Research of Big Data Production Measurement Method for SRP Wells Based on Electrical Parameters

Abstract

1. Introduction

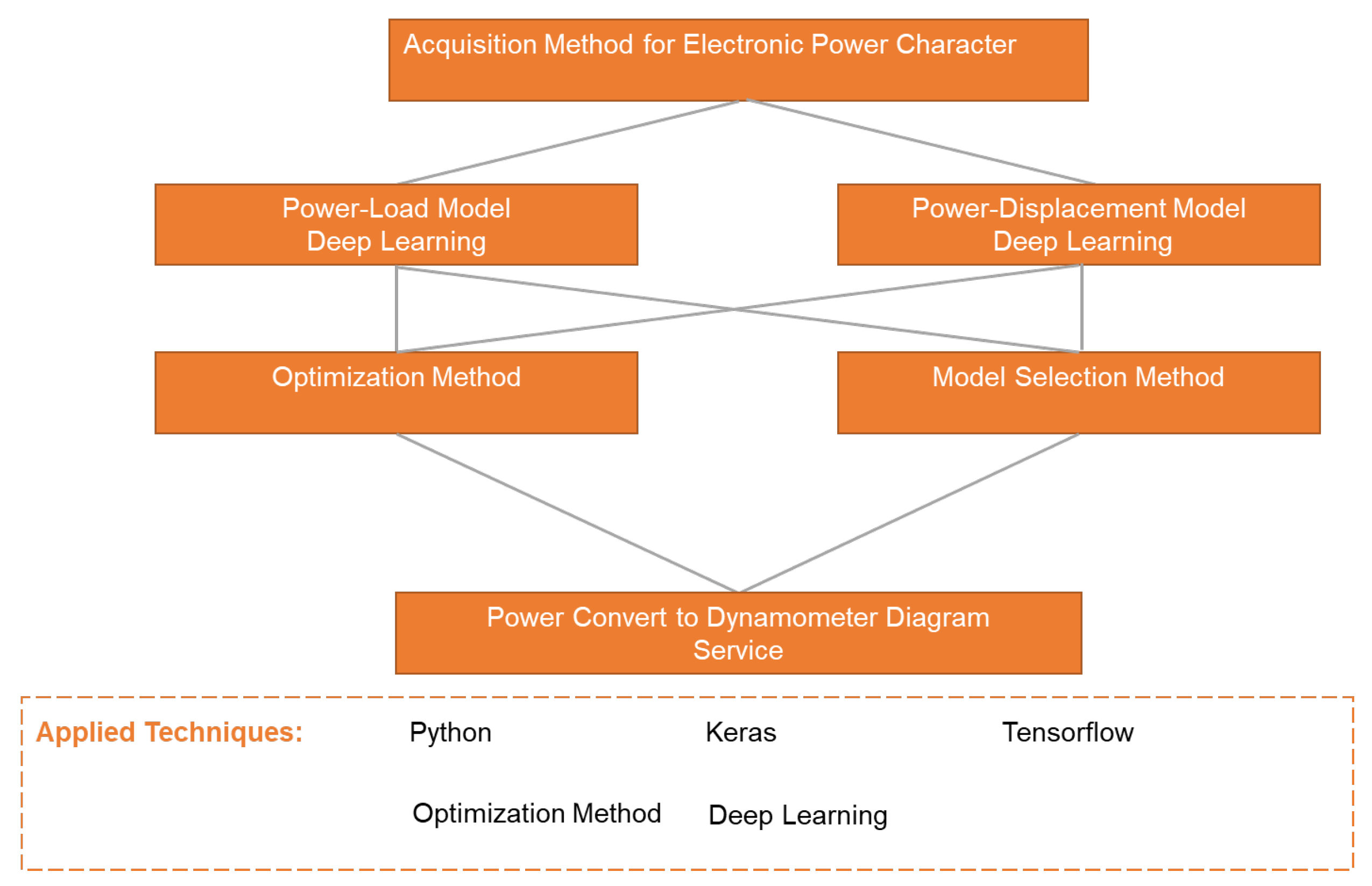

2. Description and Methodology of the System

2.1. Objective and Context

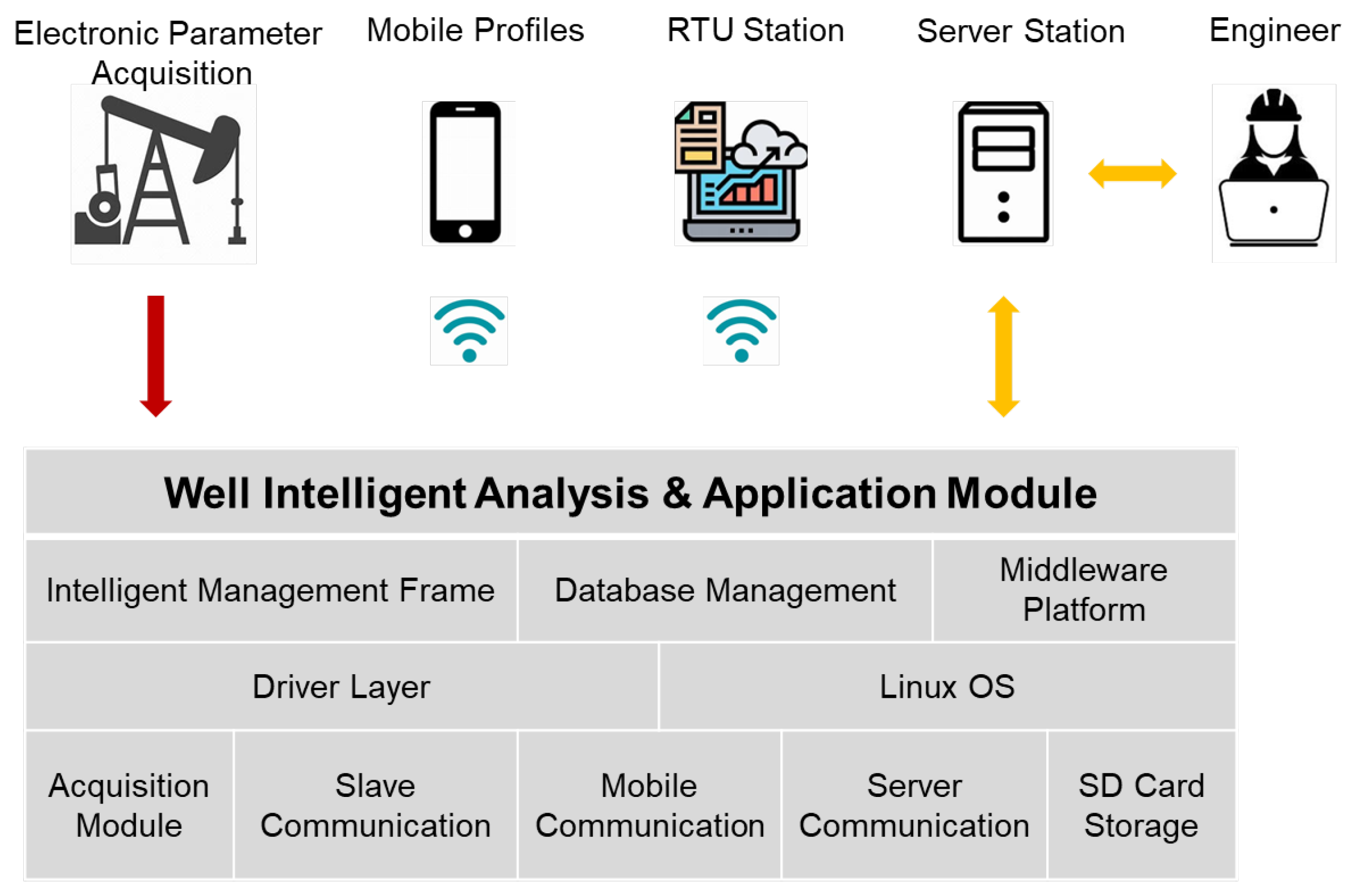

2.2. Description

2.3. Method

2.3.1. Device

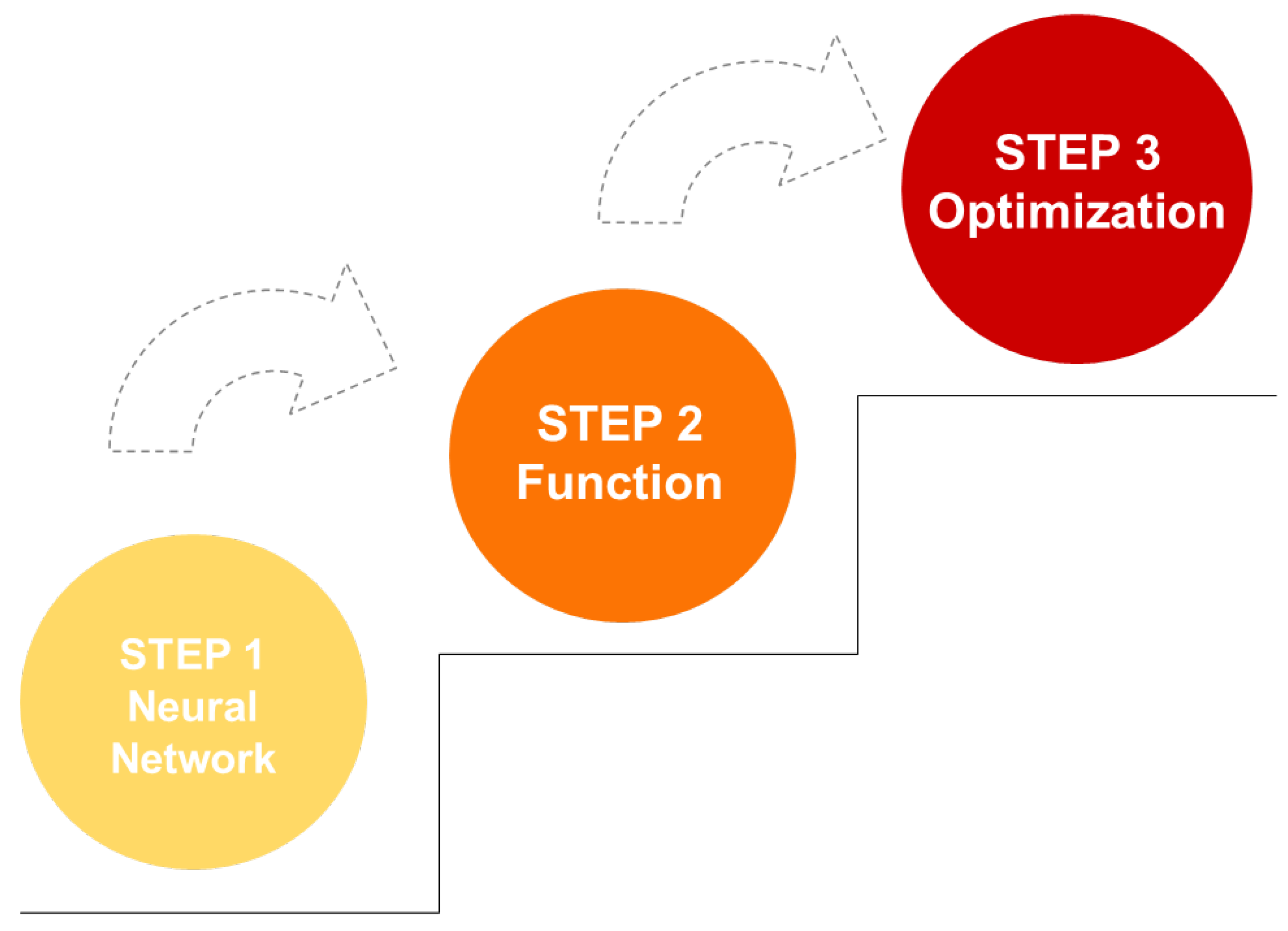

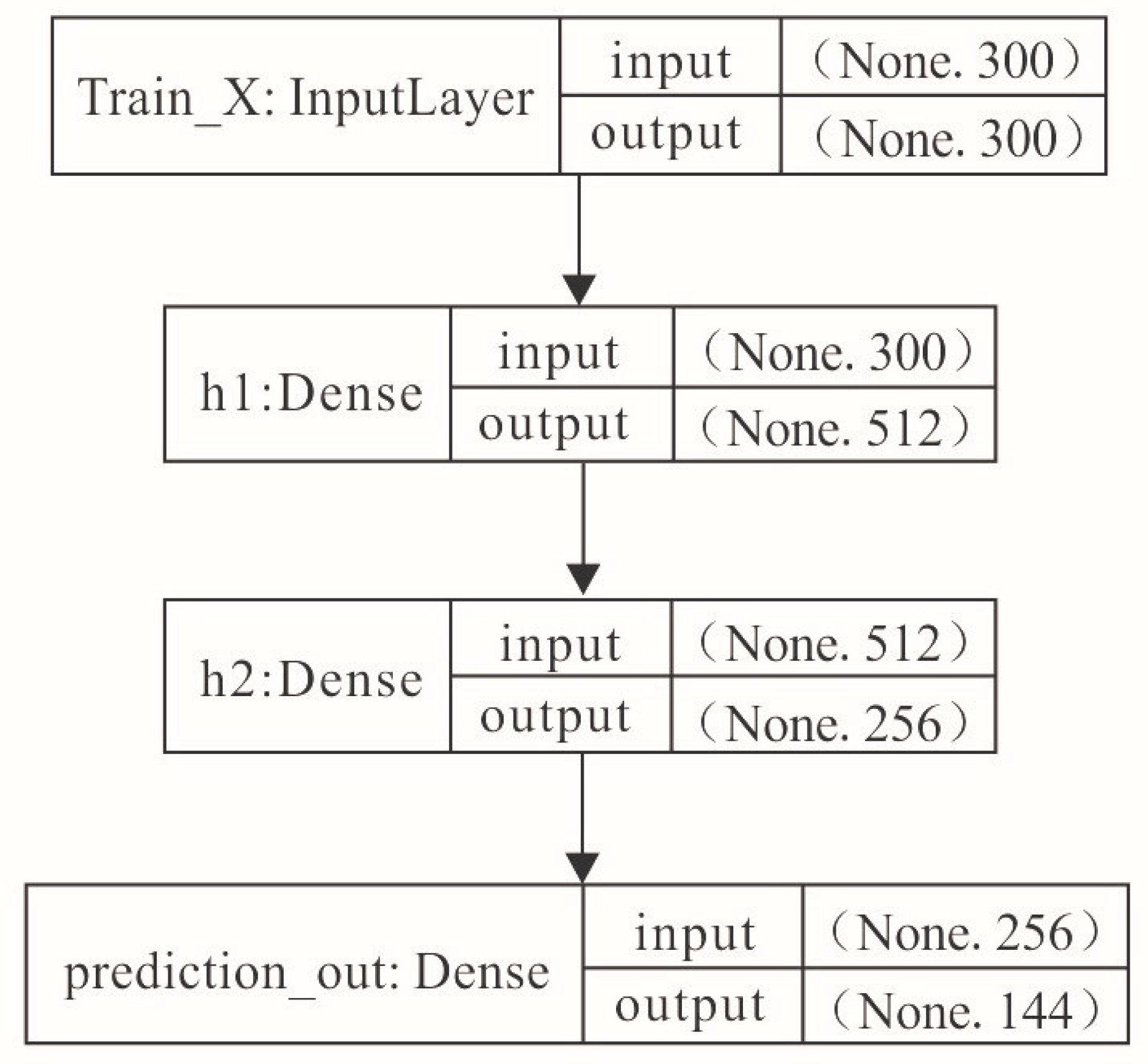

2.3.2. Model

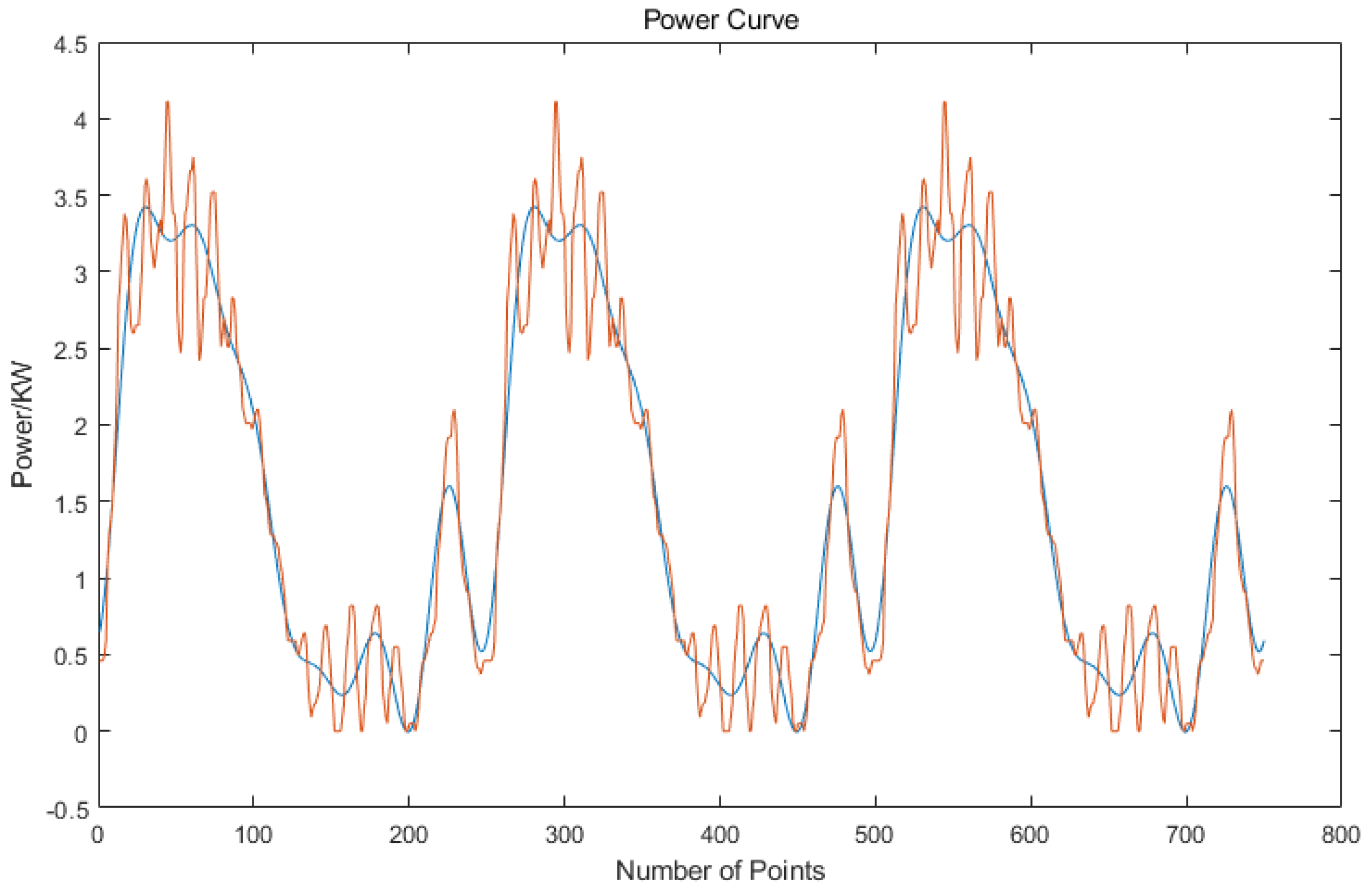

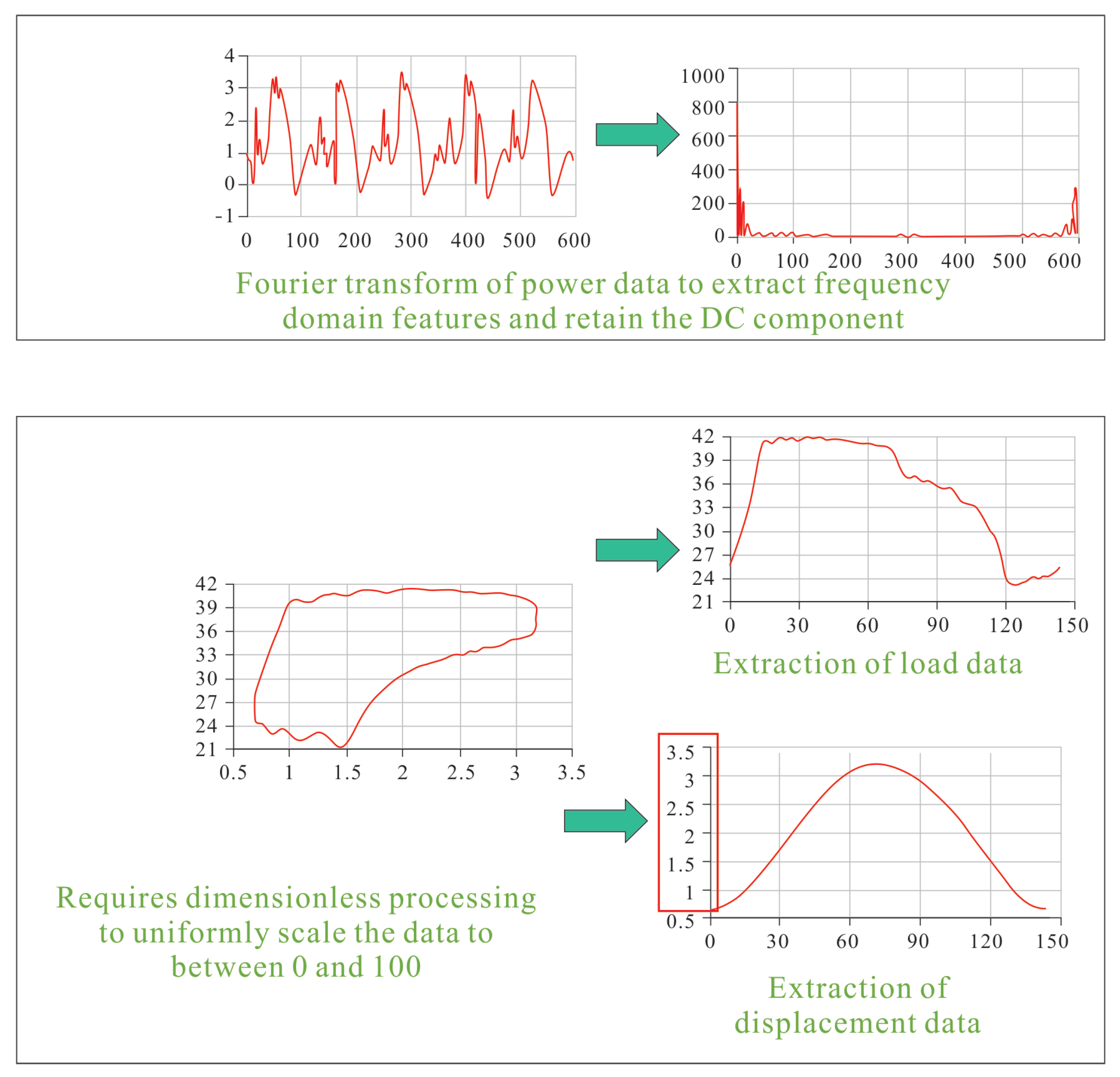

Data Preprocessing

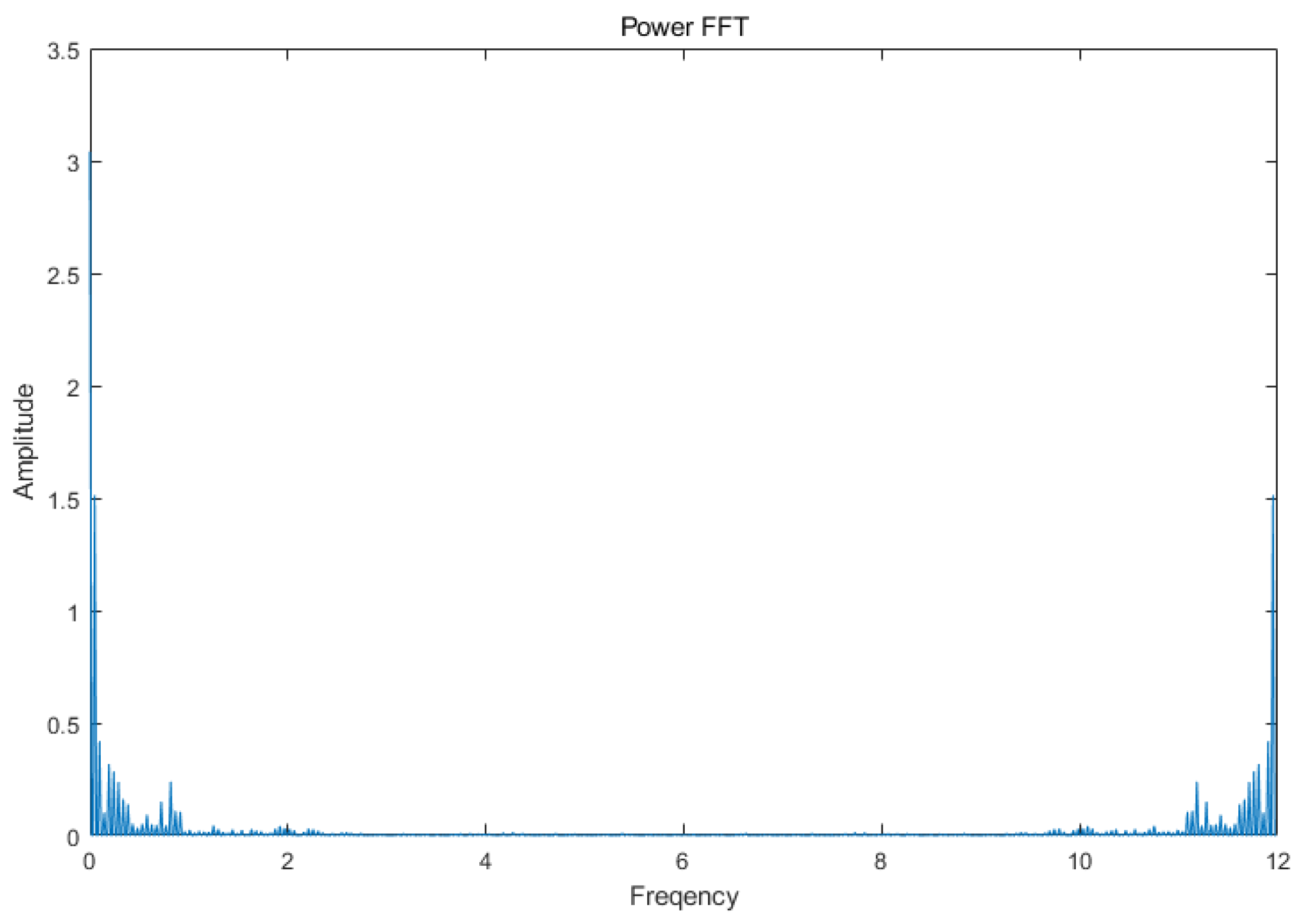

Identifying One Period of Electric Power Curve Using FFT

- Read in the electric power curve data of the oil pumping well and perform FFT operation on each set of data;

- Extract single cycle signals from the computed FFT results based on symmetry;

- Perform Inverse Fourier Transformation (IFFT) on the extracted single cycle signals to obtain a periodic curve.

Oil Well Production Forecasting Model

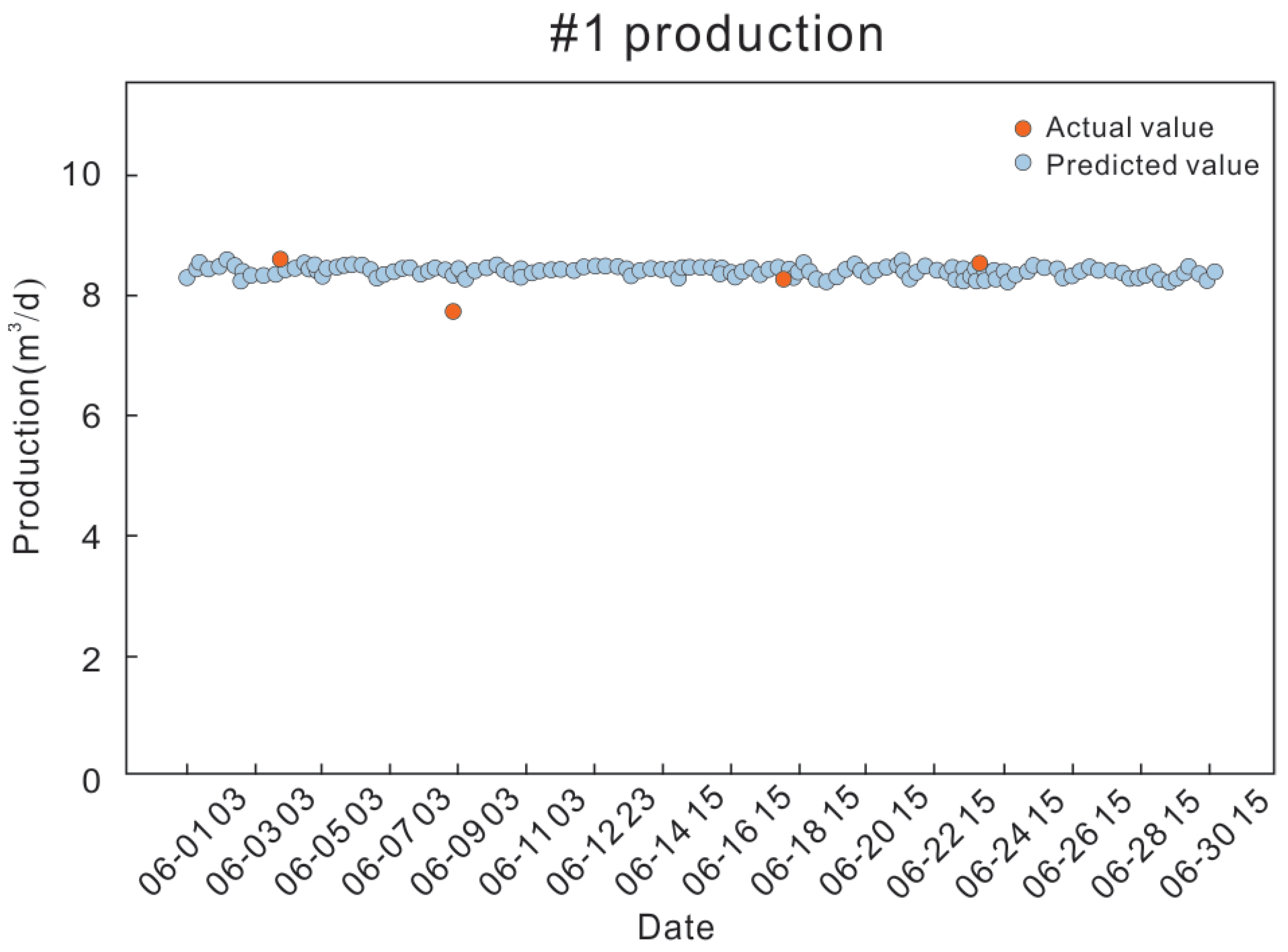

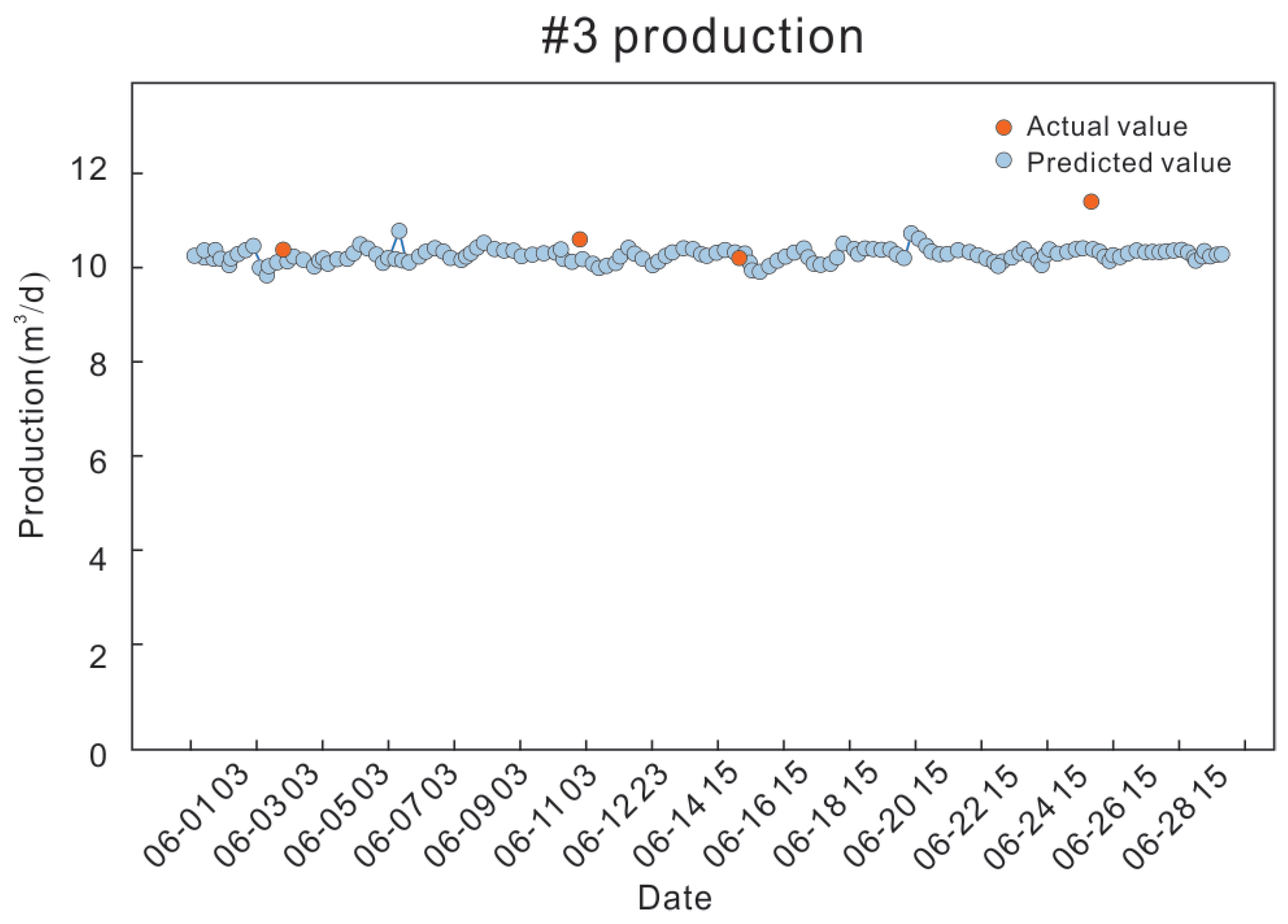

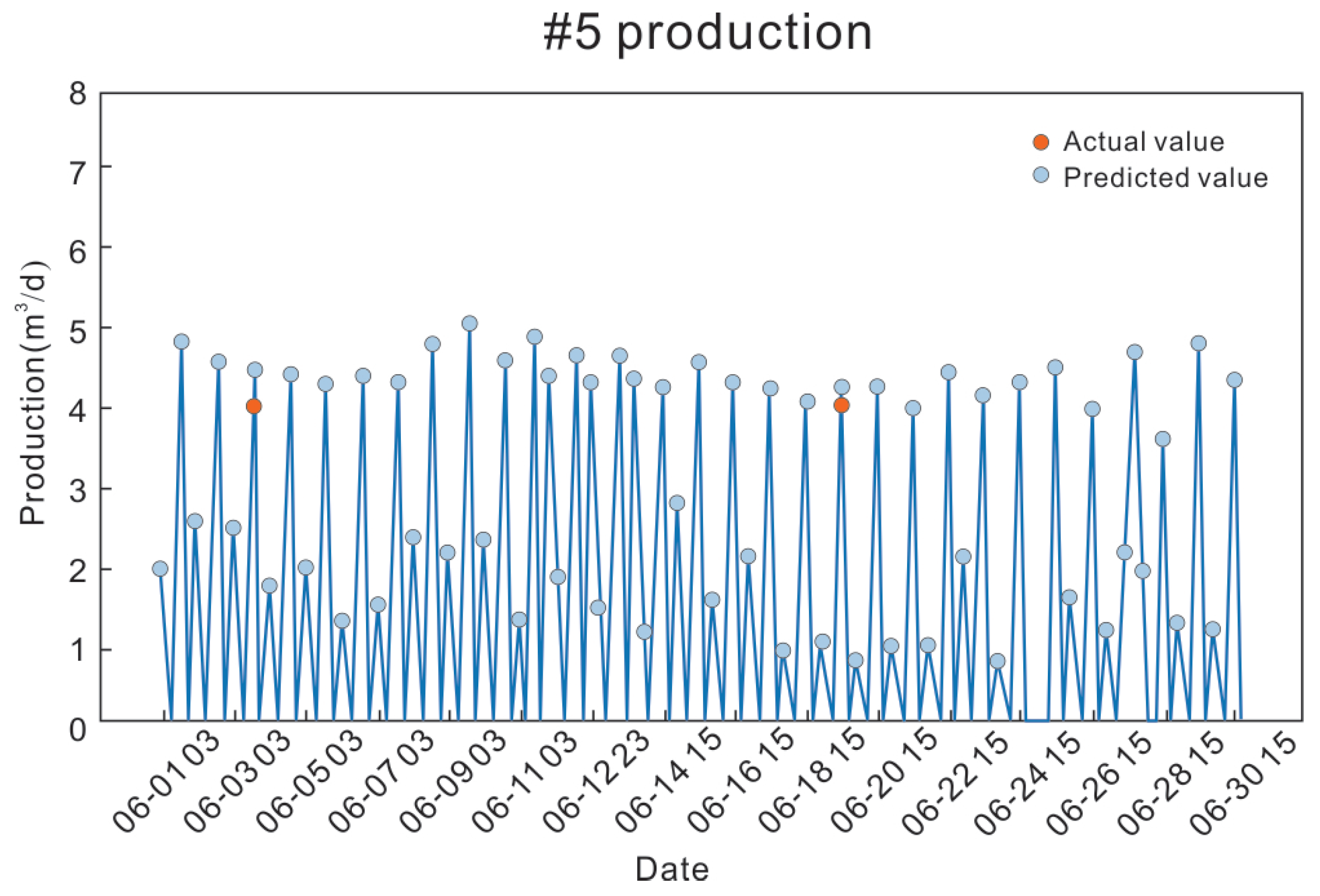

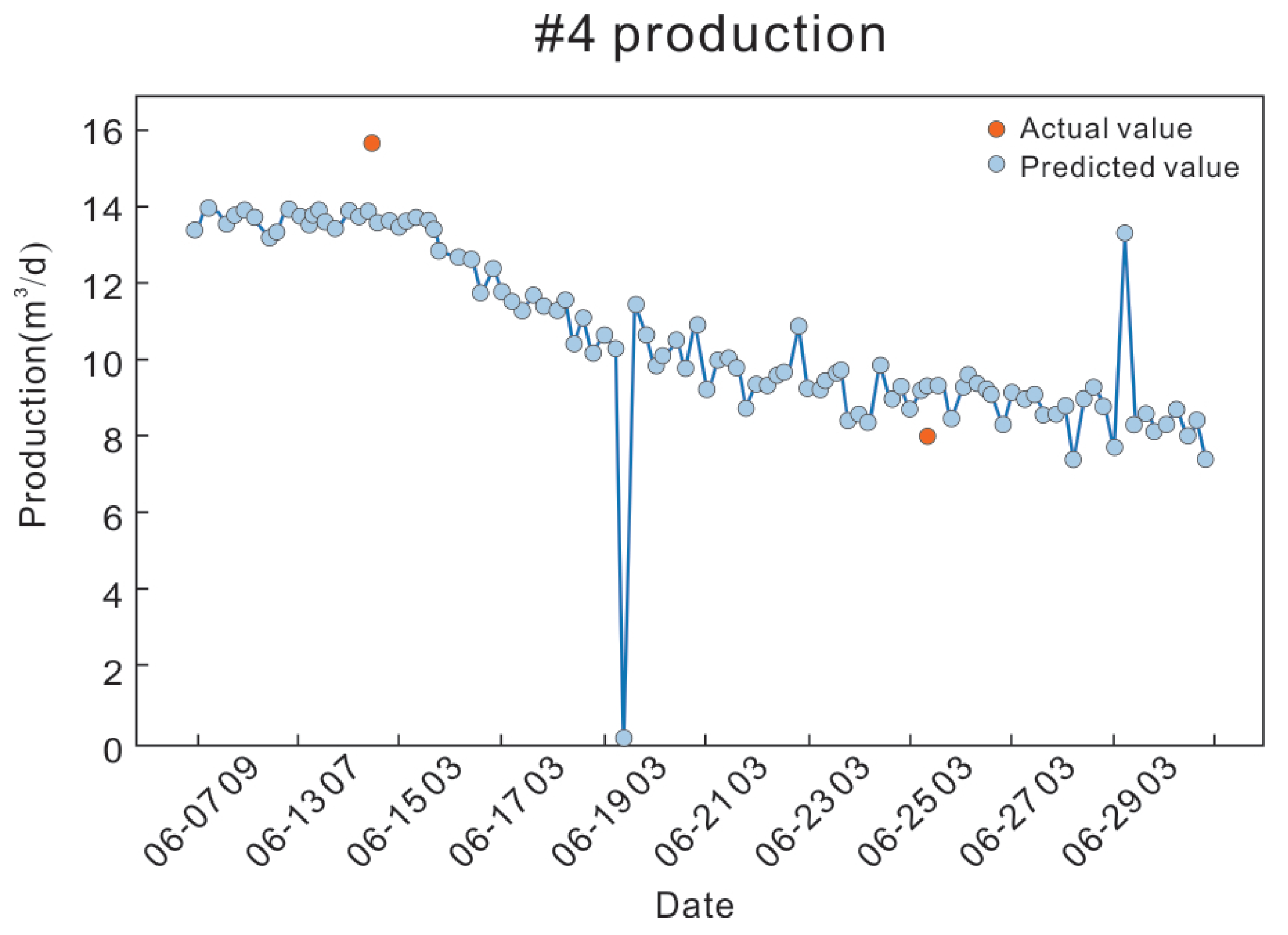

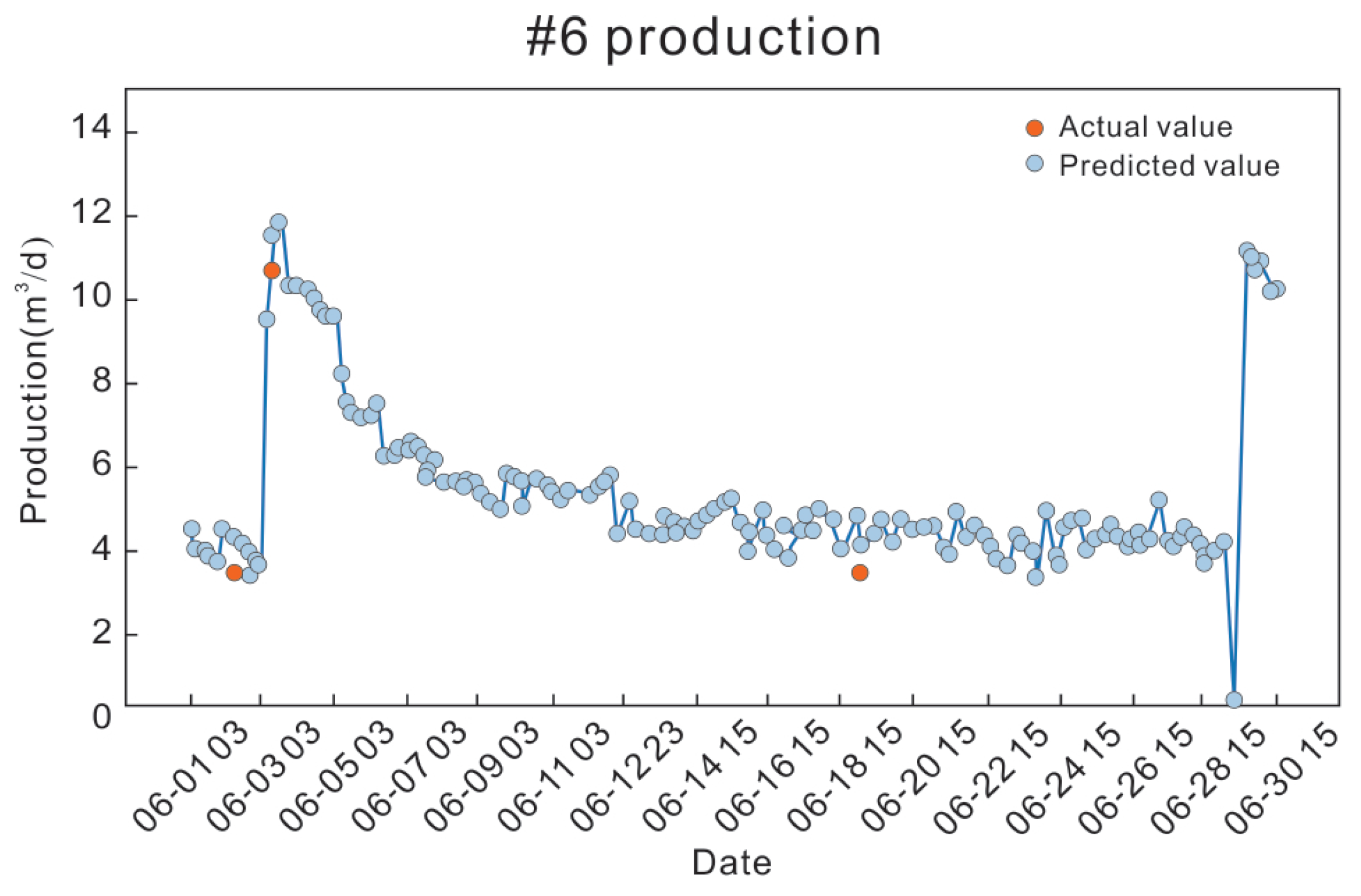

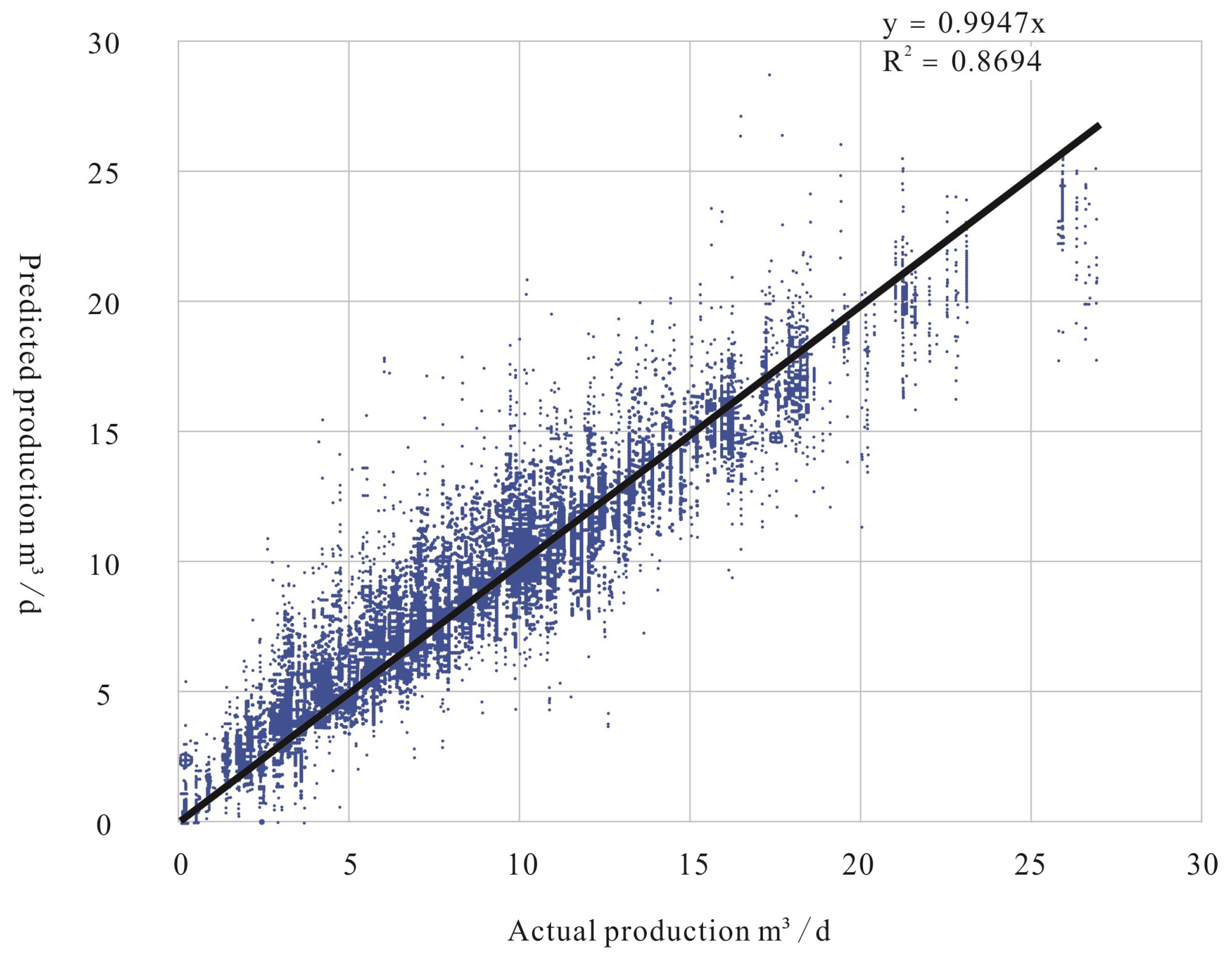

3. Field Application and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SRP | Sucker rod pump |

| FTT | Fast Fourier Transform |

| IFTT | Inverse Fast Fourier transform |

| RNN | Recurrent Neural Network |

| LSTM | Long Short-Term Memory |

References

- Zheng, B.; Gao, X. Diagnosis of Sucker Rod Pumping Based on Dynamometer Card Decomposition and Hidden Markov Model. Trans. Inst. Meas. Control 2018, 40, 4309–4320. [Google Scholar] [CrossRef]

- Zheng, B.; Gao, X. Sucker rod pumping diagnosis using valve working position and parameter optimal continuous hidden Markov model. J. Process Control 2017, 59, 1–12. [Google Scholar] [CrossRef]

- Kun, L.; Ying, H.; Tong, W. A novel prediction method for down-hole working conditions of the beam pumping unit based on 8-directions chain codes and online sequential extreme learning machine. J. Pet. Sci. Eng. 2017, 59, 285–301. [Google Scholar]

- Tao, R.; Xiaoqing, K.; Wen, S.; Hong, S. Study of Dynamometer Cards Identification Based on Root-Mean-Square Error Algorithm. Int. J. Pattern Recognit. Artif. Intell. 2018, 32, 1850004. [Google Scholar]

- Peng, X.; Shijin, X.; Yin, H. Application of self-organizing competitive neural network in fault diagnosis of suck rod pumping system. J. Pet. Sci. Eng. 2007, 58, 43–48. [Google Scholar]

- Wilamowski, B.; Kaynak, O. Oil well diagnosis by sensing terminal characteristics of the induction motor. IEEE Trans. Ind. Electron. 2000, 47, 1100–1107. [Google Scholar] [CrossRef]

- Bezerra, M.A.D.; Schnitman, L.; Filho, M.A.B.; Souza, J.F.D. Pattern Recognition for Downhole Dynamometer Card in Oil Rod Pump System using Artificial Neural Networks. Int. Conf. Enterp. Inf. Syst. 2009, 2, 351–355. [Google Scholar]

- Xiao, W.; Rui, Z.; Zhang, H.; Tao, Z.; Su, L. Key Technologies of Sucker Rod Pump Card Diagnosis Based on BP Neural Network. Adv. Mater. Res. 2011, 201–203, 433–437. [Google Scholar]

- Zhang, A.; Gao, X. Fault Diagnosis of Sucker Rod Pumping Systems Based on Curvelet Transform and Sparsemulti-graph Regularized Extreme Learning Machine. Comput. Intell. Syst. 2018, 11, 428–437. [Google Scholar] [CrossRef]

- Graves, A. Supervised Sequence Labelling with Recurrent Neural Networks. Stud. Comput. Intell. 2012, 385, 1–131. [Google Scholar]

- Yu, Y.; Si, X.; Hu, C.; Zhang, J. A Review of Recurrent Neural Networks: LSTM Cells Network Architectures. Neural. Comput. 2019, 31, 1235–1270. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Ge, L. Exploring the Attention Mechanism in LSTM-based Hong Kong Stock Price Movement Prediction. Quant. Financ. 2019, 19, 1507–1515. [Google Scholar] [CrossRef]

- Smagulova, K.; James, A.P. A Survey on LSTM Memristive Neural network Architectures and Applications. Eur. Phys. J. 2019, 228, 2313–2324. [Google Scholar] [CrossRef]

- Jonathan, W.; Ying, X. Radically Simplifying Gated Recurrent Architectures Without Loss of Performance. In Proceedings of the 2019 IEEE International Conference on Big Data (Big Data), Los Angeles, CA, USA, 9–12 December 2019; pp. 2615–2623. [Google Scholar]

- Greff, K.; Srivastava, R.K.; Koutník, J.; Steunebrink, B.R.; Schmidhuber, J. LSTM: A Search Space Odyssey. IEEE Trans. Neural Netw. Learn. Syst. 2015, 28, 2222–2232. [Google Scholar] [CrossRef] [PubMed]

- Federico, L.; Baraldi, L.; Marcella, C.; Cucchiara, R. Working Memory Connections for LSTM. Neural Netw. Off. J. Int. Neural Netw. Soc. 2021, 144, 334–341. [Google Scholar]

- Sahin, S.O.; Kozat, S.S. Nonuniformly Sampled Data Processing Using LSTM Networks. IEEE Trans. Neural Netw. Learn. Syst. 2019, 30, 1452–1461. [Google Scholar] [CrossRef] [PubMed]

| Well No. | Actual Production m/d | Predicted Production m/d | Absolute Error m/d | Relative Error |

|---|---|---|---|---|

| 01 | 5.6 | 5.000446 | 0.599554 | 10.71% |

| 02 | 9.5 | 8.413409 | 1.086591 | 11.44% |

| 03 | 5.6 | 4.742268 | 0.857732 | 15.32% |

| 04 | 5.6 | 5.631734 | 0.031734 | 0.57% |

| 05 | 3.4 | 3.768518 | 0.368518 | 10.84% |

| 06 | 3.4 | 3.385002 | 0.014998 | 0.44% |

| 07 | 8.8 | 7.485069 | 1.314931 | 14.94% |

| 08 | 3.4 | 3.898063 | 0.498063 | 14.56% |

| 09 | 4.8 | 5.26942 | 0.46942 | 9.78% |

| 10 | 6.2 | 5.38912 | 0.93058 | 15.01% |

| 11 | 5.6 | 6.47108 | 0.87108 | 15.56% |

| 12 | 7.2 | 5.674676 | 1.525324 | 21.96% |

| Total Number | Less than (Equal to) 4 m/d | 4 m/d to 10 m/d (Equal to) | More than 10 m/d | |

|---|---|---|---|---|

| Well time | 1599 | 297 | 904 | 398 |

| Average absolute error | 0.85 | 0.54 | 0.84 | 1.12 |

| Average relative error | 13.67% | 20.57% | 13.84% | 8.14% |

| Expected standard | - | Absolute error < 0.6 m/d | Relative error < 15 m/d | Relative error < 10 m/d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Zhao, R.; Deng, F.; Zhang, D.; Chen, G.; Hao, H.; Shi, J.; Zhang, X. Research of Big Data Production Measurement Method for SRP Wells Based on Electrical Parameters. Processes 2023, 11, 2158. https://doi.org/10.3390/pr11072158

Chen S, Zhao R, Deng F, Zhang D, Chen G, Hao H, Shi J, Zhang X. Research of Big Data Production Measurement Method for SRP Wells Based on Electrical Parameters. Processes. 2023; 11(7):2158. https://doi.org/10.3390/pr11072158

Chicago/Turabian StyleChen, Shiwen, Ruidong Zhao, Feng Deng, Deping Zhang, Guanhong Chen, Hao Hao, Junfeng Shi, and Xishun Zhang. 2023. "Research of Big Data Production Measurement Method for SRP Wells Based on Electrical Parameters" Processes 11, no. 7: 2158. https://doi.org/10.3390/pr11072158

APA StyleChen, S., Zhao, R., Deng, F., Zhang, D., Chen, G., Hao, H., Shi, J., & Zhang, X. (2023). Research of Big Data Production Measurement Method for SRP Wells Based on Electrical Parameters. Processes, 11(7), 2158. https://doi.org/10.3390/pr11072158