C2-Hydrocarbon Mixture Separation on Polyethylene Membranes with Grafted Sulfonated Polystyrene in H+, Li+ and Na+ Forms

Abstract

:1. Introduction

2. Materials and Methods

2.1. Membrane Preparation

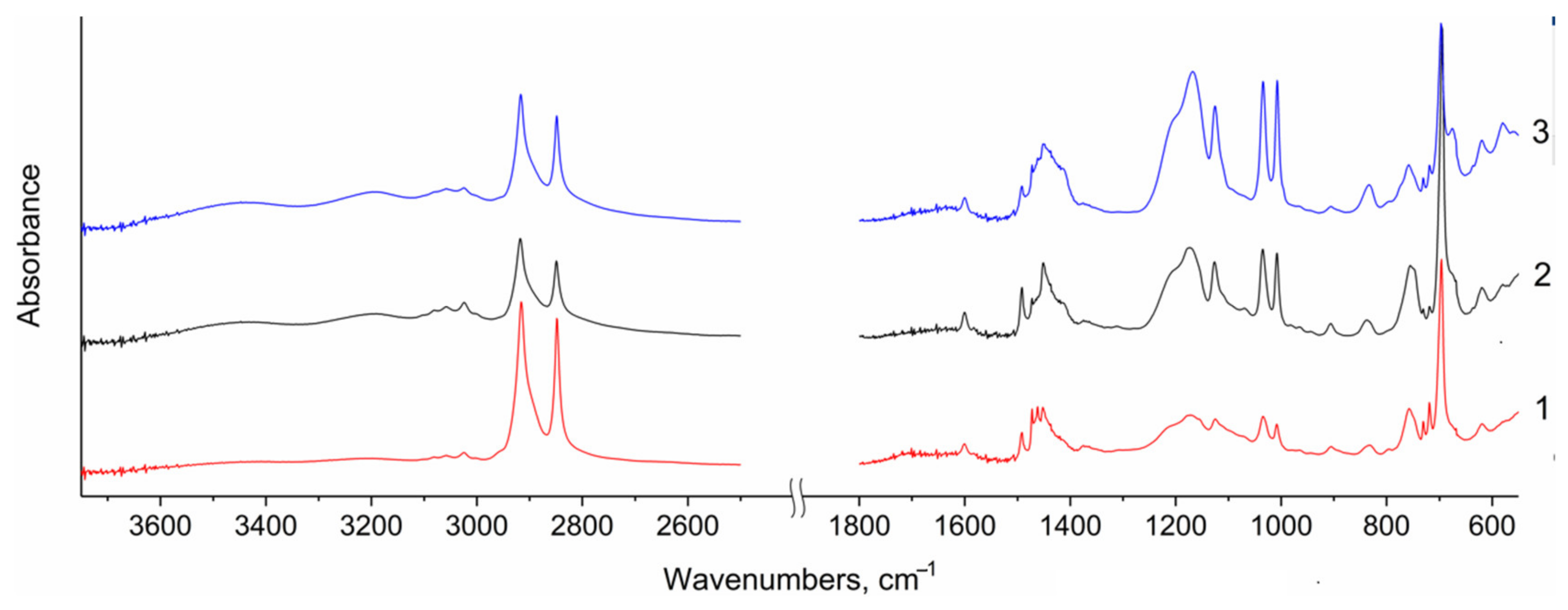

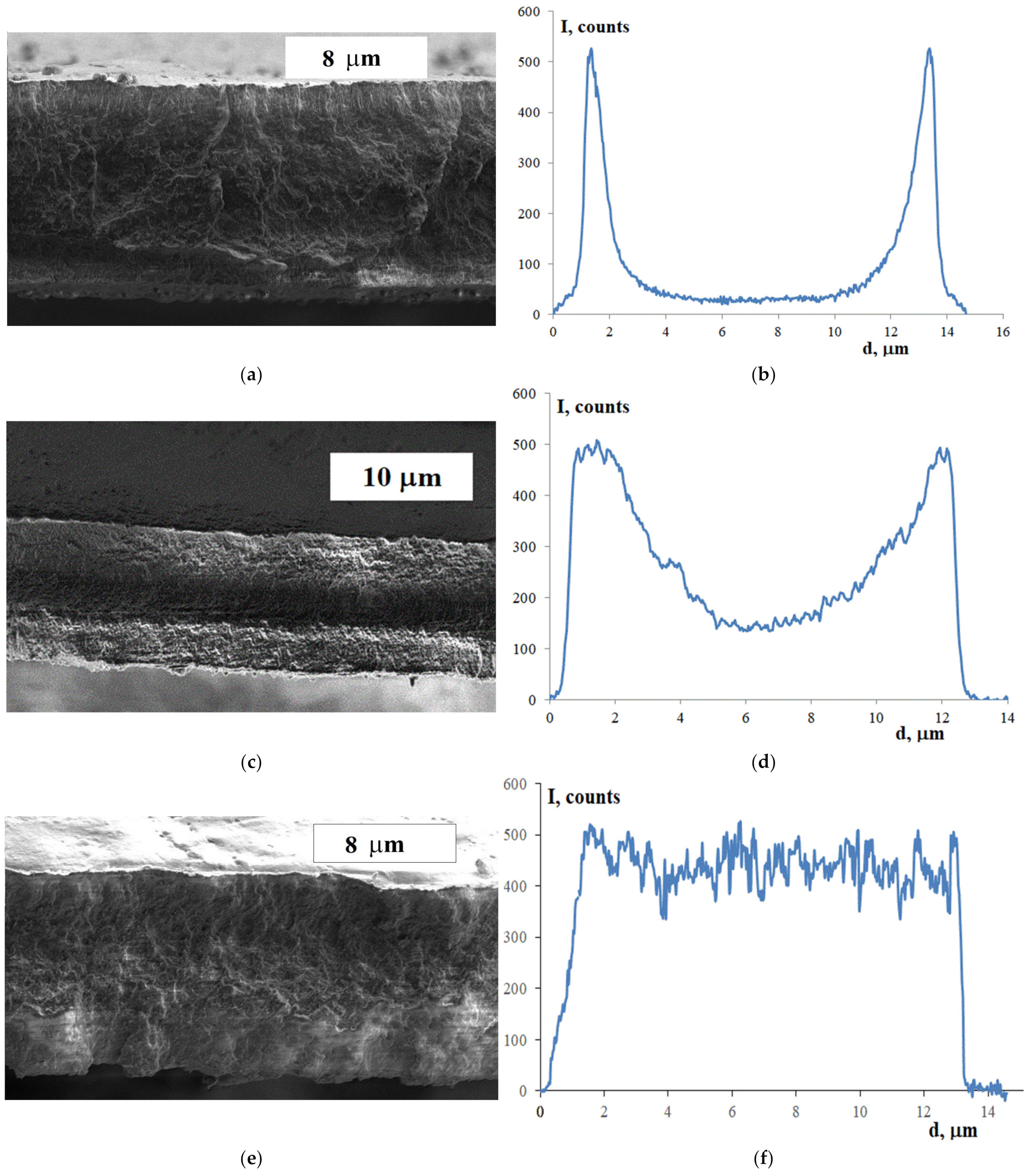

2.2. Membrane Characterization

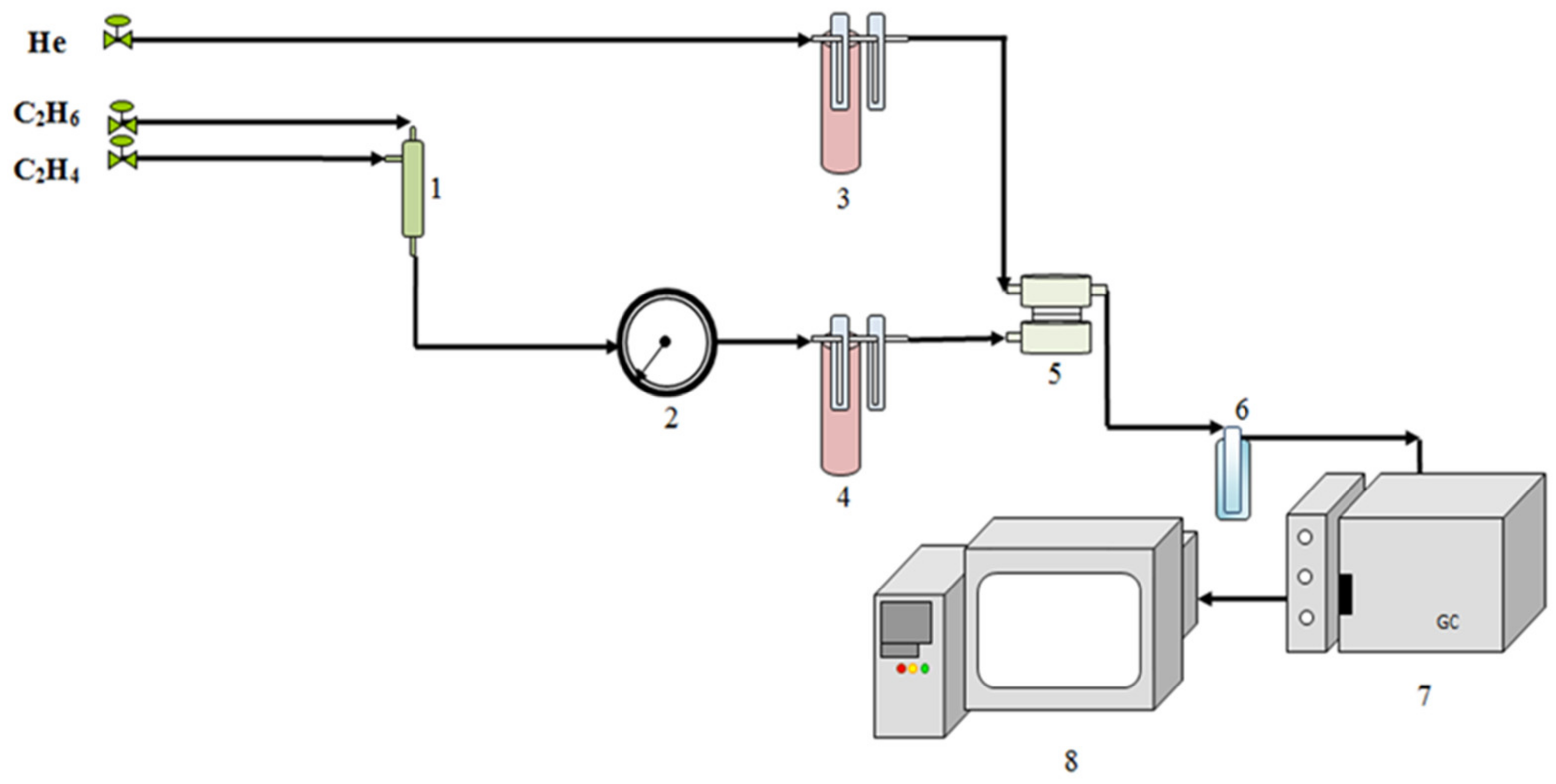

2.3. Gas Permeability Study

2.4. Analysis of Separation Products

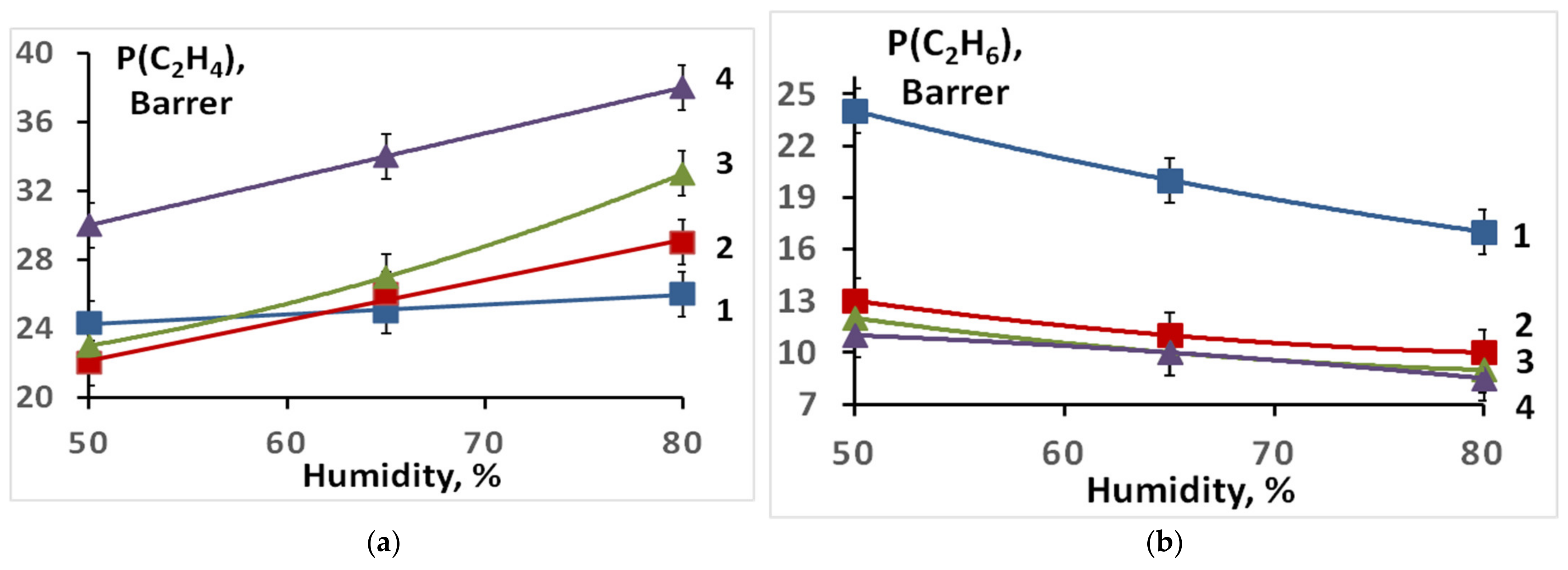

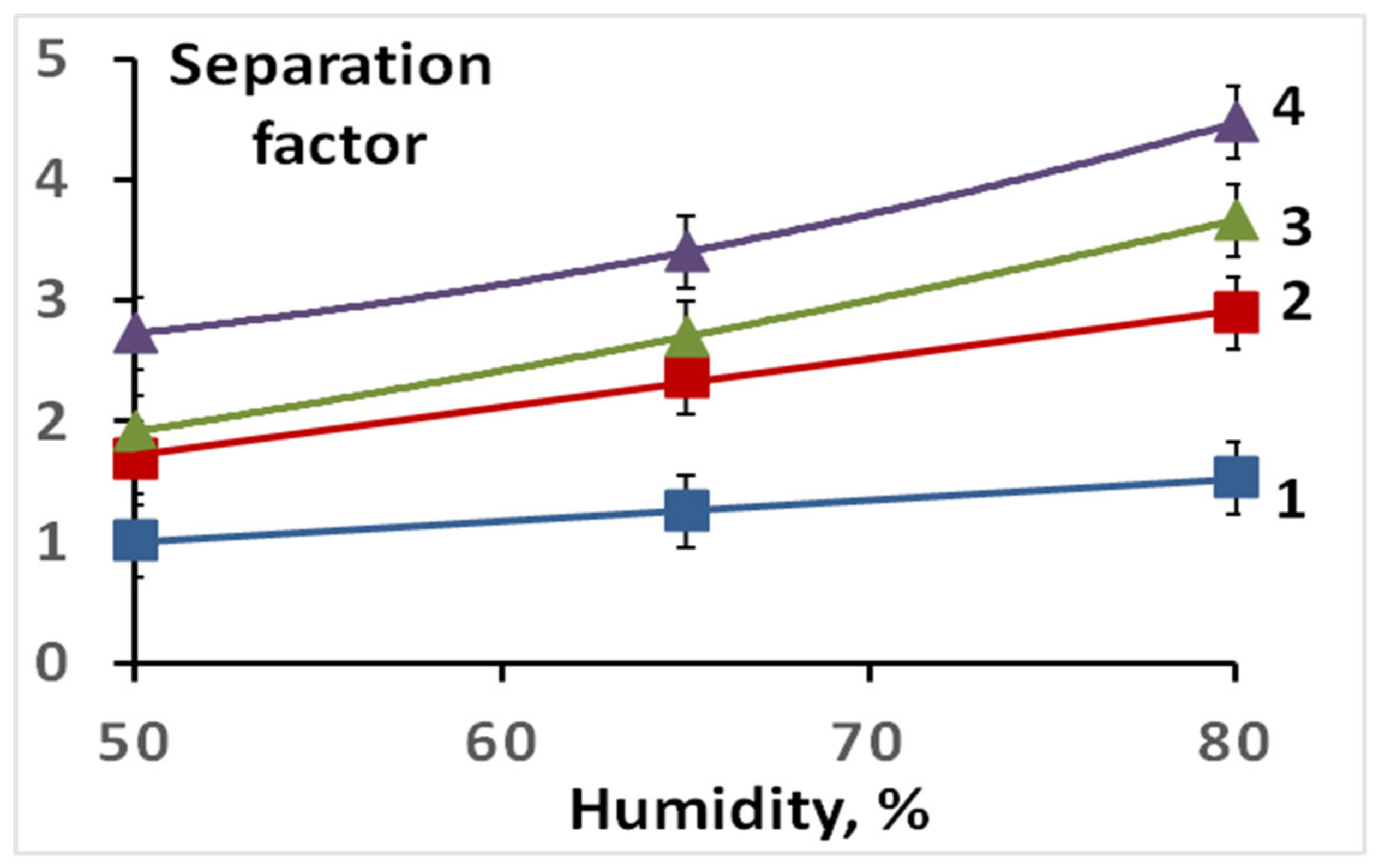

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sholl, D.S.; Lively, R.P. Seven chemical separations to change the world. Nature 2016, 532, 435–437. [Google Scholar] [CrossRef] [PubMed]

- Yi, S.; Ghanem, B.; Liu, Y.; Pinnau, I.; Koros, W.J. Ultraselective glassy polymer membranes with unprecedented performance for energy-efficient sour gas separation. Sci. Adv. 2019, 5, 5459. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Jiang, B.; Dou, H.; Yang, N.; Xiao, X.; Tantai, X.; Sun, Y.; Zhang, L. Customized facilitated transport membranes by mixed strategy for ethylene/ethane separation. Sep. Purif. Technol. 2021, 277, 119484. [Google Scholar] [CrossRef]

- Valadez Sanchez, E.P.; Gliemann, H.; Haas-Santo, K.; Ding, W.; Hansjosten, E.; Wohlgemuth, J.; Woll, C.; Dittmeyer, R. α-Al2O3-supported ZIF-8 SURMOF membranes: Diffusion mechanism of ethene/ethane mixtures and gas separation performance. J. Membr. Sci. 2020, 594, 117421. [Google Scholar] [CrossRef]

- Malakhov, A.O.; Bazhenov, S.D.; Vasilevsky, V.P.; Borisov, I.L.; Ovcharova, A.A.; Bildyukevich, A.V.; Volkov, V.V.; Giorno, L.; Volkov, A.V. Thin-film composite hollow fiber membranes for ethylene/ethane separation in gas-liquid membrane contactor. Sep. Purif. Technol. 2019, 219, 64–73. [Google Scholar] [CrossRef]

- Jiang, B.; Zhou, J.; Xu, M.; Dou, H.; Zhang, H.; Yang, N.; Zhang, L. Multifunctional ternary deep eutectic solvent-based membranes for the cost-effective ethylene/ethane separation. J. Membr. Sci. 2020, 610, 118243. [Google Scholar] [CrossRef]

- Wang, C.; Yan, J.; Ma, Z.; Wang, Z. Highly efficient separation of ethylene/ethane in microenvironment-modulated microporous polymers. Sep. Purif. Technol. 2022, 287, 120580. [Google Scholar] [CrossRef]

- Sekizkardes, A.K.; Budhathoki, S.; Zhu, L.; Kusuma, V.; Tong, Z.; McNally, J.S.; Steckel, J.A.; Yi, S.; Hopkinson, D. Molecular design and fabrication of PIM-1/polyphosphazene blend membranes with high performance for CO2/N2 separation. J. Membr. Sci. 2021, 640, 119764. [Google Scholar] [CrossRef]

- Kojabad, M.E.; Babaluo, A.; Tavakoli, A. A novel semi-mobile carrier facilitated transport membrane containing aniline/poly (ether-block-amide) for CO2/N2 separation: Molecular simulation and experimental study. Sep. Purif. Technol. 2021, 266, 118494. [Google Scholar] [CrossRef]

- Zheng, W.; Tian, Z.; Wang, Z.; Peng, D.; Zhang, Y.; Wang, J.; Zhang, Y. Dual-function biomimetic carrier based facilitated transport mixed matrix membranes with high stability for efficient CO2/N2 separation. Sep. Purif. Technol. 2022, 285, 120371. [Google Scholar] [CrossRef]

- Alent’ev, A.Y.; Volkov, A.V.; Vorotyntsev, I.V.; Maksimov, A.L.; Yaroslavtsev, A.B. Membrane technologies for decarbonization. Membr. Membr. Technol. 2021, 3, 255–273. [Google Scholar] [CrossRef]

- Han, Y.; Ho, W.S.W. Facilitated transport membranes for H2 purification from coal-derived syngas: A techno-economic analysis. J. Membr. Sci. 2021, 636, 119549. [Google Scholar] [CrossRef]

- Basov, N.L.; Ermilova, M.M.; Orekhova, N.V.; Yaroslavtsev, A.B. Membrane catalysis in the dehydrogenation and hydrogen production processes. Russ. Chem. Rev. 2013, 82, 352–368. [Google Scholar] [CrossRef]

- Checchetto, R. Accurate monitoring of gas mixture transport kinetics through polymeric membranes. Sep. Purif. Technol. 2021, 277, 119477. [Google Scholar] [CrossRef]

- Merkel, T.C.; Blanc, R.; Ciobanu, I.; Firat, B.; Suwarlim, A.; Zeid, J. Silver salt facilitated transport membranes for olefin/paraffin separations: Carrier instability and a novel regeneration method. J. Membr. Sci. 2013, 447, 177–189. [Google Scholar] [CrossRef]

- Yu, G.; Zhang, L.; Alhumaydhi, I.A.; Abdeltawab, A.A.; Bagabas, A.A.; Al-Megren, H.A.; Al-Deyab, S.S.; Chen, X. Separation of propylene and propane by alkylimidazolium thiocyanate ionic liquids with Cu+ salt. Sep. Purif. Technol. 2015, 156, 356–362. [Google Scholar] [CrossRef]

- Dou, H.; Jiang, B.; Zhang, L.; Xu, M.; Sun, Y. Synergy of high permeability, selectivity and good stability properties ofsilver-decorated deep eutectic solvent based facilitated transport membranesfor efficient ethylene/ethane separation. J. Membr. Sci. 2018, 567, 39–48. [Google Scholar] [CrossRef]

- Wang, D.; Liu, F.; Zhang, X.; Wu, M.; Wang, F.; Liu, J.; Wang, J.; Liu, Q.; Zeng, H. A Janus facilitated transport membrane with asymmetric surface wettability and dense/porous structure: Enabling high stability and separation efficiency. J. Membr. Sci. 2021, 626, 119183. [Google Scholar] [CrossRef]

- Hong, C.-H.; Ahmad, N.N.R.; Leo, C.P.; Ahmad, A.L.; Mohammad, A.W. Progress in polyvinyl alcohol membranes with facilitated transport properties for carbon capture. J. Environ. Chem. Eng. 2021, 9, 106783. [Google Scholar] [CrossRef]

- Min, J.G.; Kemp, K.C.; Hong, S.B. Silver ZK-5 zeolites for selective ethylene/ethane separation. Sep. Purif. Technol. 2020, 250, 117146. [Google Scholar] [CrossRef]

- Davenport, M.N.; Bentley, C.L.; Brennecke, J.F.; Freeman, B.D. Ethylene and ethane transport properties of hydrogen-stable Ag+-based facilitated transport membranes. J. Membr. Sci. 2022, 647, 120300. [Google Scholar] [CrossRef]

- Zhilyaeva, N.A.; Mironova, E.Y.; Ermilova, M.M.; Orekhova, N.V.; Bondarenko, G.N.; Dyakova, M.G.; Shevlyakova, N.V.; Tverskoy, V.A.; Yaroslavtsev, A.B. Polyethylene-graft-sulfonated polystyrene membranes for the separation of ethylene–ethane mixtures. Petr. Chem. 2016, 56, 1034–1041. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Jashni, E.; Habibi, M.; Nemati, M.; Van der Bruggen, B. Evaluating the ion transport characteristics of novel graphene oxide nanoplates entrapped mixed matrix cation exchange membranes in water deionization. J. Membr. Sci. 2017, 541, 641–652. [Google Scholar] [CrossRef]

- Radmanesh, F.; Rijnaarts, T.; Moheb, A.; Sadeghi, M.; de Vos, W.M. Enhanced selectivity and performance of heterogeneous cation exchange membranes through addition of sulfonated and protonated Montmorillonite. J. Colloid Interface Sci. 2019, 533, 658–670. [Google Scholar] [CrossRef]

- Sharma, P.P.; Yadav, V.; Rajput, A.; Gupta, H.; Saravaia, H.; Kulshrestha, V. Sulfonated poly (ether ether ketone) composite cation exchange membrane for selective recovery of lithium by electrodialysis. Desalin. Water Treat. 2020, 496, 114755. [Google Scholar] [CrossRef]

- Shukla, G.; Shahi, V.K. Sulfonated poly(ether ether ketone)/imidized graphene oxide composite cation exchange membrane with improved conductivity and stability for electrodialytic water desalination. Desalin. Water Treat. 2019, 451, 200–208. [Google Scholar] [CrossRef]

- Klose, C.; Breitwieser, M.; Vierrath, S.; Klingele, M.; Cho, H.; Büchler, A.; Kerres, J.; Thiele, S. Electrospun sulfonated poly(ether ketone) nanofibers as proton conductive reinforcement for durable Nafion composite membranes. J. Power Sources 2017, 361, 237e242. [Google Scholar] [CrossRef]

- Goel, P.; Mandal, P.; Bhuvanesh, E.; Shahi, V.K.; Chattopadhyay, S. Sulfonated poly (ether ether ketone) composite cation exchange membrane for NaOH production by electro-electrodialysis using agro-based paper mill green liquor. J. Environ. Chem. Eng. 2021, 9, 106409. [Google Scholar] [CrossRef]

- Avci, A.H.; Rijnaarts, T.; Fontananova, E.; Di Profio, G.; Vankelecom, I.F.V.; De Vos, W.M.; Curcio, E. Sulfonated polyethersulfone based cation exchange membranes for reverse electrodialysis under high salinity gradients. J. Membr. Sci. 2020, 595, 117585. [Google Scholar] [CrossRef]

- Titorova, V.D.; Moroz, I.A.; Mareev, S.A.; Pismenskaya, N.D.; Sabbatovskii, K.G.; Wang, Y.; Xu, T.; Nikonenko, V.V. How bulk and surface properties of sulfonated cation-exchange membranes response to their exposure to electric current during electrodialysis of a Ca2+ containing solution. J. Membr. Sci. 2022, 644, 120149. [Google Scholar] [CrossRef]

- Stránská, E. Relationships between transport and physical–mechanical properties of ion exchange membranes. Desalin. Water Treat. 2015, 56, 3220–3227. [Google Scholar] [CrossRef]

- Zhao, J.; Guo, L.; Wang, J. Synthesis of cation exchange membranes based on sulfonated polyether sulfone with different sulfonation degrees. J. Membr. Sci. 2018, 563, 957–968. [Google Scholar] [CrossRef]

- Prikhno, I.A.; Safronova, E.Y.; Stenina, I.A.; Yurova, P.A.; Yaroslavtsev, A.B. Dependence of the transport properties of perfluorinated sulfonated cation-exchange membranes on ion-exchange capacity. Membr. Membr. Technol. 2020, 2, 265–271. [Google Scholar] [CrossRef]

- Mareev, S.; Gorobchenko, A.; Ivanov, D.; Anokhin, D.; Nikonenko, V. Ion and water transport in ion-exchange membranes for power generations: Guidelines for modeling. Int. J. Mol. Sci. 2023, 24, 34. [Google Scholar] [CrossRef]

- Zhilyaeva, N.; Mironova, E.; Ermilova, M.; Orekhova, N.; Dyakova, M.; Shevlyakova, N.; Tverskoii, V.; Yaroslavtsev, A. Facilitated transport of ethylene through the polyethylene-graft-sulfonated polystyrene membranes. The role of humidity. Sep. Purif. Technol. 2018, 195, 170–173. [Google Scholar] [CrossRef]

- Volkov, A.O.; Golubenko, D.V.; Yaroslavtsev, A.B. Development of solid polymer composite membranes based on sulfonated fluorocopolymer for olefin/paraffin separation with high permeability and selectivity. Sep. Purif. Technol. 2021, 254, 117562. [Google Scholar] [CrossRef]

- Zhilyaeva, N.A.; Lytkina, A.A.; Mironova, E.Y.; Ermilova, M.M.; Orekhova, N.V.; Shevlyakova, N.V.; Tverskoy, V.A.; Yaroslavtsev, A.B. Polyethylene with radiation-grafted sulfonatedpolystyrene membranes for butane and butenes separation. Chem. Eng. Res. Des. 2020, 161, 253–259. [Google Scholar] [CrossRef]

- Jiang, S.; Sun, H.; Wang, H.; Ladewig, B.P.; Yao, Z. A comprehensive review on the synthesis and applications of ion exchange membranes. Chemosphere 2021, 282, 130817. [Google Scholar] [CrossRef]

- Kusoglu, A.; Weber, A.Z. New insights into perfluorinated sulfonic-acid ionomers. Chem. Rev. 2017, 117, 987–1104. [Google Scholar] [CrossRef]

- Yaroslavtsev, A.B.; Stenina, I.A.; Golubenko, D.V. Membrane materials for energy production and storage. Pure Appl. Chem. 2020, 92, 1147–1157. [Google Scholar] [CrossRef]

- Xiong, P.; Zhang, L.; Chen, Y.; Peng, S.; Yu, G. A Chemistry and Microstructure Perspective on Ion-Conducting Membranes for Redox Flow Batteries. Angew. Chem. Int. Ed. 2021, 60, 24770–24798. [Google Scholar] [CrossRef]

- Hsu, W.Y.; Gierke, T.D. Ion transport and clustering in nafion perfluorinated membranes. J. Membr. Sci. 1983, 13, 307–326. [Google Scholar] [CrossRef]

- Choi, S.Y.; Ikhsan, M.M.; Jin, K.S.; Henkensmeier, D. Nanostructure-Property Relationship of Two Perfluorinated Sulfonic Acid (PFSA) Membranes. Int. J. Energy Res. 2022, 46, 11265–11277. [Google Scholar] [CrossRef]

- Nikonenko, V.; Pismenskaya, N. Ion and Molecule Transport in Membrane Systems 3.0 and 4.0. Int. J. Mol. Sci. 2023, 24, 8211. [Google Scholar] [CrossRef]

- Golubenko, D.V.; Malakhova, V.R.; Yurova, P.A.; Evsiunina, M.V.; Stenina, I.A. Effect of Sulfonation Conditions on Properties of Ion-Conducting Membranes Based on Polystyrene Grafted on Gamma-Irradiated Polyvinylidene Fluoride Films. Membr. Membr. Technol. 2022, 4, 267–275. [Google Scholar] [CrossRef]

- Kang, S.W.; Kim, J.H.; Char, K.; Won, J.; Kang, Y.S. Nanocomposite silver polymer electrolytes as facilitated olefin transport membranes. J. Membr. Sci. 2006, 285, 102–107. [Google Scholar] [CrossRef]

| Sulfonation Time | IEC, mg Eq/g | Sulfonation Degree, % |

|---|---|---|

| 20 min | 1.9 | 44 |

| 1 h | 2.6 | 65 |

| 2 h | 2.9 | 75 |

| 3.5 h | 3.6 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhilyaeva, N.; Sofronov, E.; Mironova, E.; Shevlyakova, N.; Tverskoy, V.; Stenina, I.; Yaroslavtsev, A. C2-Hydrocarbon Mixture Separation on Polyethylene Membranes with Grafted Sulfonated Polystyrene in H+, Li+ and Na+ Forms. Processes 2023, 11, 2489. https://doi.org/10.3390/pr11082489

Zhilyaeva N, Sofronov E, Mironova E, Shevlyakova N, Tverskoy V, Stenina I, Yaroslavtsev A. C2-Hydrocarbon Mixture Separation on Polyethylene Membranes with Grafted Sulfonated Polystyrene in H+, Li+ and Na+ Forms. Processes. 2023; 11(8):2489. https://doi.org/10.3390/pr11082489

Chicago/Turabian StyleZhilyaeva, Natalya, Evgeny Sofronov, Elena Mironova, Nina Shevlyakova, Vladimir Tverskoy, Irina Stenina, and Andrey Yaroslavtsev. 2023. "C2-Hydrocarbon Mixture Separation on Polyethylene Membranes with Grafted Sulfonated Polystyrene in H+, Li+ and Na+ Forms" Processes 11, no. 8: 2489. https://doi.org/10.3390/pr11082489

APA StyleZhilyaeva, N., Sofronov, E., Mironova, E., Shevlyakova, N., Tverskoy, V., Stenina, I., & Yaroslavtsev, A. (2023). C2-Hydrocarbon Mixture Separation on Polyethylene Membranes with Grafted Sulfonated Polystyrene in H+, Li+ and Na+ Forms. Processes, 11(8), 2489. https://doi.org/10.3390/pr11082489