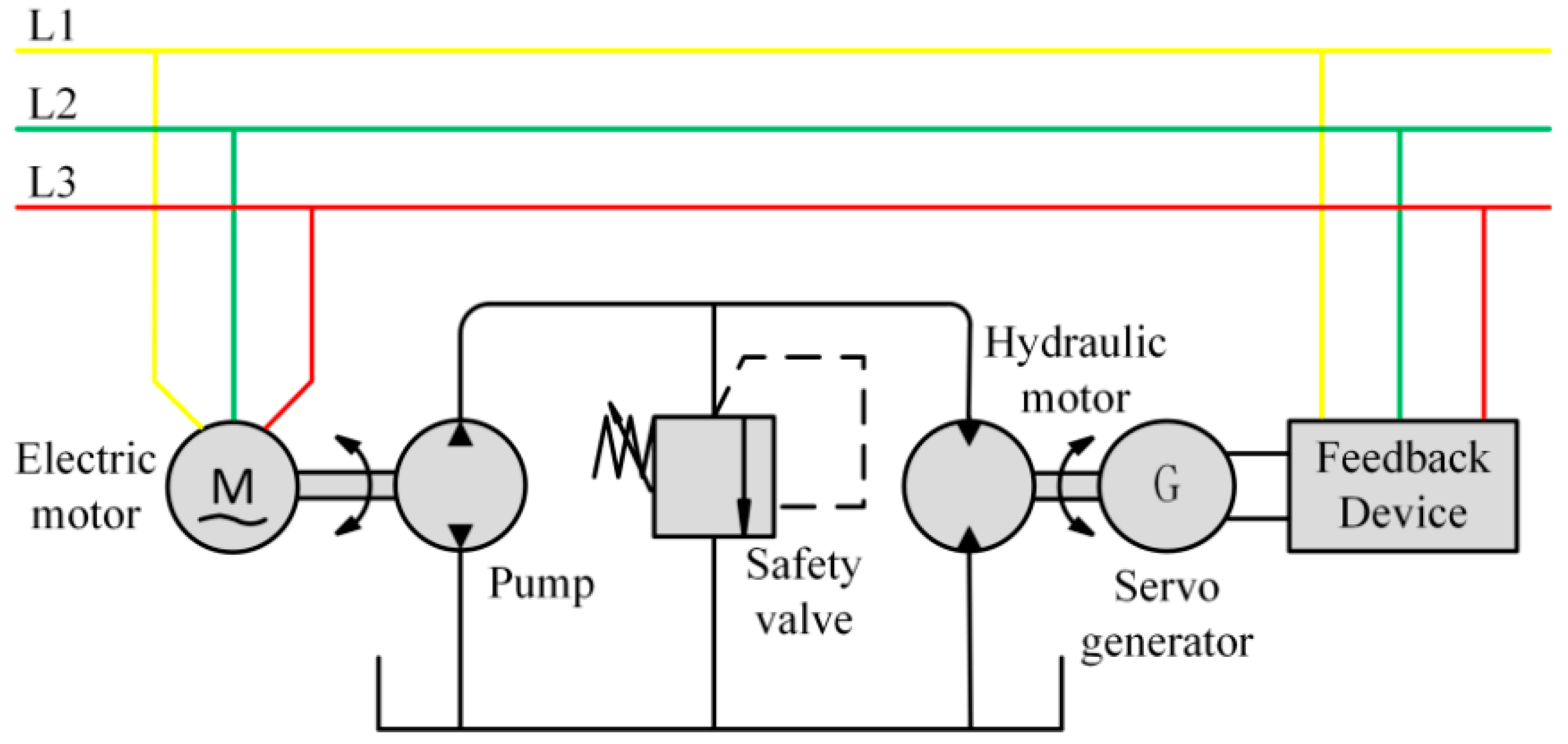

2.2. Proposal of New Solutions

3. Control Algorithm Development

4. Simulation and Experiment

4.1. Simulation Study

4.1.1. Simulation Model

4.1.2. Simulation Result

4.2. Experimental Study

4.2.1. Test Device

4.2.2. Experimental Results and Analysis

5. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Randers, J.; Goluke, U. An earth system model shows self-sustained thawing of permafrost even if all man-made GHG emissions stop in 2020. Sci. Rep. 2020, 10, 18456. [Google Scholar] [CrossRef]

- Kirikkaleli, D.; Sowah, J.K., Jr. Time-frequency dependency of temperature and sea level: A global perspective. Environ. Sci. Pollut. Res. 2021, 28, 58787–58798. [Google Scholar] [CrossRef] [PubMed]

- McIlwaine, N.; Foley, A.M.; Morrow, D.J.; Al Kez, D.; Zhang, C.; Lu, X.; Best, R.J. A state-of-the-art techno-economic review of distributed and embedded energy storage for energy systems. Energy 2021, 229, 120461. [Google Scholar] [CrossRef]

- Elsaid, A.M. A novel design, implementation and performance evaluation of the first electronic expansion ejector for energy saving of a mini split air conditioner controlled by inverter. Energ. Convers. Manag. 2022, 260, 115603. [Google Scholar] [CrossRef]

- Du, T.; Nie, W.; Chen, D.; Xiu, Z.; Yang, B.; Liu, Q.; Guo, L. CFD modeling of coal dust migration in an 8.8-m-high fully mechanized mining face. Energy 2020, 212, 118616. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z. Systematic principles of surrounding rock control in longwall mining within thick coal seams. Int. J. Min. Sci. Technol. 2019, 29, 65–71. [Google Scholar] [CrossRef]

- Tian, J.; Liu, W.; Wang, H. Testing Method for Intelligent Loading of Mining Emulsion Pump Based on Digital Relief Valve and BP Neural Network Control Algorithm. Machines 2022, 10, 896. [Google Scholar] [CrossRef]

- Li, R.; Wang, D.; Wei, W.; Li, S. Analysis of the Movement Characteristics of the Pump Valve of the Mine Emulsion Pump Based on the Internet of Things and Cellular Automata. Mob. Inf. Syst. 2021, 2021, 9032769. [Google Scholar] [CrossRef]

- Ho, T.H.; Ahn, K.K. Design and control of a closed-loop hydraulic energy-regenerative system. Autom. Constr. 2012, 22, 444–458. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Q. Efficiency analysis and evaluation of energy-saving pressure-compensated circuit for hybrid hydraulic excavator. Autom. Constr. 2014, 47, 62–68. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Xu, S.; Wang, S.; Wang, Y. Performance prediction of hydraulic energy recovery (HER) device with novel mechanics for small-scale SWRO desalination system. Desalination 2009, 249, 667–671. [Google Scholar] [CrossRef]

- Lin, T.; Huang, W.; Ren, H.; Fu, S.; Liu, Q. New compound energy regeneration system and control strategy for hybrid hydraulic excavators. Autom. Constr. 2016, 68, 11–20. [Google Scholar] [CrossRef]

- Banaszek, A.; Petrovic, R.; Andjelkovic, M.; Radosavljevic, M. Efficiency of a Twin-Two-Pump Hydraulic Power Pack with Pumps Equipped in Constant Pressure Regulators with Different Linear Performance Characteristics. Energies 2022, 15, 8100. [Google Scholar] [CrossRef]

- Banaszek, A. Identification of optimal efficiency exploitation conditions of axial-piston hydraulic motor A2FM type using Artificial Neural Network algorithms. Procedia Comput. Sci. 2021, 192, 1532–1540. [Google Scholar] [CrossRef]

- Gong, J.; Zhang, D.; Guo, Y.; Liu, C.; Zhao, Y.; Hu, P.; Quan, W. Power control strategy and performance evaluation of a novel electro-hydraulic energy-saving system. Appl. Energ. 2019, 233, 724–734. [Google Scholar] [CrossRef]

- Xiao, W.; Xu, J.; Lv, X. Establishing a georeferenced spatio-temporal database for Chinese coal mining accidents between 2000 and 2015. Geomat. Nat. Hazards Risk 2019, 10, 242–270. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.; Wu, Z.; Chen, Y. Overview of Solid Backfilling Technology Based on Coal-Waste Underground Separation in China. Sustainability 2019, 11, 2118. [Google Scholar] [CrossRef]

- Muduli, L.; Mishra, D.P.; Jana, P.K. Optimized Fuzzy Logic-Based Fire Monitoring in Underground Coal Mines: Binary Particle Swarm Optimization Approach. IEEE Syst. J. 2020, 14, 3039–3046. [Google Scholar] [CrossRef]

- Liu, Q.; Peng, Y.; Li, Z.; Zhao, P.; Qiu, Z. Hazard identification methodology for underground coal mine risk management—Root-State Hazard Identification. Resour. Policy 2021, 72, 102052. [Google Scholar] [CrossRef]

- Wang, W.; Liang, Y. Prevention and Control Technology for Harmful Toxic Gas Intrusion in High-Fire-Hazard-Risk Areas of Close-Distance Coal Seams. J. Chem. 2020, 2020, 9040825. [Google Scholar] [CrossRef]

- Zhou, R.; Meng, L.; Yuan, X.; Qiao, Z. Research and Experimental Analysis of Hydraulic Cylinder Position Control Mechanism Based on Pressure Detection. Machines 2022, 10, 1. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, Z.; Chen, G.; Cao, G. A novel energy regeneration system for emulsion pump tests. J. Mech. Sci. Technol. 2013, 27, 1155–1163. [Google Scholar]

- Xu, Q.; Huang, Y. Development and Application of Non-Circular Gear Emulsion Motor. Adv. Mater. Res. 2011, 317, 134–137. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, S.; Guo, G.; Dong, W. Modeling and Simulation of Emulsion Pump Station Pressure Control System Based on Electro-Hydraulic Proportional Relief Valve. J. Appl. Mech. Mater. 2012, 190, 860–864. [Google Scholar] [CrossRef]

- Jia, T.; Wu, Z.; Wang, J.; Feng, R.; Qin, Y. Design and Performance Analysis of Digital Pressure Relief Valve of Water-Based Hydraulic. J. Appl. Mech. Mater. 2013, 387, 369–373. [Google Scholar] [CrossRef]

- Banaszek, A.; Petrovic, R. Problem of Non Proportional Flow of Hydraulic Pumps Working with Constant Pressure Regulators in Big Power Multipump Power Pack Unit in Open System. Teh. Vjesn. 2019, 26, 294–301. [Google Scholar]

- Wang, H.; Wang, X.; Huang, J.; Quan, L. Flow Control for a Two-Stage Proportional Valve with Hydraulic Position Feedback. Chin. J. Mech. Eng. 2020, 33, 93. [Google Scholar] [CrossRef]

- Xiong, X.; Huang, J. Performance of a flow control valve with pilot switching valve. Proc. Inst. Mech. Eng. Part I 2018, 232, 178–194. [Google Scholar] [CrossRef]

- Zeng, Q.; Tian, M.; Wan, L.; Dai, H.; Yang, Y.; Sun, Z.; Lu, Y.; Liu, F. Characteristic Analysis of Digital Large Flow Emulsion Relief Valve. Math. Probl. Eng. 2020, 2020, 5820812. [Google Scholar] [CrossRef]

- Wan, L.; Dai, H.; Zeng, Q.; Lu, Z.; Sun, Z.; Tian, M.; Lu, Y. Characteristic Analysis of Digital Emulsion Relief Valve Based on the Hydraulic Loading System. Shock Vib. 2020, 2020, 8866919. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, J. Investigation of Static and Dynamic Seal Performances of a Rubber O-Ring. J. Tribol. 2018, 140, 042202. [Google Scholar] [CrossRef]

| Parameter Name | Value |

|---|---|

| Pilot valve seat diameter (mm) | 5.5 |

| Pilot valve spool diameter (mm) | 20 |

| Pilot valve spring stiffness (N/mm) | 65 |

| Orifice diameter (mm) | 0.8 |

| Orifice length (mm) | 5 |

| Diameter of the lower end of the main valve core (mm) | 14 |

| Diameter of the upper end of the main valve core (mm) | 16 |

| Half cone angle of main valve core (°) | 30 |

| Emulsion motor Volumetric efficiency | 0.7 |

| Emulsion motor Mechanical efficiency | 0.9 |

| Emulsion pump flow rate (L/min) | 125 |

| Load Moment of inertia (kg·m2) | 0.01 |

| Proportional gain of PID controller | 10 |

| Derivative gain of PID controller | 0.5 |

| Outlet Pressure of Overflow Valve (MPa) | Flow (L/min) | Pressure Difference between Inlet and Outlet of Overflow Valve (MPa) | |||

|---|---|---|---|---|---|

| 0.6 | 0.8 | 1 | 1.2 | ||

| Shaft Extension of Linear Stepping Motor (mm) | |||||

| 4 | 50 | 1.14 | 1.20 | 1.24 | 1.29 |

| 60 | 1.13 | 1.18 | 1.22 | 1.28 | |

| 70 | 1.11 | 1.16 | 1.21 | 1.26 | |

| 80 | 1.09 | 1.14 | 1.19 | 1.24 | |

| 8 | 50 | 2.36 | 2.41 | 2.45 | 2.53 |

| 60 | 2.34 | 2.39 | 2.43 | 2.52 | |

| 70 | 2.32 | 2.37 | 2.42 | 2.50 | |

| 80 | 2.30 | 2.35 | 2.40 | 2.48 | |

| 12 | 50 | 3.56 | 3.61 | 3.68 | 3.74 |

| 60 | 3.54 | 3.59 | 3.65 | 3.72 | |

| 70 | 3.53 | 3.58 | 3.63 | 3.70 | |

| 80 | 3.51 | 3.56 | 3.61 | 3.69 | |

| 16 | 50 | 4.76 | 4.81 | 4.86 | 4.91 |

| 60 | 4.75 | 4.79 | 4.85 | 4.90 | |

| 70 | 4.73 | 4.78 | 4.84 | 4.88 | |

| 80 | 4.71 | 4.76 | 4.82 | 4.86 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, J.; Liu, W.; Wang, H.; Yuan, X.; Zhou, R.; Li, J. Energy-Saving Testing System for a Coal Mine Emulsion Pump Using the Pressure Differential Flow Characteristics of Digital Relief Valves. Processes 2023, 11, 2632. https://doi.org/10.3390/pr11092632

Tian J, Liu W, Wang H, Yuan X, Zhou R, Li J. Energy-Saving Testing System for a Coal Mine Emulsion Pump Using the Pressure Differential Flow Characteristics of Digital Relief Valves. Processes. 2023; 11(9):2632. https://doi.org/10.3390/pr11092632

Chicago/Turabian StyleTian, Jie, Wenchao Liu, Hongyao Wang, Xiaoming Yuan, Rulin Zhou, and Junshi Li. 2023. "Energy-Saving Testing System for a Coal Mine Emulsion Pump Using the Pressure Differential Flow Characteristics of Digital Relief Valves" Processes 11, no. 9: 2632. https://doi.org/10.3390/pr11092632

APA StyleTian, J., Liu, W., Wang, H., Yuan, X., Zhou, R., & Li, J. (2023). Energy-Saving Testing System for a Coal Mine Emulsion Pump Using the Pressure Differential Flow Characteristics of Digital Relief Valves. Processes, 11(9), 2632. https://doi.org/10.3390/pr11092632