Abstract

With the increase in drilling fluid density requirements in low-pressure coefficient formations, traditional hollow bead drilling fluids and foam drilling fluids each have different degrees of deficiencies. Through extensive indoor experiments, an amphoteric surfactant (cocoamidopropyl betaine) with better foaming performance was selected to formulate an ultra-low-density drilling fluid that combines a foaming agent and hollow glass microbeads to reduce the density of the fluid, with the following specific formulation: 3% bentonite slurry + 0.3% xanthan gum + 0.5% carboxymethyl cellulose + 0.5% starch + 2% lignite resin + 2% blocking agent + 4% hollow glass microspheres + 0.5% foaming agent + 2% nano blocking agent. The performance of the system was evaluated, and the results showed that: the density of the ultra-low-density drilling fluid did not change much before and after aging at 80 °C and was relatively stable; the filter loss amount of the drilling fluid (tested by API) reached 4.6 mL, which meets the requirements for filter loss of drilling fluid; it can bear the pressure of 12 MPa under a 60–90-mesh sand bed and has better pressure sealing capability than hollow glass microbead drilling fluid.

1. Introduction

With the continuous development of coalbed methane, along with shale gas exploration and development, the problem of drilling oil and gas reservoirs with low-pressure coefficients is becoming more and more obvious [1,2]. Solving the problems of exploration and development of low-pressure coefficient reservoirs has high requirements for drilling fluid density [3]. Much research has been conducted on these issues. For such formations, the drilling fluids that are more frequently used at home and abroad are foam drilling fluids, fluffy capsule drilling fluids, and drilling fluids with hollow glass microspheres as a density-reducing agent [4,5,6,7,8,9,10,11,12,13,14,15]. In terms of materials used to reduce the density of drilling fluids, foaming agents and hollow glass microspheres are most commonly used. Yan Ye, Jienian Yan, et al. [16] used high-strength hollow glass microsphere-type drilling fluid as a continuous medium with incompressibility and density that can be adjusted in the range of 0.6 to 1.0 kg/L, which is suitable for drilling low-pressure oil and gas reservoirs. Zhu Jinyong et al. [17] selected suitable hollow glass microbeads for the problem of fracture-prone leakage in drilling of complex formations and evaluated the hollow glass microbeads. A low-density drilling fluid system with hollow glass microbeads as a mitigant was further optimized through experiments to obtain a good drilling fluid performance. Ma Pingping et al. [18] used DRfoam, a highly oil-resistant foaming agent, for low-pressure and low-permeability, strong, water-sensitive reservoir protection, and they enhanced foam drilling fluid stability by adding foam stabilizers to effectively extend foam life. Li Chenglin et al. [19] chose two anionic foaming agents, SDS (sodium dodecyl sulfate) compounded with ABS, to formulate a recyclable microfoam drilling fluid which has a special reticulation structure, low density, better ability to carry rock chips, and less filtration quality. Zheng Lihui et al. [20] developed a vesicle with sodium dodecylbenzene sulfonate, polyanionic cellulose, hydroxyethyl starch, and sodium dodecyl sulfonate as the main components to formulate a drilling fluid containing vesicle structure with a density of 0.85 g/cm3. Yang Xingli et al. [21] developed a new anionic surfactant foaming agent based on sodium salt of fatty alcohol polyoxyethylene ether-phthalate, which is superior to both sodium dodecyl sulfate and sodium dodecyl benzene sulfonate foaming performance in terms of stability and has better temperature and salt resistance, which is not only suitable for extending the eastern shallow extra-geo-permeable reservoirs but is also adapted to extending the western middle and deep extra-low-permeable reservoirs. Whether the drilling fluid density is reduced by using hollow glass microspheres as a mitigating agent or by formulating foam drilling fluids with foaming agents, the density can only be reduced to 0.85–0.90 g/cm3; for more complex, lower pressure formations, lower density drilling fluids are required.

In this study, based on the experiment of using hollow glass microbeads as a drilling fluid mitigating agent, a foaming agent was added to further reduce the drilling fluid density and formulate a preferred ultra-low-density drilling fluid. The effects of hollow glass microsphere, polymer, and foaming agent on drilling fluid rheology, density, and filtration quality were analyzed. The addition of foaming agent can reduce the amount of hollow glass microspheres in the drilling fluid, reduce the content of solid-phase particles, and also meet the requirements of drilling fluid density in low-pressure formations.

2. Ultra-Low-Density Drilling Fluid Construction Suitable for Low-Pressure Formations

2.1. Conceptual Design for the Drilling Fluid System

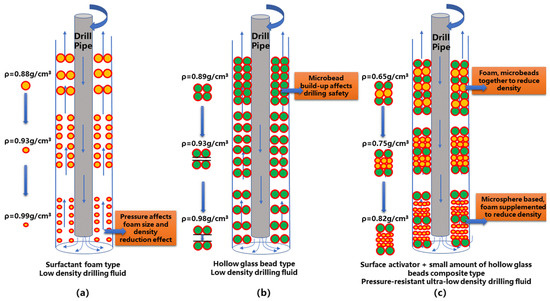

For oil and gas exploration and development in low-pressure formations, there are high requirements for drilling fluid density. The foam-type low-density drilling fluid with surfactant as a foaming agent has the advantages of low density, good rheological rock-carrying effect, and good oil and gas formation-protection performance, but with the increase in formation pressure the foam film becomes thinner and the foam gradually becomes larger and finally ruptures, which affects the size of the foam and the density reduction effect. The low-density drilling fluid with hollow glass microspheres as a mitigant has the advantages of incompressibility, no distortion of the MWD (measurement while drilling) signal [22,23], improved mud cake, no harm to the reservoir, etc. However, the general addition of hollow glass microspheres can only reduce the density of drilling fluid to a maximum of 0.7 g/cm3, and if hollow beads are added, they will cause buildup; the increase in solid-phase content within the drilling fluid affects the rheology [17], which in turn affects the drilling safety. In this paper, we mainly use the two additives to reduce the density together, mainly hollow glass microspheres, and the foaming agent is used as a supplement to achieve the requirement of reducing the density and pressure resistance of drilling fluid, and having sufficient sealing effect [24]. Therefore, this paper intends to combine the two to effectively reduce the drilling fluid density. The conceptual design for ultra-low-density drilling fluid is shown in Figure 1.

Figure 1.

Ultra-low-density drilling fluid conceptual design. (a) shows the low-density drilling fluid with surfactant-based; (b) shows the low-density drilling fluid with hollow glass beads; (c) shows the ultra-low-density drilling fluid with the synergistic effect of hollow glass beads and surfactant; orange represents foam; green represents hollow glass beads and arrows represent the density change process.

2.2. Basic Formulation of Drilling Fluid

The basic drilling fluid formulation was formulated through extensive preliminary experiments; 3% Bentonite slurry + 0.5% Carboxymethyl cellulose (LV-CMC) + 0.5% starch. Carboxymethyl cellulose (LV-CMC) dissolved in water has the obvious effect of increasing the viscosity of the solution. Both have certain viscosity-increasing effects when combined with starch and can be used in drilling fluids to reduce the level of filtration quality and strengthen the stabilizing effect of foam.

3. Materials

The main materials used in the experiments are shown in Table 1.

Table 1.

Materials used in the experiment.

4. Analysis of Ultra-Low-Density Drilling Fluid System

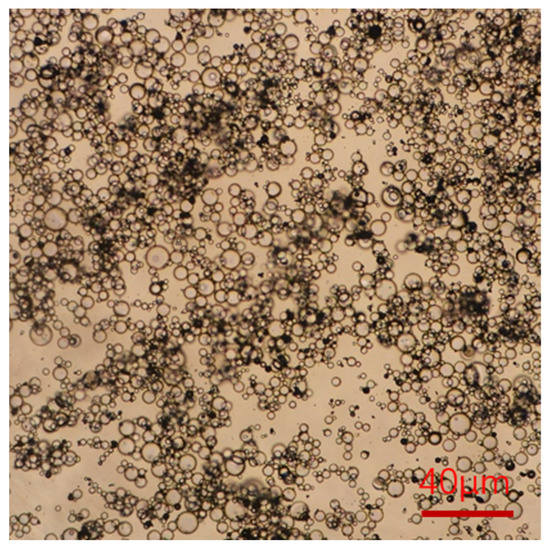

4.1. Hollow Glass Microspheres

Drilling fluid with hollow glass microspheres has low density, high compressive strength, and is easily deployed; it can be applied to deep wells, and its density remains stable. As the microbeads have a round spherical shape and excellent fluidity, they have an excellent lubricating effect which can reduce the frictional resistance during the drilling process, while the hollow glass microspheres in the drilling fluid can be recycled and reused to reduce the production cost [25]. Figure 2 shows the magnification of hollow glass microspheres under the microscope (100× magnification).

Figure 2.

Magnified view of hollow glass microspheres under the microscope (100× magnification).

In this experiment, domestic HL-type hollow glass microspheres were used as additives, and Table 2 shows the average true density of hollow glass microspheres. To control the density of drilling fluid to the greatest extent possible, hollow glass microspheres with specifications HL35 and HL42 are used in this paper.

Table 2.

Parameters of different types of hollow glass microspheres.

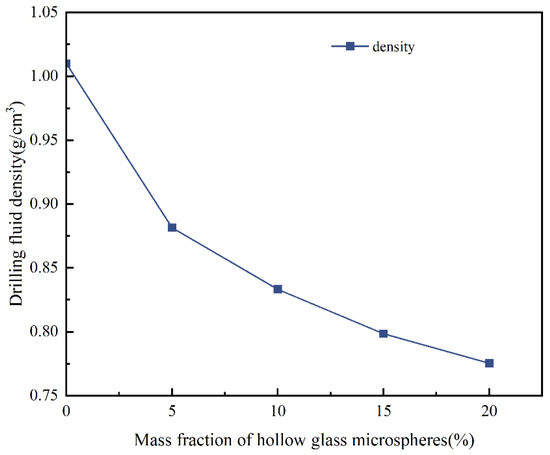

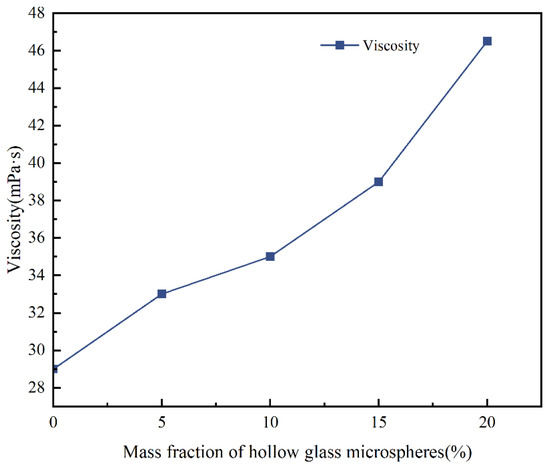

The effect of hollow glass microspheres on the density and rheology of drilling fluid was measured by adding different additions of hollow glass microspheres to the freshwater base slurry. As shown in Figure 3 and Figure 4, the drilling fluid density gradually decreases as the number of added hollow glass microspheres increases, while the viscosity of the drilling fluid shows a gradual increase. This is because the solid-phase content of the drilling fluid is larger, the relative surface area of the particles increases, and the friction between the particles becomes more frequent, resulting in a larger change in the rheological properties of the drilling fluid. From the overall view of the effect of hollow glass microspheres on drilling fluid, there is a significant decrease in density at the time of 5% addition and a steady decrease in density at the time of more than 5% addition, while the viscosity gradually increases with the increase in the number of hollow glass microspheres [17]. The drilling fluid density is 0.88 g/cm3, and the number of hollow glass microspheres can be controlled according to the required drilling fluid density and well depth in actual field application.

Figure 3.

Variation in density according to the number of hollow glass microspheres.

Figure 4.

Variation in viscosity according to the number of hollow glass microspheres.

4.2. Foaming Agent

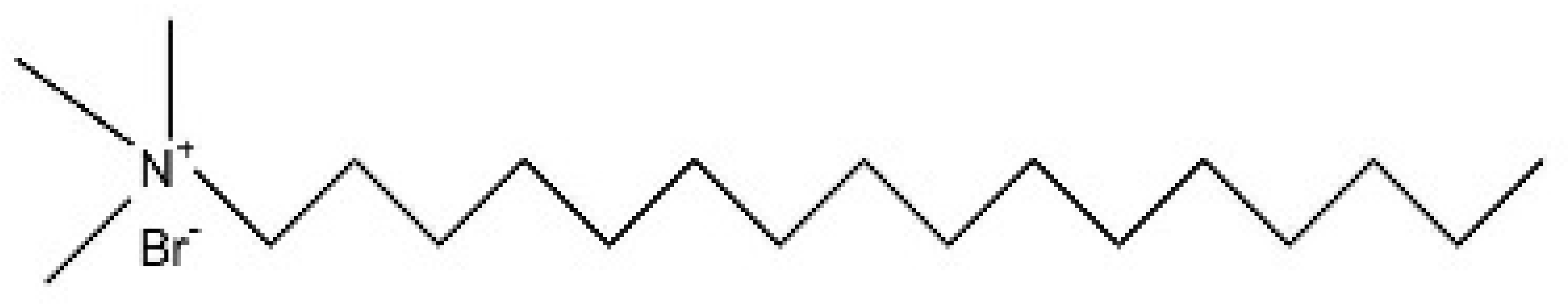

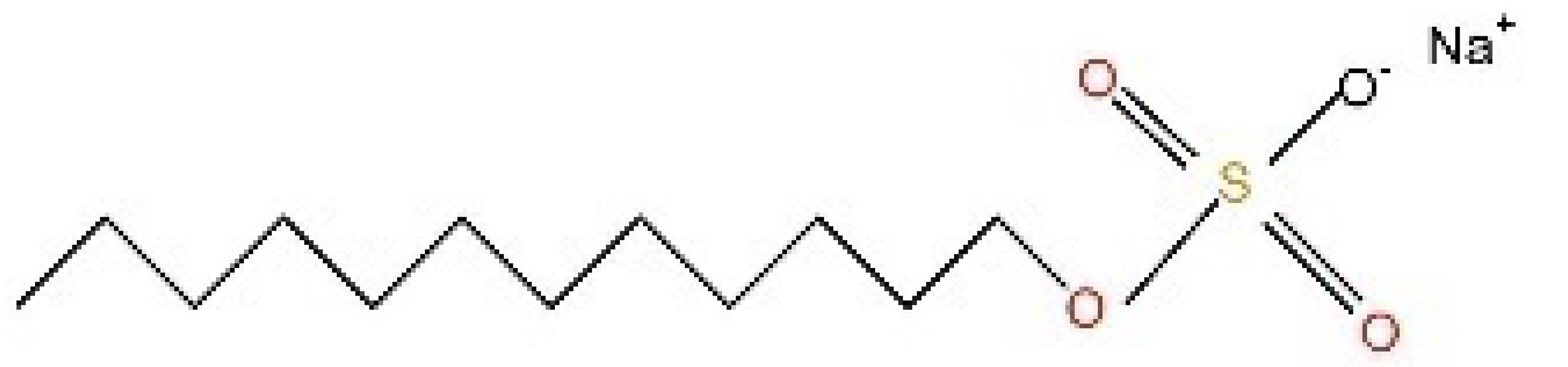

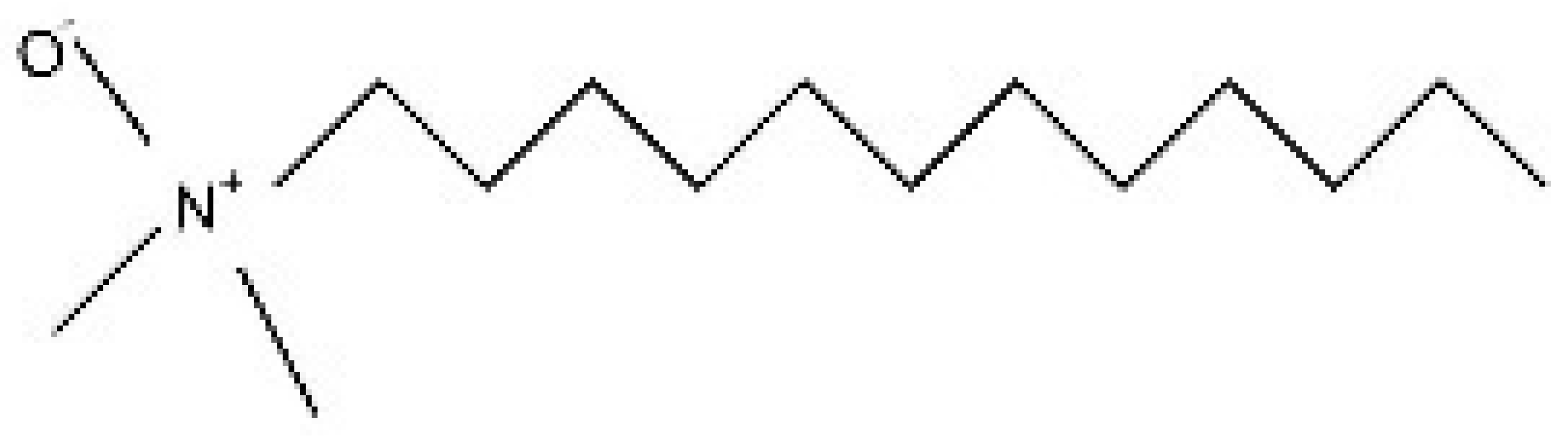

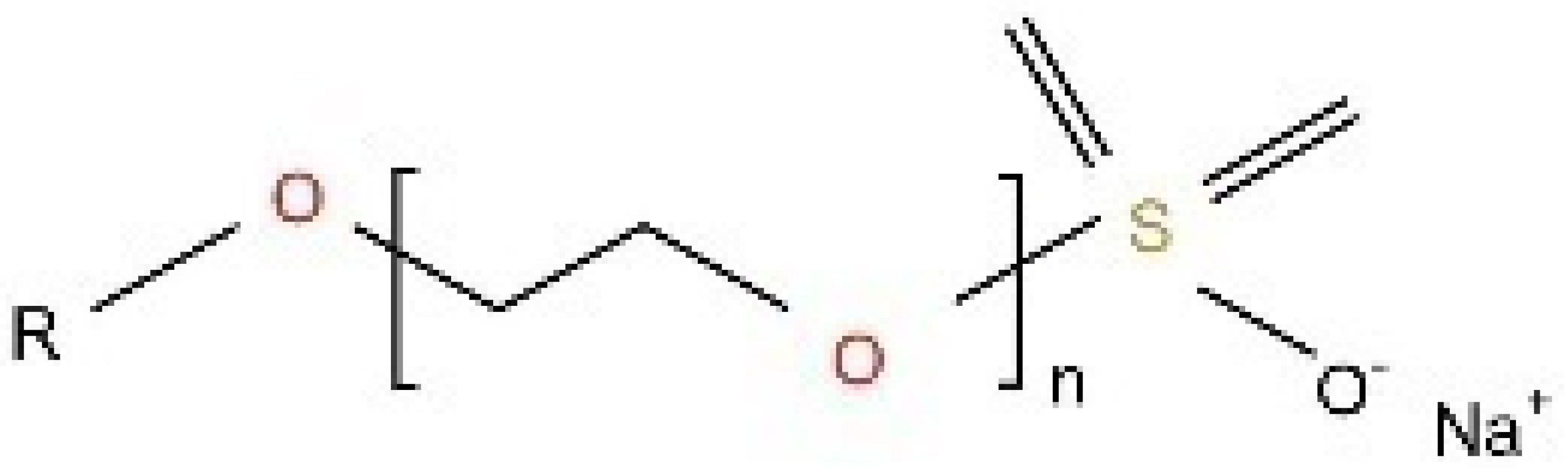

Foaming agents are commonly used in micro-foam drilling fluid systems, which require foaming agents with good foaming ability where the foaming volume is not too high and the foam is fine and uniform [26]. In this paper, we have selected several common foaming agents from which to choose the appropriate foaming agent by observing foaming volume and half-life.

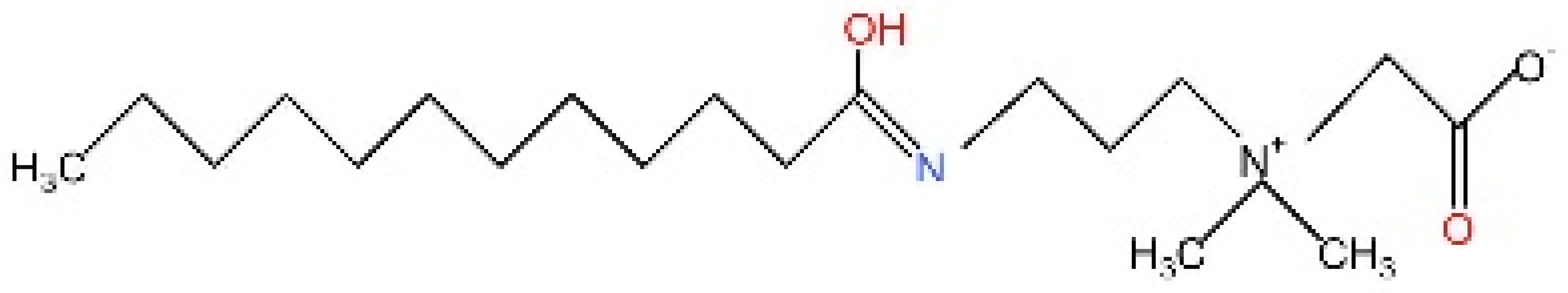

This paper uses the stirring method to measure foaming volume and half-life: add 0.5g of foaming agent to 100 mL of water, stir at 8000 r/min for 2 min using a high-speed stirrer, quickly pour into a measuring cylinder and record the height of the foam before measuring the time it takes for half of the base liquid to precipitate, thus indicating the foam’s half-life. As shown in Table 3, the above experimental comparison of foaming agent performance shows that the foaming time of dodecyl dimethyl ammonium bromide and fatty alcohol polyoxyethylene ether sulfur surfactant is shorter, the foaming amount of cetyl trimethyl ammonium bromide surfactant is lower, and the foaming performance of cocamidopropyl betaine and sodium dodecyl sulfate is better. Cocamidopropyl betaine (CAB-35) is a colorless–pale yellow transparent liquid with low irritation, mild properties, rich and stable foam, viscosity regulation, and bactericidal action [27]. Composed of quaternary ammonium cations, carboxylic acids, sulfonic acids, and phosphoric acids, cocamidopropyl betaine has good compatibility with a wide range of surfactants, polymers, and salts. Sodium dodecyl sulfate (SDS) consists of a 12-carbon tail linked to a sulfate root which combines with a polar “head group” to give the compound its amphiphilic nature. Compared to other types of foaming agents, sodium dodecyl sulfate produces more foam.

Table 3.

Comparison of foaming performance of different types of foaming agent.

4.3. Foam Stabilizer

Foam stability is an important factor in the evaluation of foam; generally, a single foaming agent can have a good foaming effect but cannot stabilize the foam, and the foam half-life is short and cannot meet the application requirements. Therefore, to improve the stability of the foam and increase its half-life, it is necessary to add foam stabilizer. Research and field application found that xanthan gum (XC) has a good foam stabilization effect [28]. This is due to the ability of xanthan gum sol molecules to form super-bonded ribbon-like helical copolymers constituted by a fragile gum-like mesh structure; thus, they can better support solid particles, droplets, and foam forms and show strong emulsion stabilization and high suspension capacity [29].

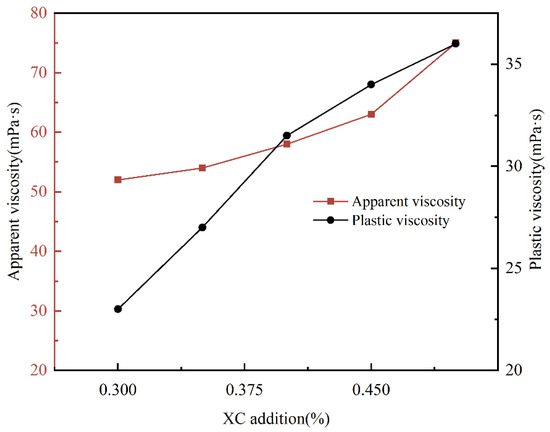

From the experimental results (Figure 5), it can be seen that with the continuous increase in the amount of XC, the drilling fluid viscosity increased from 52 mPs·s to 75 mPa·s and the shear force increased from 23 Pa to 34 Pa, indicating that the thickening effect of XC is relatively evident; the addition of more xanthan gum inhibits the foaming amount and performance. In this paper, the final choice of XC quantity for the experiment is 0.3%.

Figure 5.

Variation in apparent viscosity according to the amount of XC.

Using XC as a stabilizer is the key factor to enhancing the stability of the foam. XC was added to water as the base slurry, and after stirring for 20 min, the foaming agent was stirred at 8000 r/min for 2 min in a high-speed stirrer, after which it was quickly poured into a measuring cylinder and the foaming amount and half-life of the foaming agent were recorded to compare the foaming performance of the two foaming agents. As shown in Table 4, the foaming amount of cocamidopropyl betaine was slightly lower than that of sodium dodecyl sulfate but its stabilization time of foam was longer, so cocamidopropyl betaine was chosen as the foaming agent in this paper.

Table 4.

Comparison of foaming performance of surfactants with XC.

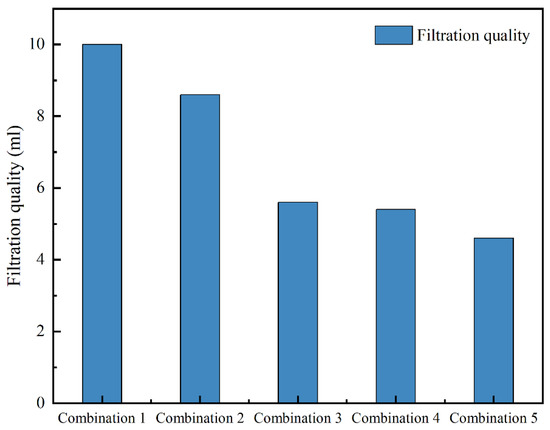

4.4. Filter Loss-Reducing Agents

Five types of filter loss-reducing agents were selected: sulfonated lignite (SMC), high temperature-resistant filter loss-reducing agent (SCP), asphalt resin anti-collapse agent (LSF), starch, and sulfonated phenolic resin (SMP-2); several combinations of these five filter loss-reducing agents were made, as follows. Combination 1: 2% sulfonated lignite + 2% sulfonated phenolic resin. Combination 2: 2% anti-high temperature filter loss reducer + 2% sulfonated lignite. Combination 3: 2% sulfonated lignite + 2% asphalt resin anti-collapse agent + 1% starch. Combination 4: 2% sulfonated lignite + 2% asphalt resin anti-collapse agent + 0.5% starch. Combination 5: 0.5% starch + 2% anti-high temperature filter loss reducer + 2% asphalt resin anti-collapse agent. The experimental results are shown in Figure 6.

Figure 6.

Effect of different combinations of filter loss-reducing agents on water loss in drilling fluids.

It can be seen from Figure 6 that starch can effectively reduce the filtration quality of drilling fluid, and the filtration quality reduction effect of high temperature-resistant filter loss reducing agents in this experimental system is better than that of sulfonated phenolic resin. Asphalt resin anti-collapse filtration quality reducer is a compound material of several filtration quality reducers which has a better filtration quality reduction ability, and after adding starch and high temperature-resistant filter loss-reducing agents, the filtration quality was reduced to 4.6 mL, which meets the drilling requirements.

4.5. Nano Leak Plugging Agent

The nano plugging agent was selected, the amount of plugging agent was chosen, and the plugging effect was evaluated. By the drilling fluid plugging evaluation method, the drilling fluid was added to the medium-pressure water loss tester and pressurized at 0.7 MPa, and the filtration quality of the drilling fluid was tested at room temperature for 30 min.

The experimental results showed (Table 5) that the rheological viscosity of the drilling fluid varied greatly at the addition amount of 3% by adding different nano plugging agents, indicating that the addition of higher amounts played a viscosity-increasing role for the system. Comparing the performance of drilling fluid with 1% and 2% amounts of nano plugging agent, the rheology of drilling fluid with 2% nano plugging agent was almost unchanged and its filtration quality was reduced to 7.1 mL. Therefore, the 2% amount of nano plugging agent was selected.

Table 5.

Rheological properties and filtration quality of nano plugging agents with different dosages.

5. Performance of Ultra-Low-Density Drilling Fluids

The drilling fluid formulations determined by the indoor evaluation were evaluated for rheology, stability, and filtration quality as follows: 3% bentonite slurry + 0.3% xanthan gum + 0.5% carboxymethyl cellulose + 0.5% starch + 2% anti-high temperature filter loss reduction agent + 2% asphalt resin anti-collapse agent + 4% hollow glass microspheres + 0.5% foaming agent + 2% nano plugging agent.

5.1. Atmospheric Pressure Rheology

Three different drilling fluids were prepared according to the determined formulations, namely base slurry, drilling fluid with hollow glass microspheres as a mitigant, and ultra-low-density drilling fluid; the rheological properties of these three drilling fluids were compared, and the results are shown in Table 5. Base slurry: 3% bentonite slurry + 0.3% xanthan gum + 0.5% carboxymethyl cellulose + 0.5% starch + 2% anti-high temperature filter loss reduction agent + 2% asphalt resin anti-collapse agent.

As can be seen from Table 6, the apparent viscosity of the ultra-low-density drilling fluid formed by adding foaming agent and foam stabilizer within the hollow glass microsphere-type drilling fluid increased from 42 mPa·s to 52 mPa·s, indicating that the addition of foaming agent and foam stabilizer increased the viscosity of the drilling fluid and was still within a feasible rheological range. The surface viscosity of the two drilling fluids rose from 52 mPa·s to 68 mPa·s and the shear force rose from 23 Pa to 30 Pa with little change after they were aged for 16 h at 80 °C in a high-temperature roller furnace, indicating that the foam within the drilling fluid has good stability.

Table 6.

Comparison of the rheological properties of the three drilling fluids.

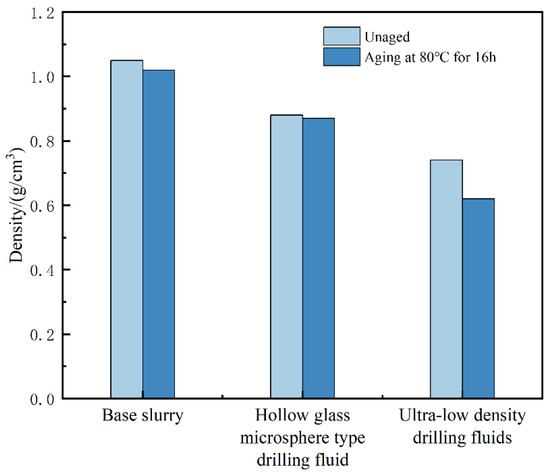

5.2. Density Stability

Comparing the density changes of the three drilling fluids before and after aging, the experimental results are shown in Figure 7.

Figure 7.

Change pattern of drilling fluid density when aged at 80 °C for 16 h.

As can be seen from Figure 7, the density of drilling fluid gradually decreases with the synergistic effect of hollow glass beads and foaming agent and the density of drilling fluid decreases slightly after aging, with no major changes overall, indicating that the foam system is more uniform at this temperature and the drilling fluid is more stable.

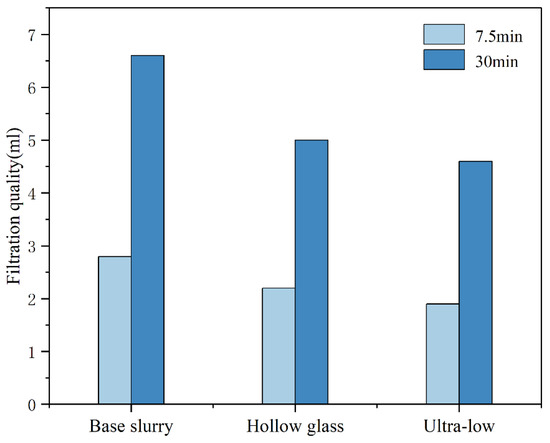

5.3. Filter Loss Performance

Due to the addition of hollow glass microbeads and foaming agent in this drilling fluid, the gradation between the particle size of the compounded HL35 and HL42 hollow glass microspheres and the foam produced with the foaming agent will affect the filtration quality of the drilling fluid.

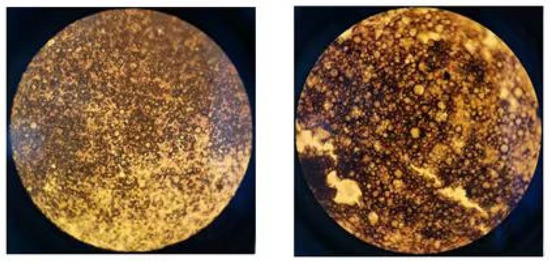

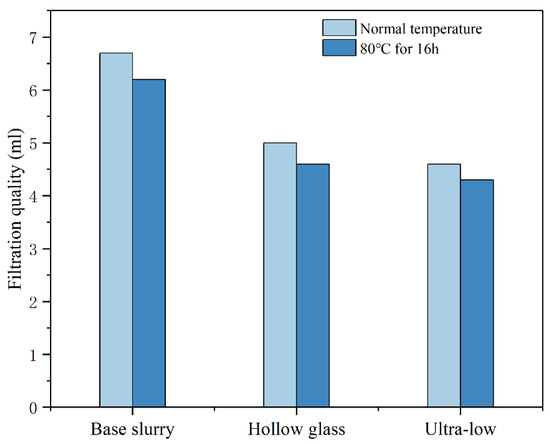

As shown in Figure 8 and Figure 9, with the addition of foaming agent the filtration quality is 1.9 mL at 7 min 30 s, which is 0.3 mL less than that of hollow glass microspheres drilling fluid, and at 30 min, the filtration quality of hollow glass microspheres drilling fluid is 5 mL and that of ultra-low-density drilling fluid is 4.6 mL, which indicates that the foaming agent and hollow glass microspheres can reduce the filtration quality in cooperation with other solid-phase particles in drilling fluid. Moreover, comparing the images of two low-density drilling fluids at 100× microscope magnification revealed that the low-density drilling fluid with only hollow glass microspheres as a mitigant had scattered solid-phase particles between the drilling fluids with well-defined aggregation, while the ultra-low-density drilling fluid was seen to form a mesh-like structure under microscope magnification, which aggregated the hollow glass microspheres with the foam and could well play a synergistic role in reducing the filtration quality [30]. In Figure 10, it can be seen that the ultra-low-density drilling fluid has a low filtration quality which further decreases due to the addition of high-temperature filtration quality-reducing agents.

Figure 8.

Variation pattern of filtration of three drilling fluids at different times.

Figure 9.

Enlarged comparison of drilling fluid with hollow glass microspheres (left) and ultra-low-density drilling fluid (right).

Figure 10.

Filtration quality of drilling fluid before and after aging.

5.4. High-Temperature and High-Pressure Rheology

For a formation scenario where the pressure coefficient is less than 1, the simulated formation pressure is 25 MPa, 80 °C is the temperature selected for high-temperature and high-pressure rheology evaluation, and the drilling fluid density is set as 0.79 g/cm3; the experimental data are shown below.

The commonly used rheological models for drilling fluids are the Bingham model and power-law model [31], etc. Using the above data to carry out the fitting of data under different rheological models with the Bingham model and power-law model as examples, the statistical parameters under different models were derived, respectively.

Based on the results of the data fit (Table 7 and Table 8), it can be seen that both the power-law model and the Bingham model have good correlation coefficients for the rheological properties of the microbubble drilling fluid under various conditions, which proves that both models are suitable for describing the rheological properties of this drilling fluid. Since the power-law model is simple and easy to use, it is considered to be a better model for describing this drilling fluid.

Table 7.

Ultra-low-density drilling fluid high-temperature and high-pressure data.

Table 8.

High-temperature and high-pressure data fitting results.

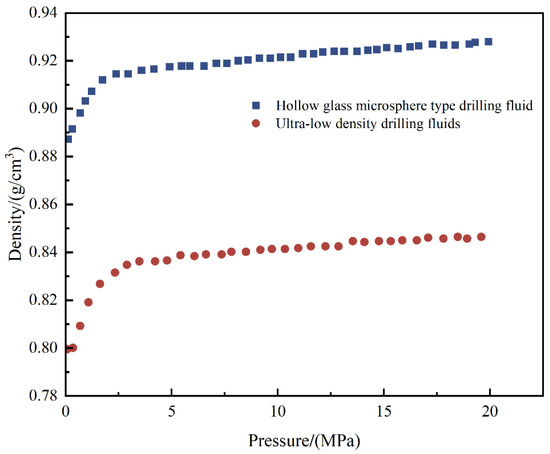

5.5. Compressibility Experiment

The “three-layer, one-film” structure of the microbubbles formed by the foaming agent added to the ultra-low-density drilling fluid [32] gives it good compression resistance compared with ordinary foam and hollow microbead drilling fluids, and the particle size variation caused by the pressure of microbubbles under high pressure also affects the leakage prevention performance of the system. Therefore, a systematic examination of the density of ultra-low-density drilling fluids under high-pressure conditions is required.

The experiment used a PVT device, which can effectively test the density and volume change law of drilling fluid under high-temperature and high-pressure conditions. First, the temperature inside the PVT barrel was raised to 80 °C, and then the drilling fluid was added to the PVT barrel. The stirring device of the PVT barrel was started; after stirring for 5 min, the pressure and volume in the PVT barrel were recorded. Then, the pressure in the PVT barrel was gradually increased and the volume of the drilling fluid system under different pressure conditions was measured. When the pressure increased to 20 MPa, the volume of drilling fluid was recorded, and then the pressure was gradually reduced to keep the wellbore pressure stable.

From Figure 11 above, we can see that the ultra-low-density drilling fluid is more compressible and the hollow glass microsphere-type drilling fluid is denser and less compressible. This is mainly because the foam can compress moderately with the pressure after adding the foaming agent and can repeat this pressurization and decompression in a shorter period. Compared to hollow glass microsphere-type drilling fluids, ultra-low-density drilling fluids have better compression resistance.

Figure 11.

Compression resistance of hollow glass microsphere-type drilling fluid and ultra-low-density drilling fluid.

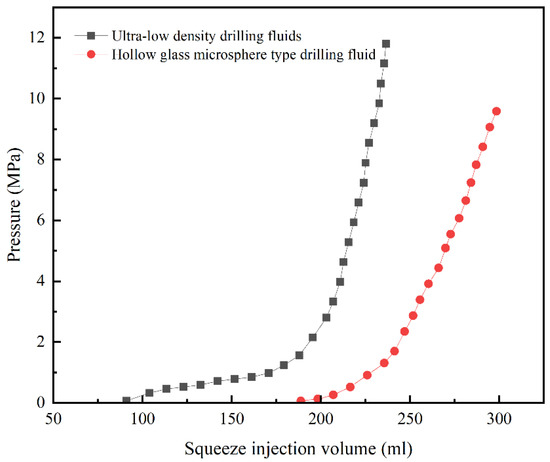

5.6. Pressure Plugging Experiment

The ultra-low-density drilling fluid can change its size in different leaky layers, and the hollow glass microspheres can also play a synergistic sealing role, thus yielding certain leak prevention and plugging effects. A systematic evaluation of the pressure-bearing and plugging properties of this drilling fluid is needed.

The pressure-bearing and plugging performance of ultra-low-density drilling fluids and hollow glass microsphere-type drilling fluids was investigated using 60–90-mesh sand beds. The drilling fluid was configured according to the above formula, at which time the density of ultra-low-density drilling fluid was 0.79 g/cm3 and the density of hollow glass microsphere-type drilling fluid was 0.89 g/cm3. The effect of the foaming agent on the pressure-bearing capacity of drilling fluid was investigated by simulating leaky formations with different pore sizes using 60–90-mesh count sand at 80 °C. The results are shown in Figure 12.

Figure 12.

Comparison of the pressure-bearing capacity of two drilling fluids at different pressures.

As can be seen from Figure 12 above, when 60–90-mesh sand beds (pore diameter is about 50–90 μm) are used, the pressure-bearing and plugging capacity of ultra-low-density drilling fluid can reach more than 12 MPa with less squeeze injection volume. The hollow glass microsphere drilling fluid can achieve a pressure-bearing and plugging capacity of more than 9 MPa in the sand bed experiment with the same number of meshes. Compared with the ultra-low-density drilling fluid, the hollow glass microsphere drilling fluid has a higher squeeze volume. This indicates that the pressure-bearing and plugging ability of the ultra-low-density drilling fluid is better than that of the hollow glass microsphere drilling fluid.

5.7. Reservoir Protection Experiments

In order to evaluate the reservoir protection performance of the ultra-low-density drilling fluid, four cores were taken from one well (well depth: 2085 m). The core permeability recovery values of the drilling fluid system were measured in the laboratory using a core flow experimental instrument and a core vacuum saturation device. The experimental results showed (Table 9) that the average core permeability recovery value of the ultra-low-density drilling fluid reached 85%, indicating that the ultra-low-density drilling fluid has good reservoir protection performance with less contamination to the reservoir.

Table 9.

Evaluation of reservoir protection effect of ultra-low-density drilling fluid.

6. Conclusions

The ultra-low-density drilling fluid developed in this paper is based on hollow glass microspheres as the main foaming agent to reduce the density of drilling fluid, which can avoid drilling health and safety accidents caused by the accumulation of hollow glass microspheres and improve the limited pressure-bearing performance of foaming agent-based foam drilling fluid. The ultra-low-density drilling fluid developed in this paper, which is composed of foaming agent and hollow glass microspheres, has good rheological properties and its density can reach about 0.7 g/cm3. At the same time, the hollow glass microspheres and foam can form a good plugging effect when combined, yielding a good pressure-bearing and plugging ability as well as reservoir protection. The density of the ultra-low-density drilling fluid did not change significantly after being maintained at 80 °C for 16 h, indicating that the drilling fluid of this system has good stability.

Author Contributions

Conceptualization, H.C. and M.L.; methodology, H.C. and W.Z.; software, H.C.; validation, H.C., C.H. and W.Z.; formal analysis, P.X.; investigation, H.C. and M.L.; resources, W.Z.; data curation, P.X.; writing—original draft preparation, H.C.; writing—review and editing, H.C.; visualization, C.H.; supervision, M.L.; project administration, H.C.; funding acquisition, H.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

No conflict of interest exists upon submission of this manuscript, and all authors approve the manuscript for publication. I wish to declare, on behalf of my co-authors, that the work described is original research that has not been published previously and is not under consideration for publication elsewhere, in whole or in part. All of the authors listed have approved the manuscript.

References

- Zhao, Y.S.; Yang, D. Study on the effective technology way for mining methane in low permeability coal seam. J. China Coal Soc. 2001, 26, 455–458. [Google Scholar]

- Zhang, Y.; Xian, B.A. Reason analysis and stimulation measures of low coalbed methane gas production wells. Nat. Gas Ind. B 2010, 30, 55–59. [Google Scholar]

- Zuo, J.L.; Sun, H.; Zhou, W.D. Study and application of light weight drilling fluid applied to coalbed methane development. J. China Coal Soc. 2012, 37, 815–819. [Google Scholar]

- Zhou, C.B. Research and Application of Underbalanced Drilling Fluid Technology in Daqing Oilfield. West-China Explor. Eng. 2020, 32, 80–83. [Google Scholar]

- Zuo, J.L.; Sun, H. Study of Light Weight Drilling Fluid for Coalbed Methane. In Proceedings of the 2011 Symposium on Coalbed Methane, San Francisco, CA, USA, 26–29 June 2011; pp. 256–262. [Google Scholar]

- Sun, F.; Zhang, J.; Li, J. Soft Capsule Drilling Fluid Technology for 215.9 mm CBM Well and Horizontal Well. China Coalbed Methane 2012, 2, 18–21. [Google Scholar]

- Luo, H.D.; Shi, L.B.; Zuo, J.J. Recyclable Micro Foam Drilling Fluid: Its Study and Application in Burial Hill Structure in Chad. Drill. Fluid Complet. Fluid 2017, 34, 8–13. [Google Scholar]

- Brookey, T. Drilling, At-Balance. “Micro-Bubbles”: New Aphron Drill-In Fluid Technique Reduces Formation Damage in Horizontal Wells. In Proceedings of the SPE Formation Damage Control Conference, Lafayette, LA, USA, 18–19 February 1998. [Google Scholar]

- Liu, Z.G. Drilling fluid technology for the Wen-23 depleted sandstone gas storage. Drill. Eng. 2022, 49, 117–122. [Google Scholar]

- Bai, H.P.; Chen, H.; Liu, X.Q. Types and characteristics of low density drilling fluid systems. Petrochem. Ind. Technol. 2020, 27, 112–113. [Google Scholar]

- Wang, G.C.; Xiong, K.J.; Zeng, X.Y. Application of recyclable oil-based foam drilling fluid in Shengbei oilfield. Drill. Fluid Complet. Fluid 2014, 31, 17–20. [Google Scholar]

- Hu, Y.D.; Zhao, J.S.; Chen, J.M. Mill 80-C1 lateral drilling horizontal well flux capsule drilling fluid practice. Drill. Prod. Technol. 2013, 36, 110–113. [Google Scholar]

- Wang, Z.F.; Liu, G.Z.; Cao, S.S. Application of new ultra-low density water-based solid-free drilling fluid in DP3 well. West-China Explor. Eng. 2010, 22, 105–107, 110. [Google Scholar]

- Chen, S.L. Applications of Hollow Glass Bubbles in Underbalanced Drilling on Well Shen-289. Pet. Drill. Tech. 2010, 38, 60–62. [Google Scholar]

- Wang, F.H.; Liang, G.C.; Guo, B.Y. A Recyclable Foaming Drilling Fluid Suitable for Drilling Low Pressure Low Permeability Reservoirs. Drill. Fluid Complet. Fluid 2009, 26, 6–8. [Google Scholar]

- Ye, Y.; Yan, J.N. Lab tests and Applications of the HGS Low-Density Water-Based Drilling Fluid. Pet. Drill. Tech. 2006, 34, 41–44. [Google Scholar]

- Dong, H.D.; Zhu, J.Y.; Chen, L.; Wu, J.; Liu, H. Research and application of low-density drilling fluid for complex formation. Coal Geol. Explor. 2017, 45, 168–172. [Google Scholar]

- Ma, P.P.; Yang, K.J.; Chen, F. Research on low density high oil resistant foam drilling fluid and its application in low-pressure oil and gas wells. Drill. Prod. Technol. 2015, 2015, 85–88. [Google Scholar]

- Lee, S.-L. Research and application of recyclable microfoam drilling fluid. Petro Chem. Equip. 2018, 21, 76–78. [Google Scholar]

- Zheng, L.H.; Cao, Y.; Han, Z.X. Novel low-density drilling fluid containing fuzzy ball structure. Acta Pet. Sin. 2010, 31, 490–493. [Google Scholar]

- Yang, X.L.; Guo, P.; He, M.M. Synthesis and performance evaluation of high stability foaming agent for air foam flooding. Drill. Prod. Technol. 2018, 40, 240–246. [Google Scholar]

- Meng, S.Z. Laboratory Research on the Low Density Hollow Glass Micro-sphere Muds. Drill. Complet. Fluid 2007, 1, 26–27. [Google Scholar]

- Zou, S.J.; Zou, X.D. Indoor study of low density water-based drilling fluid system. Xinjiang Pet. Sci. Technol. 2016, 26, 2. [Google Scholar]

- Jia, X.M. Field Application of Hollow Glass Microsphere Low Density Drilling Fluid. Drill. Fluid Complet. Fluid 2007, 24, 98–100. [Google Scholar]

- Zhang, X.N.; Kang, W.L.; He, F.Y. A Discussion on the Properties of Muds Treated with Hollow Glass Spheres Light Weight Agent. Drill. Fluid Complet. Fluid 2007, 24, 75–77. [Google Scholar]

- Zhao, C.N.; Zhang, Y.; Chen, D.J. Study of Micro-foam Drilling Fluid. Inn. Mong. Petrochem. Ind. 2011, 15, 84–86. [Google Scholar]

- Li, J.Y.; Cao, J.; Han, W. Analysis on the structure and performance of cocoamidopropyl betaine. Chem. Eng. Technol. 2007, 28, 46–50. [Google Scholar]

- Wang, H.J.; Jiao, X. Research and application of micro-foam drilling fluid in Daqing Oilfield. Oil Drill. Prod. Technol. 2007, 29, 88–92. [Google Scholar]

- Zhu, J.Y.; Hou, S.P.; Chen, L.; Wang, S.; Zou, J.; Song, J. Study on physical and chemical coordinative depressing filter loss of low density drilling fluid for coalbed methane drilling exploration. Coal Sci. Technol. 2016, 44, 122–126, 160. [Google Scholar]

- Li, X.B. Application of Ultra-low Density Drilling Fluid Technology in Leaky-prone Complex Layer of Daqing Oilfield. Technol. Superv. Pet. Ind. 2020, 36, 1–4. [Google Scholar]

- Chen, X.Y.; Fan, H.H. Four-Parameter Rheological Model and Its Application in Cementing Slurry. Pet. Drill. Tech. 2013, 5, 76–81. [Google Scholar]

- Wang, H.P.; Zhang, D.J.; Zhang, D. Application of Microbubble Drilling Fluid Technology for Lateral Drilling in Pressure Depleted Blocks. Drill. Prod. Technol. 2012, 35, 94–95. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).