Failure Analysis of Casing in Shale Oil Wells under Multistage Fracturing Conditions

Abstract

:1. Introduction

2. Failure Condition Settings

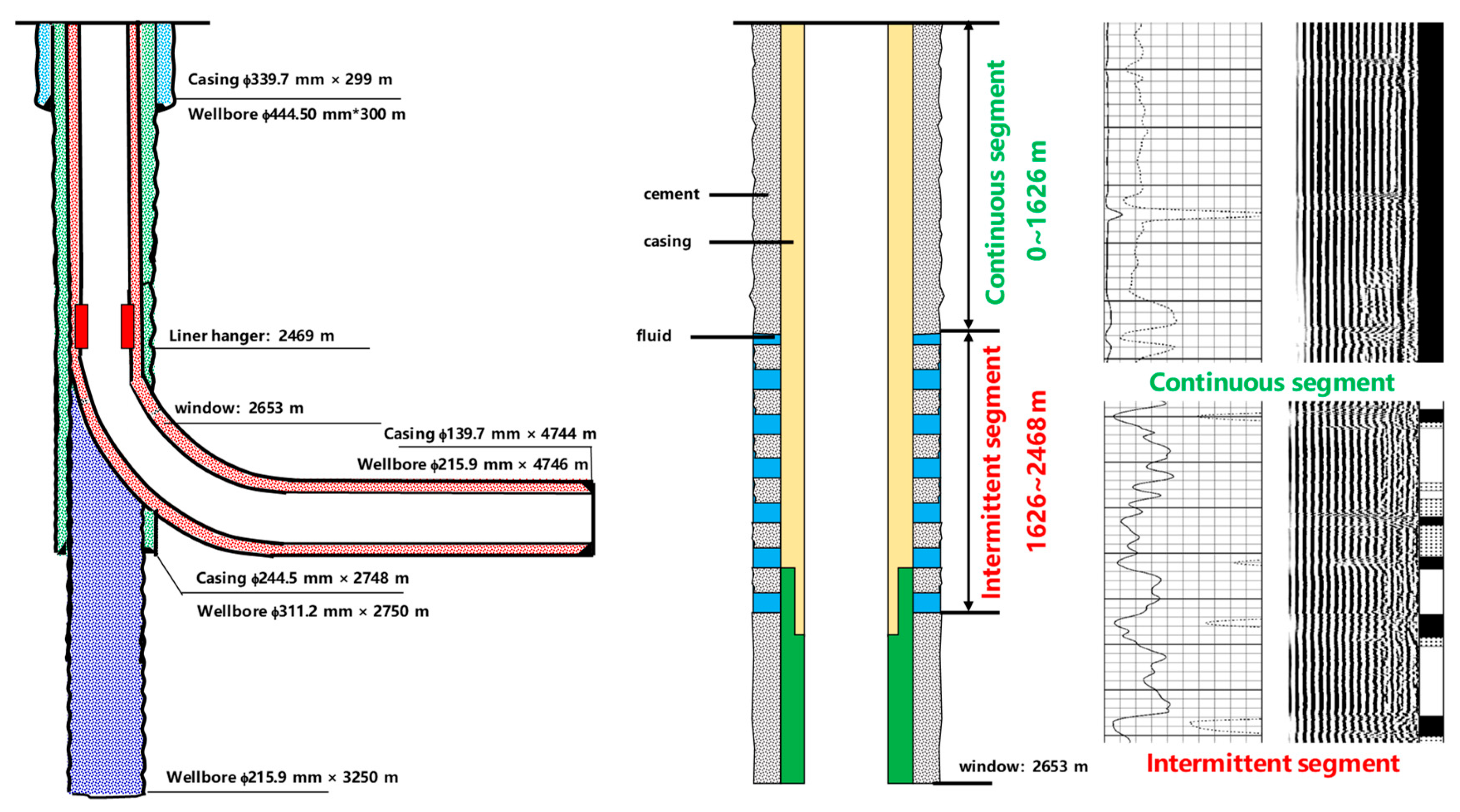

2.1. Wellbore Configuration

2.2. Failure Introduction

3. Experimental Study

3.1. Mechanical Performance Test of Casing

3.2. Cementing Strength Test of Interface between Casing and Cement

4. Numerical Simulation Study

4.1. Analysis of Wellbore Temperature and Pressure Fluctuation during Fracturing

4.2. Modeling of Whole Vertical Section Casing String with Tieback and Liner

4.3. Simulation Results

5. Discussion

6. Conclusions

- (1)

- During the multistage fracturing process, casing temperature and internal pressure change significantly repeatedly. These alternating loads result in significant changes in the axial force of the casing. As a result, the cementation between the casing and cement could be damaged under the alternating axial force.

- (2)

- High cementing quality at well depth 1626–2464 is intermittent in the LS1 well, and the longest length of cement segment with high cementing quality is 12.5 m, and the shortest length is 1.5 m. So, the axial deformation of the casing string progressively damages the cementation of the casing–cement interface from the tieback bottom (2464 m) upward.

- (3)

- During No. 13 fracturing, the tieback plug migrates 982.74 mm upward, length of broken cementation of the casing–cement interface reaches 838 m. Without the constraint of cementation from the cement ring, the 838 m casing contracted axially when the temperature dropped, resulting in the 1.1 m expansion section.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| RC | inside radius of the casing | m |

| hC | convection coefficient of the inner wall of the casing | W/m2/°C |

| TC | casing temperature | °C |

| TFR | temperature of fracture fluid in the casing | °C |

| WF | work from thermal friction between fracturing fluid and casing per unit time | W/m |

| TCa | casing temperature | °C |

| TCE | cement temperature | °C |

| TF | formation temperature | °C |

| ρFR | density of fracture fluid | kg/m3 |

| cFR | specific heat capacity of fracture fluid | J/kg°C |

| Nq | injection rate | m3/s |

| QHT | heat generated by convection heat transfer | W/m |

| QHC | heat carried by the down-flowing fracturing fluid per unit | W/m |

| QaC | axial heat conduction of a casing unit per unit time | W/m |

| QrC | radial heat conduction of a casing unit per unit time | W/m |

| RCE | inside radius of the cement | m |

| RF | inside radius of the formation | m |

| ρC | density of casing material | kg/m3 |

| cC | specific heat capacity of casing material | J/kg°C |

| μC | thermal conductivity of casing material | W/m/°C |

| EFRI | internal energy of fracturing fluid per unit | W/m |

| ECI | internal energy of casing per unit | N |

References

- Yu, H.; Mou, Y.; Lian, Z.; Zhang, Q. Is Titanium Drillpipe Applicable to Offshore Drilling? A Question from a Corrosion Fatigue Perspective. SPE J. 2021, 27, 116–132. [Google Scholar] [CrossRef]

- Yu, H.; Taleghani, A.D.; Lian, Z. On how pumping hesitations may improve complexity of hydraulic fractures, a simulation study. Fuel 2019, 249, 294–308. [Google Scholar] [CrossRef]

- Lian, Z.; Yu, H.; Lin, T.; Guo, J. A study on casing deformation failure during multi–stage hydraulic fracturing for the stimulated reservoir volume of horizontal shale wells. J. Nat. Gas Sci. Eng. 2015, 23, 538–546. [Google Scholar] [CrossRef]

- Liu, K.; Gao, D.; Wang, Y. Effects of local load on shale gas well casing deformation. Nat. Gas Ind. 2016, 36, 76–82. [Google Scholar]

- Yan, W.; Zou, L.; Li, H.; Deng, J.; Ge, H.; Wang, H. Investigation of casing deformation during hydraulic fracturing in high geo-stress shale gas play. J. Pet. Sci. Eng. 2017, 150, 22–29. [Google Scholar] [CrossRef]

- Yu, H.; Lian, Z.; Lin, T. Study on failure mechanism of casing in stimulated reservoir volume fracturing of shale gas. J. Saf. Sci. Technol. 2016, 12, 37–43. [Google Scholar]

- Yu, H.; Taleghani, A.D.; Lian, Z.; Lin, T. On how asymmetric stimulated rock volume in shales may impact casing integrity. Energy Sci. Eng. 2020, 8, 1524–1540. [Google Scholar] [CrossRef]

- Yu, H.; Taleghani, A.D.; Lian, Z.; Mou, Y. Severe Casing Failure in Multistage Hydraulic Fracturing Using Dual-Scale Modeling Approach. SPE Drill. Complet. 2022, 37, 252–266. [Google Scholar] [CrossRef]

- Liu, K.; Gao, D.; Wang, Y.; Yang, Y. Effect of local loads on shale gas well integrity during hydraulic fracturing process. J. Nat. Gas Sci. Eng. 2017, 37, 291–302. [Google Scholar] [CrossRef]

- Li, Y.; Liu, W.; Yan, W. Mechanism of casing failure during hydraulic fracturing: Lessons learned from a tight–oil reservoir in China. Eng. Fail. Anal. 2019, 98, 58–71. [Google Scholar] [CrossRef]

- Restrepo, M.M.; Teodoriu, C.; Salehi, S.; Wu, X. A novel way to look at the cement sheath integrity by introducing the existence of empty spaces inside of the cement (voids). J. Nat. Gas Sci. Eng. 2020, 77, 103274. [Google Scholar] [CrossRef]

- Li, H.; Li, Z.; Li, G.; Yu, H.; Jiang, Z.; He, L.; Guo, B.; Dong, M. Casing deformation mechanisms of horizontal wells in Weirong shale gas field during multistage hydraulic fracturing. J. Nat. Gas Sci. Eng. 2020, 84, 103646. [Google Scholar] [CrossRef]

- Yang, S.; Han, L.; Wang, J. Laboratory study on casing deformation during multistage horizontal well fracturing in shale gas development and strain based casing design. J. Nat. Gas Sci. Eng. 2021, 89, 103893. [Google Scholar] [CrossRef]

- Radakovic-Guzina, Z.; Damjanac, B.; Savitski, A.A.; Suarez, N. Analysis of the Production Casing Deformation Due to Shearing of Offset Hydraulic Fractures. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 20–22 June 2022. [Google Scholar]

- Zhang, H.; Tong, H.; Zhang, P. How can casing deformation be prevented during hydraulic fracturing of shale gas?—A case study of the Weiyuan area in Sichuan, China. J. Pet. Sci. Eng. 2023, 221, 111251. [Google Scholar] [CrossRef]

- Mou, Y.; Yang, S.; Han, L.; Wang, J.; Lian, Z. Mechanical Behavior and Optimization of Tubing String with Expansion Joint during Fracturing in HTUHP Wells. Processes 2022, 10, 1063. [Google Scholar] [CrossRef]

- Mou, Y.; Cui, J.; Wu, J.; Wei, F.; Tian, M.; Han, L. The Mechanism of Casing Deformation before Hydraulic Fracturing and Mitigation Measures in Shale Gas Horizontal Wells. Processes 2022, 10, 2612. [Google Scholar] [CrossRef]

| Type | Depth (m) | OD (mm) | Thickness (mm) | Steel Grade (ksi) | Thread Type | |

|---|---|---|---|---|---|---|

| Surface casing | 0–299 | 339.7 | 9.65 | J55 | BC | |

| Intermediate casing | 0–2748 | 244.5 | 11.99 | P110 | BC | |

| Production casing | Tieback | 0–2469 | 139.7 | 10.54 | P110 | TS1 |

| Liner | 2469–4744 | 139.7 | 10.54 | P110 | TS1 | |

| Property | At 20 °C Average ± Standard Deviation (n = 3) | At 80 °C Average ± Standard Deviation (n = 3) |

|---|---|---|

| Yield strength Rp0.2 (MPa) | 786.54 ± 2.05 | 746.49 ± 2.12 |

| Tensile strength (MPa) | 901.25 ± 2.15 | 867.46 ± 3.16 |

| Young’s modulus (GPa) | 208 ± 0.0001 | 206 ± 0.0001 |

| Elongation δ (%) | 15.67 ± 1.42 | 18.48 ± 1.09 |

| Property | Average ± Standard Deviation (n = 3) |

|---|---|

| Impact energy (J) | 75.57 ± 3.51 |

| Crack initiation energy (J) | 21.32 ± 2.15 |

| Crack propagation energy (J) | 54.26 ± 3.85 |

| Total displacement (mm) | 25.95 ± 3.47 |

| Maximum load (kN) | 9.54 ± 2.84 |

| Material | Density (kg/m3) | Specific Heat (J/kg/°C) | Thermal Conductivity (J/m/°C) | Coefficient of Expansion |

|---|---|---|---|---|

| Fracturing fluid | 1200 | 4178 | 0.84 | / |

| Casing/tieback/liner | 7849 | 460 | 51.9 | 1.25 × 10−5 |

| Cement | 3000 | 840 | 2.1 | 3.68 × 10−4 |

| Rock | 2650 | 765 | 2.5 | 6.85 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mou, Y.; Zhao, H.; Cui, J.; Wang, Z.; Wei, F.; Han, L. Failure Analysis of Casing in Shale Oil Wells under Multistage Fracturing Conditions. Processes 2023, 11, 2250. https://doi.org/10.3390/pr11082250

Mou Y, Zhao H, Cui J, Wang Z, Wei F, Han L. Failure Analysis of Casing in Shale Oil Wells under Multistage Fracturing Conditions. Processes. 2023; 11(8):2250. https://doi.org/10.3390/pr11082250

Chicago/Turabian StyleMou, Yisheng, Han Zhao, Jian Cui, Zhe Wang, Fengqi Wei, and Lihong Han. 2023. "Failure Analysis of Casing in Shale Oil Wells under Multistage Fracturing Conditions" Processes 11, no. 8: 2250. https://doi.org/10.3390/pr11082250

APA StyleMou, Y., Zhao, H., Cui, J., Wang, Z., Wei, F., & Han, L. (2023). Failure Analysis of Casing in Shale Oil Wells under Multistage Fracturing Conditions. Processes, 11(8), 2250. https://doi.org/10.3390/pr11082250