Review on Waste-to-Energy Approaches toward a Circular Economy in Developed and Developing Countries

Abstract

:1. Introduction

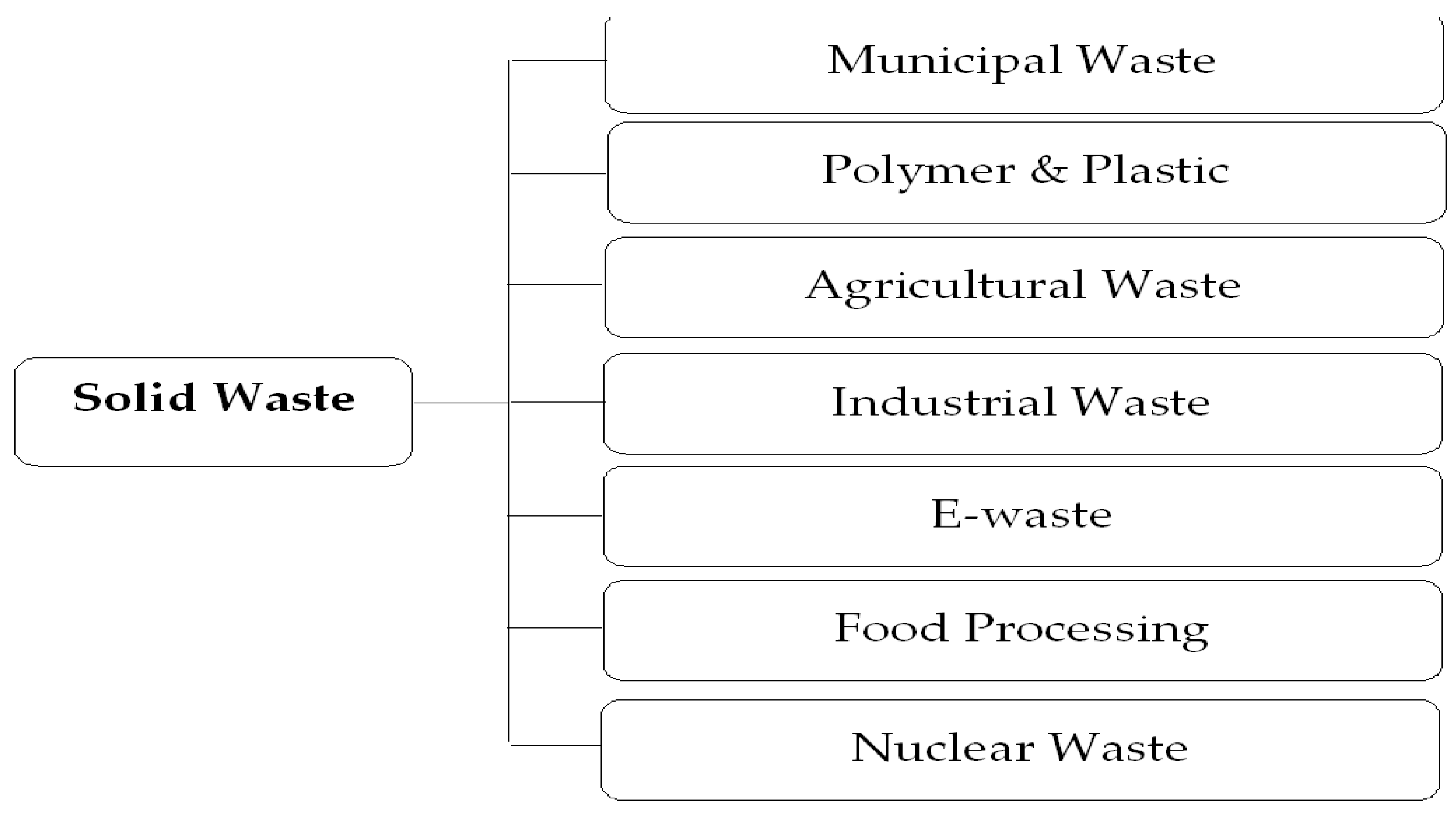

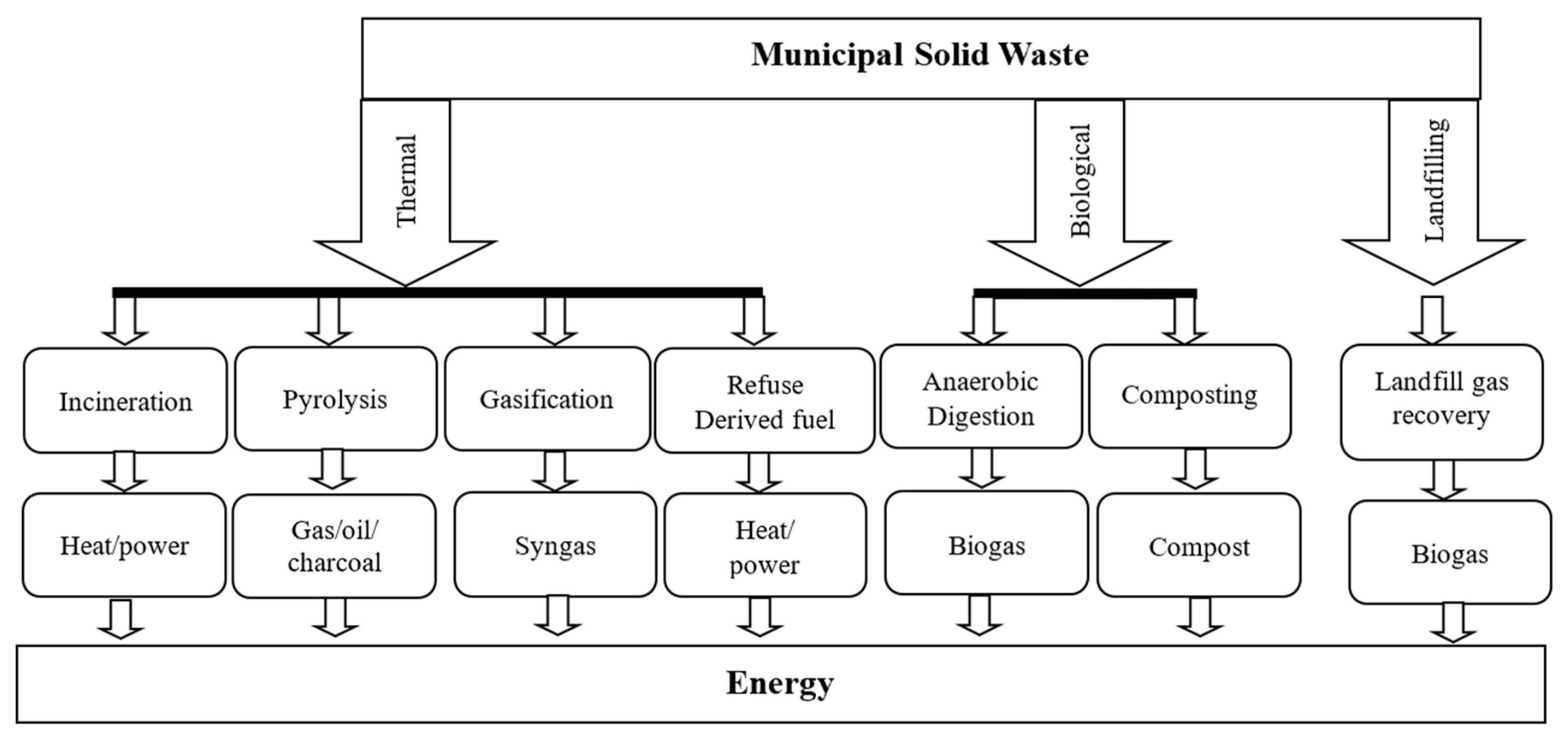

2. Waste-to-Energy Technologies

2.1. Incineration

2.2. Pyrolysis and Gasification

2.3. Landfilling

2.4. Anaerobic Digestion or Bio Methanation

2.5. Composting

3. Circular Economy

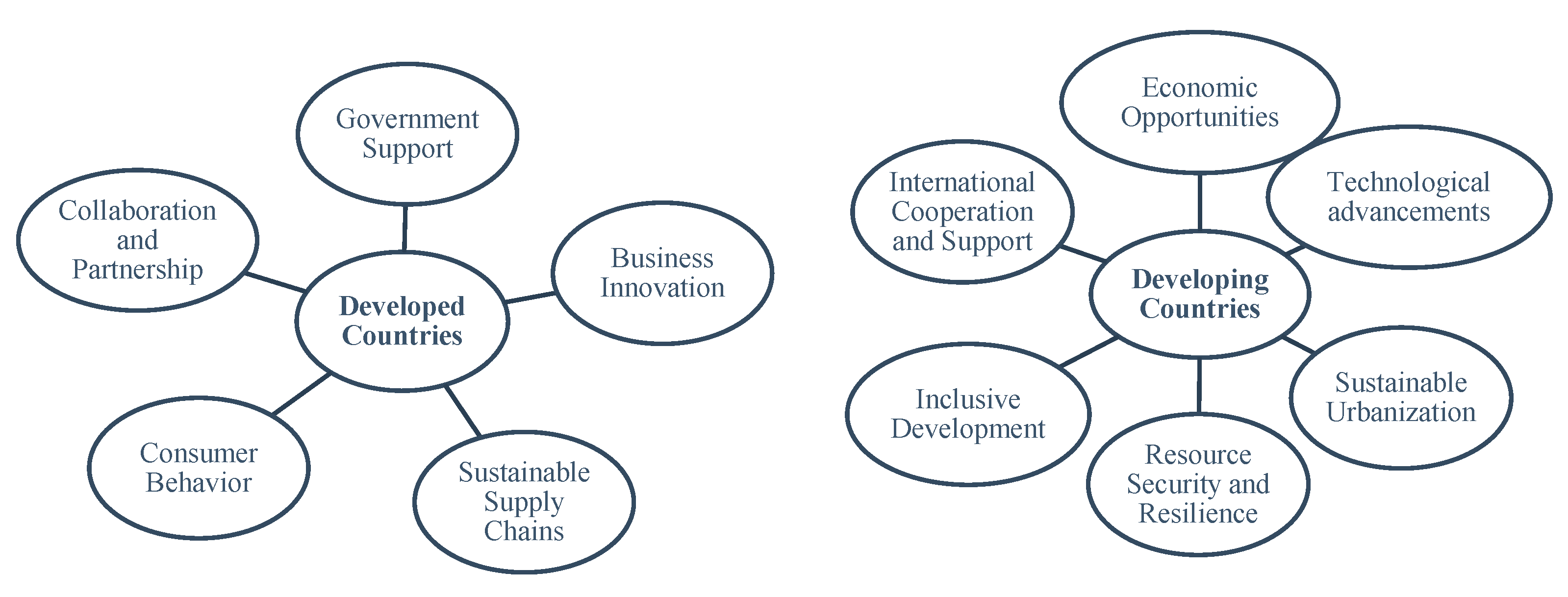

4. Implementing WtE toward CE in Different Countries

4.1. Developing Countries

4.1.1. China

4.1.2. India

4.1.3. Vietnam

4.1.4. Brazil

4.1.5. African Countries

4.2. Developed Countries

4.2.1. Singapore

4.2.2. Japan

4.2.3. Sweden

4.2.4. Denmark

4.2.5. Germany

5. Recommendation and Roadmap for the CE Using WtE

6. Conclusions and Future Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- Dastjerdi, B.; Strezov, V.; Rajaeifar, M.A.; Kumar, R.; Behnia, M. A systematic review on life cycle assessment of different waste to energy valorization technologies. J. Clean. Prod. 2021, 290, 125747. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Lange, J.P. Managing plastic waste—Sorting, recycling, disposal, and product redesign. ACS Sustain. Chem. Eng. 2021, 9, 15722–15738. [Google Scholar] [CrossRef]

- Van Fan, Y.; Jiang, P.; Klemeš, J.J.; Liew, P.Y.; Lee, C.T. Integrated regional waste management to minimise the environmental footprints in circular economy transition. Resour. Conserv. Recycl. 2021, 168, 105292. [Google Scholar] [CrossRef]

- Ly, N.H.; Joo, S.W.; Choo, J.; Vasseghian, Y.; Cho, J.; Rezania, S. Sustainable cutting-edge techniques for gold valorization from electronic wastes. Chem. Eng. J. 2023, 471, 144324. [Google Scholar]

- Yang, M.; Chen, L.; Wang, J.; Msigwa, G.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Yap, P.-S. Circular economy strategies for combating climate change and other environmental issues. Environ. Chem. Lett. 2023, 21, 55–80. [Google Scholar] [CrossRef]

- Magazzino, C.; Falcone, P.M. Assessing the relationship among waste generation, wealth, and GHG emissions in Switzerland: Some policy proposals for the optimization of the municipal solid waste in a circular economy perspective. J. Clean. Prod. 2022, 351, 131555. [Google Scholar] [CrossRef]

- Zhang, Z.; Malik, M.Z.; Khan, A.; Ali, N.; Malik, S.; Bilal, M. Environmental impacts of hazardous waste, and management strategies to reconcile circular economy and eco-sustainability. Sci. Total Environ. 2022, 807, 150856. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef] [PubMed]

- Beyene, H.D.; Werkneh, A.A.; Ambaye, T.G. Current updates on waste to energy (WtE) technologies: A review. Renew. Energy Focus 2018, 24, 1–11. [Google Scholar] [CrossRef]

- Adusei-Gyamfi, J.; Boateng, K.S.; Sulemana, A.; Hogarh, J.N. Post COVID-19 recovery: Challenges and opportunities for solid waste management in Africa. Environ. Chall. 2022, 6, 100442. [Google Scholar] [CrossRef] [PubMed]

- Singh, E.; Kumar, A.; Mishra, R.; Kumar, S. Solid waste management during COVID-19 pandemic: Recovery techniques and responses. Chemosphere 2022, 288, 132451. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.H.; López-Maldonado, E.A.; Khan, N.A.; Villarreal-Gómez, L.J.; Munshi, F.M.; Alsabhan, A.H.; Perveen, K. Current solid waste management strategies and energy recovery in developing countries—State of art review. Chemosphere 2022, 291, 133088. [Google Scholar] [CrossRef]

- Khan, A.H.; López-Maldonado, E.A.; Alam, S.S.; Khan, N.A.; López, J.R.L.; Herrera, P.F.M.; Abutaleb, A.; Ahmed, S.; Singh, L. Municipal solid waste generation and the current state of waste-to-energy potential: State of art review. Energy Convers. Manag. 2022, 267, 115905. [Google Scholar] [CrossRef]

- Zhao, X.; Jiang, G.; Li, A.; Wang, L. Economic analysis of waste-to-energy industry in China. Waste Manag. 2016, 48, 604–618. [Google Scholar] [CrossRef]

- Srivastava, V.; Vaish, B.; Singh, R.P.; Singh, P. An insight to municipal solid waste management of Varanasi city, India, and appraisal of vermicomposting as its efficient management approach. Environ. Monit. Assess. 2020, 192, 191. [Google Scholar] [CrossRef]

- Malav, L.C.; Yadav, K.K.; Gupta, N.; Kumar, S.; Sharma, G.K.; Krishnan, S.; Rezania, S.; Kamyab, H.; Pham, Q.B.; Yadav, S.; et al. A review on municipal solid waste as a renewable source for waste-to-energy project in India: Current practices, challenges, and future opportunities. J. Clean. Prod. 2020, 277, 123227. [Google Scholar] [CrossRef]

- Galvão, N.; Alves, I.R.; Bassin, J.P. Municipal solid waste management in Brazil: Overview and trade-offs between different treatment technologies. Waste Manag. Resour. Recycl. Dev. World 2023, 755–772. [Google Scholar] [CrossRef]

- Mohammadi, A.; Sandberg, M.; Venkatesh, G.; Eskandari, S.; Dalgaard, T.; Joseph, S.; Granström, K. Environmental performance of end-of-life handling alternatives for paper-and-pulp-mill sludge: Using digestate as a source of energy or for biochar production. Energy 2019, 182, 594–605. [Google Scholar] [CrossRef]

- Baran, B.; Mamis, M.S.; Alagoz, B.B. Utilization of energy from waste potential in Turkey as distributed secondary renewable energy source. Renew. Energy 2016, 90, 493–500. [Google Scholar] [CrossRef]

- Van de Velden, M.; Baeyens, J.; Brems, A.; Janssens, B.; Dewil, R. Fundamentals, kinetics and endothermicity of the biomass pyrolysis reaction. Renew. Energy 2010, 35, 232–242. [Google Scholar] [CrossRef]

- Chintala, V. Production, upgradation and utilization of solar assisted pyrolysis fuels from biomass—A technical review. Renew. Sustain. Energy Rev. 2018, 90, 120–130. [Google Scholar] [CrossRef]

- Hasan, M.; Rasul, M.; Khan, M.; Ashwath, N.; Jahirul, M. Energy recovery from municipal solid waste using pyrolysis technology: A review on current status and developments. Renew. Sustain. Energy Rev. 2021, 145, 111073. [Google Scholar] [CrossRef]

- Zhang, J.; Kan, X.; Shen, Y.; Loh, K.C.; Wang, C.H.; Dai, Y.; Tong, Y.W. A hybrid biological and thermal waste-to-energy system with heat energy recovery and utilization for solid organic waste treatment. Energy 2018, 152, 214–222. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M. Life cycle assessment of pyrolysis, gasification and incineration waste-to-energy technologies: Theoretical analysis and case study of commercial plants. Sci. Total Environ. 2018, 626, 744–753. [Google Scholar] [CrossRef] [PubMed]

- Ramos, A.; Afonso Teixeira, C.; Rouboa, A. Environmental analysis of waste-to-energy—A Portuguese case study. Energies 2018, 11, 548. [Google Scholar] [CrossRef]

- Coelho, L.M.G.; Lange, L.C. Applying life cycle assessment to support environmentally sustainable waste management strategies in Brazil. Resour. Conserv. Recycl. 2018, 128, 438–450. [Google Scholar] [CrossRef]

- Demetrious, A. Life Cycle Assessment of the Management of Residual Waste from Material Recovery Facilities by Landfill, Incineration and Gasification-Pyrolysis in Victoria. Ph.D. Thesis, RMIT University, Melbourne, VIC, Australia, 2018. [Google Scholar]

- Tang, Y.; Dong, J.; Li, G.; Zheng, Y.; Chi, Y.; Nzihou, A.; Weiss-Hortala, E.; Ye, C. Environmental and exergetic life cycle assessment of incineration-and gasification-based waste to energy systems in China. Energy 2020, 205, 118002. [Google Scholar] [CrossRef]

- Varjani, S.; Shahbeig, H.; Popat, K.; Patel, Z.; Vyas, S.; Shah, A.V.; Barceló, D.; Ngo, H.H.; Sonne, C.; Lam, S.S.; et al. Sustainable management of municipal solid waste through waste-to-energy technologies. Bioresour. Technol. 2022, 355, 127247. [Google Scholar] [CrossRef]

- Dangi, M.B.; Schoenberger, E.; Boland, J.J. Assessment of environmental policy implementation in solid waste management in Kathmandu, Nepal. Waste Manag. Res. 2017, 35, 618–626. [Google Scholar] [CrossRef]

- Nanda, S.; Berruti, F. Municipal solid waste management and landfilling technologies: A review. Environ. Chem. Lett. 2021, 19, 1433–1456. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Ibrahim, A.M.; Al-Sulaiman, A.M.; Okasha, R.A. Landfill leachate: Sources, nature, organic composition, and treatment: An environmental overview. Ain Shams Eng. J. 2023, 102293. [Google Scholar] [CrossRef]

- Shih, M.F.; Lin, C.Y.; Lay, C.H. Comparison of potential environmental impacts and waste-to-energy efficiency for kitchen waste treatment scenarios in central Taiwan. Processes 2021, 9, 696. [Google Scholar] [CrossRef]

- Ikhlayel, M. Development of management systems for sustainable municipal solid waste in developing countries: A systematic life cycle thinking approach. J. Clean. Prod. 2018, 180, 571–586. [Google Scholar] [CrossRef]

- Demetrious, A.; Verghese, K.; Stasinopoulos, P.; Crossin, E. Comparison of alternative methods for managing the residual of material recovery facilities using life cycle assessment. Resour. Conserv. Recycl. 2018, 136, 33–45. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S. Performance evaluation of anaerobic digestion technology for energy recovery from organic fraction of municipal solid waste: A review. Energy 2020, 197, 117253. [Google Scholar] [CrossRef]

- Di Maria, F.; Sisani, F.; Lasagni, M.; Borges, M.S.; Gonzales, T.H. Replacement of energy crops with bio-waste in existing anaerobic digestion plants: An energetic and environmental analysis. Energy 2018, 152, 202–213. [Google Scholar] [CrossRef]

- Lee, E.; Bittencourt, P.; Casimir, L.; Jimenez, E.; Wang, M.; Zhang, Q.; Ergas, S.J. Biogas production from high solids anaerobic co-digestion of food waste, yard waste and waste activated sludge. Waste Manag. 2019, 95, 432–439. [Google Scholar] [CrossRef]

- Ascher, S.; Watson, I.; Wang, X.; You, S. Township-based bioenergy systems for distributed energy supply and efficient household waste re-utilisation: Techno-economic and environmental feasibility. Energy 2019, 181, 455–467. [Google Scholar] [CrossRef]

- Waqas, M.; Hashim, S.; Humphries, U.; Ahmad, S.; Noor, R.; Shoaib, M.; Naseem, A.; Hlaing, P.T.; Lin, H.A. Composting Processes for Agricultural Waste Management: A Comprehensive Review. Processes 2023, 11, 731. [Google Scholar] [CrossRef]

- Liikanen, M.; Havukainen, J.; Viana, E.; Horttanainen, M. Steps towards more environmentally sustainable municipal solid waste management—A life cycle assessment study of São Paulo, Brazil. J. Clean. Prod. 2018, 196, 150–162. [Google Scholar] [CrossRef]

- Preston, F. A Global Redesign? Shaping the Circular Economy; Chatham House: London, UK, 2012. [Google Scholar]

- Stahel, W.R.; Reday, G. The Potential for Substituting Manpower for Energy; Commission of the European Communities: Brussels, Belgium, 1976. [Google Scholar]

- Chen, T.L.; Kim, H.; Pan, S.Y.; Tseng, P.C.; Lin, Y.P.; Chiang, P.C. Implementation of green chemistry principles in circular economy system towards sustainable development goals: Challenges and perspectives. Sci. Total Environ. 2020, 716, 136998. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Geng, Y.; Lai, K. Circular economy practices among Chinese manufacturers varying in environmental-oriented supply chain cooperation and the performance implications. J. Environ. Manag. 2010, 91, 1324–1331. [Google Scholar] [CrossRef]

- Millar, N.; McLaughlin, E.; Börger, T. The circular economy: Swings and roundabouts? Ecol. Econ. 2019, 158, 11–19. [Google Scholar] [CrossRef]

- Allevi, E.; Gnudi, A.; Konnov, I.V.; Oggioni, G. Municipal solid waste management in circular economy: A sequential optimization model. Energy Econ. 2021, 100, 105383. [Google Scholar] [CrossRef]

- Hoang, A.T.; Varbanov, P.S.; Nižetić, S.; Sirohi, R.; Pandey, A.; Luque, R.; Ng, K.H. Perspective review on Municipal Solid Waste-to-energy route: Characteristics, management strategy, and role in circular economy. J. Clean. Prod. 2022, 359, 131897. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- D’Amato, D.; Korhonen, J.; Toppinen, A. Circular, green, and bio economy: How do companies in land-use intensive sectors align with sustainability concepts? Ecol. Econ. 2019, 158, 116–133. [Google Scholar] [CrossRef]

- Yoshida, F. The Cyclical Economy of Japan; Hokkaido University: Hakodate, Japan, 2007. [Google Scholar]

- Ogunmakinde, O.E. A review of circular economy development models in China, Germany and Japan. Recycling 2019, 4, 27. [Google Scholar] [CrossRef]

- Halog, A.; Anieke, S. A review of circular economy studies in developed countries and its potential adoption in developing countries. Circ. Econ. Sustain. 2021, 1, 209–230. [Google Scholar] [CrossRef]

- Yuan, Z.; Bi, J.; Moriguichi, Y. The circular economy: A new development strategy in China. J. Ind. Ecol. 2006, 10, 4–8. [Google Scholar] [CrossRef]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving’leapfrog development’. Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. [Google Scholar] [CrossRef] [PubMed]

- Geng, Y.; Sarkis, J.; Ulgiati, S.; Zhang, P. Measuring China’s circular economy. Science 2013, 339, 1526–1527. [Google Scholar] [CrossRef] [PubMed]

- Qu, S.; Guo, Y.; Ma, Z.; Chen, W.Q.; Liu, J.; Liu, G.; Wang, Y.; Xu, M. Implications of China’s foreign waste ban on the global circular economy. Resour. Conserv. Recycl. 2019, 144, 252–255. [Google Scholar] [CrossRef]

- Awasthi, S.K.; Sarsaiya, S.; Kumar, V.; Chaturvedi, P.; Sindhu, R.; Binod, P.; Zhang, Z.; Pandey, A.; Awasthi, M.K. Processing of municipal solid waste resources for a circular economy in China: An overview. Fuel 2022, 317, 123478. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Liang, X.; O’Callaghan, E.; Goh, H.; Othman, M.H.D.; Avtar, R.; Kusworo, T.D. Transformation of solid waste management in China: Moving towards sustainability through digitalization-based circular economy. Sustainability 2022, 14, 2374. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Awasthi, A.K.; Li, J. Management of electrical and electronic waste: A comparative evaluation of China and India. Renew. Sustain. Energy Rev. 2017, 76, 434–447. [Google Scholar] [CrossRef]

- Priyadarshini, P.; Abhilash, P.C. Circular economy practices within energy and waste management sectors of India: A meta-analysis. Bioresour. Technol. 2020, 304, 123018. [Google Scholar] [CrossRef]

- GSO. Satitistic Handbook of Vietnam; The Statistic; GSO: Riyadh, Saudi Arabia, 2014. [Google Scholar]

- Dung, K.M. Assessment of Effective Economic Environment—Proposed Feasibility Mining Scenarios after GÈ Cát Landfill Site Stops Receipting of Garbage; Institute for the Environmental Science, Engineering and Management: Ho Chi Minh City, Vietnam, 2015. [Google Scholar]

- Tong, Y.D.; Huynh, T.D.X.; Khong, T.D. Understanding the role of informal sector for sustainable development of municipal solid waste management system: A case study in Vietnam. Waste Manag. 2021, 124, 118–127. [Google Scholar] [CrossRef]

- Schneider, P.; Anh, L.H.; Wagner, J.; Reichenbach, J.; Hebner, A. Solid waste management in Ho Chi Minh City, Vietnam: Moving towards a circular economy? Sustainability 2017, 9, 286. [Google Scholar] [CrossRef]

- Donre, H. Report on Solid Waste Management in Ho Chi Minh City; Ho Chi Minh City Department of Natural Resources and Environment (HCMC DONRE): Ho Chi Minh City, Vietnam, 2014. [Google Scholar]

- Nguyen, X.C.; Tran, T.P.Q.; Nguyen, T.T.H.; La, D.D.; Nguyen, V.K.; Nguyen, T.P.; Chang, S.; Balasubramani, R.; Chung, W.J.; Nguyen, D.D. Call for planning policy and biotechnology solutions for food waste management and valorization in Vietnam. Biotechnol. Rep. 2020, 28, e00529. [Google Scholar] [CrossRef]

- Mondelli, G.; Juarez, M.B.; Jacinto, C.; de Oliveira, M.A.; Coelho, L.H.G.; Biancardi, C.B.; Faria, J.L.d.C. Geo-environmental and geotechnical characterization of municipal solid waste from the selective collection in São Paulo city, Brazil. Environ. Sci. Pollut. Res. 2022, 29, 19898–19912. [Google Scholar] [CrossRef]

- Padilha, J.L.; Mesquita, A.L.A. Waste-to-energy effect in municipal solid waste treatment for small cities in Brazil. Energy Convers. Manag. 2022, 265, 115743. [Google Scholar] [CrossRef]

- Cetrulo, T.B.; Marques, R.C.; Cetrulo, N.M.; Pinto, F.S.; Moreira, R.M.; Mendizábal-Cortés, A.D.; Malheiros, T.F. Effectiveness of solid waste policies in developing countries: A case study in Brazil. J. Clean. Prod. 2018, 205, 179–187. [Google Scholar] [CrossRef]

- Penteado, C.S.G.; de Castro, M.A.S. COVID-19 effects on municipal solid waste management: What can effectively be done in the Brazilian scenario? Resour. Conserv. Recycl. 2021, 164, 105152. [Google Scholar] [CrossRef]

- de Oliveira, B.O.S.; de Medeiros, G.A.; Mancini, S.D.; Paes, M.X.; Gianelli, B.F. Eco-efficiency transition applied to municipal solid waste management in the Amazon. J. Clean. Prod. 2022, 373, 133807. [Google Scholar] [CrossRef]

- de Oliveira Leite, F.F.; Palacio, J.C.E.; Batista, M.J.A.; Renó, M.L.G. Evaluation of technological alternatives for the treatment of urban solid waste: A case study of Minas Gerais, Brazil. J. Clean. Prod. 2022, 330, 129618. [Google Scholar] [CrossRef]

- de Medeiros Engelmann, P.; dos Santos, V.H.J.M.; da Rocha, P.R.; dos Santos, G.H.A.; Lourega, R.V.; de Lima, J.E.A.; Pires, M.J.R. Analysis of solid waste management scenarios using the WARM model: Case study. J. Clean. Prod. 2022, 345, 130687. [Google Scholar] [CrossRef]

- Mutezo, G.; Mulopo, J. A review of Africa’s transition from fossil fuels to renewable energy using circular economy principles. Renew. Sustain. Energy Rev. 2021, 137, 110609. [Google Scholar] [CrossRef]

- Godfrey, L.; Oelofse, S. Historical review of waste management and recycling in South Africa. Resources 2017, 6, 57. [Google Scholar] [CrossRef]

- Owojori, O.M.; Mulaudzi, R.; Edokpayi, J.N. Student’s Knowledge, Attitude, and Perception (KAP) to Solid Waste Management: A Survey towards a More Circular Economy from a Rural-Based Tertiary Institution in South Africa. Sustainability 2022, 14, 1310. [Google Scholar] [CrossRef]

- Ezeudu, O.B.; Ezeudu, T.S. Implementation of circular economy principles in industrial solid waste management: Case studies from a developing economy (Nigeria). Recycling 2019, 4, 42. [Google Scholar] [CrossRef]

- Franco-García, M.L.; Carpio-Aguilar, J.C.; Bressers, H. Towards zero waste, circular economy boost: Waste to resources. In Towards Zero Waste; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–8. [Google Scholar]

- Ando, T.; Jige, M.; Ueno, H.; Henmi, T.; Abidin, Z.; Matsue, N. Evaluation of chemical stability of heavy metals in industrial waste slag by infrared spectroscopy. J. Mater. Cycles Waste Manag. 2010, 12, 302–307. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Leeke, G.A.; El-Eskandarany, M.S.; Van Haute, M.; Constantinou, A.; Dewil, R.; Baeyens, J. On the implementation of the circular economy route for E-waste management: A critical review and an analysis for the case of the state of Kuwait. J. Environ. Manag. 2022, 323, 116181. [Google Scholar] [CrossRef]

- Chan, J.K.H. The ethics of working with wicked urban waste problems: The case of Singapore’s Semakau Landfill. Landsc. Urban Plan. 2016, 154, 123–131. [Google Scholar] [CrossRef]

- Mawhood, R.; Gazis, E.; de Jong, S.; Hoefnagels, R.; Slade, R. Production pathways for renewable jet fuel: A review of commercialization status and future prospects. Biofuels Bioprod. Biorefin. 2016, 10, 462–484. [Google Scholar] [CrossRef]

- Carrière, S.; Weigend Rodríguez, R.; Pey, P.; Pomponi, F.; Ramakrishna, S. Circular cities: The case of Singapore. Built Environ. Proj. Asset Manag. 2020, 10, 491–507. [Google Scholar] [CrossRef]

- Tisserant, A.; Pauliuk, S.; Merciai, S.; Schmidt, J.; Fry, J.; Wood, R.; Tukker, A. Solid waste and the circular economy: A global analysis of waste treatment and waste footprints. J. Ind.Ecol. 2017, 21, 628–640. [Google Scholar] [CrossRef]

- Herrador, M.; de Jong, W.; Nasu, K.; Granrath, L. Circular economy and zero-carbon strategies between Japan and South Korea: A comparative study. Sci. Total Environ. 2022, 820, 153274. [Google Scholar] [CrossRef]

- Berlin, D.; Feldmann, A.; Nuur, C. Supply network collaborations in a circular economy: A case study of Swedish steel recycling. Resour. Conserv. Recycl. 2022, 179, 106112. [Google Scholar] [CrossRef]

- Behzad, M.; Zolfani, S.H.; Pamucar, D.; Behzad, M. A comparative assessment of solid waste management performance in the Nordic countries based on BWM-EDAS. J. Clean. Prod. 2020, 266, 122008. [Google Scholar] [CrossRef]

- Iyamu, H.; Anda, M.; Ho, G. A review of municipal solid waste management in the BRIC and high-income countries: A thematic framework for low-income countries. Habitat Int. 2020, 95, 102097. [Google Scholar] [CrossRef]

- Edjabou, M.E.; Faraca, G.; Boldrin, A.; Astrup, T.F. Temporal and geographical patterns of solid waste collected at recycling centres. J. Environ. Manag. 2019, 245, 384–397. [Google Scholar] [CrossRef]

- Magazzino, C.; Mele, M.; Schneider, N.; Sarkodie, S.A. Waste generation, wealth and GHG emissions from the waste sector: Is Denmark on the path towards circular economy? Sci. Total Environ. 2021, 755, 142510. [Google Scholar] [CrossRef]

- Moalem, R.M.; Schmidt, K. Municipal solid waste management in the interface between commercial and non-commercial repair: Lessons from Denmark and Sweden. Clean. Waste Syst. 2023, 5, 100095. [Google Scholar] [CrossRef]

- Hjul-Nielsen, J.; Santos, A.; Christensen, D.; Andrade, B. Factors influencing changes in island waste systems: The case of Bornholm, Denmark. Clean. Waste Syst. 2023, 4, 100080. [Google Scholar] [CrossRef]

- Velvizhi, G.; Shanthakumar, S.; Das, B.; Pugazhendhi, A.; Priya, T.S.; Ashok, B.; Nanthagopal, K.; Vignesh, R.; Karthick, C. Biodegradable and non-biodegradable fraction of municipal solid waste for multifaceted applications through a closed loop integrated refinery platform: Paving a path towards circular economy. Sci. Total Environ. 2020, 731, 138049. [Google Scholar] [CrossRef]

- BMU. Federal Ministry for the Environment, Nature Conservation and Nuclear Safety. Renewable Energy Sources in Figures, National and International Development; BMU: Rohtak, India, 2010. [Google Scholar]

- Azevedo, B.D.; Scavarda, L.F.; Caiado, R.G.G.; Fuss, M. Improving urban household solid waste management in developing countries based on the German experience. Waste Manag. 2021, 120, 772–783. [Google Scholar] [CrossRef] [PubMed]

- Munir, M.; Mohaddespour, A.; Nasr, A.; Carter, S. Municipal solid waste-to-energy processing for a circular economy in New Zealand. Renew. Sustain. Energy Rev. 2021, 145, 111080. [Google Scholar] [CrossRef]

- Smol, M.; Duda, J.; Czaplicka-Kotas, A.; Szołdrowska, D. Transformation towards Circular Economy (CE) in Municipal Waste Management System: Model Solutions for Poland. Sustainability 2020, 12, 4561. [Google Scholar] [CrossRef]

- Qin, L.; Wang, M.; Zhu, J.; Wei, Y.; Zhou, X.; He, Z. Towards Circular Economy through Waste to Biomass Energy in Madagascar. Complexity 2021, 2021, 5822568. [Google Scholar] [CrossRef]

- Brenes-Peralta, L.; Jiménez-Morales, M.F.; Campos-Rodríguez, R.; De Menna, F.; Vittuari, M. Decision-Making Process in the Circular Economy: A Case Study on University Food Waste-to-Energy Actions in Latin America. Energies 2020, 13, 2291. [Google Scholar] [CrossRef]

- Lausselet, C.; Cherubini, F.; Oreggioni, G.D.; del Alamo Serrano, G.; Becidan, M.; Hu, X.; Rørstad, P.K.; Strømman, A.H. Norwegian Waste-to-Energy: Climate change, circular economy and carbon capture and storage. Resour. Conserv. Recycl. 2017, 126, 50–61. [Google Scholar] [CrossRef]

- Rezvani Ghomi, E.; Khosravi, F.; Tahavori, M.A.; Ramakrishna, S. Circular Economy: A Comparison Between the Case of Singapore and France. Mater. Circ. Econ. 2021, 3, 2. [Google Scholar] [CrossRef]

- Bilal, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R. Current state and barriers to the circular economy in the building sector: Towards a mitigation framework. J. Clean. Prod. 2020, 276, 123250. [Google Scholar] [CrossRef]

- Singh, M.P.; Chakraborty, A.; Roy, M. Developing an extended theory of planned behavior model to explore circular economy readiness in manufacturing MSMEs, India. Resour. Conserv. Recycl. 2018, 135, 313–322. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Avtar, R.; Singh, D.; Xue, W.; Dzarfan Othman, M.H.; Hwang, G.H.; Iswanto, I.; Albadarin, A.B.; Kern, A.O. Reforming MSWM in Sukunan (Yogjakarta, Indonesia): A case-study of applying a zero-waste approach based on circular economy paradigm. J. Clean. Prod. 2021, 284, 124775. [Google Scholar] [CrossRef] [PubMed]

- Esa, M.R.; Halog, A.; Rigamonti, L. Developing strategies for managing construction and demolition wastes in Malaysia based on the concept of circular economy. J. Mater. Cycles Waste Manag. 2017, 19, 1144–1154. [Google Scholar] [CrossRef]

- Khan, F.; Ali, Y. A facilitating framework for a developing country to adopt smart waste management in the context of circular economy. Environ. Sci. Pollut. Res. 2022, 29, 26336–26351. [Google Scholar] [CrossRef]

- Moktadir, M.d.A.; Ahmadi, H.B.; Sultana, R.; Zohra, F.T.; Liou, J.J.H.; Rezaei, J. Circular economy practices in the leather industry: A practical step towards sustainable development. J. Clean. Prod. 2020, 251, 119737. [Google Scholar] [CrossRef]

- Maiurova, A.; Kurniawan, T.A.; Kustikova, M.; Bykovskaia, E.; Othman, M.H.D.; Singh, D.; Goh, H.H. Promoting digital transformation in waste collection service and waste recycling in Moscow (Russia): Applying a circular economy paradigm to mitigate climate change impacts on the environment. J. Clean. Prod. 2022, 354, 131604. [Google Scholar] [CrossRef]

- Samarasinghe, K.; Wijayatunga, P.D.C. Techno-economic feasibility and environmental sustainability of waste-to-energy in a circular economy: Sri Lanka case study. Energy Sustain. Dev. 2022, 68, 308–317. [Google Scholar] [CrossRef]

- Herrador, M.; Cho, Y.; Park, P.H. Latest circular economy policy and direction in the Republic of Korea: Room for enhancements. J. Clean. Prod. 2020, 269, 122336. [Google Scholar] [CrossRef]

- Dagilienė, L.; Varaniūtė, V.; Bruneckienė, J. Local governments’ perspective on implementing the circular economy: A framework for future solutions. J. Clean. Prod. 2021, 310, 127340. [Google Scholar] [CrossRef]

- Melles, G. Figuring the transition from circular economy to circular society in Australia. Sustainability 2021, 13, 10601. [Google Scholar] [CrossRef]

- Sharma, H.B.; Vanapalli, K.R.; Samal, B.; Cheela, V.S.; Dubey, B.K.; Bhattacharya, J. Circular economy approach in solid waste management system to achieve UN-SDGs: Solutions for post-COVID recovery. Sci. Total Environ. 2021, 800, 149605. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.J.; Colon, J.; Ponsá, S.; Al-Mansour, F.; et al. Municipal solid waste management and waste-to-energy in the context of a circular economy and energy recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Desmond, P.; Asamba, M. Accelerating the transition to a circular economy in Africa: Case studies from Kenya and South Africa. In The Circular Economy and the Global South; Routledge: New York, NY, USA, 2019; pp. 152–172. [Google Scholar]

- Tsai, F.M.; Bui, T.D.; Tseng, M.L.; Lim, M.K.; Hu, J. Municipal solid waste management in a circular economy: A data-driven bibliometric analysis. J. Clean. Prod. 2020, 275, 124132. [Google Scholar] [CrossRef]

- Ranjbari, M.; Saidani, M.; Esfandabadi, Z.S.; Peng, W.; Lam, S.S.; Aghbashlo, M.; Quatraro, F.; Tabatabaei, M. Two decades of research on waste management in the circular economy: Insights from bibliometric, text mining, and content analyses. J. Clean. Prod. 2021, 314, 128009. [Google Scholar] [CrossRef]

- Chioatto, E.; Sospiro, P. Transition from waste management to circular economy: The European Union roadmap. Environ. Dev. Sustain. 2023, 25, 249–276. [Google Scholar] [CrossRef]

| Waste Type | Location | Country Development | Findings | Ref. |

|---|---|---|---|---|

| MSW | New Zealand | Developed | To reach a CE, there are several challenges in New Zealand, such as a low-to-moderate understanding of the community, higher costs, policy uncertainty, technology readiness levels, and limited commercial success. | [100] |

| MW | Poland | Developed | Increase CE awareness among the Polish community by attaining 55% recycling by 2025 and implementing CE successfully with national and international funds. | [101] |

| Biomass | Madagascar | Developing | Madagascar’s energy supply is 80% biomass; gasification and torrefaction would help Madagascar’s energy “crisis” by utilizing wastes and moving toward a CE. | [102] |

| Food waste | Costa Rica | Developing | CE is applicable for different activities which can be shifted from one scenario to another, such as landfilling to the valorization of FW to improve WM. | [103] |

| MSW | Norway | Developed | CE creates an opportunity for WtE to strengthen and expand its role in growing new value chains, such as the valorization of new waste streams and secondary raw material production, which can be used to fund the building of the required infrastructure. | [104] |

| SW | Singapore | Singapore can reach 70% recycling by 2050 and reduce 30% landfill usage by 2030; the Singapore zero waste initiative includes government legislation, tactics, and incentives; The Sustainable Singapore Blueprint and Resource Sustainable Bill governs the CE in Singapore. | [105] | |

| SW | France | Developed | Reducing anthropogenic resource usage by 30% by 2030, 50% less non-hazardous trash dumping by 2050, 100% plastic recycling by 2050; plastic recycling reduces GHG; CE development creates 300,000 jobs. | [105] |

| MSW | Demark | Developed | GHG affects MSW generation, income, and urban population; Denmark regularly switches to a CE; waste policy efforts should focus on changing people’s behavior and firms’ decisions. | [94] |

| CW | China | Developing | Currently, the CE level is 58%, which should be 100%; to improve the adoption of the CE in the building sector, serious steps should be considered by all the stakeholders. | [106] |

| IW | India | Developing | The initiatives by the government will create employment opportunities in the local community resulting in IW reduction without exerting any additional expenditure. | [107] |

| MSW | Indonesia | Developing | Strict environmental legislation and nationwide recycling program enforcement are needed; use economic mechanisms, legal enforcement, and resource recovery to support integrated SWM and speed up its long-term transition towards a CE nationwide. | [108] |

| C&DW | Malaysia | Developing | There is a need for an integrated framework to guide the construction actors for effective and sustainable WM toward CE implementation to create a sustainable future. | [109] |

| SW | Pakistan | Developing | The government should be more responsible for formulating new policies following the CE approach; this can be accomplished by adopting new smart waste technologies in sustainable WM practices. | [110] |

| SW | Bangladesh | Developing | Eight CE challenges—lack of technical innovation, financial support from authorities, strong legislation, a reverse logistics facility, a communication framework, CE awareness, social community pressure, and long-term strategic goals—formed the framework. | [111] |

| MSW | Russian Federation | Developed | Digitalization improves garbage storage and recycling and can assist trash recycling businesses in converting to a CE. | [112] |

| WtE | Sri Lanka | Developing | WtE projects could financially and economically assist CEs; WtE plants have far lower marginal generation costs than thermal power plants. | [113] |

| PW | South Korea | Developed | The 9R model helps Korean firms and policymakers examine and improve their circularity; also, nations require the continuous efforts of consumers, governments, and companies to achieve an upright CE. | [114] |

| MW | Lithuania | Developed | Learning, vision sharing, reflexive governance, regulation, and network negotiation create a local administration for a CE framework. | [115] |

| MSW | Australia | Developed | Waste trading pinch analysis improves resource sharing and facility usage for a sustainable and mutually beneficial CE transition; social behavior analysis helps forecast waste creation during transitions and improves trash trading designs. | [116] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rezania, S.; Oryani, B.; Nasrollahi, V.R.; Darajeh, N.; Lotfi Ghahroud, M.; Mehranzamir, K. Review on Waste-to-Energy Approaches toward a Circular Economy in Developed and Developing Countries. Processes 2023, 11, 2566. https://doi.org/10.3390/pr11092566

Rezania S, Oryani B, Nasrollahi VR, Darajeh N, Lotfi Ghahroud M, Mehranzamir K. Review on Waste-to-Energy Approaches toward a Circular Economy in Developed and Developing Countries. Processes. 2023; 11(9):2566. https://doi.org/10.3390/pr11092566

Chicago/Turabian StyleRezania, Shahabaldin, Bahareh Oryani, Vahid Reza Nasrollahi, Negisa Darajeh, Majid Lotfi Ghahroud, and Kamyar Mehranzamir. 2023. "Review on Waste-to-Energy Approaches toward a Circular Economy in Developed and Developing Countries" Processes 11, no. 9: 2566. https://doi.org/10.3390/pr11092566

APA StyleRezania, S., Oryani, B., Nasrollahi, V. R., Darajeh, N., Lotfi Ghahroud, M., & Mehranzamir, K. (2023). Review on Waste-to-Energy Approaches toward a Circular Economy in Developed and Developing Countries. Processes, 11(9), 2566. https://doi.org/10.3390/pr11092566