CFD-DEM Simulation of Fast Fluidization of Fine Particles in a Micro Riser

Abstract

1. Introduction

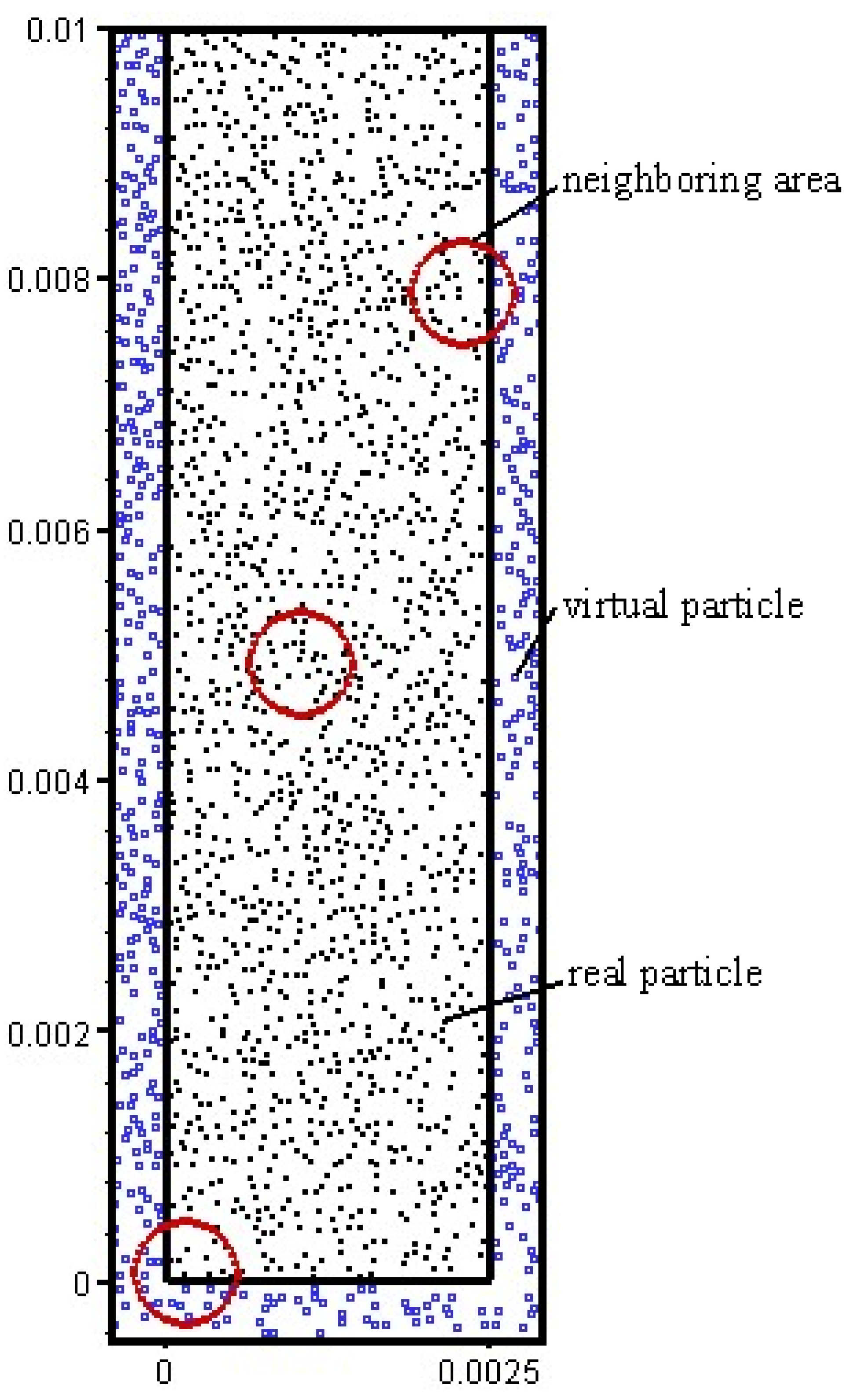

2. Drag Model

3. Simulation Method

4. Results and Discussion

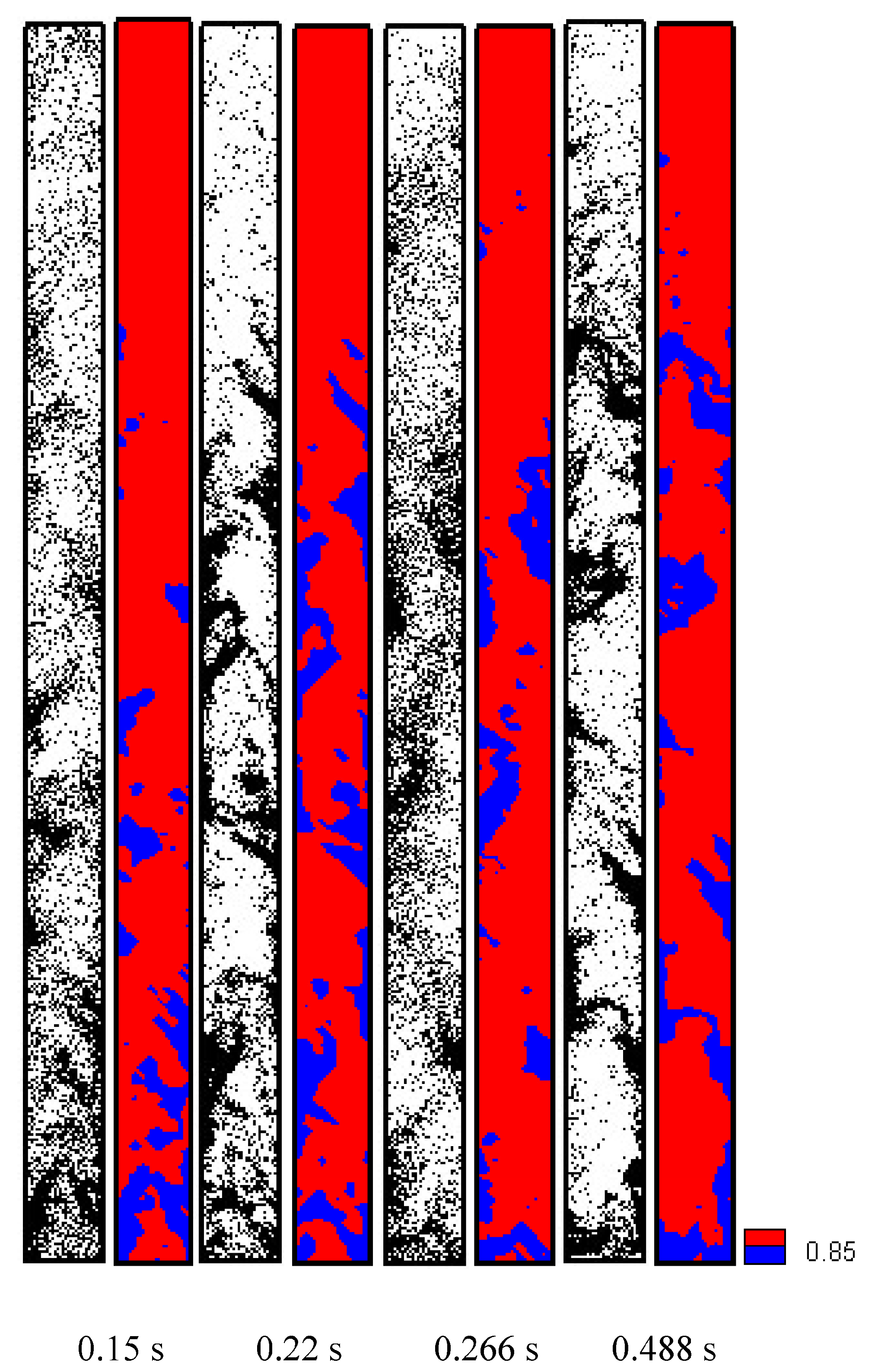

4.1. Particle Agglomeration

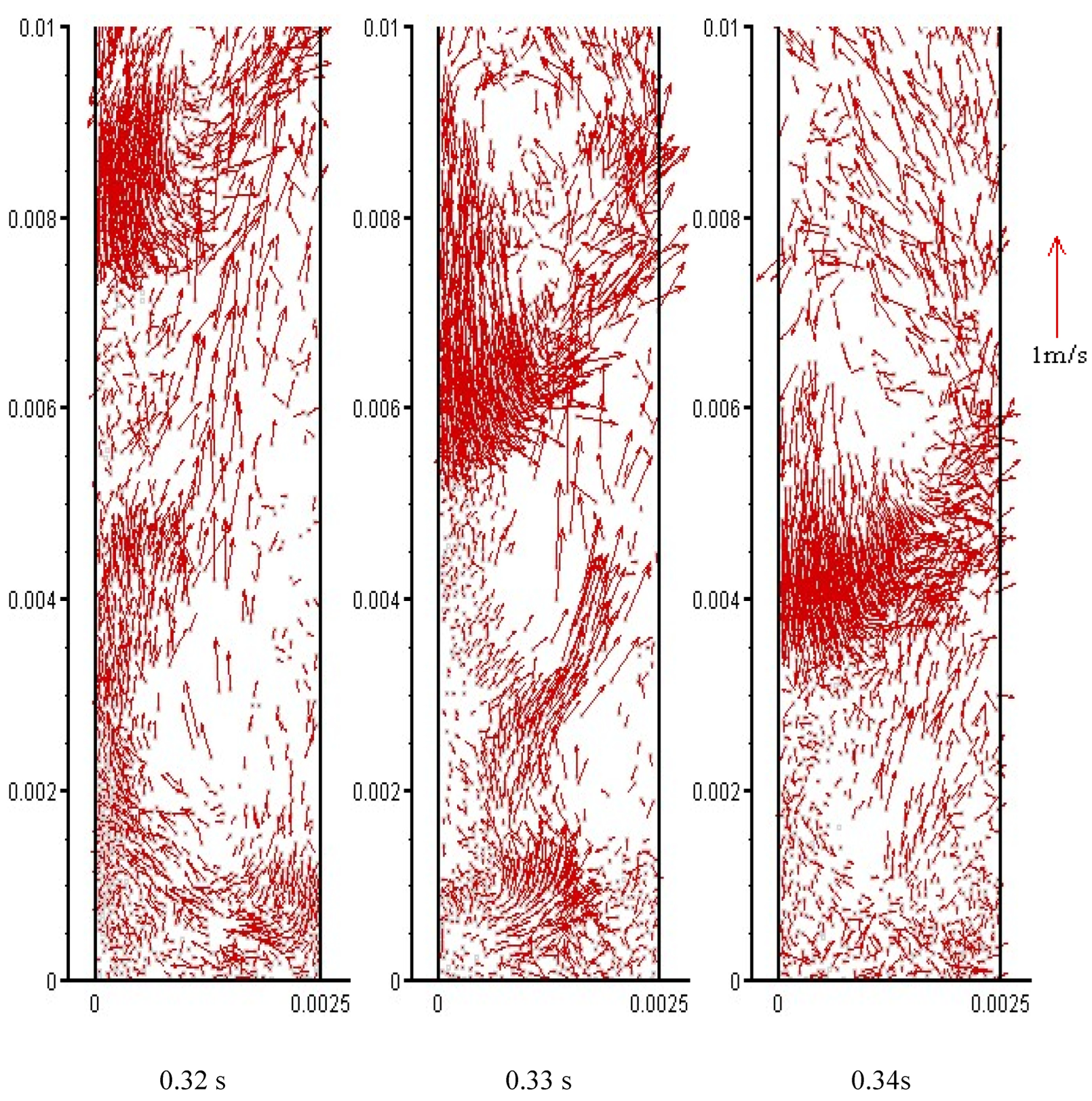

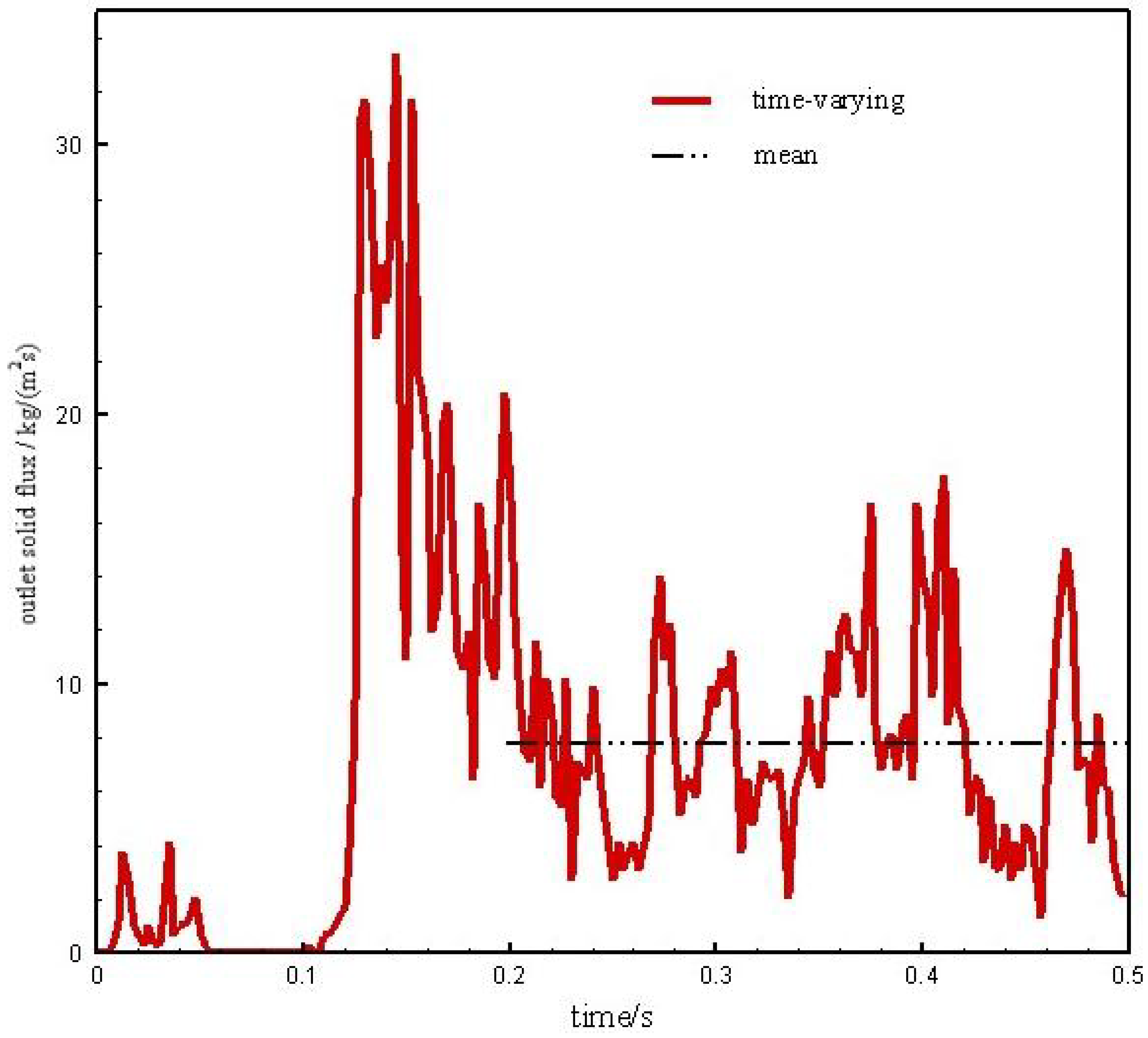

4.2. Gas–Solid Back-Mixing

4.3. Axial Structure

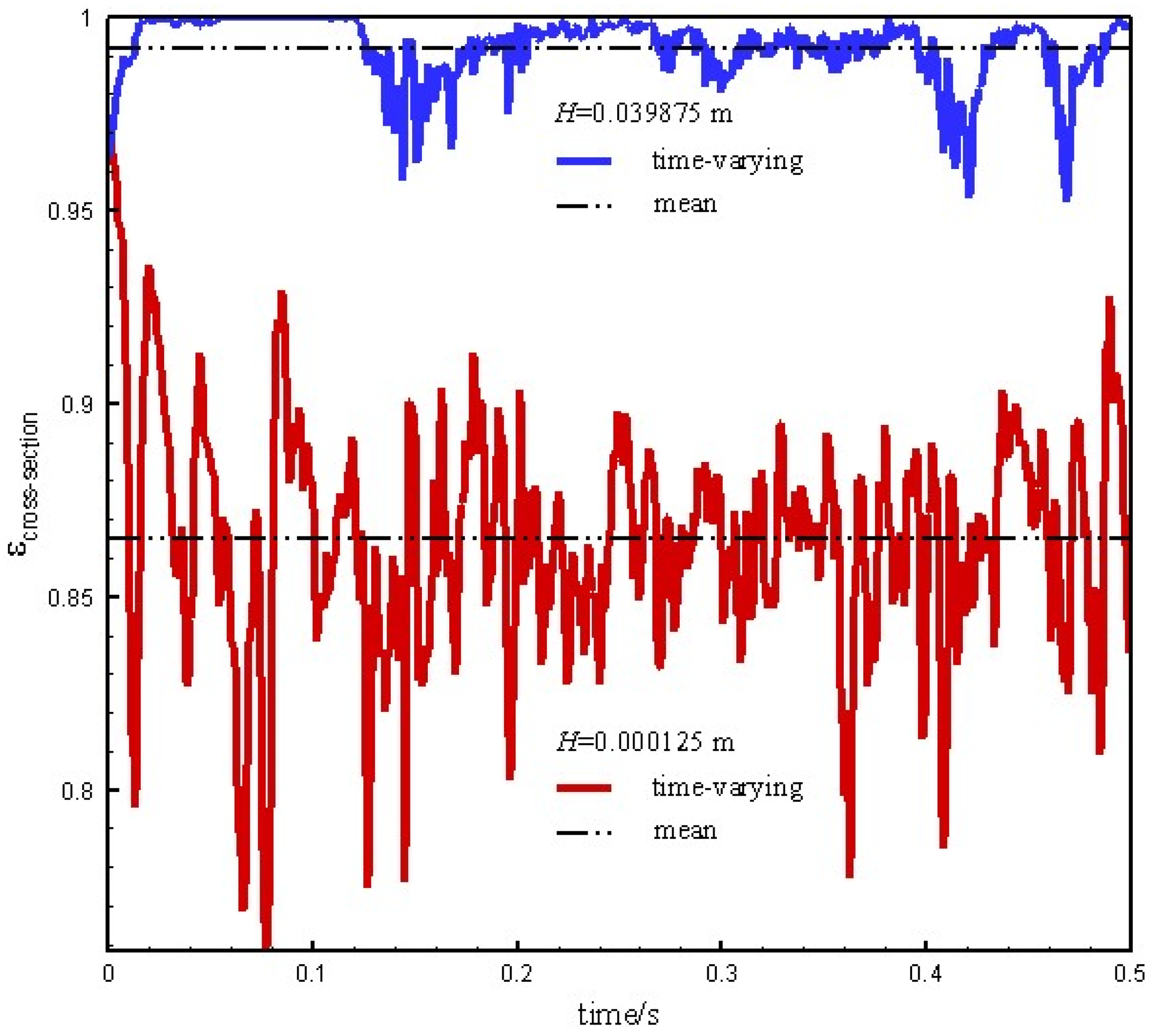

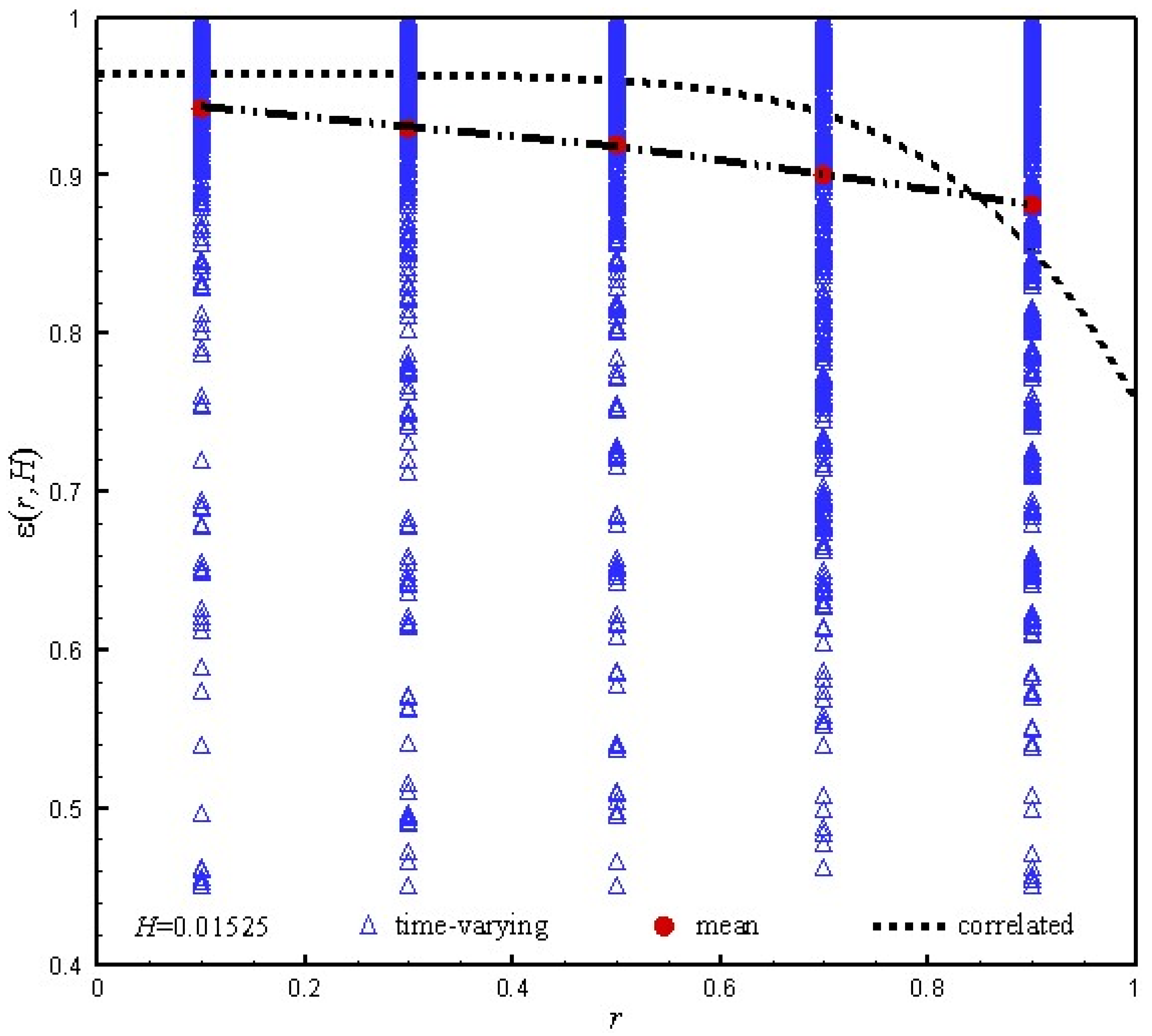

4.4. Radial Structure

5. Conclusions

- (1)

- The local structure in the MFB satisfies the natural property of fast fluidized particle agglomeration, forming a disperse dilute phase and continuous dense phase;

- (2)

- There is serious gas–solid back-mixing in the MFB, and the dense phase is the main area of gas–solid back-mixing. The wall friction factor aggravates the particle remixing effect, resulting in a relatively low outlet solid flux;

- (3)

- The axial porosity presents an increasing distribution with the bed height but does not strictly satisfy the monotonic exponential distribution. The solid volume fraction at the bottom of the bed is much lower than the correlated results for a CFB;

- (4)

- The radial porosity exhibits a weak core-annulus structure with a higher central region and lower side region. Compared with the correlated results for a CFB, the central region in the MFB is relatively dense, while the side region is relatively dilute;

- (5)

- All distinct variation results of the present simulation can be successfully explained using the relatively strong friction factor. Thus, the present drag model and simulation are both validated and effective, at least in the sense of a qualitative trend.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | area, m2 |

| Ar | Archimedes number |

| C | drag coefficient |

| D | bed wide, m |

| d | particle diameter or distance between particles, m |

| e | unit vector |

| F | force on particle, and N |

| Fr | Fred number |

| G | outlet solid flux, kg·m−2·s−1 |

| g | gravity acceleration, m·s−2 |

| h | smooth length, m |

| H | height of bed, m |

| Ha | Hamaker constant, N·m |

| H0 | Truncation distance, m |

| I | inertia moment of particle as spherical, kg·m2 |

| i, j, k | particle or grid index |

| N | number of particles |

| p | pressure, Pa |

| r | particle position vector |

| r | dimensionless radius |

| Sp | momentum exchange source term |

| T | torque, N·m |

| t | time, s |

| u0 | inlet gas velocity, m·s−1 |

| u | gas velocity, m·s−1 |

| ut | particle terminal speed |

| V | volume, m3 |

| v | particle velocity, m·s−1 |

| porosity | |

| cross-sectional porosity | |

| solid volume fraction at bottom of bed | |

| stiffness coefficient, N·m−1 | |

| solid volume fraction multiplier | |

| viscosity, N·s·m−2 | |

| density, kg·m−3 | |

| viscous stress tensor, Pa | |

| particle angular velocity, s−1 | |

| restitution coefficient | |

| subscript | |

| 2D | two-dimension |

| 3D | three-dimension |

| c | contact |

| d | drag |

| g | gas |

| i, j, k | particle or grid index |

| mf | minimal fluidized state |

| p | particle |

| s | solid |

| t | total |

| v | van der Waals |

| w | bed wall |

References

- Jin, Y.; Zhu, J.X.; Wang, Z.W.; Yu, Z.Q. Fluidization Engineering Principles; Tsinghua University Press: Beijing, China, 2001. [Google Scholar]

- Tsuji, Y.; Kawaguchi, T.; Tanake, T. Discrete particle simulation of two-dimensional fluidized bed. Powder Technol. 1993, 77, 79–87. [Google Scholar] [CrossRef]

- Hoomans, B.P.B.; Kuipers, J.A.M.; Briels, W.J.; Van Swaaij, W.P.M. Discrete particle simulation of bubble and slug formation in a two-dimensional gas-fluidised bed: A hard-sphere approach. Chem. Eng. Sci. 1996, 51, 99–108. [Google Scholar] [CrossRef]

- Xu, B.H.; Yu, A.B. Numerical simulation of the gas-solid flow in a fluidized bed by combing discrete particle method with computational fluid dynamics. Chem. Eng. Sci. 1997, 52, 2785–2809. [Google Scholar] [CrossRef]

- Ouyang, J.; Li, J.H. Particle-motion-resolved discrete model for simulating gas-solid fluidization. Chem. Eng. Sci. 1999, 54, 2077–2083. [Google Scholar] [CrossRef]

- Zhou, C.L.; Zhao, Y.Z. Discrete element method and its applications in fluidizatio. CIESC J. 2014, 65, 2520–2534. [Google Scholar]

- Yu, A.B.; Xu, B.H. Particle-scale modelling of gas–solid flow in fluidisation. J. Chem. Technol. Biotechnol. 2003, 78, 111–121. [Google Scholar] [CrossRef]

- Geldart, D. Types of gas fluidization. Powder Technol. 1973, 7, 285–292. [Google Scholar] [CrossRef]

- Ye, M.; van der Hoef, M.; Kuipers, J. A numerical study of fluidization behavior of Geldart A particles using a discrete particle model. Powder Technol. 2004, 139, 129–139. [Google Scholar] [CrossRef]

- Potic, B.; Kersten, S.R.A.; Ye, M.; van der Hoef, M.A.; Kuipers, J.A.M.; van Swaaij, W.P.M. Fluidization with hot compressed water in micro-reactors. Chem. Eng. Sci. 2005, 54, 5982–5990. [Google Scholar] [CrossRef]

- Han, Z.; Yue, J.; Geng, S.; Hu, D.; Liu, X.; Bello Suleiman, S.; Cui, Y.; Bai, D.; Xu, G. State-of-the-art hydrodynamics of gas-Solid micro fluidized beds. Chem. Eng. Sci. 2021, 232, 116345. [Google Scholar] [CrossRef]

- Ye, M.; van der Hoef, M.A.; Kuipers, J.A.M. The effects of particle and gas properties on the fluidization of Geldart A particles. Chem. Eng. Sci. 2005, 60, 4567–4580. [Google Scholar] [CrossRef]

- Liu, P.; LaMarche, C.Q.; Kellogg, K.M.; Hrenya, C.M. Fine-particle defluidization: Interaction between cohesion, Young’s modulus and static bed height. Chem. Eng. Sci. 2016, 145, 266–278. [Google Scholar] [CrossRef]

- Hou, Q.F.; Zhou, Z.Y.; Yu, A.B. Micromechanical modeling and analysis of different flow regimes in gas fluidization. Chem. Eng. Sci. 2012, 84, 449–468. [Google Scholar] [CrossRef]

- Kobayashi, T.; Tanaka, T.; Shimada, N.; Kawaguchi, T. DEM-CFD analysis of fluidization behavior of Geldart Group A particles using a dynamic adhesion force model. Powder Technol. 2013, 248, 143–152. [Google Scholar] [CrossRef]

- Li, T.; Rabha, S.; Verma, V.; Dietiker, J.F.; Xu, Y.; Lu, L.; Rogers, W.; Gopalan, B.; Breault, G.; Tucker, J.; et al. Experimental study and discrete element method simulation of Geldart Group A particles in a small-scale fluidized bed. Adv. Powder Technol. 2017, 28, 2961–2973. [Google Scholar] [CrossRef]

- Li, S.; Zhao, P.; Xu, J.; Zhang, L.; Wang, J. Direct comparison of CFD-DEM simulation and experimental measurement of Geldart A particles in a micro-fluidized bed. Chem. Eng. Sci. 2021, 64, 622–625. [Google Scholar] [CrossRef]

- Guo, Q.; Bordbar, A.; Ma, L.; Yu, Y.; Xu, S. A CFD-DEM study of the solid-like and fluid-like states in the homogeneous fluidization regime of Geldart A particles. AIChE J. 2022, 68, e17420. [Google Scholar] [CrossRef]

- Li, S.; Zhao, P.; Xu, J.; Zhang, L.; Wang, J. CFD-DEM simulation of polydisperse gas-solid flow of Geldart A particles in bubbling micro-fluidized beds. Chem. Eng. Sci. 2022, 253, 117551. [Google Scholar] [CrossRef]

- Wu, G.R.; Zuo, Z.F.; Li, Y.G.; Israr, M. Improvement of relative DEM time step range in fast fluidization simulation of Type-A FCC particles. Processes 2023, 11, 1155. [Google Scholar] [CrossRef]

- Lucy, L.B. Numerical approach to testing the fission hypothesis. Astron. J. 1977, 82, 1013–1024. [Google Scholar] [CrossRef]

- Xu, M.; Ge, W.; Li, J.H. A discrete particle model for particle–fluid flow with considerations of sub-grid structures. Chem. Eng. Sci. 2007, 62, 2302–2308. [Google Scholar] [CrossRef]

- Wu, G.R.; Ouyang, J.; Li, Q. Revised drag calculation method for coarse grid Lagrangian-Eulerian simulation of gas-solid bubbling fluidized bed. Powder Technol. 2013, 235, 959–967. [Google Scholar] [CrossRef]

- Wen, C.Y.; Yu, Y.H. Mechanics of fluidization. Chem. Eng. Progr. Symp. Ser. 1966, 62, 100–111. [Google Scholar]

- Schiller, V.L.; Naumann, A. Uber die grundlegenden berechnungen bei der schwerkraftaufbereitung. Z. Ver. Dtsch. Ing. 1993, 77, 318–320. [Google Scholar]

- Wu, G.R.; Ouyang, J. Fine grid DEM simulation of bed layer height in bubbling fluidized-bed. CIESC J. 2014, 65, 2092–2097. [Google Scholar]

- Patankar, T.V. Numerical Heat Transfer and Fluid Flow; Hemisphere Publishing Corporation: New York, NY, USA, 1980. [Google Scholar]

- Kuipers, J.A.M.; van Uuin, K.J.; van Beckum, F.P.H.; van Swaaij, W.P.M. A numerical model of gas-fluidized beds. Chem. Eng. Sci. 1992, 47, 1913–1924. [Google Scholar] [CrossRef]

- Bai, D.; Kato, K. Generalized correlations of solids holdups at dense and dilute regions of circulating fluidized beds. In Proceedings 7th SCEJ Symposium on CFB; Society of Chemical Engineers: Tokyo, Japan, 1994. [Google Scholar]

- Li, J.; Kwauk, M. Particle-Fluid Two-Phase Flow: The Energy-Minimization Multi-Scale Method; Metallurgical Industry Press: Beijing, China, 1994. [Google Scholar]

- Yang, N.; Wang, W.; Ge, W.; Li, J.H. CFD simulation of concurrent-up gas-fluid flow in circulating fluidized beds with structure-dependent drag coefficient. Chem. Eng. Sci. 2003, 96, 71–80. [Google Scholar] [CrossRef]

- Lewis, W.K.; Gilliland, E.R.; Bauer, W.C. Characteristics of fluidized particles. Ind. Eng. Chem. 1949, 41, 1104–1117. [Google Scholar] [CrossRef]

- Patience, G.S.; Chaouki, J. Solids Hydrodynamics in the Fully Developed Region of CFB Riser, 4th ed.; Large, J.F., Laguerie, C., Eds.; Engineering Foundation: New York, NY, USA, 1996. [Google Scholar]

| Particle | Gas |

|---|---|

| Density ρp = 930 kg·m−3 | Viscosity μg = 1.7 × 10−5 N·s·m−2 |

| Particle diameter dp = 54 μm | Density ρg = 1.28 kg·m−3 |

| Porosity at minimum fluidization εmf = 0.45 | Inlet gas velocity u0 = 1.7 m·s−1 |

| Stiffness Coef. κ = 10 N·m−1 | CFD time step Δ tg = 2 × 10−6 s |

| Restitution Coef. ξ = 0.9 | |

| DEM time step Δ tp = 2.5 × 10−7 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, G.; Li, Q.; Zuo, Z. CFD-DEM Simulation of Fast Fluidization of Fine Particles in a Micro Riser. Processes 2023, 11, 2417. https://doi.org/10.3390/pr11082417

Wu G, Li Q, Zuo Z. CFD-DEM Simulation of Fast Fluidization of Fine Particles in a Micro Riser. Processes. 2023; 11(8):2417. https://doi.org/10.3390/pr11082417

Chicago/Turabian StyleWu, Guorong, Qiang Li, and Zhanfei Zuo. 2023. "CFD-DEM Simulation of Fast Fluidization of Fine Particles in a Micro Riser" Processes 11, no. 8: 2417. https://doi.org/10.3390/pr11082417

APA StyleWu, G., Li, Q., & Zuo, Z. (2023). CFD-DEM Simulation of Fast Fluidization of Fine Particles in a Micro Riser. Processes, 11(8), 2417. https://doi.org/10.3390/pr11082417