All-Factor Average Method of Reserve Parameters with Crude Oil Volume and Mass Constraints

Abstract

:1. Introduction

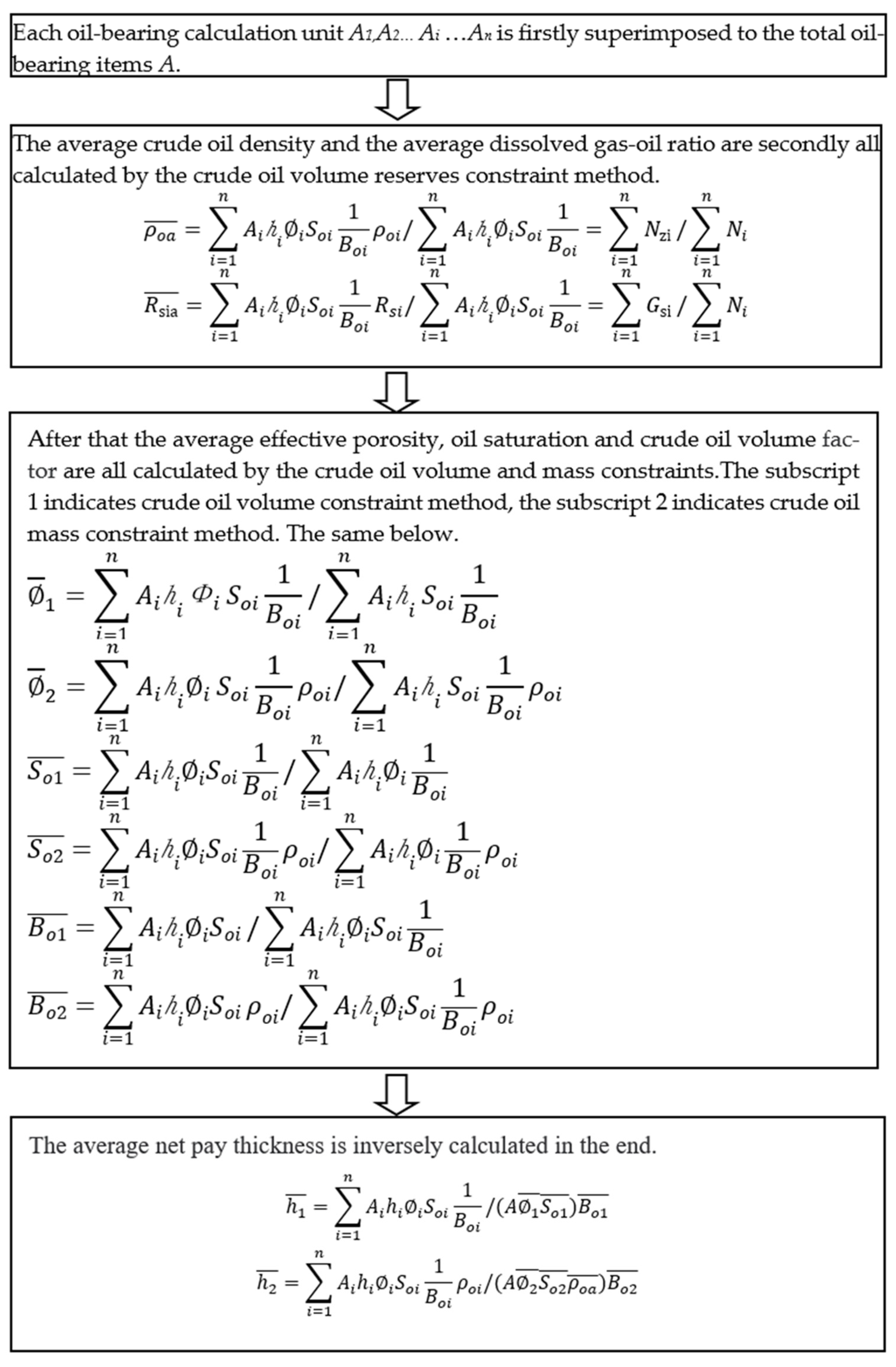

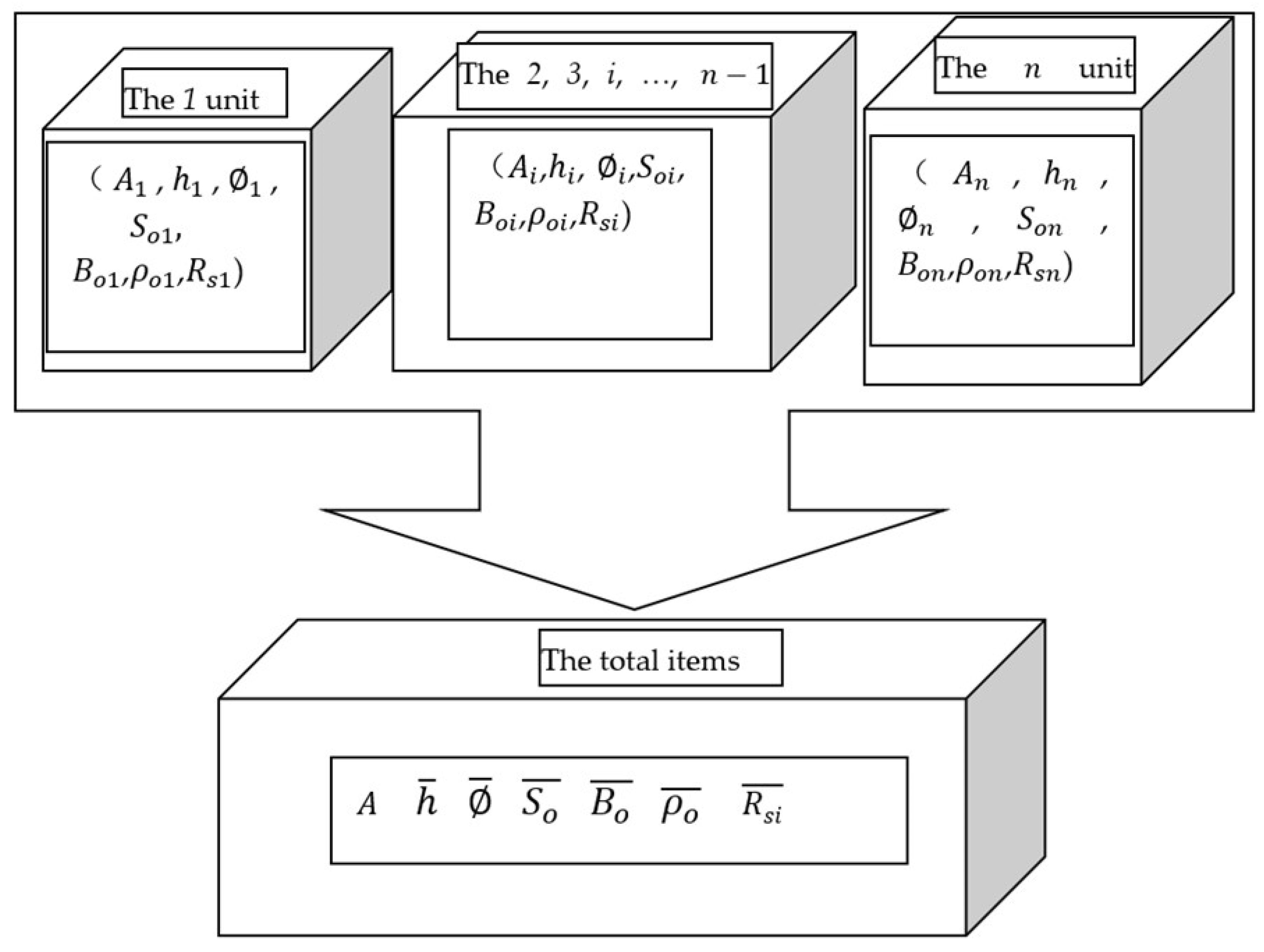

2. The All-Factor Average Method of Reserve Parameters with Crude Oil Volume and Mass Constraints

2.1. Some Fundamentas

2.2. Calculation Steps of the All-Factor Average Method (Figure 2)

2.2.1. The Oil-Bearing Area A of the Total Items

2.2.2. The Average Crude Oil Density and the Average Dissolved Gas–Oil Ratio

2.2.3. The Average Effective Porosity, Oil Saturation, and Crude Oil Volume Factor

- (1)

- The average effective porosity is calculated using the crude oil volume and mass constraints.

- (2)

- The oil saturation is calculated using the crude oil volume and mass constraints.

- (3)

- The crude oil volume factor is calculated using the crude oil volume and mass constraints.

2.2.4. The Net Pay Thickness of the Total Items

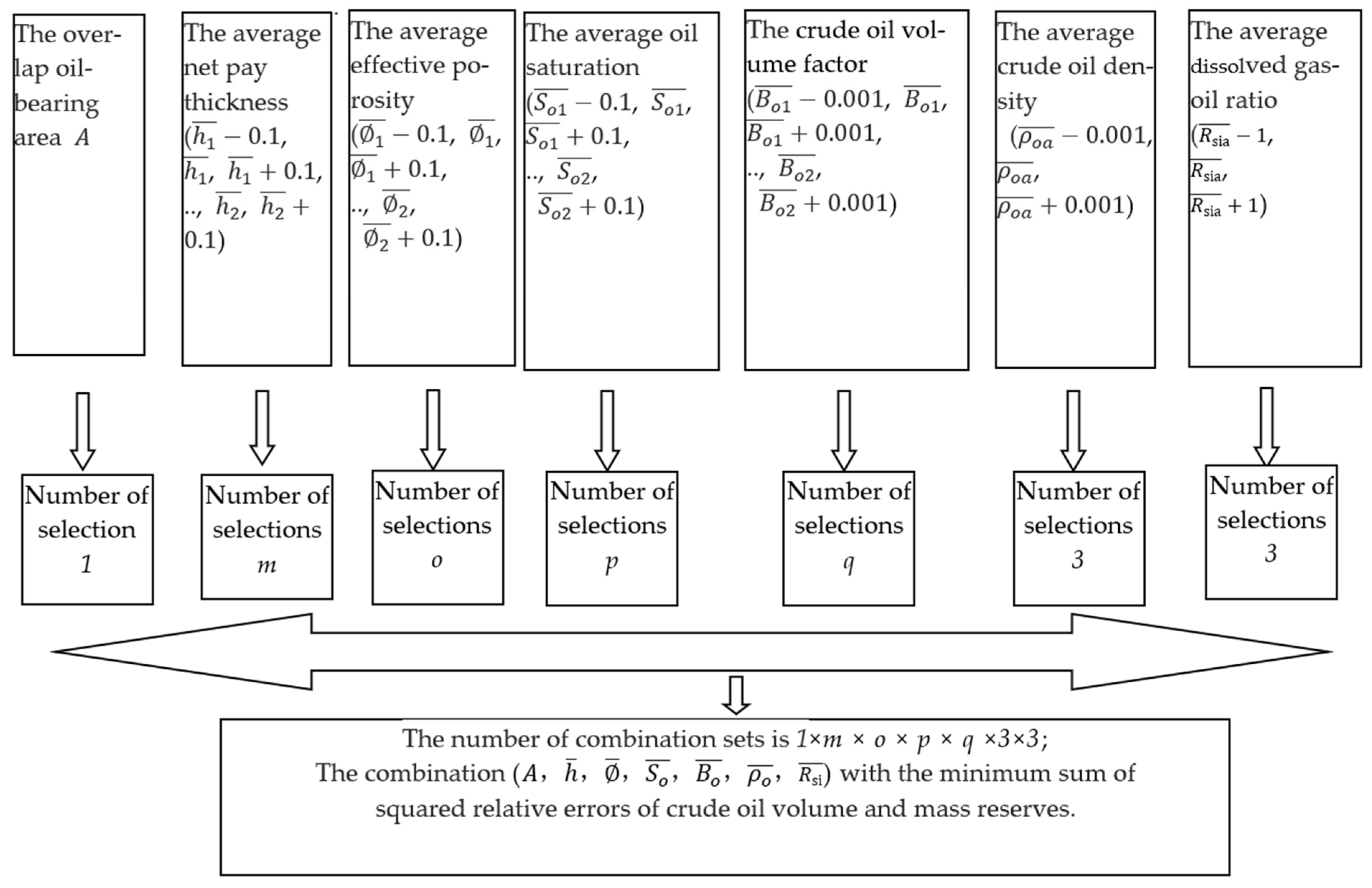

3. Method to Reduce Carry Error

3.1. Full Permutation Combination Selection Method (Figure 3)

3.2. Operation Steps to Reduce Carry Error

4. Discussion

5. Conclusions

5.1. The All-Factor Parameter Average Method

5.2. The Full Permutation Combination Selection Method

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, T.; Fan, S.; Chen, Y.; Hu, Y.; Wu, Q. Calculation Method of Petroleum and Natural Gas Reserves, 2nd ed.; Petroleum Industry Press: Beijing, China, 1998; pp. 109–114. [Google Scholar]

- Chen, G. Logging reserve calculation method for carbonate gas reservoir. Well Logging Technol. 1987, 11, 1–12. [Google Scholar] [CrossRef]

- Xiong, Q.; Wang, Z.; Cai, Y.; Wang, H.; Zhao, Y. Methods and Techniques of Petroleum Reserves Calculation for Heterogeneous Oil Field. Geol. Rev. 1996, 42, 296–301. [Google Scholar] [CrossRef]

- Wang, T. The Determination of Reserves Parameters of Jurassic and Triassic in Baihe Oil Region in the Ordos Basin. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 6 June 2014; pp. 61–64. [Google Scholar] [CrossRef]

- Yan, G.; Liu, Z.; Song, H.; Han, X.; Wang, X. Effect of Vertical Subdivision of Computing Units on Reserve Parameters and Results of Multilayer Structural Reservoir. Geol. Resour. 2020, 29, 342–350. [Google Scholar] [CrossRef]

- Lei, Q.; Song, Z.; Tang, C.; Li, N. On Reserve Estimate of Heterogeneous Reservoir in the Lower Es3 of Block Shen-84. Well Logging Technol. 2000, 24, 47–51. [Google Scholar] [CrossRef]

- Deng, P. Research and Application “SEC Estimation Approach for Oil&Gas Reserves” in China; China University of Geosciences: Beijing, China, 2006; pp. 95–103. [Google Scholar]

- Zhang, D.; Chen, C. Application of Excel Subroutine in Statistics of Reserves Parameters. Well Logging Technol. 2006, 30, 541–543. [Google Scholar] [CrossRef]

- Ma, Y. Study on OOIP Calculation of Heterogeneous Reservoirs Using Volumetric Method. Sci. Technol. Eng. 2011, 11, 3540–3542. [Google Scholar] [CrossRef]

- Wang, J. A Study on Evaluation of the Oil Reserves in Anding Zichang. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 20 May 2012; pp. 27–30. [Google Scholar] [CrossRef]

- Guo, X. Study on calculation method of lithologic reservoir reserve parameters of Chang 2 Member of Yanchang Formation in Xigou Oilfield. Inn. Mong. Petrochem. Ind. 2009, 4, 178–190. [Google Scholar]

- Jiang, W.; Mo, R.; Zhang, Y.; Fu, C. Improved Voronoi diagram for optimizing the calculation of oil and gas reserves parameter. Complex Hydrocarb. Reserv. 2013, 6, 7–9. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, C.; Geng, B.; Su, C.; Song, X.; Wang, Y.; Li, Y.; Fang, L.; Qin, D.; Zhai, X.; et al. Study on modified averaging method of reserves parameters. J. Yangtze Univ. Nat. Sci. Ed. Sci. Eng. 2012, 9, 61–64. [Google Scholar]

- DZ/T 0217-2020; Regulation of Petroleum Reserves Estimation. Geological and Mineral Industry Standards of the People’s Republic of China; Ministry of Natural Resources of the People’s Republic of China: Beijing, China, 2020.

| Unit | Oil-Bearing Area km2 | Net Pay Thickness m | Effective Porosity % | Oil Saturation % | Crude Oil Density t/m3 | Crude Oil Volume Factor | Crude Oil Reserves in Volume 104 m3 | Crude Oil Reserves in Mass 104 t |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.15 | 3.0 | 34.0 | 55.0 | 0.848 | 1.300 | 49.6269230769231 | 42.0836307692308 |

| 2 | 1.65 | 5.0 | 32.0 | 60.0 | 0.848 | 1.300 | 121.846153846154 | 103.325538461538 |

| 3 | 2.25 | 4.5 | 25.0 | 62.0 | 0.870 | 1.250 | 125.55 | 109.2285 |

| 4 | 3.11 | 7.0 | 24.0 | 65.0 | 0.874 | 1.240 | 273.88064516129 | 239.371683870968 |

| 5 | 2.80 | 6.5 | 22.0 | 68.0 | 0.878 | 1.230 | 221.359349593496 | 194.353508943089 |

| Total items | 5.00 | 792.263071677863 (the total) | 688.362862044826 (the total) |

| Average Method | Oil- Bearing Area km2 | Net Pay Thickness m | Effective Porosity % | Oil Saturation % | Crude Oil Density t/m3 | Crude Oil Volume Factor | Crude Oil Reserves in Volume 104 m3 | Crude Oil Reserves in Mass 104 t | Absolute Error in Volume 104 m3 | Absolute Error in Mass 104 t |

|---|---|---|---|---|---|---|---|---|---|---|

| Original [1] | 5.00 | 12.359 | 25.2011489602719 | 63.6828688021935 | 0.868856427432625 | 1.25177675882291 | 792.263071677863 | 688.362862044826 | 0 | 0 |

| All-factor average method (Mass constraint) | 5.00 | 12.4820381877236 | 24.90108752874 | 63.7976714236979 | 0.868856427432625 | 1.25143771766104 | 792.263071677863 | 688.362862044826 | 0 | 0 |

| All-factor average method (Volume constraint) | 5.00 | 12.472952135769 | 24.9431197701869 | 63.7538278148721 | 0.868856427432625 | 1.25177675882291 | 792.263071677863 | 688.362862044826 | 0 | 0 |

| Unit | Oil- Bearing Area km2 | Net Pay Thickness m | Effective Porosity % | Oil Saturation % | Crude Oil Density t/m3 | Crude Oil Volume Factor | Crude Oil Reserves in Volume 104 m3 | Crude Oil Reserves in Mass 104 t |

|---|---|---|---|---|---|---|---|---|

| 1 | 5.00 | 5.0 | 25.0 | 75.0 | 0.900 | 1.010 | 464.108910891089 | 417.69801980198 |

| 2 | 2.50 | 10.0 | 3.0 | 55.0 | 0.800 | 1.200 | 34.375 | 27.5 |

| Total items | 5.00 | 498.483910891089 (the total) | 445.19801980198 (the total) | |||||

| Original [1] | 5.00 | 10.0 | 14.0 | 72.8571428571429 | 0.893104090373037 | 1.02310222829123 | 498.483910891089 | 445.19801980198 |

| All-factor average method (Mass constraint) | 5.00 | 8.05706813550352 | 17.2059948979592 | 73.352365415987 | 0.893104090373037 | 1.01997565986699 | 498.483910891089 | 445.19801980198 |

| All-factor average method (Volume constraint) | 5.00 | 8.38038009403774 | 16.6035726554449 | 73.1653042688465 | 0.893104090373037 | 1.02114944428204 | 498.483910891089 | 445.19801980198 |

| Average Method | Oil-Bearing Area km2 | Net Pay Thickness m | Effective Porosity % | Oil Saturation % | Crude Oil Density t/m3 | Crude Oil Volume Factor | Crude Oil Reserves in Volume 104 m3 | Crude Oil Reserves in Mass 104 t | Absolute Error in Volume 104 m3 | Absolute Error in Mass 104 t |

|---|---|---|---|---|---|---|---|---|---|---|

| Total items | 5.00 | 792.27 (The total) | 688.36 (The total) | |||||||

| Original [1] | 5.00 | 12.4 | 25.2 | 63.7 | 0.869 | 1.252 | 794.93 | 690.79 | 2.66 | 2.43 |

| All-factor average method (Mass constraint) | 5.00 | 12.5 | 24.9 | 63.8 | 0.869 | 1.251 | 793.68 | 689.70 | 1.41 | 1.34 |

| All-factor average method (Volume constraint) | 5.00 | 12.5 | 24.9 | 63.8 | 0.869 | 1.252 | 793.04 | 689.15 | 0.77 | 0.79 |

| Average Method | Oil-Bearing Area km2 | Net Pay Thickness m | Effective Porosity % | Oil Saturation % | Crude Oil Density t/m3 | Crude Oil Volume Factor | Crude Oil Reserves in Volume 104 m3 | Crude Oil Reserves in Mass 104 t | Absolute Error in Volume 104 m3 | Absolute Error in Mass 104 t |

|---|---|---|---|---|---|---|---|---|---|---|

| Total items | 5.00 | 498.49 (The total) | 445.20 (The total) | |||||||

| Original [1] | 5.00 | 10.0 | 14.0 | 72.9 | 0.893 | 1.023 | 498.83 | 445.45 | 0.34 | 0.25 |

| All-factor average method (Mass constraint) | 5.00 | 8.1 | 17.2 | 73.4 | 0.893 | 1.020 | 501.28 | 447.64 | 2.79 | 2.44 |

| All-factor average method (Volume constraint) | 5.00 | 8.4 | 16.6 | 73.2 | 0.893 | 1.021 | 499.85 | 446.37 | 1.36 | 1.17 |

| Average Method | Oil- Bearing Area km2 | Net Pay Thickness m | Effective Porosity % | Oil Saturation % | Crude Oil Volume Factor | Crude Oil Density t/m3 | Oil Reserves | Absolute Error in Volume 104 m3 | Absolute Error in Mass 104 t | Relative Error in Volume % | Relative Error in Mass % | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| In Volume 104 m3 | In Mass 104 t | |||||||||||

| Total items | 5.00 | 792.27 (the total) | 688.36 (the total) | |||||||||

| The Original average method [1] | 5.00 | 12.4 | 25.2 | 63.7 | 1.252 | 0.869 | 794.93 | 690.79 | 2.66 | 2.43 | 0.34 | 0.35 |

| All-factor average method | 5.00 | 12.5 | 24.8 | 63.9 | 1.250 | 0.869 | 792.36 | 688.56 | 0.09 | 0.20 | 0.01 | 0.03 |

| Average Method | Oil- Bearing Area km2 | Net Pay Thickness m | Effective Porosity % | Oil Saturation % | Crude Oil Volume Factor | Crude Oil Density t/m3 | Oil Reserves | Absolute Error in Volume 104 m3 | Absolute Error in Mass 104t | Relative Error in Volume % | Relative Error in Mass % | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| In Volume 104 m3 | In Mass 104 t | |||||||||||

| Total items | 5.00 | 498.49 (The total) | 445.20 (The total) | |||||||||

| The Original average method [1] | 5.00 | 10.0 | 14.0 | 72.9 | 1.023 | 0.893 | 498.83 | 445.45 | 0.34 | 0.25 | 0.07 | 0.06 |

| All-factor average method | 5.00 | 8.3 | 16.7 | 73.5 | 1.022 | 0.893 | 498.43 | 445.09 | −0.06 | −0.11 | −0.01 | −0.03 |

| Unit | Oil-Bearing Area km2 | Net Pay Thickness m | Effective Porosity % | Oil Saturation % | Crude Oil Density t/m3 | Crude Oil Volume Factor | Crude Oil Reserves in Volume 104 m3 | Crude Oil Reserves in Mass 104 t |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.15 | 3.0 | 34.0 | 55.0 | 0.848 | 1.300 | 49.63 | 42.08 |

| 2 | 1.65 | 5.0 | 32.0 | 60.0 | 0.848 | 1.300 | 121.85 | 103.33 |

| 3 | 2.25 | 4.5 | 25.0 | 62.0 | 0.870 | 1.250 | 125.55 | 109.23 |

| 4 | 3.11 | 7.0 | 24.0 | 65.0 | 0.874 | 1.240 | 273.88 | 239.37 |

| 5 | 2.80 | 6.5 | 22.0 | 68.0 | 0.878 | 1.230 | 221.36 | 194.35 |

| Total items | 5.00 | 12.5 | 24.8 | 63.9 | 0.869 | 1.250 | 792.27 | 688.36 |

| Unit | Oil- Bearing Area km2 | Net Pay Thickness m | Effective Porosity % | Oil Saturation % | Crude Oil Density t/m3 | Crude Oil Volume Factor | Crude Oil Reserves in Volume 104 m3 | Crude Oil Reserves in Mass 104 t |

|---|---|---|---|---|---|---|---|---|

| 1 | 5.00 | 5.0 | 25.0 | 75.0 | 0.900 | 1.010 | 464.11 | 417.70 |

| 2 | 2.50 | 10.0 | 3.0 | 55.0 | 0.800 | 1.200 | 34.38 | 27.50 |

| Total items | 5.00 | 8.3 | 16.7 | 73.5 | 0.893 | 1.022 | 498.49 | 445.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Guo, H.; Wu, Y.; Chen, C.; Li, A.; Zhang, J.; Wang, Y. All-Factor Average Method of Reserve Parameters with Crude Oil Volume and Mass Constraints. Processes 2023, 11, 2558. https://doi.org/10.3390/pr11092558

Zhang D, Guo H, Wu Y, Chen C, Li A, Zhang J, Wang Y. All-Factor Average Method of Reserve Parameters with Crude Oil Volume and Mass Constraints. Processes. 2023; 11(9):2558. https://doi.org/10.3390/pr11092558

Chicago/Turabian StyleZhang, Doujuan, Haimin Guo, Yuyan Wu, Cunyuan Chen, Ao Li, Jinyan Zhang, and Yonggang Wang. 2023. "All-Factor Average Method of Reserve Parameters with Crude Oil Volume and Mass Constraints" Processes 11, no. 9: 2558. https://doi.org/10.3390/pr11092558

APA StyleZhang, D., Guo, H., Wu, Y., Chen, C., Li, A., Zhang, J., & Wang, Y. (2023). All-Factor Average Method of Reserve Parameters with Crude Oil Volume and Mass Constraints. Processes, 11(9), 2558. https://doi.org/10.3390/pr11092558