Factor Analysis of the Physical–Mechanical Properties for Geopolymers Based on Brick Dust and Biomass Bottom Ash as Eco-Friendly Building Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Brick Dust

2.1.2. Biomass Bottom Ashes Comming from Almond Shells Combustion and “Alperujo”

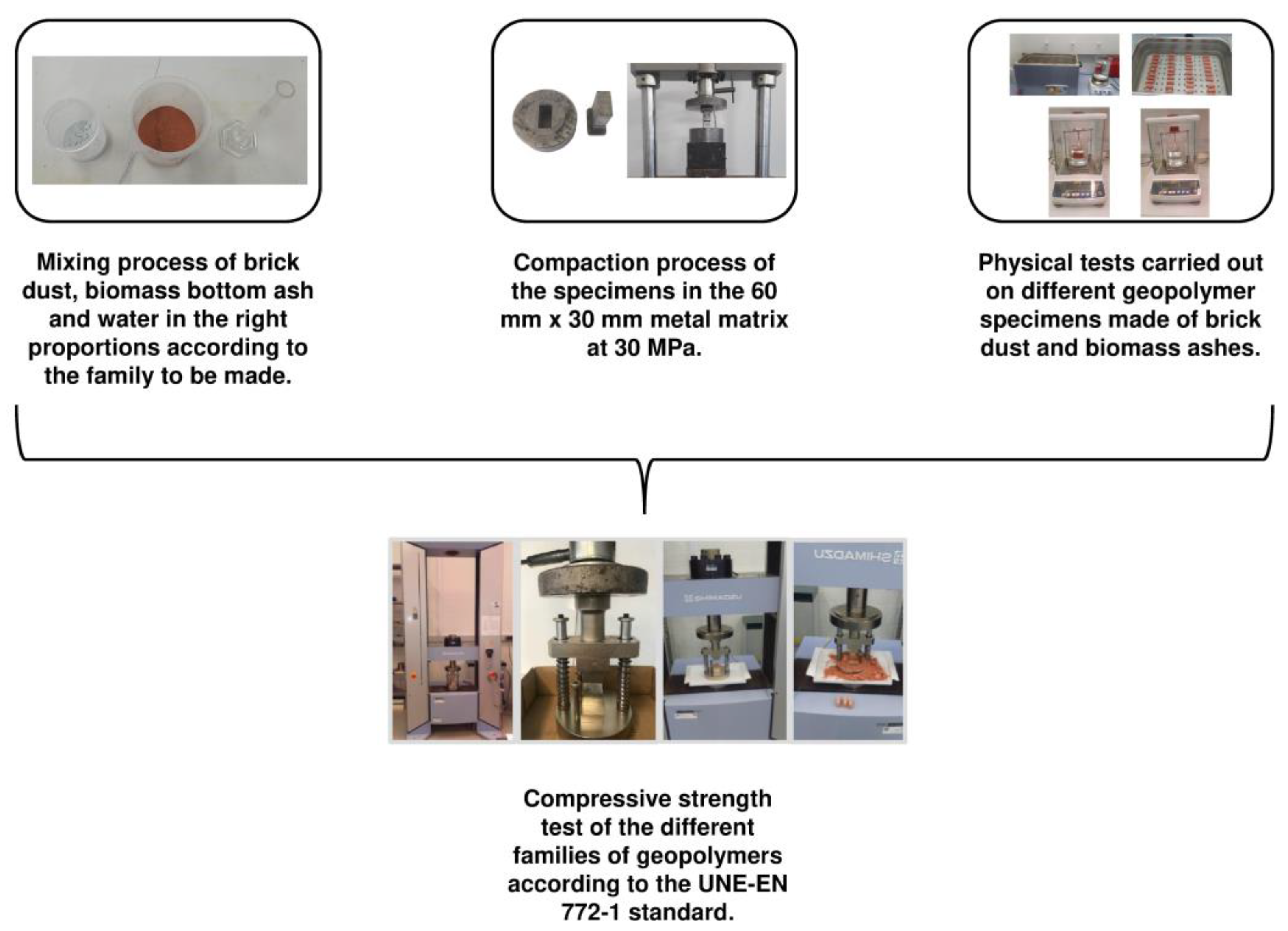

2.2. Methodology

2.2.1. Conformation of Specimens and Determination of Physical-Chemical Properties

2.2.2. Factorial Analysis

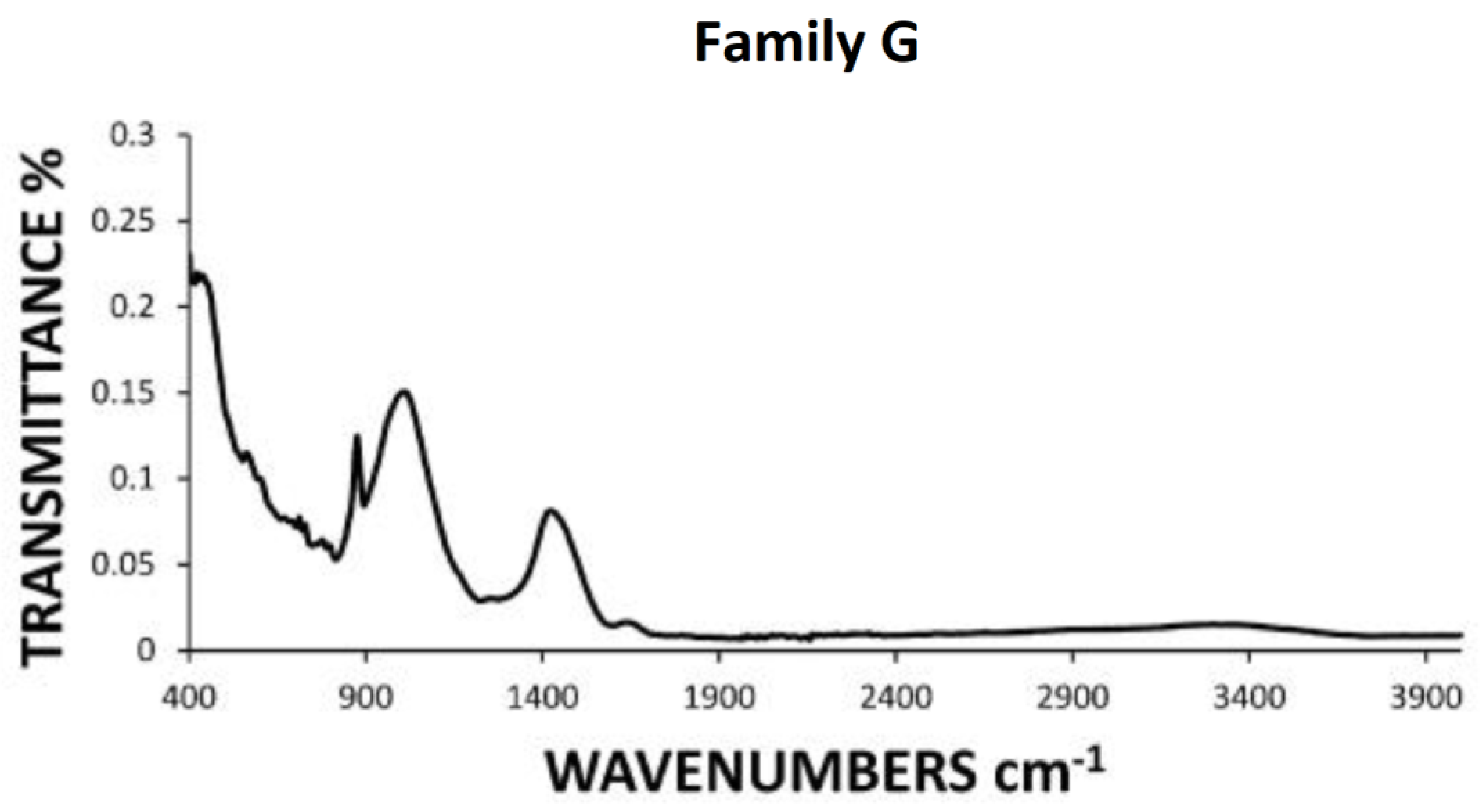

3. Results and Discussion

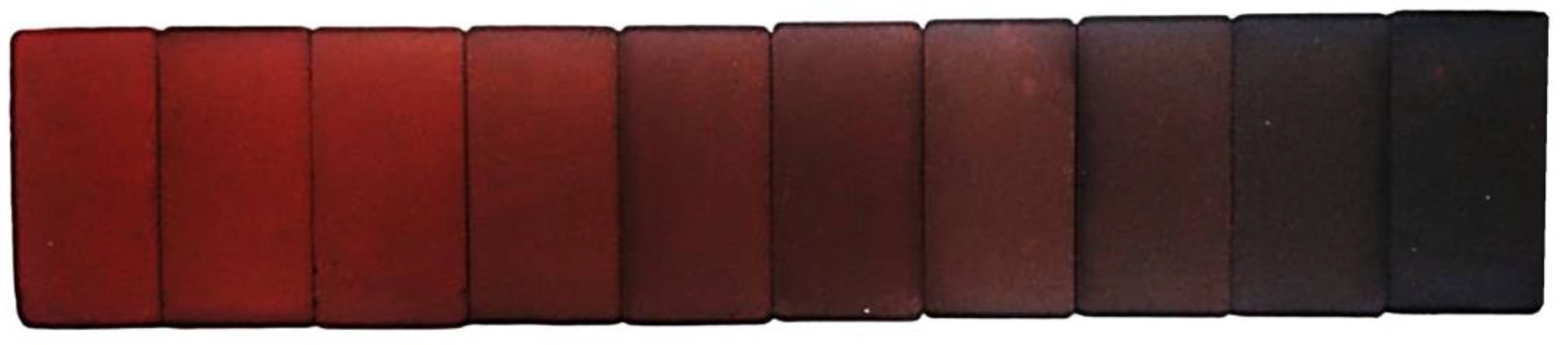

3.1. Physical Properties of the Different Families of Geopolymers Formed with Brick Dust and Biomass Bottom Ashes

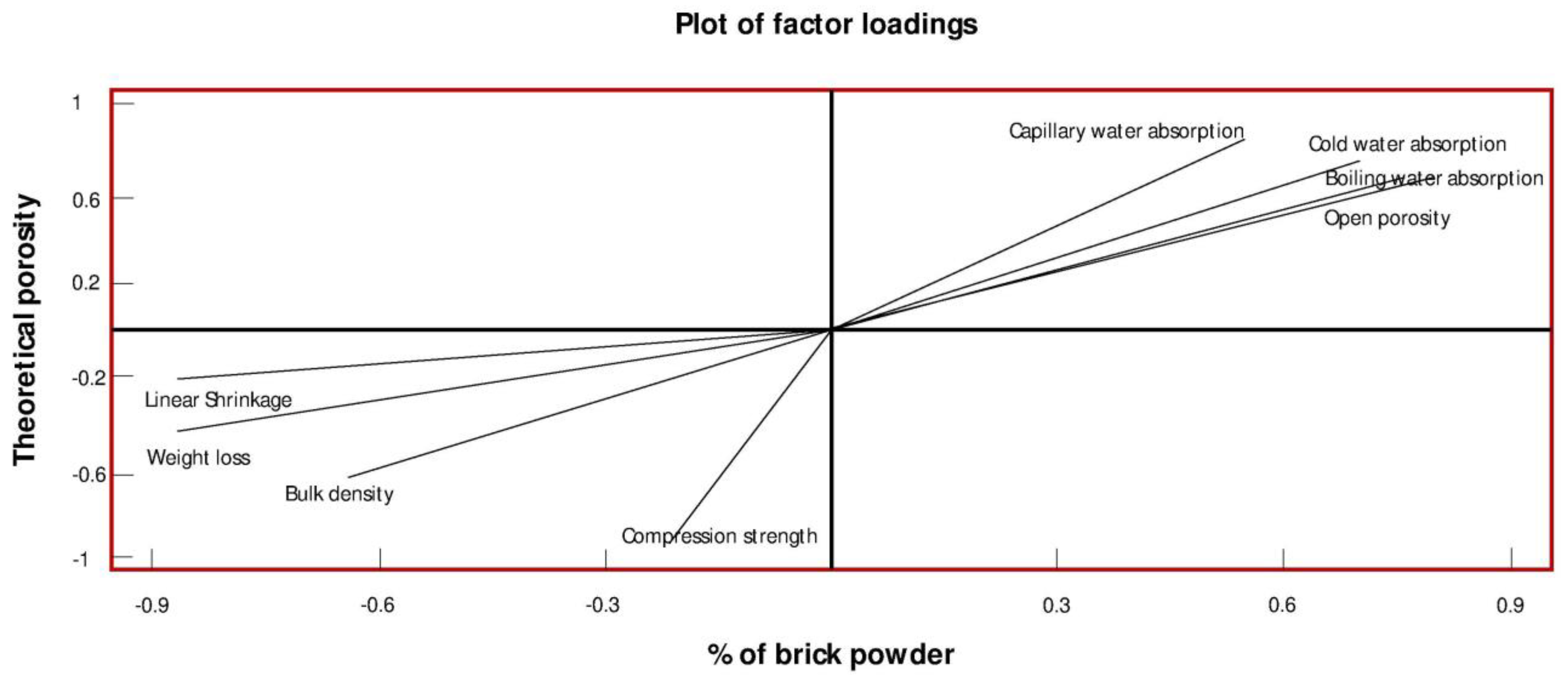

3.2. Factorial Analysis

4. Conclusions

- As the percentage of biomass bottom ashes increased, the conformation of various families of samples with varying proportions of brick dust and biomass bottom ashes showed the development of a geopolymer with a lower open porosity, lower absorption of cold water and suction, as well as a higher apparent density;

- The higher percentage of biomass bottom ashes and, consequently, the lower percentage of brick dust or “chamotte” makes creating a geopolymer with greater mechanical resistance possible. However, there is a limit on biomass bottom ashes incorporation from which the resistance decreases;

- The factorial analysis of the results demonstrated the quality of the measured data, with high percentages of correlation between them;

- The factorial analysis of the data obtained by measuring the different physical properties evaluated in the different families of geopolymers reflected a positive correlation between the absorption of water by capillarity, the absorption of cold water, the absorption of boiling water and the open porosity, as well as a positive and negative correlation with the previous properties, of mechanical strength, bulk density, weight loss and linear shrinkage;

- The factorial analysis of the physical properties of geopolymers determined statistically that there are two main factors that determine the formation of geopolymers: the percentage of brick dust and the theoretical porosity. An increase in both factors would cause greater absorption of water by capillarity, absorption of cold water, absorption of boiling water and open porosity. On the contrary, a decrease in both factors will determine a higher mechanical strength, bulk density, weight loss and linear shrinkage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Riaz, H.; Iqbal Ahmad Khan, K.; Ullah, F.; Bilal Tahir, M.; Alqurashi, M.; Alsulami, B.T. Key factors for implementation of total quality management in construction Sector: A system dynamics approach. Ain Shams Eng. J. 2023, 14, 101903. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, B.; Du, J.; Liu, C.; Li, H.; Wang, S. Internationalization trends of carbon emission linkages: A case study on the construction sector. J. Clean. Prod. 2020, 270, 122433. [Google Scholar] [CrossRef]

- Sani, R.; Nzihou, A. Production of clay ceramics using agricultural wastes: Study of properties, energy savings and environmental indicators. Appl. Clay Sci. 2017, 146, 106–114. [Google Scholar] [CrossRef]

- Barros, M.C.; Bello, P.; Roca, E.; Casares, J.J. Integrated pollution prevention and control for heavy ceramic industry in Galicia (NW Spain). J. Hazard. Mater. 2007, 141, 680–692. [Google Scholar] [CrossRef]

- Shi, Z. Green manufacturing of silicate materials using desert sand as a raw-material resource. Constr. Build. Mater. 2022, 338, 127539. [Google Scholar] [CrossRef]

- Furszyfer Del Rio, D.D.; Sovacool, B.K.; Foley, A.M.; Griffiths, S.; Bazilian, M.; Kim, J.; Rooney, D. Decarbonizing the ceramics industry: A systematic and critical review of policy options, developments and sociotechnical systems. Renew. Sustain. Energy Rev. 2022, 157, 112081. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Vieira, C.M.F. On the production of fired clay bricks from waste materials: A critical update. Constr. Build. Mater. 2014, 68, 599–610. [Google Scholar] [CrossRef]

- Martínez, C.; Cotes, T.; Corpas, F.A. Recovering wastes from the paper industry: Development of ceramic materials. Fuel Process. Technol. 2012, 103, 117–124. [Google Scholar] [CrossRef]

- Bertozzi, C. How is the construction sector perceiving and integrating the circular economy paradigm? Insights from the Brussels experience. City Cult. Soc. 2022, 29, 100446. [Google Scholar] [CrossRef]

- González, I.; Barba-Brioso, C.; Campos, P.; Romero, A.; Galán, E. Reduction of CO2 diffuse emissions from the traditional ceramic industry by the addition of Si-Al raw material. J. Environ. Manag. 2016, 180, 190–196. [Google Scholar] [CrossRef]

- Fuertes, V.; Reinosa, J.J.; Fernández, J.F.; Enríquez, E. Engineered feldspar-based ceramics: A review of their potential in ceramic industry. J. Eur. Ceram. Soc. 2022, 42, 307–326. [Google Scholar] [CrossRef]

- Kovářík, T.; Hájek, J.; Pola, M.; Rieger, D.; Svoboda, M.; Beneš, J.; Šutta, P.; Deshmukh, K.; Jandová, V. Cellular ceramic foam derived from potassium-based geopolymer composite: Thermal, mechanical and structural properties. Mater. Des. 2021, 198, 109355. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers and geopolymeric materials. J. Therm. Anal. 1989, 35, 429–441. [Google Scholar] [CrossRef]

- Raza, M.H.; Zhong, R.Y. A sustainable roadmap for additive manufacturing using geopolymers in construction industry. Resour. Conserv. Recycl. 2022, 186, 106592. [Google Scholar] [CrossRef]

- San Nicolas, R.V.R.; Walkley, B.; van Deventer, J.S.J. Fly ash-based geopolymer chemistry and behavior. In Coal Combustion Products (ccp’s); Woodhead Publishing: Cambridge, UK, 2017; pp. 185–214. [Google Scholar]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Assessment of important parameters involved in the synthesis of geopolymer composites: A review. Constr. Build. Mater. 2020, 264, 120276. [Google Scholar] [CrossRef]

- Kaplan, G.; Öz, A.; Bayrak, B.; Görkem Alcan, H.; Çelebi, O.; Cüneyt Aydın, A. Effect of quartz powder on mid-strength fly ash geopolymers at short curing time and low curing temperature. Constr. Build. Mater. 2022, 329, 127153. [Google Scholar] [CrossRef]

- Gao, X.; Yao, X.; Xie, R.; Li, X.; Cheng, J.; Yang, T. Performance of fly ash-based geopolymer mortars with waste cathode ray tubes glass fine aggregate: A comparative study with cement mortars. Constr. Build. Mater. 2022, 344, 128243. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Abd Ellatief, M.; Heneigel, A.M.; Abd Elrahman, M. Characteristics of eco-friendly ultra-high-performance geopolymer concrete incorporating waste materials. Ceram. Int. 2022, 48, 19662–19674. [Google Scholar] [CrossRef]

- Choeycharoen, P.; Sornlar, W.; Wannagon, A. A sustainable bottom ash-based alkali-activated materials and geopolymers synthesized by using activator solutions from industrial wastes. J. Build. Eng. 2022, 54, 104659. [Google Scholar] [CrossRef]

- Yavuz, E.; Kul Gul, N.I.; Kockal, N.U. Characterization of class C and F fly ashes based geopolymers incorporating silica fume. Ceram. Int. 2022, 48, 32213–32225. [Google Scholar] [CrossRef]

- Premkumar, R.; Chokkalingam, R.B.; Rajesh, S. Performance of fly ash based geopolymer concrete with partial replacement of fine aggregate by steel mill slag. Mater. Today Proc. 2022, 59, 496–500. [Google Scholar] [CrossRef]

- Allaoui, D.; Nadi, M.; Hattani, F.; Majdoubi, H.; Haddaji, Y.; Mansouri, S.; Oumam, M.; Hannache, H.; Manoun, B. Eco-friendly geopolymer concrete based on metakaolin and ceramics sanitaryware wastes. Ceram. Int. 2022, 48, 34793–34802. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Heniegal, A.M.; Abdellatief, M.; Tayeh, B.A.; Elrahman, M.A. Properties of ultra-high performance geopolymer concrete incorporating recycled waste glass. Case Stud. Constr. Mater. 2022, 17, e01393. [Google Scholar] [CrossRef]

- Riofrio, A.; Cornejo, M.; Baykara, H. Environmental performance of bamboo fibers and sugarcane bagasse reinforced metakaolin-based geopolymers. Case Stud. Constr. Mater. 2022, 17, e01150. [Google Scholar] [CrossRef]

- Suresh Kumar, A.; Muthukannan, M.; Arunkumar, K.; Sriram, M.; Vigneshwar, R.; Gulshan Sikkandar, A. Development of eco-friendly geopolymer concrete by utilizing hazardous industrial waste materials. Mater. Today Proc. 2022, 66, 2215–2225. [Google Scholar] [CrossRef]

- Oshani, F.; Allahverdi, A.; Kargari, A.; Norouzbeigi, R.; Mahmoodi, N.M. Effect of preparation parameters on properties of metakaolin-based geopolymer activated by silica fume- sodium hydroxide alkaline blend. J. Build. Eng. 2022, 60, 104984. [Google Scholar] [CrossRef]

- González-García, D.M.; Téllez-Jurado, L.; Jiménez-Álvarez, F.J.; Zarazua-Villalobos, L.; Balmori-Ramírez, H. Evolution of a natural pozzolan-based geopolymer alkalized in the presence of sodium or potassium silicate/hydroxide solution. Constr. Build. Mater. 2022, 321, 126305. [Google Scholar] [CrossRef]

- Scanferla, P.; Gharzouni, A.; Texier-Mandoki, N.; Bourbon, X.; Rossignol, S. Effects of potassium-silicate, sands and carbonates concentrations on metakaolin-based geopolymers for high-temperature applications. Open Ceram. 2022, 10, 100257. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.S.; Debbarma, S.; Rashid, R.S.M. Fire resistance of geopolymer concrete: A critical review. Constr. Build. Mater. 2022, 324, 126722. [Google Scholar] [CrossRef]

- Aziz, A.; Stocker, O.; El Amrani El Hassani, I.E.; Laborier, A.P.; Jacotot, E.; El Khadiri, A.; El Bouari, A. Effect of blast-furnace slag on physicochemical properties of pozzolan-based geopolymers. Mater. Chem. Phys. 2021, 258, 123880. [Google Scholar] [CrossRef]

- Kuranlı, Ö.F.; Uysal, M.; Abbas, M.T.; Cosgun, T.; Niş, A.; Aygörmez, Y.; Canpolat, O.; Al-mashhadani, M.M. Evaluation of slag/fly ash based geopolymer concrete with steel, polypropylene and polyamide fibers. Constr. Build. Mater. 2022, 325, 126747. [Google Scholar] [CrossRef]

- Zhang, X.; Bai, C.; Qiao, Y.; Wang, X.; Jia, D.; Li, H.; Colombo, P. Porous geopolymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106629. [Google Scholar] [CrossRef]

- Asadi, I.; Baghban, M.H.; Hashemi, M.; Izadyar, N.; Sajadi, B. Phase change materials incorporated into geopolymer concrete for enhancing energy efficiency and sustainability of buildings: A review. Case Stud. Constr. Mater. 2022, 17, e01162. [Google Scholar] [CrossRef]

- Shehata, N.; Mohamed, O.A.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G. Geopolymer concrete as green building materials: Recent applications, sustainable development and circular economy potentials. Sci. Total Environ. 2022, 836, 155577. [Google Scholar] [CrossRef]

- Das, S.; Saha, P.; Prajna Jena, S.; Panda, P. Geopolymer concrete: Sustainable green concrete for reduced greenhouse gas emission—A review. Mater. Today Proc. 2022, 60, 62–71. [Google Scholar] [CrossRef]

- Ren, B.; Zhao, Y.; Bai, H.; Kang, S.; Zhang, T.; Song, S. Eco-friendly geopolymer prepared from solid wastes: A critical review. Chemosphere 2021, 267, 128900. [Google Scholar] [CrossRef]

- Hernández, D.; Astudillo, L.; Gutiérrez, M.; Tenreiro, C.; Retamal, C.; Rojas, C. Biodiesel production from an industrial residue: Alperujo. Ind. Crop. Prod. 2014, 52, 495–498. [Google Scholar] [CrossRef]

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Formulating eco-friendly geopolymer foam concrete by alkali-activation of ground brick waste. J. Clean. Prod. 2021, 325, 129180. [Google Scholar] [CrossRef]

- Lessard, J.M.; Omran, A.; Tagnit-Hamou, A.; Gagne, R. Feasibility of using biomass fly and bottom ashes in dry-cast concrete production. Constr. Build. Mater. 2017, 132, 565–577. [Google Scholar] [CrossRef]

- Monedero, E.; Hernández, J.J.; Collado, R.; Pazo, A.; Aineto, M.; Acosta, A. Evaluation of ashes from agro-industrial biomass as a component for producing construction materials. J. Clean. Prod. 2021, 318, 128517. [Google Scholar] [CrossRef]

- Cabrera, M.; Rosales, J.; Ayuso, J.; Estaire, J.; Agrela, F. Feasibility of using olive biomass bottom ash in the sub-bases of roads and rural paths. Constr. Build. Mater. 2018, 181, 266–275. [Google Scholar] [CrossRef]

- Cui, J.; Li, J.; Cui, J.; Wang, W.; Wu, Y.; Xu, B.; Chang, Y.; Liu, X.; Li, H.; Yao, D. Removal effects of a biomass bottom ash composite on tailwater phosphate and its application in a rural sewage treatment plant. Sci. Total Environ. 2022, 812, 152549. [Google Scholar] [CrossRef] [PubMed]

- Santisteban, M.; Luís, A.T.; Grande, J.A.; Aroba, J.; Dávila, J.M.; Sarmiento, A.M.; Fortes, J.C.; Cordoba, F.; Rodriguez-Pérez, Á.M. Hydrochemical Characterization of an Acid Mine Effluent from Concepcion Mine Using Classical Statistic and Fuzzy Logic Techniques. Minerals 2022, 12, 464. [Google Scholar] [CrossRef]

- Grande, J.A.; Luís, A.T.; Córdoba, F.; Leiva, M.; Dávila, J.M.; Fortes, J.C.; Santisteban, M.; da Silva, E.F.; Sarmiento, A.M. Odiel River (SW Spain), a Singular Scenario Affected by Acid Mine Drainage (AMD): Graphical and Statistical Models to Assess Diatoms and Water Hydrogeochemistry Interactions. Int. J. Environ. Res. Public Health 2021, 18, 8454. [Google Scholar] [CrossRef] [PubMed]

- Terrones-Saeta, J.M.; Portela, D.C.; Luís, A.T.; Suárez-Macías, J.; Grande, J.A. Ceramics for Building Structures Made from Contaminated Soils: A Fuzzy Logic Intelligence Approach to Circular Mining. Processes 2023, 11, 1512. [Google Scholar] [CrossRef]

- Suárez-Macías, J.; Terrones-Saeta, J.M.; Bernardo-Sánchez, A.; Ortiz-Marqués, A.; Castañón, A.M.; Corpas-Iglesias, F.A. Reutilisation of Water Contaminated by Mining Waste for the Encapsulation of Potentially Toxic Elements. Materials 2022, 15, 1076. [Google Scholar] [CrossRef]

- Terrones-Saeta, J.M.; Suárez-Macías, J.; Bernardo-Sánchez, A.; Álvarez de Prado, L.; Menéndez Fernández, M.; Corpas-Iglesias, F.A. Treatment of Soil Contaminated by Mining Activities to Prevent Contamination by Encapsulation in Ceramic Construction Materials. Materials 2021, 14, 6740. [Google Scholar] [CrossRef]

- Terrones-Saeta, J.M.; Suárez-Macías, J.; Castañón, A.M.; Gómez-Fernández, F.; Corpas-Iglesias, F.A. Retention of Pollutants Elements from Mine Tailings of Lead in Geopolymers for Construction. Materials 2021, 14, 6184. [Google Scholar] [CrossRef]

- Terrones-Saeta, J.M.; Suárez-Macías, J.; Moreno-López, E.R.; Corpas-Iglesias, F.A. Leaching of Zinc for Subsequent Recovery by Hydrometallurgical Techniques from Electric Arc Furnace Dusts and Utilisation of the Leaching Process Residues for Ceramic Materials for Construction Purposes. Metals 2021, 11, 1603. [Google Scholar] [CrossRef]

- Terrones-Saeta, J.M.; Suárez-Macías, J.; Corpas-Iglesias, F.A.; Korobiichuk, V.; Shamrai, V. Development of Ceramic Materials for the Manufacture of Bricks with Stone Cutting Sludge from Granite. Minerals 2020, 10, 621. [Google Scholar] [CrossRef]

- Suárez-Macías, J.; Terrones-Saeta, J.M.; Iglesias-Godino, F.J.; Corpas-Iglesias, F.A. Retention of Contaminants Elements from Tailings from Lead Mine Washing Plants in Ceramics for Bricks. Minerals 2020, 10, 576. [Google Scholar] [CrossRef]

| Samples Families | % Brick Dust | % BBA |

|---|---|---|

| Family A | 100 | 0 |

| Family B | 90 | 10 |

| Family C | 80 | 20 |

| Family D | 70 | 30 |

| Family E | 60 | 40 |

| Family F | 50 | 50 |

| Family G | 40 | 60 |

| Family H | 30 | 70 |

| Family I | 20 | 80 |

| Family J | 10 | 90 |

| Family | Weight Loss, % | Linear Shrinkage, % | Capillary Water Absorption, g/m2 min | Cold Water Absorption, % | Boiling Water Absorption, % | Open Porosity, % | Bulk Density, g/cm3 | Compression Strength, MPa |

|---|---|---|---|---|---|---|---|---|

| A | 4.14 | −0.06 | 4520 | 25 | 26.54 | 41.81 | 1.58 | 7.51 |

| B | 2.82 | 0.07 | 4768 | 24.36 | 25.83 | 40.53 | 1.57 | 10.51 |

| C | 3.21 | 0.12 | 4026 | 23.68 | 24.71 | 38.59 | 1.56 | 16.53 |

| D | 4.07 | 0.12 | 3475 | 21.37 | 22 | 35.12 | 1.6 | 23.98 |

| E | 4.66 | 0.11 | 3154 | 19.51 | 19.97 | 32.21 | 1.61 | 36.95 |

| F | 6.41 | 0.12 | 2130 | 17.16 | 16.17 | 27.22 | 1.68 | 46.1 |

| G | 7.66 | 0.14 | 1719 | 15.94 | 14.29 | 24.35 | 1.7 | 59.2 |

| H | 8.65 | 0.2 | 1774 | 15.25 | 12.4 | 21.32 | 1.72 | 57.19 |

| I | 10.45 | 0.3 | 1998 | 14.64 | 11.02 | 19.15 | 1.74 | 47.36 |

| J | 12.08 | 0.45 | 2103 | 14.61 | 10.43 | 17.98 | 1.72 | 29.68 |

| Boiling Water Absorption | 1 | |||||||

| Capillary water absorption | 0.9474 | 1 | ||||||

| Cold water absorption | 0.9851 | 0.9639 | 1 | |||||

| Linear Shrinkage | −0.8200 | −0.6528 | −0.7685 | 1 | ||||

| Bulk density | −0.9183 | −0.8686 | −0.8941 | 0.6797 | 1 | |||

| Weight loss | −0.9419 | −0.8217 | −0.8966 | 0.8609 | 0.8750 | 1 | ||

| Open porosity | 0.9968 | 0.9380 | 0.9820 | −0.8363 | −0.9144 | 0.9473 | 1 | |

| Compression strength | −0.8158 | −0.9263 | −0.8595 | 0.4059 | 0.7673 | 0.6127 | −0.8024 | 1.0000 |

| Boiling water absorption | Capillary water absorption | Cold water absorption | Linear Shrinkage | Bulk density | Weight loss | Open porosity | Compression strength |

| Factor Number | EIGENVALOR | Percentage of Variance | Percentage Accumulated |

|---|---|---|---|

| 1 | 6.91589 | 90.329 | 90.329 |

| 2 | 0.670119 | 8.752 | 99.081 |

| 3 | 0.0537087 | 0.701 | 99.783 |

| 4 | 0.0112696 | 0.147 | 99.930 |

| 5 | 0.00535657 | 0.070 | 100.000 |

| 6 | 0.0 | 0.000 | 100.000 |

| 7 | 0.0 | 0.000 | 100.000 |

| 8 | 0.0 | 0.000 | 100.000 |

| Variable | Factor 1 | Factor 2 |

|---|---|---|

| Boiling water absorption | 1.00174 | 0.0484075 |

| Capillary water absorption | 0.955474 | −0.223192 |

| Cold water absorption | 0.988144 | −0.0505878 |

| Linear Shrinkage | −0.788506 | −0.451345 |

| Bulk density | −0.9110662 | 0.0148954 |

| Weight loss | −0.93085 | −0.290827 |

| Open porosity | 1.00063 | 0.077084 |

| Compression strength | −0.839198 | 0.56653 |

| Variable | Factor 1 | Factor 2 |

|---|---|---|

| Boiling water absorption | 0.766922 | 0.646266 |

| Capillary water absorption | 0.548185 | 0.81378 |

| Cold water absorption | 0.689588 | 0.709546 |

| Linear Shrinkage | −0.884903 | −0.0205916 |

| Bulk density | −0.657107 | −0.630664 |

| Weight loss | −0.879958 | −0.420399 |

| Open porosity | 0.785626 | 0.6245 |

| Compression strength | −0.229337 | −0.986206 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Terrones-Saeta, J.M.; Luís, A.T.; Romero, E.; Fortes Garrido, J.C.; Diaz-Curiel, J.; Grande, J.A. Factor Analysis of the Physical–Mechanical Properties for Geopolymers Based on Brick Dust and Biomass Bottom Ash as Eco-Friendly Building Materials. Processes 2023, 11, 2491. https://doi.org/10.3390/pr11082491

Terrones-Saeta JM, Luís AT, Romero E, Fortes Garrido JC, Diaz-Curiel J, Grande JA. Factor Analysis of the Physical–Mechanical Properties for Geopolymers Based on Brick Dust and Biomass Bottom Ash as Eco-Friendly Building Materials. Processes. 2023; 11(8):2491. https://doi.org/10.3390/pr11082491

Chicago/Turabian StyleTerrones-Saeta, Juan María, Ana Teresa Luís, Emilio Romero, Juan Carlos Fortes Garrido, Jesús Diaz-Curiel, and José Antonio Grande. 2023. "Factor Analysis of the Physical–Mechanical Properties for Geopolymers Based on Brick Dust and Biomass Bottom Ash as Eco-Friendly Building Materials" Processes 11, no. 8: 2491. https://doi.org/10.3390/pr11082491

APA StyleTerrones-Saeta, J. M., Luís, A. T., Romero, E., Fortes Garrido, J. C., Diaz-Curiel, J., & Grande, J. A. (2023). Factor Analysis of the Physical–Mechanical Properties for Geopolymers Based on Brick Dust and Biomass Bottom Ash as Eco-Friendly Building Materials. Processes, 11(8), 2491. https://doi.org/10.3390/pr11082491