Analysis of Hydrothermal Ageing on Mechanical Performances of Fibre Metal Laminates

Abstract

1. Introduction

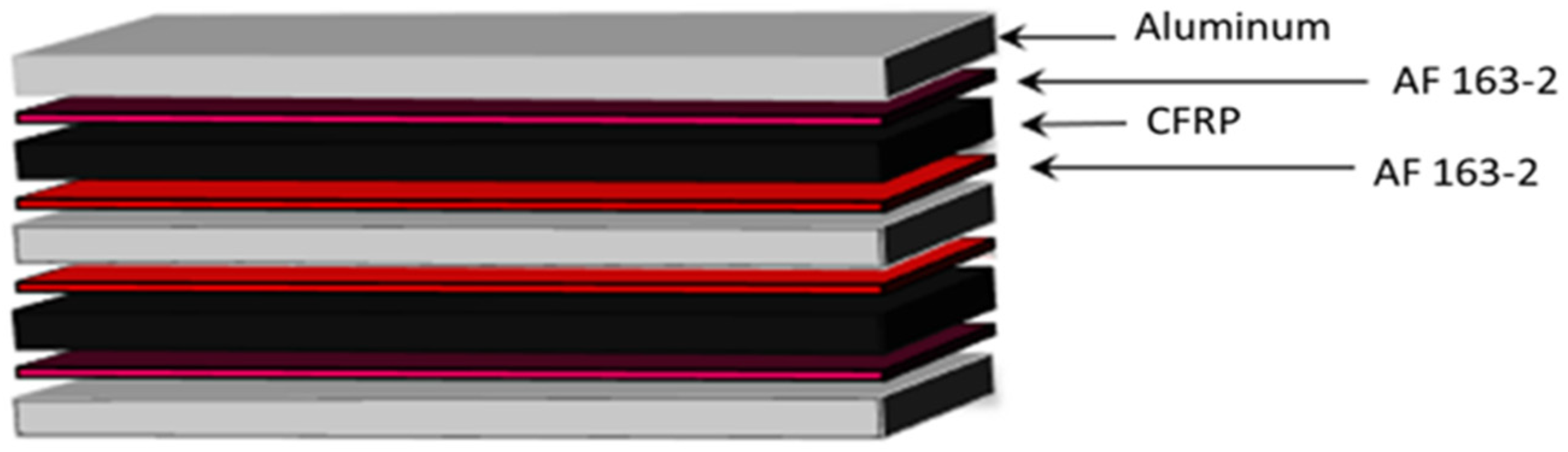

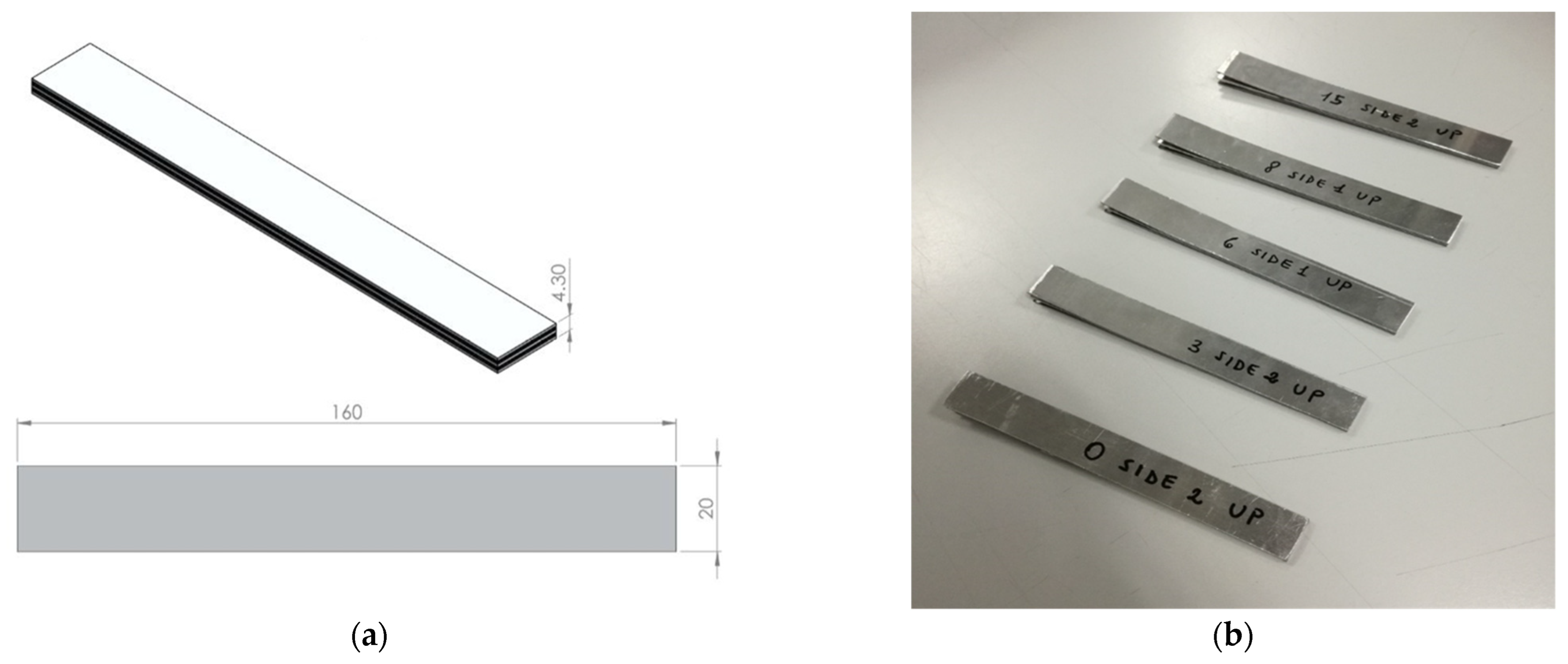

2. Materials and Methods

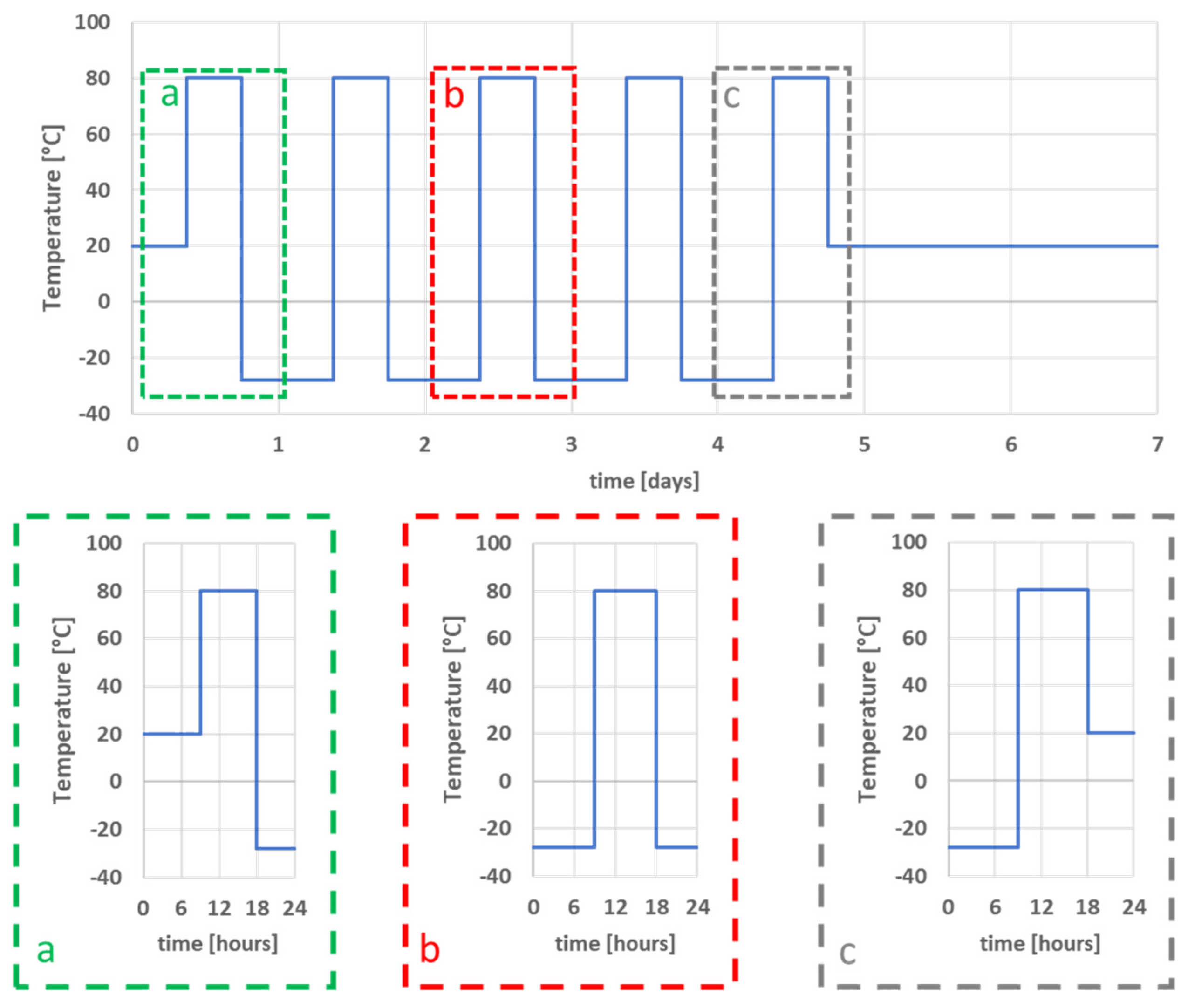

Ageing Treatments

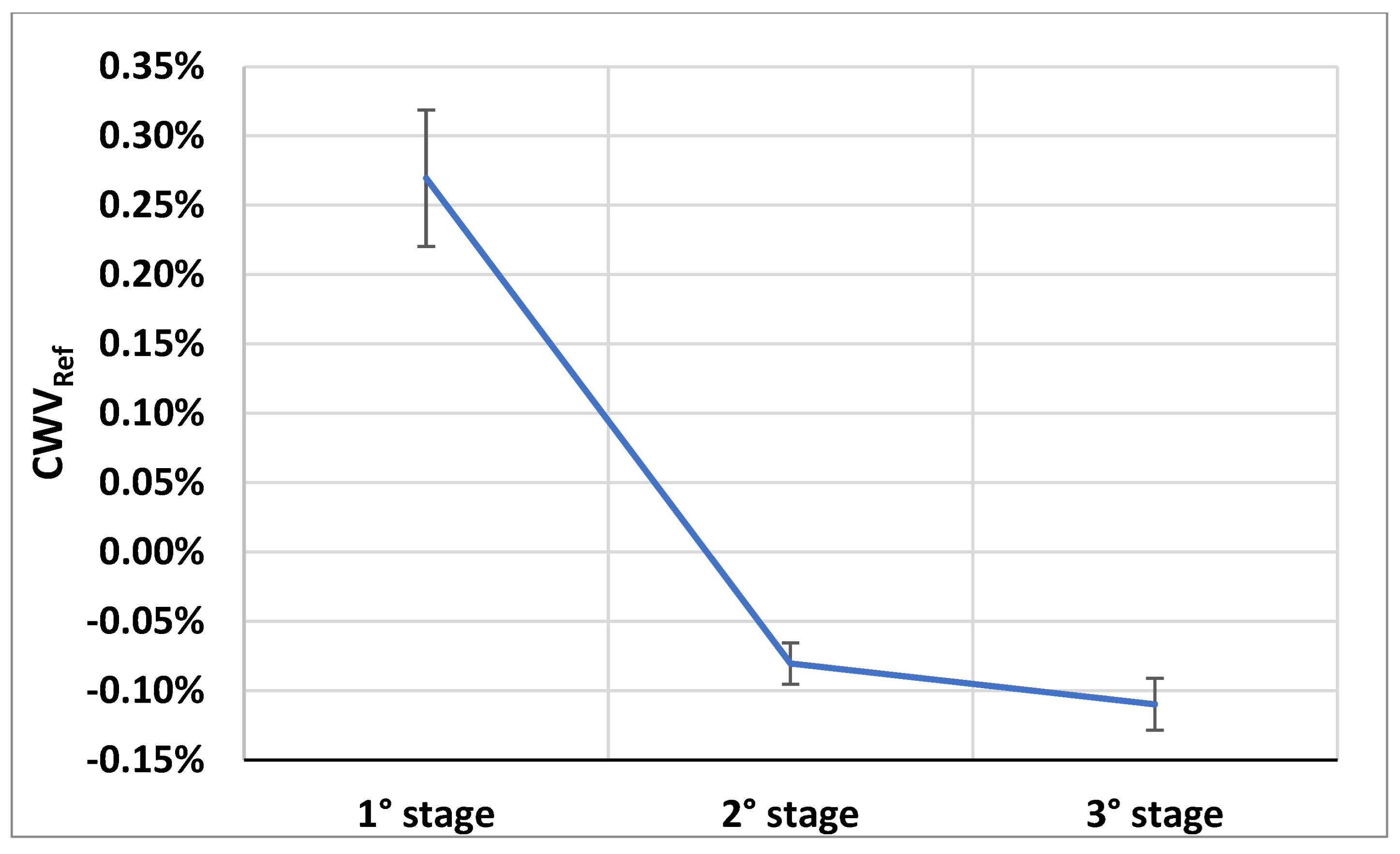

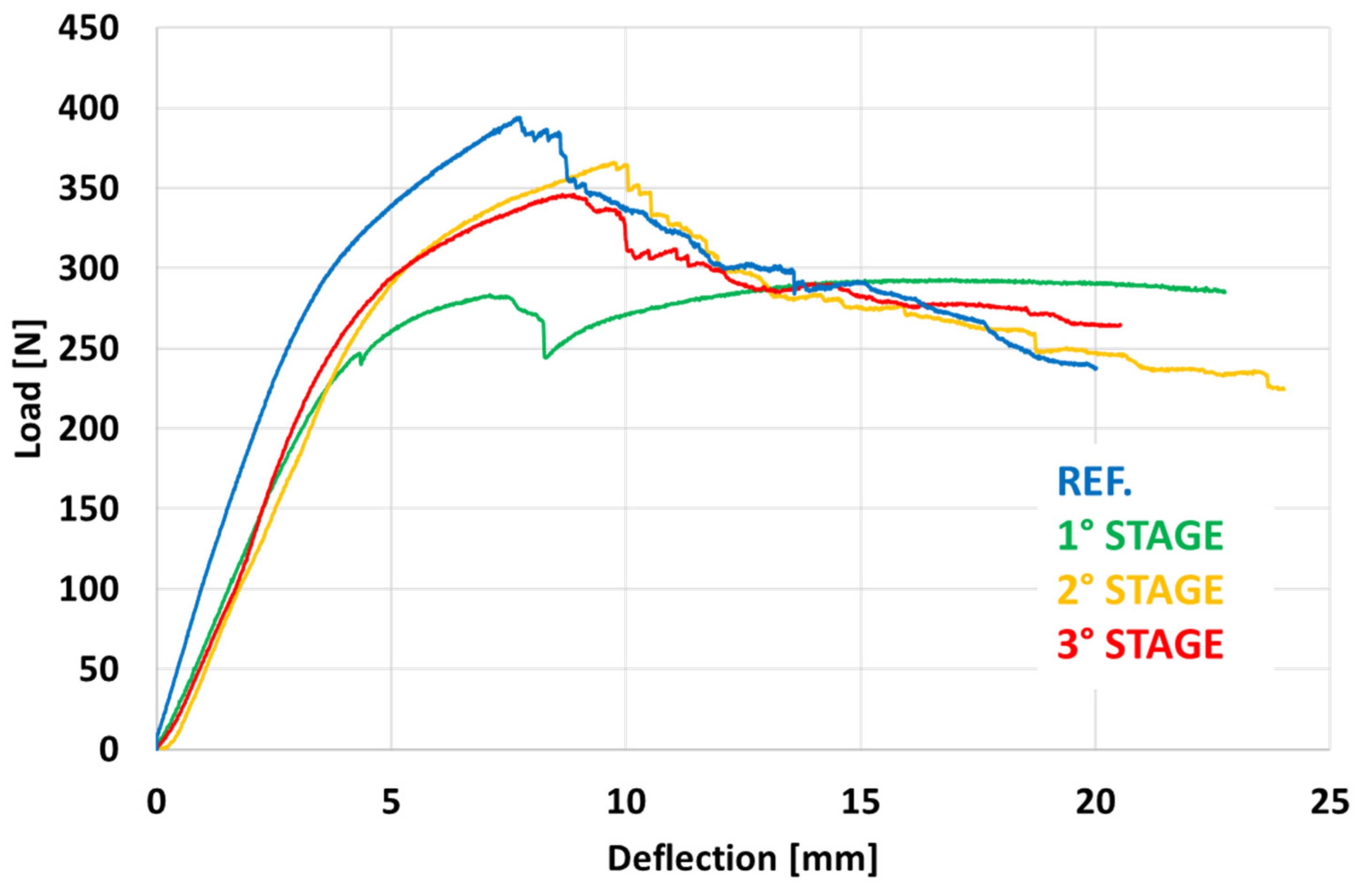

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stoll, M.; Stemmer, F.; Ilinzeer, S.; Weidenmann, K.A. Optimization of Corrosive Properties of Carbon Fiber Reinforced Aluminum Laminates Due to Integration of an Elastomer Interlayer. Key Eng. Mater. 2017, 742, 287–293. [Google Scholar] [CrossRef]

- Li, X.; Zhang, X.; Zhang, H.; Yang, J.; Nia, A.B.; Chai, G.B. Mechanical Behaviors of Ti/CFRP/Ti Laminates with Different Surface Treatments of Titanium Sheets. Compos. Struct. 2017, 163, 21–31. [Google Scholar] [CrossRef]

- Bellini, C.; Di Cocco, V.; Iacoviello, F.; Sorrentino, L. Experimental Analysis of Aluminium/Carbon Epoxy Hybrid Laminates under Flexural Load. Frat. Ed Integrità Strutt. 2019, 13, 739–747. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; da Silva, L.F.M.; Banea, M.D. Adhesive Bonding of Polymer Composites to Lightweight Metals. In Joining of Polymer-Metal Hybrid Structures: Principles and Applications; Wiley: New York, NY, USA, 2018; pp. 29–59. ISBN 9781119429807. [Google Scholar]

- Bellini, C.; Di Cocco, V.; Sorrentino, L. Interlaminar Shear Strength Study on CFRP/Al Hybrid Laminates with Different Properties. Frat. Ed Integrità Strutt. 2019, 14, 442–448. [Google Scholar] [CrossRef]

- Botelho, E.C.; Costa, M.L.; Pardini, L.C.; Rezende, M.C. Processing and Hygrothermal Effects on Viscoelastic Behavior of Glass Fiber/Epoxy Composites. J. Mater. Sci. 2005, 40, 3615–3623. [Google Scholar] [CrossRef]

- Bellini, C.; Parodo, G.; Sorrentino, L. Effect of Operating Temperature on Aged Single Lap Bonded Joints. Def. Technol. 2020, 16, 283–289. [Google Scholar] [CrossRef]

- Gibhardt, D.; Buggisch, C.; Meyer, D.; Fiedler, B. Hygrothermal Aging History of Amine-Epoxy Resins: Effects on Thermo-Mechanical Properties. Front. Mater. 2022, 9, 826076. [Google Scholar] [CrossRef]

- Odegard, G.M.; Bandyopadhyay, A. Physical Aging of Epoxy Polymers and Their Composites. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1695–1716. [Google Scholar] [CrossRef]

- Lee, J.K.; Hwang, J.Y.; Gillham, J.K. Erasure below Glass-Transition Temperature of Effect of Isothermal Physical Aging in Fully Cured Epoxy/Amine Thermosetting System. J. Appl. Polym. Sci. 2001, 81, 396–404. [Google Scholar] [CrossRef]

- Botelho, E.C.; Almeida, R.S.; Pardini, L.C.; Rezende, M.C. Elastic Properties of Hygrothermally Conditioned Glare Laminate. Int. J. Eng. Sci. 2007, 45, 163–172. [Google Scholar] [CrossRef]

- Alia, C.; Biezma, M.V.; Pinilla, P.; Arenas, J.M.; Suárez, J.C. Degradation in Seawater of Structural Adhesives for Hybrid Fibre-Metal Laminated Materials. Adv. Mater. Sci. Eng. 2013, 2013, 869075. [Google Scholar] [CrossRef]

- Ali, A.; Pan, L.; Duan, L.; Zheng, Z.; Sapkota, B. Characterization of Seawater Hygrothermal Conditioning Effects on the Properties of Titanium-Based Fiber-Metal Laminates for Marine Applications. Compos. Struct. 2016, 158, 199–207. [Google Scholar] [CrossRef]

- Yu, B.; He, P.; Jiang, Z.; Yang, J. Interlaminar Fracture Properties of Surface Treated Ti-CFRP Hybrid Composites under Long-Term Hygrothermal Conditions. Compos. Part A Appl. Sci. Manuf. 2017, 96, 9–17. [Google Scholar] [CrossRef]

- Ostapiuk, M.; Bieniaś, J.; Surowska, B. Analysis of the Bending and Failure of Fiber Metal Laminates Based on Glass and Carbon Fibers. Sci. Eng. Compos. Mater. 2018, 25, 1095–1106. [Google Scholar] [CrossRef]

- Rajan, B.M.C.; Kumar, A.S. The Influence of the Thickness and Areal Density on the Mechanical Properties of Carbon Fibre Reinforced Aluminium Laminates (CARAL). Trans. Indian Inst. Met. 2018, 71, 2165–2171. [Google Scholar] [CrossRef]

- Mamalis, D.; Obande, W.; Koutsos, V.; Blackford, J.R.; Brádaigh, C.M.Ó.; Ray, D. Novel Thermoplastic Fibre-Metal Laminates Manufactured by Vacuum Resin Infusion: The Effect of Surface Treatments on Interfacial Bonding. Mater. Des. 2019, 162, 331–344. [Google Scholar] [CrossRef]

- Romli, N.K.; Rejab, M.R.M.; Bachtiar, D.; Siregar, J.; Rani, M.F.; Salleh, S.M.; Merzuki, M.N.M. Failure Behaviour of Aluminium/CFRP Laminates with Varying Fibre Orientation in Quasi-Static Indentation Test. IOP Conf. Ser. Mater. Sci. Eng. 2018, 319, 012029. [Google Scholar] [CrossRef]

- Wang, S.; Cao, M.; Wang, G.; Cong, F.; Xue, H.; Meng, Q.; Uddin, M.; Ma, J. Effect of Graphene Nanoplatelets on Water Absorption and Impact Resistance of Fibre-Metal Laminates under Varying Environmental Conditions. Compos. Struct. 2022, 281, 114977. [Google Scholar] [CrossRef]

- Pan, L.; Ali, A.; Wang, Y.; Zheng, Z.; Lv, Y. Characterization of Effects of Heat Treated Anodized Film on the Properties of Hygrothermally Aged AA5083-Based Fiber-Metal Laminates. Compos. Struct. 2017, 167, 112–122. [Google Scholar] [CrossRef]

- Hamill, L.; Hofmann, D.C.; Nutt, S. Galvanic Corrosion and Mechanical Behavior of Fiber Metal Laminates of Metallic Glass and Carbon Fiber Composites. Adv. Eng. Mater. 2018, 20, 1700711. [Google Scholar] [CrossRef]

- Viandier, A.; Cramer, J.; Stefaniak, D.; Schröder, D.; Krewer, U.; Hühne, C.; Sinapius, M. Degradation Analysis of Fibre-Metal Laminates under Service Conditions to Predict Their Durability. UPB Sci. Bull. Ser. D Mech. Eng. 2016, 78, 49–58. [Google Scholar]

- Hu, Y.; Li, H.; Fu, X.; Zhang, X.; Tao, J.; Xu, J. Hygrothermal Characterization of Polyimide-Titanium-Based Fibre Metal Laminate. Polym. Compos. 2018, 39, 2819–2825. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, C.; Wang, C.; Fu, X.; Zhang, Y. Study on the Hygrothermal Aging Behavior and Diffusion Mechanism of Ti/CF/PMR Polyimide Composite Laminates. Mater. Res. Express 2020, 7, 076508. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, J.; Liu, C.; Hu, Y.; She, F. Reduced Graphene Oxide Modified Ti/CFRP Structure-Function Integrated Laminates for Surface Joule Heating and Deicing. Compos. Part A Appl. Sci. Manuf. 2023, 166, 107377. [Google Scholar] [CrossRef]

- Bellini, C.; Di Cocco, V.; Iacoviello, F.; Sorrentino, L. Numerical Model Development to Predict the Process-Induced Residual Stresses in Fibre Metal Laminates. Forces Mech. 2021, 3, 100017. [Google Scholar] [CrossRef]

- ASTM D7905/D7905M-19e1; Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM D1141-98; Standard Practice for Preparation of Substitute Ocean Water. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM D5573-99; Standard Practice for Classifying Failure Modes in Fiber-Reinforced-Plastic (FRP) Joints. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bellini, C.; Di Cocco, V.; Iacoviello, F.; Mocanu, L.P.; Parodo, G.; Sorrentino, L.; Turchetta, S. Analysis of Hydrothermal Ageing on Mechanical Performances of Fibre Metal Laminates. Processes 2023, 11, 2413. https://doi.org/10.3390/pr11082413

Bellini C, Di Cocco V, Iacoviello F, Mocanu LP, Parodo G, Sorrentino L, Turchetta S. Analysis of Hydrothermal Ageing on Mechanical Performances of Fibre Metal Laminates. Processes. 2023; 11(8):2413. https://doi.org/10.3390/pr11082413

Chicago/Turabian StyleBellini, Costanzo, Vittorio Di Cocco, Francesco Iacoviello, Larisa Patricia Mocanu, Gianluca Parodo, Luca Sorrentino, and Sandro Turchetta. 2023. "Analysis of Hydrothermal Ageing on Mechanical Performances of Fibre Metal Laminates" Processes 11, no. 8: 2413. https://doi.org/10.3390/pr11082413

APA StyleBellini, C., Di Cocco, V., Iacoviello, F., Mocanu, L. P., Parodo, G., Sorrentino, L., & Turchetta, S. (2023). Analysis of Hydrothermal Ageing on Mechanical Performances of Fibre Metal Laminates. Processes, 11(8), 2413. https://doi.org/10.3390/pr11082413