Effect of Diethyl Ether on the Performance and Emission Characteristics of a Diesel Engine Fueled with a Light Fraction of Waste Cooking Oil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fuel Preparation

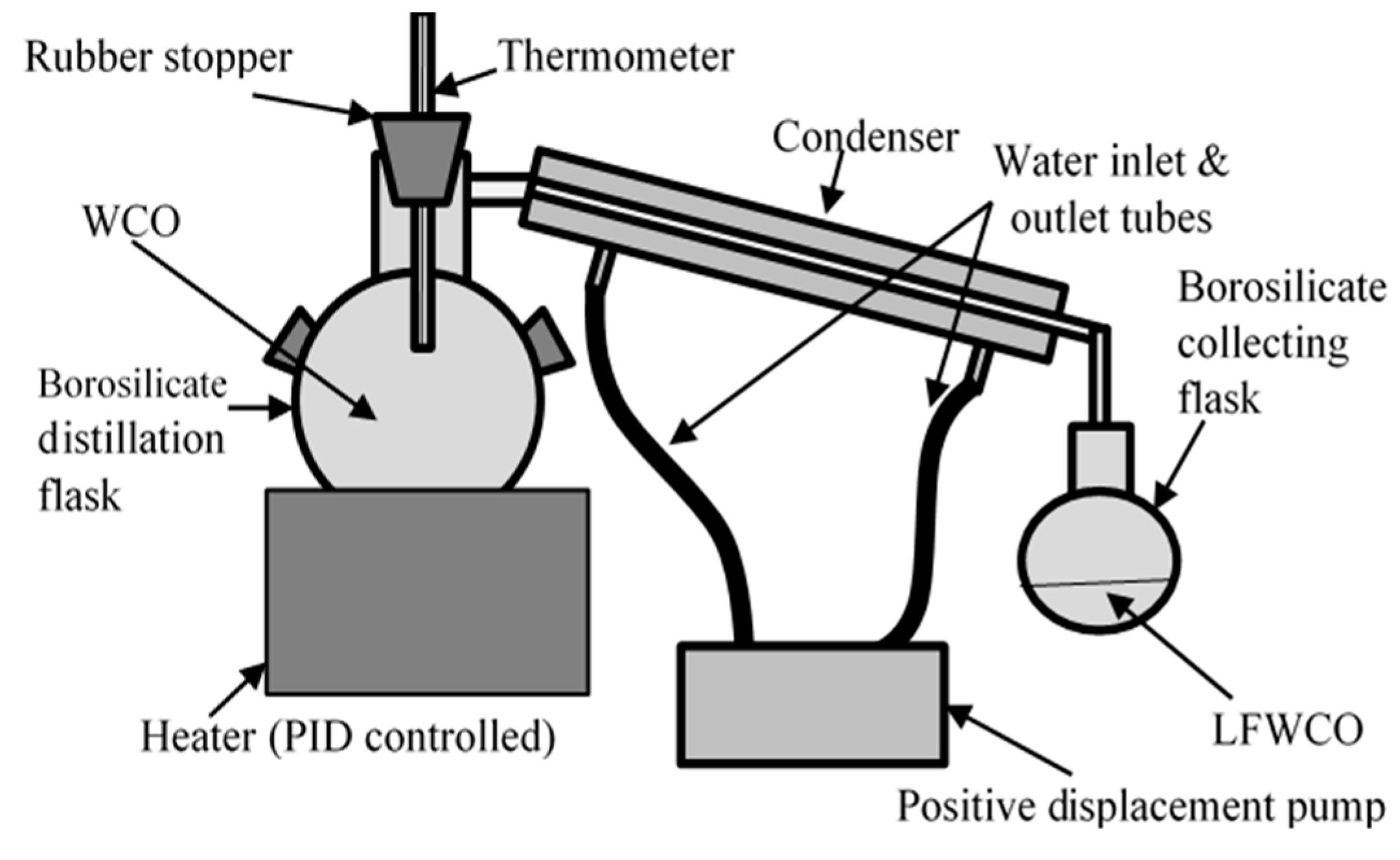

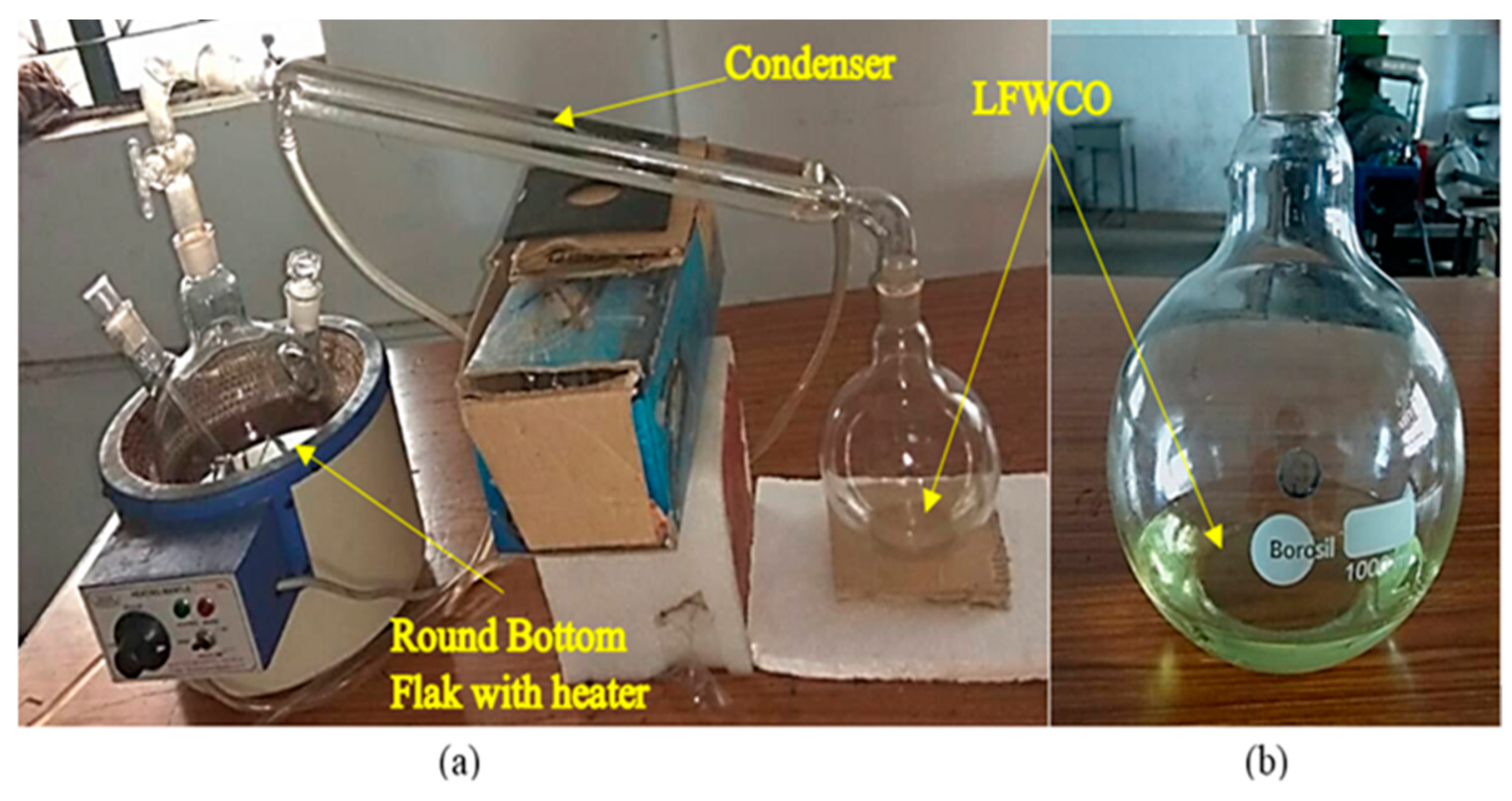

2.2. Production of LFWCO

2.3. Test Fuels

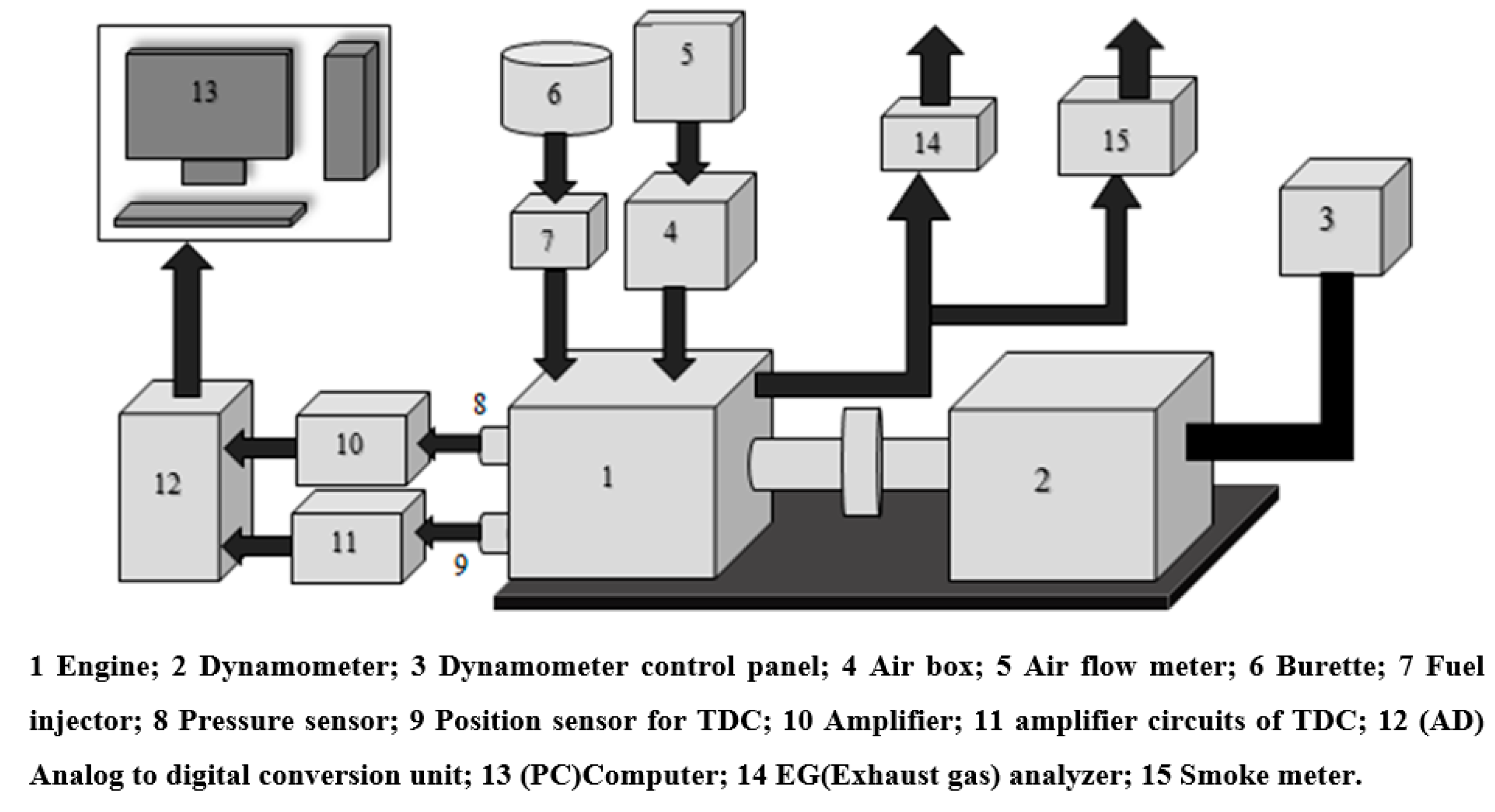

2.4. Experimental Setup

2.5. Design of Experiment

2.6. Error Analysis

3. Results and Discussion

3.1. Performance Factors

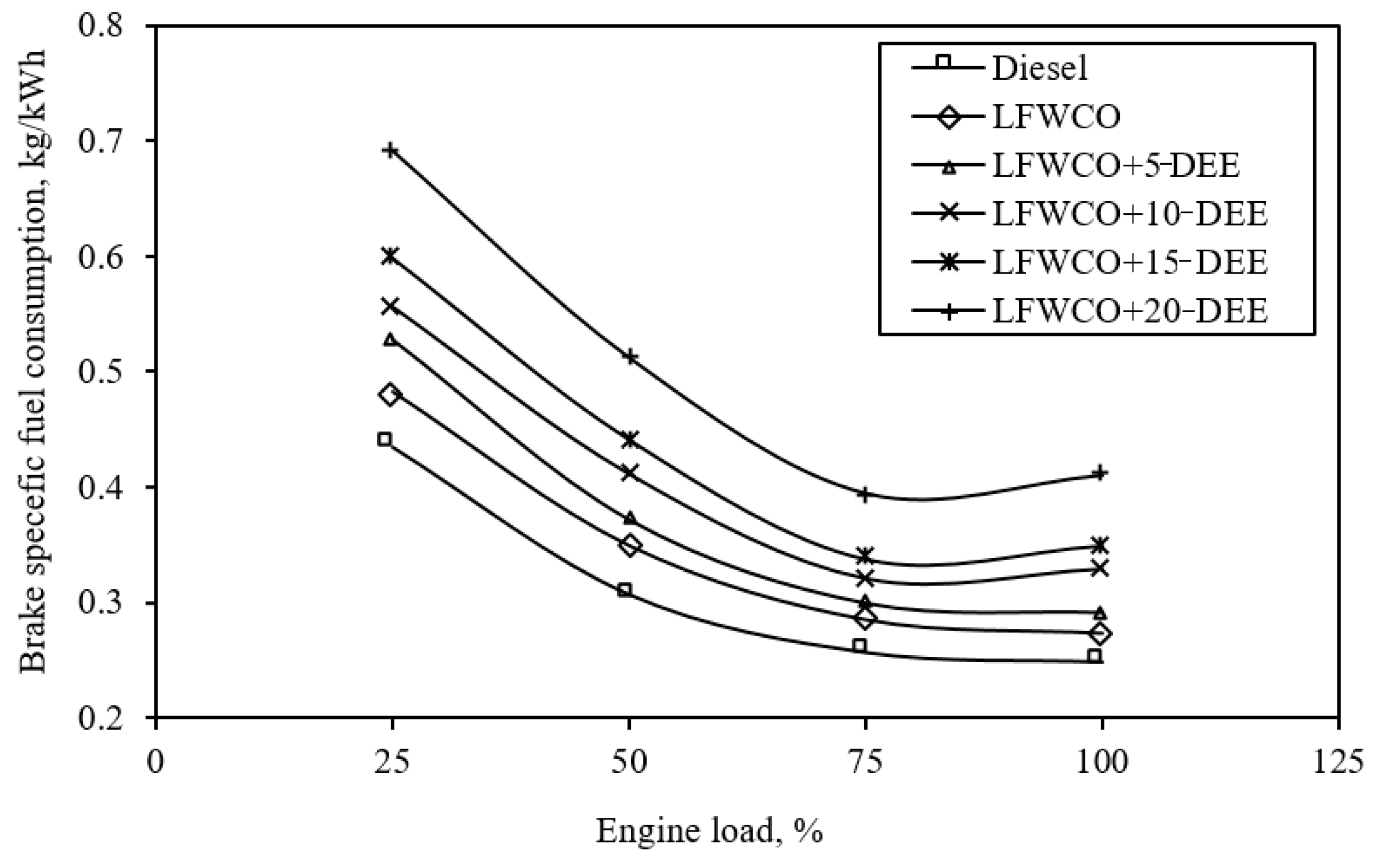

3.1.1. Brake-Specific Fuel Consumption (BSFC)

3.1.2. Brake Thermal Efficiency (BTE)

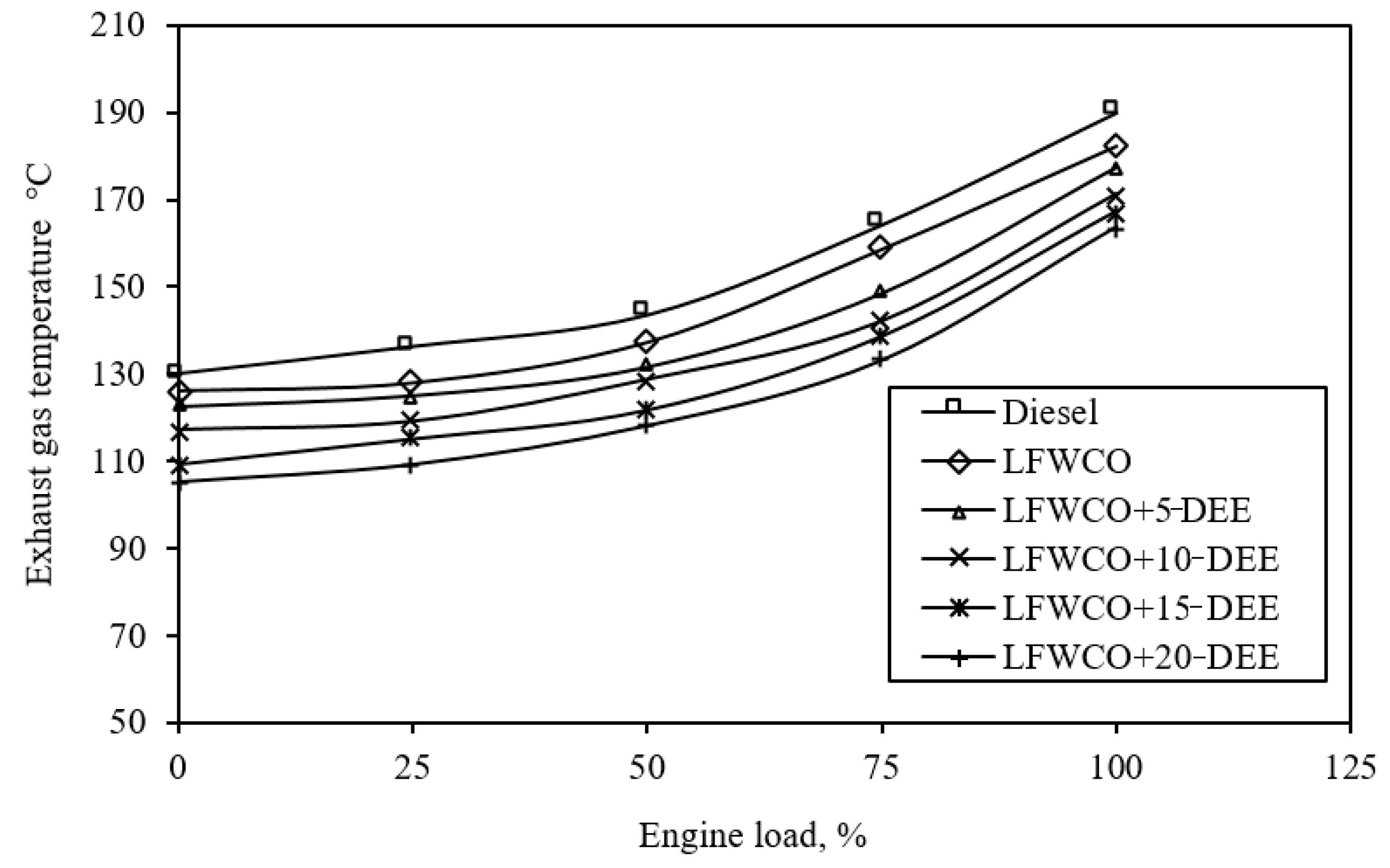

3.1.3. Exhaust Gas Temperature (EGT)

3.2. Emission Factors

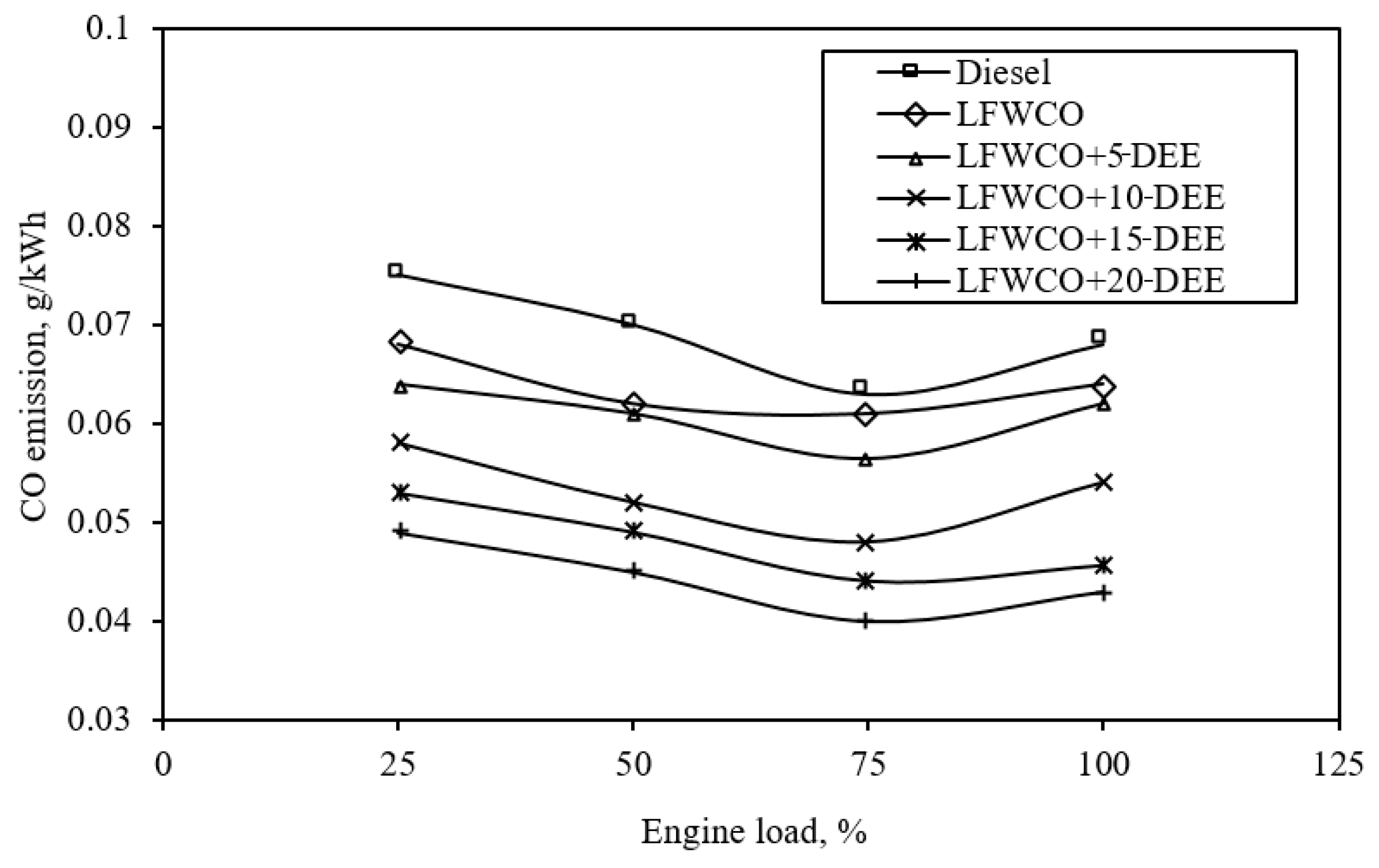

3.2.1. CO

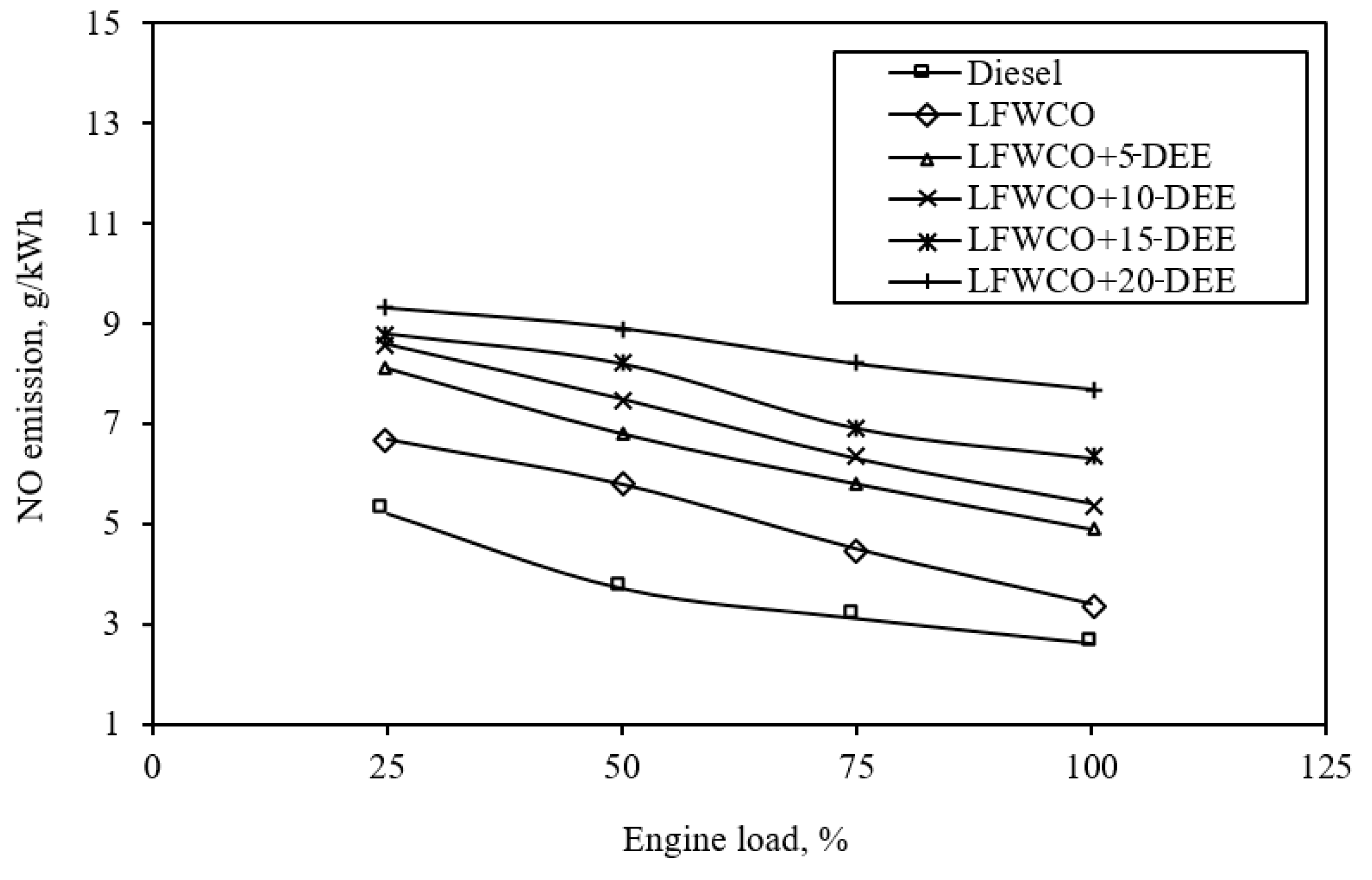

3.2.2. NO

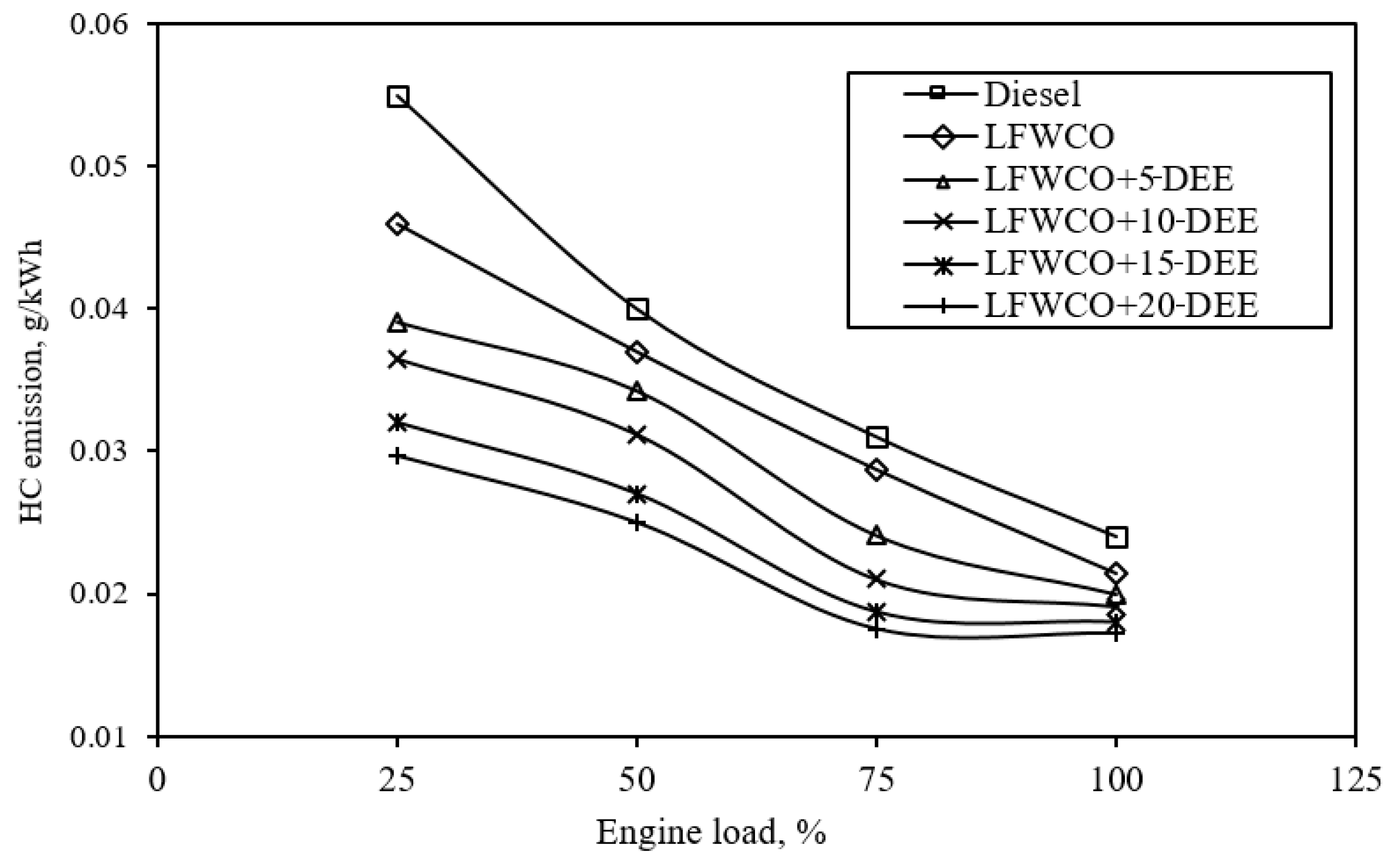

3.2.3. HC

3.2.4. Smoke Opacity

4. Conclusions

- LFWCO can be used as a potential biomass-based renewable fuel in a CI DI diesel engine for heat and power production.

- The mixing of DEE with LFWCO increased the CN of the fuel and decreased its viscosity near diesel.

- LFWCO+15-DEE was found to give optimum results regarding performance and emission characteristics. When compared to neat diesel and other LFWCO DEE blends, the LFWCO+15-DEE blend performed better in terms of higher BTE and lower BSFC and EGT. It also had lower emissions of HC, CO, and Smoke Opacity, demonstrating its potential as an alternative fuel option. Overall, LFWCO+15-DEE has the potential to improve engine performance while reducing environmental effects.

- The BSFC for LFWCO+15-DEE was found to be higher by about 28.9%, and the BTE was identified to be lower by about 7.56% on par with diesel at 100% load correspondingly.

- For LFWCO+15-DEE the exhaust temperature of gas was identified to be less by about 11.9% on par with plain diesel at 100% load.

- The HC, CO, and smoke opacity for LFWCO+15-DEE seemed to be inferior by 32.9%, 25%, and 29.4% on par with diesel at 100% load.

- The NO production for LFWCO+15-DEE seemed to be larger by about 36% in contrast with neat diesel at 100% load.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| WCO | Waste cooking oil |

| LFWCO | Light Fraction waste cooking oil |

| DEE | Diethyl ether |

| BTE | Brake thermal efficiency |

| BSFC | Brake-specific fuel consumption |

| EGT | Exhaust gas temperature |

| HC | Hydrocarbon |

| CO | Carbon monoxide |

| NO | Nitrous oxide |

| CR | Compression ratio |

| CI DI | Compression-Ignition Direct injection |

| IT | Injection time |

| CA | Crank Angle |

| CN | Cetane number |

| CV | Calorific Value |

| HV | Heating Value |

References

- Patel, K.; Dhiman, V. Effect of hybrid nanoparticles MgO and Al2O3 added water-in-diesel emulsion fueled diesel engine using hybrid deep neural network-based spotted hyena optimization. Heat Transf. 2022, 51, 5748–5788. [Google Scholar] [CrossRef]

- Olkiewicz, M.; Torres, C.M.; Jiménez, L.; Font, J.; Bengoa, C. Scale-up and economic analysis of biodiesel production from municipal primary sewage sludge. Bioresour. Technol. 2016, 214, 122–131. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, R.; Chatterjee, S.; Mukhopadhyay, P.; Barman, S. Progresses in Waste Biomass derived Catalyst for Production of Biodiesel and Bioethanol: A Review. Procedia Environ. Sci. 2016, 35, 546–554. [Google Scholar] [CrossRef]

- Abu-Jrai, A.M.; Jamil, F.; Al-Muhtaseb, A.H.; Baawain, M.; Al-Haj, L.; Al-Hinai, M.; Al-Abri, M.; Rafiq, S. Valorization of waste Date pits biomass for biodiesel production in presence of green carbon catalyst. Energy Convers. Manag. 2017, 135, 236–243. [Google Scholar] [CrossRef]

- Balat, M.; Balat, M.; Kırtay, E.; Balat, H. Main routes for the thermo-conversion of biomass into fuels and chemicals. Part 1: Pyrolysis systems. Energy Convers. Manag. 2009, 50, 3147–3157. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Production of high grade fuels and chemicals from catalytic pyrolysis of biomass. Catal. Today 1996, 29, 285–295. [Google Scholar] [CrossRef]

- Kucuk, M.M.; Demirbas, A. Biomass conversion processes. Energy Convers. Manag. 1997, 38, 151–165. [Google Scholar] [CrossRef]

- Vasudevan, P.; Sharma, S.; Kumar, A. Liquid fuel from biomass: An Overview. J. Sci. Ind. Res. 2005, 64, 822–831. [Google Scholar]

- Demirbas, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U., Jr.; Steele, P.H. Pyrolysis of Wood/Biomass for Bio-oil: A Critical Review. Energy Fuels 2006, 20, 848–889. [Google Scholar] [CrossRef]

- Yanik, J.; Kornmayer, C.; Saglam, M.; Yüksel, M. Fast pyrolysis of agricultural wastes: Characterization of pyrolysis products. Fuel Process. Technol. 2007, 88, 942–947. [Google Scholar] [CrossRef]

- Chen, G.; Andries, J.; Spliethoff, H. Catalytic pyrolysis of biomass for hydrogen rich fuel gas production. Energy Convers. Manag. 2003, 44, 2289–2296. [Google Scholar] [CrossRef]

- Prakash, R.; Singh, R.; Murugan, S. Experimental investigation on a diesel engine fueled with bio-oil derived from waste wood-biodiesel emulsions. Energy 2013, 55, 610–618. [Google Scholar] [CrossRef]

- Singhabhandhu, A.; Tezuka, T. The waste-to-energy framework for integrated multi-waste utilization: Waste cooking oil, waste lubricating oil, and waste plastics. Energy 2010, 35, 2544–2551. [Google Scholar] [CrossRef]

- Ito, T.; Sakurai, Y.; Kakuta, Y.; Sugano, M.; Hirano, K. Biodiesel production from waste animal fats using pyrolysis method. Fuel Process. Technol. 2012, 94, 47–52. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Liang, D.T.; Zheng, C. Mechanism of Palm Oil Waste Pyrolysis in a Packed Bed. Energy Fuels 2006, 20, 1321–1328. [Google Scholar] [CrossRef]

- Wisniewski, A., Jr.; Wiggers, V.R.; Simionatto, E.L.; Meier, H.F.; Barros, A.A.C.; Madureira, L.A.S. Biofuels from waste fish oil pyrolysis: Chemical composition. Fuel 2010, 89, 563–568. [Google Scholar] [CrossRef]

- Phan, A.N.; Phan, T.M. Biodiesel production from waste cooking oils. Fuel 2008, 87, 3490–3496. [Google Scholar] [CrossRef]

- Ozsezen, A.N.; Canakci, M. Determination of performance and combustion characteristics of a diesel engine fueled with canola and waste palm oil methyl esters. Energy Convers. Manag. 2011, 52, 108–116. [Google Scholar] [CrossRef]

- Ryan, T.W.; Bagby, M.O. Identification of changes occurring during the transient injection of selected vegetable oils. SAE Trans. 1993, 102, 1440–1449. [Google Scholar]

- Cinar, C.; Can, Ö.; Sahin, F.; Yucesu, S.H. Effects of premixed diethyl ether (DEE) on combustion and exhaust emissions in a HCCI-DI diesel engine. Appl. Therm. Eng. 2010, 30, 360–365. [Google Scholar] [CrossRef]

- Qi, D.H.; Chen, H.; Geng, L.M.; Bian, Y.Z. Effect of diethyl ether and ethanol additives on the combustion and emission characteristics of biodiesel-diesel blended fuel engine. Renew. Energy 2011, 36, 1252–1258. [Google Scholar] [CrossRef]

- Sezer, I. Thermodynamic, performance and emission investigation of a diesel engine running on dimethyl ether and diethyl ether. Int. J. Therm. Sci. 2011, 50, 1594–1603. [Google Scholar] [CrossRef]

- Idem, R.O.; Katikaneni, S.P.R.; Bakhshi, N.N. Thermal cracking of canola oil: Reaction products in the presence and absence of steam. Energy Fuels 1996, 10, 1150–1162. [Google Scholar] [CrossRef]

- Schwab, A.W.; Dykstra, G.J.; Sekke, E.; Sorenson, S.C.; Pryde, E.H. Diesel fuel from thermal decomposition of soybean oil. J. Am. Oil Chem. Soc. 1988, 65, 1781–1786. [Google Scholar] [CrossRef]

- Alencar, J.W.; Alves, P.B.; Craveiro, A.A. Pyrolysis of tropical vegetable oils. J. Agric. Food Chem. 1983, 31, 1268–1270. [Google Scholar] [CrossRef]

- Adebanjo, A.O.; Dalai, A.K.; Bakhshi, N.N. Production of diesel-like fuel and other value-added chemicals from pyrolysis of animal fat. Energy Fuels 2005, 19, 1735–1741. [Google Scholar] [CrossRef]

- Dandik, L.; Aksoy, H.A. Effect of catalyst on the pyrolysis of used oil carried out in a fractionating pyrolysis reactor. Renew. Energy 1999, 16, 1007–1010. [Google Scholar] [CrossRef]

- Gopal, K.N.; Pal, A.; Sharma, S.; Samanchi, C.; Sathyanarayanan, K.; Elango, T. Investigation of emissions and combustion characteristics of a CI engine fueled with waste cooking oil methyl ester and diesel blends. Alex. Eng. J. 2014, 53, 281–287. [Google Scholar] [CrossRef]

- Can, O. Combustion characteristics, performance and exhaust emissions of a diesel engine fueled with a waste cooking oil biodiesel mixture. Energy Convers. Manag. 2014, 87, 676–686. [Google Scholar] [CrossRef]

- Wei, L.; Cheung, C.S.; Ning, Z. Influence of waste cooking oil biodiesel on combustion, unregulated gaseous emissions and particulate emissions of a direct-injection diesel engine. Energy 2017, 127, 175–185. [Google Scholar] [CrossRef]

- Prabu, S.S.; Asokan, M.; Roy, R.; Francis, S.; Sreelekh, M. Performance, combustion and emission characteristics of diesel engine fuelled with waste cooking oil bio-diesel/diesel blends with additives. Energy 2017, 122, 638–648. [Google Scholar] [CrossRef]

- Yu, C.W.; Bari, S.; Ameen, A. A comparison of combustion characteristics of waste cooking oil with diesel as fuel in a direct injection diesel engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2002, 216, 237–243. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Hsu, K.-H.; Chen, C.-B. Experimental investigation of the performance and emissions of a heavy-duty diesel engine fueled with waste cooking oil biodiesel/ultra-low sulfur diesel blends. Energy 2011, 36, 241–248. [Google Scholar] [CrossRef]

- Kumar, M.S.; Jaikumar, M. A comprehensive study on performance, emission and combustion behavior of a compression ignition engine fuelled with WCO (waste cooking oil) emulsion as fuel. J. Energy Inst. 2014, 87, 263–271. [Google Scholar] [CrossRef]

- An, H.; Yang, W.M.; Maghbouli, A.; Li, J.; Chou, S.K.; Chua, K. Performance, combustion and emission characteristics of biodiesel derived from waste cooking oils. Appl. Energy 2013, 112, 493–499. [Google Scholar] [CrossRef]

- Attia, A.M.; Hassaneen, A.E. Influence of diesel fuel blended with biodiesel produced from waste cooking oil on diesel engine performance. Fuel 2016, 167, 316–328. [Google Scholar] [CrossRef]

- Geng, P.; Mao, H.; Zhang, Y.; Wei, L.; You, K.; Ju, J.; Chen, T. Combustion characteristics and NOx emissions of a waste cooking oil biodiesel blend in a marine auxiliary diesel engine. Appl. Therm. Eng. 2017, 115, 947–954. [Google Scholar] [CrossRef]

- Hariharan, S.; Murugan, S.; Nagarajan, G. Effect of diethyl ether on tyre pyrolysis oil fueled diesel engine. Fuel 2014, 104, 109–115. [Google Scholar] [CrossRef]

- Devaraj, J.; Robinson, Y.; Ganapathi, P. Experimental investigation of performance, emission and combustion characteristics of waste plastic pyrolysis oil blended with diethyl ether used as fuel for diesel engine. Energy 2015, 85, 304–309. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Dimaratos, A.M. Characteristics of performance and emissions in high-speed direct injection diesel engine fueled with diethyl ether/diesel fuel blends. Energy 2012, 43, 214–224. [Google Scholar] [CrossRef]

- Coleman, H.W.; Steele, W.G., Jr. Experimentation and Uncertainty Analysis for Engineers; John Wiley & Sons: New York, NY, USA, 1989. [Google Scholar]

- Yang, H.; Li, X.; Mu, M.; Kou, G.; Li, L. Performance and emissions analysis of a diesel engine directly fuelled with waste cooking oil biodiesel. Int. J. Ambient Energy 2017, 38, 428–434. [Google Scholar] [CrossRef]

- Ashraful, A.M.; Masjuki, H.H.; Kalam, M.A.; Rashedul, H.K.; Habibullah, M.; Rashed, M.M.; Mosarof, M.H.; Arslan, A. Impact of edible and non-edible biodiesel fuel properties and engine operation condition on the performance and emission characteristics of unmodified DI diesel engine. Biofuels 2016, 7, 219–232. [Google Scholar] [CrossRef]

- Lobo, A.; Ramesh, D.; Chowdhury, D.R.; Mitra, A. Experimental Investigation on Influence of Additives on Emissions, Combustion and Performance of Diesel Engine along with EGR fueled with Waste Cooking Oil derived Biodiesel. Int. J. Emerg. Technol. 2020, 11, 671–680. [Google Scholar]

- Chaudhari, T.S.; Chandrahas, R.V.; Bidwe, R.R.; Chaudhari, R.; Dole, P.N.; Bobade, D.S. To Study the Effect of Compression Ratio and Additives on Performance and Emission Characteristics of Hybrid Methyl Ester (Undi + Waste Cooking Oil) on Diesel Engine. 2021. Available online: https://www.semanticscholar.org/paper/To-Study-the-Effect-of-Compression-Ratio-and-on-and-Chaudhari-Chandrahas/a0d517d0b85befd326749b301bf38183d609ef1c (accessed on 6 July 2023).

- Padmanabhan, S.; Selvamuthukumar, M.; Mahalingam, S.; Giridharan, K.; Ganesan, S. Influential study of oxygenated additives in waste cooking biodiesel blends on diesel engine performance. Multidiscip. Sci. J. 2023, 5, 2023015. [Google Scholar] [CrossRef]

- Barik, D.; Vijayaraghavan, R. Effects of waste chicken fat derived biodiesel on the performance and emission characteristics of a compression ignition engine. Int. J. Ambient Energy 2020, 41, 88–97. [Google Scholar] [CrossRef]

- Senthil, R.; Silambarasan, R. Environmental effect of antioxidant additives on exhaust emission reduction in compression ignition engine fuelled with Annona methyl ester. Environ. Technol. 2015, 36, 2079–2085. [Google Scholar] [CrossRef]

- Tudu, K.; Murugan, S.; Patel, S.K. Experimental study of diethyl ether addition on the performance and emissions of a diesel engine. Int. J. Ambient Energy 2017, 38, 332–338. [Google Scholar] [CrossRef]

- Barik, D.; Murugan, S. Investigation on combustion performance and emission characteristics of a DI (direct injection) diesel engine fueled with biogas–diesel in dual fuel mode. Energy 2014, 72, 760–771. [Google Scholar] [CrossRef]

- Barik, D.; Murugan, S. Effects of diethyl ether (DEE) injection on combustion performance and emission characteristics of Karanja methyl ester (KME)–biogas fueled dual fuel diesel engine. Fuel 2016, 164, 286–296. [Google Scholar] [CrossRef]

| Properties | ASTM | Diesel | WCO |

|---|---|---|---|

| Density, kg/m3 | D 4052 | 830 | 876 |

| Calorific values, kJ/kg | D 4809 | 43,800 | 39,767 |

| Auto-ignition temperature, °C | E 659 | 210–350 °C | 250–380 °C |

| Flashpoint, °C | D 93 | 50 °C | 160 °C |

| Fire point, °C | D 93 | 56 | 164 |

| Cetane number | D 613 | 50 | 42 |

| Oxygen, wt.% | E 385 | Nil | 20 |

| Properties | Test Method, ASTM | LFWCO |

|---|---|---|

| Density, kg/m3 | D 4052 | 812 |

| Calorific value, kJ/kg | D 4809 | 41,670 |

| Auto Ignition temperature, °C | E 659 | 230–320 |

| Flashpoint, °C | D 93 | 110 |

| Fire point, °C | D 93 | 130 |

| Cetane number | D 613 | 43 |

| Octane number | D909 | 66 |

| Carbon, % | - | 70.8 |

| Hydrogen, % | - | 6.1 |

| Nitrogen, % | - | 1.099 |

| Sulphur, % | - | 0.001 |

| Oxygen, wt.% | - | 22 |

| Properties | Test Method, ASTM | LFWCO | DEE | LFWCO+5-DEE | LFWCO+10-DEE | LFWCO+15-DEE | LFWCO+20-DEE |

|---|---|---|---|---|---|---|---|

| Density, kg/m3 | D 4052 | 812 | 713 | 807.05 | 802.1 | 797.15 | 792.2 |

| Calorific values, kJ/kg | D 4809 | 41,670 | 33,900 | 41,281.5 | 40,893 | 40,504.5 | 40,116 |

| Auto-ignition temperature, °C | E 659 | 230–320 | 150–160 | 180–215 | 168–184 | 160–181 | 159–178 |

| Flashpoint, °C | D 93 | 110 | −40 | 102.5 | 95 | 87.5 | 80 |

| Fire point, °C | D 93 | 130 | 44 | 125.7 | 121.4 | 117.1 | 112.8 |

| Cetane number | D 613 | 43 | 125 | 47.1 | 51.2 | 55.3 | 59.4 |

| Oxygen, wt.% | E 385 | 22 | 28.2 | 22.31 | 22.62 | 22.93 | 23.24 |

| Parameters | Description |

|---|---|

| Engine type | 1 cylinder, 4-stroke, H2O cooled |

| Power | 3.7 kilowatt |

| Speed | 1500 rpm |

| Compression ratio | 18 (standard) |

| Cylinder bore diameter | 87.5 mm |

| Stroke length | 110 mm |

| Ignition type | Compression |

| Dynamometer type | Eddy current dynamometer |

| Injector type | Plunger type |

| Injection pressure, bar | 200 |

| Injector nozzle holes | 3 nos. |

| Injection type | Direct |

| Injection angle, bTDC | 23° |

| Temperature sensor | K-type |

| Fuel | Acronyms Used | Compression Ratio | Injection Time, °CA bTDC |

|---|---|---|---|

| Diesel | Diesel | 18 | 23 |

| LFWCO (100%) | LFWCO | 18 | 23 |

| LFWCO (95%) + DEE (5%) | LFWCO+5-DEE | 18 | 23 |

| LFWCO (90%) + DEE (5%) | LFWCO+10-DEE | 18 | 23 |

| LFWCO (85%) + DEE (5%) | LFWCO+15-DEE | 18 | 23 |

| LFWCO (80%) + DEE (5%) | LFWCO+20-DEE | 18 | 23 |

| Instruments | Parameters Measured | Range | Accuracy | Unreliability, % |

|---|---|---|---|---|

| Gas analyzer | Exhaust emissions | NO 0–5000 ppm CO 0–10% HC 0–10,000 ppm CO2 0–20% | ||

| Dynamometer | Brake power | 0–100 Nm | ||

| Crank angle encoder | Crank position | 0–720° | ||

| Speed sensor | Engine speed | 0–10,000 rpm | ||

| Smoke meter | Smoke opacity | 0–100% | ||

| Burette | Fuel consumption | 0–100 mL | ||

| Pressure transducer | In-cylinder pressure | 0–100 bar |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samraj, A.; Barik, D.; Bhatlu, M.L.D.; Rout, S.K.; Ayadi, B.; Aich, W.; Kadhim Hussein, A.; Kolsi, L. Effect of Diethyl Ether on the Performance and Emission Characteristics of a Diesel Engine Fueled with a Light Fraction of Waste Cooking Oil. Processes 2023, 11, 2613. https://doi.org/10.3390/pr11092613

Samraj A, Barik D, Bhatlu MLD, Rout SK, Ayadi B, Aich W, Kadhim Hussein A, Kolsi L. Effect of Diethyl Ether on the Performance and Emission Characteristics of a Diesel Engine Fueled with a Light Fraction of Waste Cooking Oil. Processes. 2023; 11(9):2613. https://doi.org/10.3390/pr11092613

Chicago/Turabian StyleSamraj, Aravind, Debabrata Barik, Metta Laxmi Deepak Bhatlu, Sachindra Kumar Rout, Badreddine Ayadi, Walid Aich, Ahmed Kadhim Hussein, and Lioua Kolsi. 2023. "Effect of Diethyl Ether on the Performance and Emission Characteristics of a Diesel Engine Fueled with a Light Fraction of Waste Cooking Oil" Processes 11, no. 9: 2613. https://doi.org/10.3390/pr11092613

APA StyleSamraj, A., Barik, D., Bhatlu, M. L. D., Rout, S. K., Ayadi, B., Aich, W., Kadhim Hussein, A., & Kolsi, L. (2023). Effect of Diethyl Ether on the Performance and Emission Characteristics of a Diesel Engine Fueled with a Light Fraction of Waste Cooking Oil. Processes, 11(9), 2613. https://doi.org/10.3390/pr11092613